Page 1

Quick Start Guide

00825-0800-4408, Rev AA

February 2020

Rosemount™ 5408 Level Transmitter

with Modbus® Protocol

Page 2

Quick Start Guide February 2020

Contents

About this guide...........................................................................................................................3

Confirm approval type..................................................................................................................5

Components of the parabolic antenna......................................................................................... 6

Mount the transmitter..................................................................................................................7

Adjust the inclination of the antenna..........................................................................................11

Plug and seal the air purge entry.................................................................................................14

Adjust display orientation (optional).......................................................................................... 15

Prepare the electrical connections..............................................................................................16

Connect wiring and power up.....................................................................................................19

Performance specifications........................................................................................................ 23

Functional specifications............................................................................................................ 25

Physical specifications................................................................................................................ 27

2 Rosemount 5408 Level Transmitter

Page 3

February 2020 Quick Start Guide

1 About this guide

This Quick Start Guide provides basic guidelines for the Rosemount 5408

Level Transmitter with Modbus® Protocol.

WARNING

Failure to follow safe installation and servicing guidelines could result in

death or serious injury.

• Ensure the transmitter is installed by qualified personnel and in

accordance with applicable code of practice.

• Use the equipment only as specified in this Quick Start Guide. Failure to

do so may impair the protection provided by the equipment.

• For installations in hazardous locations, the transmitter must be installed

according to the Rosemount 5408 Product Certifications document and

System Control Drawing (D7000005-811).

• Repair, e.g. substitution of components, etc. may jeopardize safety and

is under no circumstances allowed.

Explosions could result in death or serious injury.

• Verify that the operating atmosphere of the transmitter is consistent

with the appropriate hazardous locations certifications.

• Before connecting a handheld communicator in an explosive

atmosphere, ensure the instruments are installed in accordance with

intrinsically safe or non-incendive field wiring practices.

• In Explosion-proof/Flameproof installations, do not remove the

transmitter covers when power is applied to the unit.

• Both transmitter covers must be fully engaged to meet Explosion-proof/

Flameproof requirements.

Electrical shock could cause death or serious injury.

• In Explosion-proof/Flameproof installations, avoid contact with the leads

and terminals. High voltage that may be present on leads can cause

electrical shock.

• Ensure the mains power to the transmitter is off and the lines to any

other external power source are disconnected or not powered while

wiring the transmitter.

Quick Start Guide 3

Page 4

Quick Start Guide February 2020

WARNING

Process leaks could result in death or serious injury.

• Ensure that the transmitter is handled carefully. If the process seal is

damaged, gas might escape from the tank.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

CAUTION

Hot surfaces

The flange and process seal may be hot at high process temperatures. Allow

to cool before servicing.

4 Rosemount 5408 Level Transmitter

Page 5

February 2020 Quick Start Guide

2 Confirm approval type

For hazardous locations transmitters labeled with multiple approval types:

Procedure

Permanently mark the checkbox of the selected approval type(s).

Figure 2-1: Label with Multiple Approval Types

Quick Start Guide 5

Page 6

2x

[

(

[

*

[

'

[

&

[

%

[

$

[

)

Quick Start Guide February 2020

3 Components of the parabolic antenna

3.1 Components of the threaded version

Figure 3-1: Components

A. Antenna

B. Purge plug kit (blind plug and bonded seal)

C. Threaded sleeve

D. M20 adapter

E. Lock nut BSPP (G) 3½-in.

F. Antenna adapter with ball joint

G. O-ring

6 Rosemount 5408 Level Transmitter

Page 7

B

A

February 2020 Quick Start Guide

4 Mount the transmitter

4.1 Mount the threaded version

Procedure

1. Remove the lock nut.

2. Mount the O-ring.

3. Mount the antenna adapter on the mounting flange plate. Ensure the

antenna adapter fits tightly to the mounting flange plate.

A. Ø 3.98 ± 0.02 in. (Ø 101 ± 0.6 mm) or G 3½-in.

B. Max. 0.59 in. (15 mm)

Quick Start Guide 7

Page 8

27 mm

Torque 180 in-lb (20 N-m)

Quick Start Guide February 2020

4. Remove the M20 adapter and visually inspect the O-rings for damage

and dirt.

5. Carefully insert the antenna.

6. Secure the antenna.

8 Rosemount 5408 Level Transmitter

Page 9

H2 mm

Torque 5 in-lb (0.5 N-m)

February 2020 Quick Start Guide

7. Tighten the set screw.

8. Position the antenna assembly onto the mounting frame.

Example

Deck/platform mounted

9. Tighten the bolts and nuts.

It is recommended that insulating bushes are fitted to the mounting

bolts.

Quick Start Guide 9

Page 10

Quick Start Guide February 2020

Postrequisites

1. Adjust the inclination of the antenna (see Adjust the inclination of

the antenna).

2. Plug and seal the air purge entry (see Plug and seal the air purge

entry).

10 Rosemount 5408 Level Transmitter

Page 11

H6 mm

February 2020 Quick Start Guide

5 Adjust the inclination of the antenna

Prerequisites

WARNING

Contents may be under pressure.

• Do not loosen the M8 screws while in operation. Attempting to do so

may release pressurized gases, resulting in serious injury or death.

Procedure

1. Loosen the M8 screws until the antenna can rotate smoothly.

2. Rotate the antenna so the air purge connection is directed toward

the host platform/structure.

Quick Start Guide 11

Page 12

H6 mm

Torque 65 in-lb (7 N-m)

Quick Start Guide February 2020

3. Place the supplied circular level on top of the antenna assembly.

4. Adjust the inclination of the antenna.

5. Gradually tighten the M8 screws.

12 Rosemount 5408 Level Transmitter

Page 13

Torque 355 in-lb (40 N-m)

60 mm

36 mm

February 2020 Quick Start Guide

6. Remove the circular level.

7. Mount the transmitter head.

Align the marking on the sensor module with the air purge

connection.

Quick Start Guide 13

Page 14

17 mm

Torque 180 in-lb (20 N-m)

Quick Start Guide February 2020

6 Plug and seal the air purge entry

Procedure

Plug and seal the entry with the supplied blind plug and bonded seal.

14 Rosemount 5408 Level Transmitter

Page 15

Torque 30 in-lb (3 N-m)

H3/32 in.

February 2020 Quick Start Guide

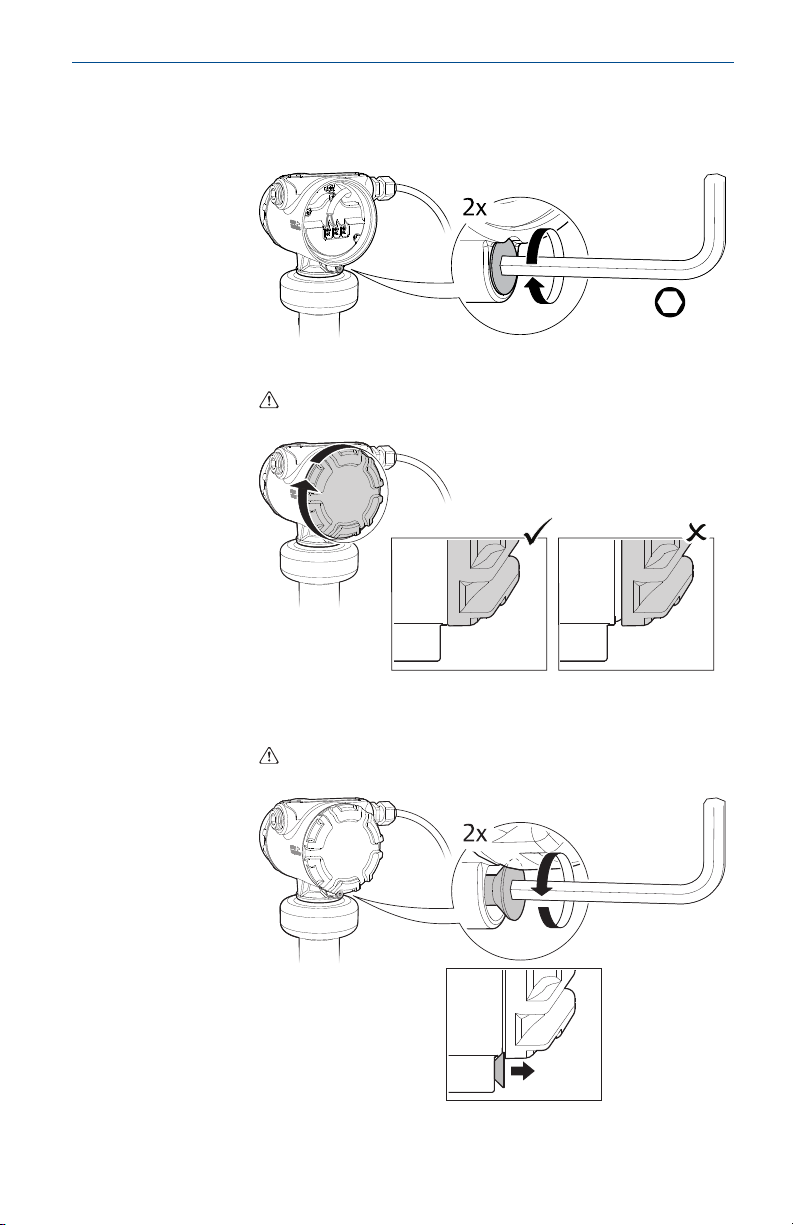

7 Adjust display orientation (optional)

To improve field access to wiring or to better view the optional LCD display:

Prerequisites

Note

In high vibration applications, the transmitter housing must be fully

engaged into the sensor module to meet the vibration test specifications.

This is achieved by rotating the transmitter housing clockwise to thread

limit.

Procedure

1. Loosen the set screw until the transmitter housing can rotate

smoothly.

2. First, rotate the housing clockwise to the desired location. If the

desired location cannot be achieved due to thread limit, rotate the

housing counterclockwise to the desired location (up to 360° from

thread limit).

3. Re-tighten the set screw.

Figure 7-1: Rotate the Transmitter Housing

Quick Start Guide 15

Page 16

$

%

Quick Start Guide February 2020

8 Prepare the electrical connections

8.1 Cable selection

RS-485 bus

Power

supply

Use wire rated at least 5 °C above maximum ambient temperature.

Use shielded twisted pair wiring with a characteristic

impedance of 120 Ω (typically 24 AWG).

Use 24-14 AWG wire. Twisted pairs and shielded wiring are

recommended for environments with high EMI

(electromagnetic interference).

8.2 Cable gland/conduit

For explosion-proof/flameproof installations, only use cable glands or

conduit entry devices certified explosion-proof or flameproof.

8.3 Grounding

Make sure grounding is done according to national and local electrical

codes. Failure to do so may impair the protection provided by the

equipment.

Transmitter housing

The most effective grounding method is direct connection to earth ground

with minimal impedance. There are two grounding screw connections

provided (see Figure 8-1).

Figure 8-1: Ground Screws

A. Internal ground screw

B. External ground screw

Cable shield grounding

Make sure the instrument cable shield is:

• Trimmed close and insulated from touching the transmitter housing.

• Connected to a good earth ground at the power supply end.

16 Rosemount 5408 Level Transmitter

Page 17

C

C

B

February 2020 Quick Start Guide

Figure 8-2: Cable Shield

A. Insulate shield and drain wire

B. Minimize distance

C. Connect drain wire to a good earth ground

Note

Do not ground the shield and its drain wire at the transmitter. If the cable

shield touches the transmitter housing, it can create ground loops and

interfere with communications.

Common signal reference ground for RS-485

Best practice is to connect a third reference wire to the "COM" terminal

(common signal reference ground).

If a common reference wire is not used, then the "COM" terminal should be

connected to the “–“ power terminal. The common mode difference

between the host RS-485 and the negative power supply must be between

-7 V and +12 V.

8.4

Quick Start Guide 17

Power supply

The transmitter operates on 9-36 Vdc at the transmitter terminals.

Page 18

H

I

J

G

F

A

B

D

120Ω

-

+

E C

D

MA

MB

COM

-

+

Quick Start Guide February 2020

8.5 Wiring diagram

Figure 8-3: Modbus® RS-485 Communication

A. "A" line

B. "B" line

C. Modbus RS-485 host

D. Common signal reference ground

E. Power supply

F. Modbus RS-485 B connection (RX/TX+)

G. Modbus RS-485 A connection (RX/TX-)

H. Positive power input terminal

(1) The designation of the connectors do not follow the EIA-485 standard, which states

I. Negative power input terminal

J. Built-in 120 Ω termination resistor (connect jumper if last device on the

bus)

(1)

(1)

that RX/TX- should be referred to as 'A' and RX/TX+ as 'B'.

18 Rosemount 5408 Level Transmitter

Page 19

February 2020 Quick Start Guide

9 Connect wiring and power up

Procedure

1. Verify the power supply is disconnected.

2. Remove the cover.

3. Remove the plastic plugs.

4. Pull the cable through the cable gland/conduit.

(2)

Identification of thread size and type:

(2) Unless marked, the conduit/cable entries in the transmitter housing use a ½–14 NPT

thread form.

Quick Start Guide 19

Page 20

Torque 7 in-lb (0.8 N-m)

Quick Start Guide February 2020

5. Connect the cable wires (see Wiring diagram).

6. Ensure proper grounding (see Grounding).

7. Tighten the cable gland.

Apply PTFE tape or other sealant to the threads.

Note

Make sure to arrange the wiring with a drip loop.

8. Seal any unused ports with the enclosed metal plug.

Apply PTFE tape or other sealant to the threads.

20 Rosemount 5408 Level Transmitter

Page 21

H2.5 mm

February 2020 Quick Start Guide

9. Attach and tighten the cover.

a) Verify the cover jam screw is completely threaded into the

housing.

b) Attach and tighten the cover.

Make sure the cover is fully engaged. There should be no

gap between the cover and the housing.

c) Turn the jam screw counterclockwise until it contacts the

cover.

Required for explosion-proof/flameproof installations

only.

Quick Start Guide 21

Page 22

Quick Start Guide February 2020

d) Turn the jam screw an additional ½ turn counterclockwise to

secure the cover.

10. Connect the power supply.

22 Rosemount 5408 Level Transmitter

Page 23

February 2020 Quick Start Guide

10 Performance specifications

10.1 General

10.1.1 Reference conditions

• Measurement target: Stationary metal plate, no disturbing objects

• Temperature: 59 to 77 °F (15 to 25 °C)

• Ambient pressure: 14 to 15 psi (960 to1060 mbar)

• Relative humidity: 25-75%

• Damping: Default value, 0 s

10.1.2 Instrument accuracy (under reference conditions)

Range < 130 ft. (40 m)

Range > 130 ft. (40 m)

10.1.3 Measuring range

10 to 262 ft. (3 to 80 m)

10.1.4 Repeatability

±0.04 in. (±1 mm)

±0.12 in. (±3 mm)

±0.25 in. (±6 mm)

(3)

(3)

10.1.5 Ambient temperature effect

±0.04 in. (±1 mm)/10 K

(4)

10.1.6 Sensor update rate

Measuring rate

10 Hz

Burst rate

5 Hz (or configurable 2 to 10 Hz)

10.1.7 Beam width

4.5°

(3)

Refers to inaccuracy according to IEC 60770-1 when excluding installation

dependent offset. See the IEC 60770-1 standard for a definition of radar specific

performance parameters and if applicable corresponding test procedures.

(4)

Ambient temperature effect specification valid over temperature range -40 °F to 176

°F (-40 °C to 80 °C).

Quick Start Guide 23

Page 24

Quick Start Guide February 2020

10.2 Environment

10.2.1 Vibration resistance

• 2 g at 10-180 Hz according to IEC 61298-3, level “field with general

application”

• IACS UR E10 test 7

For compliance with these standards, the transmitter housing must be fully

engaged into the sensor module. This is achieved by rotating the transmitter

housing clockwise to thread limit.

10.2.2 Electromagnetic compatibility (EMC)

• EMC Directive (2014/30/EU): EN 61326-1

• EN 61326-2-3

• NAMUR recommendations NE21

Tests are performed with the recommended electrical wiring using a third

wire interconnecting the COM terminals of the RS-485 network, termination

at each end, and good protective earth.

10.2.3 Built-in lightning protection

EN 61326, IEC 61000-4-5, level 6kV

(5)

10.2.4 Radio approvals

• Radio Equipment Directive (2014/53/EU): ETSI EN 302 372, ETSI EN 302

729 and EN 62479

• Part 15 of the FCC Rules

• Industry Canada RSS 211

(5) In challenging applications where the dynamic of the transmitter sensitivity is

utilized by multiple factors such as small aperture antenna, very low product

dielectric constant and/or turbulent surface, the margin for additional influence due

to extreme EMC may be limited.

24 Rosemount 5408 Level Transmitter

Page 25

February 2020 Quick Start Guide

11 Functional specifications

11.1 General

11.1.1 Field of application

Measurement of waves, sea level and air gap in offshore, maritime and

coastal environments.

11.1.2 Measurement principle

Frequency Modulated Continuous Wave (FMCW)

11.1.3 Frequency range

24.05 to 26.5 GHz

11.1.4 Maximum output power

-5 dBm (0.32 mW)

11.1.5 Power consumption

Max. 1 W, average < 0.4 W

11.1.6 Humidity

0 - 100% relative humidity, non-condensing

11.1.7 Turn-on time

(6)

< 10 s

11.2

Quick Start Guide 25

Temperature limits

Verify that the operating atmosphere of the transmitter housing is

consistent with the appropriate hazardous locations certifications, see the

Product Certifications document.

Table 11-1: Ambient Temperature Limits

Description Operating limit Storage limit

Without LCD

display

With LCD

(1)

display

(1) LCD display may not be readable and LCD display updates will be slower at

temperatures below -4 °F (-20 °C).

(6)

Time from when power is applied to the transmitter until performance is within

specifications.

-40 °F to 176 °F (-40 °C to 80 °C)

-58 °F to 176 °F (-50 °C to 80 °C)

-40 °F to 176 °F (-40 °C to 80 °C)

Page 26

104 (40)

176 (80)

482

(250)

-76

(-60)

248

(120)

-40 (-40)

A

B

Quick Start Guide February 2020

The ambient temperature limits may be further restricted by the process

temperature as described by Figure 11-1.

Figure 11-1: Ambient Temperature vs. Process Temperature

A. Ambient temperature °F (°C)

B. Process temperature °F (°C)

Aside from ambient temperature variations, heat from the process may be

transferred to the transmitter housing. Being exposed to a high process

temperature without extra cooling for an extended period of time may

cause the electronics temperature to exceed the allowed limit and thereby

affect the transmitter's performance and reliability. The latter are potential

risks whenever a transmitter has shut down due to high electronics

temperature. The transmitter will warn about the electronics temperature

being out of limits.

26 Rosemount 5408 Level Transmitter

Page 27

February 2020 Quick Start Guide

12 Physical specifications

12.1 Housing and enclosure

12.1.1 Electrical connections

Two cable/conduit entries (½-14 NPT or M20 x 1.5)

Optional adapters: M12 4-pin male eurofast connector or A size Mini 4-pin

male minifast connector

12.1.2 Materials

• Electronics housing: Stainless Steel Grade CF-8M (ASTM A743)

• Sensor module: 316L SST

12.1.3 Weight

• Stainless steel housing: 10.0 lb (4.5 kg)

• Parabolic antenna assembly: 8.8 lb (4.0 kg)

12.1.4 Ingress protection

IP 66/67/68

(9)

and NEMA® 4X

12.2 Material exposed to tank atmosphere

(7)

(8)

Parabolic antenna

• 316/316L SST (EN 1.4404)

• PTFE fluoropolymer

• FVMQ fluorosilicone (O-ring)

(7) Fully functional transmitter with sensor module, housing, terminal block, LCD

display, and covers.

(8) Weight does not include mounting flange plate.

(9)

The transmitter meets IP 68 at 9.8 ft. (3 m) for 30 minutes.

Quick Start Guide 27

Page 28

*00825-0800-4408*

00825-0800-4408, Rev. AA

Quick Start Guide

February 2020

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

Manufactured by

Rosemount Tank Radar AB

Layoutvägen 1

S-435 33 Mölnlycke

Sweden

+46 31 337 00 00

+46 31 25 30 22

Linkedin.com/company/Emerson-

Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/

RosemountMeasurement

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

©

2020 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric

Co. Rosemount is a mark of one of the Emerson

family of companies. All other marks are the

property of their respective owners.

Loading...

Loading...