Page 1

Quick Start Guide

00825-0400-4702, Rev GE

Rosemount™ 702 Wireless Discrete

Transmitter

April 2018

Page 2

Quick Start Guide

April 2018

About this guide

This manual supplement provides information on installing, operating, and maintaining the

Rosemount 702 Wireless Discrete Transmitter for plunger arrival detection. The table below lists

the variants of the Rosemount 702 transmitter; refer to the table if looking for documentation on

variants. Refer to the Rosemount 702 Reference Manual for more instruction. This guide and the

manual are available electronically on Emerson.com/Rosemount

Model

number Functionality Manual

702DX22

/32/42

702DX61 One channel for Tyco TraceTek

702DX52 Discrete Transmitter for Plung-

Product description

The Roseount 702 for plunger arrival detection is designe dto work with the ETC Cyclops plunger

arrival sensor (ET-11000). The transmitter provides power to the plunger arrival sensor, reads and

communication the sensor state via wirelessHART. Features of the Rosemount 702 Transmitter

include:

Two channel discrete I/O Rosemount 702 Wireless Discrete Transmitter Refer‐

liquid hydrocarbon leak detection

er Arrival Detection

• Simple and easy installations proctices currently being used for robust installations

• Flexibility to meet your most demanding applications

• Sensor state latching for host system compatibility

• Provides poiwer to external plunger arrival sensor

• The integral LCD display conveniently displays the latched plunger sensor state,

power output state, and diagnostics of the transmitter

ence Manual

Rosemount 702 Wireless Discrete Transmitter Refer‐

ence Manual

Rosemount 702 Wireless Desicrete Transmitter

Reference Manual Supplement

2 Rosemount 702 Wireless Discrete Transmitter

Page 3

Quick Start Guide April 2018

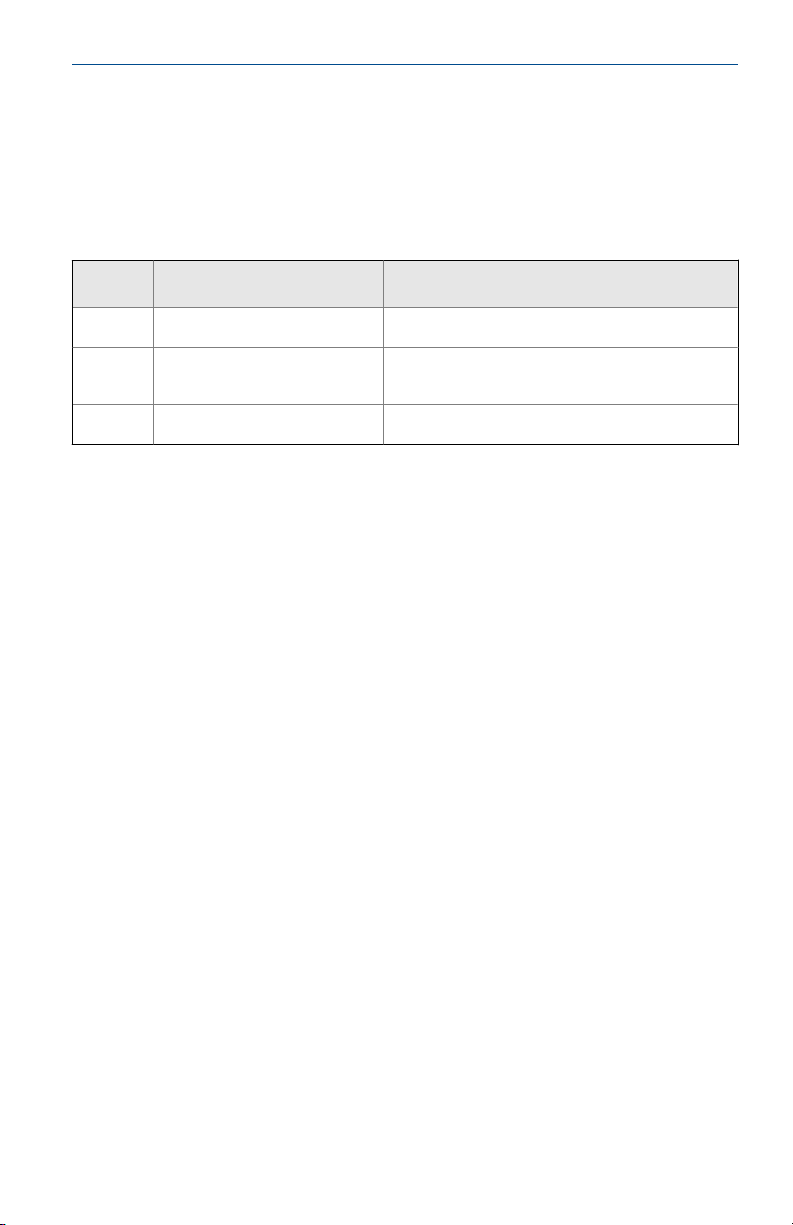

Rosemount 702 Transmitter for Plunger ArrivalFigure A-:

A Plunger Arrival Sensor (ETC Cyclops) G Lower Lubricator Outlet

B 702 Plunger Arrival H Well Casing

C Lubricator I Production gas

D Plunger J Well casing/production tube

E Wastewater K Well casing

F Upper Lubricator Outlet

Contents

Wireless considerations ................................ 4

Physical installation ...................................... 7

Device network configuration .....................14

3 Rosemount 702 Wireless Discrete Transmitter

Verify operation ..........................................16

Reference information: wiring switch inputs,

output circuits, and leak sensors ................. 20

Safety shower and eye wash

monitoring ................................................. 39

Product Certifications ................................. 42

Page 4

Quick Start Guide April 2018

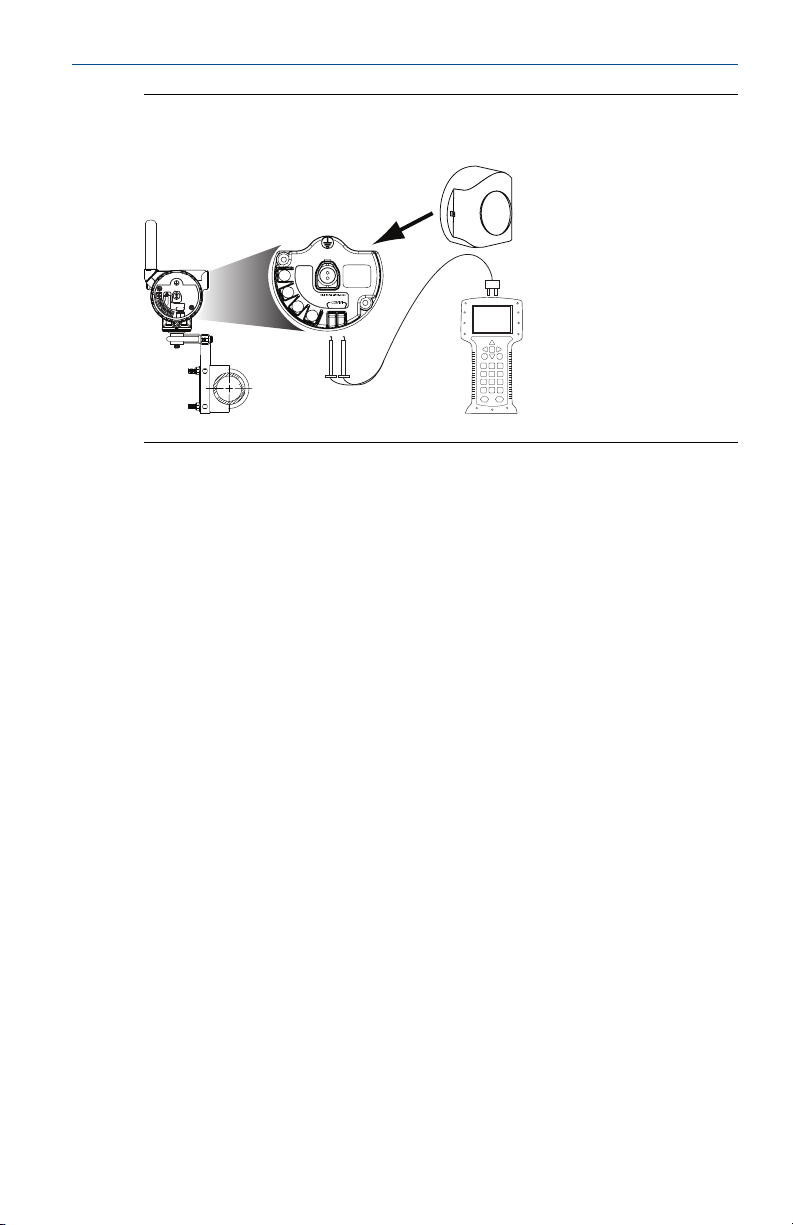

1 Wireless considerations

1.1 Power up sequence

The Smart Wireless Gateway should be installed and functioning properly

before any wireless field devices are powered. Install the Black Power Module,

SmartPower™ Solutions model number 701PBKKF (part number

00753-9220-0001) into the Rosemount 702 Transmitter to power the

device. Wireless devices should be powered up in order of proximity from the

Gateway, beginning with the closest device, then working outward from the

Gateway. This results in a simpler and faster network installation. Enable

Active Advertising on the Gateway to ensure new devices are able to join the

network faster. For more information see the Emerson™ Wireless 1420

Gateway Reference Manual.

1.2

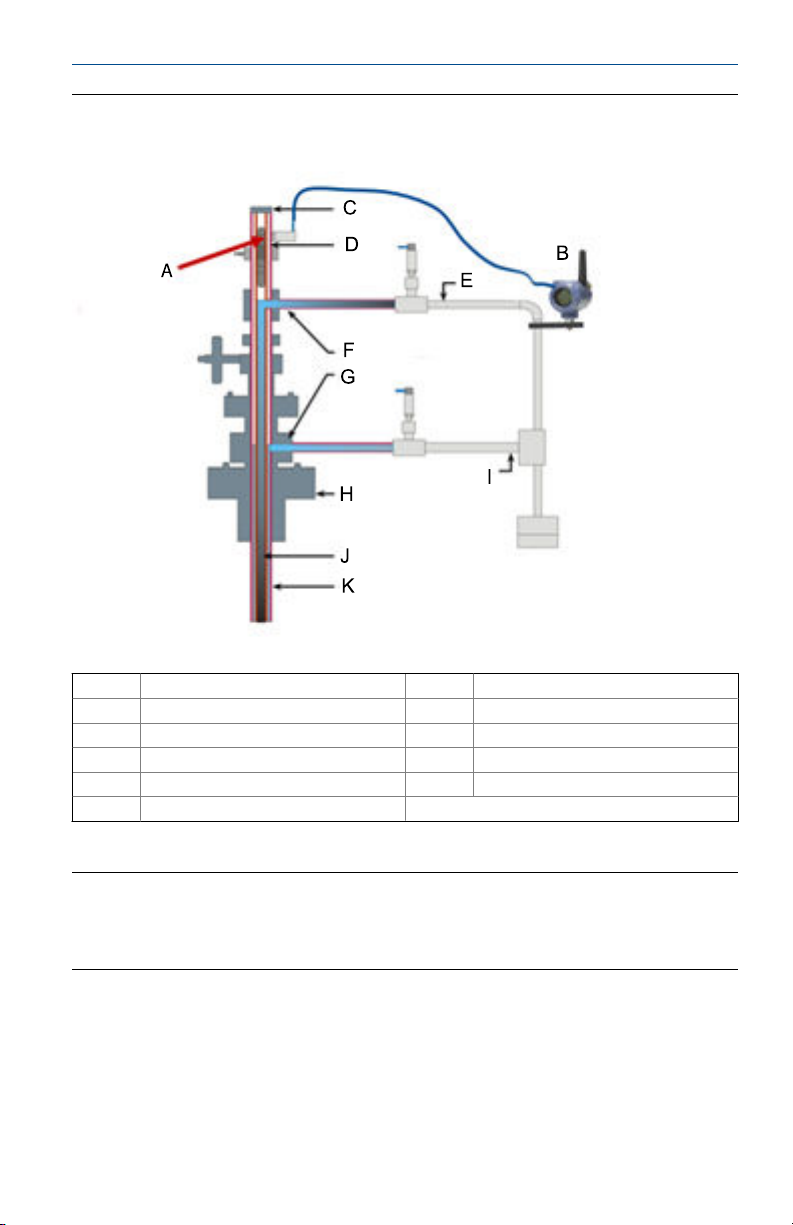

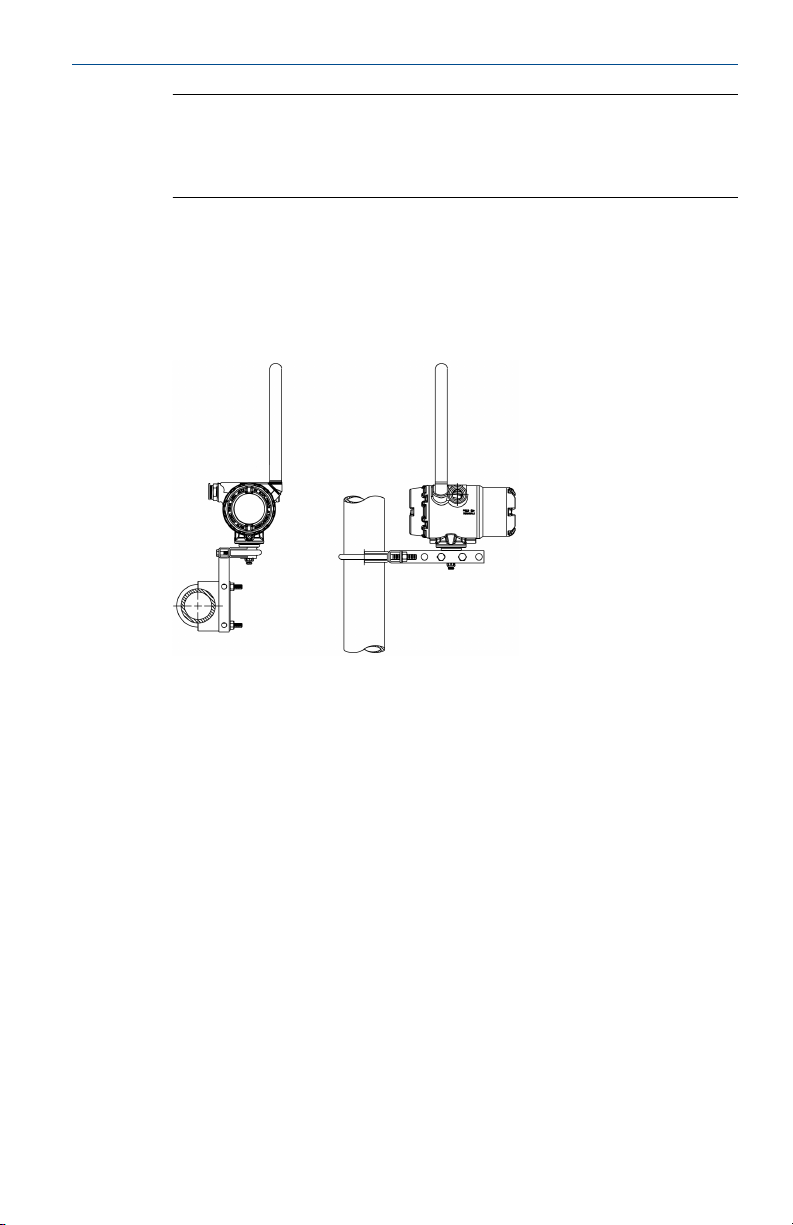

Antenna position

The antenna should be positioned vertically, either straight up or straight

down, and it should be approximately 3 ft. (1 m) from any large structure,

building, or conductive surface to allow for clear communication to other

devices.

Antenna PositionFigure 1-1:

4 Rosemount 702 Wireless Discrete Transmitter

Page 5

$

$

April 2018

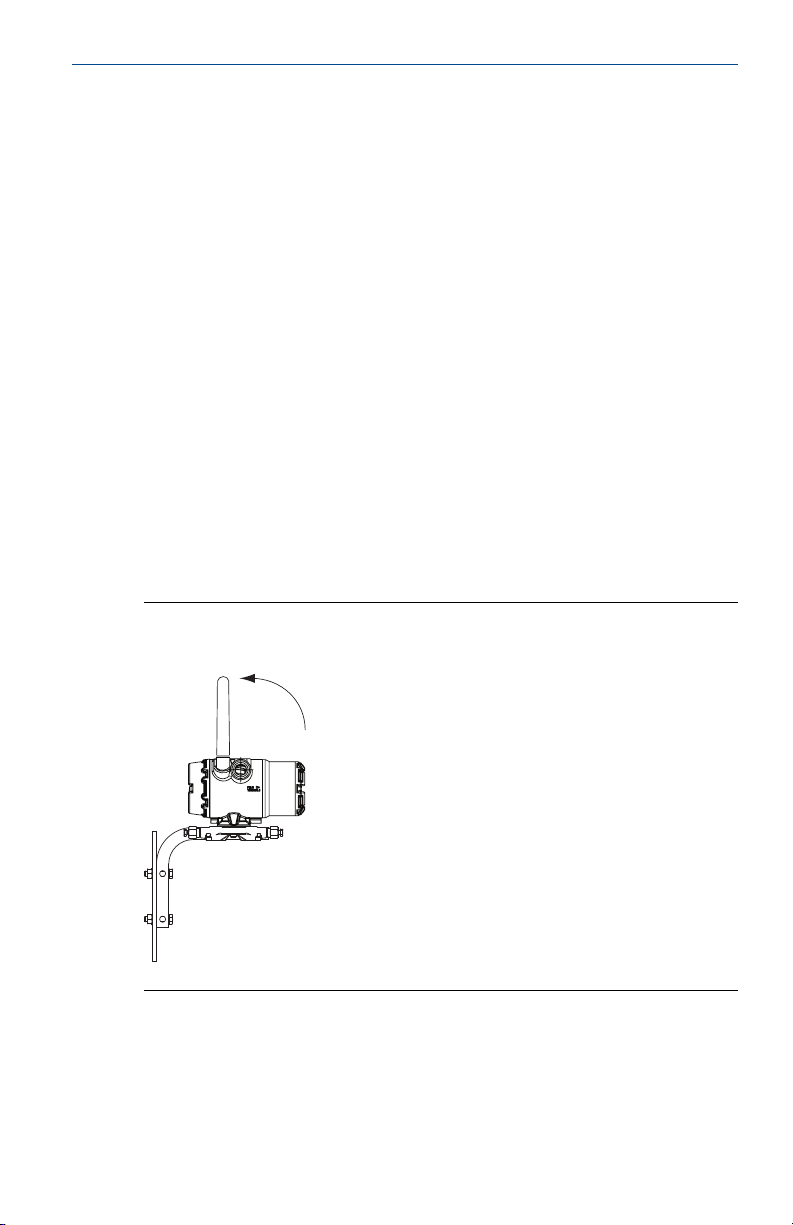

1.3 Conduit entry

Upon installation, ensure each conduit entry is either sealed with a conduit

plug using approved thread sealant, or has an installed conduit fitting or

cable gland with appropriate threaded sealant. Note the conduit entries on

the Rosemount 702 Transmitter are threaded ½–14 NPT.

Conduit EntryFigure 1-2:

A. Conduit entry

Quick Start Guide

1.4

Quick Start Guide 5

Field Communicator connections

The power module needs to be installed before the Field Communicator can

interface with the Rosemount 702 Transmitter. This transmitter uses the

Black Power Module; Order model number 701PBKKF or part number

00753-9220-0001.

Page 6

COMM

P/N 00753-9200-0020

1

2

3

4

CH1 +

CMN

CH2 +

CMN

CH Input Mode:

Dry Contact Only

CH Output Mode:

26VDC Max

100mA Max

Quick Start Guide

The Rosemount 702 Transmitter and all other wireless devices should not be

set up until after the Smart Wireless Gateway has been installed and is

functioning properly.

April 2018

Connection DiagramFigure 1-3:

6 Rosemount 702 Wireless Discrete Transmitter

Page 7

April 2018

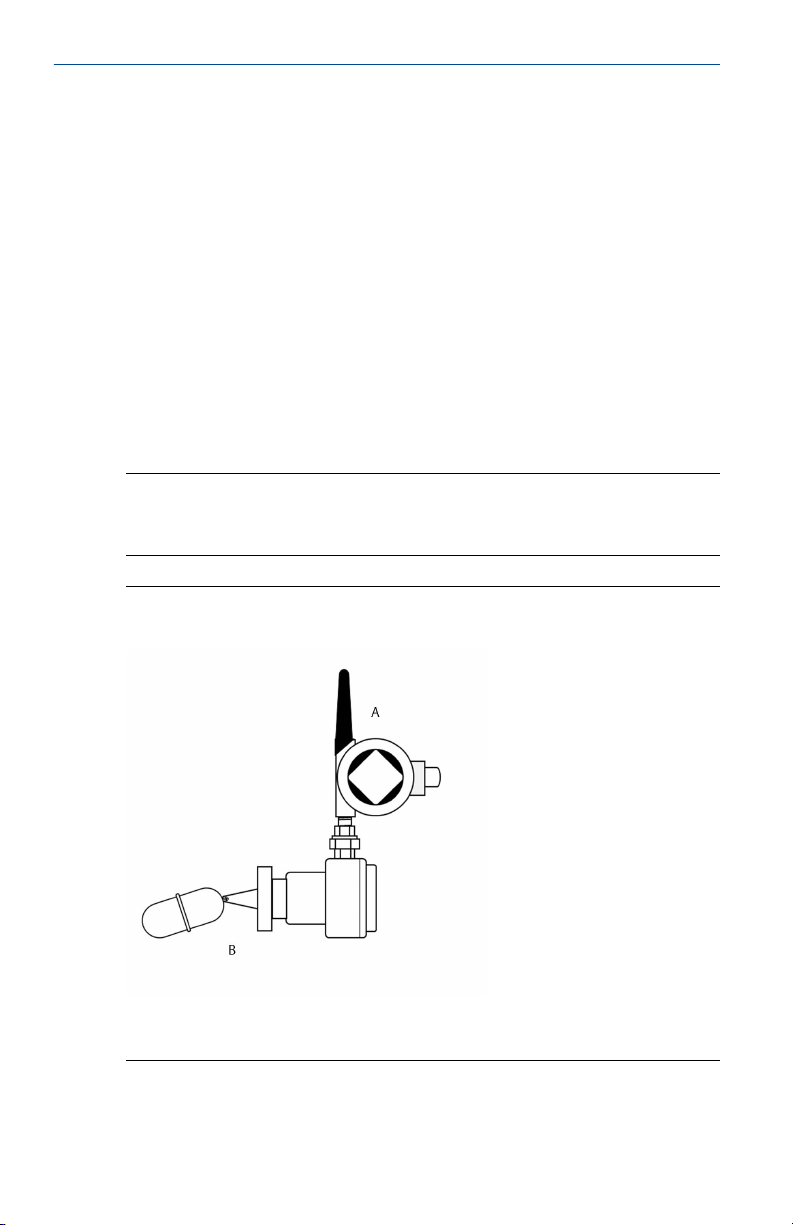

2 Physical installation

The Rosemount 702 Transmitter can be installed in one of two

configurations:

• Direct mount, where the switch is connected directly to the Rosemount

702 Transmitter housing’s conduit entry.

• Remote mount, where the switch is mounted separate from the

Rosemount 702 Transmitter housing, then connected to the Rosemount

702 Transmitter via conduit.

Select the installation sequence that corresponds to the mounting

configuration.

Quick Start Guide

2.1

Direct mount

Note

Direct mount installation should not be employed when using tubing and

connectors such as Swagelok® fittings.

Direct MountFigure 2-1:

A. Rosemount 702 Transmitter

B. Float switch

Quick Start Guide 7

Page 8

Quick Start Guide

Procedure

1. Install the switch according to standard installation practices making sure

to use thread sealant on all connections.

2. Attach the Rosemount 702 Transmitter housing to the switch using the

threaded conduit entry.

3. Attach the switch wiring to the terminals as indicated on the wiring

diagram (see Chapter 5).

4. Connect the Black Power Module.

Note

Wireless devices should be powered up in order of proximity from the

Smart Wireless Gateway, beginning with the closest device to the

Gateway. This will result in a simpler and faster network installation.

April 2018

5. Close the housing cover and tighten to safety specification. Always

ensure a proper seal so the metal touches metal, but do not over tighten.

6. Position antenna vertically, either straight up or straight down. The

antenna should be approximately 3 ft. (0.91 m) from any large structures

or buildings, to allow clear communication to other devices.

8 Rosemount 702 Wireless Discrete Transmitter

Page 9

April 2018

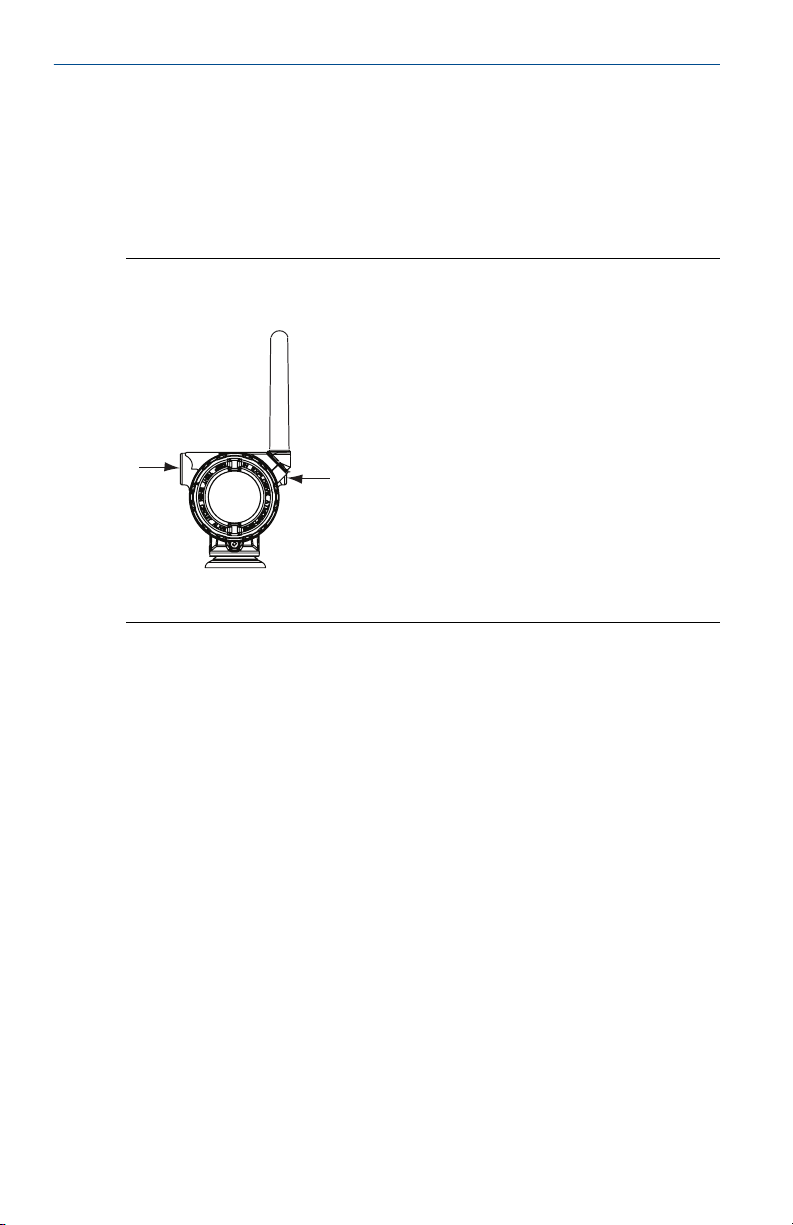

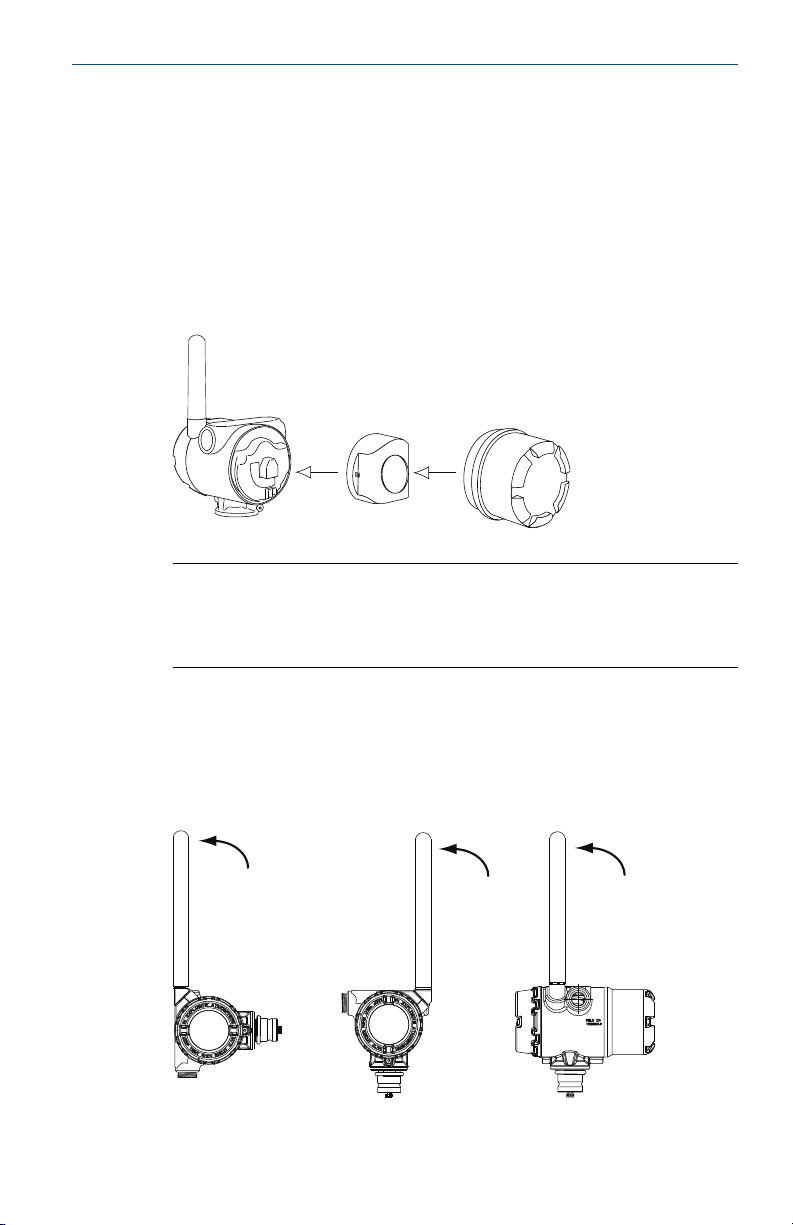

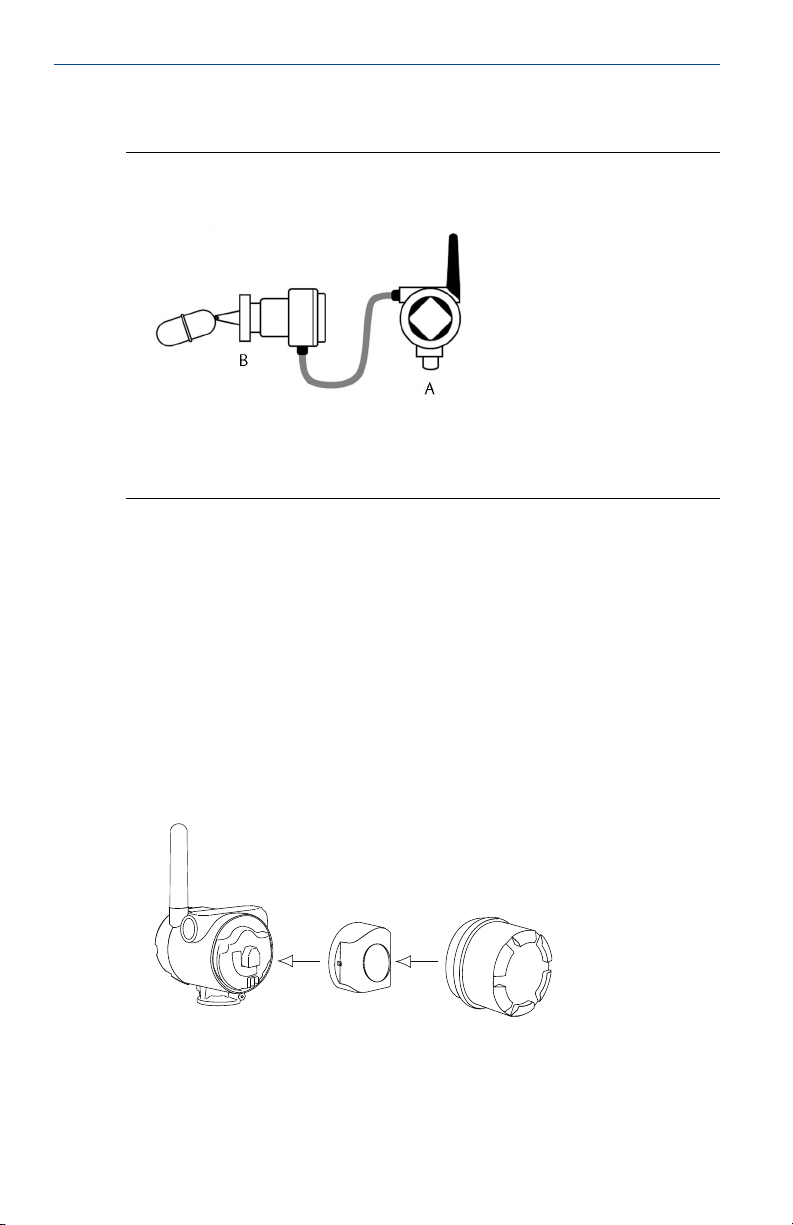

2.2 Remote mount

Remote MountFigure 2-2:

A. Rosemount 702 Transmitter

B. Float switch

Procedure

1. Install the switch according to standard installation practices making sure

to use thread sealant on all connections.

2. Run wiring (and conduit if necessary) from the switch to the Rosemount

702 Transmitter.

3. Pull the wiring through the threaded conduit entry of the Rosemount 702

Transmitter.

4. Attach the switch wiring to the terminals as indicated on the wiring

diagram (see Chapter 5).

5. Connect the black power module.

Quick Start Guide

Quick Start Guide 9

Page 10

Quick Start Guide

Note

Wireless devices should be powered up in order of proximity from the

Smart Wireless Gateway, beginning with the closest device to the

gateway. This will result in a simpler and faster network installation.

6. Close the housing cover and tighten to safety specification. Always

ensure a proper seal so the metal touches metal, but do not over tighten.

7. Position antenna vertically, either straight up or straight down. The

antenna should be approximately 3 ft. (0.91 m) from any large structures

or buildings, to allow clear communication to other devices.

April 2018

2.3 High gain, remote antenna (optional)

The high gain, remote antenna options provide flexibility for mounting the

Rosemount 702 Transmitter based on wireless connectivity, lightning

protection, and current work practices.

10 Rosemount 702 Wireless Discrete Transmitter

Page 11

April 2018

Quick Start Guide

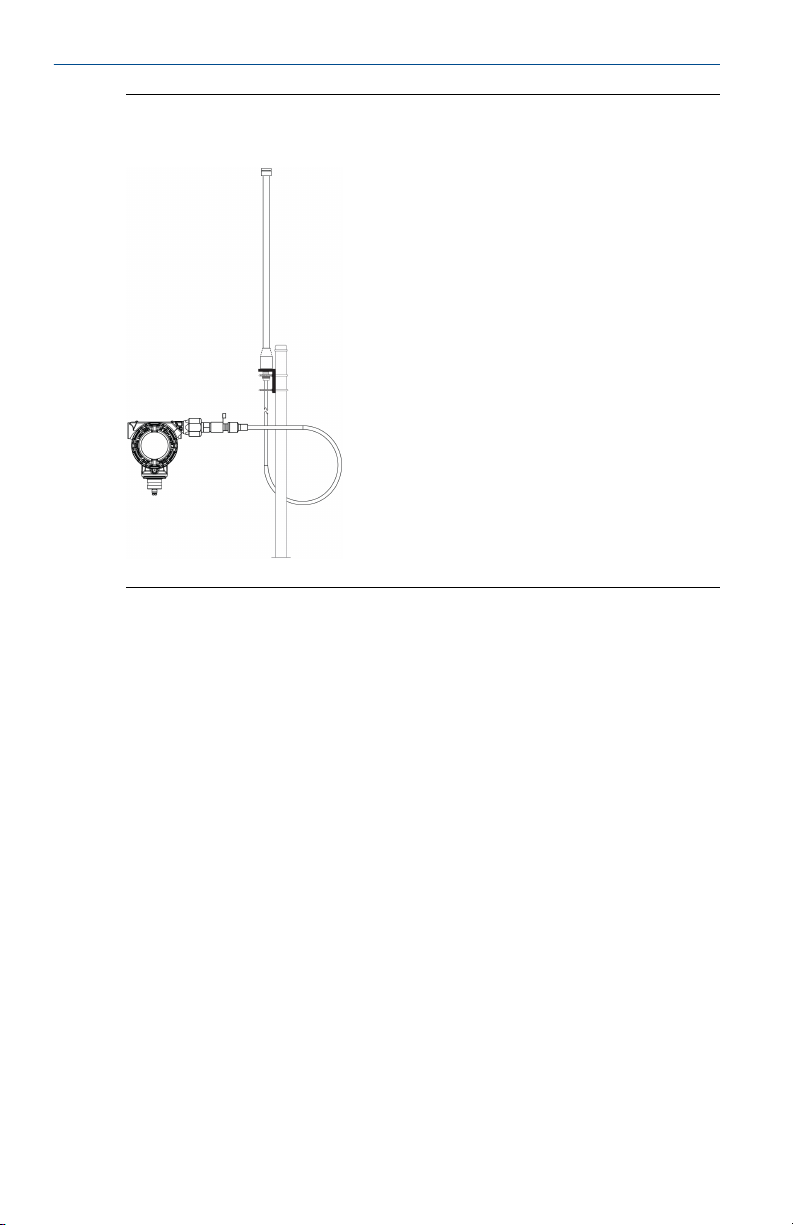

Figure 2-3:

Rosemount 702 Transmitter with High Gain, Remote

Antenna

2.3.1 Install the high gain, remote antenna (WN option)

Prerequisites

Find a location where the remote antenna has optimal wireless performance.

Ideally this will be 15–25 ft. (4.6–7.6 m) above the ground or 6 ft. (2 m)

above obstructions or major infrastructure.

Quick Start Guide 11

Page 12

Quick Start Guide

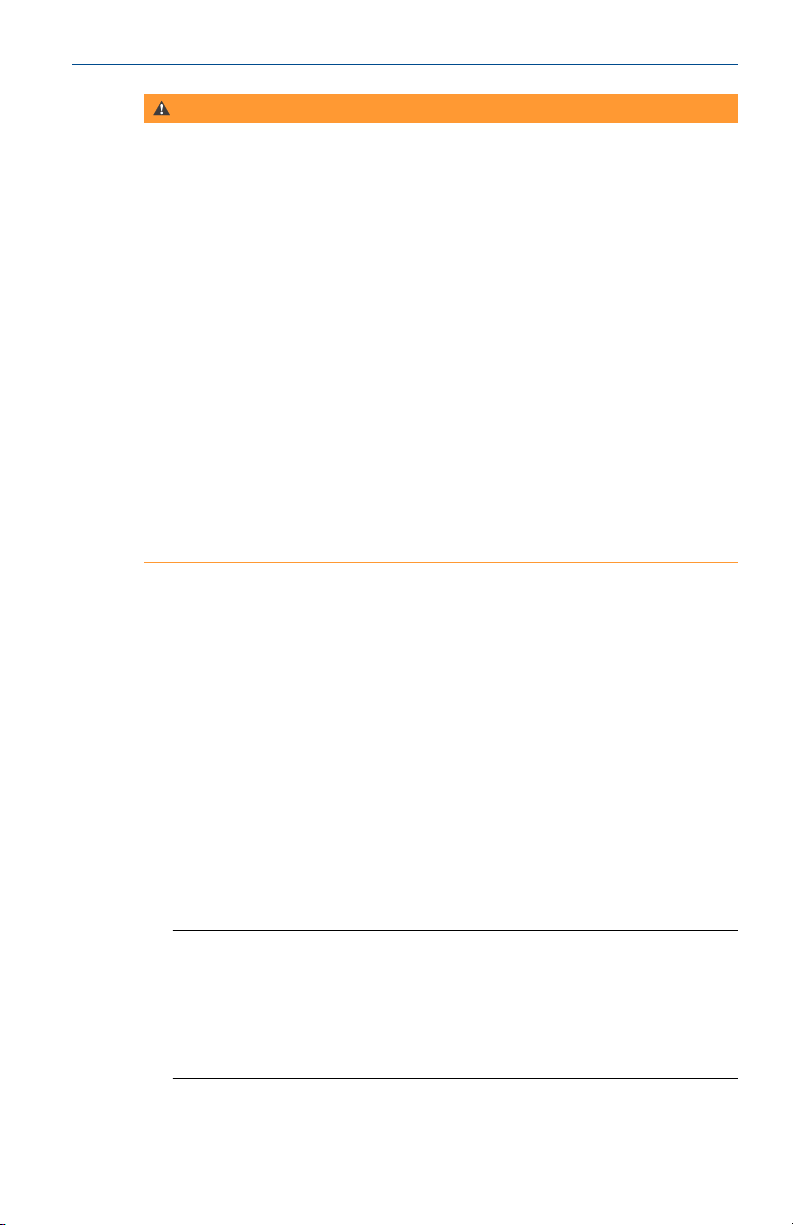

WARNING!

When installing remote mount antennas for the Rosemount 702 Transmitter,

always use established safety procedures to avoid falling or contact with

high-power electrical lines.

Install remote antenna components for the Rosemount 702 Transmitter in

compliance with local and national electrical codes and use best practices for

lightning protection.

Before installing, consult with the local area electrical inspector, electrical

officer, and work area supervisor.

The Rosemount 702 Transmitter remote antenna option is specifically

engineered to provide installation flexibility while optimizing wireless

performance and local spectrum approvals. To maintain wireless

performance and avoid non-compliance with spectrum regulations, do not

change the length of cable or the antenna type.

If the supplied remote mount antenna kit is not installed per these

instructions, Emerson is not responsible for wireless performance or noncompliance with spectrum regulations.

Procedure

April 2018

1. Mount the antenna on a 1.5 to 2-in. pipe mast using the supplied

mounting equipment.

2. Connect the lightning arrestor directly to the top of the Rosemount 702

Transmitter.

3. Install the grounding lug, lock washer, and nut on top of lightning

arrestor.

4. Connect the antenna to the lightning arrestor using the supplied

LMR-400 coaxial cable ensuring the drip loop is not closer than 1 ft. (0.3

m) from the lightning arrestor.

5. Use the coaxial sealant to seal each connection between the wireless field

device, lightning arrestor, cable, and antenna.

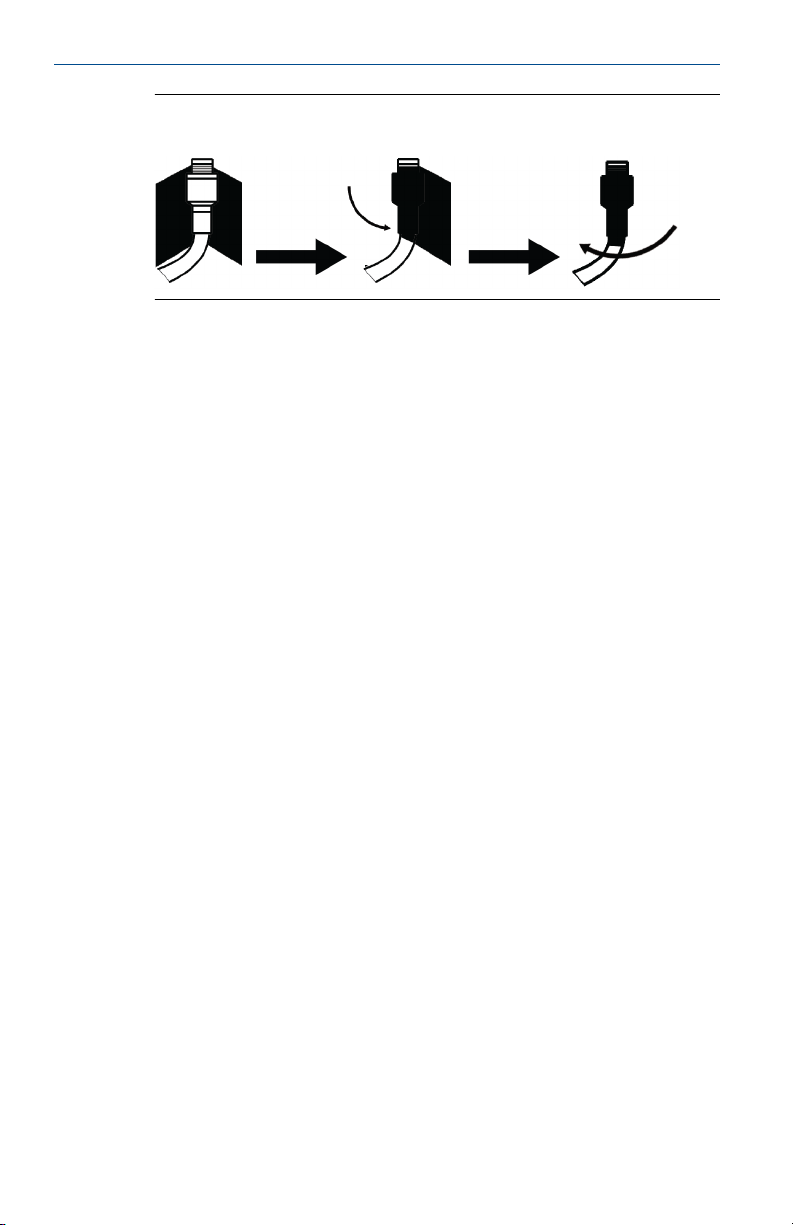

Note

The remote mount antenna kit includes coaxial sealant for

weatherproofing the cable connections for the lightning arrestor,

antenna, and Rosemount 702 Transmitter. Coaxial sealant must be

applied to guarantee performance of the wireless field network. See

Figure 2‐4 for details on how to apply coaxial sealant.

12 Rosemount 702 Wireless Discrete Transmitter

Page 13

April 2018

Quick Start Guide

Applying Coaxial Sealant to Cable ConnectionsFigure 2-4:

6. Ensure the mounting mast and lightning arrestor are grounded according

to local/national electrical code.

Any spare lengths of coaxial cable should be placed in 12-in. (0.3 m) coils.

Quick Start Guide 13

Page 14

Quick Start Guide

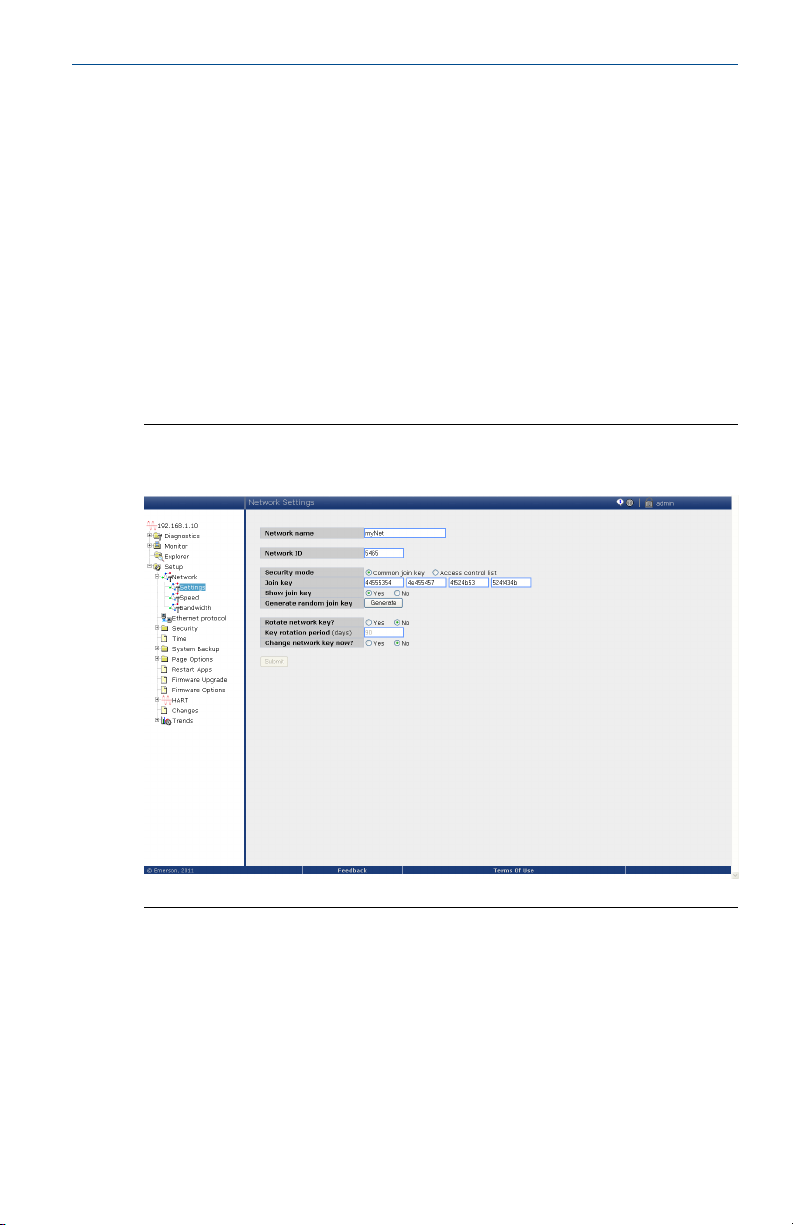

3 Device network configuration

In order to communicate with the Smart Wireless Gateway, and ultimately

the host system, the transmitter must be configured to communicate with

the wireless network. This step is the wireless equivalent of connecting wires

from a transmitter to the information system. Using a Field Communicator or

AMS Wireless Configurator, enter the Network ID and Join Key so they match

the Network ID and Join Key of the Gateway and other devices in the

network. If the Network ID and Join Key do not match that of the Gateway,

the Rosemount 702 Transmitter will not communicate with the network. The

Network ID and Join Key may be obtained from the Smart Wireless Gateway

on the Setup Network Settings page on the web interface, shown in

Figure 3‐1.

Gateway Network SettingsFigure 3-1:

April 2018

3.1 AMS Wireless Configurator

1. Right click on the Rosemount 702 Transmitter.

2. Select Configure.

3. When the menu opens, select Join Device to Network.

4. Follow the method to enter the Network ID and Join Key.

14 Rosemount 702 Wireless Discrete Transmitter

Page 15

April 2018 Quick Start Guide

3.2 Field Communicator

The Network ID and Join Key may be changed in the wireless device by using

the following Fast Key sequence. Set both Network ID and Join Key.

Function Fast Key sequence Menu items

Wireless setup 2,2,1 Network ID, Join Device to Network

Quick Start Guide 15

Page 16

N E T w K

S R C H N G

n e t w k

N E G O T

n e t w k

L I M - O P

n e t w k

O K

Quick Start Guide April 2018

4 Verify operation

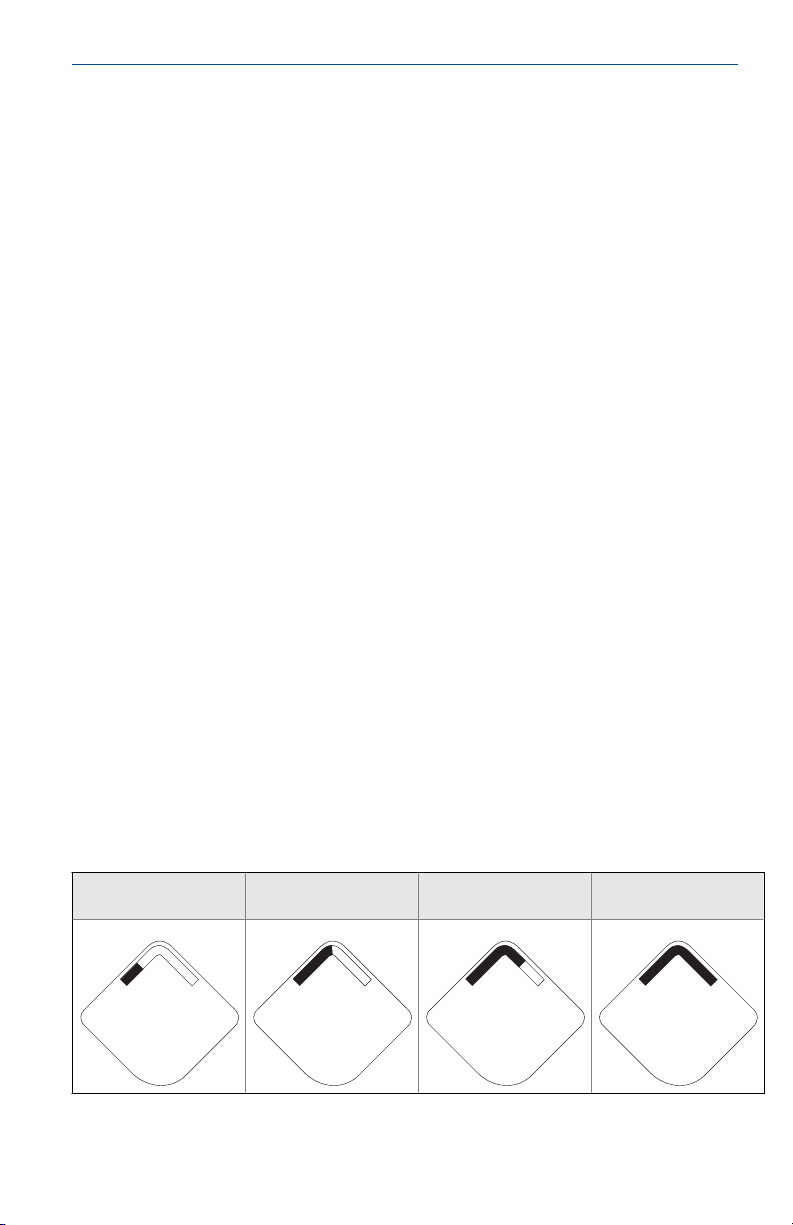

There are four ways to verify operation: using the optional local display (LCD),

using the Field Communicator, using the Smart Wireless Gateway’s

integrated web interface, or by using AMS Suite Wireless Configurator. If the

Rosemount 702 Transmitter was configured with the Network ID and Join

Key, and sufficient time has passed, the transmitter will be connected to the

network.

4.1 Local display

4.1.1 Start-up sequence

When the Rosemount 702 Transmitter is first powered up, the LCD display

will display a sequence of screens: All Segments On, Device Identification,

Device Tag, and then the user chosen variables of the periodic display.

During steady state operation, the LCD display gives a periodic display of user

chosen variables at the configured wireless update rate. These variables can

be selected from a list of six:

• Channel 1 State

• Channel 1 Count

• Channel 2 State

• Channel 2 Count

• Electronics Temperature

• Supply Voltage

Refer to the Rosemount 702 Reference Manual for error codes and other LCD

display messages. The chevron-shaped status bar at the top of the screen

indicates the progress of the network join process. When the status bar is

filled, the device is successfully connected to the wireless network.

Searching for network

16 Rosemount 702 Wireless Discrete Transmitter

Joining network

Connected with limited

bandwidth Connected

Page 17

April 2018

4.2 Field Communicator

For HART® Wireless transmitter communication, a Rosemount 702

Transmitter DD is required.To obtain the latest DD, visit the Emerson Easy

Upgrade site at: Emerson.com/Device‐Install‐Kits.

Function Key sequence Menu items

Communications 3, 3 Join Status, Wireless Mode, Join Mode, Number of Available

Neighbors, Number of Advertisements Heard, Number of

Join Attempts

4.3 Smart Wireless Gateway

In the Gateway’s integrated web server, navigate to the Explorer page. This

page shows whether the device has joined the network and is

communicating properly.

Note

It may take several minutes for the device to join the network.

Note

If the device joins the network and immediately has an alarm present, it is

likely caused by the sensor configuration. Check the sensor wiring (see

Figure 5‐1) and the sensor configuration (see Table 5‐6).

Quick Start Guide

Quick Start Guide 17

Page 18

Quick Start Guide April 2018

Smart Wireless Gateway Explorer PageFigure 4-1:

4.4 AMS Wireless Configurator

When the device has joined the network, it will appear in AMS Wireless

Configurator as illustrated below.

AMS Wireless Configurator, Device Explorer ScreenFigure 4-2:

18 Rosemount 702 Wireless Discrete Transmitter

Page 19

April 2018

4.5 Troubleshooting

If the device is not joined to the network after power up, verify the correct

configuration of the Network ID and Join Key, and that Active Advertising has

been enabled on the Smart Wireless Gateway. The Network ID and Join Key in

the device must match the Network ID and Join Key of the Gateway.

Procedure

1. From the Gateway's integrated web interface, select Setup Network

Settings to obtain the Network ID and Join Key (see Figure 4‐3).

Gateway Network SettingsFigure 4-3:

Quick Start Guide

2. To change the Network ID and Join Key in the wireless device, use a Field

Communicator and enter the following Fast Key sequence.

Function

Wireless 2, 1, 1 Join Device to Network

Fast Key sequence Menu items

3. Follow the on screen prompts.

Quick Start Guide 19

Page 20

Quick Start Guide

April 2018

5 Reference information: wiring switch inputs,

output circuits, and leak sensors

5.1 Dry contact switch inputs

The Rosemount 702 Transmitter has a pair of screw terminals for each of two

channels, and a pair of communication terminals. These terminals are labeled

as follows:

CH1+: Channel one positive

CMN: Common

CH2+: Channel two positive

CMN: Common

COMM: Communication

Rosemount 702 Transmitter TerminalFigure 5-1:

5.2 Wireless output specifications

5.2.1 Dual input

The Rosemount 702 Transmitter will accept the input from one or two single

pole single throw switches on inputs CH1 and CH2. The wireless output of

the transmitter will be both a primary variable (PV) and a secondary variable

20 Rosemount 702 Wireless Discrete Transmitter

Page 21

April 2018

Quick Start Guide

(SV). The PV is determined by the CH1 input. The SV is determined by the

CH2 input. A closed switch drives a TRUE output. An Open switch drives a

FALSE output.

Note

Any dry contact input may optionally be inverted by the device, so change

the discrete logic state. This is useful, for instance, if a normally open switch

is used to replace a normally closed switch.

Single and Dual InputFigure 5-2:

A. Single Input

B. Dual Input

Single or Dual InputTable 5-1:

Switch input Wireless output Switch input Wireless output

CH1 PV CH2 SV

Closed TRUE (1.0) Closed TRUE (1.0)

Open FALSE (0.0) Open FALSE (0.0)

5.2.2 Dual input, limit contact logic

When configured for Limit Contact Logic, the Rosemount 702 Transmitter

will accept the input from two single pole single throw switch on inputs CH1

and CH2, and will use limit contact logic for the determination of the wireless

outputs.

Quick Start Guide 21

Page 22

Quick Start Guide

A. TRUE

B. FALSE

Switch input Wireless output

CH1 CH2 PV SV

Open Open TRAVEL (0.5) TRAVEL (0.5)

Open Closed FALSE (0.0) FALSE (0.0)

Closed Open TRUE (1.0) TRUE (1.0)

Closed Closed FAULT(NaN) FAULT(NaN)

April 2018

Dual Input, Limit ContactsFigure 5-3:

Dual Input, Limit Contact LogicTable 5-2:

5.2.3 Dual input, opposing contact logic

When configured for Opposing Contact Logic, the Rosemount 702

Transmitter will accept the input from a double pole single throw switch on

inputs CH1 and CH2, and will use opposing contact logic for the

determination of the wireless outputs.

22 Rosemount 702 Wireless Discrete Transmitter

Page 23

April 2018

Quick Start Guide

Dual Input, Opposing ContactFigure 5-4:

A. TRUE

B. FALSE

Dual input, Opposing Contact LogicTable 5-3:

Switch inputs Wireless outputs

CH1 CH2 PV SV

Open Open FAULT(NaN) FAULT(NaN)

Open Closed FALSE (0.0) FALSE (0.0)

Closed Open TRUE (1.0) TRUE (1.0)

Closed Closed FAULT(NaN) FAULT(NaN)

5.3 Momentary discrete inputs, measurement option code 32 and 42

The Rosemount 702 Transmitter is capable of detecting momentary discrete

inputs of 10 milliseconds or more in duration, regardless of the wireless

update rate. At each wireless update, the device reports current discrete

input state along with an accumulating count of close-open cycles for each

input channel.

Quick Start Guide 23

Page 24

Quick Start Guide

A. Input Switch State

B. Closed

C. Open

D. State

E. Count

F. Wireless Updates

April 2018

Momentary Inputs and Accumulating CountFigure 5-5:

Figure 5-6:

Reporting of Current Discrete State and Count in AMS Device

Manager

A. Current State

B. Count

24 Rosemount 702 Wireless Discrete Transmitter

Page 25

April 2018

5.3.1 Setting variable reporting

The Rosemount 702 Transmitter has two choices for variable reporting:

Classic - Discrete State Only, or Enhanced – Discrete State and Count.

1. In AMS Device Manager, select Configure > Manual Setup > HART.

2. Set Variable Reporting as desired.

Option Description

Classic - Discrete State

Only

Enhanced – Discrete

State with Count

Table 5‐4 shows the variable mapping for both cases.

Variable MappingTable 5-4:

Variable reporting PV SV TV QV

Classic – Discrete State Only CH1 State CH2 State Electronics tem-

Enhanced – Discrete State

with Count

The Rosemount 702 Transmitter will report variables exactly like

the previous version of the device (measurement option code

22).

The Rosemount 702 Transmitter will provide both current state

of the discrete channels, and a count of the discrete state

change cycles.

Quick Start Guide

Supply voltage

perature

CH1 State CH2 State CH1 Count CH2 Count

5.4 Discrete output circuits, measurement option code 42

The Rosemount 702 Transmitter has two channels that can each be

configured for discrete input or output. Inputs must be dry contact switch

inputs and these were described in a preceding section of this document.

Outputs are a simple switch closure to activate an output circuit. The

Rosemount 702 Transmitter output does not provide any voltage or current,

the output circuit must have power of its own. The Rosemount 702

Transmitter output has maximum switch capacity per channel of 26 volts DC

and 100 milliamps.

Note

It is very important that the polarity of the output circuit is as shown in the

wiring diagrams, with the positive (+) side of the circuit wired to the +

terminal of each channel, and the negative (-) side of the circuit wired to the

CMN terminal. If the output circuit is wired backwards it will remain active

(switch closed) regardless of the state of the output channel.

Quick Start Guide 25

Page 26

Quick Start Guide

5.5 Discrete output switch functionality

The discrete output of the Rosemount 702 Transmitter is driven by the host

control system, through the Smart Wireless Gateway, and out to the

Rosemount 702 Transmitter. The time required for this wireless

communication from the Gateway to the Rosemount 702 Transmitter is

dependent on many factors, including the size and topology of the network

and the total amount of downstream traffic on the wireless network. For a

network that is constructed to our best practices, typical delays in

communication of a discrete output from the Gateway to the Rosemount

702 Transmitter are 15 seconds or less. Remember that this delay is only part

of the latency that well be observed in a control loop.

Note

The output switch functionality of the Rosemount 702 Transmitter requires

that the network is managed by a version 4 Smart Wireless Gateway, with

v4.3 or greater firmware installed.

Output Circuit WiringFigure 5-7:

April 2018

A. LOAD

B. OUTPUT

26 Rosemount 702 Wireless Discrete Transmitter

Page 27

April 2018

Quick Start Guide

Possible Configurations for Both Channel 1 and Channel 2Figure 5-8:

A. INPUT

B. LOAD

C. OUTPUT

5.6

Quick Start Guide 27

Special considerations for dual output circuits

If both channels are connected to output circuits, it is very important that the

CMN terminal of each circuit be at the same voltage. Employing a common

ground for both output circuits is one way to ensure that both circuits have

CMN terminals at the same voltage.

Page 28

Quick Start Guide

A. LOAD

B. OUTPUT

If two output circuits are connected to a single Rosemount 702 Transmitter

with a single power supply, both CH + and CMN terminals must be connected

to each output circuit. The negative power supply wires must be at the same

voltage and connected to both CMN terminals.

April 2018

Dual Output Circuits with a Common GroundFigure 5-9:

Dual Output Circuits with One Power SupplyFigure 5-10:

A. LOAD

B. OUTPUT

28 Rosemount 702 Wireless Discrete Transmitter

Page 29

April 2018 Quick Start Guide

5.7 Switching greater currents or voltages

It is important to note that the maximum output switching capacity is 26

volts DC and 100 milliamps. If a greater voltage or current is to be switched,

an interposing relay circuit can be used. Figure 5‐11 shows an example of a

circuit to switch higher currents or voltages.

Wiring an Interposing Relay to Switch Greater Currents or

Voltages

5.8

Figure 5-11:

A. Power Supply

B. LOAD

Plunger arrival detection

5.8.1 Terminal block connections

The plunger arrival detection configuration for measurement option code 52

is intended for use with the ETC Cyclops Plunger Arrival Sensor.

Plunger Arrival Terminal DiagramFigure 5-12:

Quick Start Guide 29

Page 30

1

2

3

3

2

1

Quick Start Guide

The wiring connections to the ETC Cyclops sensor are made according to

Figure 5-13, where 1 connects to 3, 2 connects to 2, and 3 connects to 1

between the transmitter and the sensor.

Plunger Arrival Sensor ETC Cyclops Sensor

April 2018

Wiring ConfigurationFigure 5-13:

Rosemount 702 Transmitter ETC Cyclops Sensor

1. PWR OUT

2. SIG

3. COM

1. COM

2. SIG

3. PWR

For mounting and maintenance of the ETC Cyclops Sensor, refer to the ETC

Cyclops Plunger Arrival Sensor Manual.

5.8.2 Latching feature

The Rosemount 702 has a latching feature that, when enabled, allows

detection of momentary state changes to be held for a configurable latch

period. The latching feature can be configured to detect either high or low

state changes. By default, the Plunger state (channel 1) is enabled to latch

high state changes for a period of one minute.

The following are some examples to demonstrate how the latching time

works.

30 Rosemount 702 Wireless Discrete Transmitter

Hold time is set to four seconds for illustration in the following examples.

Note

Page 31

A

B

A

B

A

B

April 2018

Quick Start Guide

Short events (less than latch hold time) of the measured value will be latched

to the reported value for the duration of latch hold time.

Latch Time Short EventsFigure 5-14:

A. Measured

B. Reported

The start of the ltach hold timer begins when the measured signal first

transitions to active state.

Latch Hold Time StartFigure 5-15:

A. Measured

B. Reported

The latch only applies to transitions into the active state. As soon as the

reported value is no longer latched,the devices is armed for the next event.

Latch Applies to Transitions to Active StateFigure 5-16:

A. Measured

B. Reported

If the measured value goes inactive and active again before the initial latch

hold timer experies, the latch hold timer will restart from the beginning of

the most recent event.

Quick Start Guide 31

Page 32

A

B

Quick Start Guide

Latch Hold Timer RestartsFigure 5-17:

A. Measured

B. Reported

5.8.3 Latching warnings

WARNING!

When state latching is enabled, the discrete variable reported to the system

will represent the latched value which may not be the actual state value

measured by the Rosemount 702 Transmitter

WARNING!

Ensure that the state latch time value is long enough for the value to be

reported throughout the entire system to guarantee the state transition is

not missed. After configuring discrete latching function, check for proper

operation at the system level to ensure the desired state transitions are

captured as desired.

5.8.4 System Verification

April 2018

After installation of the 702DX52 for plunger arrival one must verify

functionality.

• Verify the sensor: To do so, pass a ferrous object (ex. Wrench) past the

cyclops sensor to simulate an arrival. Verify via the LCD screen and/or

field communicator that channel 1 indicates a state change. If a state

change is seen, sensor wiring is correct; if nothing is seen, please go back

through the installation steps and confirm that everything has been done

accordingly.

• Verify System integration: It is important to verify the latch time is

configured correctly. The default latch period is set to one minute. Verify

the host system can detect the arrival event by moving a ferrous metal

object (ex. Wrench) past the arrival sensor. The signal should be passed

from the device, through the Wireless Gateway and detected at the final

host application (ex. PLC, Modbus/OPC, etc.). If nothing is seen, confirm

the latch time is appropriate considering the full system scan cycle.

32 Rosemount 702 Wireless Discrete Transmitter

Page 33

April 2018

5.9 Leak sensors, liquid hydrocarbon detection, measurement option code 61

5.9.1 Terminal block connections

The Liquid Hydrocarbon Detection configuration is intended for use with the

Tyco® TraceTek® Fast Fuel Sensor, or TraceTek sensing cable.

Fuel Sensor TerminalFigure 5-18:

Quick Start Guide

Fuel Sensor ConnectionFigure 5-19:

5.9.2 Connecting to the fast fuel sensor and TraceTek sensing cable

The connections to the Fast Fuel Sensor TraceTek sensing cable are made by

matching the appropriately colored wires to the matching colored

termination lugs.

Quick Start Guide 33

Page 34

$

&

'

(

)

%

Quick Start Guide

Note

All part numbers associated with the fuel sensor cable wiring refer to

products sold by Tyco Thermo Controls, LLC.

The Rosemount 702 Wireless Discrete Transmitter can support up to 3 Fast

Fuel sensors. These Fast Fuel sensors are connected using TraceTek Modular

Leader Cable (TT-MLC-MC-BLK), optional modular jumper cables (TT-MJC-xxMC-BLK) and branching connectors (TT-ZBC-MC-BLK) as suggested in

Figure 5‐20.

April 2018

Fuel Sensor WiringFigure 5-20:

A. TT‐MLC‐MC‐BLK (Leader cable)

B. TT‐FFS‐100 or TT‐FFS‐250 (Fast fuel sensor probe)

C. TT‐MLC‐MC‐BLK (Leader cable)

D. TT‐MJC‐xx‐MC‐BLK (Optional jumper cable)

E. TT‐ZBC‐xx‐MC‐BLK (Branch connector)

F. TT‐FFS‐100 or TT‐FFS‐250 (Fast fuel sensor probe)

The Rosemount 702 Wireless Discrete Transmitter can support up to 500

feet of TraceTek hydrocarbon or solvent sensor cable (TT5000 or TT5001

series). The total amount of sensor cable connected to a single Rosemount

34 Rosemount 702 Wireless Discrete Transmitter

702 Transmitter is not to exceed 500 ft. (150 m). However leader cable,

jumper cables (if used) and branch connectors are not included in the 500

foot limit. See Figure 5‐21 for typical configurations.

Page 35

$

'

(

)

+*

%

&

April 2018

Quick Start Guide

Fuel Sensor Cable WiringFigure 5-21:

A. TT‐MLC‐MC‐BLK (Leader Cable)

B. TT5000/TT5001 Sensor cable (up to 500 ft.)

C. TT‐MET‐MC (End termination)

D. TT‐MJC‐xx‐MC‐BLK (Optional jumper cable)

E. TT‐ZBC‐xx‐MC‐BLK (Branch connector)

F. TT‐MET‐MC (End termination)

G. TT‐MET‐MC (End termination)

H. Up to 500‐ft. TT5000 or TT5001 sensor cable (Total per 702)

Important notes regarding the use of Tyco TraceTek Fast Fuel Sensor and

TraceTek sensing cable:

• Tyco TraceTek sensors must be installed as per manufacturer

recommendations.

• Do not run the Rosemount 702 Transmitter for long periods (more than

two weeks) with a Tyco fuel sensor in the leak state as this will more

rapidly deplete the power module.

5.9.3 Liquid hydrocarbon detection interface, for Modbus® mapping

Table 5‐5 describes use of the Rosemount 702 Transmitter for hydrocarbon

Quick Start Guide 35

detection in other communications protocols such as Modbus or OPC. It is

imperative that both PV and SV be mapped to the host system so as to make

a good interpretation of the condition and status of the leak detector.

Page 36

Quick Start Guide

April 2018

Table 5-5:

Liquid Hydrocarbon Detection Interface, for Modbus

Mapping

PV SV Description/interpretation

1.0 1.0 Normal condition, no leak detected, sensor status good

0.0 1.0 or 0.0 Leak detected, sensor status good

1.0 0.0 Sensor Not Connected, Assume Leak, take appropriate action

NOTICE

It is imperative that both PV and SV be mapped to the host system so the

diagnostic information on the sensor status is captured.

In addition, system considerations must be observed to ensure that the

device is still connected to the wireless network and reporting values. On an

Emerson Smart Wireless Gateway, this can be done by referring to the

parameter: PV_HEALTHY. PV_HEALTHY has a “True” state when the device is

on the network and its updates are current, not late or stale, and the device is

functioning properly. A “False” state of PV_HEALTHY means the device is

either off the network, the data updates are not current, or that there is a

malfunction of the device (such as an electronics failure). In the case of a

“False” state of PV_HEALTHY, it is recommended to assume the device is not

connected to the network and take appropriate action.

Mapping the PV, SV, and PV_HEALTHY variables and parameter

Below is a the Gateway screen where the PV, SV, and PV_HEALTHY variables

and parameter can be mapped.

36 Rosemount 702 Wireless Discrete Transmitter

Page 37

April 2018 Quick Start Guide

Smart Wireless Gateway Modbus Register MapFigure 5-22:

The Fast Fuel Sensor Diagnostics will propagate via the SV variable. This

additional information will provide additional sensor Status information while

using the TraceTek Fast Fuel Sensor.

WARNING!

If a device is not present on the wireless network, appropriate action must be

taken by the host system.

5.10

Quick Start Guide 37

Field Communicator use

Note

In order to communicate with a Field Communicator, power the Rosemount

702 Transmitter by connecting the power module.

Rosemount 702 Transmitter Fast Key SequenceTable 5-6:

Function

Device information

Fast Key sequence Menu items

2, 2, 4, 3 Manufacturer Model, Final Assembly Number, Universal,

Field Device, Software, Hardware, Descriptor, Message,

Date, Model Number I, II, III, SI Unit Restriction, Country

Page 38

COMM

P/N 00753-9200-0020

1

2

3

4

CH1 +

CMN

CH2 +

CMN

CH Input Mode:

Dry Contact Only

CH Output Mode:

26VDC Max

100mA Max

Quick Start Guide April 2018

Rosemount 702 Transmitter Fast Key Sequence (continued)Table 5-6:

Function

quence Menu items

Guided setup 2, 1 Join Device to Network, Configure Update Rate, Config-

ure Sensor, Calibrate Sensor, Configure Display, Configure Process Alarms

Manual setup 2, 2 Wireless, Process Sensor, Percent of Range, Device Tem-

peratures, Device Information, Device Display, Other

Wireless 2, 2, 1 Network ID, Join Device to Network, Configure Update

Rate, Configure Broadcast Power Level, Power Mode,

Power Source

Fast Key se-

Sensor calibra-

3, 4, 1 Output configuration, input configuration

tion

Field Communicator ConnectionsFigure 5-23:

38 Rosemount 702 Wireless Discrete Transmitter

Page 39

April 2018

Quick Start Guide

6 Safety shower and eye wash monitoring

The Rosemount 702 Transmitter can be used to monitor safety showers and

eye wash stations by using switch kits provided by TopWorx™, an Emerson

company. These kits are ordered as a part of the Rosemount 702 model

code, or separately as an accessory kit, and are available for both insulated

and un-insulated pipes. These kits contain the switches, brackets and cables

that are necessary to install the Rosemount 702 to monitor both the safety

shower and the eye wash in a single station. Because each has two input

channels, one Rosemount 702 Transmitter can be used to monitor both a

safety shower and an eye wash.

Each Safety Shower Monitoring kit contains:

• Two TopWorx GO™ Switch magnetic proximity switches

• Two cables, one six foot and one twelve foot

• Two black polymer cable glands

• Mounting kit for safety shower and eye wash

Safety shower monitoring

When the shower valve is activated (valve open) by pulling down on the

handle, the TopWorx switch is activated (closed switch) and the Rosemount

702 Transmitter senses that switch closure. This switch state is then

transmitted by the Rosemount 702 Transmitter to the Gateway, which then

sends that information to the control host or alert system. When the shower

valve is closed, the switch remains in the activated state until it is reset by a

technician. The switch can be re-set only by placing a ferrous metal object on

the far side of the sensing area of the switch.

Quick Start Guide 39

Page 40

Quick Start Guide

Eye wash monitoring

When the eye wash valve is activated (valve open) by pushing down on the

hand paddle, the TopWorx switch is activated (closed switch) and the

Rosemount 702 Transmitter senses that switch closure. This switch state is

then transmitted by the Rosemount 702 Transmitter to the Gateway, which

then sends that information to the control host or alert system. When the

eye wash valve is closed, the switch remains in the activated state until it is

reset by a technician. The switch can be re-set only by placing a ferrous metal

object on the far side of the sensing area of the switch.

April 2018

TopWorx Switch Installed on a Safety ShowerFigure 6-1:

40 Rosemount 702 Wireless Discrete Transmitter

Page 41

April 2018 Quick Start Guide

TopWorx Switch Installed on an Eye Wash StationFigure 6-2:

Quick Start Guide 41

Page 42

Quick Start Guide April 2018

7 Product Certifications

Rev 1.0

7.1 European directive information

A copy of the EU Declaration of Conformity can be found at the end of the

Quick Start Guide. The most recent revision of the EU Declaration of

Conformity can be found at Emerson.com/Rosemount.

7.2 Telecommunication compliance

All wireless devices require certification to ensure that they adhere to

regulations regarding the use of the RF spectrum. Nearly every country

requires this type of product certification. Emerson is working with

governmental agencies around the world to supply fully compliant products

and remove the risk of violating country directives or laws governing wireless

device usage.

7.3

7.4

7.5

7.6

FCC and IC

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following conditions: This device may not cause harmful interference.

This device must accept any interference received, including interference

that may cause undesired operation. This device must be installed to ensure

a minimum antenna separation distance of 20 cm from all persons.

Ordinary location certification

As standard, the transmitter has been examined and tested to determine

that the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

Installing equipment in North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in the respective codes.

USA

7.6.1 I5 U.S.A. Intrinsically Safe (IS) and Non-incendive

Certificate:

42 Rosemount 702 Wireless Discrete Transmitter

[CSA] 1143113

Page 43

April 2018

Quick Start Guide

Standards:

Class 3600 - 2011,Class 3610 - 2010, Class 3611 - 2004,Class

3810 - 2005, UL 50E (11th Edition), UL 61010-1 (3rd Edition),

ANSI/ISA-60079-0 (12.00.01) - 2013, ANSI/ISA 60079-11

(12.02.01): 2014, ANSI/IEC 60529-2004

Markings:

IS CL I, DIV 1, GP, A, B, C, D; CL II, DIV 1, GP E, F, G; Class III;

Class 1, Zone 0 AEx ia IIC Ga T4; NI CL I, DIV 2, GP A, B, C, D T4;

T4(–50 °C ≤ Ta ≤ +70 °C) when installed per Rosemount

drawing 00702-1020; Type 4X/IP66/67

Special Conditions for Safe Use (X):

1. The Rosemount 702 Transmitter housing contains aluminum and is

considered a potential risk of ignition by impact or friction. Care must be

taken into account during installation and use to prevent impact and

friction.

2. The surface resistivity of the polymeric antenna is greater than 1GΩ. To

avoid electrostatic charge build-up, it must not be rubbed or cleaned with

solvents or a dry cloth.

3. The model 702 may only be used with either the 701PBKKF Rosemount

Smartpower Black Power Module or the Computational Systems, Inc.

(CSI) MHM-89004.

Sensor terminal parameters (option code

32)

UO = 6.6 V UO = 7.8 V

IO = 13.37 mA IO = 92 mA

PO = 21.77 mW PO = 180 mW

CO = 21.78 µF CO = 9.2 µF

LO = 198 mH LO = 4.2 mH

Fuel sensor terminal parameters (option

code 61)

7.6.2 N5 U.S.A. Nonincendive

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. The model 702 may only be used with either the 701PBKKF Rosemount

Smartpower Black Power Module or the Computational Systems, Inc.

(CSI) MHM-89004.

Quick Start Guide 43

[CSA] 1143113

Class 3600 - 2011, Class 3611 - 2004, Class 3810 - 2005, UL

50E (11th Edition), UL 61010-1 (3rd Edition), ANSI/IEC

60529-2004

NI CL I, DIV 2, GP A, B, C, D T4; T4(-50 °C ≤ Ta ≤ +70 °C) Type

4X/IP66/67

Page 44

Quick Start Guide April 2018

7.7 Canada

7.7.1 I6 Canada Intrinsically Safe

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. The Rosemount 702 Transmitter housing contains aluminum and is

considered a potential risk of ignition by impact or friction. Care must be

taken into account during installation and use to prevent impact and

friction.

2. The surface resistivity of the polymeric antenna is greater than 1GΩ. To

avoid electrostatic charge build-up, it must not be rubbed or cleaned with

solvents or a dry cloth.

3. The model 702 may only be used with either the 701PBKKF Rosemount

Smartpower Black Power Module or the Computational Systems, Inc.

(CSI) MHM-89004.

[CSA] 1143113

CAN/CSA C22.2 No. 0-10, CSA Std. C22.2 No. 94-M1991

(R2011), CAN/CSA Std C22.2 60079-0-11, CAN/CSA

60079-11-14, CSA Std C22.2 No. 60529:05, CAN/CSA-C22.2

No. 61010-1-12

Intrinsically Safe Class I, Division 1; Groups A, B, C, and D, T4;

suitable for Class 1, Zone 0, IIC, T4; when connected per

Rosemount drawing 00702-1020; Type 4X

7.7.2 N6 Canada Class I Division 2

Certificate:

Standards:

Markings:

[CSA] 1143113

CAN/CSA C22.2 No. 0-10, CAN/CSA C22.2 No. 94-M91, CSA

C22.2 No. 213-M1987, CSA Std C22.2 No. 60529:05

Suitable for Class 1, Division 2, Groups A, B, C, and D, T4; Cl. I,

Zone 2, IIC, T4

Special Condition for Safe Use (X):

1. The model 702 may only be used with either the 701PBKKF Rosemount

Smartpower Black Power Module or the Computational Systems, Inc.

(CSI) MHM-89004.

7.8

Europe

7.8.1 I1 ATEX Intrinsic Safety

Certificate:

Standards:

44 Rosemount 702 Wireless Discrete Transmitter

Baseefa07ATEX0239X

IEC 60079-0: 2011, IEC 60079-11: 2012

Page 45

April 2018 Quick Start Guide

Markings:

II 1 G Ex ia IIC T4 Ga, T4(-60 °C ≤ Ta ≤ +70 °C) Ex ia IIC T4 Ga,

T4(-60 °C ≤ Ta ≤ +40 °C)

For use with Rosemount SmartPower power module part number

753-9220-0001, or for use with Emerson SmartPower option 701PBKKF.

Sensor terminal parameters (option code 32)

UO = 6.51 V UO = 7.8 V

IO = 13.37 mA IO = 92 mA

PO = 21.76 mW PO = 180 mW

Ci = 0.216 µF Ci = 10 nF

CO

= 21.78 µF CO

IIC

CO

= 549.78 µF CO

IIB

COIIA = 1000 µF CO

Li = 0 Li = 0

LO

= 200 mH LO

IIC

LO

= 800 mH LO

IIB

LO

= 1000 mH LO

IIA

Special Conditions for Safe Use (X):

1. The surface resistivity of the antenna is greater than 1 GΩ. To avoid

electrostatic charge build-up, it must not be rubbed or cleaned with

solvents or a dry cloth.

7.8.2 IU ATEX Intrinsic Safety for Zone 2

Fuel sensor terminal parameters (option

code 61)

= 9.2 µF

IIC

= 129 µF

IIB

= 1000 µF

IIA

= 4.2 mH

IIC

= 16.8 mH

IIB

= 33.6 mH

IIA

Certificate:

Standards:

Markings:

Baseefa12ATEX0122X

IEC 60079-0: 2011, IEC 60079-11: 2012

II 1 G Ex ia IIC T4 Ga, T4(-60 °C ≤ Ta ≤ +70 °C)

Ex ia IIC T5 Gc, T5(-60 °C ≤ Ta ≤ +40 °C)

Sensor terminal parameters (input) Switch terminal parameters (output)

UO = 6.6 V Ui = 26 V

IO = 13.4 mA Ii = 100 mA

PO = 21.8 mW Pi = 0.65 W

CO = 10.9 µF N/A

LO = 25 µH N/A

Quick Start Guide 45

Page 46

Quick Start Guide

Special Conditions for Safe Use (X):

1. The surface resistivity of the antenna is greater than 1 GΩ. To avoid

electrostatic charge build-up, it must not be rubbed or cleaned with

solvents or dry cloth.

2. The Rosemount 701PB Power Module may be replaced in a hazardous

area. The power module has surface resistivity greater than 1 GΩ and

must be properly installed in the wireless device enclosure. Care must be

taken during transportation to and from the point of installation to

prevent electrostatic charge build-up.

7.9 International

7.9.1 I7 IECEx Intrinsic Safety

April 2018

Certificate:

Standards:

Markings:

IECEx BAS 07.0082X

IEC 60079-0: 2011, IEC 60079-11: 2011

Ex ia IIC T4 Ga, T4(-40 °C ≤ Ta ≤ +70 °C); Ex ia IIC T5 Ga,

T5(-40 °C ≤ Ta ≤ +40 °C)

Sensor terminal parameters (option code 32)

UO = 6.51 V UO = 7.8 V

IO = 13.37 mA IO = 92 mA

PO = 21.76 mW PO = 180 mW

Ci = 0.216 µF Ci = 10 nF

CO

= 21.78 µF CO

IIC

CO

= 549.78 µF CO

IIB

CO

= 1000 µF CO

IIA

Li = 0 Li = 0

LO

= 200 mH LO

IIC

LO

= 800 mH LO

IIB

LO

= 1000 mH LO

IIA

Fuel sensor terminal parameters (option

code 61)

= 9.2 µF

IIC

= 129 µF

IIB

= 1000 µF

IIA

= 4.2 mH

IIC

= 16.8 mH

IIB

= 33.6 mH

IIA

Special Conditions for Safe Use (X):

1. The surface resistivity of the antenna is greater than 1 GΩ. To avoid

electrostatic charge build-up, it must not be rubbed or cleaned with

solvents or dry cloth.

2. The Rosemount 701PBKKF Power Module may be replaced in a hazardous

area. The power modules have a surface resistivity greater than 1GΩ and

must be properly installed I the wireless device enclosure. Care must be

taken during transportation to and from the point of installation to

prevent electrostatic charge build-up.

46 Rosemount 702 Wireless Discrete Transmitter

Page 47

April 2018 Quick Start Guide

3. The Rosemount 702 enclosure may be made of aluminum alloy and given

a protective polyurethane paint finish; however, care should be taken to

protect it from impact or abrasion if located in a Zone 0 area.

7.9.2 IY IECEx Intrinsic Safety for Zone 2

Certificate:

Standards:

Markings:

IECEx BAS 12.0082X

IEC 60079-0: 2011, IEC 60079-11: 2011

Ex nA IIC T4 Gc, T4(-40 °C ≤ Ta ≤ +70 °C); Ex nA IIC T5 Gc,

T5(-40 °C ≤ Ta ≤ +40 °C)

Sensor terminal parameters (input)

UO = 6.6 V Ui = 26 V

IO = 13.4 mA Ii = 100 mA

PO = 21.8 mW Pi = 0.65 W

CO = 10.9 µF N/A

LO = 25 µH N/A

Switch terminal parameters

(output)

Special Conditions for Safe Use (X):

1. The surface resistivity of the antenna is greater than 1 GΩ. To avoid

electrostatic charge build-up, it must not be rubbed or cleaned with

solvents or dry cloth.

2. The Rosemount 701PBKKF Power Module may be replaced in a hazardous

area. The power modules have a surface resistivity greater than 1 GΩ and

must be properly installed I the wireless device enclosure. Care must be

taken during transportation to and from the point of installation to

prevent electrostatic charge build-up.

3. The Rosemount 702 enclosure may be made of aluminum alloy and given

a protective polyurethane paint finish; however, care should be taken to

protect it from impact or abrasion if located in a Zone 0 area.

7.10

China

7.10.1 I3 China Intrinsic Safety

Certificate:

Standards:

Markings:

Quick Start Guide 47

GYJ13.1238X

GB3836.1-2010, GB3836.4-2010, GB3836.20-2010

(option 32, 61): Ex ia IIC T4/T5 Ga, T4(-60 ≤ Ta ≤ 70 °C)/T5(-60

≤ Ta ≤ 40 °C)

(option 32, 42): Ex ic IIC T4/T5 Gc, T4(-60 ≤ Ta ≤ 70 °C)/T5(-60

≤ Ta ≤ 40 °C)

Page 48

Quick Start Guide April 2018

Sensor terminal parameters

(option code 32)

UO = 6.6 V UO = 6.6 V Ui = 26 V UO = 7.8 V

IO = 13.4 mA IO = 13.4 mA Ii = 100 mA IO = 92 mA

PO = 21.8 mW PO = 21.8 mW Pi = 650 mW PO = 180 mW

CO

= 21.78 µF CO = 10.9 µF N/A CO = 9.29 µF

IIC

CO

= 499.78 µF N/A N/A N/A

IIB

CO

= 1000 µF N/A N/A N/A

IIA

LO

= 200 mH LO = 0.025 mH N/A LO = 2 mH

IIC

LO

= 800 mH N/A N/A N/A

IIB

LO

= 1000 mH N/A N/A N/A

IIA

Special Conditions for Safe Use (X):

1. See certificate for special conditions.

7.11

Japan

7.11.1 I4 TIIS Intrinsic Safety

Certificates:

Markings:

TC20411 (Option 32), TC20412 (Option 61)

Ex ia IIC T4 X (-20≤ Ta ≤ +60 °C)

Terminal parameters (option code

42)

Fuel sensor terminal

parameters (option

code 61)Sensor Switch

7.12 EAC – Belarus, Kazakhstan, Russia

7.12.1 IM Technical Regulation Customs Union (EAC) Intrinsic Safety

Certificate:

Markings:

Sensor terminal parameters

(option code 32)

UO = 6.6 B UO = 6.6 B Ui, B = 26 B UO = 7.8 B

IO = 13.4 MA IO = 13.4 MA Ii, MA = 100 MA IO = 92 MA

PO = 21.8 MBT PO = 21.8 MBT Pi, BT = 650 MBT PO = 180 MBT

Ci = 216 HΦ Ci = 216 HΦ N/A Ci = 10 HΦ

CO

= 23.78 мкΦ CO

IIC

CO

= 549.78 мкΦ CO

IIB

48 Rosemount 702 Wireless Discrete Transmitter

RU C-US.Gb05.B.00578

(option 32, 61): 0Ex ia IIC T4/T5 X, T4(-60 °C ≤ Ta ≤ +70 °C)/

T5(-60 °C ≤ Ta ≤ +40 °C)

(option 32, 42): 2Ex ic IIC T4/T5 X, T4(-60 °C ≤ Ta ≤ +70 °C)/

T5(-60 °C ≤ Ta ≤ +40 °C)

Terminal parameters (option code 42) Fuel sensor terminal

= 23.78 мкΦ N/A N/A

IIC

= 549.78 мкΦ N/A N/A

IIB

parameters (option

code 61)Sensor Switch

Page 49

April 2018 Quick Start Guide

7.13

Sensor terminal parameters

(option code 32)

CO

= 1000 мкΦ COIIA = 1000 мкΦ N/A N/A

IIA

Li = 0 Li = 0 Li = 0 Li = 0

LO

= 200 MГH LO

IIC

LO

= 800 MГH LO

IIB

LO

= 1000 MГH LO

IIA

Terminal parameters (option code 42) Fuel sensor terminal

= 200 MГH N/A N/A

IIC

= 800 MГH N/A N/A

IIB

= 1000 MГH N/A N/A

IIA

Special Conditions for Safe Use (X):

1. See certificate for special conditions.

Combinations

KQ

Combination of I1, I5, and I6

parameters (option

code 61)Sensor Switch

Quick Start Guide 49

Page 50

Quick Start Guide April 2018

7.14 EU Declaration of Conformity

EU Declaration of ConformityFigure 7-1:

50 Rosemount 702 Wireless Discrete Transmitter

Page 51

April 2018 Quick Start Guide

Quick Start Guide 51

Page 52

Quick Start Guide April 2018

52 Rosemount 702 Wireless Discrete Transmitter

Page 53

ᴹ

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

Rosemount 702

Rosemount 702

List of Parts with China RoH S Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘/ Hazardous Substances

䫵

Lead

(Pb)

⊎

Mercury

(Hg)

䭹

Cadmium

(Cd)

ޝԧ䬜

Hexavalent

Chromium

(Cr +6)

ཊⓤ㚄㤟

Polybrominated

biphenyls

(PBB)

ཊⓤ㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

X O O

O O O

༣փ㓴Ԧ

Housing

Assembly

X O O

X O O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

April 2018 Quick Start Guide

7.15 China RoHS

Quick Start Guide 53

Page 54

Quick Start Guide April 2018

54 Rosemount 702 Wireless Discrete Transmitter

Page 55

April 2018 Quick Start Guide

Quick Start Guide 55

Page 56

*00825-0400-4702*

Quick Start Guide

00825-0400-4702, rev. GE

April 2018

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd

Shakopee, MN 55379 USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

Sunrise, FL 33323, USA

T +1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRF@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

T +41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

©

2018 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are available

upon request. The Emerson logo is a trademark and

service mark of Emerson Electric Co. Rosemount is

mark of one of the Emerson family of companies.

All other marks are the property of their respective

owners.

Loading...

Loading...