Rosemount 5900 Instruction for Installation, Configuration, and Operation of Proof Test Function with Reference Reflector Manuals & Guides

Page 1

Manual Supplement

00809-0200-5900, Rev AC

November 2019

Rosemount™ 5900

Instruction for Installation, Configuration, and Operation of

Proof Test Function with Reference Reflector

Page 2

Page 3

Manual Supplement

00809-0200-5900, Rev AC

Contents

1Section 1: Introduction

2Section 2: Installation

Contents

November 2019

1.1 Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.2 Service support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.3 Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.3 Installation considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4 Installing the Reference Reflector for Parabolic Antenna . . . . . . . . . . . . . . . . . . . . .7

2.4.1 Reference Reflector Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.2 Tank Geometry - Parabolic Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.3 Installing the Reference Reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5 Installing the Reference Reflector for Array Antenna . . . . . . . . . . . . . . . . . . . . . . .18

2.5.1 Reference Reflector Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.5.2 Tank Geometry - Array Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.5.3 Installing the Reference Reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3Section 3: Configuration of Reference Reflector

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.3 Configuration using TankMaster WinSetup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.3.2 Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.3.3 Configuration procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Contents

i

Page 4

Contents

November 2019

Manual Supplement

00809-0200-5900, Rev AC

4Section 4: Operation

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.3 Proof Test operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4.3.1 Proof Test status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.4 Scheduling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.4.1 Pop-up message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

4.5 History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.6 Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.6.1 Viewing a report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

4.7 Removing a Reference Reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

5Section 5: Service and Troubleshooting

5.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

5.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

5.3 Tank spectrum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

ii

Contents

Page 5

Manual Supplement

Reference Reflector for

Proof Testing

Reference Reflector for

Proof Testing

ROSEMOUNT 5900 WITH PARABOLIC ANTENNA ROSEMOUNT 5900 WITH ARRAY ANTENNA

00809-0200-5900, Rev AC

Section 1: Introduction

November 2019

Section 1 Introduction

The Rosemount 5900 Radar Level Gauge is designed with functionality that lets you proof test

high alarms and verify correct product surface measurement. The Rosemount 5900 allows you

to combine continuous product level monitoring with proof testing at regular intervals. It is

based on a dedicated Reference Reflector that introduces a radar echo at a predefined position

in the tank.

Figure 1-1. The Rosemount 5900 can be equipped with an optional Reference Reflector that allows proof

testing the gauge on a regular basis.

Introduction

1

Page 6

Section 1: Introduction

November 2019

1.1 Section overview

This document is a supplement to the Rosemount 5900S Reference Manual (Document No.

00809-0100-5900).

The sections in this reference manual supplement provide information on installing, operating,

and maintaining the Rosemount 5900 Proof Test System. The sections are organized as follows:

Section 1: Introduction gives a brief introduction to the Rosemount 5900 Proof Test function

and the recommended installation procedure.

Section 2: Installation provides instructions on how to install the Reference Reflector on the

Rosemount 5900 with Parabolic Antenna and Array Antenna.

Section 3: Configuration contains instructions on how to calibrate and configure the

Rosemount 5900 Proof Test function.

Section 4: Operation provides instructions for how to use the proof test function.

Section 5: Service and Troubleshooting provides troubleshooting techniques for the most

common operating problems.

Manual Supplement

00809-0200-5900, Rev AC

1.2 Service support

For service support contact the nearest Emerson Process Management/Rosemount Tank Gauging

representative. Contact information can be found on the web site www.Emerson.com.

2

Introduction

Page 7

Manual Supplement

Review installation considerations.

See “Installation considerations” on page 6.

Mount the Proof Test Reference Reflector.

See “Installing the Reference Reflector for Parabolic Antenna” on

page 7 and “Installing the Reference Reflector for Array Antenna”

on page 18.

Wire the Rosemount 5900

(1)

gauge.

Ensure covers and cable gland/conduit connections are tight.

Configure the Rosemount 5900 for proof testing.

See Section 3: Configuration of Reference Reflector

Verify operation.

(1) See the Rosemount 5900S Reference manual (Document No. 00809-0100-5900 or the

Rosemount 5900C Reference manual (Document No. 00809-0100-5901)

00809-0200-5900, Rev AC

1.3 Installation procedure

Follow these steps for a proper installation of the Reference Reflector for Proof Testing a

Rosemount 5900 Radar Level Gauge.

Section 1: Introduction

November 2019

Introduction

3

Page 8

Section 1: Introduction

November 2019

Manual Supplement

00809-0200-5900, Rev AC

4

Introduction

Page 9

Manual Supplement

00809-0200-5900, Rev AC

Section 2 Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Installation considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Installing the Reference Reflector for Parabolic Antenna . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Installing the Reference Reflector for Array Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

2.1 Overview

The information in this section covers installation of Reference Reflector for proof testing the

Rosemount 5900 Radar Level Gauge.

2.2 Safety messages

Section 2: Installation

November 2019

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operation. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock:

Avoid contact with leads and terminals.

Make sure the main power to the 2460 System Hub is off and the lines to any other external

power source are disconnected or not powered while wiring the 2460.

Electrical shock could cause death or serious injury:

Use extreme caution when making contact with the leads and terminals.

Installation

Handle the wire and assembly with care to avoid permanent bends.

5

Page 10

Section 2: Installation

November 2019

2.3 Installation considerations

Before you start installing the Reference Reflector, ensure that the following items are

considered in order to fulfill the installation requirements for the Reference Reflector at the

desired position:

Maximum product level in the tank

High Alarm position

Minimum / maximum distance between Gauge Reference Point and Reference

Reflector

See “Tank Geometry - Parabolic Antenna” on page 9 and “Tank Geometry - Array Antenna” on

page 20 for further information on tank geometry and position of the Reference Reflector.

Note

The Reference Reflector for Array Antenna may need to be removed to allow product sampling

through the Still-pipe.

Manual Supplement

00809-0200-5900, Rev AC

6

Installation

Page 11

Manual Supplement

Nut M8

Spring washer

Washer

Nut M8

M8 terminal

Wire Ø 4 mm

Length 5 m

Wire Ø 4 mm

Length 5 m

M8 terminal

Nut M12

Spring washer

Weight

M6 screw (x2)

Allen key size 3

00809-0200-5900, Rev AC

Section 2: Installation

November 2019

2.4 Installing the Reference Reflector for Parabolic Antenna

The Reference Reflector is installed under the antenna. It is attached to a wire fixed to the

Parabolic Antenna. The Reference Reflector introduces a radar echo that is used for proof testing

the Rosemount 5900 Radar Level Gauge. Proof testing can be performed without the need to

open the tank.

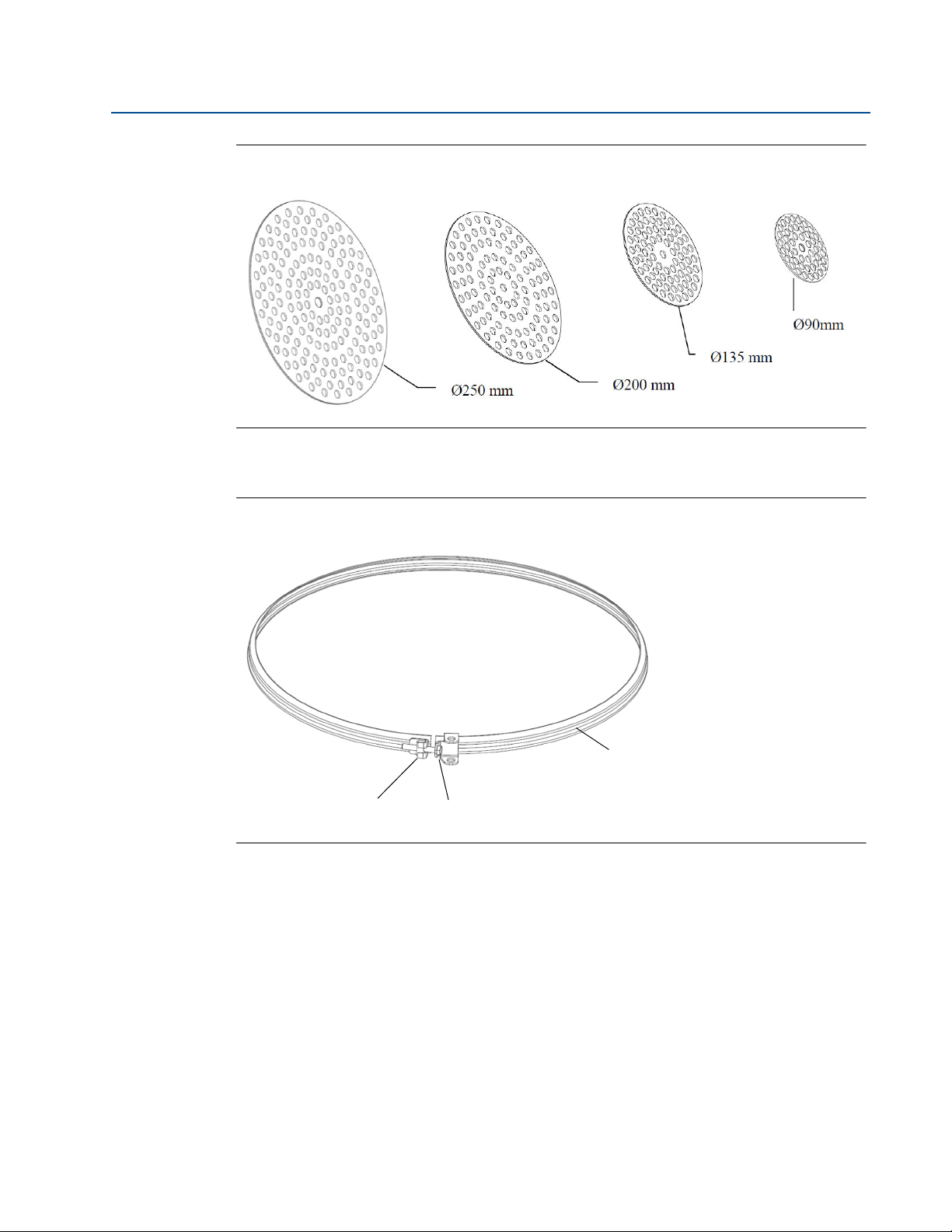

2.4.1 Reference Reflector Kit

The Reference Reflector is delivered with all parts needed for proper installation on a Rosemount

5900 with Parabolic Antenna. The Reference Reflector kit includes the following parts:

Wire assembly

Weight assembly

Reference Reflector

Ring Clamping assembly

Figure 2-1. Wire and Weight Assembly

Installation

7

Page 12

Section 2: Installation

M6 cylinder nut M6 screw

Clamping ring

November 2019

Figure 2-2. Reference Reflector

Figure 2-3. Clamping Ring

Manual Supplement

00809-0200-5900, Rev AC

8

Installation

Page 13

Manual Supplement

Wire

Distance

Reference Reflector (RR) Distance

Minimum: 600 mm

Maximum: 5000 mm

Reference Reflector (RR) Position

Minimum 500 mm

3

4

1

2

Zero Level

Max. product level

Gauge Reference Point

00809-0200-5900, Rev AC

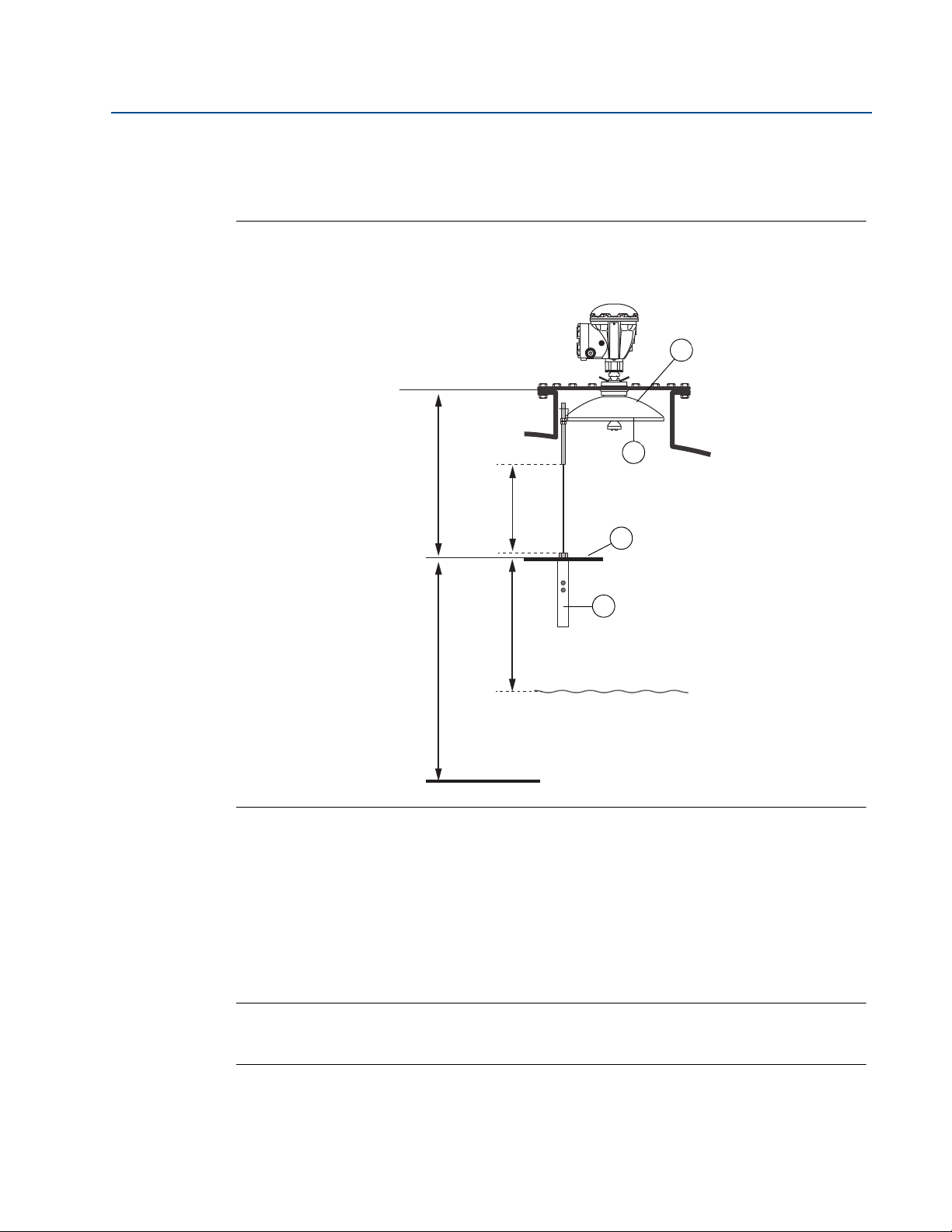

2.4.2 Tank Geometry - Parabolic Antenna

Figure 2-4. Tank geometry for Rosemount 5900 with Parabolic Antenna and Proof Test

Reference Reflector.

Section 2: Installation

November 2019

1. Reference Reflector (RR). Maximum inclination 2.5°.

2. Weight

3. Clamping ring

4. Parabolic antenna

Note

See “Safety Instrumented System (SIS)” on page 10 for installation requirements in Safety

Instrumented Systems (SIS).

Installation

9

Page 14

Section 2: Installation

4

21

Max. product level

Gauge Reference Point

3

5

November 2019

Manual Supplement

00809-0200-5900, Rev AC

Safety Instrumented System

(1)

(SIS)

1. Decide position of SIL High Alarm.

2. Find a position for the Reference Reflector (RR) that fulfills the following requirements:

a. Minimum 500 mm above SIL High Alarm Limit.

b. Distance RR - Gauge Reference Point: 600 to 5000 mm.

c. Minimum 500 mm to maximum product level.

Figure 2-5. Tank geometry for Rosemount 5900 with Parabolic Antenna and Proof Test

Reference Reflector in Safety Instrumented System (SIS).

1. SIL Surface Distance

2. SIL High Alarm Limit

3. Distance RR - Gauge Reference Point: 600 to 5000 mm

4. Minimum distance RR - SIL High Alarm = 500 mm

5. Reference Reflector (RR)

(1) See the Rosemount 5900 and 2410 Safety Manual (Document No. 00809-0200-5100) for information on how to install and con-

figure the Rosemount 5900 Radar Level Gauge and 2410 Tank Hub in a Safety Instrumented System.

10

Installation

Page 15

Manual Supplement

1

4

1. Reference Reflector (RR)

2. M12 Nut. Torque=18 Nm

3. Spring washer

4. Weight

3

2

00809-0200-5900, Rev AC

2.4.3 Installing the Reference Reflector

The length of the wire that holds the Reference Reflector needs to be calculated before the

Reference Reflector can be installed in the tank. The wire must be long enough to allow the

Reflector to be properly positioned in the tank including the weight that is attached under the

Reflector.

Handle the wire and assembly with care to avoid permanent bends.

1. Specify the position of the Reference Reflector (RR) and calculate the Reference

Reflector Distance (see Figure 2-4 on page 9).

2. Choose the appropriate reflector size. As a result of the radar beam geometry, a smaller

reflector can be used further away from the radar gauge. There are four different

Reference Reflectors to choose from depending on the Reference Reflector Distance as

shown in Table 2-1.

Section 2: Installation

November 2019

Table 2-1. Reference Reflector Size for Various Distances

Reference Reflector Distance (mm) Diameter (mm)

600 RR Distance < 2000 250

2000 RR Distance < 3000 200

3000 RR Distance < 4000 135

4000 RR Distance < 5000 90

3. Mount the appropriate Reference Reflector on the weight.

4. Tighten the M12 nut to a torque value of 18 Nm.

Installation

11

Page 16

Section 2: Installation

1

2

Wire Distance

1. Reference Reflector (RR)

2. Weight

M6 x 2

Allen key size 3

Torque=2.5 Nm

Cut the wire 0 - 150 mm

under the weight

November 2019

5. Calculate the required Wire Distance. See “Wire Distance calculation” on page 15.

6. Feed the wire through the weight and the Reference Reflector (RR).

Manual Supplement

00809-0200-5900, Rev AC

12

7. Position the weight so the calculated Wire Distance is obtained.

8. Tighten the two screws (size M6) to a torque value of 2.5 Nm.

9. Cut the wire. You may leave 0 to 150 mm of the wire below the weight.

Installation

Page 17

Manual Supplement

Parabolic antenna

A - A

M6 Screw

Torque = 2.3

Clamping ring

A

A

Clamping ring

Parabolic antenna

Nut M8

Torque = 8 Nm

Tank center

Nut M8

Spring washer

Washer

Wire

M8 terminal

Clamping ring

Antenna

00809-0200-5900, Rev AC

10. Mount the clamping ring (see Figure 2-3 on page 8) on the Parabolic Antenna. Ensure

Section 2: Installation

November 2019

that the Reference Reflector is directed towards the center of the tank as illustrated in

Figure 2-4 on page 9.

11. Mount the M8 terminal (which holds the weight and Reference Reflector) on the

clamping ring.

12. Tighten the M8 nut to the specified torque of 8 Nm.

Installation

13

Page 18

Section 2: Installation

Reference Reflector (RR)

Tank center

Parabolic antenna

Tank wall

November 2019

13. Ensure that:

the Reference Reflector is correctly aligned towards the center of the tank

inclination of Reference Reflector is less than 2.5°.

Figure 2-6. Align the Reference Reflector

Manual Supplement

00809-0200-5900, Rev AC

14

Installation

Page 19

Manual Supplement

1

2

Wire Distance

1. Reference Reflector (RR)

2. Weight

00809-0200-5900, Rev AC

Wire Distance calculation

There are two different connections available for the Parabolic Antenna; the Welded and the

Clamped versions. Since the vertical position of the flange will differ slightly for these two

connections, you will have to use different formulas for calculating the proper Wire Distance in

order to obtain the correct position (Reference Reflector Distance) of the Reference Reflector.

Figure 2-7. Wire Distance

Section 2: Installation

November 2019

Installation

15

Page 20

Section 2: Installation

60 mm

Flange

Antenna

W

Ga

November 2019

Welded tank connection

Use the following formula to calculate the required Wire Distance for the welded connection:

Wire Distance=RR + Ga -W - 194 (mm)

where

W= see Figure 2-8 on page 16

Ga= thickness of the flange gasket (see Figure 2-8 on page 16)

RR= Reference Reflector Distance (see Figure 2-4 on page 9)

Figure 2-8. Welded Connection

Manual Supplement

00809-0200-5900, Rev AC

16

Installation

Page 21

Manual Supplement

T = flange thickness

Ga

00809-0200-5900, Rev AC

Clamped tank connection

Use the following formula to calculate the required Wire Distance for the clamped connection:

Wire Distance=RR + Ga + T - 243 (mm)

where

T= flange thickness (see Figure 2-9)

Ga= thickness of the flange gasket (see Figure 2-9)

RR= Reference Reflector Distance (see Figure 2-4 on page 9)

Figure 2-9. Clamped Connection

Section 2: Installation

November 2019

Installation

17

Page 22

Section 2: Installation

Nut M12

Spring washer

Weight

M6 screw (x2)

Allen key size 3

Bronze rod

Wire 4 mm

Length 8 m

November 2019

Manual Supplement

00809-0200-5900, Rev AC

2.5 Installing the Reference Reflector for Array Antenna

2.5.1 Reference Reflector Kit

The Reflector is delivered with all parts needed for proper installation on a Rosemount 5900

with Array Antenna. The Reference Reflector kit includes the following parts:

Wire assembly

Weight assembly

Reference Reflector

Safety Wire

Flexible Ring

Figure 2-10. Wire and Weight Assembly

18

Installation

Page 23

Manual Supplement

Open space to allow

hand dipping

Note!

The reflector may need to be

removed for product sampling

through the pipe.

To secure the Reference

Reflector during installation

in Still-Pipe

M6 Nut

Rod attachment

The Flexible Ring provides an

attachment point in the Still-Pipe for

the wire and weight assembly

00809-0200-5900, Rev AC

Figure 2-11. Reference Reflector

Figure 2-12. Safety Wire

Section 2: Installation

November 2019

Installation

Figure 2-13. Flexible Ring

19

Page 24

Section 2: Installation

Wire Distance

Reference Reflector (RR) Distance

Minimum: 1000 mm

Maximum: 8000 mm

Reference Reflector (RR) Position

Min. 500 mm

4

5

Zero Level

Max. product level

Gauge Reference Point

1

3

2

November 2019

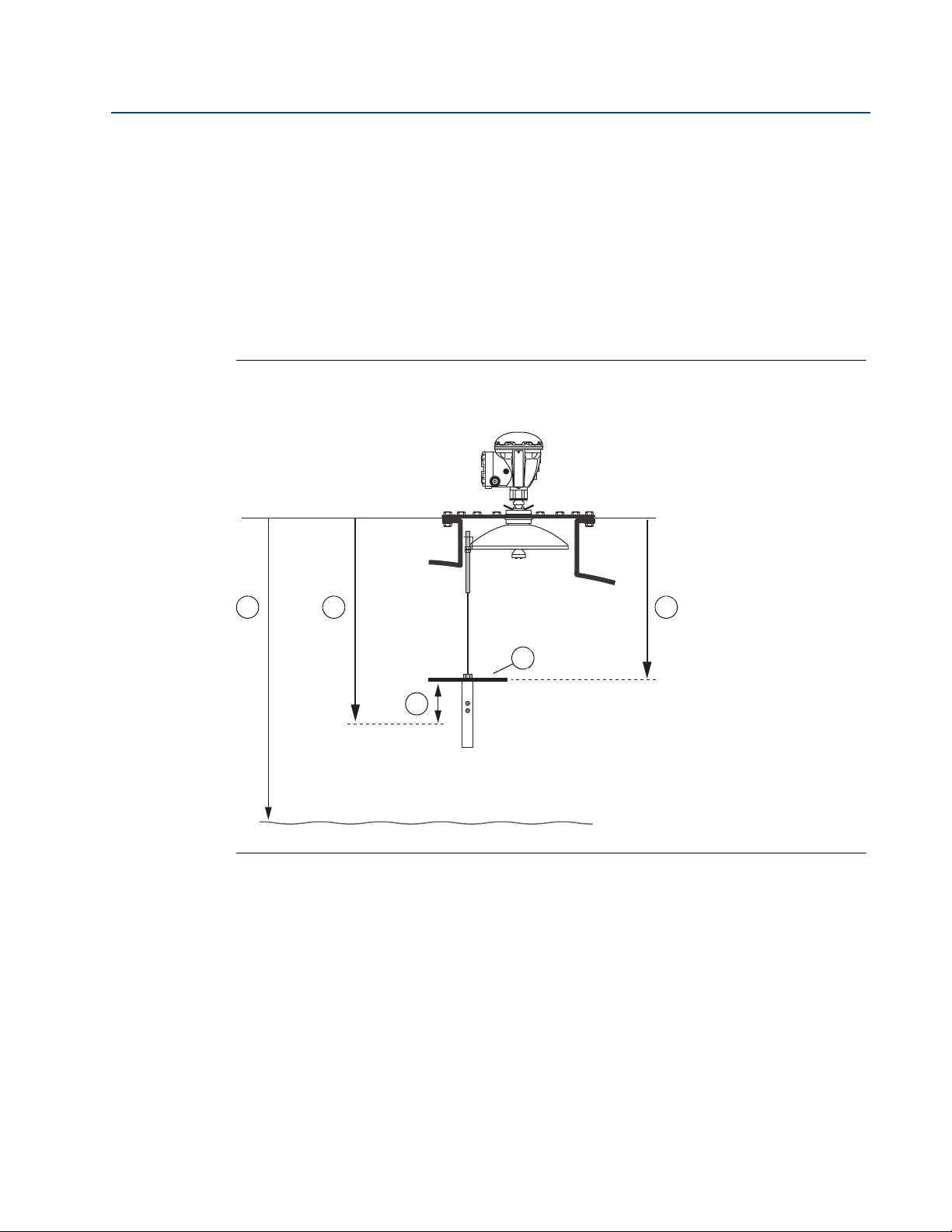

2.5.2 Tank Geometry - Array Antenna

Figure 2-14. Tank Geometry for Rosemount 5900 with Array Antenna Fixed Version and

Proof Test Reference Reflector.

Manual Supplement

00809-0200-5900, Rev AC

20

1. Array antenna

2. Flexible Ring

3. Bronze Rod

4. Reference Reflector (RR). Maximum inclination 2.5

°.

5. Weight

Note!

See “Safety Instrumented System (SIS)” on page 22 for installation requirements in Safety

Instrumented Systems (SIS).

Installation

Page 25

Manual Supplement

Wire Distance

Reference Reflector (RR) Distance

Minimum: 1000 mm

Maximum: 8000 mm

Reference Reflector (RR) Position

Min. 500 mm

4

5

Zero Level

Max. product level

Gauge Reference Point

1

2

3

00809-0200-5900, Rev AC

Figure 2-15. Tank Geometry for Rosemount 5900 with Array Antenna Hatched Version and

Proof Test Reference Reflector.

Section 2: Installation

November 2019

1. Array antenna

2. Flexible Ring

3. Bronze Rod

4. Reference Reflector (RR). Maximum inclination 2.5

5. Weight

Note!

See “Safety Instrumented System (SIS)” on page 22 for installation requirements in Safety

Installation

Instrumented Systems (SIS).

°.

21

Page 26

Section 2: Installation

4

21

Max. product level

Gauge Reference Point

5

3

November 2019

Manual Supplement

00809-0200-5900, Rev AC

Safety Instrumented System

(1)

(SIS)

1. Decide position of SIL High Alarm.

2. Find a position for the Reference Reflector (RR) that fulfills the following requirements:

a. Minimum 500 mm above SIL High Alarm Limit.

b. Distance RR - Gauge Reference Point: see Figure 2-16 and Table 2-2.

c. Minimum 500 mm to maximum product level.

Figure 2-16. Tank geometry for Rosemount 5900 with Array Antenna and Proof Test

Reference Reflector in SIS System (SIL).

Table 2-2. Tank Geometry Parameters for Array Antenna in Safety Instrumented Systems

Item Description Item Description

1 SIL Surface Distance 4 Minimum distance RR - SIL High Alarm Limit: 500 mm

2 SIL High Alarm Limit 5 Reference Reflector (RR)

3 Distance RR - Gauge Reference Point.

(1) See Rosemount 5900 and 2410 Safety Manual (Document No. 00809-0200-5100) for information on how to install and configure

the Rosemount 5900 Radar Level Gauge and 2410 Tank Hub in a Safety Instrumented System.

22

Array antenna 6 inch: 1100 to 8000 mm

Array antenna 8 inch: 1400 to 8000 mm

Array antenna 10 inch: 1800 to 8000 mm

Array antenna 12 inch: 2000 to 8000 mm

Note! These requirements are applicable for both the fixed and

hatched versions of the Array antenna.

Installation

Page 27

Manual Supplement

1

3

1. Reference Reflector (RR)

2. Spring washer

3. Weight

M12 Nut

Torque = 18 Nm

2

00809-0200-5900, Rev AC

2.5.3 Installing the Reference Reflector

You need to calculate the length of the wire that holds the Reference Reflector before the

Reference Reflector can be installed in the tank. The wire must be long enough to allow the

Reflector to be properly positioned in the tank including the weight that is attached under the

Reflector.

Handle the wire and assembly with care to avoid permanent bends.

1. Specify the position of the Reference Reflector (RR).

2. Calculate the Reference Reflector Distance. This is the distance from the Gauge

Reference Point to the Reference Reflector as illustrated in Figure 2-14 on page 20 and

Figure 2-15 on page 21.

Section 2: Installation

November 2019

3. Mount the Reference Reflector on the weight.

4. Tighten the M12 nut to a torque value of 18 Nm.

Installation

23

Page 28

Section 2: Installation

1

2

Wire Distance

1. Reference Reflector (RR)

2. Weight

M6 x 2

Torque=2.5 Nm

Cut the wire 0 - 150 mm

under the weight

Bronze rod

November 2019

5. Calculate the Wire Distance as described in “Wire Distance calculation” on page 27.

6. Feed the wire through the weight and Reference Reflector (RR).

Manual Supplement

00809-0200-5900, Rev AC

24

7. Position the weight to the correct Wire Distance.

8. Tighten the two screws. Torque=2.5 Nm.

9. Cut the wire 0 to 150 mm below the end of the weight.

Installation

Page 29

Manual Supplement

D

90 mm

M6 NUT

Torque=5 Nm

D

Flexible ring

Flexible ring

Rod

attachment

Rod attachment

00809-0200-5900, Rev AC

10. Install the Flexible Ring at the top of the Still-pipe. The ring can be adjusted to fit a wide

11. Ensure that the Flexible Ring fits tightly inside the pipe.

12. Tighten the M6 nut to the specified torque value of 5 Nm.

Section 2: Installation

November 2019

range of Still-Pipe inner diameters according to Table 2-3.

Table 2-3. The Flexible Ring Fits a Wide Range of Still-pipe Inner Diameters

Inner diameter (D)

6 inch pipe 8 inch pipe 10 inch pipe 12 inch pipe

152 - 164 mm 195.5 - 210.2 mm 254.5 - 268 mm 298.4 - 318.1

Installation

25

Page 30

Section 2: Installation

November 2019

13. Fasten one end of the Safety Wire to the Bronze Rod and the other end to the tank.

14. Lower the weight and reflector into the Still-pipe to the full length of the wire.

15. Put the wire into the rod attachment through the slot.

Manual Supplement

00809-0200-5900, Rev AC

26

16. Lower the Bronze Rod until it stops as illustrated below.

17. Remove the Safety Wire from the Bronze Rod.

Installation

Page 31

Manual Supplement

00809-0200-5900, Rev AC

Wire Distance calculation

Use the following formulas to calculate the required Wire Distance.

Array Antenna hatch version:

Wire Distance=RR - Ga - 362 (mm)

Array Antenna fix version:

Wire Distance=RR - 324 (mm)

where

Ga= thickness of the flange gasket

RR= Reference Reflector Distance (see Figure 2-14 on page 20 and Figure 2-15 on page 21)

Section 2: Installation

November 2019

Installation

27

Page 32

Section 2: Installation

November 2019

Manual Supplement

00809-0200-5900, Rev AC

28

Installation

Page 33

Manual Supplement

00809-0200-5900, Rev AC

Section 3: Configuration of Reference Reflector

November 2019

Section 3 Configuration of Reference

Reflector

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Configuration using TankMaster WinSetup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 30

3.1 Overview

The information in this section covers configuration and calibration of the Reference Reflector

for proof testing the Rosemount

™

5900 Radar Level Gauge.

3.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end user’s equipment. This could be intentional or unintentional and

needs to be protected against.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access by unauthorized personnel to protect end

user’s assets. This is true for all systems used within the facility.

Configuration of Reference Reflector

29

Page 34

Section 3: Configuration of Reference Reflector

November 2019

Manual Supplement

00809-0200-5900, Rev AC

3.3 Configuration using TankMaster WinSetup

3.3.1 Introduction

The Rosemount 5900 is configured by using the TankMaster Winsetup configuration program.

WinSetup supports standard configuration of the Rosemount 5900 Radar Level Gauge as well as

configuration of the Reference Reflector for Proof Test applications.

See the Tank Gauging System Configuration Manual

TankMaster WinSetup software to configure a Rosemount Tank Gauging system.

Note

The Proof Test function requires gauge firmware version 1.B9 or higher and Rosemount

TankMaster 6.E1 or higher .

Proof test features

The Rosemount 5900 Proof Test function in TankMaster Winsetup includes the following

functions:

Configure proof test

Perform proof test

View proof test history

Schedule proof tests

3.3.2 Considerations

The following requirements and recommendations must be considered when using the

Rosemount 5900 Proof Test function:

for more information on using the

30

Do not perform calibration of Proof Test function during activities in the tank, for

example when it is filled or emptied.

Do not perform calibration of Proof Test function during extreme environmental

conditions.

Proof Test calibration must be repeated whenever configuration of tank geometry

parameters has been changed. This may for example include parameters such as

Calibration Distance or Pipe Diameter.

For Still-Pipes the slots must not be wider than one inch (1”)

Configuration of Reference Reflector

Page 35

Manual Supplement

Proof Test

00809-0200-5900, Rev AC

3.3.3 Configuration procedure

The Proof Test function needs to be configured prior to any proof test can be performed. This

means calibrating the reference reflector by specifying the actual position of the reflector and

the nominal amplitude of the reflected radar signal.

Configuration also includes setting up the approved amplitude range (Min./Max. Amplitude

Factor) and allowed deviations from the calibrated reflector position (Tolerance). This step

needs to be done for physical as well as simulated reference reflectors.

Ensure that a standard configuration of the Rosemount 5900 is performed prior to the proof test

configuration.

To configure a Rosemount 5900 with Reference Reflector for Proof Test applications do the

following:

1. Ensure that the TankMaster WinSetup program is up and running.

2. In the Winsetup workspace, click the right mouse button on the Rosemount 5900

device icon and select the Proof Test option.

Section 3: Configuration of Reference Reflector

November 2019

Configuration of Reference Reflector

31

Page 36

Section 3: Configuration of Reference Reflector

November 2019

3. The Proof Test window appears. It lets you perform proof tests, view previous tests, and

schedule future tests. There are two different versions:

Option Proof Test Window

SIL2 Model Code S

and non-SIL

Manual Supplement

00809-0200-5900, Rev AC

SIL3

4. Click the Reference Reflector Configuration/Configuration button to open the

Reference Reflector Configuration window:

32

Configuration of Reference Reflector

Page 37

Manual Supplement

00809-0200-5900, Rev AC

Section 3: Configuration of Reference Reflector

November 2019

5. In case no previous Proof Test configuration has been performed, or if the Proof Test

calibration has been reset, the status message “ Not Calibrated” will be displayed.

6. The Proof Test Configuration window lets you specify calibration parameters for the

Reference Reflector. It also lets you set up the approved amplitude range and approved

deviations from the calibrated reflector position.

Configuration of Reference Reflector

33

Page 38

Section 3: Configuration of Reference Reflector

November 2019

7. In the Calibrate Reference Reflector pane, enter the actual position of the Reference

Reflector (RR) in the RR Distance field. The RR Distance value will be used by the level

gauge as a starting point when searching for the Reference Reflector. A position

between 0.5 m and 8.0 m below the Tank Reference Point is allowed depending on the

antenna type that is used. See Section 2: Installation for more information.

8. Specify the desired Distance Tolerance value. This is the region around the specified

RR Distance within which the level gauge searches for a radar echo when calibrating the

Reference Reflector (see Figure 3-1 on page 38). The default value is 0.3 m.

9. Click the Calibrate button.

Manual Supplement

00809-0200-5900, Rev AC

10. Click Yes. Now the level gauge starts searching for the Reference Reflector. When the

search is finished, the Calibrate window appears showing the distance to the Reference

Reflector and the amplitude of the reflected radar signal.

11. Verify that the radar echo originates from the Reference Reflector and not from any

other object in the tank. The measured Distance and Amplitude values will be used as

reference values when future Proof Tests are performed.

34

Configuration of Reference Reflector

Page 39

Manual Supplement

00809-0200-5900, Rev AC

12. For Safety Instrumented Systems (SIL) verify that the amplitude is within the following

13. Click the Save button to store the current calibration.

Section 3: Configuration of Reference Reflector

November 2019

recommended range:

Rosemount 5900 with Parabolic antenna: 600 to 1200 mV

Rosemount 5900 with Array antenna (Still-Pipe): 1000 to 3500 mV

Rosemount 5900 with simulated antenna: approximately 600 mV

14. In case the product surface is too close to the Reference Reflector during the

calibration, a warning message will appear allowing you to choose whether to cancel or

to save the calibration data.

See Section 2: Installation for information on requirements for minimum distance

between Reference Reflector and product surface.

15. If calibration failed you may consider the following:

Check that the actual position of the reference reflector (RR) is within the search

window given by the calibration parameters RR Distance and Distance Tolerance.

Verify that the reference reflector is horizontal within the specifications for maximum

inclination (see “Tank Geometry - Parabolic Antenna” on page 9.

Verify that there are no disturbing objects near the reference reflector that may

interfere.

Configuration of Reference Reflector

35

Page 40

Section 3: Configuration of Reference Reflector

November 2019

16. Return to the Proof Test Configuration window and proceed with configuration of

Reference Reflector Settings.

Manual Supplement

00809-0200-5900, Rev AC

17. Normally, the default settings of Min./Max. Amplitude Factors and Tolerance can be

used without any changes. Proof tests must be within these limits in order to be

approved. If needed, these settings can be changed.

18. Verify that Reference Reflector Status is OK. RR Status will be OK as long as the actual

distance (Echo Distance) and amplitude (Echo Amplitude) are within the specified

tolerances as specified in the Reference Reflector Settings pane. Click the Apply button

to store the parameters.

19. Specify the desired Default Test Time. This value will be used as the default value in the

Level Sensor Test window. The actual test time can be changed when running the test.

20. If Reference Reflector Status is OK, click the OK button to close the Proof Test

Configuration window. Now the level gauge is ready for Proof Testing.

36

Configuration of Reference Reflector

Page 41

Manual Supplement

00809-0200-5900, Rev AC

Example

Table 3-1 shows an example of a proof test configuration for a Rosemount 5900 Radar Level

Gauge with Reference Reflector. Table 3-2 shows the actual distance and amplitude as

measured by the Rosemount 5900 gauge.

In the example, the measured distance to the Reference Reflector (Echo Distance) is 2.020 m.

This is within the approved distance range as shown in Table 3-1. The amplitude of 450 mV

(Echo Amplitude) is within the approved amplitude range. See also Figure 3-1 on page 38.

Table 3-1. Configuration

Section 3: Configuration of Reference Reflector

November 2019

Parameter Configuration

Min. Amplitude Factor

Max. Amplitude Factor

Tolerance

Calibrated Amplitude

Calibrated Distance

Approved amplitude

Approved distance

0.25

2.5

0.06 m

400 mV

2.000 m

100 to 1000 mV

1.940 to 2.060 m

Table 3-2. Measurements

Parameter Measurement

Echo Distance 2.020 m

Echo Amplitude 450 mV

Note

For Safety Instrumented Systems (SIL) the amplitude should be within the recommended

range:

- Rosemount 5900 with Parabolic antenna: 600 to 1200 mV.

- Rosemount 5900 with Array antenna (Still-Pipe): 1000 to 3500 mV.

Configuration of Reference Reflector

37

Page 42

Section 3: Configuration of Reference Reflector

Approved amplitude

Distance

Tolerance

Calibrated Distance

Distance

Echo

Amplitude

Calibrated Amplitude

Max. amplitude

Min. amplitude

Product surface

November 2019

Figure 3-1. Proof Test Calibration

Manual Supplement

00809-0200-5900, Rev AC

38

Table 3-3. Configuration Parameters for a Proof Test Setup

Parameter Description

Calibrated Amplitude Amplitude of the measurement signal that was reflected by the

Reference Reflector during calibration.

calibration.

Rosemount 5900 searches for a radar echo when calibrating the

Reference Reflector.

proof test.

Calibrated Distance Distance to the Reference Reflector measured by the gauge during

Distance Tolerance The region around the specified RR Distance within which the

Approved Amplitude Approved range of signal amplitudes during a proof test.

Min./Max. Amplitude Minimum and maximum amplitude values that will be allowed during a

RR Distance Distance from the Gauge Reference Point to the reference reflector (RR).

Configuration of Reference Reflector

Page 43

Manual Supplement

00809-0200-5900, Rev AC

Section 4 Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 39

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 39

Proof Test operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 40

Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 44

History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 46

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 47

Removing a Reference Reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 50

4.1 Overview

This section contains information on the Light Emitting Diodes (LED) on the front of the

Rosemount 2460 System Hub.

Section 4: Operation

November 2019

4.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

Operation

39

Page 44

Section 4: Operation

Proof Test

November 2019

4.3 Proof Test operation

Prior to running a Proof Test you will have to ensure that the Proof Test function is properly

calibrated and configured as described in Section 3: Configuration of Reference Reflector.

Manual Supplement

00809-0200-5900, Rev AC

To run a proof test for a Rosemount

1. Ensure that the TankMaster

™

5900 with Reference Reflector do the following:

™

WinSetup program is up and running.

40

2. In the TankMaster Winsetup workspace, click the right mouse button on the

Rosemount 5900 device icon and choose the Proof Test option.

3. The Proof Test window appears. It lets you perform various tasks such as performing

Proof tests, viewing Proof Test history, and schedule future Proof Tests.

Operation

Page 45

Manual Supplement

SIL2 MODEL CODE S AND NON-SIL SIL3

00809-0200-5900, Rev AC

Section 4: Operation

November 2019

4. To perform a proof test, select the check box for Reference Reflector test, and click the

Start Guided Proof Test button. For SIL3 gauges; in the Level Sensor (ATG) pane click

the Test button.

5. The High Level Alarm Test window lets you start a proof test if a proof test configuration

is performed. In case the Start Proof Test button is disabled you will have to make a

calibration of the Reference Reflector first. See Section 3: Configuration of Reference

Reflector for more information.

Operation

41

Page 46

Section 4: Operation

November 2019

6. The following measurement data is presented:

Manual Supplement

00809-0200-5900, Rev AC

Parameter Description

Level Distance from the Zero Reference Point to the product surface or the

Reference Reflector, respectively

Ullage Distance from the Gauge Reference Point to the product surface

Distance Distance from the Gauge Reference Point to the Reference Reflector

Amplitude Amplitude of the radar signal reflected by the product surface or the

Reference Reflector, respectively.

7. Specify duration of the test in the Proof Test Time field. It can be set to any value

between 30 seconds and 60 minutes. The default value is 120 seconds.

8. Ensure that device status is OK. See different status messages that may appear

according to Table 4-1 on page 4-43.

9. Click the Start Proof Test button to perform the test for the specified Proof Test Time.

10. Note the Warning that appears when starting the Proof Test. Ensure that the necessary

actions are taken in order to maintain safety during the test.

42

11. When the proof test is finished you will have to fill in a proof test form in order to create

a report (see “Proof Test Report” on page 49). A report in PDF format will be created

automatically and will be available from the Proof Test History window. See “Viewing a

report” on page 48.

Operation

Page 47

Manual Supplement

00809-0200-5900, Rev AC

4.3.1 Proof Test status

Table 4-1. Proof Test Status Options

Status options

Proof Test Active

Test Finished

Test Ended by User

RR Not Found

RR not Calibrated

Level Surface Too Close

Proof Test Status not Available

Section 4: Operation

November 2019

Operation

43

Page 48

Section 4: Operation

SIL2 MODEL CODE S AND NON-SIL SIL3

Type an email address in this field

November 2019

4.4 Scheduling

You may specify a scheduling interval in order to be reminded when it is time for a new Proof

Test. There are two reminder options available:

e-mail

pop-up window

To specify scheduling options and reminder settings:

1. Open the Proof Test window.

Manual Supplement

00809-0200-5900, Rev AC

44

2. Click the Scheduling button.

3. Enter the desired date, time, and scheduling interval.

4. Choose one or both of the reminder options; Pop-up Message and/or E-mail. The

More button opens the Email Details window which lets you type a subject line and a

message text for the email reminder.

Operation

Page 49

Manual Supplement

00809-0200-5900, Rev AC

4.4.1 Pop-up message

The Reminder pop-up message will appear at the scheduled time.

Figure 4-1. Pop-up Message with Reminder to Perform Proof Test

In case you choose to accept, you will be directed to the Proof Test window in order to start the

Proof Test procedure as described in Section 4: Proof Test operation“Proof Test operation” on

page 40.

Section 4: Operation

November 2019

You may choose to skip the test altogether by clicking the Skip This Test button, or you may let

WinSetup remind you later by choosing one of the options in the Remind In drop-down list:

1 Day, 1 Week, or 1 Month.

Figure 4-2. If Proof Test Is Skipped You May Choose To Be Reminded Later

Operation

45

Page 50

Section 4: Operation

November 2019

4.5 History

The Proof Test History function lets you view previously performed proof tests for a device. You

can also view tests that were interrupted resulting in no report creation.

Figure 4-3. Proof Test History

Manual Supplement

00809-0200-5900, Rev AC

46

Using Back and Forward buttons, or selecting the test date, you may navigate through the

tests. The following information about test parameters will be shown:

RR Status

Proof Test Status

Echo Distance

Echo Amplitudes

Date

Performed By

Approved By

Note

Test reports are available by pressing the Show Test Report button, see “Viewing a report” on

page 48.

Operation

Page 51

Manual Supplement

SIL2 MODEL CODE S AND NON-SIL SIL3

00809-0200-5900, Rev AC

4.6 Reports

When a proof test is finished a report will be generated. For SIL3 you will have to fill in a

questionnaire in order to create the report.

1. When prompted, fill in the proof test report form.

Section 4: Operation

November 2019

2. Click the Save button to store the proof test form.

3. A report in PDF format will be created automatically. It will be available from the Proof

Test History window. See “Viewing a report” on page 48.

Operation

47

Page 52

Section 4: Operation

Show the selected report

Select a test report

November 2019

4.6.1 Viewing a report

Reports in Adobe Acrobat pdf format are available via the Proof Test History window.

To view a report:

1. In TankMaster WinSetup, click the Rosemount 5900 icon and select the Proof Test

option to open the Proof Test window.

2. In the Level Sensor (ATG) pane, click the History button.

3. In the Proof Test History window, select the desired test.

Manual Supplement

00809-0200-5900, Rev AC

48

4. Click the Show Test Report button. Acrobat Reader opens and displays a report for the

selected proof test.

Operation

Page 53

Manual Supplement

SIL2 MODEL CODE “S” AND NON-SIL SIL3

00809-0200-5900, Rev AC

The report includes device information and device status. There is also information regarding

the result of the proof test, for example whether alarms did sound or if emergency shutdown

was activated.

Figure 4-4. Proof Test Report

Section 4: Operation

November 2019

Operation

49

Page 54

Section 4: Operation

November 2019

4.7 Removing a Reference Reflector

There may be a situation when you would like to remove the Reference Reflector and disable the

Proof Test function. Then you can use the Reset function to remove all Proof Test calibration

data. This ensures that there is no data stored in the Rosemount 5900 database that may

interfere with the current measurements.

1. Open the Proof Test window and click the Configuration button.

2. In the Reference Reflector Configuration window, click the Reset button to open the Reset

window.

Manual Supplement

00809-0200-5900, Rev AC

50

3. The Reset window shows the current Reference Reflector calibration data for the

Rosemount 5900 Radar Level Gauge.

4. Click the Reset button to clear all calibration data. Status will be changed to Not

Calibrated.

Operation

Page 55

Manual Supplement

00809-0200-5900, Rev AC

Section 5: Service and Troubleshooting

November 2019

Section 5 Service and Troubleshooting

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 51

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 52

Tank spectrum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 53

5.1 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock:

Avoid contact with leads and terminals.

Make sure the main power to the 2410 Tank Hub is off and the lines to any other external

power source are disconnected or not powered while wiring the 2460.

Service and Troubleshooting

51

Page 56

Section 5: Service and Troubleshooting

November 2019

5.2 Troubleshooting

Table 5-1 provides summarized troubleshooting suggestions for the most common operating

problems.

Table 5-1. Troubleshooting Chart

Symptom Possible cause Action

Manual Supplement

00809-0200-5900, Rev AC

Reference Reflector (RR) not

found

Proof Test could not be started Product surface too close to the RRMake sure that the product surface is below the

Proof Test was aborted

unexpectedly

RR calibration could not be

performed

Incorrect configuration

RR inclination too high Adjust the RR and make sure that the RR is

The Reference Reflector is

within the Hold Off region

Wrong search window due to

using incorrect reference

system

RR Calibration could not be

performed

Write protection is enabled Disable write protection

Check RR Distance

Check Distance Tolerance

horizontal within specified limit see Section 2:

Installation.

Check that the reflector is installed according to the

instructions in Section 2: Installation. Ensure that it

is installed according to the requirements for

minimum Reference Reflector Distance.

Ensure that distances are measured in the correct

reference system as described in “Tank Geometry -

Parabolic Antenna” on page 9 and “Tank Geometry

- Array Antenna” on page 20. Note for example,

that the Gauge Reference Point is located at the

flange of the tank nozzle.

See “RR calibration could not be performed”.

maximum level that is allowed for RR calibration,

see Section 2: Installation.

Reference Reflector does not

appear in the Tank Scan

window

(1) See “Tank spectrum” on page 53

52

(1)

Tank Signal Mean (TSM)

function (near-zone

improvement) filters away the

Reference Reflector

Enable Peak Labels by checking the box

Service and Troubleshooting

Page 57

Manual Supplement

00809-0200-5900, Rev AC

5.3 Tank spectrum

The Tank Scan function is a useful tool to verify that the Rosemount™ 5900 level gauge is able to

locate the product surface and the reference reflector. It lets you locate possible disturbing

objects, and you may also check that amplitude thresholds are properly set so that the

Reference Reflector echo is not filtered away.

Figure 5-1. Tank Spectrum with Radar Echoes from Reference Reflector and Product

Surface.

Section 5: Service and Troubleshooting

November 2019

Note

Simulated reference reflector will not be shown in tank scan.

Service and Troubleshooting

53

Page 58

Section 5: Service and Troubleshooting

Properties

November 2019

To open the Tank Scan window:

1. In the WinSetup workspace, click the right mouse button on the device icon.

Manual Supplement

00809-0200-5900, Rev AC

2. Choose the Properties option.

3. Select the Advanced tab an click the Tank Scan button.

54

Service and Troubleshooting

Page 59

Manual Supplement

00809-0200-5900, Rev AC

Index

Index

November 2019

A

Amplitude Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

C

Calibrate button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Calibrate window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Clamped tank connection . . . . . . . . . . . . . . . . . . . . . . . 17

Clamping ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

D

Distance Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . 34, 35

F

Flexible Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

H

History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

I

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

M

Max. Amplitude Factor . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Min. Amplitude Factor . . . . . . . . . . . . . . . . . . . . . . . . . . 36

P

Proof Test Configuration window . . . . . . . . . . . . . . . . . 33

R

Reference Reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parabolic Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . 11

Reference Reflector kit. . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Reminder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

RR Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34, 35

S

Safety Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

T

Tank Geometry

Array Antenna

Parabolic Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

W

Welded tank connection . . . . . . . . . . . . . . . . . . . . . . . . 16

Wire Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12, 15

Wire Distance Calculation . . . . . . . . . . . . . . . . . . . . 15, 27

clamped tank connection. . . . . . . . . . . . . . . . . . . . 17

Welded tank connection . . . . . . . . . . . . . . . . . . . . 16

O

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Index

Index-1

Page 60

Index

November 2019

Manual Supplement

00809-0200-5900, Rev AC

Index-2

Index

Page 61

Page 62

Global Headquarters and Europe Regional Office

Tank Gauging

Emerson Automation Solutions

Box 150

(Visiting address: Layoutvägen 1)

SE-435 23 Mölnlycke

+46 31 337 00 00

+46 31 25 30 22

sales.rtg@emerson.com

North America Regional Office

Tank Gauging

Emerson Automation Solutions

6005 Rogerdale Road

Mail Stop NC 136

Houston TX 77072

United States

+1 281 988 4000 or +1 800 722 2865

sales.rtg.hou@emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Manual Supplement

00809-0200-5900, Rev AC

November 2019

Linkedin.com/company/Emerson-Process-Management

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Tank Gauging

Emerson Automation Solutions

P.O Box 20048

Manama

Bahrain

+973 1722 6610

+973 1722 7771

RFQ.RMTMEA@Emerson.com

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

© 2019 Rosemount\ Inc. All rights reserved.

Emerson Terms and Conditions of Sale are available upon request. The

Emerson logo is a trademark and service mark of Emerson Electric Co.

Rosemount is a mark of one of the Emerson family of companies. All

other marks are the property of their respective owners.

Loading...

Loading...