Page 1

Quick Start Guide

00825-0200-4708, Rev DA

Rosemount™ 708 Wireless Acoustic

Transmitter

June 2016

Page 2

Quick Start Guide

June 2016

NOTICE

This guide provides basic guidelines for the Rosemount 708. It does not provide instructions for detailed

configuration, diagnostics, maintenance, service, troubleshooting, or installations. Refer to the Rosemount

708 Reference Manual (document number 00809-0100-4708) for more instruction. This guide and the

manual are available electronically on www.rosemount.com.

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the appropriate

local, national, and international standards, codes, and practices. Review the Product Certifications

section for any restrictions associated with a safe installation.

Before connecting a Field Communicator in an explosive atmosphere, ensure the instruments are

installed in accordance with intrinsically safe field wiring practices.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following conditions:

This device may not cause harmful interference.

This devi ce must accept any interferen ce received, including interference that may cause undesired

operation.

This device must be installed to ensure a minimum antenna separation distance of 8-in. (20 cm) from all

persons.

The power module may be replaced in a hazardous area. The power module has surface resistivity greater

than one gigaohm and must be properly installed in the wireless device enclosure. Care must be taken

during transportation to and from the point of installation to prevent a potential electrostatic charging

hazard.

Polymer enclosure has surface resistivity greater than one gigaohm. Care must be taken during

transportation to and from the point of installation to prevent a potential electrostatic charging hazard.

NOTICE

Shipping considerations for wireless products

The unit was shipped without the power module installed. Remove the power module prior to shipping the

unit.

Each power module contains one “D” size primary lithium battery. Primary lithium batteries are regulated in

transportation by the U.S. Department of Transportation, and are also covered by IATA (International Air

Transport Association), ICAO (International Civil Aviation Organization), and ARD (European Ground

Transportation of Dangerous Goods). It is the responsibility of the shipper to ensure compliance with these

or any other lo cal requirem ents. Consult current regulations and requirements before shipping.

Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Wireless considerations . . . . . . . . . . . . . . . . . . . . 3

Physical installation . . . . . . . . . . . . . . . . . . . . . . . 4

2

Device network configuration . . . . . . . . . . . . . . 8

Verify operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product certifications. . . . . . . . . . . . . . . . . . . . . 13

Page 3

June 2016

1.0 Overview

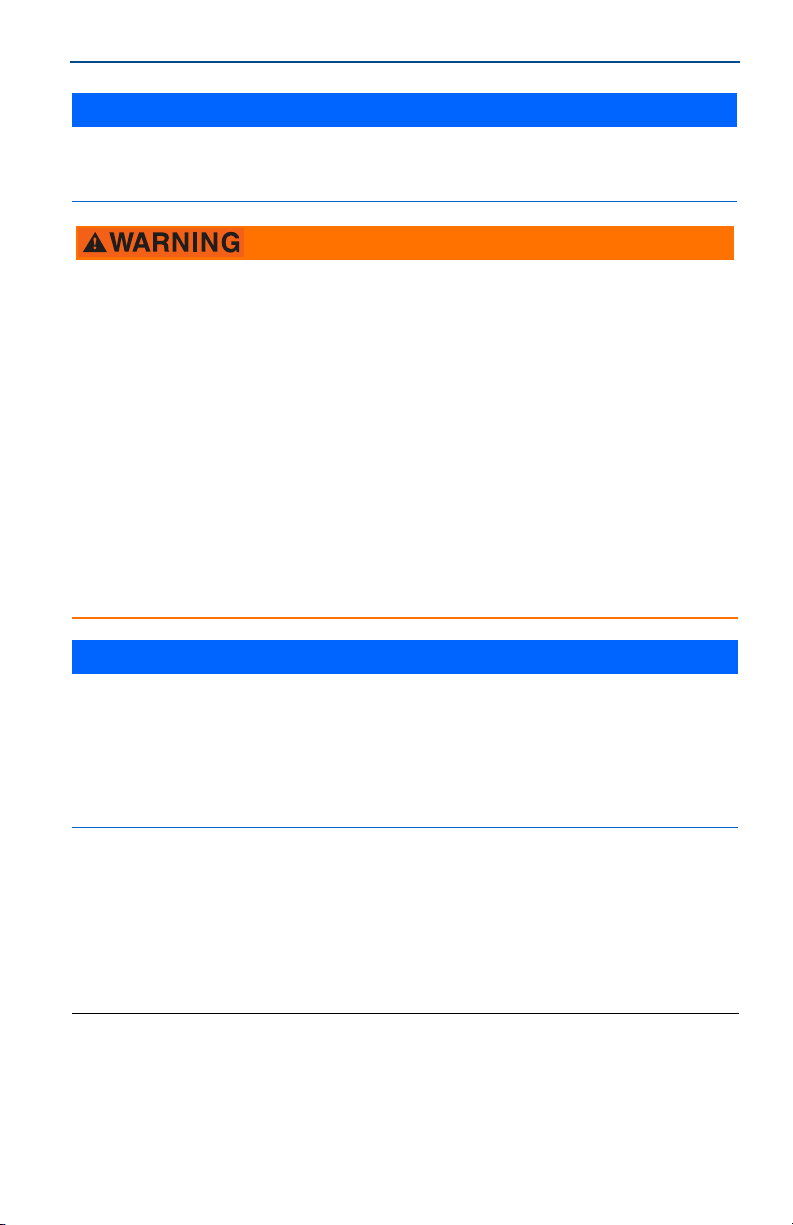

Figure 1. Rosemount 708 Wireless Acoustic Transmitter

D

Quick Start Guide

B

C

A

A. Power module cover — power module is inside device; unscrew cap for access

B. Waveguide — acoustic and temperature sensors

C. Electronics cover — cover is sealed and cannot be removed

D. Stainless steel mounting bands — used to connect the acoustic transmitter to the piping

E. Pipe — the acoustic transmitter is installed directly to the pipe

E

2.0 Wireless considerations

2.1 Power up sequence

The Emerson™ Smart Wireless Gateway should be installed and functioning

properly before any wireless devices are powered. Install the power module,

Smart Wireless 701PGNKF into the Rosemount 708 to power the device. This

results in a simpler and faster network installation. Enabling active advertising on

the Gateway ensures new devices are able to join the network faster. For more

information see the Smart Wireless Gateway Manual (document number

00809-0200-4420).

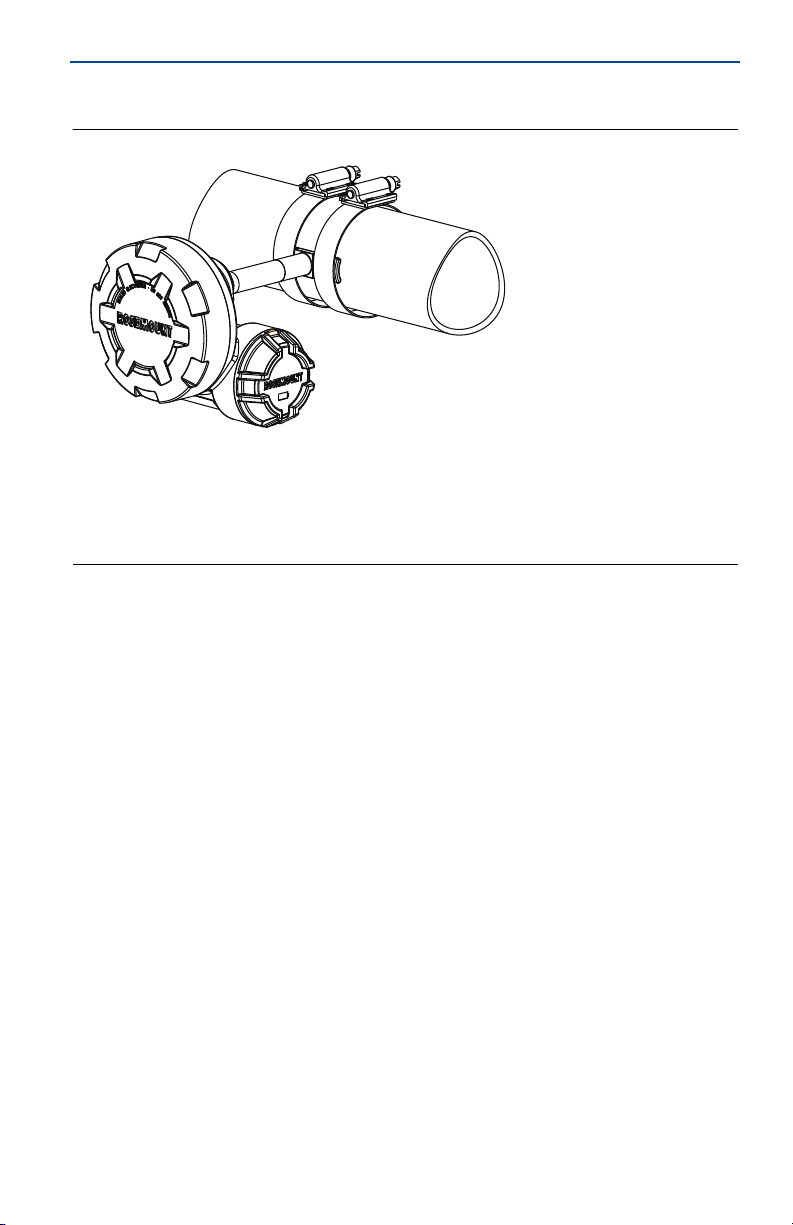

2.2 Antenna position

The antenna is internal to the acoustic transmitter. To achieve optimal range,

orient the transmitter with the waveguide horizontal and the power module

closest to the ground as shown in Figure 2. Good connectivity can also be

achieved in other orientations. The antenna should also be approximately 3 ft.

(1 m) from any large structure, building, or conductive surface to allow for clear

communication to other devices.

3

Page 4

Quick Start Guide

Figure 2. Antenna Position

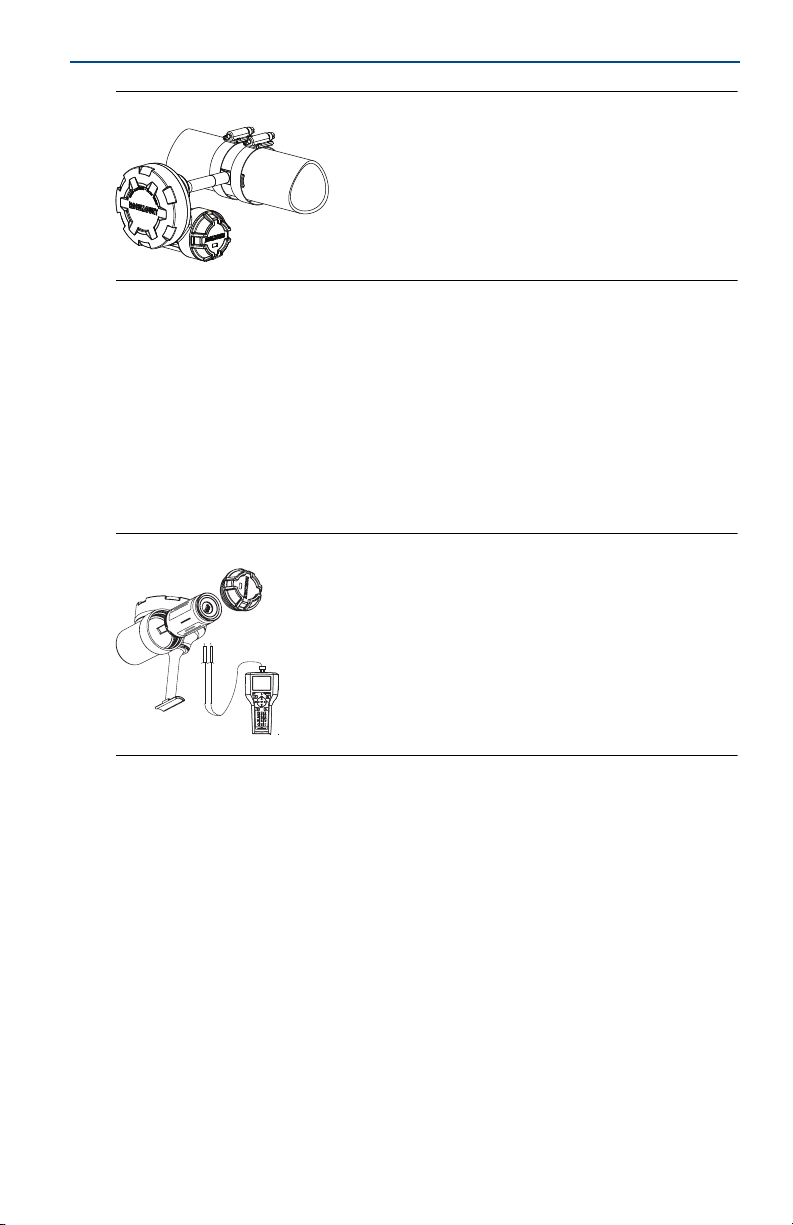

3.0 Field Communicator connections

The power module needs to be installed in the device for the Field Communicator

to interface with the Rosemount 708. This transmitter uses the green power

module; order model number 701PGNKF. Field communication with this device

requires a HART

Field Communicator connections are located on the power module. The power

module is keyed and can only be inserted in one orientation. Refer to Figure 3 for

instructions on connecting the Field Communicator to the Rosemount 708.

Figure 3. Connection Diagram

®

protocol-based Field Communicator using the correct 708 DD.

June 2016

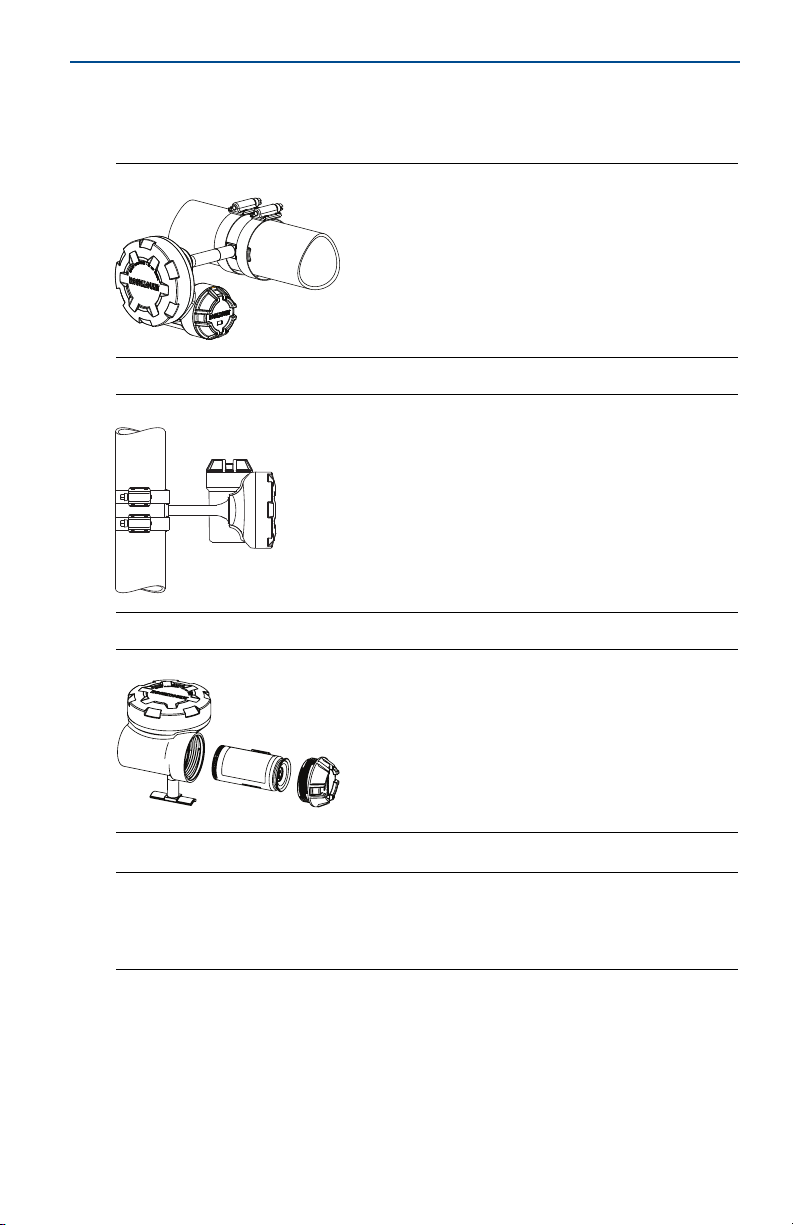

4.0 Physical installation

The acoustic transmitter is connected directly to the piping being measured.

4.1 Mounting

For high temperature mounting, see page 5.

1. Locate the Rosemount 708 on a horizontal section of piping as close as

possible to the equipment to be monitored. Align the waveguide of the

transmitter as shown in Figure 4 and Figure 5.

2. The mounting location should be free of foreign matter and corrosion to

ensure good contact between the piping and the waveguide.

3. Tighten each clamp to 90 in-lb (10,2 N-m). Trim the excess clamp band

material to prevent unwanted acoustic noise.

4. If commissioning the device, install the green power module (see Figure 6).

4

Page 5

June 2016

Quick Start Guide

5. Ensure the power module cover is fully tightened to prevent moisture ingress.

The lip of the polymer power module cover should be in contact with the

surface of the polymer enclosure to ensure a proper seal. Do not over tighten.

Figure 4. Transmitter Alignment

Figure 5. Transmitter Alignment Top View

Figure 6. Power Module Installation

Note

Wireless devices should be powered up in order of proximity from the Smart Wireless

Gateway, beginning with the closest device to the Smart Wireless Gateway. This will result

in faster network formation.

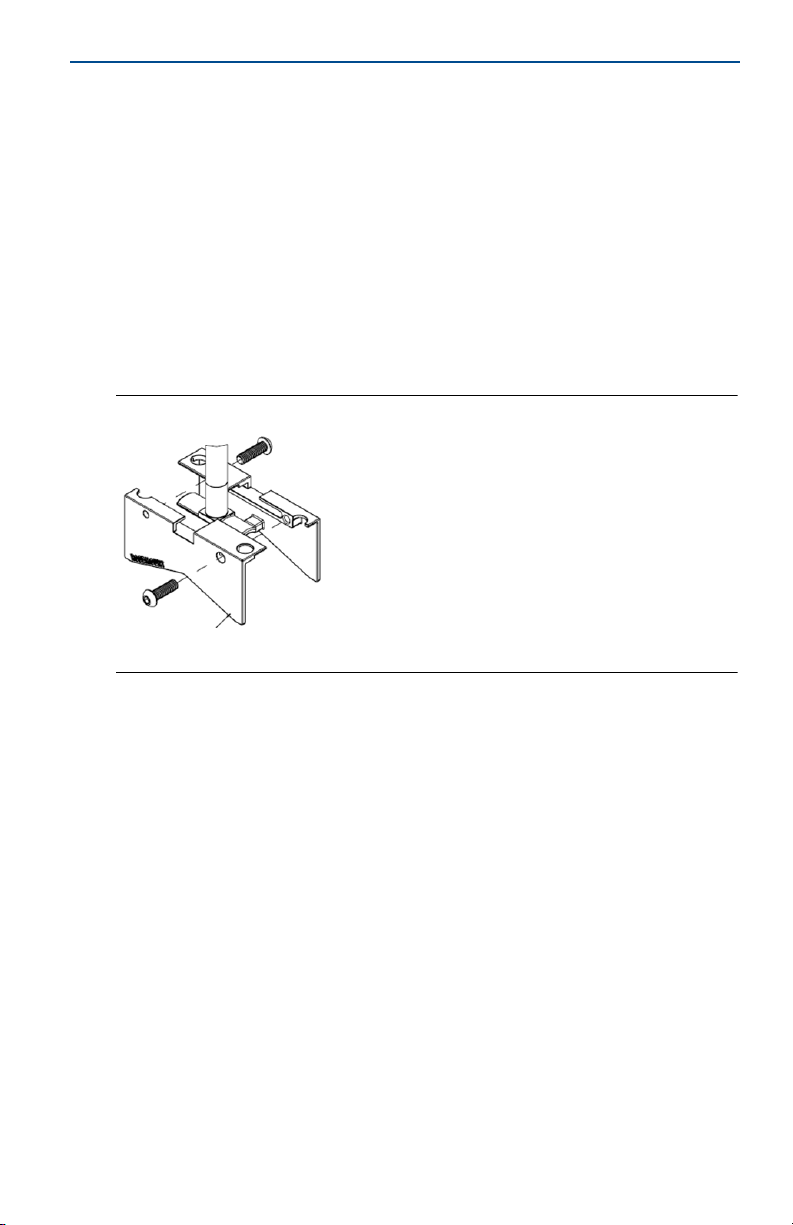

4.2 Mounting in a high temperature application

High temperature mounting hardware should be used when process

temperatures exceed 260 °C (500 °F).

1. Place the foot of the transmitter in between the standoff mounting hardware

plates as shown in Figure 7.

2. Press standoff plates together so plates and transmitter foot are aligned.

5

Page 6

Quick Start Guide

3. Tighten each screw to 90 in-lb (10,2 N-m).

4. Locate the Rosemount 708 and high temperature mounting hardware on a

horizontal section of the piping as close as possible to the equipment to be

monitored. The mounting location should be free of foreign matter and

corrosion to ensure good contact between the piping and the mounting

hardware.

5. Insert the U-bolt through the standoff mounting hardware.

6. Tighten each bolt to 90 in-lb (10,2 N-m) (see Figure 8).

7. If commissioning the device, install the green power module (see Figure 6).

8. Ensure the power module cover is fully tightened to prevent moisture ingress.

The lip of the polymer power module cover should be in contact with the

surface of the polymer enclosure to ensure a proper seal. Do not over tighten.

Figure 7. High Temperature Mounting Hardware

June 2016

6

Page 7

June 2016

(97)

Figure 8. Rosemount 708 Acoustic Transmitter with High Temperature

Standoff and Fastener Kit

6.86

(174)

1.81

(46)

Quick Start Guide

3.80

A. For pipe sizes 0.5 to 2.5-in.

Dimensions are in inches (millimeters).

A

4.3 Mounting considerations

1. Mounting bands should be inspected periodically and re-tightened if

necessary. Some loosening may occur after initial installation due to thermal

expansion/contraction.

2. The waveguide must be in direct contact with the pipe unless the high

temperature mounting hardware is being used.

3. Insulate process piping to minimize ambient temperature effects (see Figure

9). Insulation thickness over the top of the waveguide foot should not exceed

1-in. (2,54 cm).

4. For best results, mount the transmitter within 6-in. (15,24 cm) of the

equipment to be monitored.

5. The stainless steel mounting bands could be affected by stress corrosion and

potentially fail when in the presence of chlorides.

6. The transmitter should be installed such that steam or other high temperature

fluids do not directly impinge the housing of the device.

7. If installing the device on a steam trap, the device should be installed on the

upstream side of the trap.

7

Page 8

Quick Start Guide

1-in.

Figure 9. Piping Insulation Side View

5.0 Device network configuration

In order to communicate with the Smart Wireless Gateway, and ultimately the

information system, the transmitter must be configured to communicate with

the wireless network. This step is the wireless equivalent of connecting wires

from a transmitter to the host system. Using a Field Communicator or AMS

Device Manager, enter the network ID and join key so they match the network ID

and join key of the Gateway and other devices in the network. If the network ID

and join key are not the same as the Gateway, the acoustic transmitter will not

communicate with the network. The network ID and join key may be obtained

from the Smart Wireless Gateway on the Setup>Network>Settings page on the

web server, shown in Figure 10.

June 2016

®

Figure 10. Gateway Network Settings

8

Page 9

June 2016

Quick Start Guide

5.1 AMS Device Manager

Right click on the acoustic transmitter and select Configure. When the menu

opens, select Join Device to Network and follow the method to enter the

network ID and join key.

5.2 Field Communicator

The network ID and join key may be changed in the wireless device by using the

following Fast Key sequence. Set both network ID and join key.

Table 1. Setting the Network ID and Join Key

Function Fast Key sequence Menu items

Join Device to Network 2, 1, 2 Network ID, Set Join Key

6.0 Verify operation

There are three ways to verify operation: using the Field Communicator, using the

Smart Wireless Gateway’s integrated web interface, or by using AMS Suite

Wireless Configurator or AMS Device Manager.

If the Rosemount 708 was configured with the network ID and join key, and

sufficient time has passed, the transmitter will be connected to the network. If

network ID and join key were not configured, reference “Troubleshooting” on

page 11.

Note

It may take several minutes for the device to join the network.

6.1 Field Communicator

For HART protocol Wireless transmitter communication, a Rosemount 708

Device Driver (DD) is required. To obtain the latest DD, visit the Emerson Process

Management Easy Upgrade site at:

http://www2.emersonprocess.com/en-US/documentation/deviceinstallkits. The

communication status may be verified in the wireless device using the following

Fast Key sequence.

Table 2. Communication Status Verification Fast Key Sequence

Func tion Fast Key sequence Menu items

Join Status, Wireless Mode, Join Mode, Number of

Communications 3, 4

Available Neighbors, Number of Advertisements Heard,

Number of Join Attempts

9

Page 10

Quick Start Guide

6.2 Smart Wireless Gateway

Using the Smart Wireless Gateway’s integrated web interface, navigate to the

Explorer page as shown in Figure 11. Locate the device in question and verify all

status indicators are good (green).

Figure 11. Smart Wireless Gateway Explorer Page

6.3 AMS Suite Wireless Configurator

When the device has joined the network, it will appear in the Device Manager as

illustrated in Figure 12. For HART protocol Wireless transmitter communication, a

708 DD is required. To obtain the latest DD, visit the Emerson Process

Management Easy Upgrade site at:

http://www2.emersonprocess.com/en-US/documentation/deviceinstallkits.

June 2016

Figure 12. Device Manager

10

Page 11

June 2016

Quick Start Guide

Note

SteamLogic™ software is provided for viewing steam trap status. Refer to the manual on the

CD for more information.

6.4 Troubleshooting

If the device is not joined to the network after power up, verify the correct

configuration of the network ID and join key, and that active advertising has been

enabled on the Smart Wireless Gateway. The network ID and join key in the

device must match the network ID and join key of the Gateway.

The network ID and join key may be obtained from the Gateway on the

Setup>Network>Settings page of the web server (see Figure 13 on page 11). The

network ID and join key may be changed in the wireless device by following the

Fast Key sequence shown below.

Table 3. Changing Network ID and Join Key Fast Key Sequence

Func tion Fast Key sequence Menu items

Join Device to Network 2, 1, 2 Network ID, Set Join Key

Figure 13. Smart Wireless Gateway Network Settings

11

Page 12

Quick Start Guide

6.5 Field Communicator use

Note

In order to communicate with a Field Communicator, power the Rosemount 708 by

connecting the power module. For more information on the power module, refer to the

Product Data Sheet (document number 00813-0100-4701).

Table 4 includes Fast Key sequences frequently used to interrogate and configure

the device. For additional information, refer to the Rosemount 708 Reference

Manual (document number 00809-0100-4708).

Table 4. Rosemount Fast Key Sequence

Function Fast Key sequence Menu items

Device Information 2, 2, 5

Guided Setup 2, 1

Manual Setup 2, 2

Wireless 2, 2, 1 Network ID, Join Device to Network, Broadcast Information

Figure 14. Field Communicator Connections

Tag, Long Tag, Descriptor, Message, Date, Country, SI Unit

Basic Setup, Join Device to Network, Configure Update

Wireless, Sensor, HART, Security, Device Information,

Control

Rates, Alert Setup

Power

June 2016

12

Page 13

June 2016

Quick Start Guide

7.0 Product certifications

Rev 1.0

7.1 European Directive Information

A copy of the EC Declaration of Conformity can be found at the end of the Quick

Start Guide. The most recent revision of the EC Declaration of Conformity can be

found at www.rosemount.com.

7.2 Telecommunication Compliance

All wireless devices require certification to ensure they adhere to regulations

regarding the use of the RF spectrum. Nearly every country requires this type of

product certification.

Emerson is working with governmental agencies around the world to supply fully

compliant products and remove the risk of violating country directives or laws

governing wireless device usage.

7.3 FCC and IC

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions: This device may not cause harmful interference. This device

must accept any interference received, including interference that may cause

undesired operation. This device must be installed to ensure a minimum antenna

separation distance of 20 cm from all persons.

7.4 Ordinary Location Certification from FM Approvals

As standard, the transmitter has been examined and tested to determine that the

design meets the basic electrical, mechanical, and fire protection requirements

by FM Approvals, a nationally recognized test laboratory (NRTL) as accredited by

the Federal Occupational Safety and Health Administration (OSHA).

7.5 Installing in North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code (CEC)

permit the use of Division marked equipment in Zones and Zone marked

equipment in Divisions. The markings must be suitable for the area classification,

gas, and temperature class. This information is clearly defined in the respective

codes.

USA

I5 FM Intrinsically Safe (IS)

Certificate: 3043245

Standards: FM Class 3600 – 1998, FM Class 3610 – 2010, FM Class 3810 – 2005, NEMA

Markings: IS CL I, DIV 1, GP A, B, C, D T4; CL 1, Zone 0 AEx ia IIC T4;

250 – 2003, ANSI/IEC 60529 - 2004

T4(–40 °C ≤ T

00708-1000; Type 4X

≤ +70 °C) when installed per Rosemount drawing

a

13

Page 14

Quick Start Guide

Special Conditions for Safe Use (X):

1. The Rosemount 708 shall only be used with the 701PGNKF Rosemount

SmartPower™ Battery Pack.

2. Potential Electrostatic charging Hazard — See Instructions.

Canada

I6 CSA Intrinsically Safe

Certificate: 2439890

Standards: CAN/CSA C22.2 No. 0-M91, CAN/CSA C22.2 No. 94-M91, CSA Std C22.2 No.

142-M1987, CSA Std C22.2 No. 157-92, CSA Std C22.2 No. 60529:05

Markings: IS CL I, DIV 1, GP A, B, C, D when installed per Rosemount drawing

00708-1001; T3C; Type 4X

Europe

I1 ATE X Int rinsi c Sa fety

Certificate: Baseefa11ATEX0174X

Standards: EN 60079-0: 2012, EN 60079-11: 2012

Markings: II 1 G Ex ia IIC T4 Ga, T4(–40 °C ≤ T

Special Conditions for Safe Use (X):

1. The plastic enclosure of the Rosemount 708 may constitute a potential

electrostatic ignition risk and must not be rubbed or cleaned with a dry cloth.

2. The Model 701PGNKF Power Module may be replaced in a hazardous area. The

power module has a surface resistivity greater than 1 GΩ and must be

properly installed in the wireless device enclosure. Care must be taken during

transportation to and from the point of installation to prevent electrostatic

charge build-up.

≤ +70 °C)

a

June 2016

International

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 11.0091X

Standards: IEC 60079-0: 2011, IEC 60079-11: 2011

Markings: Ex ia IIC T4 Ga, T4(–40 °C ≤ T

Special Condition for Safe Use (X):

≤ +70 °C)

a

1. The plastic enclosure of the Rosemount 708 may constitute a potential

electrostatic ignition risk and must not be rubbed or cleaned with a dry cloth.

Brazil

I2 INMETRO Intrinsic Safety

Certificate: NCC 12.0817X

Standards: ABNT NBR IEC60079-0:2008, ABNT NBR IEC60079-11:2009

Markings: Ex ia IIC T4 Ga, T4(–40 °C ≤ T

Special Condition for Safe Use (X):

1. See certificate for special conditions.

14

≤ +70 °C)

a

Page 15

June 2016

China

I3 China Intrinsic Safety

Certificate: GYJ13.1445X

Standards: GB3836.1-2010, GB3836.4-2010, GB3836.20-2010

Markings: Ex ia IIC Ga T4, –40 ~ +70 °C

Special Condition for Safe Use (X):

1. See certificate for special conditions.

Japan

I4 TIIS Intrinsic Safety

Certificate: TC20395

Markings: Ex ia IIC T4 X (–20 ~ +60 °C)

EAC - Belarus, Kazakhstan, Russia

IM Technical Regulation Customs Union (EAC) Intrinsic Safety

Certificate: RU C-US.Gb05.B.00643

Markings: 0Ex ia IIC T4 Ga X, T4(–40 °C ≤ T

Special Condition for Safe Use (X):

1. See certificate for special conditions.

a

Quick Start Guide

≤ +70 °C)

15

Page 16

Quick Start Guide

Figure 15. Rosemount 708 Declaration of Conformity

June 2016

16

Page 17

June 2016

Quick Start Guide

17

Page 18

Quick Start Guide

June 2016

18

Page 19

June 2016

ᴹ

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

List of Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘䍘/ Hazardous Substances

䫵

Lead

(Pb)

⊎

Mercury

(Hg)

䭹

Cadmium

(Cd)

ޝԧ䬜䬜

Hexavalent

Chromium

(Cr +6)

ཊⓤ㚄㚄㤟

Polybrominated

biphenyls

(PBB)

ཊⓤ㚄㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

X O O O O

O

Րᝏಘ㓴Ԧ

Sensor

Assembly

X O O O O

O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

Rosemount 708

Rosemount 708

Quick Start Guide

19

Page 20

Global Headquarters

Emerson Process Management

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@EmersonProcess.com

North America Regional Office

Emerson Process Management

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Process Management

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@EmersonProcess.com

Europe Regional Office

Emerson Process Management Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@EmersonProcess.com

Asia Pacific Regional Office

Emerson Process Management Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.EmersonProcess.com

Middle East and Africa Regional Office

Emerson Process Management

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emi rates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

*00825-0200-4708*

Quick Start Guide

00825-0200-4708, Rev DA

Linkedin.com/company/Emerson-Process-Management

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/us er/RosemountMeasur ement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found at

www.Emerson.com/en-us/pages/Terms-of-Use.aspx

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

AMS, SmartPower, SteamLogic, Rosemount, and Rosemount

logotype are trademarks of Emerson Process Management.

HART is a registered trademark of the FieldComm Group.

National Electrical Code is a registered trademark of National Fire

Protection Association, Inc.

All other marks are the property of their respective owners.

© 2016 Emerson Process Management. All rights reserved.

June 2016

Loading...

Loading...