Page 1

Product Data Sheet

00813-0100-4648 Rev GD

Rosemount™ 648 Wireless Temperature

Transmitter

with Rosemount X-well™ Technology

July 2016

Rosemount X-well Technology provides accurate process temperature without the

requirement of a thermowell or process penetration.

Industry-leading temperature transmitter delivers field reliability as a wireless

measurement solution.

Achieve optimal efficiency with best-in-class product specifications and capabilities.

Smart Wireless delivers innovative wireless solutions for temperature measurement and

overall transmitter performance.

Page 2

Rosemount 648 Wireless

July 2016

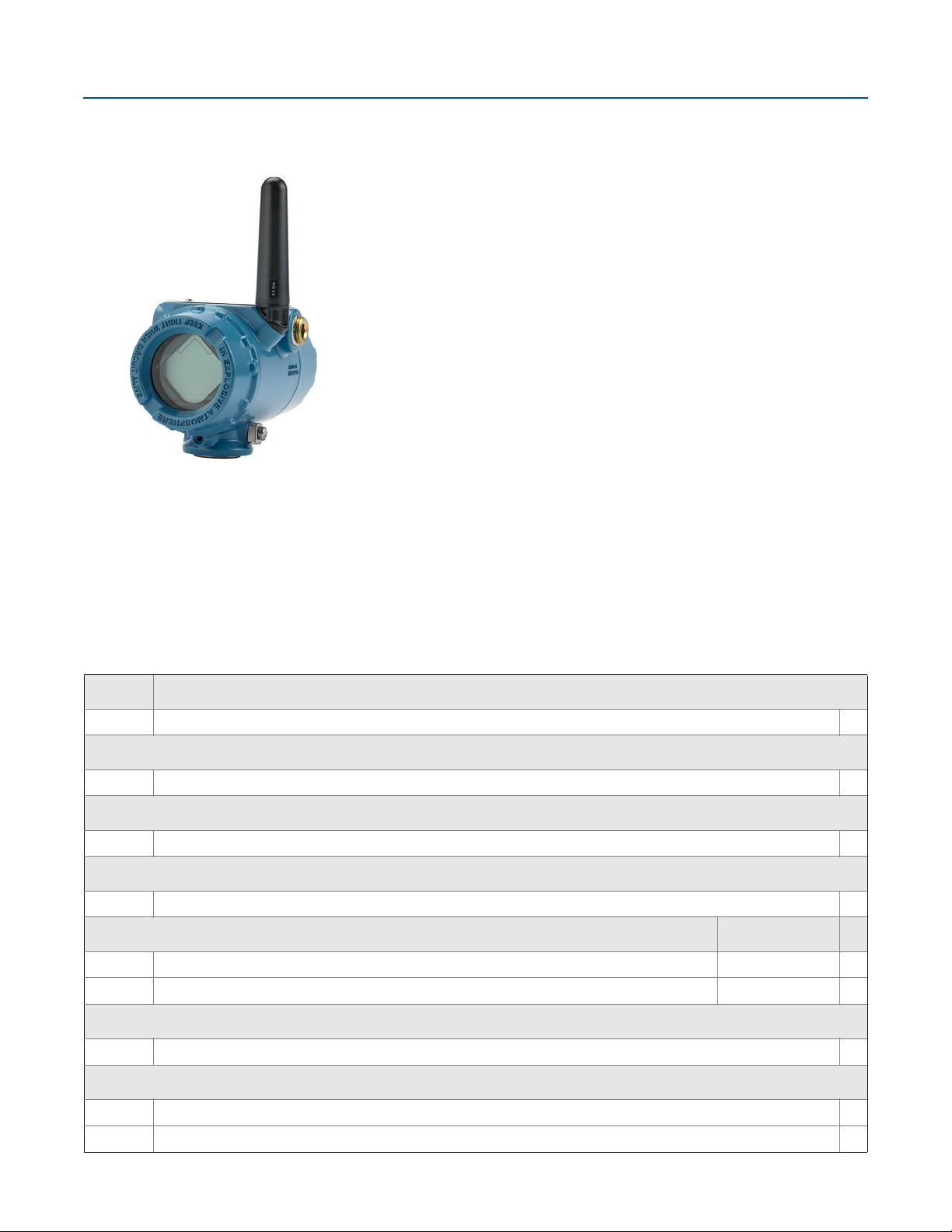

Rosemount 648 Wireless Temperature Transmitter

Rosemount X-well Technology provides a Complete Point Solution™ for accurately measuring

process temperature without the requirement of a thermowell or process penetration.

Simplify temperature measurement point specification, installation and maintenance, and eliminate

possible leak points.

Calculates a repeatable and accurate process temperature measurement via an in-transmitter thermal

conductivity algorithm

Measures pipe surface and ambient temperature, and utilizes the thermal conductivity properties of

the installation and process piping in order to provide an accurate process measurement

Industry-leading temperature transmitter delivers field reliability as a wireless measurement

solution

Superior accuracy and stability

Single sensor capability with universal sensor inputs

(RTD, T/C, mV, ohms)

Transmitter-Sensor Matching with Callendar-Van Dusen

IEC-approved WirelessHART

Dual-compartment housing, available in aluminum or stainless steel

Large LCD display

Extended range antenna options available

®

protocol

Achieve optimal efficiency with best-in-class product specifications and capabilities

Two-year stability rating reduces maintenance costs

Transmitter-sensor matching eliminates the interchangeability error of sensors, improving measurement point accuracy by

75 percent

User-centric Device Dashboards communicate important diagnostics and ensure process health

Compensation for ambient temperature enhances transmitter performance

Dual-compartment housing provides the highest reliability in harsh industrial environments.

Contents

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How to order Rosemount X-well Technology . . . . . . . . . 8

Specifications

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

EmersonProcess.com/Rosemount

Page 3

July 2016

Rosemount 648 Wireless

A standard diagnostic offering increases measurement reliability

and provides visibility into process conditions

Four user-configurable alerts provide increased process information and measurement

point insight

Open/short sensor diagnostics assist with detecting issues in sensor loops

Terminal temperature feature verifies installation location temperature conditions to

ensure optimal transmitter operation.

Smart Wireless delivers innovative wireless solutions for temperature measurement and

overall transmitter performance

Self-organizing network delivers information rich data with > 99% data reliability

and establishes a highly stable network.

Smart Wireless capabilities extend the full benefits of PlantWeb

inaccessible temperature measurement locations.

SmartPower

™

Solutions provide an intrinsically safe power module, allowing field

replacements without removing the transmitter from the process, keeping

personnel safe, and reducing maintenance costs.

Emerson

™

Process Management’s layered approach to wireless network security

ensures that data transmissions are secure.

Explore the benefits of a Complete Point Solution from Emerson

An “Assemble To Sensor” option enables Emerson Process Management to

provide a complete point temperature solution, delivering an

installation-ready transmitter and sensor assembly.

Emerson offers a selection of RTDs, thermocouples, and thermowells that

bring superior durability and Rosemount reliability to temperature sensing,

complementing the Rosemount Transmitter portfolio.

™

to previously

EmersonProcess.com/Rosemount

3

Page 4

Rosemount 648 Wireless

July 2016

Experience global consistency and local support from numerous worldwide Emerson manufacturing

sites

World-class manufacturing provides globally consistent

product from every factory and the capacity to fulfill the

needs of any project, large or small.

Experienced instrumentation consultants help select the right

product for any temperature application and advise on best

installation practices.

An extensive global network of Emerson service and support

personnel can be on-site when and where they are needed.

Make wireless installation and configuration easy with the

Smart Wireless Gateway.

For installations that have a high number of temperature measurements in close proximity, consider the

Rosemount 848T High Density Temperature Trans mitter.

Explore how Emerson's intrinsically safe SmartPower Solutions reduce maintenance costs.

4

EmersonProcess.com/Rosemount

Page 5

July 2016

Ordering Information

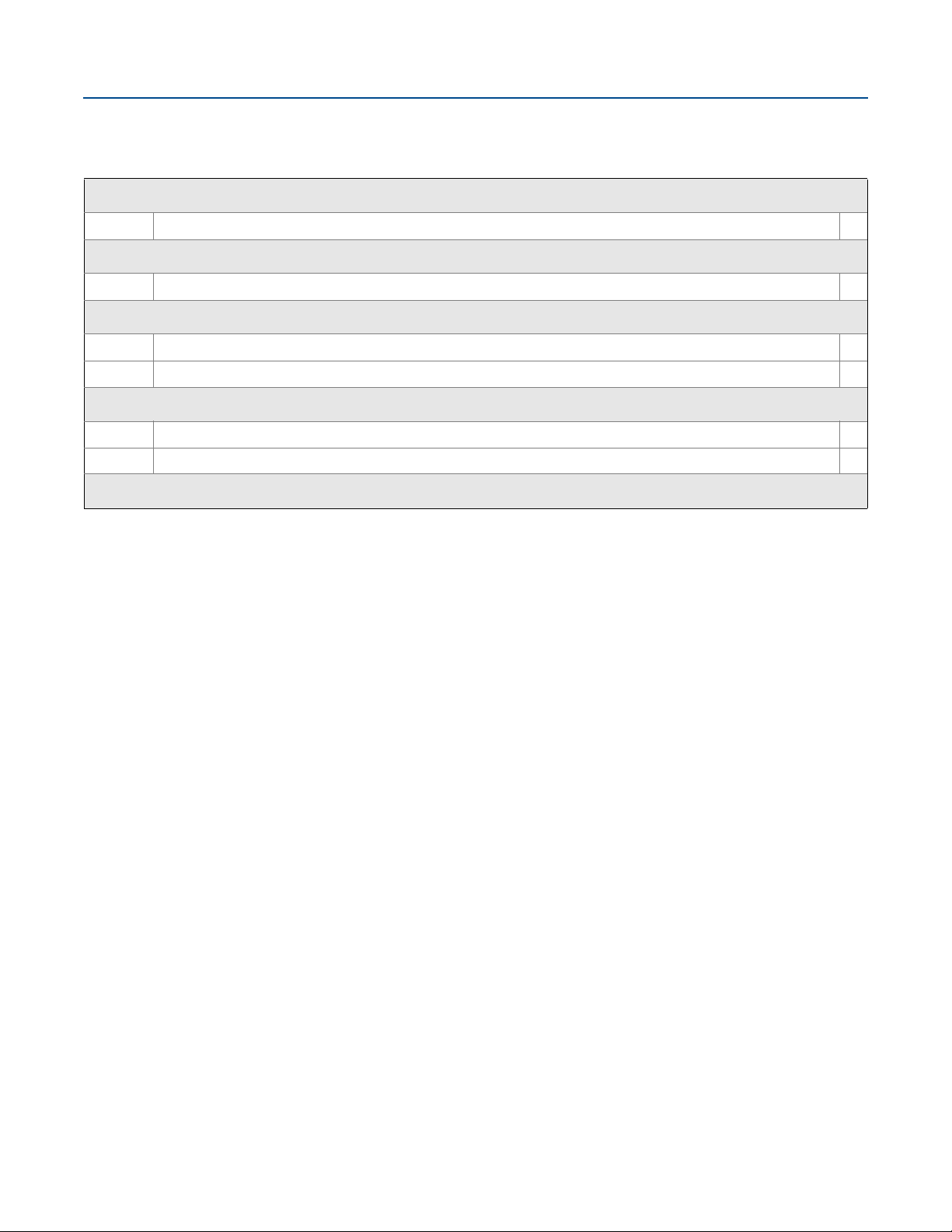

The Rosemount 648 Wireless delivers industry-leading temperature field reliability as a

wireless process measurement with Best-in-Class specifications and capabilities.

Transmitter features include:

Temperature Measurement Assembly with Rosemount X-well Technology (Option

Code PT)

IEC-approved WirelessHART protocol (Option Code WA3)

External antenna (Option Code WK1)

Extended range, External antenna (Option Code WM1)

Large LCD display (Option Code M5)

Transmitter-sensor matching (Option Code C2)

3-point calibration certificate (Option Code Q4)

Assemble to sensor (Option Code XA)

Rosemount 648 Wireless

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment. See

page 10 for more information on Material Selection.

When ordering Rosemount X-well Technology, specific option codes are required see page 8 for more information.

Table 1. Rosemount 648 Wireless Temperature Transmitter Ordering Information

★ The standard offering represents the most common options. The starred options (★) should be selected for best delivery.

__The expanded offering is subject to additional delivery lead time.

Model Product description

648 Temperature transmitter

Transmitter typ e

D Wireless field mount

Transmitter ou tput

X Wireless

Measurement configuration

1 Single-sensor Input

Housing style Material

D Dual compartment housing Aluminum

E Dual compartment housing SST

★

★

★

★

★

Conduit entry size

1

1

/2-14 NPT

Product certifications

NA No approval

I5 FM Intrinsically Safe, Non-Incendive, and Dust Ignition-proof

EmersonProcess.com/Rosemount

★

★

★

5

Page 6

Rosemount 648 Wireless

Table 1. Rosemount 648 Wireless Temperature Transmitter Ordering Information

★ The standard offering represents the most common options. The starred options (★) should be selected for best delivery.

__The expanded offering is subject to additional delivery lead time.

Product certifications

July 2016

N5 FM Non-Incendive and Dust Ignition-proof

I6 CSA Intrinsically Safe

I1 ATEX Intrinsic Safety

I7 IECEx Intrinsic Safety

I2 INMETRO Intrinsic Safety

I4 TIIS Intrinsic Safety

I3 China Intrinsic Safety

IM Technical Regulations Customs Union (EAC) Intrinsic Safety

KQ USA, Canada, ATEX Intrinsic Safety Combination (combination of I1, I5, and I6)

Wireless options (include with selected model number)

Assemble to options

(1)

XA

Sensor specified separately and assembled to transmitter

XC Hand tight assembly of a transmitter and sensor

Wireless update rate, operating frequency, and protocol

WA3 User configurable update rate, 2.4 GHz DSSS, IEC 62591 (WirelessHART)

Omni-directional wireless antenna and SmartPower

(2)

★

★

★

★

★

★

★

★

★

★

★

★

WK1 External antenna, adapter for black power module (I.S. power module sold separately)

WM1 Extended range, external antenna, adapter for black power module (I.S. power module sold separately)

Mounting bracket

(1)

B5 “L” mounting bracket for 2-in. pipe and panel mounting - All SST

Display

M5 LCD display

Enhanced performance

(3)

PT Temperature measurement assembly with Rosemount X-well Technology

Software configuration

C1 Custom configuration of date, descriptor, message, and wireless parameters (requires CDS with order)

Line filter

F5 50 Hz line voltage filter

F6 60 Hz line voltage filter

Sensor trim

C2 Transmitter-sensor matching - trim to specific Rosemount RTD calibration schedule (CVD Constants)

★

★

★

★

★

★

★

★

★

6

EmersonProcess.com/Rosemount

Page 7

July 2016

Rosemount 648 Wireless

Table 1. Rosemount 648 Wireless Temperature Transmitter Ordering Information

★ The standard offering represents the most common options. The starred options (★) should be selected for best delivery.

__The expanded offering is subject to additional delivery lead time.

5-point calibration

C4 5-point calibration (requires Q4 option code to generate a Calibration Certificate)

Calibration certificate

Q4 Calibration Certificate (3-point calibration)

Cable gland option

G2 Cable gland (7.5 – 11.9 mm)

G4 Thin wire cable gland (3 – 8 mm)

Extended product warranty

WR3 3-year limited warranty

WR5 5-year limited warranty

Typical model number: 648 D X 1 D 1 NA WA 3 WK 1 M5 C1 F6

1. When ordering the XA option, a mounting bracket is not included. If a bracket is required, please order option code B5.

2. Black power module must be shipped separately, order Model 701PBKKF or Part #00753-9220-0001.

3. When ordering the PT option code, the C1 and XA option codes are required. Rosemount X-well Technology is only available as a Rosemount 648 Wireless

Temperature Transmitter and 0085 Pipe Clamp Sensor direct mount assembly.

★

★

★

★

★

★

EmersonProcess.com/Rosemount

7

Page 8

Rosemount 648 Wireless

July 2016

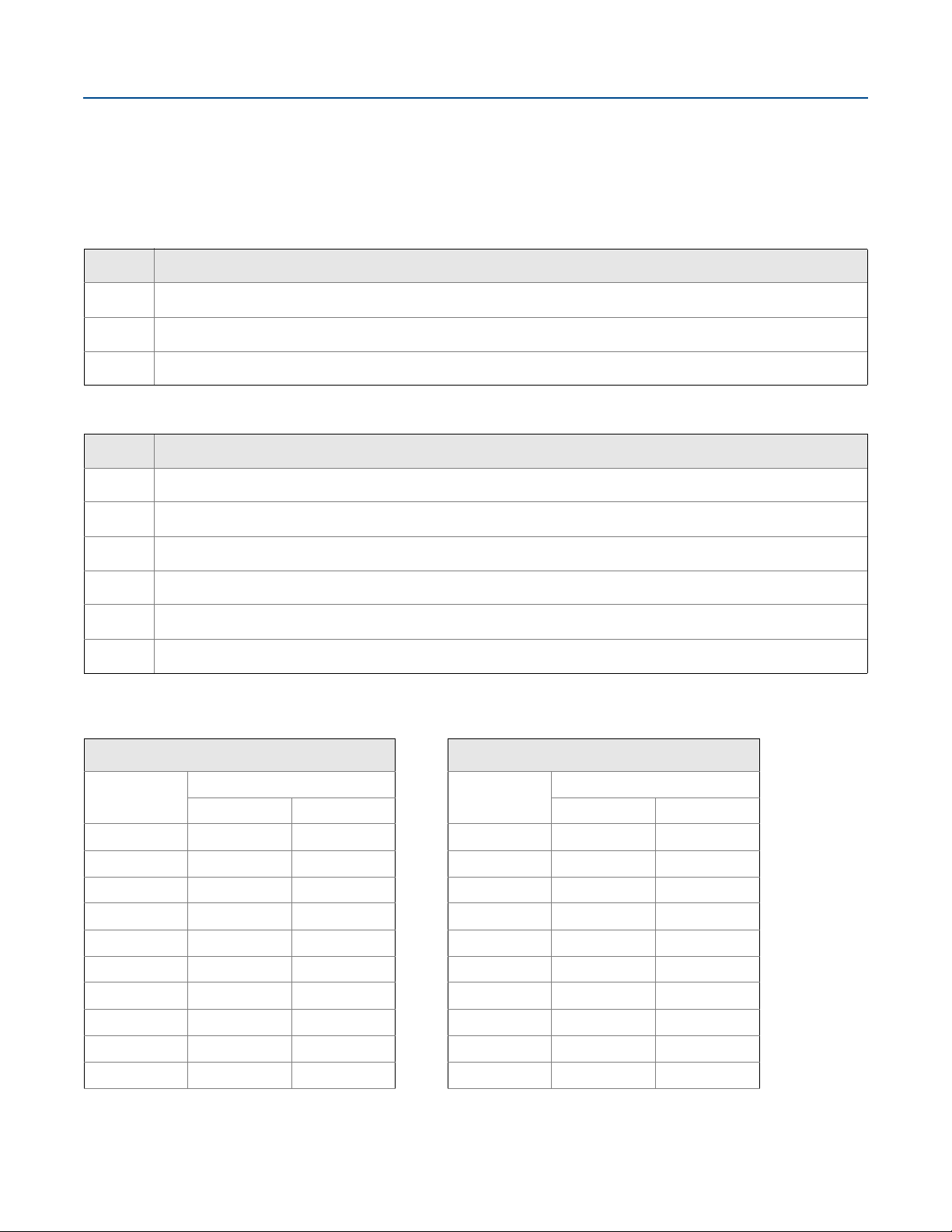

How to order Rosemount X-well Technology

Rosemount X-well Technology is only available as a Rosemount 648 Wireless and 0085 Pipe Clamp sensor direct mount assembly.

:

Table 2. Rosemount 648 Wireless Option Code Requirements

Code Description

PT

XA

C1

:

Temperature measurement assembled with Rosemount X-well Technology

Sensor specified separately and assembled to transmitter

Custom configuration of date, descriptor, message, and wireless parameters (requires CDS with order)

Table 3. Rosemount 0085 Pipe Clamp Sensor Option Code Requirements

Code Description

N

3

P1

J

0080

XA

Rosemount X-well assemblies are available in most Rosemount 0085 Pipe Clamp Sensor diameter sizes depending on the pipe

schedule. The pipe diameters that correspond to the pipe schedules are:

No connection head

Sensor connection

Sensor type

Extension type

Extension length

Assemble sensor to specific temperature transmitter

Pipe schedule 40 and 80 Pipe schedule 40 and 80

Code

0022

0027

0034 1 DN 25 0407 16 DN 400

0043 11/4 DN 32 0458 18 DN 450

0049 11/2 DN 40 0508 20 DN 500

0061 2 DN 50 0610 24 DN 600

0077 21/2 DN 65 0660 26 N/A

0089 3 DN 80 0762 30 DN 790

0115 4 DN 100 0813 32 DN 900

0140 5 DN 125 0915 36 DN 1000

Suitable pipe size

inch DIN inch DIN

1

/2 DN15 0324 12 DN 300

3

/4 DN 20 0356 14 DN 350

Code

8

Suitable pipe size

EmersonProcess.com/Rosemount

Page 9

July 2016

0169 6 DN 150 1016 42 N/A

0220 8 DN 200 1070 42 N/A

0273 10 DN 250 1219 48 N/A

Pipe schedule 120

Rosemount 648 Wireless

Code

0115 4 DN 100

0140 5 DN 125

0169 6 DN 150

0220 8 DN 200

0273 10 DN 250

0324 12 DN 300

0356 14 DN 350

0407 16 DN 400

0458 18 DN 450

0508 20 DN 500

0610 24 DN 600

Suitable pipe size

inch DIN

Note

For pipe schedules larger than 120, consult factory for

more information.

Typical model number of the assembly: 648 D X 1 D 1 NA WA3 WK1 M5 PT C1 XA

0085 N 3 P1 J 0080 C 00169 N XA

EmersonProcess.com/Rosemount

9

Page 10

Rosemount 648 Wireless

Specifications

July 2016

Functional specifications

Input

Supports Thermocouple, RTD, millivolt, and ohm input types.

See “Transmitter accuracy” on page 13 for sensor options.

Output

IEC 62591 (WirelessHART), 2.4 GHz DSSS

Local display

The optional five-digit integral LCD display can display sensor

temperature in engineering units (°F, °C, °R, K, Ω, and millivolts)

and percent of range. The display updates based on the Wireless

Update Rate.

Humidity limits

0–99% Non-condensing Relative Humidity

Update rate

WirelessHART, user-selectable one second to 60 minutes

Accuracy

Physical specifications

Material selection

Emerson Process Management provides a variety of Rosemount

product with various product options and configurations

including materials of construction that can be expected to

perform well in a wide range of applications. The Rosemount

product information presented is intended as a guide for the

purchaser to make an appropriate selection for the application.

It is the purchaser’s sole responsibility to make a careful analysis

of all process parameters (such as all chemical components,

temperature, pressure, flow rate, abrasives, contaminants, etc.),

when specifying product, materials, options and components

for the particular application. Emerson Process Management is

not in a position to evaluate or guarantee the compatibility of

the process fluid or other process parameters with the product,

options, configuration or materials of construction selected.

Conformance to specification (±3σ [Sigma])

Technology leadership, advanced manufacturing techniques,

and statistical process control ensure measurement

specification conformance to at least ±3σ.

(Pt 100 at reference condition: 20 °C)

±0.225 °C (±0.405 °F)

Radio frequency power output from antenna

External Antenna (WK1 option): Maximum of 10 mW (10 dBm)

EIRP

Electrical connections

Power module

The Emerson SmartPower Power Module is field replaceable,

featuring keyed connections that eliminate the risk of incorrect

installation.

The power module is an Intrinsically Safe solution, containing

Lithium-thionyl chloride with a polybutadine terephthalate

(PBT) enclosure.

The Rosemount 648 Wireless has power module life time rating

of 10 years with a one-minute update rate, at reference

conditions.

Sensor terminals

Sensor terminals permanently fixed to terminal block.

(1)

Field Communicator connections

Communication Terminals

Clips permanently fixed to terminal block, designated by the

text “COMM.”

1. Reference conditions are 70 °F (21 °C), and routing data for three

additional network devices.

NOTE: Continuous exposure to ambient temperature limits (–40 °F or

185 °F; –40 °C or 85 °C) may reduce specified life by less than 20 percent.

10

EmersonProcess.com/Rosemount

Page 11

July 2016

Rosemount 648 Wireless

Materials of construction

Enclosure

Housing - Low-copper aluminum or stainless steel

Paint - Polyurethane

Cover O-ring - Buna-N

Terminal block and power module

PBT

Antenna

PBT/Polycarbonate (PC) integrated omni-directional antenna

Mounting

Transmitters may be attached directly to the sensor. Mounting

brackets also permit remote mounting. See “Dimensional

Drawings” on page 20.

Weight

Low-copper aluminum

Rosemount 648 without LCD display - 4.1 lb. (1.9 kg)

Self calibration

The analog-to-digital measurement circuitry automatically

self-calibrates for each temperature update by comparing the

dynamic measurement to extremely stable and accurate

internal reference elements.

Vibration effect

Tested to the following with no effect on performance per IEC

60770-1, 1999:

High Vibration Level - field or pipeline (10–60 Hz 0.21 mm

displacement peak amplitude/60–2000 Hz 3 g).

Frequency Acceleration

10-60 Hz 0.21 mm peak displacement

60-2000 Hz 3 g

Rosemount 648 with M5 LCD display - 4.2 lb. (2.0 kg)

Stainless steel

Rosemount 648 without LCD display - 8.0 lb. (3.5 kg)

Rosemount 648 with M5 LCD display - 8.1 lb. (3.6 kg)

Enclosure ratings (Rosemount 648)

Housing style option codes D and E are Type 4X and IP66/67

rated dual-compartment housings.

Performance specifications

Electromagnetic compatibility (EMC)

All Models:

Meets all relevant requirements of EN 61326-1; 2006; EN

61326-2-3; 2006

Transmitter stability

The Rosemount 648 has a stability of ±0.15% of output reading

or 0.15 °C (whichever is greater) for 24 months.

EmersonProcess.com/Rosemount

11

Page 12

Rosemount 648 Wireless

1 2 3 4 1 2 3 4

1 2 3 4

1 2 3 4

Figure 1. Sensor Connections

Figure 2. Rosemount 648 Wireless Sensor Connections

July 2016

2-wire RTD

(1)

and Ω

1. Emerson Process Management provides 4-wire sensors for all single

element RTD s. You can use these RTDs in 3- or 2-wire conf igurations by

leaving the unneeded leads disconnected and insulated with electrical

tape.

3-wire RTD

(1)

and Ω

4-wire RTD

and Ω

T/C and mV

Temperature limits

Description Operating limit Storage limit

Without LCD display

With LCD display

–40 to 185 °F

–40 to 85 °C

–4 to 175 °F

–20 to 80 °C

–40 to 185 °F

–40 to 85 °C

–40 to 185 °F

–40 to 85 °C

12

EmersonProcess.com/Rosemount

Page 13

July 2016

Rosemount 648 Wireless

Transmitter accuracy

Table 4. Rosemount 648 Wireless Input Options and Accuracy

Sensor options Sensor reference Input ranges Digital accuracy

2-, 3-, 4-wire RTDs °C °F °C °F

Pt 100 (α = 0.00385) IEC 751 –200 to 850 –328 to 1562 ±0.225 ±0.405

(1)

Rosemount X-well Pt 100

(α = 0.00385)

IEC 751 -50 to 300 -58 to 572 ±0.29 ±0.52

Pt 200 (α = 0.00385) IEC 751 –200 to 850 –328 to 1562 ±0.405 ±0.729

Pt 500 (α = 0.00385) IEC 751 –200 to 850 –328 to 1562 ±0.285 ±0.513

Pt 1000 (α = 0.00385) IEC 751 –200 to 300 –328 to 572 ±0.285 ±0.513

Pt 100 (α = 0.003916) JIS 1604 –200 to 645 –328 to 1193 ±0.225 ±0.405

Pt 200 (α = 0.003916) JIS 1604 –200 to 645 –328 to 1193 ±0.405 ±0.729

Ni 120 Edison Curve No. 7 –70 to 300 –94 to 572 ±0.225 ±0.405

Cu 10 Edison Copper Winding No. 15 –50 to 250 –58 to 482 ±2.1 ±3.78

Pt 50 (α = 0.00391) GOST 6651-94 –200 to 550 –328 to 990 ±0.45 ±0.81

Pt 100 (α = 0.00391) GOST 6651-94 –200 to 550 –328 to 990 ±0.225 ±0.405

Cu 50 (α = 0.00426) GOST 6651-94 –50 to 200 –58 to 392 ±0.72 ±1.296

Cu 50 (α = 0.00428) GOST 6651-94 –185 to 200 –301 to 392 ±0.72 ±1.296

Cu 100 (α = 0.00426) GOST 6651-94 –50 to 200 –58 to 392 ±0.36 ±0.648

Cu 100 (α = 0.00428) GOST 6651-94 –185 to 200 –301 to 392 ±0.36 ±0.648

Thermocouples

(3)

Type B

(2)

NIST Monograph 175, IEC 584 100 to 1820 212 to 3308 ±1.155 ±2.079

Type E NIST Monograph 175, IEC 584 –200 to 1000 –328 to 1832 ±0.30 ±0.54

Type J NIST Monograph 175, IEC 584 –180 to 760 –292 to 1400 ±0.525 ±0.945

(4)

Type K

NIST Monograph 175, IEC 584 –180 to 1372 –292 to 2501 ±0.75 ±1.35

Type N NIST Monograph 175, IEC 584 –200 to 1300 –328 to 2372 ±0.75 ±1.35

Type R NIST Monograph 175, IEC 584 0 to 1768 32 to 3214 ±1.125 ±2.025

Type S NIST Monograph 175, IEC 584 0 to 1768 32 to 3214 ±1.05 ±1.89

Type T NIST Monograph 175, IEC 584 –200 to 400 –328 to 752 ±0.525 ±0.945

DIN Type L DIN 43710 –200 to 900 –328 to 1652 ±0.525 ±0.945

DIN Type U DIN 43710 –200 to 600 –328 to 1112 ±0.525 ±0.945

Type W5Re/W 26Re ASTM E 988-96 0 to 2000 32 to 3632 ±1.05 ±1.89

GOST L GOST R 8.585-2001 –200 to 800 –328 to 1472 ±0.525 ±0.945

Other input types

Millivolt Input –10 to 100 mV ±0.0225 mV

2-, 3-, 4-wire Ohm Input 0 to 2000 ohms ±0.675 ohm

1. The published digital accuracy applies over the entire sensor input range. Digital outpu t can be accessed by HART® Communications or WirelessHART.

2. Total digital accuracy for thermocouple measurement: sum of digital accuracy +0.8 °C. (cold junction accuracy).

3. Digital accuracy for NIST Type B T/C is ±4.5 °C (±8.1 °F) from 100 to 300 °C (212 to 572 °F).

4. Digital accuracy for NIST Type K T/C is ±1.05 °C (±1.895 °F) from –180 to –90 °C (–292 to –130 °F).

EmersonProcess.com/Rosemount

13

Page 14

Rosemount 648 Wireless

Ambient temperature effect

Table 5. Ambient Temperature Effect on Digital Accuracy

July 2016

Sensor options Sensor reference

2-, 3-, 4-wire RTDs

Pt 100 (α = 0.00385) IEC 751 0.0045 °C (0.0081 °F) Entire sensor input range

Rosemount X-well Pt 100

(α = 0.00385)

Pt 200 (α = 0.00385) IEC 751 0.006 °C (0.0108 °F) Entire sensor input range

Pt 500 (α = 0.00385) IEC 751 0.0045 °C (0.0081 °F) Entire sensor input range

Pt 1000 (α = 0.00385) IEC 751 0.0045 °C (0.0081 °F) Entire sensor input range

Pt 100 (α = 0.003916) JIS 1604 0.0045 °C (0.0108 °F) Entire sensor input range

Pt 200 (α = 0.003916) JIS 1604 0.006 °C (0.0108 °F) Entire sensor input range

Ni 120 Edison Curve No. 7 0.0045 °C (0.0081 °F) Entire sensor input range

Cu 10 Edison Copper Winding No. 15 0.045 °C (0.081 °F) Entire sensor input range

Pt 50 (α = 0.003910) GOST 6651-94 0.009 °C (0.0162 °F) Entire sensor input range

Pt 100 (α = 0.003910) GOST 6651-94 0.0045 °C (0.0081 °F) Entire sensor input range

Cu 50 (α = 0.00426) GOST 6651-94 0.009 °C (0.0162 °F) Entire sensor input range

Cu 50 (α = 0.00428) GOST 6651-94 0.009 °C (0.0162 °F) Entire sensor input range

Cu 100 (α = 0.00426) GOST 6651-94 0.0045 °C (0.0081 °F) Entire sensor input range

Cu 100 (α = 0.00428) GOST 6651-94 0.0045 °C (0.0081 °F) Entire sensor input range

Thermocouples

Type B NIST Monograph 175, IEC 584

Type E NIST Monograph 175, IEC 584 0.0075 °C +(0.000645% of T) All

Type J NIST Monograph 175, IEC 584

Type K NIST Monograph 175, IEC 584

Type N NIST Monograph 175, IEC 584 0.0102 °C +(0.00054% of T) All

Type R NIST Monograph 175, IEC 584

Type S NIST Monograph 175, IEC 584

Type T NIST Monograph 175, IEC 584

DIN Type L DIN 43710

DIN Type U DIN 43710

Type W5Re/W 26Re ASTM E 988-96

GOST L GOST R. 8.585-2001

Other input types

Millivolt Input 0.0008 mV Entire sensor input range

2-, 3-, 4-wire Ohm Input 0.0126 Ω Entire sensor input range

IEC 751 0.0058 °C (0.0104 °F) Entire sensor input range

Effects per 1.0 °C (1.8 °F) change in

ambient temperature

0.021 °C T ≥ 1000 °C

0.048 °C – [0.00375% of (T – 300)] 300 °C ≤ T < 1000 °C

0.081 °C – [0.0165% of (T – 100)] 100 °C ≤ T< 300 °C

0.0081 °C +(0.000435%of T) T ≥ 0 °C

0.0081 °C + (0.00375% of absolute value T) T < 0 °C

0.0092 °C +(0.00081% of T) T ≥ 0 °C

0.0092 °C + (0.00375% of absolute value T) T < 0 °C

0.024 °C T ≥ 200 °C

0.0345 °C – (0.0108% of T) T < 200 °C

0.024 °C T ≥ 200 °C

0.0345 °C – (0.0108% of T) T < 200 °C

0.0096 °C T ≥ 0 °C

0.0096 °C +(0.00645% of absolute value T) T < 0 °C

0.0081 °C + (0.000435% of T) T ≥ 0 °C

0.0081 °C +(0.00375% of absolute value T) T < 0 °C

0.0096 °C T ≥ 0 °C

0.0096 °C +(0.00645% of absolute value T) T < 0 °C

0.024 °C T ≥ 200 °C

0.0345 °C – (0.0108% of T) T < 200 °C

0.0105 °C T ≥ 0 °C

0.0105 °C + (0.0045% of absolute value T) T < 0 °C

(1)(2)

Input temperature (T)

1. Change in ambient is with reference to the calibration temperature of the transmitter 68 °F (20 °C) from factory.

2. Ambient temperature effect specification valid over minimum temperature span of 28 °C (50 °F).

14

EmersonProcess.com/Rosemount

Page 15

July 2016

0.22520.045

2

+

0.2920.05820.70

2

++

Rosemount 648 Wireless

Transmitters can be installed in locations where the ambient temperature is between –40 and 85 °C (–40 and 185 °F). In order to

maintain excellent accuracy performance, each transmitter is individually characterized over this ambient temperature range at the

factory.

Process temperature effects

Table 6. Ambient and Process Temperature Difference Effect on Digital Accuracy

Sensor option

Rosemount X-well Pt 100

(α = 0.00385)

1. Valid under steady state and process ambient conditions.

Sensor reference

IEC 751 ± 0.01 °C (0.018 °F) Entire Sensor Input Range

Effects per 1.0 °C(1.8 °F) difference in

Ambient and Process temperature

Temperature effects example

When using a Pt 100 (α = 0.00385) sensor input at 30 °C

ambient temperature:

Digital Temperature Effects: 0.0045 °C x (30 - 20) = 0.045 °C

Worst Case Error: Digital + Digital Temperature Effects =

0.225 °C + 0.045 °C = 0.27 °C

Total Probable Error: = 0.23 °C

Input temperature (T)

(1)

Rosemount X-well temperature effects example

When using Rosemount X-well Technology at 30 °C ambient

temperature and 100 °C process temperature:

Digital Ambient Temperature Effects:

0.0058 °C ⫻(30 - 20) =.058 °C

Process Temperature Effects: 0.01 °C ⫻(100 – 30) =.70 °C

Worst Case Error: Digital Accuracy + Digital Ambient

Temperature Effects + Process Temperature Effects =

0.29 °C + 0.058 °C+ 0.70 °C = 1.05 °C

Total Probable Error: = 0.76 °C

EmersonProcess.com/Rosemount

15

Page 16

Rosemount 648 Wireless

Product Certifications

Rev 3.0

July 2016

European Directive Information

A copy of the EC Declaration of Conformity can be found at the

end of the Quick Start Guide.The most recent revision of the EC

Declaration of Conformity can be found at

EmersonProcess.com/Rosemount.

Telecommunication Compliance

All wireless devices require certification to ensure they adhere to

regulations regarding the use of the RF spectrum. Nearly every

™

country requires this type of product certification. Emerson

Process Management is working with governmental agencies

around the world to supply fully compliant products and remove

the risk of violating country directives or laws governing wireless

device usage.

FCC and IC

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following conditions: This device may not cause

harmful interference, this device must accept any interference

received, including interference that may cause undesired

operation. This device must be installed to ensure a minimum

antenna separation distance of 20 cm from all persons.

Ordinary Location Certification

As standard, the transmitter has been examined and tested to

determine that the design meets the basic electrical,

mechanical, and fire protection requirements by a nationally

recognized test laboratory (NRTL) as accredited by the Federal

Occupational Safety and Health Administration (OSHA).

Installing in North America

The US National Electrical Code® (NEC) and the Canadian

Electrical Code (CEC) permit the use of Division marked

equipment in Zones and Zone marked equipment in Divisions.

The markings must be suitable for the area classification, gas,

and temperature class. This information is clearly defined in the

respective codes.

North America

I5 U.S. Intrinsic Safety (IS), Nonincendive (NI), and Dust

Ignition-proof (DIP)

Certificate: FM 3027705

Standards: FM Class 3600 - 2011, FM Class 3610 - 2010,

FM Class 3611 - 2004, FM Class 3810 - 2005,

ANSI/NEMA

2009, ANSI/ISA-60079-11 - 2009

Markings: IS CL I, DIV 1, GP 1, A, B, C, D; CL II, DIV 1, GP E,

F, G; Class III, T4/T5; Class 1, Zone 0 AEx ia IIC

T4/T5; T4(–50 °C ≤ T

≤ +40 °C) when installed per Rosemount

drawing 00648-1000; NI CL I, DIV 2, GP A, B, C,

D T4/T5; T4(–50 °C ≤ T

T

≤ +40 °C) when installed per Rosemount

a

drawing 00648-1000; DIP CL II, DIV 1, GP E, F,

G; CL III, T5; T5(–50 °C ≤ Ta ≤ +85 °C) Type 4X;

IP66

Special Conditions for Safe Use (X):

1. The Rosemount 648 Wireless Transmitter housing

contains aluminum and is considered a potential risk of

ignition by impact or friction. Care must be taken into

account during installation and use to prevent impact and

friction

2. The surface resistivity of the polymeric antenna is greater

than 1 GΩ. To avoid electrostatic charge build-up, it must

not be rubbed or cleaned with solvents or a dry cloth.

3. The Rosemount 648 Wireless Transmitter shall only be

used with the 701PBKKF Rosemount SmartPower Battery

Pack (P/N 00753-9220-0001).

Sensor terminal parameters

UO = 6.6 V

IO = 26.2 mA

P

= 42.6 mW

O

C

= 23.8 μF

O

LO = 50 mH

N5 U.S. Nonincendive (NI) and Dust Ignition-proof (DIP)

Certificate: FM 3027705

Standards: FM Class 3600 - 2011, FM Class 3611 - 2004,

FM Class 3810 - 2005, ANSI/NEMA 250 - 2003

Markings: NI CL I, DIV 2, GP A, B, C, D

T4/T5; T4(–50 °C ≤ T

T5(–50 °C ≤ T

DIP CL II, DIV 1, GP E, F, G; CL III, T5;

T5(–50 °C ≤ T

®

250 - 2003, ANSI/ISA-60079-0 -

≤ +70 °C), T5(–50 °C ≤ Ta

a

≤ +70 °C), T5(–50 °C ≤

a

≤ +70 °C),

a

≤ +40 °C)

a

≤ +85 °C)Type 4X; IP66/67

a

16

EmersonProcess.com/Rosemount

Page 17

July 2016

Rosemount 648 Wireless

Special Condition for Safe Use (X):

1. For use only with the Model 701PBKKF or Rosemount P/N

753-9220-XXXX SmartPower Battery Module.

Canada

I6 Canada Intrinsically Safe

Certificate: CSA 1143113

Standards: CAN/CSA C22.2 No. 0-10,

CAN/CSA C22.2 No. 94-M91,

CSA Std C22.2 No. 142-M1987,

CSA Std C22.2 No. 157-92,

CSA Std C22.2 No. 60529:05

Markings: Intrinsically Safe Class I, Division 1, Groups A,

B, C and D T3C; Class 1, Zone 0, IIC, T3C; when

connected per Rosemount drawing

00648-1020; Type 4X

Sensor terminal parameters

UO = 6.6 V

I

= 26.2 mA

O

PO = 42.6 mW

C

= 23.8 μF

a

L

= 50 mH

a

Europe

I1 ATEX Intrinsic Safety

Certificate: Baseefa07ATEX0011X;

Standards: EN 60079-0: 2012 + A11:2013, EN 60079-11:

2012

Markings: II 1 G Ex ia IIC T4 Ga,

T4(–60 °C ≤ T

II 1 GEx ia IIC T5 Ga,

T5(–60 °C ≤ T

For use with Rosemount SmartPower power module part

number 753-9220-0001, or for use with Emerson SmartPower

option 701PBKKF.

Sensor terminal parameters

UO = 6.6 V

I

= 26.2 mA

O

PO = 42.6 mW

C

= 11 μF

O

L

= 25 mH

O

≤ +70 °C)

a

≤ +40 °C)

a

Special Condition for Safe Use (X):

1. The surface resistivity of the antenna is greater than 1 GΩ.

To avoid electrostatic charge build-up, it must not be

rubbed or cleaned with solvents or a dry cloth.

2. The power module may be replaced in a hazardous area.

The power module has a surface resistivity greater than 1

GΩ and must be properly installed in the wireless device

enclosure. Care must be taken during transportation to

and from the point of installation to prevent electrostatic

charge build-up.

NM ATEX Intrinsic Safety for Mining

Certificate: Baseefa07ATEX0011X;

Standards: EN 60079-0: 2012 + A11:2013, EN 60079-11:

2012

Markings: I M 1 Ex ia I Ma (-60 °C ≤ T

≤+70 °C)

a

Sensor terminal parameters

UO = 6.6 V

IO = 26.2 mA

P

= 42.6 mW

O

C

= 11 μF

O

LO = 25 mH

Special Condition for Safe Use (X):

1. The surface resistivity of the antenna is greater than

1 GΩ. To avoid electrostatic charge build-up, it must not

be rubbed or cleaned with solvents or a dry cloth.

2. The power module may be replaced in a hazardous area.

The power module has a surface resistivity greater than 1

GΩ and must be properly installed in the wireless device

enclosure. Care must be taken during transportation to

and from the point of installation to prevent electrostatic

charge build-up.

International

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 07.0007X

Standards: IEC 60079-0: 2011, IEC 60079-11: 2011

Markings: Ex ia IIC T4 Ga, T4 (–60 °C ≤ T

Ex ia IIC T5 Ga, T5 (–60 °C ≤ T

Sensor terminal parameters

UO = 6.6 V

I

= 26.2 mA

O

P

= 42.6 mW

O

C

= 11 μF

o

Lo = 25 mH

≤ +70 °C)

a

≤ +40 °C)

a

EmersonProcess.com/Rosemount

17

Page 18

Rosemount 648 Wireless

July 2016

Special Conditions for Safe Use (X):

1. The surface resistivity of the antenna is greater than

1 GΩ. To avoid electrostatic charge build-up, it must not

be rubbed or cleaned with solvents or a dry cloth.

2. The Model 701PBKKF Power Module may be replaced in a

hazardous area. The Power Modules have a surface

resistivity greater than 1 GΩ and must be properly

installed I the wireless device enclosure. Care must be

taken during transportation to and from the point of

installation to prevent electrostatic charge build-up.

3. The Rosemount 648 Wireless enclosure may be made of

aluminum alloy and given a protective polyurethane paint

finish; however, care should be taken to protect it from

impact or abrasion if located in a Zone 0 area.

Brazil

I2 INMETRO Intrinsic Safety

Certificate: UL-BR 15.0140X

Standards: ABNT NBR IEC 60079-0:2008 + Errata 1:2011,

ABNT NBR IEC60079-11:2009

Markings: Ex ia IIC T4 (–60 °C ≤ T

≤ +70 °C),

a

Ex ia IIC T5(–60 °C ≤ Ta ≤+40 °C) IP66

Sensor terminal parameters

UO = 6.6 V

IO = 26.2 mA

P

= 42.6 mW

O

C

= 11 μF

o

Lo = 25 mH

Special Condition for Safe Use (X):

1. See certificate for special conditions.

China

Special Condition for Safe Use (X):

1. See certificate for special conditions.

Japan

I4 TIIS Intrinsic Safety

Certificates: TC18638

Markings: Ex ia IIC T4 (–20 ~ +60 °C)

Special Condition for Safe Use (X):

1. See certificate for special conditions.

Sensor terminal parameters

UO = 6.6 V

I

= 26.2 mA

O

P

= 42.6 mW

O

CO= 11 μF

L

= 25 μF

O

EAC - Belarus, Kazakhstan, Russia

IM Technical Regulation Customs Union Intrinsic Safety

Certificate: RU C-US.Gb05.B.00289

Markings: 0Ex ia IIC T4/T5 X

T4 (-60 °C ≤ T

T5(-60 °C ≤ T

Sensor terminal parameters

UO = 6.6 V

I

= 26.2 mA

O

P

= 42.6 mW

O

CO= 11 μF

L

= 25 μF

O

≤ +70 °C)

a

≤ +40 °C)

a

I3 China Intrinsic Safety

Certificate: GYJ11.1706X

Standards: GB3836.1-2010,

GB3836.4-2010,

GB3836.20-2010

Markings: Ex ia IIC T4/T5 Ga

T code Ambient temperature

T4 –60 °C ≤ Ta ≤ +70 °C

T5 –60 °C ≤ Ta ≤ +45 °C

Sensor terminal parameters

UO = 6.6 V

I

= 26.2 mA

O

PO= 42.6 mW

C

= 11 μF

O

L

= 25 μF

O

18

Special Condition for Safe Use (X):

1. See certificate for special conditions.

Republic of Korea

IP Republic of Korea Intrinsic Safety

Certificate: 11-KB4BO-0071

Markings: Ex ia IIC T4/T5

T4 (-60 °C

T5 (-60 °C

Sensor terminal parameters

UO = 6.6 V

I

= 26.2 mA

O

PO= 42.6 mW

C

= 10.9 μF

O

L

= 25 μF

O

+70 °C)

~

+40 °C)

~

EmersonProcess.com/Rosemount

Page 19

July 2016

Special Condition for Safe Use (X):

1. See certificate for special conditions

Combination of Certification

KQ Combination of I1, I5, and I6

Rosemount 648 Wireless

EmersonProcess.com/Rosemount

19

Page 20

Rosemount 648 Wireless

3.67

(93)

A

Dimensional Drawings

Figure 3. Rosemount 648 Wireless Remote Mount

Pipe mounting For transmitter mounting

July 2016

Dimensions are in inches (millimeters).

A. 2-in. U-bolt for pipe mounting

20

EmersonProcess.com/Rosemount

Page 21

July 2016

A

B

C

D

E

F

11.23

(285)

4.20

(107)

7.81

(198)

11.16

(248)

90°

7.88

(200)

6.71

(170)

6.05

(154)

.42

(11)

Figure 4. Rosemount 648 Wireless Direct Mount

Rosemount 648 Wireless

Shown with 2.4 GHz extended range antenna

A. 2.4 GHz extended range antenna

B. Ground screw assembly

C. Digital display cover

Dimensions are in inches (millimeters).

Shown with optional digital

display and 2.4 GHz antenna

D. Field terminals (This side)

E. Transmitter electronics (This side)

F. 2.4 GHz anten na

Shown without optional

digital display

EmersonProcess.com/Rosemount

21

Page 22

Rosemount 648 Wireless

Figure 5. Rosemount 648 with Option Code PT

July 2016

Dimensions are in inches (millimeters).

22

EmersonProcess.com/Rosemount

Page 23

July 2016

Rosemount 648 Wireless

EmersonProcess.com/Rosemount

23

Page 24

Rosemount 648 Wireless

00813-0100-4648 Rev GD

Global Headquarters

Emerson Process Management

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@EmersonProcess.com

North America Regional Office

Emerson Process Management

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Process Management

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@EmersonProcess.com

Product Data Sheet

July 2016

Europe Regional Office

Emerson Process Management Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@EmersonProcess.com

Asia Pacific Regional Office

Emerson Process Management Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.EmersonProcess.com

Middle East and Africa Regional Office

Emerson Process Management

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Process-Management

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found at:

Emerson.com/en-us/pages/Terms-of-Use.aspx

The Emerson logo is a trademark and service mark of Emerson Electric Co.

SmartPower, Complete Point Solution, PlantWeb, Rosemount X-well,

Rosemount, and the Rosemount logotype are of trademarks Emerson

Process Management.

HART and WirelessHART are registered trademarks of the FieldComm

Group.

All other marks are the property of their respective owners.

© 2016 Emerson Process Management. All rights reserved.

Loading...

Loading...