Page 1

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series Radar

Level Transmitter with HART

OUNDATION

F

™

fieldbus protocol

®

and

www.rosemount.com

Page 2

Page 3

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

Rosemount 5600 Series

Radar Level Transmitter

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers.

Customer Central: 1-800-999-9307(7:00 a.m. to 7:00 p.m. CST)

Technical support, quoting, and order-related questions.

North American Response Center:1-800-654-7768 (24 hours a day – Includes Canada)

Equipment service needs.

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Rosemount

Sales Representative.

.

.

Rosemount and the Rosemount logotype are registered trademarks of Rosemount Inc.

PlantWeb is a registered trademark of the Fisher-Rosemount group of companies.

HART is a registered trademark of the HART Communication Foundation.

Teflon, VITON, and Kalrez are registered trademarks of E.I. du Pont de Nemours & Co.

OUNDATION is a trademark of the Fieldbus Foundation.

F

DeltaV is a trademark of Emerson Process Management group of companies.

All other marks are the property of their respective owners.

Cover Photo: 5600_01ad

www.rosemount.com

Page 4

Page 5

Reference Manual

00809-100-4024, Rev BA

September 2005

Rosemount 5600 Series

Table of Contents

SECTION 1

Introduction

SECTION 2

Mechanical Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Specific FCC Requirements (USA only) . . . . . . . . . . . . . . . . . . . . . . . 1-6

Measuring Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Unpacking your 5600 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Within USA: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Outside USA: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

General Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Customer Supplied Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Nozzle Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Free Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Beam Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Special Antennas and Space Requirements Reference . . . . . . . . 2-5

Wave Guide Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Mounting the Rod Antenna, Flanged Version . . . . . . . . . . . . . . . . . . . 2-7

Mounting the Rod Antenna, Threaded Version . . . . . . . . . . . . . . . . . 2-11

Mounting the Cone Antenna - PTFE sealing . . . . . . . . . . . . . . . . . . . 2-14

Mounting the Cone Antenna - Quartz sealing . . . . . . . . . . . . . . . . . . 2-17

Mounting the Process Seal Antenna . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Mounting the Cone Antenna in a Still-pipe/Bridle . . . . . . . . . . . . . . . 2-25

For Still Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

For Bridle Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Mounting the Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Mounting the Parabolic Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Mounting the Extended Cone Antenna . . . . . . . . . . . . . . . . . . . . . . . 2-37

Setting the Tank Connection Length (TCL) . . . . . . . . . . . . . . . . . 2-38

Setting the Hold Off Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Installation Requirements Extended Cone Antenna. . . . . . . . . . . 2-40

Mounting the Cone Antenna with Flushing Connections . . . . . . . . . . 2-43

SECTION 3

Electrical Installation

www.rosemount.com

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

HART Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

External Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Connecting HART devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Page 6

Rosemount 5600 Series

FOUNDATION Fieldbus Electrical Installation. . . . . . . . . . . . . . . . . . . 3-8

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Fieldbus Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Model Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

External Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Hazardous Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Connecting fieldbus devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Connecting the 2210 Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Temperature Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Reference Manual

00809-0100-4024, Rev BA

September 2005

SECTION 4

Configuration

SECTION 5

HART Configuration

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Advanced Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Tank Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Advanced Tank Geometry Configuration . . . . . . . . . . . . . . . . . . . . 4-6

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Process Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Temperature Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Volume Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Advanced Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Disturbance Echo Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Bottom Echo Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Full Tank Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Empty Tank Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Surface Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

PC Configuration Software Radar Master . . . . . . . . . . . . . . . . . . . . . . 5-2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Main Configuration Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Hand-Held Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

HART Fast Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Setting the Loop to Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Connections and Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Using a Hand Held Communicator . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Level Configuration Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

SECTION 6

FOUNDATION Fieldbus

Configuration

TOC-2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Foundation Fieldbus Function Blocks. . . . . . . . . . . . . . . . . . . . . . . 6-2

Assigning Device Tag and Node Address . . . . . . . . . . . . . . . . . . . . . . 6-3

Configure Transmitter using Delta V . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Configure the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Configure the AI Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Application Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Application Example: Radar Level Transmitter, Level Value . . . . 6-13

Application Example:

Page 7

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

Radar Level Transmitter, Level value in percent (%) . . . . . . . . . . 6-14

Application Example:

Radar Level Transmitter used to Display Volume . . . . . . . . . . . . 6-15

Configuration Using the Sensor Bus Port . . . . . . . . . . . . . . . . . . . . . 6-16

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Switching to Sensor Bus Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

SECTION 7

2210 Display Unit

Configuration

SECTION 8

Maintenance and

Troubleshooting

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Rosemount 2210 Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Viewing Level Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Display Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Installing a Rosemount 5600 Radar Level Transmitter . . . . . . . . . 7-8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

HART Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 8-2

Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Service Using the Rosemount 2210 Display Unit. . . . . . . . . . . . . . 8-2

Field Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Connection via Sensor Bus Port. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Fieldbus Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . 8-4

Configure Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Service Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Calibration Distance Configuration . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Master Reset Method (Resource Block) . . . . . . . . . . . . . . . . . . . . 8-4

Write Protection (Resource Block) . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Block Instantiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Field Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Transducer Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Analog Input (AI) Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

APPENDIX A

Reference Data

APPENDIX B

Product Certifications

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Measuring Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Display/Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Electric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Analog Output Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Fieldbus Output Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

2210 Display Unit Output Characteristics. . . . . . . . . . . . . . . . . . . . A-5

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

European Union Directive Information. . . . . . . . . . . . . . . . . . . . . . . . . B-1

5600 Series Radar Level Transmitter. . . . . . . . . . . . . . . . . . . . . . . B-1

TOC-3

Page 8

Rosemount 5600 Series

2210 Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

ATEX Directive (94/9/EC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Ordinary Location Certification for Factory Mutual . . . . . . . . . . . . . . .B-5

Canadian Registration Number (CRN) . . . . . . . . . . . . . . . . . . . . . . . . B-5

Hazardous Locations Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

ATEX Approval Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

CSA Approval Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

Reference Manual

00809-0100-4024, Rev BA

September 2005

APPENDIX C

Level Transducer Block

APPENDIX D

Resource Block

APPENDIX E

Register Transducer

Block

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Parameters and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Diagnostics Device Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Supported Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Unit codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Parameters and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Register Access Transducer Block Parameters . . . . . . . . . . . . . . . . . E-1

TOC-4

Page 9

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

Section 1 Introduction

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Specific FCC Requirements (USA only) . . . . . . . . . . . . . . page 1-6

Unpacking your 5600 Transmitter . . . . . . . . . . . . . . . . . . .page 1-8

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-9

SAFETY MESSAGES Procedures and instructions in this manual may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the safety messages listed at the beginning of each section before performing

an operation preceded by this symbol.

Explosions could result in death or serious injury:

Verify that the operating environment of the transmitter is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART-based communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform these procedures.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

This product is an electrical apparatus and must be installed in the hazardous area in

accordance with the requirements of the EC Type Examination Certificate.

The installation and maintenance must be carried out in accordance with all appropriate

international, national and local standard codes of practice and site regulations for

intrinsically safe apparatus and in accordance with the instructions contained within this

manual. Access to the circuitry must not be made during operation.

www.rosemount.com

Page 10

Reference Manual

00809-0100-4024, Rev BA

Rosemount 5600 Series

September 2005

OVERVIEW This manual provides information about mechanical and electrical installation

of the 5600 Series Radar Level Transmitter. It also describes how to start up

and configure the transmitter. The main purpose of the book is to act as guide

to installing and operating the 5600 Series Radar Level Transmitter. It is not

intended to cover service tasks such as changing circuit boards or internal

software.

Section 2: Mechanical Installation

• Mechanical installation instructions

Section 3: Electrical Installation

• Electrical installation instructions

Section 4: Operation

•Operation

Section 5: HART Configuration

• Commissioning

• Software functions

• Configuration parameters

• Online variables

Section 6: FOUNDATION Fieldbus Configuration

• Commissioning with Delta V

• Software functions

• Configuration parameters

• Online variables

Section 7: 2210 Display Unit Configuration

• Commissioning

Section 8: Maintenance and Troubleshooting

• Troubleshooting techniques for the most common operating problems

for HART and F

OUNDATION fieldbus protocol only.

1-2

Page 11

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

Appendix A: Reference Data

• Specifications

• Dimensional Drawings

• Ordering information for HART and F

Appendix B: Product Certifications

• Intrinsic safety approval information

• European ATEX directive information

• Approval drawings for HART and fieldbus protocols

Appendix C: Level Transducer Block

• Supplies Level Transducer Block data

Appendix D: Resource Block

• Contains information relating to the operation of the resource block.

Appendix E: Register Transducer Block

• Contains information relating to the operation of the register transducer

block.

OUNDATION fieldbus protocols

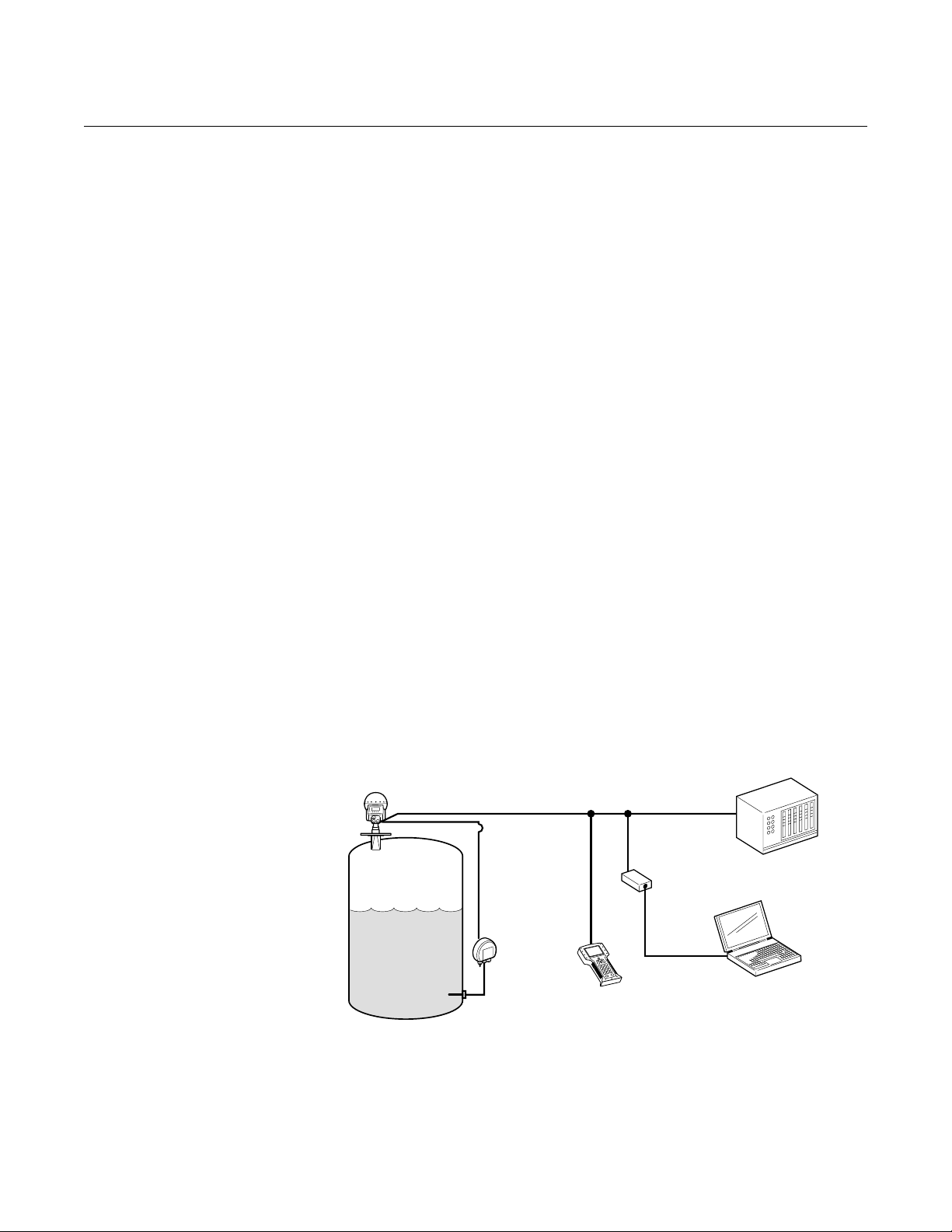

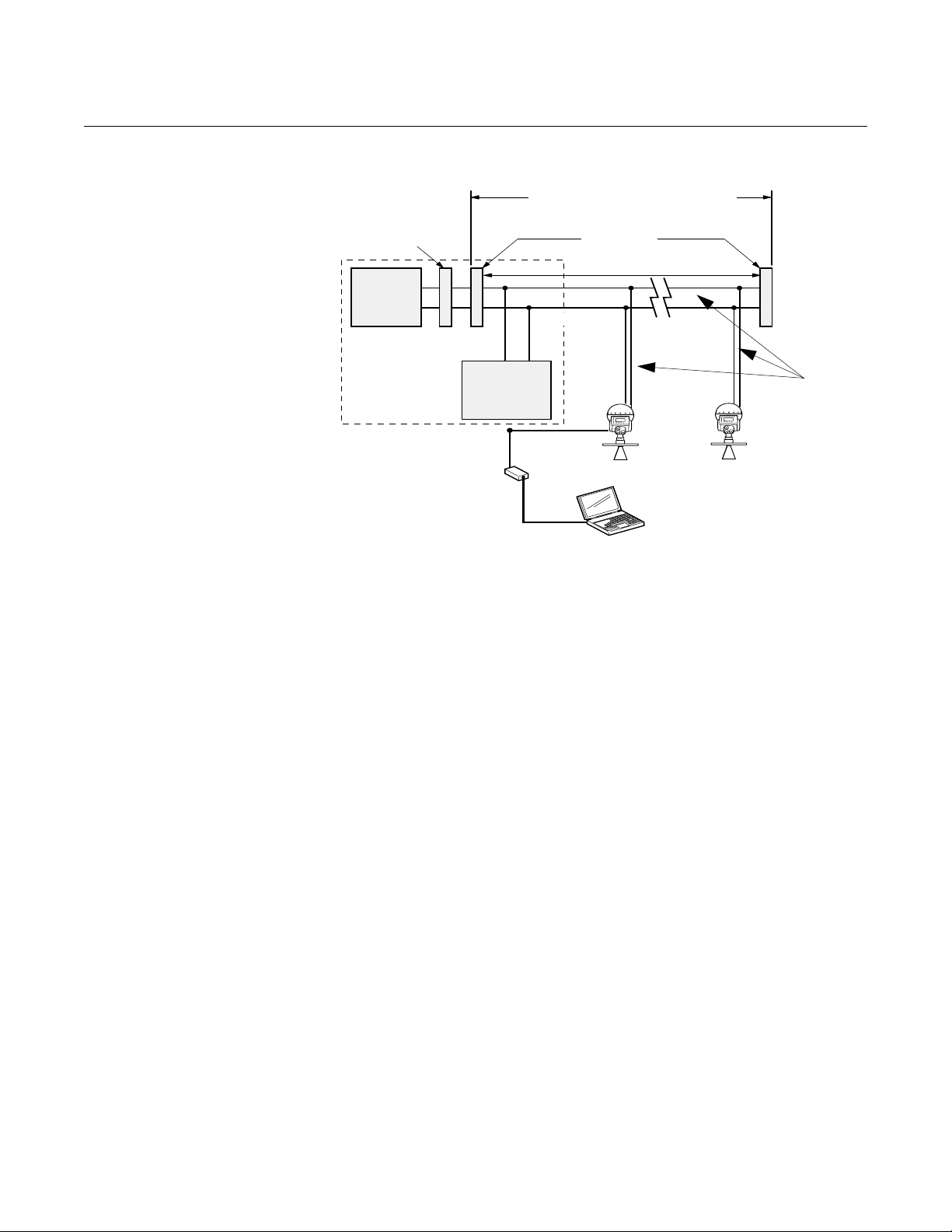

Figure 1-1. System Integration

using the Hand-held

Communicator

The 5600 Series Radar Level Transmitter is a powerful radar level transmitter

suitable for non-contact level measurements in process tanks, storage tanks,

and other types of tanks. It is designed for easy installation and maintenance

free operation.

Together with the Rosemount Radar Master Configuration Tool you are able,

in an easy and user-friendly way, to configure the 5600 transmitters. The

Radar Master program is a Microsoft

®

Windows-based software package

designed for the 5600 transmitters, and offers great assistance, from startup

and commissioning to advanced service. It includes waveform plots, off-line

configuration, logging, and an extensive on-line Help.

4-20 mA/HART

Control System

Remote

Display

(Optional)

Hand-held

Communicator

HART Modem

Configuration PC with

Radar Master software

5600/PDS/BILD_1.EPS

1-3

Page 12

Rosemount 5600 Series

Figure 1-2. System Integration

using F

OUNDATION fieldbus

Integrated Power

Power

Supply

The power supply,

filter, first terminator,

and configuration

tool are typically

located in the

control room.

Note:

Intrinsically safe

installations may allow

fewer devices per I.S.

barrier due to current

limitations.

Conditioner

and Filter

OUNDATION

F

fieldbus

Configuration

Tool

RS485 Modem

6234 ft (1900 m) max

(depending upon cable

characteristics)

Terminators

Fieldbus

Segment

(Trunk)

(Spur)

Reference Manual

00809-0100-4024, Rev BA

September 2005

(Spur)

fieldbus

devices on

segment

Configuration with Radar Master (in

a fieldbus system hooked up to the

device Sensor Bus Port).

Signal

Wiring

5600/PDS/5600_01A.EPS

For stand-alone systems, or as a complement to a PC or a control system,

you can monitor level data using one or two analog outputs depending on the

particular hardware configuration.

As an option, your Rosemount 5600 Radar Level Transmitter can be

equipped with an easy-to-use Rosemount 2210 Display Panel. It offers

basically the same functionality as the Radar Master package. Four sturdy

softkeys give you access to configuration routines, service functions, and

level monitoring.

Measurement Principle

The level of the product in the tank is measured by radar signals transmitted

from the antenna at the tank top. After the radar signal is reflected by the

product surface the echo is picked up by the antenna. As the signal is varying

in frequency the echo has a slightly different frequency compared to the signal

transmitted at that moment. The difference in frequency is proportional to the

distance to the product surface, and can be accurately calculated. This

method is called FMCW (Frequency Modulated Continuous Wave) and is

used in all high performance radar transmitters.

1-4

Page 13

Reference Manual

00809-0100-4024, Rev BA

September 2005

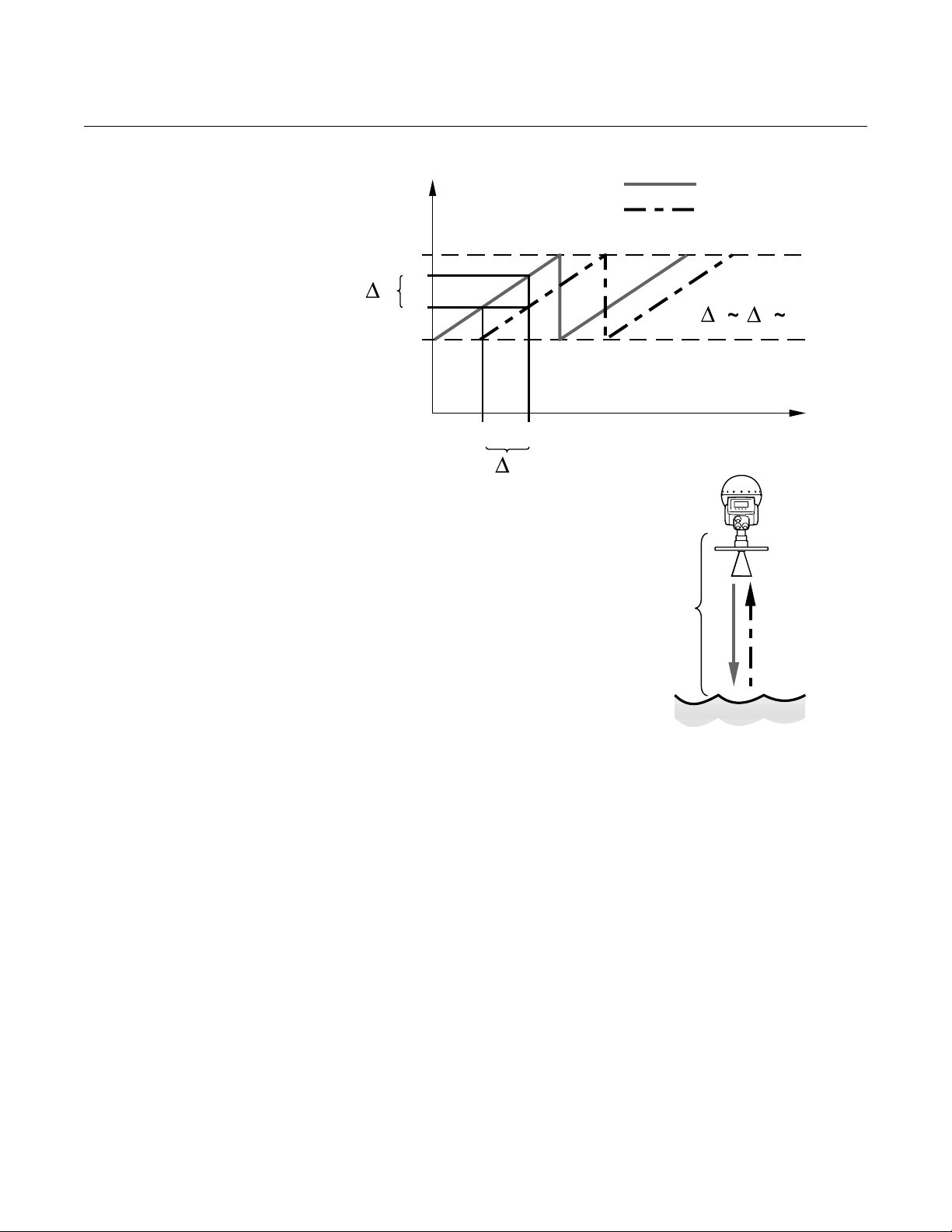

Figure 1-3. Frequency

Modulated Continuous Wave

Frequency (GHz)

f

max

f

1

f

f

0

f

min

t

t

0

1

t

The FMCW method is based on

a radar sweep with continuous

changes in frequency.

Rosemount 5600 Series

Transmitted

Reflected

td

f

Time

d

f

f

1

0

5600_PDS_FMCW.EPS

1-5

Page 14

Rosemount 5600 Series

The 5600 Series Radar Level Transmitter sends a microwave signal with a

continuously varying frequency towards the product surface. When the

reflected signal returns to the antenna, it is mixed with the outgoing signal.

Since the transmitter continuously changes the frequency of the transmitted

signal, there will be a difference in frequency between the transmitted and the

reflected signals.

The transmitter mixes the two signals, resulting in a low frequency signal

which is proportional to the distance to the product surface. This signal can be

measured very accurately allowing fast, reliable, and accurate level

measurements.

The 5600 Series Radar Level Transmitter uses micro frequency to reduce

sensitivity to vapor, foam, and contamination of the antenna, and keeps the

radar beam narrow in order to minimize influence from walls and disturbing

objects.

The 5600 Series Radar Level Transmitter uses Fast Fourier Transformation

(FFT), which is a well established signal processing technique, to obtain a

frequency spectrum of all echoes in the tank. From this frequency spectrum

the surface level is extracted. In combination with the echofixer, FFT allows

measurements in tanks with agitators, mixers and other disturbing objects.

The echofixer provides a technique to adapt measurements to various

situations, by using information from previous measurements.

Reference Manual

00809-0100-4024, Rev BA

September 2005

SPECIFIC FCC

REQUIREMENTS

(USA ONLY)

This device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

The Rosemount 5600 generates and uses radio frequency energy. If it is not

installed and used properly (in strict accordance with the manufacturer´s

instructions) it may violate FCC regulations on radio frequency emission.

Installation on non-metallic tanks, tanks with open manholes,

external-floating-roof tanks without stillpipes etc. are not covered by this

certificate, and require a Part 90 site-license. If you have an installation like

this, contact your local Emerson Process Management representative for help

with the necessary license application.

1-6

Page 15

Reference Manual

00809-0100-4024, Rev BA

Rosemount 5600 Series

September 2005

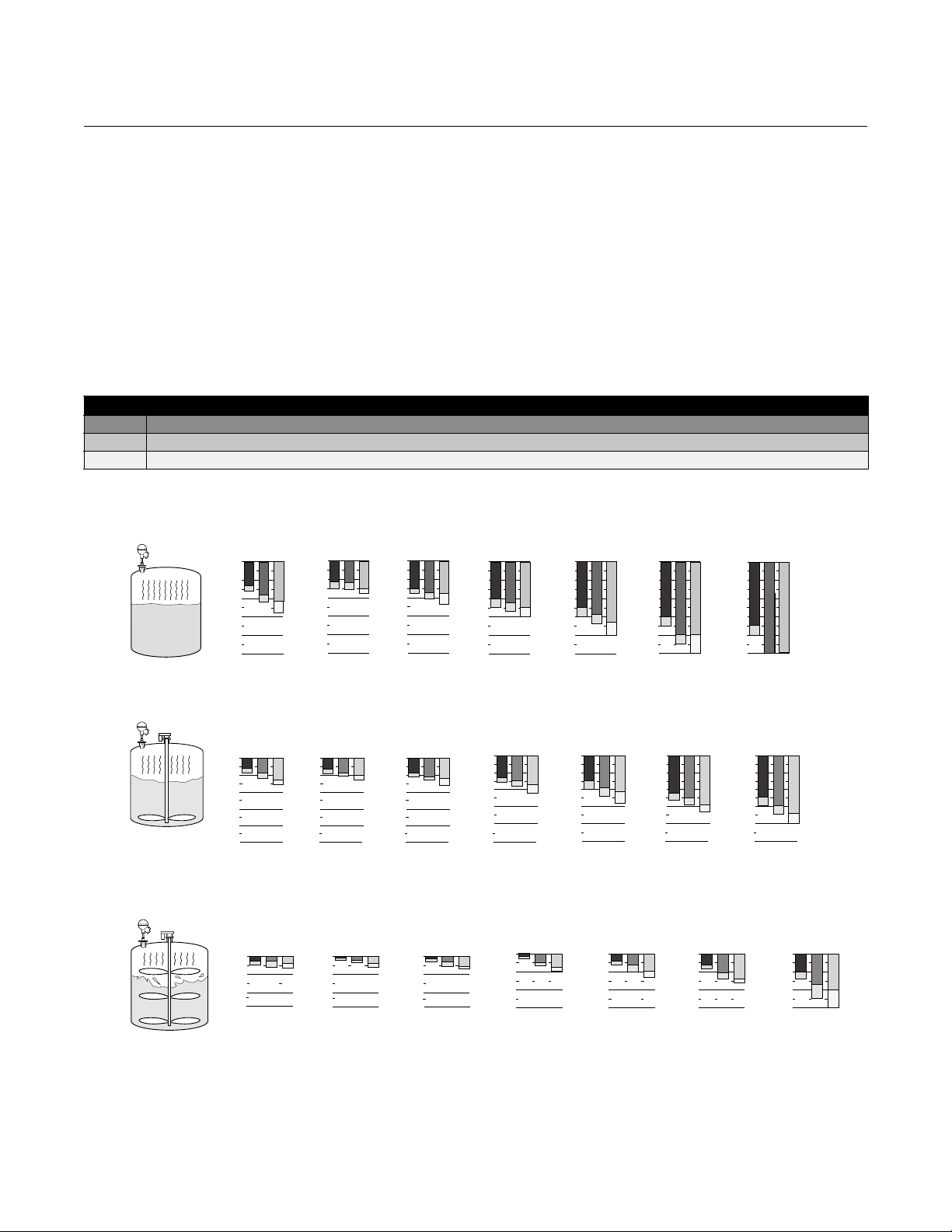

Measuring Range The diagrams below show how the measuring range is influenced by the

antenna type, dielectric constant of the liquid (ε

For optimum performance the maximum measuring distance should be kept

within the range indicated with darker color in the diagrams. Values are valid

for free propagation measurement without still-pipes (bridles).

) and the process conditions.

r

For liquids with ε

that are smaller than 1.9 such as liquefied gases, an 8 inch

r

or bigger diameter antenna is recommended if measurement is done with free

propagation. In this case the measuring range in calm surface tanks is in

typical cases 50 ft. (15 m).

To increase the measuring range further in turbulent tanks, a still-pipe can be

used. For still-pipe mounted 5600 transmitters the typical measuring range is

115-160 ft. (35-50 m) in turbulent tanks with liquids having ε

Table 1-1. Categories of liquids

a Oil, gasoline and other hydrocarbons, petrochemicals (dielectric constant, ε

b Alcohols, concentrated acids, organic solvents, oil/water mixtures and acetone (ε

c Conductive liquids, e.g. water based solutions, dilute acids and alkalis (ε

Figure 1-4. Applications with calm product surface

3” Cone

abc abc abc abc

33 (10)

66 (20)

98 (30)

131 (40)

164 (50)

4” Process

Seal

abc abc

33 (10)

66 (20)

98 (30)

131 (40)

164 (50)

33 (10)

66 (20)

98 (30)

131 (40)

164 (50)

(1)

6” Process

Seal

00

Rod/

4”Cone

33 (10)

66 (20)

98 (30)

131 (40)

164 (50)

> 10)

r

33 (10)

66 (20)

98 (30)

131 (40)

164 (50)

=1.9-4.0)

r

=4.0-10)

r

6” Cone

0000

33 (10)

66 (20)

98 (30)

131 (40)

164 (50)

Figure 1-5. Applications where the product is gently stirred, causing minor turbulence

4” Process

3” Cone

abc abc abc

33 (10)

66 (20)

98 (30)

131 (40)

164 (50) 164 (50) 164 (50) 164 (50)

Seal

33 (10)

66 (20)

98 (30)

131 (40)

33 (10)

66 (20)

98 (30)

131 (40)

6” Process

Seal

000

131 (40)

Rod/

4”Cone

abc abc

33 (10)

66 (20)

98 (30)

6” Cone

00

33 (10)

66 (20)

98 (30)

131 (40)

164 (50) 164 (50)

33 (10)

66 (20)

98 (30)

131 (40)

8” Cone

(1)

8” Cone

abc

0

less than 1.9.

r

Parabolic

abc

0

33 (10)

66 (20)

98 (30)

131 (40)

164 (50)

Parabolic

0

33 (10)

66 (20)

98 (30)

131 (40)

164 (50)

5600-OC_1AA

abc

5600-OC_2AB

Figure 1-6. Applications with turbulent product surface conditions

33 (10)

66 (20)

98 (30)

(1) Measuring range in ft. (m).

1-7

4” Process

3” Cone

abc abc abc

33 (10)

66 (20)

98 (30)

Seal

Note: 4” and 6” Process Seal Cones are not

recommended for turbulent conditions

33 (10)

66 (20)

98 (30)

6” Process

Seal

000

33 (10)

66 (20)

98 (30)

(1)

Rod/

4”Cone

abc abc

6” Cone

00

33 (10)

66 (20)

98 (30)

33 (10)

66 (20)

98 (30)

8” Cone

abc

0

33 (10)

66 (20)

98 (30)

Parabolic

abc

0

5600-OC_3AA

Page 16

Rosemount 5600 Series

Minimum Measuring Distance

The minimum distance the radar can measure depends on the antenna

selected. Typically the level can come as close as 0.79-in. (20 mm) from the

antenna tip, before the software disregards the signal. Being this close to the

antenna may however reduce the measurement accuracy. Table 2-1 on

page 2-3 includes the value Hold Off Distance, which is the default setting for

this minimum distance. It can not be decreased, only increased if needed.

Measuring Close to Tank Bottom

When measuring products with low dielectric constants, i.e. DC range 1.4 -

2.5, some of the radar energy will go thru the product. This could lead to that

the radar will see the Flat Tank Bottom, even though there is a small amount

of product covering the bottom of the tank. This could reduce the accuracy of

the measurement at these lower product levels. This could occur at product

levels of 4-6 inch (100-150 mm) or lower, but depends on the product as well

as the tank bottom type. There are special software settings that could

improve this situation, or alternatively mechanical changes could be

implemented to minimize the influence from the bottom of the tank.

Reference Manual

00809-0100-4024, Rev BA

September 2005

UNPACKING YOUR 5600

TRANSMITTER

Verify that you have received:

• 1 box with the transmitter head. This box also includes a Hook spanner

(used to open the terminal compartments), Reference manual

(00809-0100-4024), Rosemount Radar Master CD-Rom

(0822-0100-4757), and a Quick Installation Guide.

• 1 box with the antenna. This box contains the complete antenna

assembly, including the Waveguide Tube (see page 2-6) which is to be

inserted in the transmitter head foot.

NOTE

If you ordered flanges, the flanges are typically stored at the bottom of the

bigger wooden crate that the transmitter is delivered in. They are held in place

with bolts and nuts.

1-8

Page 17

Reference Manual

00809-0100-4024, Rev BA

Rosemount 5600 Series

September 2005

SERVICE SUPPORT If you have reason to believe that your Rosemount 5600 Radar Level

Transmitter may need to be returned for service, contact the appropriate

representative.

Within USA: Please contact a Level Applications Support Specialist at Rosemount

Customer Central (1-800-999-9307). They will help you determine the best

course of action, and may transfer you to either an Order Administrator or to

the Rosemount North American Response Center (NARC) to arrange for the

return of your transmitter for service or repair.

Outside USA: For Service Support outside the United States, please contact your nearest

Rosemount Representative.

NOTE

Most radar problems encountered in the field are applications-related and can

best be dealt with while the transmitter is installed.

The representative will assist you with any needed information or materials.

The representative will ask for the following information:

• Product model

• Serial numbers

• The last process material to which the product was exposed

The representative will provide:

• A Return Material Authorization (RMA) number

• Instructions and procedures that are necessary to return goods that

were exposed to hazardous substances

Spare Parts

Any substitution of non-recognized spare parts may jeopardize safety. Repair,

e.g. substitution of components etc., may also jeopardize safety and is under

no circumstances allowed.

1-9

Page 18

Rosemount 5600 Series

Reference Manual

00809-0100-4024, Rev BA

September 2005

1-10

Page 19

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

Section 2 Mechanical Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

General Installation Requirements . . . . . . . . . . . . . . . . . . page 2-2

Wave Guide Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-6

Mounting the Rod Antenna, Flanged Version . . . . . . . . . page 2-7

Mounting the Rod Antenna, Threaded Version . . . . . . . . page 2-11

Mounting the Cone Antenna - PTFE sealing . . . . . . . . . . page 2-14

Mounting the Cone Antenna - Quartz sealing . . . . . . . . . page 2-17

Mounting the Process Seal Antenna . . . . . . . . . . . . . . . . page 2-22

Mounting the Parabolic Antenna . . . . . . . . . . . . . . . . . . . . page 2-31

Mounting the Extended Cone Antenna . . . . . . . . . . . . . . . page 2-37

Mounting the Cone Antenna with Flushing Connections page 2-43

SAFETY MESSAGES Procedures and instructions in this manual may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the safety messages listed at the beginning of each section before performing

an operation preceded by this symbol.

Explosions could result in death or serious injury:

Verify that the operating environment of the transmitter is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART-based communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

This product is an electrical apparatus and must be installed in the hazardous area in

accordance with the requirements of the EC Type Examination Certificate.

The installation and maintenance must be carried out in accordance with all appropriate

international, national and local standard codes of practice and site regulations for

intrinsically safe apparatus and in accordance with the instructions contained within this

manual. Access to the circuitry must not be made during operation.

www.rosemount.com

Page 20

Rosemount 5600 Series

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform these procedures.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

The quartz seal is not suitable for use in environments where there is a risk for variations or

other mechanical impacts.

For quartz seal, mechanical shocks may permanently damage the seal. A damaged tank

seal must be replaced. Replacement must be done when the tank is unpressurized.

The customer must always make sure that exposed material of antenna and tank seal is

compatible with the tank content, e.g. the quartz seal is not suitable for use with

Hydrofluoric acid (HF).

A damaged quartz tank seal will typically cause one or many disturbance echoes which will

be seen in a tank spectrum plot during gauge configuration.

Reference Manual

00809-0100-4024, Rev BA

September 2005

INTRODUCTION This section describes the mechanical installation. Start by reading the

General Installation Requirements for your antenna. This includes Nozzle and

Free Space Requirements. The last part of this section includes mounting

instructions for all antenna types, including special requirements for still

pipe/bridle installations and applications.

Tools The following set of tools are needed for installation of a 5600 Series Radar

Level Transmitter:

• Screw driver.

• Adjustable wrench.

• Allen key.

• Circlip plier (snap ring plier).

• Hook spanner (comes delivered with the transmitter).

GENERAL

INSTALLATION

REQUIREMENTS

Position the transmitter in a way that allows the microwaves to propagate

without disturbance from the tank wall. In order to achieve optimum

performance you should consider the following recommendations:

• Try to avoid obstacles in the radar beam.

• Mount the transmitter away from pipe inlets which cause turbulent

conditions.

• Choose as large antenna as possible to ensure maximum antenna

gain.

• For best measurement performance it is recommended that the

antenna tip ends outside the nozzle, see Figure 2-2.

Customer Supplied

Flanges

2-2

The simple design of cone and rod antennas tank connection allows the use

of customer supplied flanges. If a hole is drilled in a standard blind flange the

pressure performance may be reduced. In such a case the flange should be

marked with new rating for Maximum Allowed Working Pressure (MAWP).

Page 21

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

Nozzle Requirements In order to allow the microwaves to propagate undisturbed, the nozzle

dimensions should be kept within the specified limits for the different

antennas.

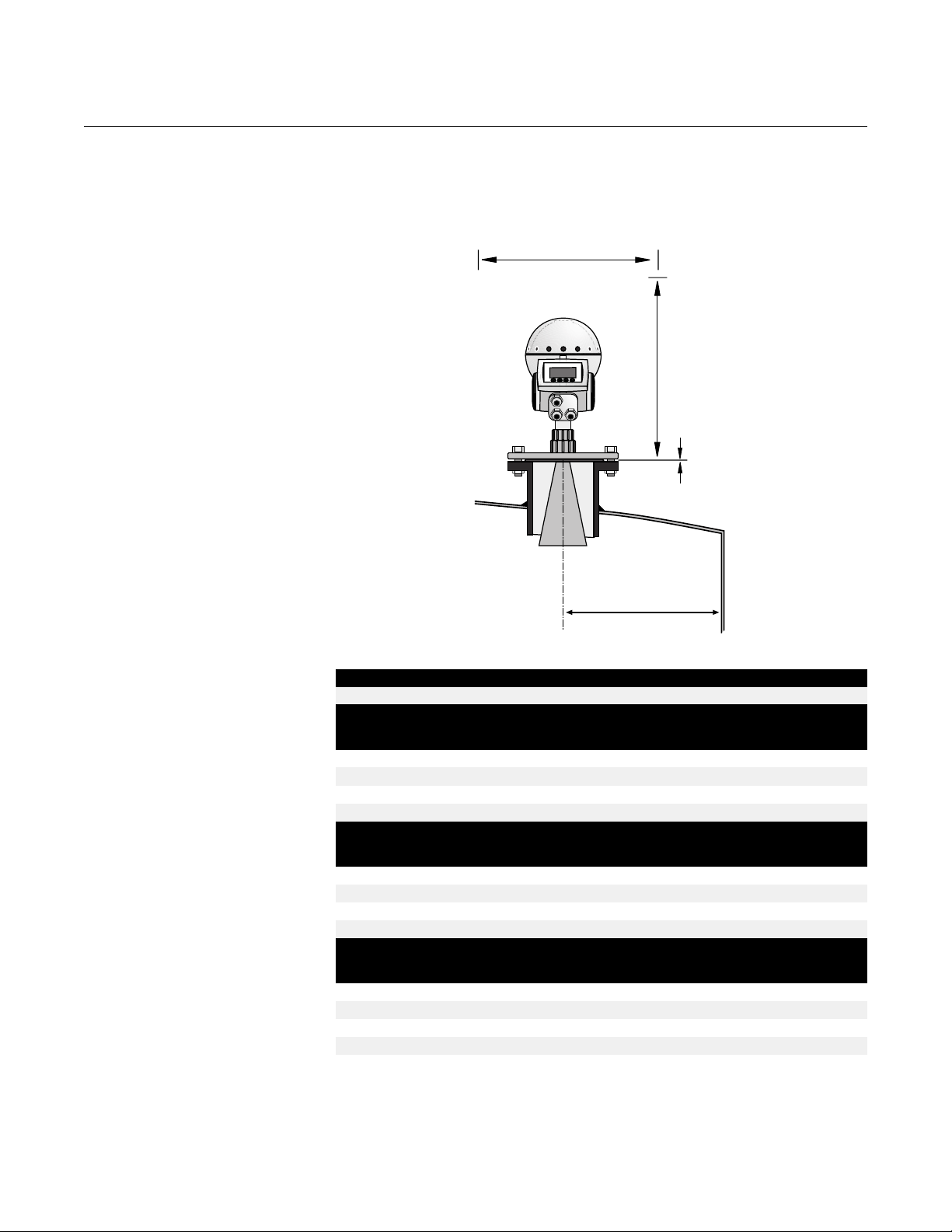

Figure 2-1. Nozzle

Requirements, see Table 2-1

Hold Off

Distance

Ø

min

L

maximum

SOCKET_REQUIREMENT_02

Table 2-1. Nozzle Requirements in inches (millimeters)

Antenna L

Rod100 3.9 (100) or less 1.6 (43) 3.9 (100) 23.6 (600)

Rod250 9.8 (250) or less 1.6 (43) 9.8 (250) 30.7 (780)

Cone 3 in. 3.7 (95) or less 2.9 (75) 9.6 (245) 4.7 (120)

Cone 4 in. 5.9 (150) or less 3.8 (98) 11.8 (300) 6.7 (170)

Cone 6 in. 10.2 (260) or less 5.7 (146) 16.1 (410) 11.0 (280)

Cone 8 in. 14.6 (370) or less 7.6 (194) 20.6 (525) 15.8 (400)

Parabolic 6.3 (160) or less 19.7 (500) 23.6 (600) 7.9 (200)

Process Seal 4 in. 11.8 (300) or less 3.9 (100) 11.8 (300) 7.9 (200)

Process Seal 6 in. 11.8 (300) or less 5.9 (150) 11.8 (300) 7.9 (200)

Extended Cone 3 in. 19.5 (495) or less 3.0 (75) 19.5 (495) 20.5 (520)

Extended Cone 4 in. 19.5 (495) or less 3.9 (98) 19.5 (495) 20.5 (520)

Extended Cone 6 in. 19.5 (495) or less 5.8 (146) 19.5 (495) 20.5 (520)

Flushing Cone 4 in. 5.9 (150) or less 3.9 (98) 11.8 (300) 6.7 (170)

Flushing Cone 6 in. 10.2 (260) or less 5.8 (146) 16.1 (410) 11.0 (280)

Flushing Cone 8 in. 14.6 (370) or less 7.6 (194) 20.7 (525) 15.8 (400)

recommended

Diam

min

L

maximum

Hold Off Distance

NOTE

For Parabolic Antennas mounted in solid applications, minimize the L

Distance to allow the Parabolic Antenna to reach into the tank. See

Measuring Solids with a Rosemount 5600 Non-contacting Radar (part

number 00830-0800-4024).

Figure 2-2. Antenna Tip Outside

Nozzle to get the Best

Measurement Performance

Parabolic Antenna

Cone Antenna

SOCKET_REQ

2-3

Page 22

Rosemount 5600 Series

Free Space

Requirements

Figure 2-3. Free Space

Requirements, see Table 2-2

Reference Manual

00809-0100-4024, Rev BA

September 2005

A

B

C

D

Table 2-2. Free Space Requirements

A. Service Space Width Distance in. (mm)

All antennas 22 (550)

B. Service Space Height

Antenna Distance in. (mm)

Rod 27 (700)

Cone, Extended Cone, Flushing Cone 25 (650)

Process Seal 31 (800)

Parabolic 27 (700)

C. Inclination

Antenna Maximum Angle

Rod 3°

Cone 1°

Process Seal 3°

Parabolic 3°

D. Minimum distance to tank wall

Antenna Distance in. (mm)

Rod 24 (600)

Cone 24 (600)

Process Seal 24 (600)

Parabolic 24 (600)

(1) Mounting closer to the tank wall may be allowed if reduced accuracy is accepted.

(1)

FREESPACE_V2

2-4

Page 23

Reference Manual

00809-0100-4024, Rev BA

September 2005

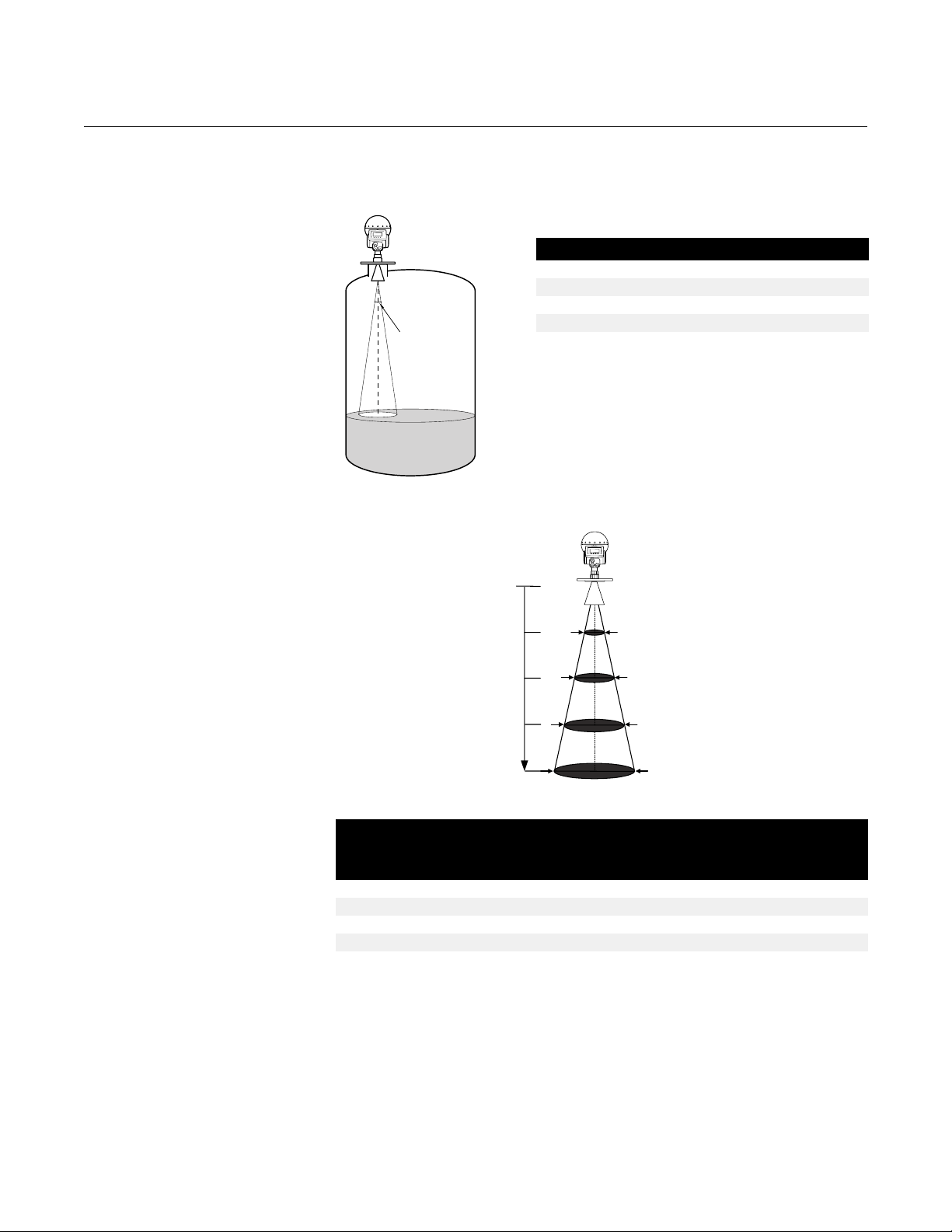

Beam Width

Rosemount 5600 Series

Figure 2-4. Beam width angle,

see Table 2-3

Figure 2-5. Beam width

distance, see Table 2-4

Table 2-3. Beam width angle

Antenna Beam Width

Cone 3 in. 25°

Rod/Cone 4 in./ Process Seal 4 in. 21°

Cone 6 in./ Process Seal 6 in. 18°

Beam

Angle

BILD_24

Cone 8 in. 15°

Parabolic 10°

5m

Special Antennas and

Space Requirements

Reference

10m

Distance

15m

20m

BEAMAREA

Table 2-4. Beam width distance

Diameter of radiated area at different

distances from flange, ft. (m)

Antenna

Cone 3 in. 7.2 (2.2) 14 (4.4) 22 (6.7) 29 (8.9)

Rod/Cone 4 in./ Process Seal 4 in. 6.2 (1.9) 12 (3.7) 18 (5.6) 24 (7.4)

Cone 6 in./ Process Seal 6 in. 5.2 (1.6) 10 (3.1) 15 (4.7) 21 (6.3)

Cone 8 in. 3.3 (1.0) 7.9 (2.4) 13 (3.9) 17 (5.2)

Parabolic 3.0 (0.9) 5.6 (1.7) 8.5 (2.6) 11 (3.5)

16 ft (5 m) 33 ft (10 m) 49 ft (15 m) 66 ft (20 m)

Pipe Installation

See page 2-40 and page 2-25.

Extended Cone Installation

See page 2-40 and page 2-37.

2-5

Page 24

Rosemount 5600 Series

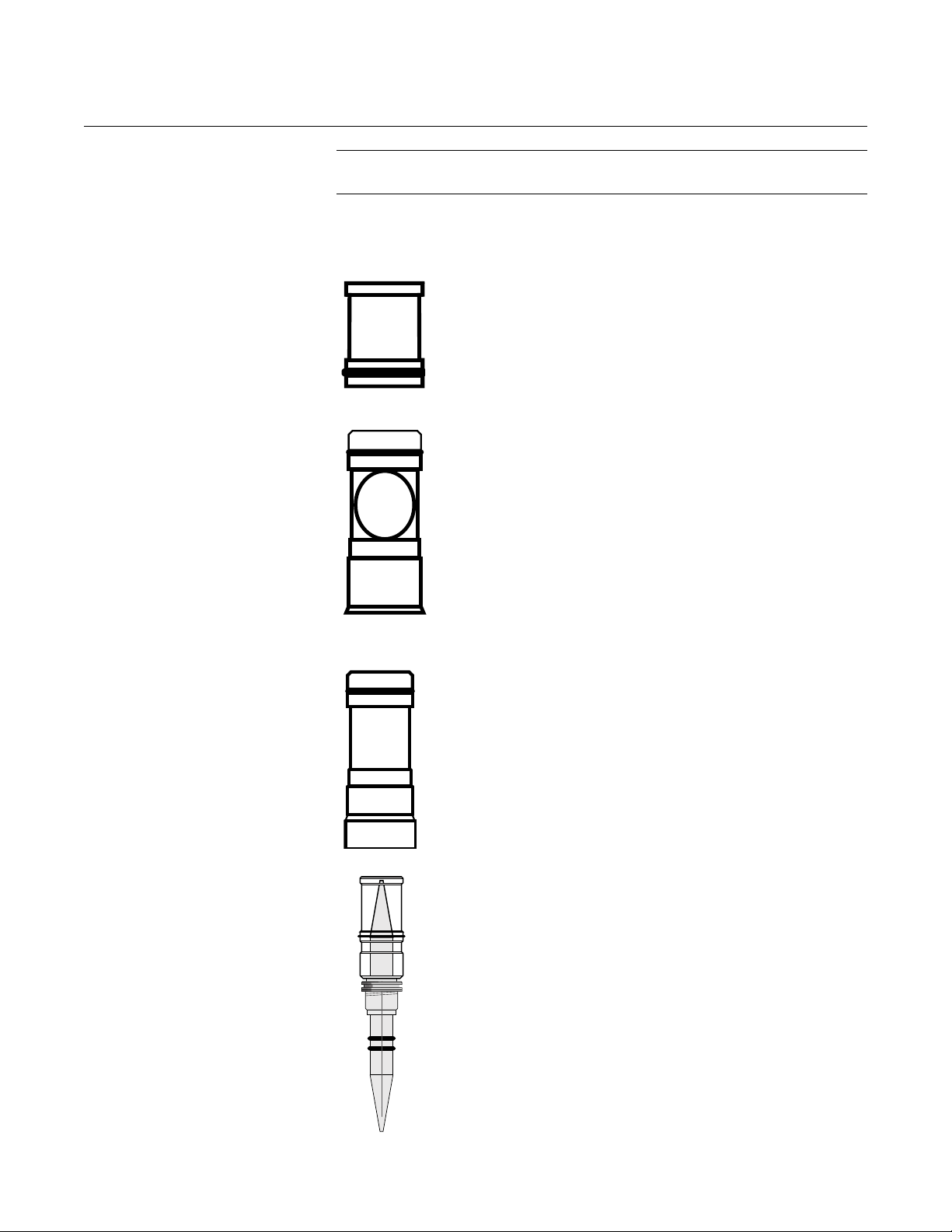

WAVE GUIDE TUBES NOTE

The Waveguide Tubes are parts of the antenna kits.

Reference Manual

00809-0100-4024, Rev BA

September 2005

Cone and Rod Antenna

• For model codes 1xx, 2xx, 7xx, and 9xx

(with PTFE Seal for Cone)

• Distinguishing features:

a. Length: 1.57-in. (40 mm)

Process Seal

• For model codes 34S and 36S.

• Distinguishing features:

a. Length: 2.93-in. (74.5 mm)

b. O-ring on the inside

Parabolic

• For model codes 45S and 46S

• Distinguishing features:

a. Length: 2.93-in. (74.5 mm)

b. No o-ring on the inside

Cone Antenna with Quartz Seal

• Model code option Q (with Quartz Seal)

• Distinguishing features:

a. Complete assembly

b. No loose waveguide tube

• Not available as spare part. If spare part is

required, order complete antenna.

2-6

Page 25

Reference Manual

00809-0100-4024, Rev BA

September 2005

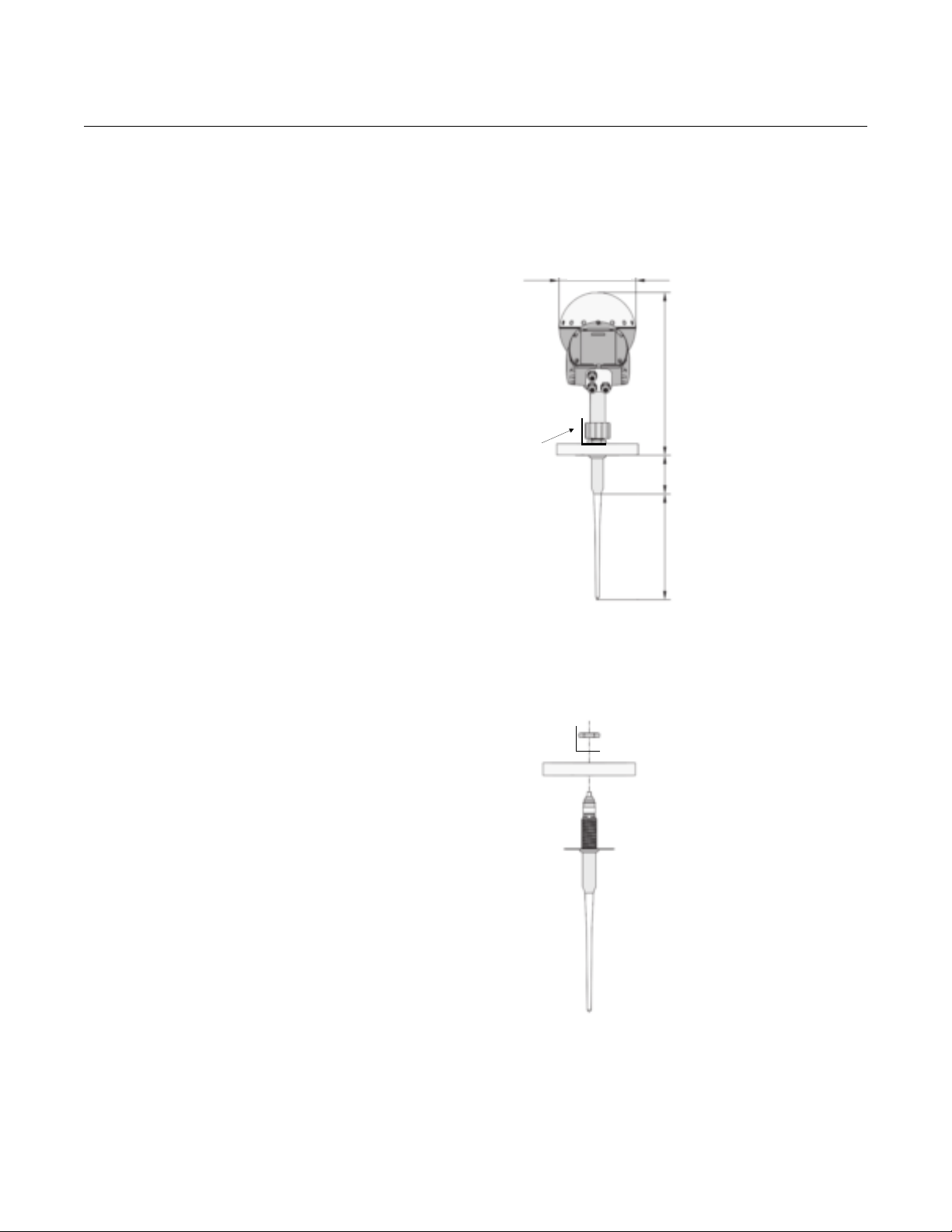

MOUNTING THE ROD

ANTENNA, FLANGED

VERSION

Rosemount 5600 Series

Figure 2-6. Rod Antenna

Dimensions, Flanged Version

Figure 2-7. Mount the flange

7.87 (200)

15.75 (400)

Antenna Label

Plate

NOTE

Dimensions are in

inches (millimeters)

Inactive length 3.94 (100) or

Inactive length 9.84 (250)

11.81 (3 00)

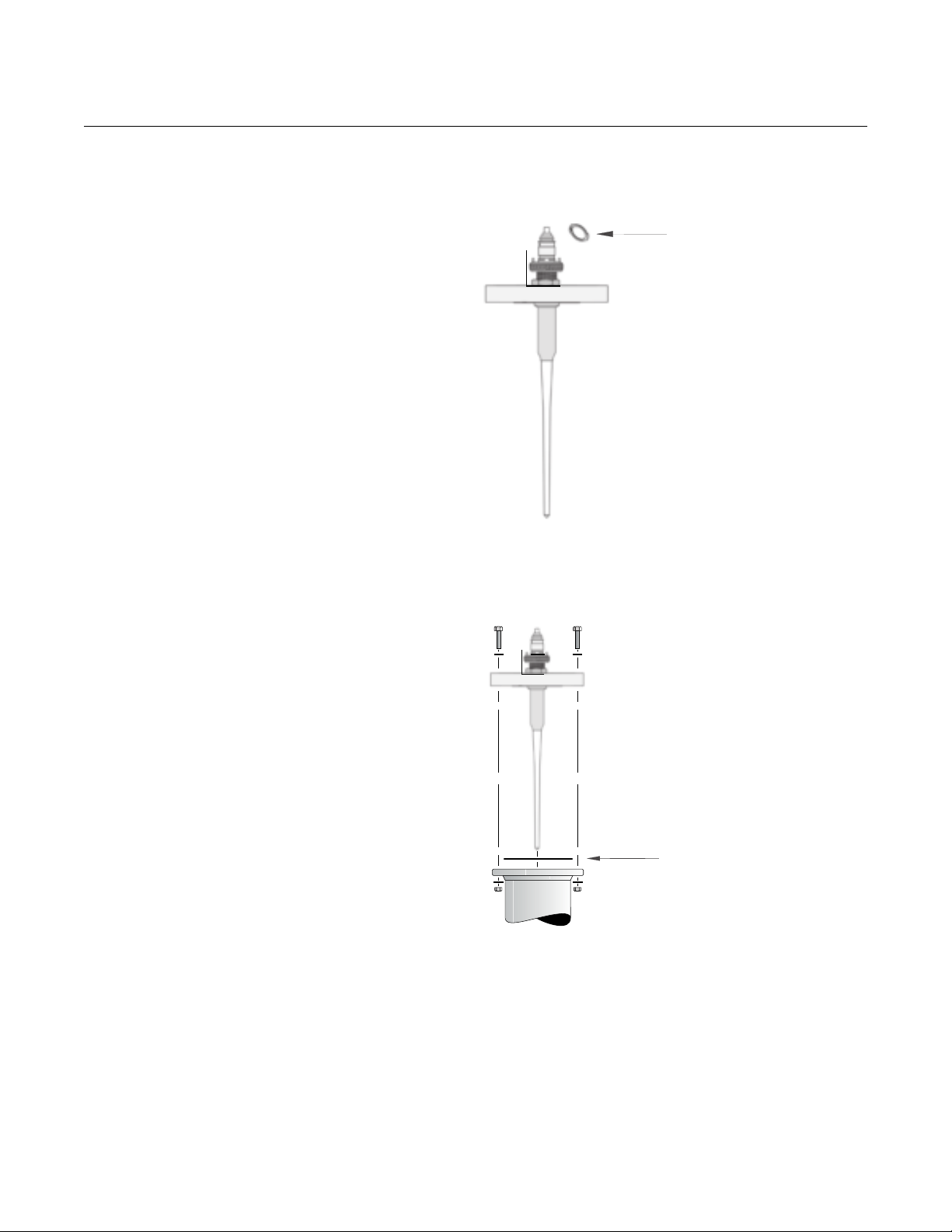

1. Mount the flange on top of the rod plate. Make sure the bottom side of

the flange is flat and all parts are clean and dry.

ROD_MOUNT_DIMENSIONS

ROD_MOUNT_FLANGE

2-7

Page 26

Rosemount 5600 Series

2. Secure the flange and label plate with the locking nut. Make sure the nut

fits tightly to the flange.

Figure 2-8. Secure the flange

with the locking nut

Reference Manual

00809-0100-4024, Rev BA

September 2005

Locking Nut

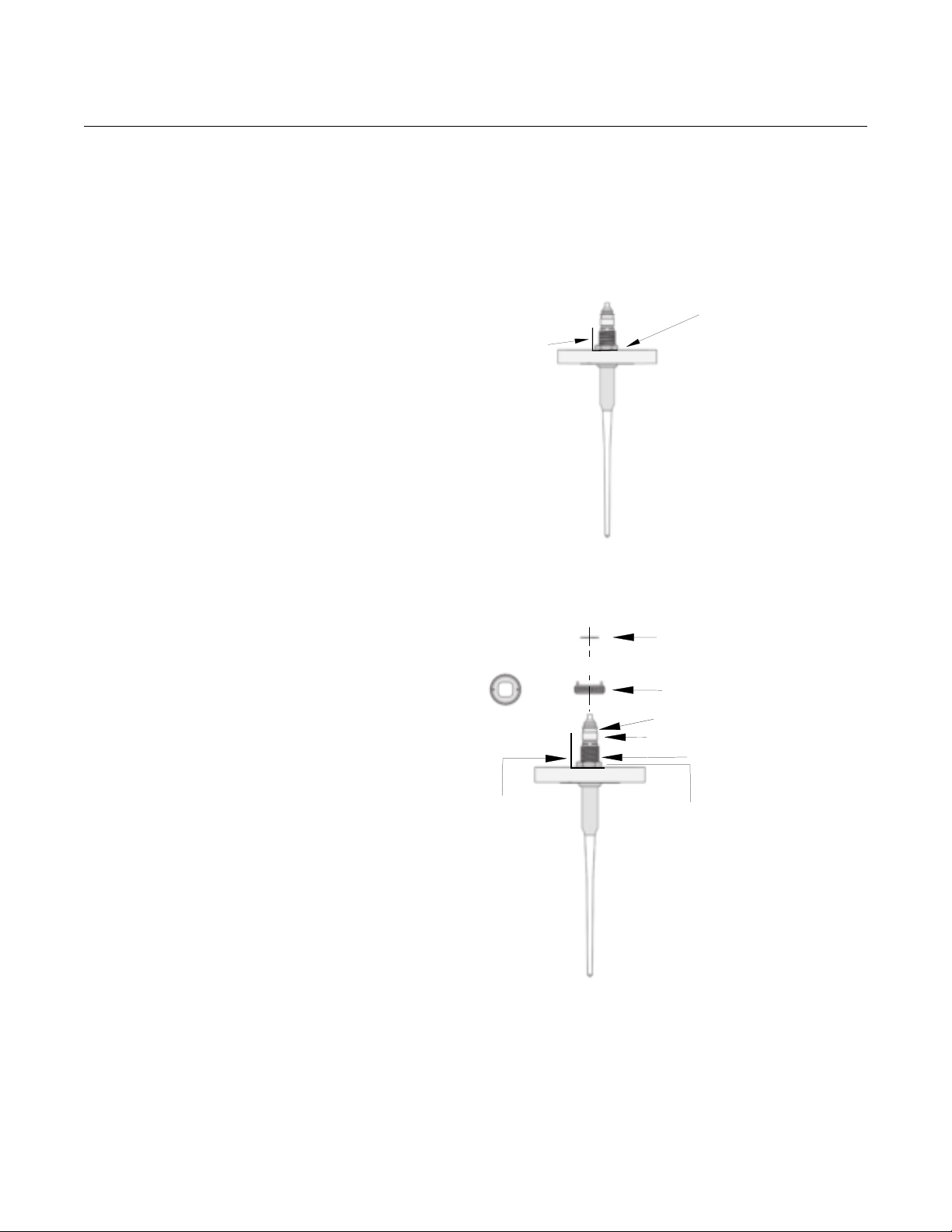

Figure 2-9. Mounting the

adapter

Antenna Label

Plate

ROD_MOUNT_NUT

3. Mount the adapter on top of the sleeve.

Locking Ring

Adapter

O-ring

Wave guide

Sleeve

2-8

Antenna

Label Plate

Nut

ROD_MOUNT_APDATER

Page 27

Reference Manual

00809-0100-4024, Rev BA

September 2005

Figure 2-10. Use the locking ring

to secure the adapter

Rosemount 5600 Series

4. Secure the adapter with the locking ring.

Locking Ring

Figure 2-11. Mount the flange

and rod antenna on the nozzle

ROD_MOUNT_RING

5. Carefully fit the flange and the rod antenna on the tank nozzle with an

appropriate gasket in between. Tighten with screws and nuts.

Gasket

ROD_MOUNT.EPS

2-9

Page 28

Rosemount 5600 Series

6. Insert the wave guide tube into the upper wave guide. Make sure the

o-ring at the lower end of the wave guide tube is in place.

Figure 2-12. Mount the

transmitter head

Reference Manual

00809-0100-4024, Rev BA

September 2005

Upper Wave Guide

WAVEGUIDE_TUBE.EPS

Wave Guide Tube

O-ring

Figure 2-13. Completed

mechanical installation

7. Place the protection sleeve on the flange. Mount the transmitter head

and tighten the nut. Check that the guide pins on the adapter enter the

corresponding grooves on the upper wave guide.

Protection

Sleeve

TH40HEAD_NOZZLE.EPS

8. Proceed with the electrical installation.

2-10

Page 29

Reference Manual

00809-0100-4024, Rev BA

September 2005

MOUNTING THE ROD

ANTENNA, THREADED

VERSION

Figure 2-14. Rod Antenna

Dimensions, Threaded Version

Rosemount 5600 Series

7.87 (200)

15.75 (400)

Inactive length 3.94 (100) or

Inactive length 9.84 (250)

NOTE

Dimensions are in

inches (millimeters)

11.81 (300)

1. Carefully fit the rod antenna into the threaded nozzle and screw it in

place.

NOTE

For adapters with NPT threads, pressure-tight joints may require a sealant.

5600/9150074-921AA.EPS

2-11

Page 30

Rosemount 5600 Series

Figure 2-15. Mount the rod

antenna

Reference Manual

00809-0100-4024, Rev BA

September 2005

Antenna Label Plate

Gasket for BSP

(G) threads

Figure 2-16. Mount the

transmitter head

ROD_MOUNT_BSP.EPS

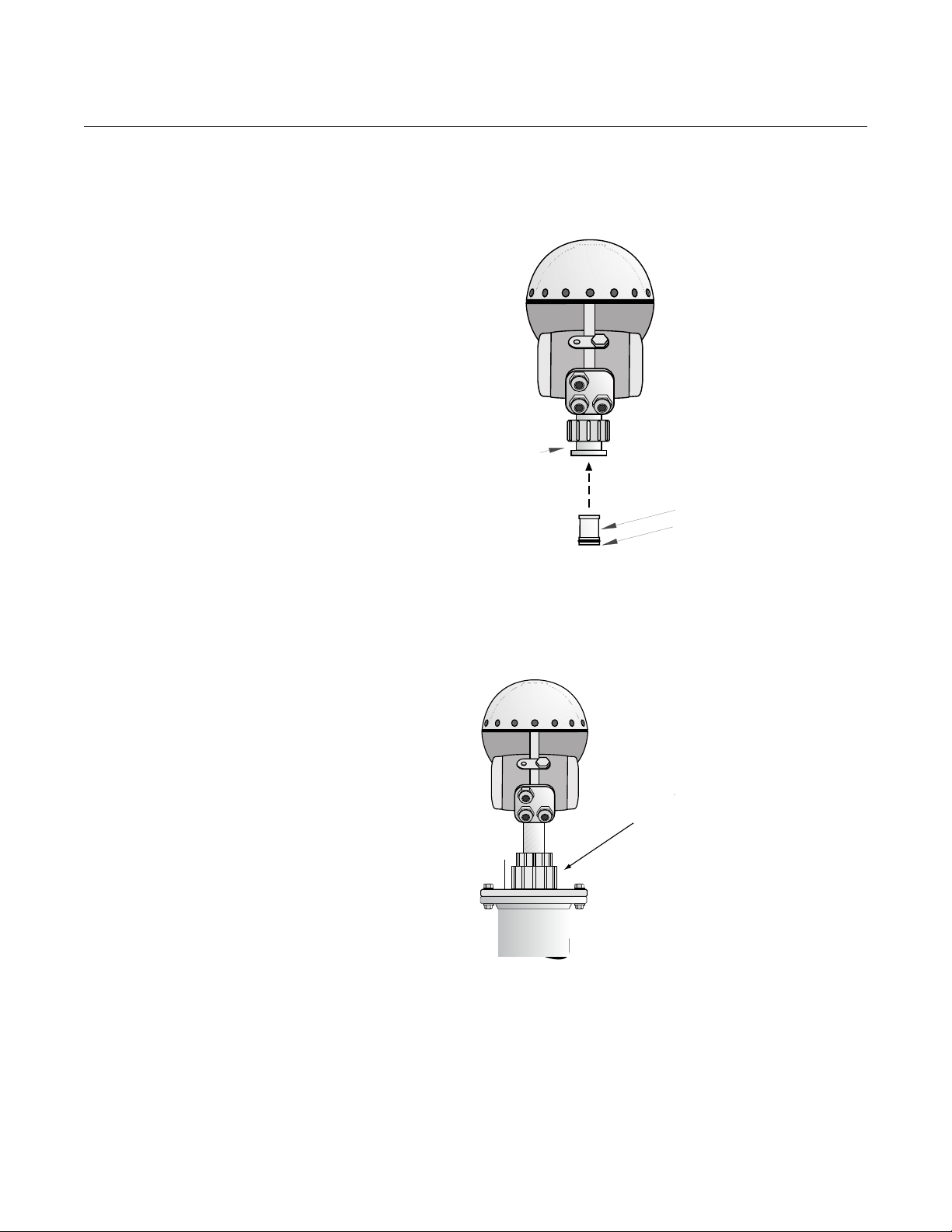

2. Insert the wave guide tube into the upper wave guide. Make sure the

o-ring at the lower end of the wave guide tube is in place.

Upper Wave Guide

Wave Guide Tube

O-ring

WAVEGUIDE_TUBE.EPS

2-12

Page 31

Reference Manual

00809-0100-4024, Rev BA

September 2005

Figure 2-17. Completed

mechanical installation

Rosemount 5600 Series

3. Place the protection sleeve on the flange. Mount the transmitter head

and tighten the nut. Check that the guide pins on the adapter enter the

corresponding grooves on the upper wave guide.

Protection

Sleeve

4. Proceed with the electrical installation.

TH40HEAD_NOZZLE_BSP.EPS

2-13

Page 32

Rosemount 5600 Series

MOUNTING THE CONE

ANTENNA - PTFE

SEALING

Reference Manual

00809-0100-4024, Rev BA

September 2005

Figure 2-18. Cone Antenna

Dimensions

7.87 (200)

15.75 (400)

Junction Box

3.74 (95) (3 in. Cone)

5.91 (150) (4 in. Cone)

10.24 (260) (6 in. Cone)

14.57 (370) (8 in. Cone)

NOTE

Dimensions are in

inches (millimeters)

2.76 (70)(3 in. Cone)

3.66 (93) (4 in. Cone)

5.55 (141) (6 in. Cone)

7.44 (189) (8 in. Cone)

1. Remove locking ring and adapter from antenna.

2. Mount the flange on top of the cone plate. Make sure that the bottom

side of the flange is flat and all parts are clean and dry.

Figure 2-19. Mount the flange

2-14

Antenna Label Plate

FLANGE_MOUNT_PTFE_50%

Page 33

Reference Manual

00809-0100-4024, Rev BA

September 2005

Figure 2-20. Secure the flange

with the locking nut

Rosemount 5600 Series

3. Secure the flange with the locking nut.

Make sure that the nut fits tightly to the flange.

CONE_FLANGE_ASSY_PTFE_50%

4. Mount the adapter on top of the sleeve.

Figure 2-21. Mounting the

adapter

Figure 2-22. Use the locking ring

to secure the adapter

Locking Ring

Top view of

adapter

5. Secure the adapter with the locking ring.

Locking Ring

Adapter

O-ring

Wave guide unit

Sleeve

ADAPTER_TOPVIEW,

ADAPTER_MOUNT_PTFE

ADAPTER_LOCKRING_PTFE

2-15

Page 34

Rosemount 5600 Series

6. Carefully fit the flange and the cone antenna on the tank nozzle.

7. Tighten with screws and nuts.

Figure 2-23. Mount the flange

and cone antenna on the nozzle

Reference Manual

00809-0100-4024, Rev BA

September 2005

Gasket

Figure 2-24. Mount the

transmitter head

CONETANK_PTFE.EPS

8. Insert the wave guide tube into the upper wave guide.

Make sure the gasket at the lower end of the wave guide tube is in place.

Upper Wave Guide

WAVEGUIDE_TUBE

Wave guide tube

O-ring

2-16

Page 35

Reference Manual

00809-0100-4024, Rev BA

September 2005

Figure 2-25. Completed

mechanical installation

Rosemount 5600 Series

9. Place the protection sleeve on the flange.

Mount the transmitter head and tighten the nut. Check that the guide pins

on the adapter enter the corresponding grooves on the upper wave

guide.

Protection

Sleeve

MOUNTING THE CONE

ANTENNA - QUARTZ

SEALING

Figure 2-26. Cone Antenna

Dimensions

TH40HEAD_NOZZLE1

10. Proceed with the electrical installation.

7.87 (200)

15.75 (400)

Junction Box

3.74 (95) (3 in. Cone)

5.91 (150) (4 in. Cone)

10.24 (260) (6 in. Cone)

14.57 (370) (8 in. Cone)

NOTE

Dimensions are in

inches (millimeters)

2.76 (70)(3 in. Cone)

3.66 (93) (4 in. Cone)

5.55 (141) (6 in. Cone)

7.44 (189) (8 in. Cone)

2-17

Page 36

Rosemount 5600 Series

Antennas including tank seal of quartz material are suitable for high pressure

applications.

NOTE

The quartz seal shall be protected against mechanical shocks or impacts. It is

important to handle the antenna carefully in order to avoid any mechanical

stresses such as bending or pressing the sealing.

1. Remove locking ring and adapter from antenna.

2. Mount the range on top of the cone plate. Make sure the bottom side of

the flange is flat and all parts are clean and dry.

Figure 2-27. Mount the flange

Reference Manual

00809-0100-4024, Rev BA

September 2005

Flange

Note:

No gasket

on top of

this plate

FLANGE_MOUNT_QUARTZ

2-18

Page 37

Reference Manual

00809-0100-4024, Rev BA

September 2005

Figure 2-28. Secure the flange

with the locking nut

Rosemount 5600 Series

3. Secure the flange and label plate with the locking nut using a spanner

with key width 1.6-in. (41 mm). Make sure the locking nut fits tightly to the

flange without any visible gap between the plate and the flange.

Label Plate

Locking nut

CONE_FLANGE_ASSY_QUARTZ

4. Mount the adapter on top of the sleeve.

Figure 2-29. Mounting the

adapter

Figure 2-30. Use the locking ring

to secure the adapter

Locking Ring

Top view of

adapter

5. Secure the adapter with the locking ring.

Locking Ring

Adapter

O-ring

Sleeve

ADAPTER_TOPVIEW,

ADAPTER_MOUNT_QUARTZ

ADAPTER_LOCKRING_QUARTZ

2-19

Page 38

Rosemount 5600 Series

6. Fit the flange with the cone antenna on the horizontal tank flange. If the

tank flange is not horizontal, the performance of the gauge may be

negatively impacted.

7. Tighten with screws and nuts.

Figure 2-31. Mount the flange

and cone antenna on the nozzle

Reference Manual

00809-0100-4024, Rev BA

September 2005

CONETANK_QUARTZ.EPS

2-20

Page 39

Reference Manual

00809-0100-4024, Rev BA

September 2005

Figure 2-32. Completed

mechanical installation

Rosemount 5600 Series

8. Before mounting the transmitter head, visually verify that the quartz tank

seal is undamaged and free from moisture and dirt.

9. Place the protection sleeve on the flange.

10. Mount the transmitter head on the adapter in one of the four possible

positions.

Figure 2-33. Completed

Installation

Quartz tank seal shall not be

removed when tank is

pressurized.

11. Check the guide pins on the adapter enter the corresponding grooves on

the upper wave guide. Maximum allowed spacing is 0.2-in. (5 mm).

Tighten the nut manually or with a wrench using approximately 20-50 Nm

torque until it stops on the adapter. It is normal that the transmitter head

can be rotated a fraction corresponding to the play between the guide

pins and the grooves. This will not have any negative impact on the

performance of the gauge.

12. Proceed with the electrical installation.

2-21

Page 40

Rosemount 5600 Series

MOUNTING THE

PROCESS SEAL

ANTENNA

Figure 2-34. Process Seal

Antenna Dimensions

Reference Manual

00809-0100-4024, Rev BA

September 2005

7.87 (200)

21.65 (550) 4 inch process seal

25.59 (650) 6 inch process seal

Note

Dimensions are in

inches (millimeters)

5600/PDS/MS_4.EPS

6.30 (160) 4 inch process seal

8.58 (218) 6 inch process seal

2-22

Page 41

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

Preparations:

It is important that the tank flange surface is flat. The maximum deviation must

be within the following specifications as illustrated:

NOZZLE

d

Flange Surface

Tolerance: d< ±0.05 mm

NOZZLE_FLATNESS_CONCAVE_V2

Internal Electronics

Display Interface

(Part of TA43)

XA40

d

Passive 4-20mA

XA40 + IS40

Active 4-20mA

Active

Passive

TM40

Flange Surface

Tolerance: d< ±0.05 mm

TRL/2 MODBUS

AA40

PROFIBUS DP

Power Supply

Unit

(PS43)

TA43

4-20 mA

TA43

FF43

via TA43

FOUNDATION

HART

4-20 mA

HART

X7

X7

X6

X6

X3, X5, or X6

X3, X5, or X6

X3

X3

X3 or X5

FIELDBUS

X4

X4

X2

7

6

5

4

X6

3

2

X5

1

Junction Box

EEx i

Junction Box

EEx e

1

X3

2

3

4

X1

24-240 V

DC/AC 0-60 Hz

10 W

15 VA

Level

6.767

m

NOZZLE_FLATNESS_COVEX_V2

To mount the antenna do the following:

1. Place the teflon gasket supplied by Emerson Process Management on

top of the nozzle and mount the antenna.

NOTE

The teflon gaskets are optimized for use with microwave emitting equipment.

No other gaskets than Rosemount original may be used for Process Seal

antennas.

2-23

Page 42

Rosemount 5600 Series

2. Put the loose flange on top of the antenna.

Figure 2-35. Put the flange on

top of the antenna

Reference Manual

00809-0100-4024, Rev BA

September 2005

Figure 2-36. Tighten the flange

FALNGE_MOUNT_PS

3. Tighten the flange to the antenna by using screws and nuts. Use

lubricating grease to minimize friction when the screws are tightened.

2-24

ANTENNA_FLANGE_SCREW_ASSY

NOTE

Tighten the screws carefully to the recommended torque according to

Table 2-5. Tighten opposite screws in pair.

Page 43

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

4. Insert the wave guide tube into the upper wave guide.

(See Figure 2-24 on page 2-16.)

5. Mount the transmitter head onto the adapter.

6. Tighten the nut and make sure that the transmitter head fits tightly to the

antenna.

Torque

Tighten the flange screws to the following torque:

Table 2-5. Recommended Torque (Nm)

PTFE

DIN Flange PN16 PN40

DN100 11 15

DN150 15

ANSI Flange 150 Psi 300 Psi

4 in. 11 15

6 in. 15 10

MOUNTING THE CONE

ANTENNA IN A

STILL-PIPE/BRIDLE

Figure 2-37. Example of a Bridle

mount (left) and a Still-pipe

mount(right)

NOTE

See Technical Note “Using Radar Transmitters in Stilling Wells and By-pass

Cages” (part number 00830-2100-4024)

Installation Requirements for Cone Antenna in a Still-pipe/Bridle

The 5600 Series Radar Level Transmitter is suitable for measurements in still

pipes and bridles. The high signal processing capacity allows measurements

even when there are several pipe inlets, provided that the mechanical

installation is done per the guidelines in this manual or related technical note.

20,03

20,03B

Still-pipe or bridle pipe mounting is recommended for LPG tanks and other

applications where surface conditions may be extremely turbulent. By using a

pipe, foam and turbulence is reduced. Accuracy may, however, be reduced in

bridle and still pipe applications.

2-25

Page 44

Reference Manual

00809-0100-4024, Rev BA

Rosemount 5600 Series

September 2005

For Still Pipes The 3, 4 and 6 in. cone antennas are designed to fit into new or existing still

pipes with the corresponding pipe size. A gap between the antenna opening

and the pipe of up to 0.4 in. (10 mm) may occur. In most applications this gap

has only a limited effect on the measuring performance.

It is always recommended to have the gap as small as possible, since larger

gaps cause larger inaccuracies.

Figure 2-38. 3, 4, and 6 in. Cone

Antenna in still pipe - gap

between pipe and antenna

max 0.4 in.

(10 mm)

20,07_MAX10MM_01

2-26

Page 45

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

For Bridle Pipes For Bridle applications the basic guidelines are similar to the guidelines

written above for Still Pipes, i.e. that the 3, 4 and 6" Cone antennas will fit the

corresponding pipe sizes, and you should try to get the gap as small as

possible. If possible, and if the application allows for it, another general

guideline is to keep the pipe inlet as small as possible.

In more difficult bridle applications with inlet pipes larger than 2 in. or in pipes

with severe contamination can be expected, the antenna size should be

customized to better fit the pipe. In this case do the following:

a. Measure the inner diameter of the pipe.

b. Cut the cone antenna so that it fits inside the Bridle Pipe.

c. Make sure that the gap between the pipe and the antenna is smaller

than 0.04 inches (1 mm).

Please contact your local Emerson Process Management representative for

details about a factory-cut antenna.

Figure 2-39. Bridle Pipe

installation guidelines

maximum

0.04 in. (1 mm)

Recommended distance

>4-in. (100 mm)

Inlet pipe

At least

20-in. (500 mm)

5600_07_AB.EPS

Recommended distance

>6-in. (150 mm)

2-27

Page 46

Rosemount 5600 Series

MEASUREMENT IN LARGE PIPES

When using standard cones in larger (8-in. or larger) still pipe installations,

there is a risk for measurement problems. When standard linear shaped

cones are used in pipes, more than one microwave mode is generated and

each mode has a unique propagation speed. This is a radar physics problem

that is common to all radar gauges when linear shaped cones are used.

In larger pipes, the amplitude of echoes generated by the “unwanted” modes

may become rather high, and may result in loss of the surface echo at certain

locations in the pipe. In addition, there may be measurement errors

associated with two closely spaced echoes where the gauge will not lock on a

single target.

The relative amplitude of the unwanted modes in a straight cone is

proportional to the product of the cone angle and the diameter in the cone

opening. Therefore measurement error increases as pipe diameter increases

since the cone angle is the same for all the cones.

Reference Manual

00809-0100-4024, Rev BA

September 2005

Due to this issue, Emerson Process Management does not recommend

using

the 5600 Series 8-in. cone antennas for larger pipe measurements. Instead, a

special pipe antenna should be used.

Table 2-6. Recommendations

Pipe Size

3-in. (76 mm) 4-in. (102 mm) 6-in. (152 mm)

Maximum measuring range 65 ft (20 m) 65 ft (20 m) 65 ft (20 m)

Maximum hole size ( ) 0.24 (6 mm) 0.28 (7 mm) 0.39 (10 mm)

Maximum number of holes per meter 2 2 2

Deflection plate required Yes Ye s Yes

∅

2-28

Page 47

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

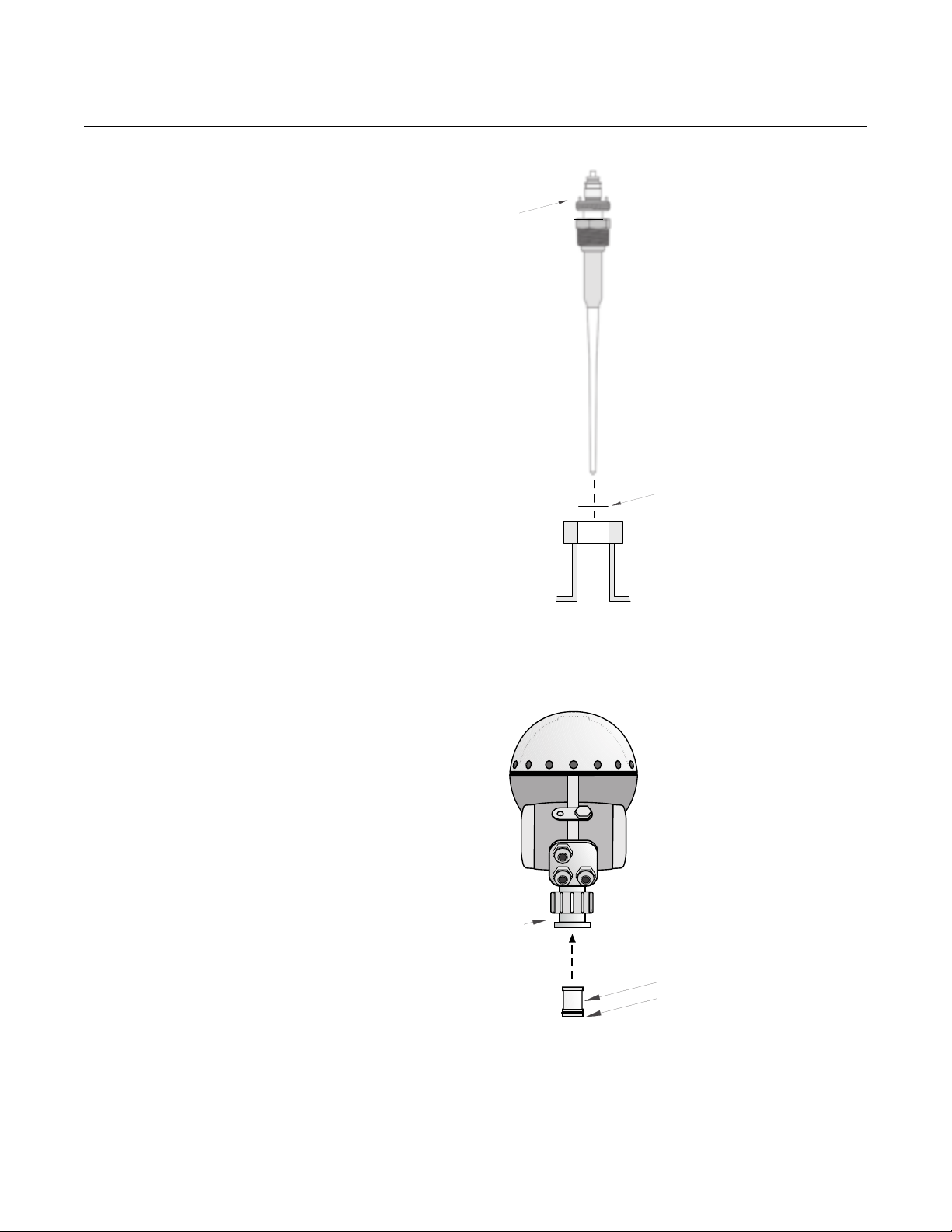

Mounting the Antenna 1. Mount the antenna and the transmitter head in the same way as a

standard cone antenna (see “Mounting the Cone Antenna - PTFE

sealing” on page 2-14).

Figure 2-40. Mounting the

antenna and transmitter head

Nut

Wave Guide Tube

Protection Sleeve

Adapter

Figure 2-41. Inclination

less than 1°

Antenna

Gasket

ANTENNA_HEAD_MOUNT

2. Make sure that the inclination of the transmitter is less than 1°.

max 1°

20,07_INCLINATION

2-29

Page 48

Rosemount 5600 Series

3. In order to minimize the influence of disturbing echoes from inlet and

outlet pipes you may need to rotate the transmitter head 90°.

Figure 2-42. Example of rotating

the transmitter head to

minimize disturbing echoes

Reference Manual

00809-0100-4024, Rev BA

September 2005

90˚

Cover Lock

90˚

BRIDLE_HEADROTATE

2-30

Page 49

Reference Manual

00809-0100-4024, Rev BA

September 2005

MOUNTING THE

PARABOLIC ANTENNA

Figure 2-43. Parabolic Antenna

Dimensions

Rosemount 5600 Series

7.87 (200)

18.11 (460)

6.4 (162)

NOTE

Dimensions are in

inches (millimeters)

Figure 2-44. Recess Hole

17.36 (441)

Mounting the Flange Ball

1. The flange should be between 0.24 and 1.18 inches (6 and 30 mm) thick.

Make sure the diameter of the hole is 3.78 in (96 mm).

2. Make a small recess in the flange hole.

Recess

0.24-1.18

(6-30)

3.78

(96)

1.97

(50)

.5600/5600_09_AA.EPS

PARANT_FLANGE

2-31

Page 50

Rosemount 5600 Series

3. Put the O-ring on the flange and insert the Flange Ball into the hole.

Make sure the pin on the side of the Flange Ball fits into the

corresponding recess on the flange.

Reference Manual

00809-0100-4024, Rev BA

September 2005

Figure 2-45. Put the O-ring on

the flange

Figure 2-46. Secure the nut

Flange Ball

O-ring

Nut

PARANT_FLANGEBALL

4. Tighten the nut. Make sure the Flange Ball fits tightly to the flange.

5. Secure the nut by tightening the locking screw.

Locking

Screw

2-32

PARANT_NUT_LOCKSCREW

Page 51

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

Mounting the antenna

1. Fit the Parabolic Reflector to the Antenna Feeder and mount the five M5

screws that were delivered by Emerson Process Management.

Figure 2-47. Mount the five M5

screw

Figure 2-48. Put the two O-rings

in the grooves

M5 x 5

Parabolic Reflector

Antenna Feeder

PARANT_PARABOLICREFLECTOR

2. Tighten the screws.

3. Put the two O-rings in the grooves on the upper surface of the Flange

Ball.

O-rings x 2

Flange Ball

PARANT_FLANGEBALL

2-33

Page 52

Rosemount 5600 Series

4. Turn the flange around and mount the antenna feeder on the flange.

Mount the washers and nuts.

Figure 2-49. Mount washers and

nuts

Flange

Reference Manual

00809-0100-4024, Rev BA

September 2005

Lock Nut

Tab Washer

Finger Nut

Washer Ball

Lock Washer

Figure 2-50. Tighten the flange

screws

Groove on

Feeder

Antenna

Feeder

5. Tighten the Finger Nut and the Lock Nut loosely.

6. Place the antenna on the tank nozzle and tighten the flange screws.

PARANT_TANKNOZZLE_T30

7. Rotate the antenna so the groove on the Antenna Feeder is directed 90°

to the tank wall.

5600/5600_12_AA.EPS

2-34

Page 53

Reference Manual

00809-0100-4024, Rev BA

September 2005

Figure 2-51. Groove on Antenna

Feeder

Figure 2-52. Insert the

Waveguide Tube into the Upper

Waveguide

Rosemount 5600 Series

Antenna Feeder

Groove

PARANTANTENNAFEEDER.EPS

8. Tighten the Finger Nut and the Lock Nut.

9. Mount the adapter nut on top of the antenna feeder.

Tighten the adapter nut firmly.

10. Insert the Waveguide Tube into the Upper Waveguide.

Figure 2-53. Mount the

Transmitter

Upper Waveguide

Waveguide Tube

PA_WAVEGUIDETUBE.EPS

11. Carefully mount the Transmitter Head onto the adapter and tighten the

Upper Waveguide Nut by hand. Make sure that the guide pins on the

adapter fits into the holes on the Upper Waveguide.

Upper Waveguide Nut

Adapter

PARANT_PRO_THMOUNT_T30.EPS

2-35

Page 54

Rosemount 5600 Series

12. When the antenna inclination is adjusted to obtain optimum performance

(Figure 2-54), tighten the finger nut and the lock nut firmly. Secure by

folding the tab washer over the lock nut (Figure 2-55).

Figure 2-54. Inclination of

Parabolic Antenna.

0 Degrees

Reference Manual

00809-0100-4024, Rev BA

September 2005

1 to 3 Degrees

5600_03_AA, 5600_04_AA.EPS

Figure 2-55. Fold the tab washer

over the lock nut.

NOTE

Normally the antenna should be mounted with inclination 0°. However, in

some applications, for example solid products, a small inclination of the

antenna may improve the performance. This may also be the case if there are

disturbing echoes from objects in the tank.

5600_01_AA.EPS

2-36

Page 55

Reference Manual

00809-0100-4024, Rev BA

September 2005

Rosemount 5600 Series

MOUNTING THE

EXTENDED CONE

ANTENNA

Figure 2-56. Mounting the

antenna and transmitter head

1. Mount the antenna and transmitter head in the same way as a

transmitter with a standard cone antenna (see “Mounting the Cone

Antenna - PTFE sealing” on page 2-14).

Nut

Wave Guide Tube

Protection Sleeve

Antenna Feeder

Adapter

Gasket

Antenna

ANTENNA_HEAD_MOUNT

2. When the transmitter is mounted, the following antenna parameters must

be adjusted by using the configuration software:

• Tank Connection Length (TCL),

• Hold Off (H) distance.

See page 2-38 and page 2-39 for more information on how to set the Hold Off

distance and the Tank Connection Length for a Cone Extension antenna. See

also Section 4: Configuration for more information about these parameters.

2-37

Page 56

Rosemount 5600 Series

Reference Manual

00809-0100-4024, Rev BA

September 2005

Setting the Tank

Connection Length (TCL)

To set the Tank Connection Length, use one of the following procedures for

Standard and Non-Standard Extended Cone Antenna.

Standard Extended Cone Antenna

For the 20 in. (500 mm) extended cone the following TCL

values can be

ext

used:

Table 2-7. Standard Extended Cone Antenna

3 inch

Antenna Type

/PTFE 0.019 (0.489) 1.90 (0.482) 1.88 (0.477)

TCL

ext

TCL

/Quartz 2.08 (0.529) 2.06 (0.522) 2.04 (0.517)

ext

diameter = 68mm

4 inch

diameter = 90mm

6 inch

diameter = 138mm

Non-Standard Extended Cone Antenna

To adjust the TCL value do the following:

1. Start the Radar Master configuration software.

2. From the Antenna Type drop down list choose User Defined.

3. Enter the new TCL value.

Use the following formula to calculate the appropriate Tank Connection

Length (TCL):

TCL

= TCL

ext

cone

+ K*(L

ext

- L

antenna

)

where:

•TCL

= the TCL adjusted to the extended cone antenna

ext

(See Table 2-7).

•TCL

= the default TCL for a standard cone antenna without

cone

extension. Note that there are different TCL values for tank sealing

PTFE and Quartz, see Table 2-8.

•L

•L

= the measured length of the extended cone antenna.

ext

= the length of the standard cone antenna without extension.

antenna

• K = a constant related to the antenna inner diameter.

2-38

Table 2-8. Non-Standard Extended Cone Antenna

Antenna Type

K 0.035 0.020 0.008

L

antenna

/PTFE 0.475 0.475 0.475

TCL

cone

TCL

/Quartz 0.515 0.515 0.515

cone

3 inch

diameter = 68mm

0.094 0.148 0.261

4 inch

diameter = 90mm

6 inch

diameter = 138mm

Page 57

Rosemount 5600 Series

Reference Manual

00809-0100-4024, Rev BA

September 2005

Setting the Hold Off

Distance

Figure 2-57. Extended cone

antenna

To set a new Hold Off distance do the following:

1. Start the configuration software.

2. In the Hold Off/New input field type the desired Hold Off distance.

Use the following formula in order to calculate the appropriate Hold Off

(H) distance:

H=1.2 inches + L

(H=0.03 meters + L

ext

ext

)

where:

•L

is the length of the extended cone antenna

ext

Hold Off (H)

1.2 in.

(30 mm)

L

ext

CONE_EXTENSION_1B

2-39

Page 58

Rosemount 5600 Series

Installation

Requirements Extended

Cone Antenna

Figure 2-58. Extended Cone

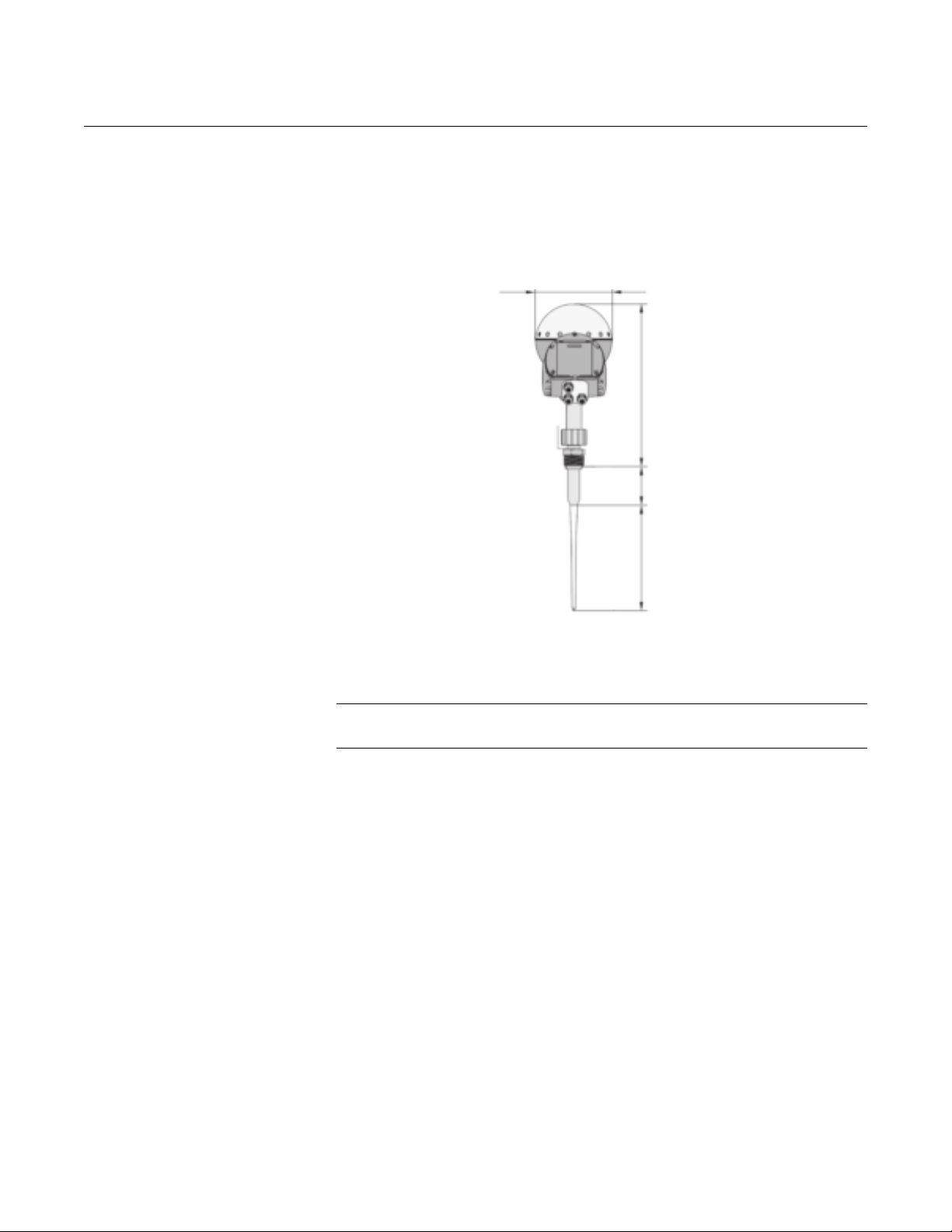

Antenna Dimensions

Reference Manual

00809-0100-4024, Rev BA

September 2005

7.87 (200)

15.75 (400)

19.69 (500)

NOTES

Other extended cone

lengths available upon

request. Consult factory.

Dimensions are in

inches (millimeters)

15° Angle

2.76 (70) (3 in. Cone)

3.66 (93) (4 in. Cone)

5.55 (141) (6 in. Cone)

5600_PDS_MS_2BB.EPS

The Extended Cone antenna is suitable for tanks with long nozzles or tanks

where measurements should be avoided in the region close to the nozzle.

Use the Extended Cone antenna if:

• the nozzle is high, see Figure 2-59:

ANSI 3” antenna for nozzles higher than 9.8 in. (250 mm),

ANSI 4” antenna for nozzles higher than 11.8 in. (300 mm),

ANSI 6” antenna for nozzles higher than 15.8 in. (400 mm),

• there are disturbing objects close to the tank opening, see Figure 2-60,

or

• there is a rough surface at the inside of the nozzle or there is a height

difference between nozzle sides, see Figure 2-61.

2-40

Page 59

Rosemount 5600 Series

Figure 2-59. Example of a high

nozzle

Figure 2-60. Example of

disturbing objects close to the

tank nozzle

Reference Manual

00809-0100-4024, Rev BA

September 2005

TANK_UNDERGROUND

Figure 2-61. Examples of

problem nozzles

2-41

Rust or deposit

Height

difference

TANK_INSULATED

Bad welding

5600/ROUGH_SURFACES

Page 60

Rosemount 5600 Series

Figure 2-62. Total distance

between flange and product

level

1. Measure the total distance A between the flange and the maximum

product level.

2. The standard length of the Extended Cone antenna is 20 in. (500 mm). If

A is less than 20 inches (500mm), then the cone may be cut so these

minimum dimensions are met.

minimum 0.8 in

(20 mm)

maximum level

Reference Manual

00809-0100-4024, Rev BA

September 2005

A

15°

min. 1.2 in