Page 1

Model 54eC

Conductivity/Resistivity HART

®

Analyzer/Controller

Instruction Manual

51-54eC/rev.F

May 2006

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PRO-

CEEDING!

Rosemount Analytical designs, manufactures, and tests its

products to meet many national and international standards. Because these instruments are sophisticated technical products, you must properly install, use, and maintain

them to ensure they continue to operate within their normal

specifications. The following instructions must be adhered

to and integrated into your safety program when installing,

using, and maintaining Rosemount Analytical products.

Failure to follow the proper instructions may cause any one

of the following situations to occur: Loss of life; personal

injury; property damage; damage to this instrument; and

warranty invalidation.

• Read all instructions prior to installing, operating, and

servicing the product. If this Instruction Manual is not the

correct manual, telephone 1-800-654-7768 and the

requested manual will be provided. Save this Instruction

Manual for future reference.

• If you do not understand any of the instructions, contact

your Rosemount representative for clarification.

• Follow all warnings, cautions, and instructions marked

on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

• Install your equipment as specified in the Installation

Instructions of the appropriate Instruction Manual and

per applicable local and national codes. Connect all

products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel

to install, operate, update, program, and maintain the

product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by

Rosemount. Unauthorized parts and procedures can

affect the product’s performance and place the safe

operation of your process at risk. Look alike substitutions may result in fire, electrical hazards, or improper

operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is

being performed by qualified persons, to prevent electrical shock and personal injury.

WARNING

ELECTRICAL SHOCK HAZARD

Making cable connections to and servicing this

instrument require access to shock hazard level

voltages which can cause death or serious injury,

therefore, disconnect all hazardous voltage

before accessing the electronics.

Relay contacts made to separate power sources

must be disconnected before servicing.

Electrical installation must be in accordance

with the National Electrical Code (ANSI/NFPA-

70) and/or any other applicable national or local

codes.

Unused cable conduit entries must be securely

sealed by non-flammable closures to provide

enclosure integrity in compliance with personal

safety and environmental protection requirements. Use NEMA 4X or IP65 conduit plugs supplied with the instrument to maintain the ingress

protection rating (IP65).

For safety and proper performance this instrument must be connected to a properly grounded

three-wire power source.

Proper relay use and configuration is the

responsibility of the user. No external connection to the instrument of more than 60VDC or

43V peak allowed with the exception of power

and relay terminals. Any violation will impair the

safety protection provided.

Do not operate this instrument without front

cover secured. Refer installation, operation and

servicing to qualified personnel.

WARNING

This product is not intended for use

in the residential, commercial or

light industrial environment per

certification to EN50081-2.

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2006

Page 3

Page 4

About This Document

This manual contains instructions for installation and operation of the Model 54eC

Conductivity/Resitivity HART Analyzer/Controller.

The following list provides notes concerning all revisions of this document.

Rev. Level

Date Notes

0 9/99 This is the initial release of the product manual. The manual

has been reformatted to reflect the Emerson documentation

style and updated to reflect any changes in the product offering.

0 11/01 Added trim output info

A 12/01 Revised spec and temp slope info

B 6/02 updated drawings on page 8

C 2/03 Removed Figure 3-2 (sensor wiring photo)

D 4/03 Updated CE info

E 4/05 Added note re ordering circuit board stack on page 63.

F 5/06 Noted 0-20 mA limitation for HART versions on pp. 21, 26, & 32.

Page 5

MODEL 54eC TABLE OF CONTENTS

MODEL 54eC

MICROPROCESSOR ANALYZER

TABLE OF CONTENTS

Section Title Page

1.0 DESCRIPTION AND SPECIFICATIONS ................................................................ 1

1.1 General Description................................................................................................. 1

1.2 Description of Controls ............................................................................................ 1

1.3 Specifications........................................................................................................... 2

1.4 Ordering Information................................................................................................ 4

2.0 INSTALLATION....................................................................................................... 5

2.1 Locating the Controller ............................................................................................ 5

2.2 Unpacking and Inspection ....................................................................................... 5

2.3 Mechanical Installation ............................................................................................ 5

3.0 WIRING ................................................................................................................... 7

3.1 General.................................................................................................................... 7

3.2 Power Input Wiring .................................................................................................. 7

3.3 Analog Output Wiring .............................................................................................. 7

3.4 Alarm Relay Output Wiring...................................................................................... 7

3.5 Sensor Wiring.......................................................................................................... 9

3.6 Final Electrical Check.............................................................................................. 9

4.0 CALIBRATION ........................................................................................................ 11

4.1 Initial SetUp ............................................................................................................. 12

4.2 Entering the Cell Constant ...................................................................................... 13

4.3 Zeroing the Controller.............................................................................................. 14

4.4 Selecting the Temperature Compensation Type ..................................................... 15

4.5 Temperature Calibration .......................................................................................... 16

4.6 Calibrating the Sensor............................................................................................. 17

4.7 Temperature Compensation Options....................................................................... 18

4.8 Hold Mode ............................................................................................................... 19

4.9 Output Trim.............................................................................................................. 19

5.0 SOFTWARE CONFIGURATION ............................................................................. 20

5.1 Changing Output Setpoints (PID only) .................................................................... 24

5.2 Changing Alarm Setpoints....................................................................................... 25

5.3 Changing Output Setpoints (Normal) ...................................................................... 26

5.4 Testing Outputs and Alarms .................................................................................... 27

5.5 Choosing Display Options ....................................................................................... 29

5.6 Changing Output Parameters.................................................................................. 31

5.7 Changing Alarm Parameters ................................................................................... 34

6.0 THEORY OF OPERATION ..................................................................................... 40

6.1 Conductivity ............................................................................................................. 40

6.2 Temperature Correction........................................................................................... 40

6.3 Interval Timer........................................................................................................... 41

6.4 Alarm Relays ........................................................................................................... 42

6.5 Time Proportional Control (TPC) Mode................................................................... 42

6.6 Normal Mode........................................................................................................... 43

6.7 Analog Outputs........................................................................................................ 43

6.8 Controller Mode Priority........................................................................................... 44

6.9 PID Control.............................................................................................................. 45

i

Page 6

MODEL 54eC TABLE OF CONTENTS

TABLE OF CONTENTS (Continued)

Section Title Page

7.0 SPECIAL PROCEDURES AND FEATURES ......................................................... 49

7.1 Password Protection................................................................................................ 49

7.2 Configuring Security ................................................................................................ 50

7.3 Temperature Slope Procedure (Linear Compensation) ........................................... 51

7.4 Determining Unknown Temperature Slopes (Linear Compensation)...................... 52

7.5 Changing the Reference Temperature..................................................................... 53

7.6 Special Substance Calibration................................................................................. 54

8.0 TROUBLESHOOTING ........................................................................................... 55

8.1 Displaying Diagnostic Parameters........................................................................... 58

8.2 Troubleshooting Guidelines..................................................................................... 59

8.3 Replacement Parts .................................................................................................. 63

9.0 RETURN OF MATERIALS ..................................................................................... 64

LIST OF FIGURES

Figure No. Title Page

1-1 Main Display Screen............................................................................. 1

2-1 Wall Mounting....................................................................................... 5

2-2 Pipe Mounting....................................................................................... 6

2-3 Panel Mounting..................................................................................... 6

3-1 Power Input and Relay Output Wiring for Model 54eC......................... 8

3-2 Sensor Wiring Diagram ........................................................................ 10

5-1 Outline of Menu Levels......................................................................... 23

5-2 Interval Timer Examples....................................................................... 38

6-1 Time Proportional Control..................................................................... 42

6-2 The Process Reaction Curve................................................................ 47

LIST OF TABLES

Table No. Title Page

4-1 Typical Temperature Slopes ................................................................. 15

5-1 Conductivity Settings List ..................................................................... 20

6-1 Controller Mode Priority Chart .............................................................. 44

8-1 Diagnostic Messages ........................................................................... 56

8-2 Quick Troubleshooting Guide ............................................................... 57

8-3 Troubleshooting Guide ......................................................................... 60

ii

Page 7

1

MODEL 54eC SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.1 GENERAL DESCRIPTION

The Model 54eC conductivity controller is a device

used to measure conductivity in chemical processes.

Conductivity is a function of ion concentration, ionic

charge, and ion mobility. Ions in water conduct current

when an electrical potential is applied across electrodes immersed in the solution. A controller system

consists of a microprocessor-based controller, a conductivity probe, and mounting hardware.

The controller can use an electrodeless toroidal probe

or a contacting probe with metal electrodes. Electrodeless (also called inductive) conductivity measurement

is especially useful for solutions containing abrasive

solids, highly conductive, or highly corrosive materials.

The contacting probe is used where conductivity is

below 200 micromhos, such as water rinses in metal

finishing or ultrapure boiler water applications. It uses

an electrode design for greater sensitivity because

these water solutions tend to be non-fouling.

All adjustments to the current outputs, alarm relays,

and calibration of the pH and temperature inputs can

be made using the controller's membrane keypad.

1.2 DESCRIPTION OF CONTROLS

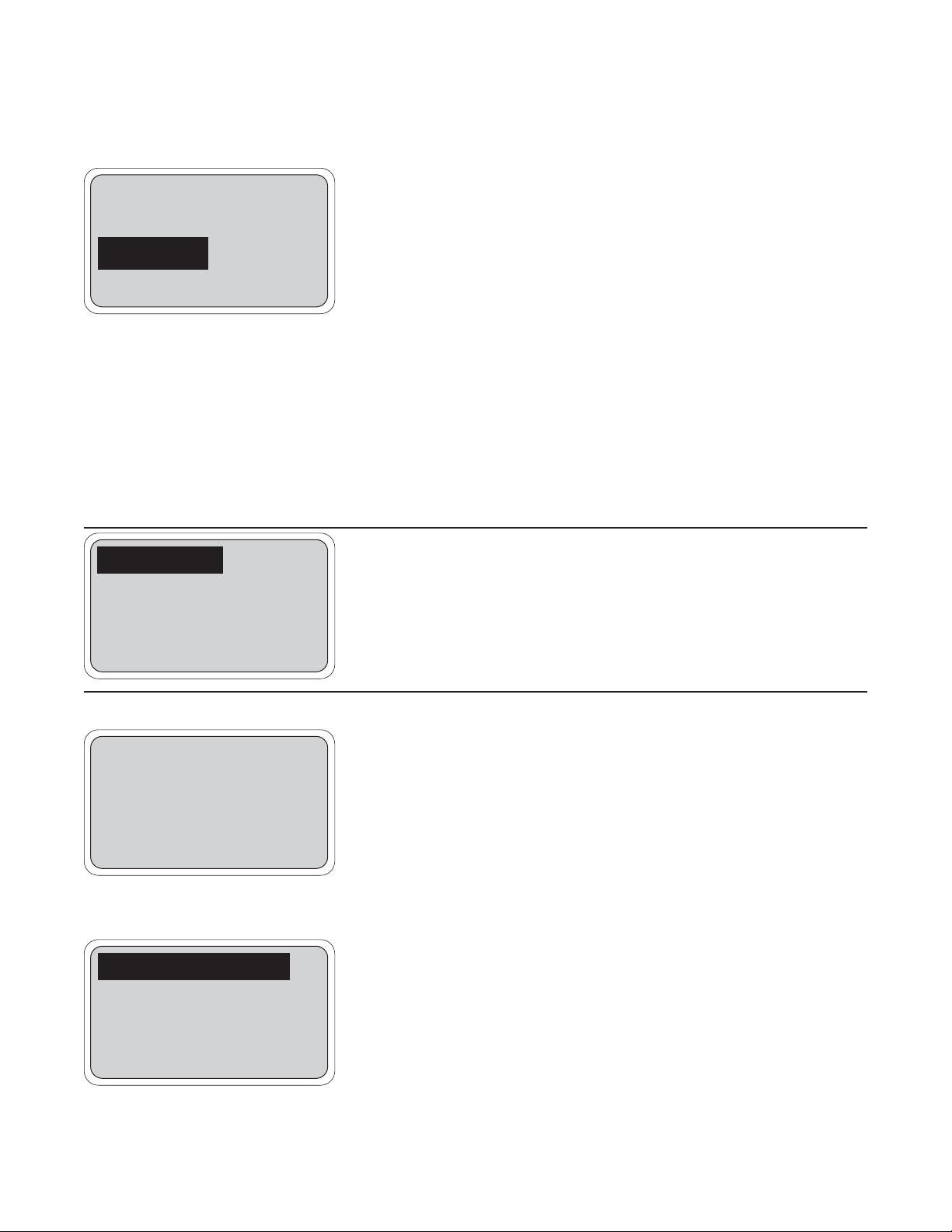

Figure 1-1 shows a diagram of the main display

screen. Similar diagrams are used throughout this

manual. The primary variable is continuously displayed in large numerals. The process temperature

and primary current output value are always displayed

on the second line of the main display screen. The

third line can be configured to read several different

items, as desired. In this case, it is displaying setpoints for alarms 1 and 2.

The F1-F4 keys are multifunction. The active operation

for that key is displayed as a label just above each

function key as needed. For example, F1 is usually

labeled Exit and F4 may be labeled Edit, Save, or

Enter. Pressing Enter 4 will access sub-menus, while

pressing Edit allows changing values and Save stores

the values in memory. Esc 3 can be used to abort

unwanted changes. Exit 1 returns to the previous

screen. Other labels may appear for more specialized

tasks.

The up t and down b keys are used to:

1. Move the cursor (shown in reverse video) up and

down on the menu screens.

2. Scroll through the list of options available for the

field shown in reverse video. When the last item

of a menu has been reached, the cursor will

rest on the third line of the display. If the cursor

is on the second line, there are more items to

see with the down arrow key.

3. Scroll through values when a highlighted numerical

value is to be set or changed.

The right and left keys are used to move the cursor to

the next digit of a number.

Green LEDs (labeled 1, 2, and 3) indicate when alarm

relays 1, 2, and 3 are energized. The fourth relay

indicates a fault condition. When a fault occurs, the

red LED (labeled FAIL) lights up, a descriptive error

message is displayed, and the action of the outputs

and relays will be as described in Section 5.6 and

Section 5.7 under fault value (e.g. 22 mA).

The red LED also indicates when the interval timer routine is activated and when the time limit has been

reached on a feed limit timer. For more information on

these subjects, see Section 5.7.

FIGURE 1-1. Main Display Screen

500

µS/cm

26.2°C. 12.0 mA

AL1: 2000μS AL2: 500μS

Page 8

MODEL 54eC SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.3 SPECIFICATIONS

PHYSICAL SPECIFICATIONS - GENERAL

Enclosure: Epoxy-painted cast aluminum

NEMA 4X (IP65),144 X 144 X 132mm, DIN size

(5.7 X 5.7 X 5.2 in.)

Front Panel: Membrane keyboard with tactile feed

back and user selectable security. Light gray, blue

and white overlay. Light gray enclosure, dark gray

bezel.

Display: Back-lit dot matrix LCD (7.0 x 3.5 cm), blue

on gray-green. The display contrast is compensated for ambient temperature.

Process Variable Character Height: 16mm (0.6 inch)

Electrical Classification:

Class I, Division 2, Groups A, B, C, & D.

T5 Ta=50°C. Dust ignition proof: Class II,

Division 1, Groups E, F, & G; Class III.

CSA-LR34186:

Max. relay contact rating: 28 Vdc; 110 Vac;

230 Vac; 6 amps resistive

FM: Max. relay contact rating: 28 Vdc resistive

150 mA - Groups A & B;

400 mA - Group C;

540 mA - Group D

Power:

Code -01: 100 - 127 VAC, 50/60 Hz ± 6%, 6.0 W;

200 - 253 VAC, 50/60 Hz ± 6%, 6.0 W

Code -02: 20 - 30 VDC, 6.0 W

Current Outputs:

Output 1: Process, Raw conductivity, or

Temperature

Output 2: Process, Raw conductivity, or

Temperature

Each output is galvanically isolated, 0-20 mA or 420 mA into 500 ohms maximum load at 115/230

Vac or 24 Vdc (Code -02) or 500 ohms maximum

load at 100/200 Vac. Output 1 includes digital signal 4-20 mA superimposed HART (Code -09 only).

EMI/RFI :EN61326

LVD (Code -01 only) : EN61010-1

Ambient Temperature:

0 to 50°C (32 to 122°F)

NOTE: The analyzer is operable from

-20 to 60°C (-4 to

140°F) with some degradation in display performance.

Relative Humidity: 95%, non-condensing

Alarms:

Relay 1 - Process, Temperature, or Interval Timer

Relay 2 - Process, Temperature, or Interval Timer

Relay 3 - Process, Temperature, or Interval Timer

Relay 4 - Fault alarm

Each relay has a dedicated LED on the front panel.

Relay Contacts: Relays 1-3: Epoxy sealed form A

contacts, SPST, normally open.

Relay 4: Epoxy sealed form C, SPDT.

Resistive Inductive

28 Vdc 5.0 Amps 3.0 Amps

115 Vac 5.0 Amps 3.0 Amps

230 Vac 5.0 Amps 1.5 Amps

Weight/Shipping Weight: 1.1 kg/1.6 kg (2.5 lb/3.5 lb)

2

Page 9

MODEL 54eC SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

3

INSTRUMENT SPECIFICATIONS @ 25°C

Measurement Range: –15 to 200°C (5 to 392°F)

Contacting: 0-20,000 µS/cm

Toroidal: 0-2 S/cm

Accuracy of Analyzer: (Analyzer connected to simulated sensor input)

Contacting Sensors: ±0.5% of reading, ± .005 µS/cm

Inductive Sensors: ±1% of reading, 200 µS/cm to 2 S/cm, ± 5 µS/cm

Repeatability: ±0.25% of reading

Stability: ±0.25% of output range/month, noncumulative

Ambient Temperature Coefficient: ± 0.01% of reading/°C

Temperature Compensation: -15 to 200°C (5 to 392°F) (automatic or manual)

Temperature Correction: High purity water (dilute sodium chloride), cation conductivity (dilute hydrochloric

acid), linear temperature coefficient (0.0 to 5.00%/°C), or none. High purity water and cation conductivity

temperature correction apply between 0 and 100°C. Linear temperature coefficient can be applied between

-5 and 200°C (23 to 392°F).

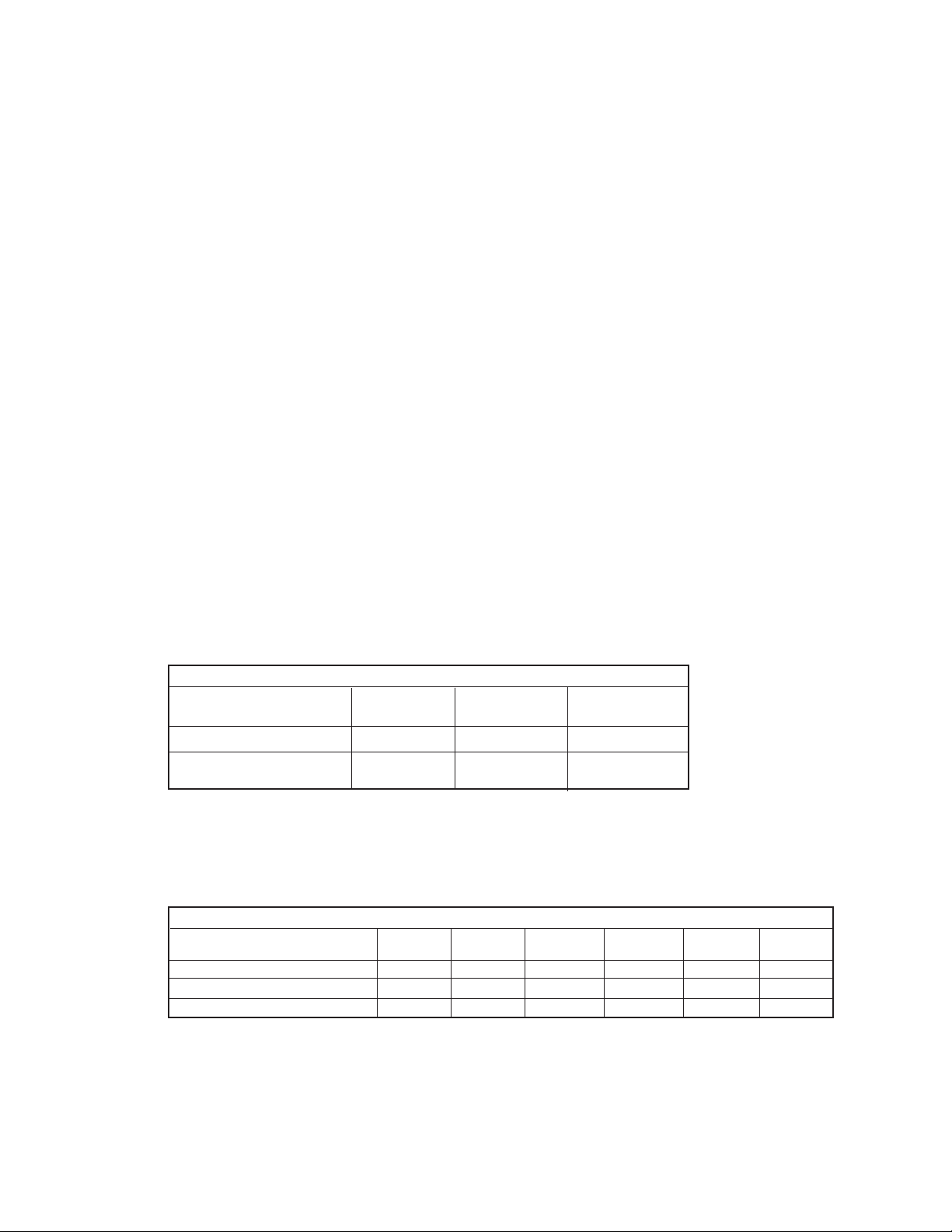

CONTACTING SENSORS

Conductivity Sensor 142, 400 142, 400 140, 141

Model Number 402, 403, 404 402, 403, 404 400, 402, 403

Cell Constant (/cm) 0.01 0.1 1.0

Recommended Conductivity 0-25 1-2000 10-10,000**

Range* (μS/cm)

INDUCTIVE SENSORS

Conductivity Sensor

Model Number 226 228 225 222 (1in.) 222 (2 in.) 242

Nominal Cell Constant 1.0 3.0 3.0 6.0 4.0 *

Minimum Conductivity (μS/cm) 50 200 200 500 500 100*

Maximum Conductivity (μS/cm) 1,000,000 2,000,000 2,000,000 2,000,000 2,000,000 1,500,000*

* Model 242 values depend on sensor configuration and wiring.

* For sensor linearity equal to or better than 1% with ENDURANCE series.

** ENDURANCE sensors with cell constant of 1.0/cm may be used for conductivity up to

20,000 μS/cm with linearity equal to or better than 2%.

SENSOR CHOICE GUIDELINES

The Model 54eC is compatible with both contacting and inductive conductivity sensors. The best sensor for an

application depends on many factors, among them are the conductivity to be measured, the compatibility of the

sensor's wetted materials with the process chemicals and conditions, and the mounting arrangement. The tables

below are provided as an aid for choosing an appropriate sensor.

Page 10

MODEL 54eC SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

4

1.4 ORDERING INFORMATION

The Model 54eC Conductivity Microprocessor Analyzer is housed in a rugged, NEMA 4X (IP65) epoxy-

painted cast aluminum enclosure and is compatible with both contacting and inductive conductivity sensors.

Standard features include a back-lit dot-matrix liquid crystal display, sensor diagnostics, dual isolated outputs,

and four relays. The analyzer can measure conductivity, resistivity, or percent (%) concentration as configured by

the user.

CODE OPTIONS

01 115/230 VAC, 50/60 Hz Power

02 24 VDC, 50/60 Hz Power

MODEL

54eC MICROPROCESSOR ANALYZER

CODE OPTIONS

09 HART Communications Protocol

20 Controller Outputs - PID and TPC

ACCESSORIES

PART NO. DESCRIPTION

2002577 Wall and two inch pipe mounting kit

23545-00 Panel mounting kit

23554-00 Cable glands, kit (Qty 5 of PG 13.5)

9240048-00 Stainless steel tag (specify marking)

54eC -01 -20 EXAMPLE

Page 11

5

MODEL 54eC SECTION 2.0

INSTALLATION

SECTION 2.0

INSTALLATION

This section is for installation of the controller.

WARNING

All electrical installation must conform to the

National Electrical Code, all state and local

codes, and all plant codes and standards for

electrical equipment. All electrical installations

must be supervised by a qualified and responsible plant electrician.

2.1 LOCATING THE CONTROLLER

Position the Model 54eC controller to minimize the effects of temperature extremes and to avoid vibration

and shock. Locate the controller away from your

chemical process to protect it from moisture and

fumes.

Select an installation site that is more than 2 ft from

high voltage conduit, has easy access for operating

personnel, and is not exposed to direct sunlight.

2.2 UNPACKING AND INSPECTION

Inspect the exterior of the shipping container for any

damage. Open the container and inspect the controller

and related hardware for missing or damaged parts.

If there is evidence of damage, notify the carrier immediately. If parts are missing, contact Rosemount

Analytical customer support.

2.3 MECHANICAL INSTALLATION

2.3.1 Mounting the Controller

The Model 54eC controller may be supplied with a

mounting bracket accessory. If you use the mounting

bracket on wall or pipe installations, avoid mounting

on pipes which vibrate or are close to the process.

The bracket may be modified to mount the controller

on I-beams or other rigid members. You can also fabricate your own bracket or panel mount the controller

using the bracket as an example.

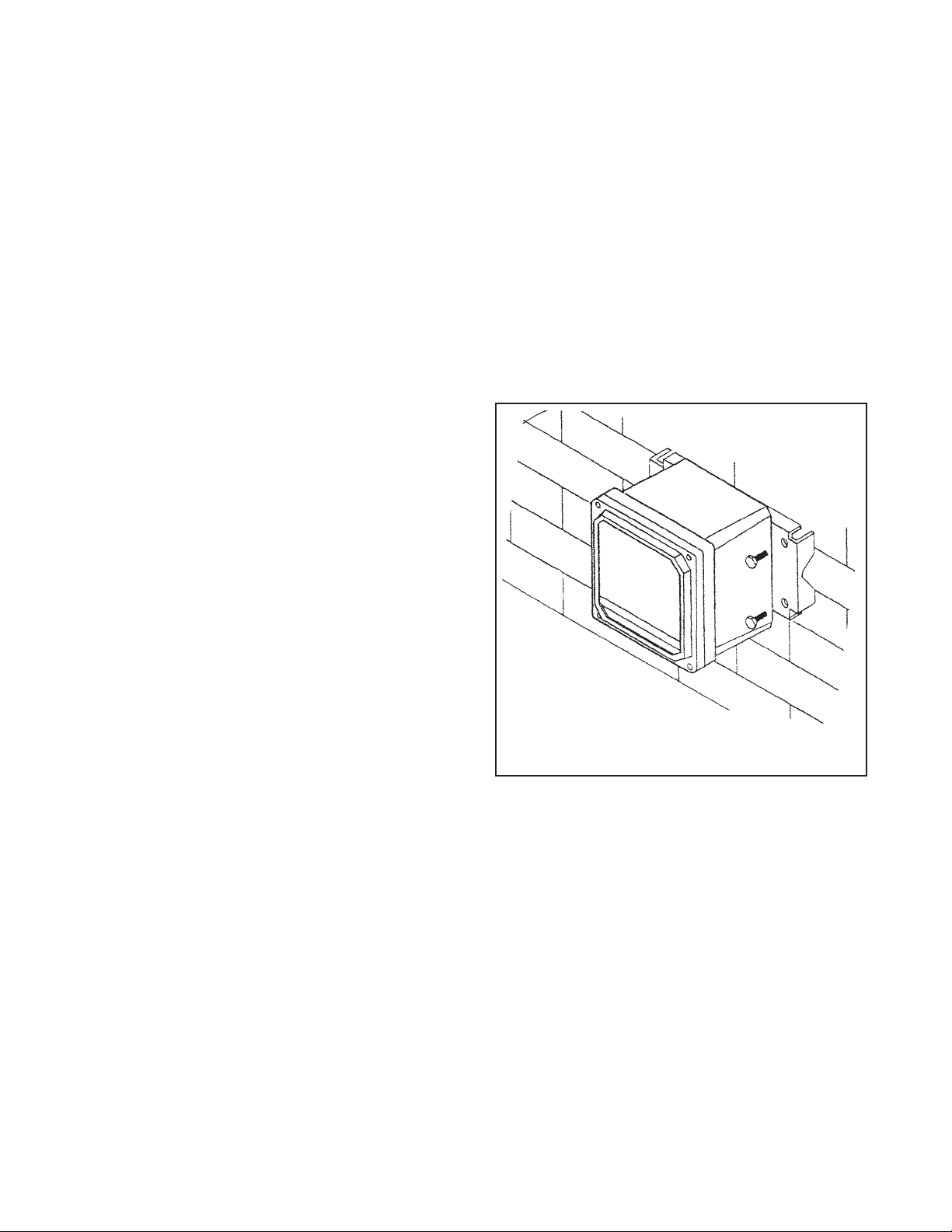

2.3.2 Wall or Surface Mounting:

1. Mount the bracket to the controller using the supplied four screws as shown in Figure 2-2.

2. Mount controller mounting bracket to wall using

any appropriate fastener such as screws, bolts,

etc (see Figure 2-1 below).

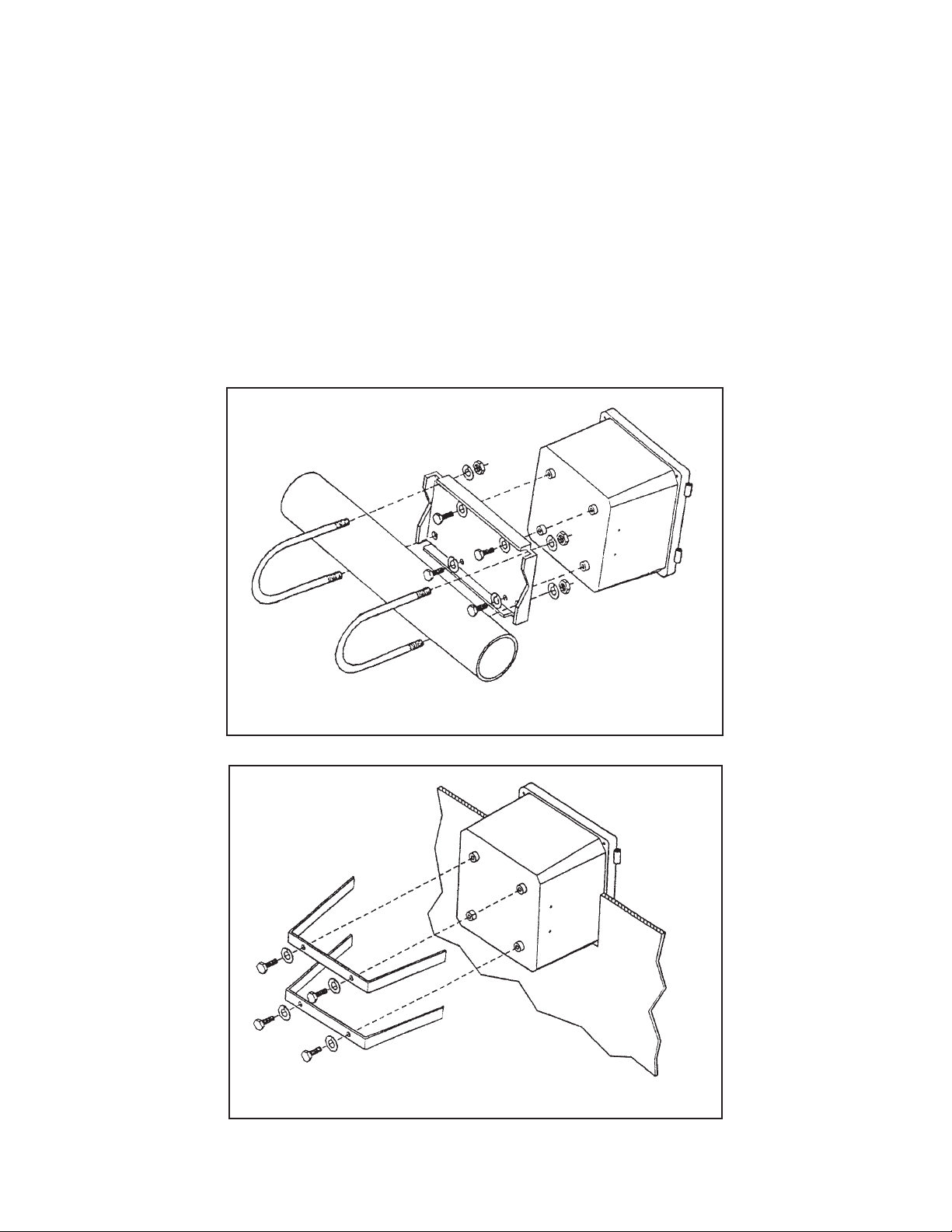

2.3.3 Pipe Mounting:

1. Attach the mounting bracket to the rear of the controller and tighten the four screws as shown in

Figure 2-2.

2. Place supplied U bolts around the mounting pipe

and through the pipe mounting bracket and

mounting bracket. Tighten the U bolt nuts until the

controller is securely mounted to the pipe.

FIGURE 2-1. Wall Mounting

Page 12

6

FIGURE 2-2. Pipe Mounting

MODEL 54eC SECTION 2.0

INSTALLATION

FIGURE 2-3. Panel Mounting

2.3.4 Panel Mounting:

The controller is designed to fit into a 5.43 x 5.43 inch (DIN standard 137.9 x 137.9 mm) panel cutout (Figure

2-3). Installation requires both front and rear access.

1. Install the controller as shown in Figure 2-3. Insert the instrument enclosure through the front of the panel

cutout and align the panel mounting brackets as shown.

2. Insert two mounting bracket screws through each of the two mounting brackets and into the tapped holes in

the rear of the controller enclosure and tighten each screw.

3. Insert four panel mounting screws through each hole in the mounting brackets. Tighten each screw until the

mounting bracket holds controller firmly in place. To avoid damaging the controller mounting brackets, do not

use excessive force.

Page 13

MODEL 54eC SECTION 3.0

WIRING

SECTION 3.0

WIRING

3.1 GENERAL

WARNING

All electrical installation must conform to the

National Electrical Code, all state and local

codes, and all plant codes and standards for

electrical equipment. All electrical installations must be supervised by a qualified and

responsible plant electrician.

NOTE

Wire only the analog and alarm outputs

required for your application. Be sure to read

the warning at the beginning of Section 2.0.

The Model 54eC has five access holes in the bottom of

the instrument housing which accept ½-in. strain relief

connectors or conduit fittings. Be sure to seal any

unused access holes. As you face the front of the unit,

the rear openings are for input power, and alarm relay

signals. The opening on the front left is for sensor

wiring only (DC). The front right is for analog output

wiring.

NOTE

For best EMI/RFI protection, the output

cable should be shielded and enclosed in an

earth grounded, rigid, metal conduit.

Connect the output cable's outer shield to

the earth ground connection on TB2 (Figure

3-1).

3.2 POWER INPUT WIRING

Figure 3-1 depicts the wiring detail for the Model 54eC.

Code -01: connect AC power to TB3, terminals 1 and

2 for 115 VAC (terminals 2 and 3 for 230 VAC). Code

-02: connect DC power to TB3 terminals 1, 2, and 3.

Connect earth ground to the nearby ground lug. A

good earth ground is essential for proper operation of

the controller. Be sure to provide a means of disconnecting the main power to the controller.

CAUTION

Do not apply power to the controller until all

electrical connections are made.

WARNING

Electrical connections to this equipment

must be made in accordance with the current National and Local Electrical Codes

in effect for the installation location.

3.3 ANALOG OUTPUT WIRING

The analog output wiring consists of two 4-20 mA signals: output one from terminals 4 and 5, output 2

from 1 and 2 on TB2, as shown in Figure 3-1. These

signals can be used for chart recorder, computer

monitoring, or PID control output. The analog outputs

can be programmed for 4-20 mA or for 0-20 mA,

direct or reverse acting. Current output 1 includes

superimposed HART (code -09 only).

3.4 ALARM RELAY OUTPUT WIRING

The controller has 3 "dry" alarm relay contacts which

are normally open. Alarm 1 is across terminals 4 and 5

on TB3. This alarm is typically used to control the pump

in a chemical feed system. Alarm 2 across terminals 6

and 7 on TB3 is usually used to operate a light or horn

as a means of alerting the chemical process operator

when conductivity/resistivity/%concentration is outside

the control range. Alarm 3 is across terminals 8 and 9

on TB3. All 3 of these alarms may be activated on conductivity/resistivity/%concentration or temperature.

They can also be used to control other pumps or valves

provided they are programmed to do so. Refer to

Section 5.0 to set up these functions.

All three alarm contacts on the Model 54eC are rated

for a maximum of 3 A, 115 VAC (1.5A, 230 VAC). If

your associated pump or valve exceeds this, use a

separate contact or relay rated for the external

device.

To use a contact output to control a pump, valve, or

light, the contact must be wired into a circuit together with a source of power for the device to be controlled. The power can be jumpered from the main

power into the controller and the circuit can be wired

as shown on the wiring diagrams, Figure 3-1.

7

Page 14

8

MODEL 54eC SECTION 3.0

WIRING

FIGURE 3-1. Power Input and Relay Output Wiring for Model 54eC

NOTE: Maximum inductive load is 3.0 A at 115 V, 1.5 A at 230V. External power must be brought to relay contact. HART

communications superimposed on Output 1.

DWG. NO. REV.

4054EC03 C

Page 15

9

MODEL 54eC SECTION 3.0

WIRING

3.5 SENSOR WIRING

Be sure that the conductivity sensor has been properly installed and mounted. Wire the sensor to the junction box

(if so equipped) and/or Model 54eC according to Figure 3-2, or use the wiring diagram drawing included inside the

controller.

The wiring diagrams show connections between the Model 54eC and the junction box used where distance

from the sensor to the controller exceeds the integral sensor cable length and interconnecting wire is

required. The interconnecting sensor wire recommended for contacting sensors is PN 9200275. Use of this

cable provides EMI/RFI protection and complete sensor diagnostics (for sensors so equipped). The maximum interconnecting wire length is 180 ft. For toroidal sensors, please see sensor manual for recommended interconnecting cable.

IMPORTANT

All interconnecting sensor cable ends must be properly dressed to prevent the individual sensor

and shield wires from shorting. All shields must be kept electrically separate all the way back to

the terminals on the Model 54eC. Check that there is no continuity between the shield wires and

any other sensor conductors or shields prior to connecting the sensor wiring to the terminals on

the Model 54eC. FAILING TO FOLLOW THESE INSTRUCTIONS WILL RESULT IN CONTROLLER

MALFUNCTION.

3.6 FINAL ELECTRICAL CHECK

CAUTION

To prevent unwanted chemical feed into the process and to prevent injury to operating personnel, disconnect the chemical feed pump and other external devices until the controller

is checked out, programmed, and calibrated.

When all wiring is completed, apply power to the controller. Observe the controller for any questionable behavior

and remove power if you see a problem. With the sensor in the process, the display will show a conductivity

although it may not be accurate.

Page 16

MODEL 54eC SECTION 3.0

WIRING

10

FIGURE 3-2. Sensor Wiring Diagram

Page 17

11

MODEL 54eC SECTION 4.0

CALIBRATION

SECTION 4.0

CALIBRATION

The following procedures are described in this section:

• Initial Setup (Section 4.1)

• Entering the cell constant (Section 4.2)

• Zeroing the controller (Section 4.3)

• Entering the temperature slope (Section 4.4)

• Standardizing temperature (Section 4.5)

• Standardizing conductivity (Section 4.6)

• Manual Temperature Compensation (Section 4.7)

• Hold Mode (Section 4.8)

NOTE

First Time Users should perform ALL of the

procedures in Sections 4.1 to 4.6.

INTRODUCTION

Calibration is the process of adjusting or standardizing the controller to a lab test (such as free acid titration) or a calibrated laboratory instrument, or standardizing to some known reference (such as a commercial chemical standard). Calibration ensures that

the controller reads an accurate, and therefore,

repeatable reading of conductivity and temperature.

This section contains procedures for the first time

use and for routine calibration of the Model 54eC

controller.

Since conductivity measurements are affected by

temperature, the Model 54eC reads the temperature

at the probe and compensates for the changing temperature by referencing all conductivity measurements to 25°C (77°F).

To ensure the controller's accuracy, it is important to

perform all the calibration procedures provided in this

section if you are:

• installing this unit for the first time

• changing or replacing a probe

• troubleshooting

After the initial calibration, the accuracy of the conductivity reading should be checked periodically against

some known standard of conductivity and temperature. This is described here and in Section 6.0,

Operating Procedures.

WARNINGS

Before performing any of these procedures, be sure to disable or disconnect the chemical feed

pumps or other external devices. (see placing controller in hold mode, Section 4.8)

Perform the calibration procedures in this section only in the order they are given. For an introduction to the controller keypad functions, see Section 1.0, Description and Specifications.

Do not attempt to calibrate the controller if the fault LED is lit or the display is showing fault messages. If either of these conditions exist, refer to Section 8.0, Troubleshooting.

Page 18

12

4.1 INITIAL SETUP

MODEL 54eC SECTION 4.0

CALIBRATION

1000

µS/cm

Hold mode: Off

Exit Cont Edit

500

µS/cm

26.2°C. 12.0 mA

AL1: 2000μS AL2: 500μS

NOTE

The controller has been configured at the factory for a toroidal

sensor ("inductive" mode). If the contacting conductivity probe is

used instead, go to Section 5.5 and change the Display Type to

"Contacting", BEFORE continuing with Initial Setup here.

The initial setup procedure should be used when first commissioning the

controller and when changing the conductivity probe. Some menu headers may appear that are not discussed here, but are included in Section

7.0 as advanced features of the controller that most new users will not

need. Initial setup should be conducted with the conductivity probe wired

to the controller with full length of extension cable (if any) for best results.

1. From the main display, press any key to obtain the main menu. With

the cursor on "Calibrate", press Enter 4.

NOTE

The hold mode screen (top left) will appear if the hold mode was

enabled in Section 5.6. Activate hold mode by pressing Edit 4,

using the arrow key to change Off to On, and then pressing Save

4. The hold mode holds the outputs and relays in a fixed state

to avoid process upsets to a control system. To leave the hold

mode in it's current state, press Cont 3.

2. The display will appear as on the left. Press the down arrow key 3

times to obtain the screen below and press Enter 4 to access the

menu for initial setup.

Note that the menu item shown in reverse video is at the bottom of

the display. This is the visual cue that you have reached the last

menu selection at this level.

Continue the initial setup procedure in Section 4.2

3. To return to the Main Display, keep pressing Exit until the main display appears.

Calibrate sensor

Adjust temperature

Temp compensation

Exit Enter

Temp compensation

Initial setup

Output Trim

Exit Enter

MAIN DISPLAY

Calibrate

Diagnostic variables

Program

Exit Enter

MAIN MENU

Page 19

4.2 ENTERING THE CELL CONSTANT

MODEL 54eC SECTION 4.0

CALIBRATION

Adjust temperature

Temp compensation

Initial setup

Exit Enter

The cell constant should be entered:

• When the unit is installed for the first time

• When the probe is replaced

• During troubleshooting

This procedure sets up the controller for the probe type connected to the

controller. Each type of probe has a specific cell constant:

• Small toroidal (Model 228 or 225) = 3.0

• Large toroidal (Model 226) = 1.0

• Flow-through toroidal (Model 222): 1-inch = 6.0; 2-inch = 4.0

• Low conductivity (contacting sensors) = 0.01 to 10.0

All cell constants can be located on the cable label of the conductivity

probe.

1. With the above screen showing on the display, press Enter 4. To get

to the above screen, see Section 4.1. Some of the following screens

will depend on how the controller was configured in Section 5.5.

2. The screen to the left will be shown.

Press Enter 4 to display or change the cell constant.

3. The display changes as shown on the left. Press Edit 4 to change

the indicated cell constant. If the value is correct, press Exit 1.

NOTE

The cell constant you are about to enter is changed after

the Standardizing Conductivity procedure is performed

(Section 3.6). For inductive sensors and contacting

sensors that only show nominal cell constants, do

not change it back to the value on the probe.

The Edit key changes to the Save key and the 3 key now has become

the Esc(ape) key. Numerical changes can now be made to the cell constant using the four arrow keys. Once the correct cell constant is shown,

press Save 4 to enter the value into memory.

Continue the initial setup by pressing Exit 1 and following directions in

Section 4.3.

NOTE

For sensors that show a "cal constant" on the label,

the actual cell constant can be calculated adding 500

to the cal constant, multiply this value by the nominal cell constant, then divide the result by 1000.

Cell constant

Sensor zero

Exit Enter

Cell constant 03.00

Exit Edit

Cell constant 01.00

Esc Save

13

Page 20

14

4.3 ZEROING THE CONTROLLER

MODEL 54eC SECTION 4.0

CALIBRATION

This procedure is used to compensate for small offsets to the conductivity signal that are present even when there is no conductivity to be measured. This procedure is affected by the length of extension cable and

should always be repeated if any changes in extension cable or sensor

have been made. Electrically connect the conductivity probe as it will

actually be used and place the measuring portion of the probe in air.

1. Obtain the screen above (see Section 4.2 for directions) and press

the down arrow key to highlight "Sensor Zero".

2. Press Enter 4 to access the zero routine.

3. This display indicates the conductivity reading in air. When in the

"Inductive sensor" mode, the reading is displayed to the nearest

µS/cm. When configured in the "Contacting sensor" mode, the

reading is shown to the nearest .001 µS/cm.

Verify that the sensor is actually in air. If the displayed value is not

very close to zero, then press Cont 3 and the controller will establish a

new zero. While setting the zero, the message "please wait" is displayed.

After a few seconds, the display will return to a value of 0 µS/cm and may

then change slightly. A slight variation from zero is to be expected, and

the procedure may be repeated several times, if necessary. A successful zero is indicated with a message of "Sensor zero completed"

An unsuccessful zero will result if the conductivity reading is more than

1000 µS/cm or if the reading is too unstable. The "Zero offset error" message indicates the reading is too high for the zero routine. If repeated

attempts do not result in an acceptable zero, there is a good chance that

there is a wiring problem. Check Section 8.0, Troubleshooting, for help.

Once the reading is close enough to zero, then press Exit 1 and continue initial setup by setting the temperature slope (Section 4.4) or calibrating the temperature reading (Section 4.5).

Cell constant

Sensor zero

Exit Enter

Cell constant

Sensor zero

Exit Enter

5 μS/cm

Sensor Zero

Sensor must be in air

Exit Cont

5 μS/cm

Sensor Zero

Sensor must be in air

please wait

Exit Cont

2 μS/cm

Sensor Zero

Sensor must be in air

Sensor zero completed

Exit Cont

1035 μS/cm

Sensor Zero

Sensor must be in air

Zero offset error

Exit Cont

Page 21

4.4 SELECTING THE TEMPERATURE COMPENSATION TYPE

MODEL 54eC SECTION 4.0

CALIBRATION

Temperature has a significant effect on the conductivity signal. The size

of this effect depends on what kind of liquid is being measured. This procedure is used to adjust the type of compensation used by the controller.

1. Obtain the screen above (see Section 4.1 for procedure) and press

the down arrow key twice to highlight "Temp compensation".

2. Press Enter 4.

3. Press Edit 4 and use up & down arrow keys to select the appropri-

ate temperature compensation: "Linear", "Neutral Salt", or "Cation". If

"Linear" is selected, the linear slope may need adjusting (step 4).

Press 4 again to select.

For an explanation of the temperature compensation, refer to Section 6.0.

4. The compensation is in the form of a constant slope of 0-5%/°C.

Table 4-1 lists some representative values of temperature slopes.The

temperature slope currently being used by the controller is shown

here. If this value is acceptable, press Exit 1. 2%/°C is a good

value for natural waters. For more specialized applications, use the

representative values of Table 4-1. To change the temperature slope,

press Edit 4.

As before, the Edit key changes to the Save key and the F3 key now has

become the Esc(ape) key. Use the four arrow keys to change to the correct temperature slope for your process. Once the correct value is

shown, press Save 4 to enter it into memory. Press Esc 3 to cancel.

Adjust temperature

Temp compensation

Initial setup

Exit Enter

Comp type: Linear

Linear slope: 2.00%/°C

Auto temp: On

Exit Enter

Comp type: Linear

Linear slope: 2.00%/°C

Auto temp: On

Exit Enter

TABLE 4-1. Typical Temperature Slopes

Chemical Slope (%/°C)

Cleaner (alkaline) 2.25

Cleaner (acid) 1.4

Conversion coating 1.6

15

Page 22

16

4.5 TEMPERATURE CALIBRATION

MODEL 54eC SECTION 4.0

CALIBRATION

This procedure is used to ensure an accurate temperature measurement

by the temperature sensor. It enables the controller to display process

temperature accurately as well as to compensate for the effect of temperature on the conductivity reading when the temperature in your

process changes. The following steps should be performed with the sensor in the process or in a grab sample near the operating temperature.

1. Check the controller temperature reading (main display) to make sure

the sensor has acclimated to the process temperature. Compare the

controller temperature to a calibrated temperature reading device.

Proceed to the next step if the reading requires adjustment.

2. From the main display, press any key and then press Enter 4 to

access the Calibrate menu.

NOTE

The hold mode screen may appear (as in Section 4.1) if

the hold mode was enabled in Section 5.6. See note on

Section 4.1 for instructions.

Press the arrow key once to bring up the screen to the left.

Then press Enter 4.

NOTE

(To verify that the controller is using automatic temperature compensation, highlight the "Temp compensation"

menu item and press Enter 4. For more details, see

Section 4.7)

3. Press Edit 4 with this display shown to adjust the temperature. The

screen below will then appear. Using the arrow keys, input the correct temperature value and press Save 4. The controller will enter

the value into memory. To abort the change, press Esc 3.

Afterwards, go to Section 4.6 to standardize the conductivity, otherwise press Exit 1 three times for the main display.

NOTE

If hold mode was turned ON, be certain to install the sensor back in the process and change the setting to OFF to

resume normal operation before leaving the controller.

The Hold screen will appear again before the main display is shown. Follow the same routine as in the Note for

Section 4.1 to turn the Hold Mode Off and then press Exit

1.

Calibrate sensor

Adjust temperature

Temp compensation

Exit Enter

25.1 °C

Adjust temp: 25.1°C

Exit Enter

25.1 °C

Adjust temp: +25.1°C

Exit Enter

Page 23

4.6 CALIBRATING THE SENSOR

MODEL 54eC SECTION 4.0

CALIBRATION

This procedure is used to check and correct the conductivity reading of

the Model 54eC to ensure that the reading is accurate. This is done by

submerging the probe in the sample of known conductivity, then adjusting the displayed value, if necessary, to correspond to the conductivity

value of the sample.

This procedure must always be done after cleaning the probe. The temperature reading must also be checked and standardized if necessary,

prior to performing this procedure (see Section 4.5).

Important: If you are submerging the probe in the commercial conductivity standard solution, follow steps 1 through 3. If you are leaving the probe submerged in the bath and checking conductivity

against a laboratory instrument skip steps 1-3 and start at step 4.

1. Be sure that the probe has been cleaned of heavy deposits of dirt,

oils, or chemical residue.

2. Commercial standards are referenced to a known temperature, for

example, 4000 micromhos at 25°C (77°F). As the temperature of the

standard changes, the conductivity will change. Therefore it is recommended that this procedure be performed at a temperature

between 22 and 28 °C. Be sure the probe has reached a stable

temperature before standardizing.

3. Pour the standard into a clean container. Submerge the clean probe

in the standard solution. Place the probe so that a minimum of 1 in.

of liquid surrounds the probe. Do not allow the probe to be closer

than 1 in. to the sides or bottom of the container. Shake the probe

slightly to eliminate any trapped air bubbles. Observe the displayed

conductivity to determine if the sensor needs to be moved. Go to step

6.

4. Take a grab sample that is as close to the sensor as possible.

5. Using a calibrated laboratory instrument with automatic tempera-

ture compensation, determine the conductivity of the process or

grab sample (as close to actual process temperature as possible).

Continue with this procedure if an adjustment is needed.

Next, the steps below allow you to change the controller's displayed conductivity reading to match the known value of conductivity of your sample.

6. From the main display, press any key to obtain the main menu. With

the cursor on "Calibrate", press Enter 4. Press Enter 4 again

when the screen to the left appears.

NOTE

The Hold Mode screen may appear if the feature was

enabled in Section 5.6. Changing the Hold Mode to ON

holds the outputs in a fixed state, and avoids process

upsets during calibration. Remember to change the Hold

Mode back to OFF when calibration is completed.

Calibrate sensor

Adjust temperature

Temp compensation

Exit Enter

17

Page 24

18

4.6 CALIBRATING THE SENSOR (continued)

4.7 TEMPERATURE COMPENSATION OPTIONS

MODEL 54eC SECTION 4.0

CALIBRATION

7. The conductivity reading in large numbers is the live process reading.

The next line displays the conductivity reading when this screen was

first accessed. Press Edit 4 to perform the standardize.

Use the arrow keys to change the second line standardize value to

the correct conductivity and press Save 4 to complete the procedure. Esc 3 will cancel.

The conductivity reading in the large display will change to the new

value and the cell constant or cell factor will be recalculated. The cell

factor can be viewed under "diagnostic variables" (Section 8.1).

If too large an adjustment is attempted, the controller will display

"standardization error" and no change will be made. See Section 8.0

for troubleshooting.

NOTE

Before exiting the calibration mode, remember to change

the hold mode setting to OFF (if it was turned on in step 3).

Automatic Temperature Compensation is a standard option for conductivity equipment and is used in virtually all conductivity measurement situations. If compensation is not desired, the temperature signal from the

sensor can be ignored by placing the controller in the manual temperature compensation mode.

Manual mode allows the input of a fixed value that will be used instead of

the sensor value. The manual temperature value need only be entered if

the temperature compensation setting is manual. In this case, a value

may be entered between -15 and 200°C (5 and 392°F).

To change these settings, obtain the top screen by pressing Enter 4

when "Calibrate" is highlighted in the main menu and then press the

arrow key b twice. Press Enter 4 again to obtain the lower screen.

Highlight the desired item and press Edit 4 to change the value as

needed. Options are Auto or Manual temperature compensation and the

temperatures within the range listed above. Press Save 4 to save the

change. Esc 3 will cancel the change.

NOTE

When the temperature compensation setting is manual,

all temperature specific faults are disabled.

2002

µS/cm

Calibrate: 2000 μS/cm

Exit Edit

1000

µS/cm

Calibrate: 2000 μS/cm

Esc Save

Adjust temperature

Temp compensation

Initial setup

Exit Enter

Auto temp: On

Manual temp: 25.0°C

Ref temp: 25°C

Exit Edit

Page 25

4.8 HOLD MODE

MODEL 54eC SECTION 4.0

CALIBRATION

Placing the Controller on Hold for Maintenance. Before performing maintenance or repair of the probe, the Controller can be placed in hold (refer

to Section 5.6 to enable this feature) to prevent process upsets while the

reading is off-line. This will place the current outputs into the selected

default states (see Section 5.6). The relays will act as selected in relay

default, see Section 5.7.

Before removing the probe from the process, press any key and then

Enter 4. When the hold mode has been enabled, the hold mode screen

(on the left) will appear prior to calibration. To continue without putting the

controller in hold, simply press Cont 3. To put the controller in hold,

press Edit 4, use the arrow key to change the "Off" to "On" and press

Save 4.

NOTE

When the Hold Mode is Activated (or "On"), the message

"Hold Mode Activated" will always appear on the bottom

line of the display.

Always calibrate after cleaning or repair of the conductivity probe. After

installing the probe back into the process, always change the Hold Mode

setting to OFF.

The instrument’s current outputs may be calibrated (trimmed) if necessary. If either the power board or the CPU board is replaced, the outputs

must be calibrated. To perform this procedure, a calibrated meter must be

connected to the output being calibrated.

To perform an output calibration, from the main display press any key to

obtain the main menu. With the cursor on “calibrate,” press Enter (F4).

With the cursor on “Output trim,” press Enter (F4) again. Select “Trim output 1” or “Trim output 2” as appropriate.

Press Edit (F4) to select Cal point 1 (4 mA expected and simulated) or Cal

point 2 (20 mA expected and simulated). Adjust the Meter value to match

the reading of the calibrated meter connected to the output. Press Enter

(F4) to complete the calibration.

2002

µS/cm

Hold mode: Off

Exit Cont Edit

2002

µS/cm

26.2 12.0mA

Hold Mode Activated

19

4.9 TRIM OUTPUTS

Temp compensation

Initial Setup

Output trim

Exit Enter

Page 26

20

MODEL 54eC SECTION 5.0

SOFTWARE CONFIGURATION

SECTION 5.0

SOFTWARE CONFIGURATION

This section contains the following:

• An introduction to using the configuration process

• A List of Settings for the controller

• Step-by-step instructions and explanations for each

parameter on the List

INTRODUCTION TO CONFIGURATION

The controller arrives from the factory configured to

work with the inductive (toroidal) conductivity sensor. If

the contacting (electrode) type of sensor will be

used, then first go to Section 5.5 and select the

appropriate sensor type. If the measurement type is

changed to Resistivity or one of the % concentration

choices, then some of the default settings shown in

Table 5-1 will also change.

Figure 5-1 is an outline of the menu structure. Before

attempting any changes refer to the parameter setup

list shown in Table 5-1. This table presents a brief

description and the possible options.

The factory setting is listed with a space for the user

setting. It is recommended that the list be carefully

reviewed before any changes are made.

On initial configuration, it is recommended that the

parameters be entered in the order shown on the worksheet. This will reduce the chance of accidentally omitting a needed parameter.

Configuration setups for special applications will be

provided as supplements to this manual.

ITEM CHOICES FACTORY SETTINGS USER SETTINGS

PROGRAM LEVEL (Sections 5.1 - 5.3)

A. Alarm Setpoints (Section 5.2)

1. Alarm 1 (low action) 0 - 2,000 mS/cm 1,000 mS/cm _______

2. Alarm 2 (high action) 0 - 2,000 mS/cm 1,000 mS/cm _______

3. Alarm 3 (high action) 0 - 2,000 mS/cm 1,000 mS/cm _______

B. Output Setpoints (Section 5.1, 5.3)

1. Output 1: 4 mA 0 - 2,000 mS/cm 0 mS/cm _______

2. Output 1: 20 mA 0 - 2,000 mS/cm 1,000 mS/cm _______

3. Output 2: 4 mA –25 - 210 °C 0.0 °C _______

4. Output 2: 20 mA –25 - 210 °C 100.0 °C _______

CONFIGURE LEVEL (Sections 5.5-5.7)

A. Display (Section 5.5)

1. Sensor type Inductive/Contacting Inductive _______

2. Measure Resistivity/ConductivityCustom/

0-15% HCl/98% H2SO4/

0-25% H2SO4/0-12% Na OH Conductivity

3. Temperature Units °C/°F °C _______

4. Output 1 Units mA/% of full scale mA _______

5. Output 2 Units mA/% of full scale mA _______

6. Language

English/Français/Español/Deutsch/Italiano

English _______

7. Display lower left See Section 5.5 Alarm 1 Setpoint _______

8. Display lower right See Section 5.5 Alarm 2 Setpoint _______

9. Display contrast 0-9 (9 darkest) 4 _______

10. Timeout On/Off On _______

11. Timeout Value 1-60 min 10 min _______

12. Polling Address 0-100 0 _______

TABLE 5-1. Conductivity Settings List

Continued on the following page

Page 27

MODEL 54eC SECTION 5.0

SOFTWARE CONFIGURATION

ITEM RANGES FACTORY SETTINGS USER SETTINGS

B. Outputs (Section 5.6)

1. Output 1 Control

(a) Output Measurement Process/Raw cond/Temperature Process (Cond) _______

(b) Output Control Mode Normal/PID Normal _______

2a. Output 1 Setup (Normal)

(a) Current Range 4-20 mA/0-20 mA* 4-20 mA _______

(b) Dampen 0-299 Sec 0 Sec _______

(c) Hold Mode Last value/Fixed value Last value _______

(d) Fixed Hold Value (if (c) Fixed) 0-22 mA 21 mA _______

(e) Fault value 0-22 mA 22 mA _______

2b. Output 1 Setup (PID)

(a) Setpoint 0-2000 mS/cm or 0-200°C 0 mS/cm _______

(b) Proportional 0-299.9% 100.0% _______

(c) Integral 0-2999 sec 0 sec _______

(d) Derivative 0-299.9% 0.0% _______

(e) LRV (4 mA) 0-2000 mS/cm or 0-200°C 0 mS/cm _______

(f) URV (20 mA) 0-2000 mS/cm or 0-200°C 100 mS/cm _______

3. Output 2 Control

(a) Output Measurement Process/Raw cond/Temperature Temperature _______

(b) Output Control Mode Normal/PID Normal _______

4a. Output 2 Setup (Normal)

(a) Current Range 4-20 mA/0-20 mA 4-20 mA _______

(b) Dampen 0-255 Sec 0 Sec _______

(c) Hold Mode Last value/Fixed value Last value _______

(d) Fixed Hold Value (if (c) Fixed) 0-22 mA 21 mA _______

(e) Fault value 0-22 mA 22 mA _______

4b. Output 2 Setup (PID)

(a) Setpoint 0-2000 mS/cm or 0-200°C 0 mS/cm _______

(b) Proportional 0-299.9% 100.0% _______

(c) Integral 0-2999 sec 0 sec _______

(d) Derivative 0-299.9% 0.0% _______

(e) LRV (4 mA) 0-2000 mS/cm or 0-200°C 0 mS/cm _______

(f) URV (20 mA) 0-2000 mS/cm or 0-200°C 100 mS/cm _______

5. Hold (Outputs and Relays) Disable/Enable/ 20 min timeout Disable feature _______

C. Alarms (Section 5.7)

1. Alarm 1 Control

(a) Activation Method Process/Temperature Process _______

(b) Control Mode Normal/TPC Normal _______

2a. Alarm 1 Setup (Normal)

(a) Alarm Logic Low/High/Off High _______

(b) Setpoint 0-2000 mS/cm or 0-200°C 1000 mS _______

(c) Hysteresis (deadband) 0-200 mS/cm or 0-200°C 0 _______

(d) Delay Time 0-99 sec 0 sec _______

(e) Relay Fault Open/Closed/None None _______

2b. Alarm 1 Setup (TPC)

(a) Setpoint 0-2000 mS/cm or 0-200°C 0 mS/cm _______

(b) Proportional 0-299.9% 100.0% _______

(c) Integral 0-2999 sec 0 sec _______

(d) Derivative 0-299.9% 0.0% _______

(e) Time Period 10-2999 sec 30 sec _______

(f) LRV (100% On) 0-2000 mS/cm or 0-200°C 100 mS/cm _______

(g) URV (100% Off) 0-2000 mS/cm or 0-200°C 0 mS/cm _______

(h) Relay Fault None/Open/Closed None _______

TABLE 5-1. Conductivity Settings List (continued)

Continued on the following page

21

* Option-09, HART-enabled version operates at 4-20 mA only on output 1.

Page 28

MODEL 54eC SECTION 5.0

SOFTWARE CONFIGURATION

TABLE 5-1. Conductivity Settings List (continued)

ITEM RANGES FACTORY SETTINGS USER SETTINGS

3. Alarm 2 Control

(a) Alarm logic Process/Temperature Process _______

(b) Control Mode Normal/TPC Normal _______

4a. Alarm 2 Setup (Normal)

(a) Configuration Low/High/Off High _______

(b) Setpoint 0-2000 mS/cm or 0-200°C 1000 mS _______

(c) Hysteresis (deadband) 0-200 mS/cm or 0-200°C 0 _______

(d) Delay Time 0-99 sec 0 sec _______

(e) Relay Fault Open/Closed/None None _______

4b. Alarm 2 Setup (TPC)

(a) Setpoint 0-2000 mS/cm or 0-200°C 0 mS/cm _______

(b) Proportional 0-299.9% 100.0% _______

(c) Integral 0-2999 sec 0 sec _______

(d) Derivative 0-299.9% 0.0% _______

(e) Time Period 10-2999 sec 30 sec _______

(f) LRV (100% On) 0-2000 mS/cm or 0-200°C 100 mS/cm _______

(g) URV (100% Off) 0-2000 mS/cm or 0-200°C 0 mS/cm _______

(h) Relay Fault None/Open/Closed None _______

5. Alarm 3 Control

(a) Alarm Logic Process/Temperature Process _______

(b) Control Mode Normal/TPC Normal _______

6a. Alarm 3 Setup (Normal)

(a) Configuration Low/High/Off High _______

(b) Setpoint 0-2000 mS/cm or 0-200°C 1000 mS _______

(c) Hysteresis (deadband) 0-200 mS/cm or 0-200°C 0 _______

(d) Delay Time 0-99 sec 0 sec _______

(e) Relay Fault Open/Closed/None None _______

6b. Alarm 3 Setup (TPC)

(a) Setpoint 0-2000 mS/cm or 0-200°C 0 mS/cm _______

(b) Proportional 0-299.9% 100.0% _______

(c) Integral 0-2999 sec 0 sec _______

(d) Derivative 0-299.9% 0.0% _______

(e) Time Period 10-2999 sec 30 sec _______

(f) LRV (100% On) 0-2000 mS/cm or 0-200°C 100 mS/cm _______

(g) URV (100% Off) 0-2000 mS/cm or 0-200°C 0 mS/cm _______

(h) Relay Fault None/Open/Closed None _______

7. Alarm 4 Setup

(a) Alarm logic Fault/Off Fault _______

8. Feed Limit Timer

(a) Feed Limit Disable/alarm 3/alarm 2/alarm 1 Disable _______

(b) Timeout Value 0-10,800 sec 3600 sec _______

9. Interval Timer

(a) Timer (selection) Disable/alarm 3/alarm 2/alarm 1 Disable _______

(b) Interval 0-999.9 hr 24.0 hr _______

(c) Repeats 1-60 1 _______

(d) On Time 0-2999 sec 120 sec _______

(e) Off Time 0-2999 sec 1 sec _______

(f) Recovery 0-999 sec 600 sec _______

D. Security (Section 3.6)

1. Lock all 000-999 000 (no security) _______

2. Lock Program (Lock all except Calibrate) 000-999 000 (no security) _______

3. Lock Config. (Lock all except Calibrate,

Output setpoints (PID), Simulated Tests

Alarm Setpoints, and Rerange Outputs) 000-999 000 (no security) _______

E. Special Substance Calibration (Custom Curve) (Section 7.6)

By changing the standard output configuration, you can set up the Model 54eC to perform a wide variety of control and monitoring tasks. The configuration procedures allow you to program the controller to meet the specific control and monitoring requirements of your particular plant. This is done by

recording the desired configuration parameters on the List of Settings Form and then configuring them by using the keys on the controller front panel.

22

Page 29

MODEL 54eC SECTION 5.0

SOFTWARE CONFIGURATION

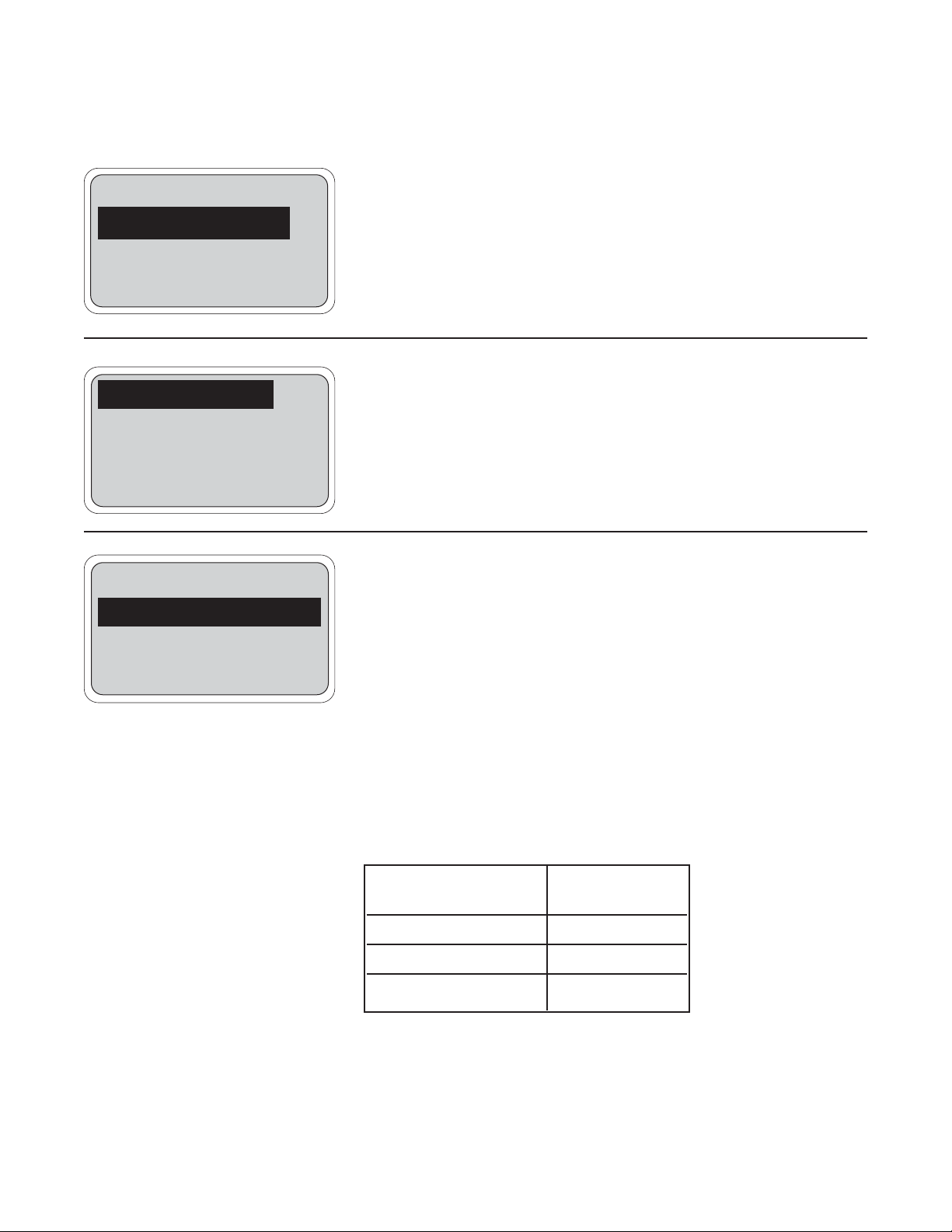

Accessing Calibrate, Program and Configure

Menus. Operating configuration changes are made

at the levels shown in Figure 5-1. Pressing any key

from the main display will access the main menu (top

left).

Level 1 Calibrate. To access calibration selections

from the main menu, with the cursor on "Calibrate"

press Enter 4. Initial Setup, conductivity standardization and temperature adjustments are made at this

level (refer to Section 4.0 for these procedures).

Level 2 Program. To access the program level from

the main menu, place the cursor over "Program" with

the down arrow key. Then press Enter 4. From the

program level menu, changes can be made to the

alarm setpoints and the output setpoints.

Level 3 Configure. To access the configure level

from the main menu place cursor over "Program" and

Enter 4, then place cursor over "Configure" and

Enter 4. This level contains advanced selections,

such as detailed configuration of current outputs,

alarms, and display.

Calibrate

Diagnostic variables

Program

Exit Enter

Alarm setpoints

Output setpoints

Simulated tests

Exit Enter

Display

Outputs

Alarms

Exit More Enter

PROGRAM MENU SECTION

Output Setpoints 5.1

Alarm Setpoints 5.2

Rerange Outputs 5.3

Simulated Tests 5.4

CALIBRATE MENU SECTION

Initial Setup 4.1-4.4

Adjust Temperature 4.5

Standardize Cond 4.6

Temp Compensation 4.7

CONFIGURATION MENU

SECTION

Display 5.5

Outputs 5.6

Alarms 5.7

Security 7.0

Custom Curve 7.6

Security

Custom Curve

Factory defaults

Exit More Enter

Calibrate sensor

Adjust temperature

Temp Compensation

Exit Enter

Adjust temperature

Temp Compensation

Initial setup

Exit Enter

Simulated tests

Configure

Exit Enter

FIGURE 5-1. Outline of Menu Levels

PRESS b TWICE, THEN 4

PRESS

b

PRESS

b

PRESS

4

PRESS

b

PRESS 4

23

Page 30

24

MODEL 54eC SECTION 5.0

SOFTWARE CONFIGURATION

5.1 CHANGING OUTPUT SETPOINTS (PID ONLY)

This section describes how the two output setpoints can be changed.

This selection is only active if the current output control mode has been

set to "PID" (see Section 5.6). For reranging normal outputs, go to

Section 5.3.

1. From the main display, press any key to obtain the main menu. With

the down arrow key b, move the cursor to "Program" and press

Enter 4.

With the cursor on "Output setpoints" (as on the left), press Enter 4.

2. Highlight the desired Output setpoint and press Enter 4.

3. The setpoint now being used is displayed. If the control mode is set

to "Normal", "setpoint" will not be displayed. Press Edit 4 and use

the arrow keys to change the display to the new value.

4 mA is the deviation from setpoint that will result in a 4 mA out. 20

mA is the deviation from setpoint that will result in a 20 mA setpoint.

Highlight the desired item and press Edit 4 and the arrow keys to

change the display to the new value.

Example: A setpoint of 500 μS/cm with a URV of +1000 μS/cm and a

LRV of 0.0 μS/cm. When the conductivity is 1000 μS/cm, the output

will be (1000-500)/(1000-0) = 50% of range (12 mA). If the setpoint is

changed to 1500 μS/cm, the output will be (1500-1000)/(1000-0) =

25% of range (8 mA).

4. Press Save 4 to enter into memory or Esc 3 to abort the change.

The Control setpoint is typically the condition where the current output is

at a minimum. The P and I control calculations use the setpoint to adjust

the current output to the desired level based on the parameters established in Section 5.6.

Alarm setpoints

Output setpoints

Simulated tests

Exit Enter

Output 1 setpoints

Output 2 setpoints

Exit Enter

Setpoint: 1000 μS/cm

4 mA: 0.0000 μS/cm

20 mA: 1000 mS/cm

Exit More Enter

Setpoint: 1000 μS/cm

4 mA: 0.0000 μS/cm

20 mA: 1000 mS/cm

Exit More Enter

Page 31

MODEL 54eC SECTION 5.0

SOFTWARE CONFIGURATION

5.2 CHANGING ALARM SETPOINTS

This section describes how the three alarm setpoints can be changed.

Move the cursor down by pressing the arrow b key.

1. From the main menu, move the cursor down to "Program" and press

Enter 4. On the next display, move the cursor to "Alarm setpoints"

and press Enter 4.

2. Select the desired alarm by moving the cursor down to highlight it.

When the correct alarm is highlighted, press Enter 4 to get to the

adjustment screen.

In this example we have pressed the arrow key down once to access

the alarm 2 setpoint.

NOTE

There are 2 different possible screens at the next point,

depending on whether the alarm has been configured as

normal or TPC.

3a. (normal alarm). The setpoint now being used for this alarm and the

kind of alarm (high or low) are displayed. (If the alarm has been

turned off, then "off" will be displayed instead of "High") The "Enter"

key has now changed to the "Edit" key and will allow changing the

setpoint once the F4 key has been pressed. If the setpoint is ok,

then press Exit 1.

After the Edit 4 key is pressed, use the arrow keys to change the

display to the desired setpoint and press Save 4 to enter into

memory. The plus (+) sign can be changed to a minus sign by pressing the down arrow key when the (+) is highlighted. To abort the

change, press Esc 3 to return to the previous menu.

3b. (TPC alarms only). When the alarm has been configured as TPC,

the setpoint is used for the TPC calculation of how long the alarm

should stay on. The "Enter" key has now changed to the "Edit" key

and will allow changing the setpoint once the F4 key has been

pressed. If the setpoint is ok, then press Exit 1.

After the F4 key is pressed, use the arrow keys to change the display to the desired setpoint and press Save 4 to enter into memory. The plus + sign can be changed to a minus sign by pressing the

down arrow key. To abort the change, press Esc 3 to return to the

previous menu.

NOTE

This alarm setpoint will replace the 0% On point entered

in Section 5.7. The 100% On point will also be moved

to preserve the exact same range of operation. This

kind of action is referred to as a "sliding window". Refer

to Section 6.0 for more technical details.

Alarm setpoints

Output setpoints

Simulated tests

Exit Enter

Alarm 1 setpoint

Alarm 2 setpoint

Alarm 3 setpoint

Exit Enter

Alarm High: 2000 μS/cm

Exit More Enter

Setpoint: 1500 μS/cm

Exit More Enter

25

Page 32

26

MODEL 54eC SECTION 5.0

SOFTWARE CONFIGURATION

5.3 CHANGING OUTPUT SETPOINTS (NORMAL)

This section describes how the 4 (or 0) to 20 mA current outputs can be

reranged. Note that the current outputs can be configured to represent

conductivity (or resistivity), raw conductivity, % concentration, or temperature.

See Section 5.6 for details on configuration.

1. From the main menu, move the cursor down to "Program" and press

Enter 4. On this display, move the cursor to "Output setpoints" and

press Enter 4.

Note: 0-20 mA output range is disabled on output 1 with HARTenabled version (-09 option).

2. Select the desired output by moving the cursor down to highlight it.

When the correct output is highlighted, press Enter 4 to get to the

adjustment screen.

3. This message asks for confirmation of the requested change.

Changes in these settings may degrade process control, so use caution when making changes. Press Cont 3 to continue. Otherwise

press Abort 1.

This screen allows changing the setpoints for output 1. A similar screen

is available for output 2. The live current output now being transmitted

by the controller is shown on the third line.

4. Press Edit 4 to make changes in the setpoints. The Edit key

changes to a Save key and the F3 key becomes active as an Esc

key. Use the arrow keys to make the display read the desired values for the high and low current output limits. When done, press

Save 4 to enter the changes into memory. Press Esc 3 to cancel changes.

NOTE

Outputs that have been configured as 0-20 mA in

Section 5.6, will show 0 mA instead of 4 mA on the top

line. Outputs that are based on temperature or resistivity values will show matching units such as °C or MΩ-cm.

See Section 5.6 for output configuration.

Alarm setpoints

Output setpoints

Simulated tests

Exit Enter

Output 1 setpoints

Output 2 setpoints

Exit Enter

4 mA: 0 mS/cm

20 mA: 2000 mS/cm

Output 1: 12.00 mA

Exit Edit

CAUTION: Current output 1 will be affected.

Abort Cont

4 mA: +0000 mS/cm

20 mA: 2000 mS/cm

Output 1: 12.00 mA

Esc Save

Page 33

MODEL 54eC SECTION 5.0

SOFTWARE CONFIGURATION

5.4 TESTING OUTPUTS AND ALARMS

This section describes how the current outputs and alarm relays can be

manually set for the purposes of checking devices such as valves,

pumps, or recorders.

1. From the main menu, move the cursor down to "Program" and press

Enter 4. On this display, move the cursor to "Simulated tests" and

press Enter 4.

2. At this point there are six separate screens for testing each of the

current outputs and each of the alarm relays. Highlight the desired

item by pressing the arrow b t keys as needed.

When the desired item is highlighted, press Enter 4 to continue.

Go to step 3a for outputs and 3b for alarms.

NOTE

A cautionary message will appear to warn that the output or alarm that was selected will be changed by the following action. Be sure to alert plant personnel that

these changes are simulated and do not represent a

change in the actual process. Press Cont 3 to continue or Abort 1 to cancel the simulation.

3a. The output is now being simulated. In the example to the left, out-

put 1 has been set to 10.00 mA. The output will remain at 10.00 mA

until either Exit 1 (or Edit 4 see below) is pressed or the test is

concluded by timeout. The default value for the timeout is 10 minutes, so after 10 minutes, the output would go back to normal operation. To configure the timeout option, see Section 5.5.

If the displayed current is not the desired value, press the Edit 4

key and the next screen will allow changing the value. Use the arrow

keys to change the display as needed, and press Test 4 to use that

value. Press Esc 3 to cancel the change in the value and continue simulating the previous current.

Output setpoints

Simulated tests

Configure

Exit Enter

Test output 1

Test output 2

Test alarm 1

Exit Enter

Test alarm 2

Test alarm 3

Test alarm 4

Exit Edit

27

Page 34

28

MODEL 54eC SECTION 5.0

SOFTWARE CONFIGURATION

5.4 TESTING OUTPUTS AND ALARMS (continued)

3b. The alarm relay is now being simulated. In the example to the left,

alarm 1 has been set to Open. This means that the relay is not energized (i.e. off). The alarm will remain open until either Exit 1 or Edit

4 is pressed or the test is concluded by timeout. The default value

for the timeout is 10 minutes, so after 10 minutes, the alarm would

go back to normal operation and the display will return to the main

menu. To configure the timeout option, see Section 5.5.

If the displayed alarm action is not as desired, press the Edit 4 key

and the next screen will allow changing it. Use the arrow keys to

change the display as needed, and press Test 4 to enter the

change. Press Esc 3 to cancel the change in the value and continue simulating the previous action.

NOTE

Alarm relays may be simulated in the energized

(Closed) position or the de-energized (Open) position.

Test alarm 1: Open

Exit More Enter

Test alarm 1: Open

Simulating alarm1

Exit Edit

Page 35

MODEL 54eC SECTION 5.0

SOFTWARE CONFIGURATION

5.5 CHOOSING DISPLAY OPTIONS

This section describes the options available for the changing of engineering units and variables on the main display.

1. From the main menu, move the cursor down to "Program" and press

Enter 4. From the program menu, move the cursor down using the

arrow key to highlight "Configure" and press Enter 4.

The first configuration menu is displayed. With the cursor on "Display"

press Enter 4.

2. Menu Item Options

Sensor Inductive/Contacting

Measure Conductivity/Resistivity/Custom%/

0-15% HCl/98% H2SO4/

25% H2SO4/ 0-12% NaOH

Temperature units °C/°F

The values now being used by the controller are displayed. To

change any of these items, use the arrow key to highlight the desired

item and press Edit 4. Use the arrow keys to make the change and

press Save 4 to enter the change into memory. Applications using

the toroidal probe should always use the "Inductive" setting.

Applications using probes with exposed electrodes should use the

"Contacting" setting. Note that all these measure choices are referred

to as "Process" by the controller and in other places in this manual.

See Sections 6.0 and 7.0 for measure explanation.

MEASURE WARNING