Page 1

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Two-wire Radar Level Transmitter with FOUNDATION™ Fieldbus

www.rosemount.com

Page 2

Page 3

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Rosemount 5400 Series

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers.

Customer Central: 1-800-999-9307(7:00 a.m. to 7:00 p.m. CST)

Technical support, quoting, and order-related questions.

North American Response Center:

Equipment service needs.

1-800-654-7768 (24 hours a day – Includes Canada)

For equipment service or support needs outside the United States, contact your local

Rosemount representative.

NOTICE

There are no health hazards from the Rosemount 5400 Series transmitter. The microwave

power density in the tank is only a small fraction of the allowed power density according to

international standards.

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Rosemount

Sales Representative.

This product is designed to meet FCC and R&TTE requirements.

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

Rosemount 5400 Series Radar Transmitter may be protected by one or more U.S. Patents pending and foreign

patents pending.

Rosemount and the Rosemount logotype are registered trademarks of Rosemount Inc.

HART is a registered trademark of the HART Communication Foundation.

Teflon, VITON, and Kalrez are registered trademarks of DuPont Performance Elastomers.

AMS Suite is a trademark of Emerson Process Management.

F

OUNDATION is a trademark of the Fieldbus Foundation.

Cover Photo: 5400_08

www.rosemount.com

Page 4

Page 5

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Table of Contents

SECTION 1

Introduction

SECTION 2

Transmitter Overview

SECTION 3

Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Components of the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

System Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Process Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Dielectric constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Foam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Turbulence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Temperature/Pressure/

Density and Vapor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Tank Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Antenna Selection Guide/Measuring Range . . . . . . . . . . . . . . . . . . . . 2-5

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Socket Recommendation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Free Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Recommended Mounting Position . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Beam Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Vessel Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Disturbing objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Mounting in Pipes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Recommendations for pipe installations . . . . . . . . . . . . . . . . . 3-11

Mounting in Bypass Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Cable/conduit entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Cable Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Hazardous Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

External Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Connecting the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Shield Wire Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Connecting Fieldbus Devices . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Non-Intrinsically Safe Power Supply . . . . . . . . . . . . . . . . . . . . . . 3-17

Intrinsically Safe Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

www.rosemount.com

Page 6

Rosemount 5400 Series

Reference Manual

00809-0100-4032, Rev AA

November 2005

SECTION 4

Configuration/Start-Up

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Assigning Device Tag and Node Address . . . . . . . . . . . . . . . . . . . 4-3

Foundation Fieldbus Block Operation . . . . . . . . . . . . . . . . . . . . . . 4-3

Level Transducer Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Register Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Advanced ConfigurationTransducer Block . . . . . . . . . . . . . . . . 4-3

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Analog Input Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Echo Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Advanced Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Configuration Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Tank Geometry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Tank Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Tank Type and Tank Bottom Type . . . . . . . . . . . . . . . . . . . . . . 4-7

Pipe Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Dead Zone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Process Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Rapid Level Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Turbulent Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Foam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Solid Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Product Dielectric Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Strapping Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Echo Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Amplitude Threshold Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Registration of False Echoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Configuration Using DeltaV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Advanced Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Amplitude Threshold Curve. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

False Echo Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Configuration Using Rosemount Radar Master. . . . . . . . . . . . . . . . . 4-18

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Help In RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Installing the RRM Software for Foundation Fieldbus . . . . . . . . . 4-19

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Specifying Measurement Units. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Guided Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Using the Setup Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Configure the AI Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

CHANNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

L_TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

XD_SCALE and OUT_SCALE . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Engineering Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Application Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

TOC-2

Page 7

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Radar Level Transmitter, Level Value . . . . . . . . . . . . . . . . . . . . . 4-30

Situation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Radar Level Gauge, Level value in percent (%). . . . . . . . . . . . . . 4-31

Situation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

SECTION 5

Operation

SECTION 6

Service and

Troubleshooting

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Viewing Measurement Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Using the Display Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Specifying Display Panel Variables . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Using a Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Using Rosemount Radar Master (RRM) . . . . . . . . . . . . . . . . . . 5-3

Using DeltaV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Viewing Measurement Data in RRM . . . . . . . . . . . . . . . . . . . . . . . 5-5

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Viewing Input and Holding Registers . . . . . . . . . . . . . . . . . . . . . . . 6-2

Radar Master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

DeltaV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Logging Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Backing Up the Transmitter Configuration . . . . . . . . . . . . . . . . . . . 6-5

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Rosemount Radar Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

DeltaV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Using the Spectrum Plot in RRM . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Surface Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Peak Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Record Tank Spectra . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Configuration Mode Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

File Mode Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Reset to Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Rosemount Radar Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

DeltaV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Surface Search. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

DeltaV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Using the Simulation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

DeltaV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Enter Service Mode in RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Write Protecting a Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

DeltaV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Block Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Analog Input (AI) Function Block . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Device Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

TOC-3

Page 8

Rosemount 5400 Series

Measurement Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Volume Calculation Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Application Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Reference Manual

00809-0100-4032, Rev AA

November 2005

APPENDIX A

Reference Data

APPENDIX B

Product Certifications

APPENDIX C

Advanced Configuration

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Process Temperature and Pressure Rating . . . . . . . . . . . . . . . . . .A-4

Working Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Temperature restrictions due to O-ring selection . . . . . . . . . . .A-4

Pressure restrictions due to flange selection. . . . . . . . . . . . . . . A-4

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

EU Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

European ATEX Directive Information. . . . . . . . . . . . . . . . . . . . . . . . . B-3

Intrinsic Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Special Conditions for Safe Use (X):. . . . . . . . . . . . . . . . . . . . . B-3

Special Conditions for Safe Use (X):. . . . . . . . . . . . . . . . . . . . . B-4

Flameproof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Special Conditions for Safe Use (X):. . . . . . . . . . . . . . . . . . . . . B-5

Hazardous Locations Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Factory Mutual (FM) Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Canadian Standards Association (CSA) Approval . . . . . . . . . . . . . B-8

Approval Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Tank Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Distance Offset (G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Minimum Level Offset (C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Hold Off Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Calibration Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Advanced Transmitter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Antenna Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Tank Connection Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Empty Tank Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Empty Tank Detection Area . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Bottom Echo Visible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Tank Bottom Projection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Extra Echo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Level Alarm is not set when Tank is Empty. . . . . . . . . . . . . . . .C-4

Full Tank Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Full Tank Detection Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Level above Hold Off Distance Possible . . . . . . . . . . . . . . . . . .C-4

Level Alarm is Not Set when Tank is Full . . . . . . . . . . . . . . . . .C-4

Double Bounce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Surface Echo Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Slow Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Slow Search Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Double Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Upper Product Dielectric Constant . . . . . . . . . . . . . . . . . . . . . .C-5

Select Lower Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Echo Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Close Distance Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

TOC-4

Page 9

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Filter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Damping Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Activate Jump Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Advanced Functions in RRM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Empty Tank Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Bottom Echo Visible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Empty Tank Detection Area . . . . . . . . . . . . . . . . . . . . . . . . . . .C-8

Extra Echo Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9

Full Tank Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-10

Double Bounce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-11

APPENDIX D

Level Transducer Block

APPENDIX E

Register Transducer

Block

APPENDIX F

Advanced Configuration

Transducer Block

APPENDIX G

Resource Transducer

Block

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Channel Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Parameters and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Supported Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-7

Unit Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-7

Diagnostics Device Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Register Access Transducer Block Parameters. . . . . . . . . . . . . . . E-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Advanced Configuration Transducer Block Parameters. . . . . . . . . F-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1

Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1

Parameters and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1

PlantWeb

Alarm Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-7

Process Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-7

Recommended Actions for PlantWeb Alerts . . . . . . . . . . . . . . . . .G-8

™

Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-5

FAILED_ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-5

MAINT_ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-5

Advisory Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-6

RECOMMENDED_ACTION . . . . . . . . . . . . . . . . . . . . . . . . . . .G-8

APPENDIX H

Analog-Input Block

Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-3

Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-4

Signal Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-5

Direct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-5

Indirect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-5

Indirect Square Root . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-5

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-6

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-6

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-7

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-8

Advanced Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-8

TOC-5

Page 10

Rosemount 5400 Series

Configure the AI Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-9

Reference Manual

00809-0100-4032, Rev AA

November 2005

CHANNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-9

L_TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-9

XD_SCALE and OUT_SCALE . . . . . . . . . . . . . . . . . . . . . . . .H-10

TOC-6

Page 11

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Section 1 Introduction

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

SAFETY MESSAGES Procedures and instructions in this manual may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the safety messages listed at the beginning of each section before performing

an operation preceded by this symbol.

Failure to follow these installation guidelines could result in death or serious

injury.

• Make sure only qualified personnel perform the installation.

• Use the equipment only as specified in this manual. Failure to do so may

impair the protection provided by the equipment.

Explosions could result in death or serious injury.

• Verify that the operating environment of the transmitter is consistent with the

appropriate hazardous locations certifications.

• Before powering a F

make sure the instruments in the loop are installed in accordance with

intrinsically safe or non-incendive field wiring practices.

Electrical shock could cause death or serious injury.

• Use extreme caution when making contact with the leads and terminals.

OUNDATION fieldbus segment in an explosive atmosphere,

www.rosemount.com

Any substitution of non-recognized parts may jeopardize safety. Repair, e.g. substitution

of components etc., may also jeopardize safety and is under no circumstances allowed.

Page 12

Reference Manual

00809-0100-4032, Rev AA

Rosemount 5400 Series

November 2005

MANUAL OVERVIEW This manual provides installation, configuration and maintenance information

for the Rosemount 5400 Series Radar Transmitter.

Section 2: Transmitter Overview

• Theory of Operation

• Descripton of the transmitter

• Process and vessel characteristics

Section 3: Installation

• Mounting considerations

• Mechanical installation

• Electrical installation

Section 4: Configuration/Start-Up

• Configuration instructions

• Configuration using DeltaV

• Configuration using the RRM software

Section 5: Operation

• Viewing measurement data with a Display panel

• Viewing measurement data with Rosemount Radar Master

Section 6: Service and Troubleshooting

• Service Functions

• Error and Warning Codes

• Communication Errors

• Troubleshooting

Appendix A: Reference Data

• Specifications

• Dimensional Drawings

• Ordering Information

Appendix B: Product Certifications

• Examples of labels

• European ATEX Directive information

• FM approvals

• CSA approvals

•Drawings

1-2

Appendix C: Advanced Configuration

• Advanced Tank Geometry

• Advanced Transmitter Configuration

Appendix D: Level Transducer Block

Describes the operation and parameters of the Level transducer block.

Appendix E: Register Transducer Block

Describes the operation and parameters of the Register transducer block.

Page 13

Reference Manual

00809-0100-4032, Rev AA

November 2005

Appendix F: Advanced Configuration Transducer Block

Describes the operation and parameters of the Advanced Configuration

transducer block.

Appendix G: Resource Transducer Block

Describes the operation and parameters of the Resource transducer

block.

Appendix H: Analog-Input Transducer Block

Describes the operation and parameters of the Analog Input transducer

block.

Rosemount 5400 Series

SERVICE SUPPORT To expedite the return process outside of the United States, contact the

nearest Rosemount representative.

Within the United States, call the Rosemount National Response Center using

the 1-800-654-RSMT (7768) toll-free number. This center, available 24 hours

a day, will assist you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a

Return Material Authorization (RMA) number. The center will also ask for the

process material to which the product was last exposed.

Rosemount National Response Center representatives will explain the

additional information and procedures necessary to return goods exposed to

hazardous substance can avoid injury if they are informed of and understand

the hazard. If the product being returned was exposed to a hazardous

substance as defined by Occupational Safety and Health Administration

(OSHA), a copy of the required Material Safety Data Sheet (MSDS) for each

hazardous substance identified must be included with the returned goods.

1-3

Page 14

Rosemount 5400 Series

Reference Manual

00809-0100-4032, Rev AA

November 2005

1-4

Page 15

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Section 2 Transmitter Overview

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Components of the transmitter . . . . . . . . . . . . . . . . . . . . . page 2-2

System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-3

Antenna Selection Guide/Measuring Range . . . . . . . . . . page 2-5

Process Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

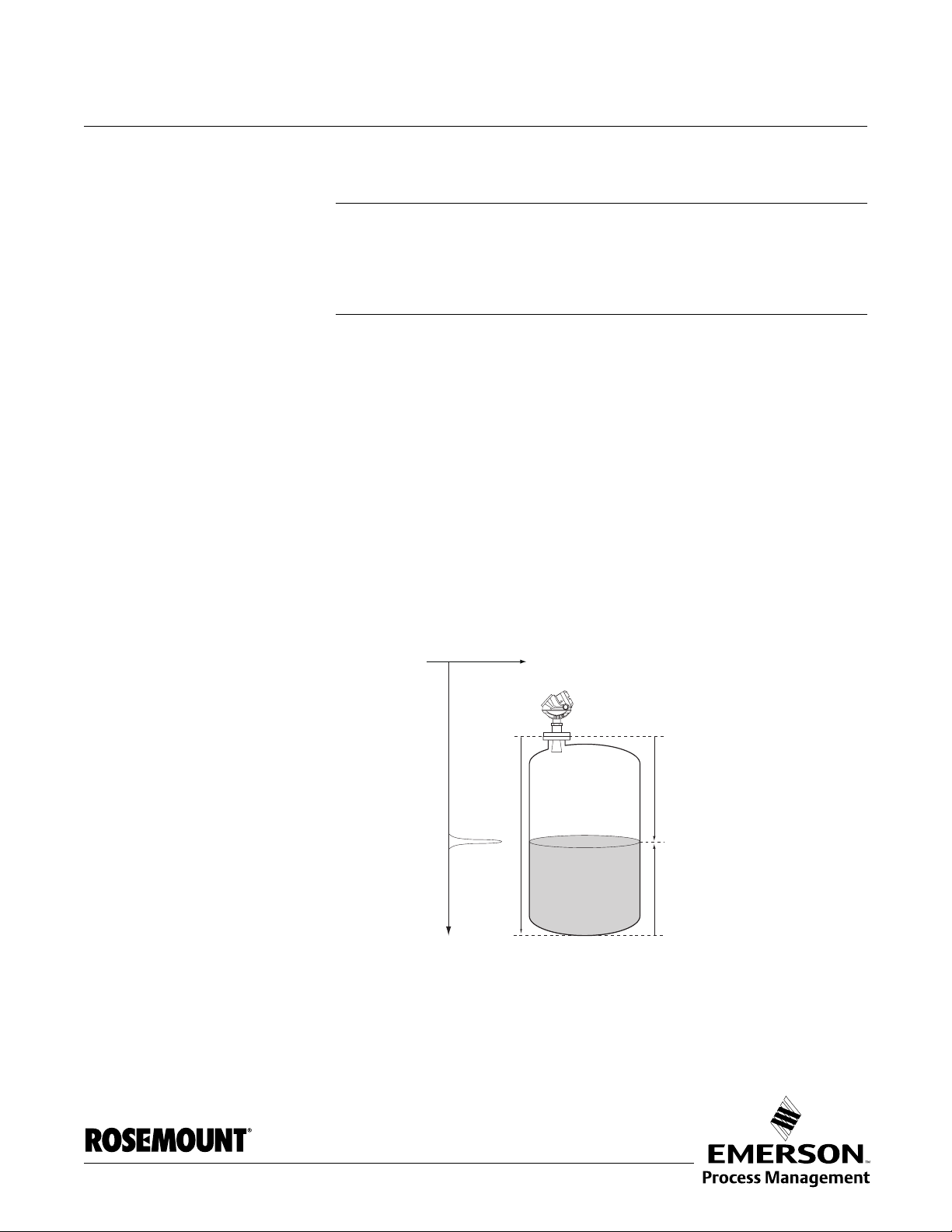

THEORY OF OPERATION The Rosemount 5400 Series Radar Transmitter is a smart, two-wire

continuous level transmitter. A 5400 transmitter is installed at the tank top and

emits short microwave pulses towards the product surface in the tank. When

a pulse reaches the surface of the material it is measuring, part of the energy

is reflected back to the antenna for subsequent processing by the transmitter

electronics. The time difference between the transmitted and reflected pulse

is detected by a micro-processor and is converted into a distance from which

the level is calculated.

The product level is related to the tank height and the measured distance by

the following expression:

Figure 2-1. Measurement

principle for the 5400 Series.

Level=Tank Height - Distance.

Signal amplitude

Tank Height

Radar pulse

Time

Distance

Level

TDR_PRINCIPLES(2).EPS

www.rosemount.com

Page 16

Rosemount 5400 Series

Reference Manual

00809-0100-4032, Rev AA

November 2005

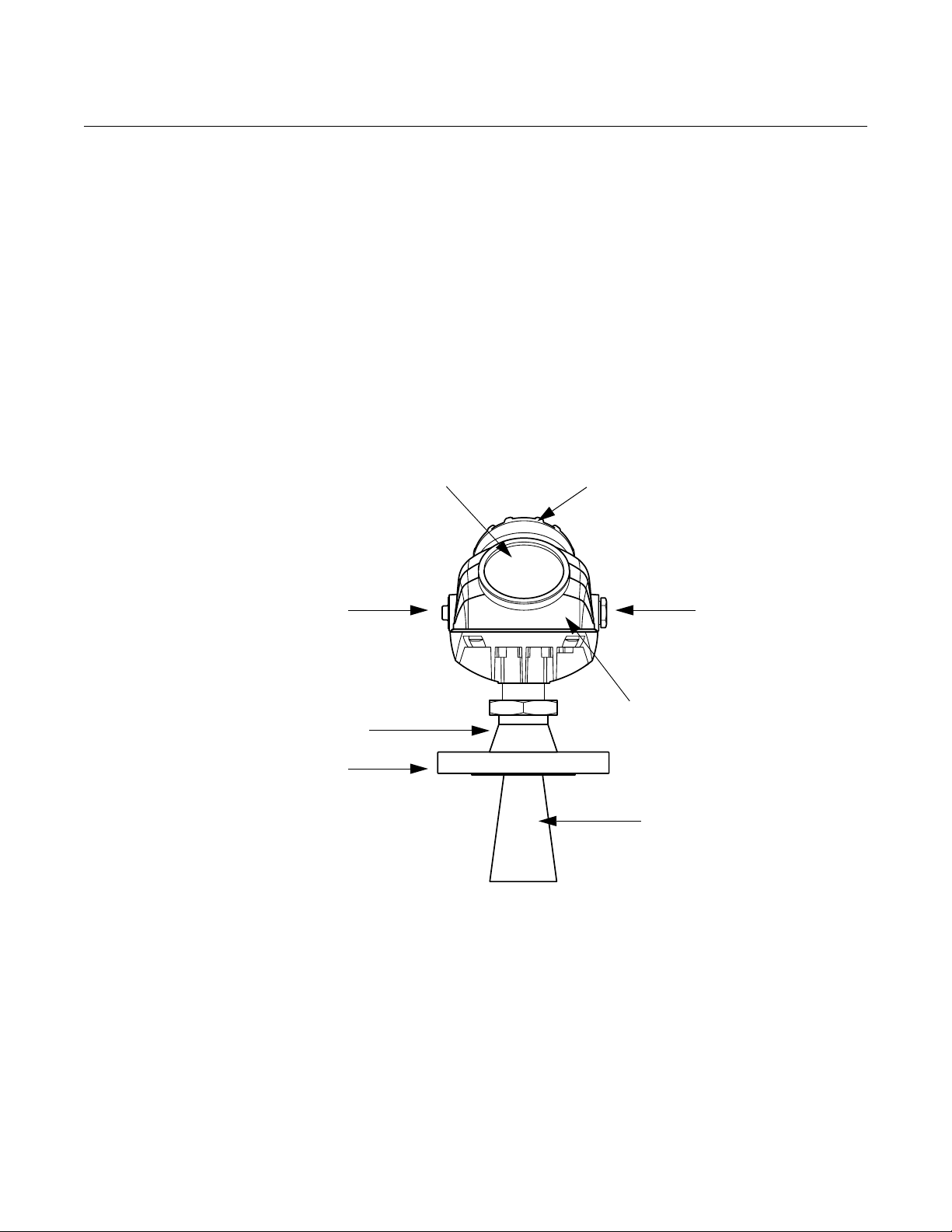

COMPONENTS OF THE TRANSMITTER

Figure 2-2. Transmitter

components.

Cable Entry:

½" NPT.

Optional adapters: M20

The Rosemount 5400 Series Radar Transmitter has a die-cast aluminum

housing which contains advanced electronics for signal processing.

The radar electronics produces the electromagnetic pulse that is emitted

through the antenna. There are different antenna types and sizes available for

various applications.

The transmitter head has separate compartments for electronics and

terminals. The head can be removed without opening the tank. The head has

two entries for conduit/cable connections.

The tank connection consists of a Tank Seal and a flange

(ANSI, EN (DIN) or JIS).

Display Panel Terminal side

Cable Entry:

½" NPT.

Optional adapters: M20

Transmitter Head with

Tank Seal

Flange

TRANSMITTER_COMPONENTS.EPS

Radar Electronics

Antenna

2-2

Page 17

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

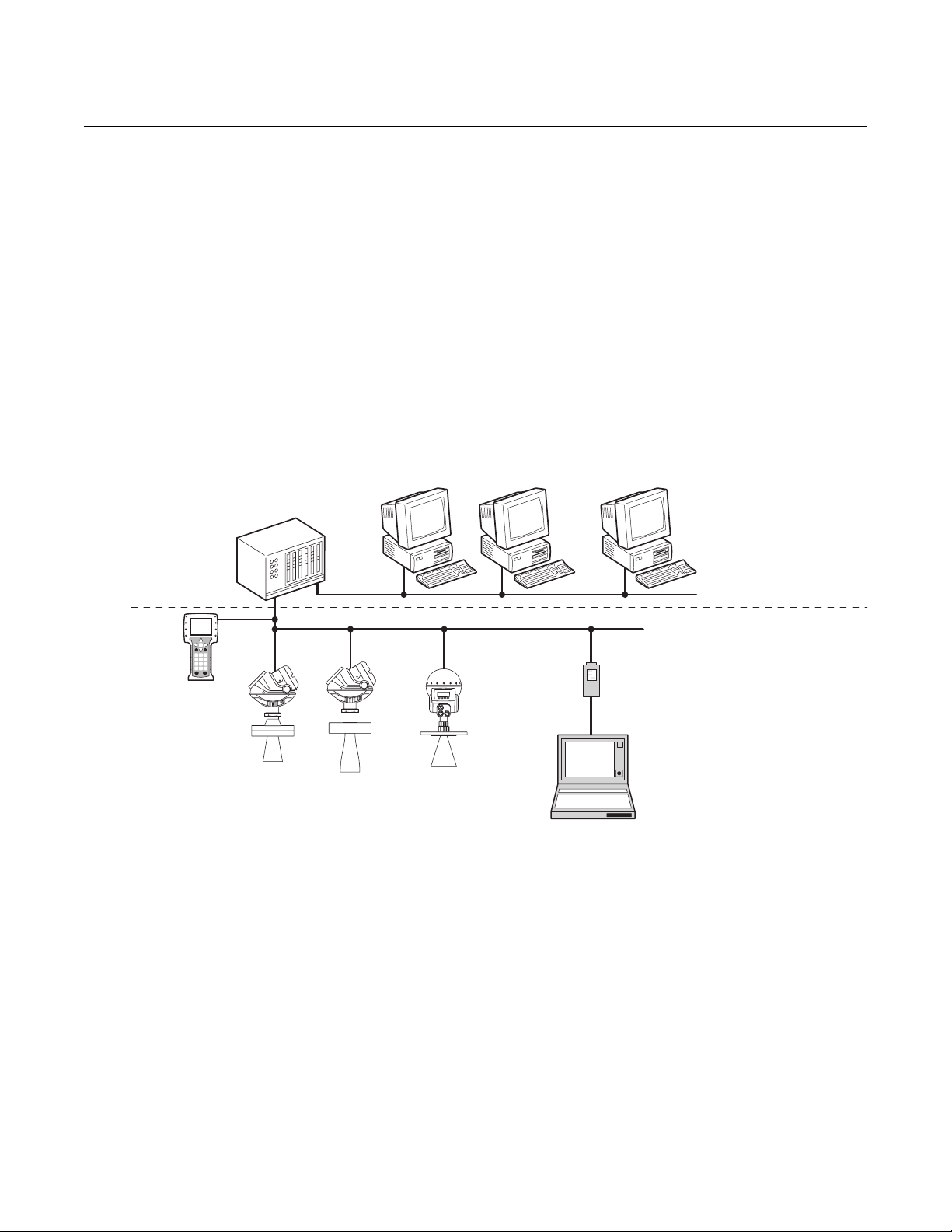

SYSTEM ARCHITECTURE

Figure 2-3. System Integration.

F

OUNDATION™

fieldbus

The 5400 Series Radar Level Transmitter is a powerful radar level transmitter

suitable for non-contact level measurements in process tanks and other types

of tanks. It is designed for easy installation and maintenance free operation.

The Rosemount 5400 Series Radar Transmitter is loop-powered which

means it uses the same two wires for both power supply and F

fieldbus signal. For HART

®

based systems the output is a 4-20 mA analog

OUNDATION

TM

signal superimposed with a digital HART signal.

The Rosemount 5400 Series Radar Transmitter can easily be configured by

using a PC and the Rosemount Radar Master (RRM) software package or via

a 375 Field Communicator. RRM offers configuration and service capabilities

and functions for presentation of measurement data. The transmitter is also

compatible with the AMS

™

Suite software which can be used for

configuration.

Host / DCS system (e.g. DeltaV) Maintenance

H2 - High Speed Field Bus

375 Field

Communicator

Note:

Intrinsically safe

installations may allow

fewer devices per I.S.

barrier due to current

limitations.

Rosemount

5401

Rosemount

5402

Rosemount

5601

Fieldbus Modem

H1 - Low Speed Field Bus

6234 ft (1900 m) max

(depending upon cable

characteristics)

Configuration with

RadarMaster (hooked up on

Fieldbus segment)

FF.EPS

2-3

Page 18

Rosemount 5400 Series

PROCESS CHARACTERISTICS

Reference Manual

00809-0100-4032, Rev AA

November 2005

Dielectric constant

The reflectivity of the product is a key parameter for measurement

performance. A high dielectric constant of the media gives better reflection

and thus enables a longer measuring range.

Foam How well the Rosemount 5400 Series Radar Transmitter measures in foamy

applications depends upon the properties of the foam; light and airy or dense

and heavy, high or low dielectrics, etc. If the foam is conductive and creamy

the transmitter will probably measure the surface of the foam. If the foam is

less conductive the microwaves will probably penetrate the foam and

measure the liquid surface.

Turbulence A calm surface gives better reflection than a turbulent surface. For turbulent

applications, the maximum range of the radar transmitters is reduced. The

range is dependent upon the frequency, the antenna size, the dielectric of the

material and the degree of turbulence. Consult Table 2-1 on page 2-5 and

Table 2-2 on page 2-5 for the expected maximum range with the variables

listed.

Temperature/Pressure/ Density and Vapor

Temperature and pressure generally have no impact on measurements.

Measurements are also insensensitive to product density and vapor.

Condensation For applications where heavy condensation may occur the low frequency

version Rosemount 5401 is recommended.

Tank Characteristics The conditions inside the tank have a significant impact on measurement

performance. For more information see Vessel Characteristics on page 3-8.

2-4

Page 19

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

ANTENNA SELECTION GUIDE/MEASURING RANGE

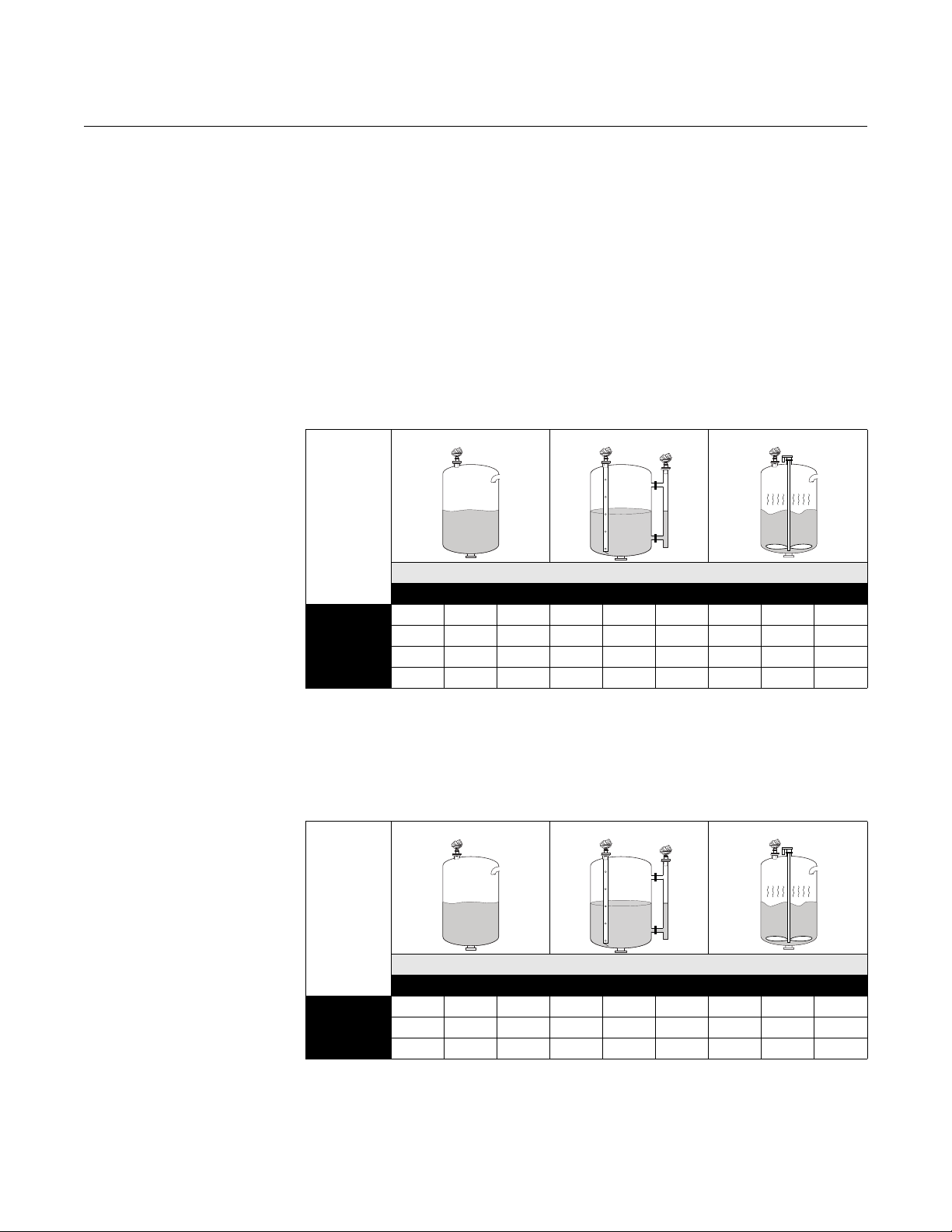

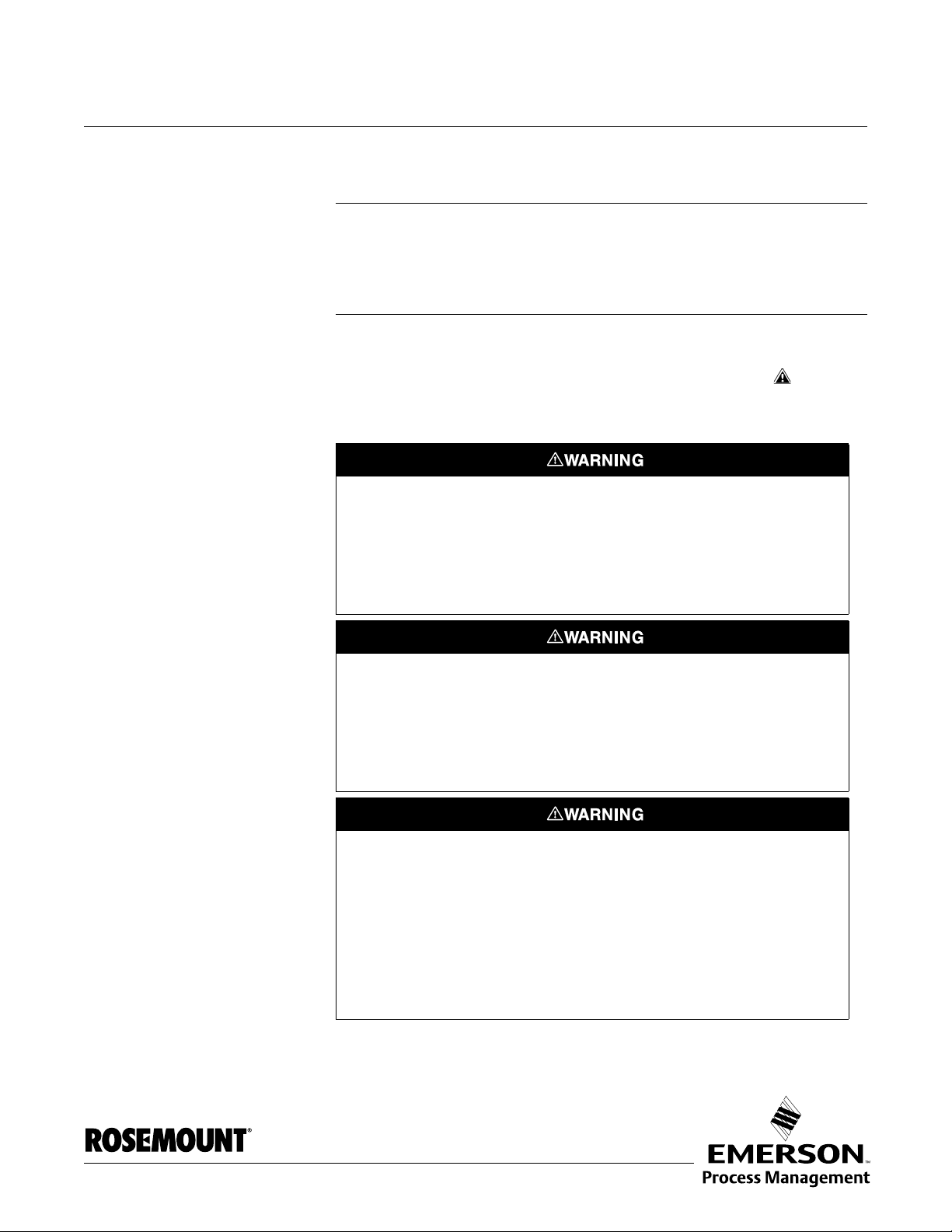

Table 2-1. Measuring range for

the Rosemount 5401 model.

The measuring range primarily depends on the antenna type and size, the

dielectric constant (ε

) of the liquid and process conditions. For optimum

r

performance, make sure not to exceed the maximum measuring range values

below.

A. Oil, gasoline and other hydrocarbons, petrochemicals (ε

=1.9-4.0).

r

B. Alcohols, concentrated acids, organic solvents, oil/water mixtures and

acetone (ε

=4.0-10.0).

r

C. Conductive liquids, e.g. water based solutions, dilute acids and alkalis

(ε

>10.0).

r

Low

Frequency

Antennas

Units: feet (m)

Dielectric Constant

A B C A B C A B C

(1)

Cone, 3 in

Cone, 4 in/Rod

Cone, 6 in

Cone, 8 in

(1) Pipe installations only. NA=Not Applicable.

NA NA NA 66 (20) 66 (20) 66 (20) NA NA NA

20 (6) 33 (10) 43 (13) 66 (20) 66 (20) 66 (20) 9.9 (3) 16 (5) 23 (7)

33 (10) 49 (15) 66 (20) 66 (20) 66 (20) 66 (20) 16 (5) 23 (7) 30 (9)

49 (15) 66 (20) 98 (30) 66 (20) 66 (20) 98 (30) 23 (7) 30 (9) 36 (11)

Table 2-2. Measuring range for

the Rosemount 5402 model.

High

Frequency

Antennas

Units: feet (m)

Cone, 2 in

Cone, 3 in

Cone, 4 in

Dielectric Constant

A B C A B C A B C

16 (5) 33 (10) 49 (15) 66 (20) 66 (20) 66 (20) 6.6 (2) 9.8 (3) 13 (4)

33 (10) 49 (15) 66 (20) 66 (20) 66 (20) 66 (20) 9.8 (3) 13 (4) 20 (6)

49 (15) 66 (20) 98 (30) 66 (20) 66 (20) 98 (30) 13 (4) 20 (6) 26 (8)

2-5

Page 20

Rosemount 5400 Series

Reference Manual

00809-0100-4032, Rev AA

November 2005

2-6

Page 21

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Section 3 Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . page 3-3

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-9

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-13

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury:

Verify that the operating environment of the transmitter is consistent with the appropriate

hazardous locations certifications.

Before powering a F

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

OUNDATION fieldbus segment in an explosive atmosphere, make

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock:

Avoid contact with leads and terminals.

Make sure the main power to the 5400 transmitter is off and the lines to any other

external power source are disconnected or not powered while wiring the gauge.

To prevent ignition of flammable or combustible atmospheres, disconnect power before

servicing.

Antennas with non-conducting surfaces (e.g. Rod antenna and All PTFE antenna) may

generate an ignition-capable level of electrostatic charge under extreme conditions.

Therefore, when the antenna is used in a potentially explosive atmoshpere, appropriate

measures must be taken to prevent electrostatic discharge.

www.rosemount.com

Page 22

Rosemount 5400 Series

Reference Manual

00809-0100-4032, Rev AA

November 2005

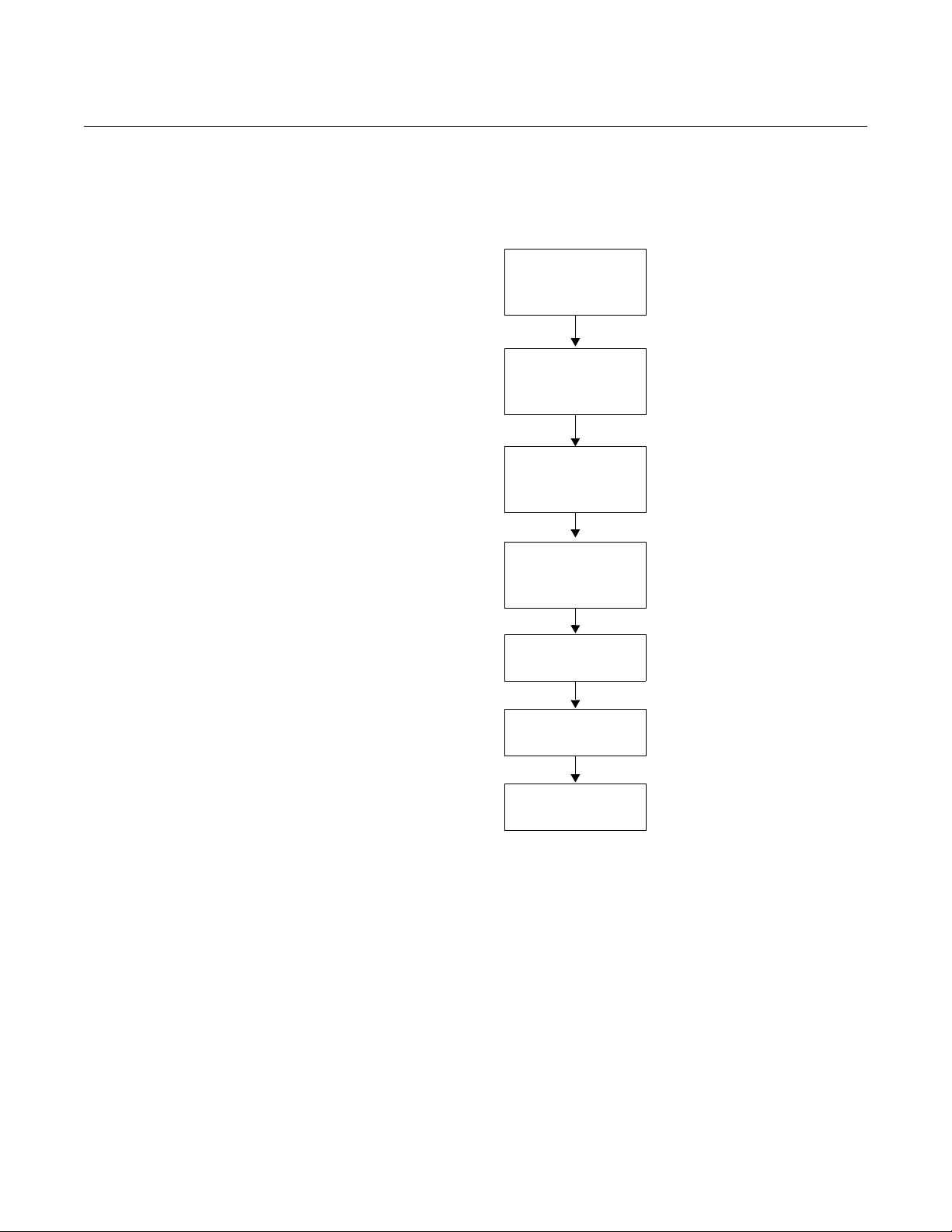

INSTALLATION PROCEDURE

Follow these steps for proper installation:

Review Installation

Considerations

(see page 3-3)

Mount the transmitter

(see page 3-9)

Wire the transmitter

(see page 3-13)

Make sure covers

and cable/conduit

connections are

tight.

Power Up the

transmitter

Configure the

transmitter

(see page 4-1)

Verify measurements

3-2

Page 23

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

MOUNTING CONSIDERATIONS

Before you install the Rosemount 5400 Series, be sure to consider specific

mounting requirements, vessel characteristics and process characteristics.

Socket Recommendation The Rosemount 5400 Series is mounted on a nozzle by using appropriate

flanges. For best performance it is recommended that the socket meets the

following recommendations:

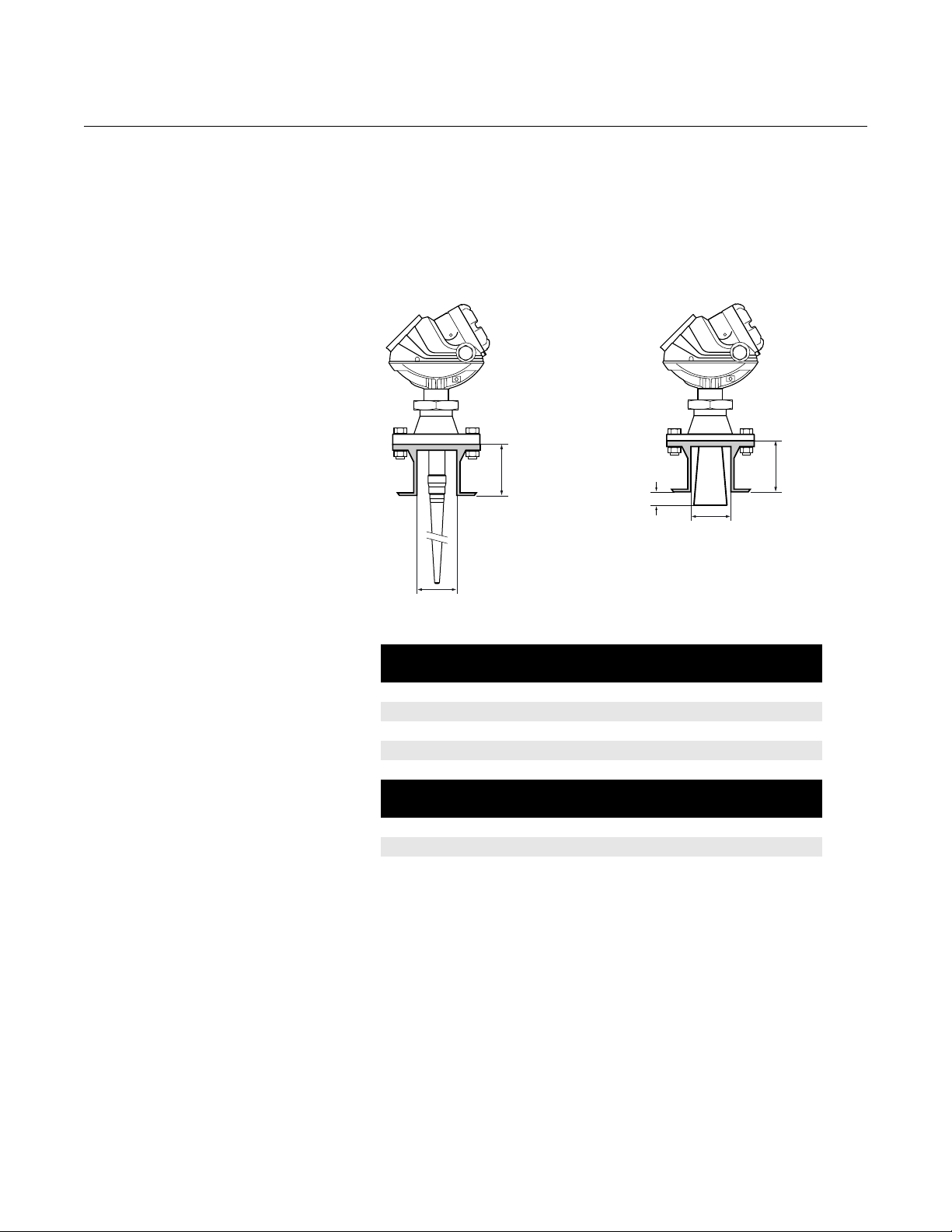

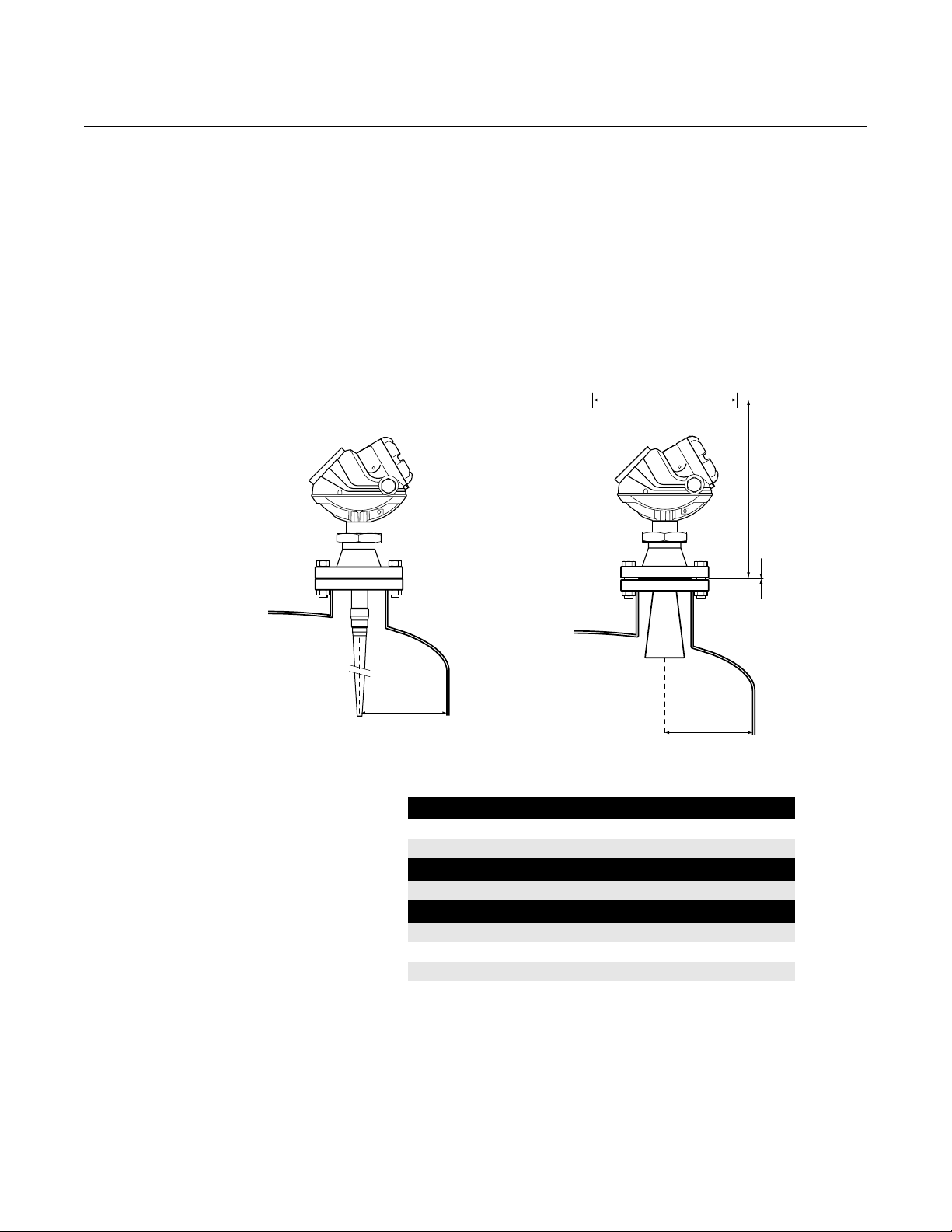

Figure 3-1. Mounting of the 5400

Series transmitter.

L

>0.4 inch/

10 mm

Minimum Diameter

Minimum Diameter

L

SOCKETREQ ROD.EPS/SOCKETREQ.EPS

Table 3-1. Requirements on

socket height and width.

5401 Antenna L

Cone 4 in. 5.5 (140) 3.8 (97)

Cone 6 in. 6.9 (175) 5.7 (145)

Cone 8 in. 10.2 (260) 7.6 (193)

Rod (short) 4.0 (100) 1.5 (38)

Rod (long) 10 (250) 1.5 (38)

5402 Antenna L

Cone 2 in. 5.5 (140) 2.2 (55)

Cone 3 in. 5.5 (140) 2.8 (72)

Cone 4 in. 8.5 (215) 3.8 (97)

inch (mm)

max

inch (mm)

max

Min. Diameter

inch (mm)

Min. Diameter

inch (mm)

The transmitter should be installed as follows:

• The antenna must be aligned vertically.

• Choose as large antenna diameter as possible. A larger receiving area

concentrates the radar beam and ensures maximum antenna gain.

Increased antenna gain means greater margin for weak surface

echoes. A larger antenna also results in a smaller beam angle and

thereby, less interference from any internal obstructions.

• For best measurement performance, the antenna should extend below

the nozzle by 0.4 inches (10 mm) or more.

• For the 5402 model 3-in. and 4-in. antennas can be used in nozzles

with an unobstructed length of up to 39 in. (1 m). The 2-in. antenna

may be used in nozzles where the total length is less than 12 in.

(0.3) m.

3-3

Page 24

Reference Manual

00809-0100-4032, Rev AA

Rosemount 5400 Series

November 2005

Free Space For easy access to the transmitter make sure that it is mounted with sufficient

service space.

Mounting close to a tank wall, nozzle or obstruction may have a negative

influence on measurement perfomance. For maximum measurement

performance the transmitter should be mounted according to the following

recommendations:

Figure 3-2. Free space

recommendations.

Rod Antenna Cone Antenna

A

B

D

Service space Distance inch (mm)

A 20 (500)

B 24 (600)

C. Inclination Maximum angle

Cone antenna 3°

D. Minimum distance to tank wall Distance inch (mm)

Cone antenna 5401 20 (500)

Cone antenna 5402 10 (250)

Rod antenna 5401 20 (500)

C

D

FREESPACE_ROD.EPS/FREESPACE.EPS

3-4

Page 25

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

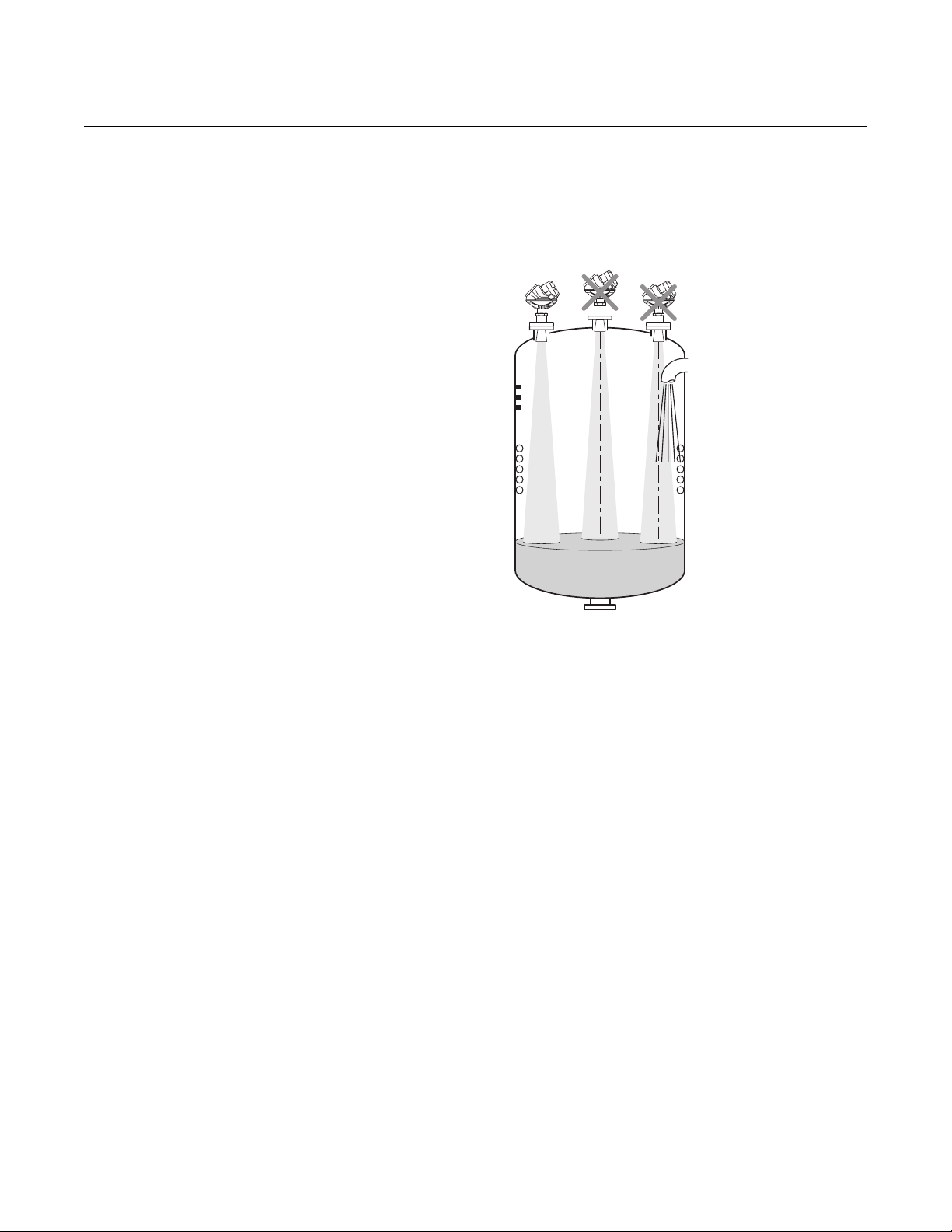

Recommended Mounting Position

Figure 3-3. It is important to

consider the proper mounting

position.

When finding an appropriate mounting position for the transmitter the

conditions of the tank must be carefully considered. The transmitter should be

mounted so that the influence of disturbing objects is kept to a minimum.

MOUNTING_RESTRICTIONS.EPS

• Disturbing objects and filling inlets creating turbulence should be kept

at a distance, outside the signal beam (see Figure 3-4 for beam width

information).

• Avoid installing the transmitter at the center of the tank roof.

• A bridle / still-pipe can be used to avoid interference from disturbing

objects, turbulence or foam.

3-5

Page 26

Reference Manual

00809-0100-4032, Rev AA

Rosemount 5400 Series

November 2005

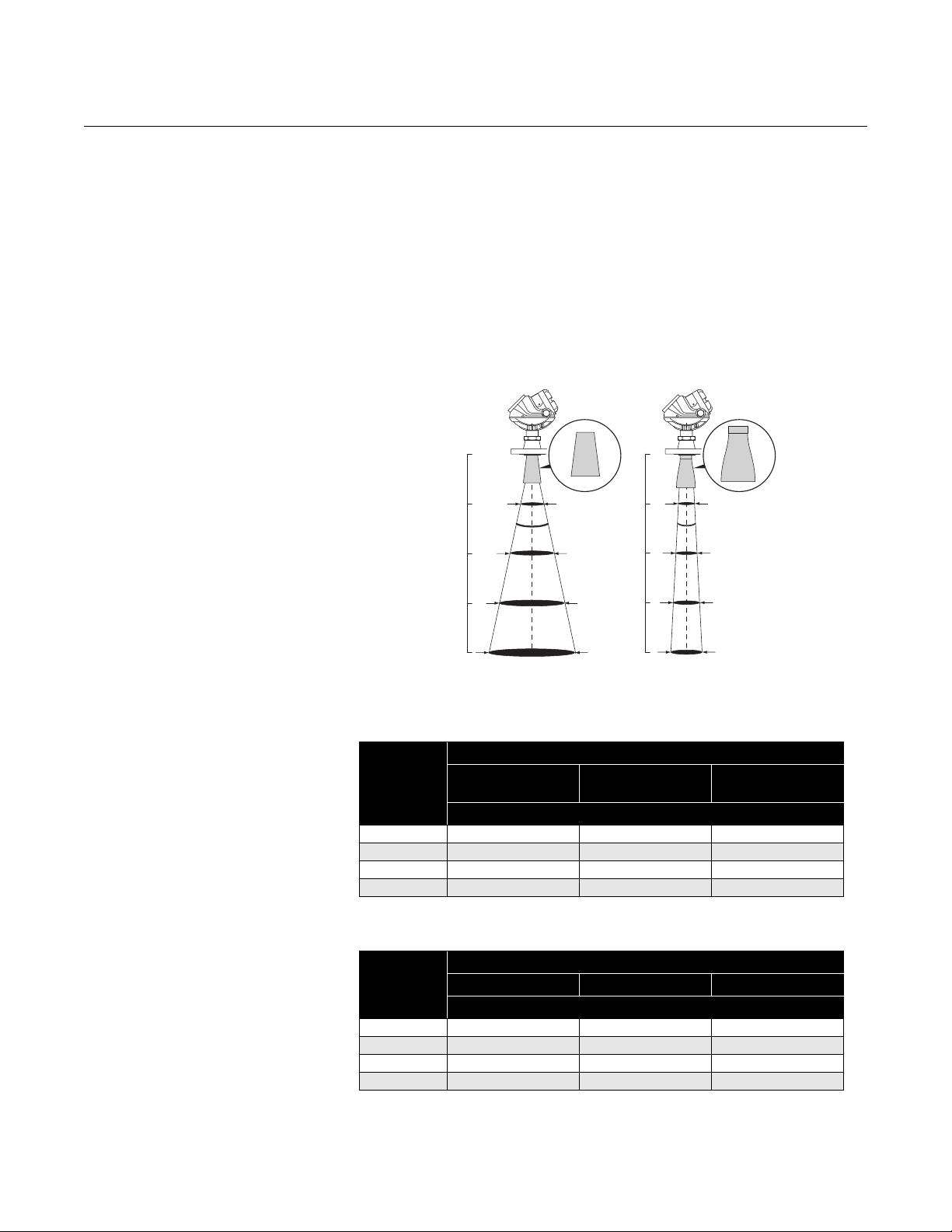

Beam Width The following recommendations should be considered when mounting the

transmitter:

• The transmitter should be mounted with as few internal structures as

possible within the beam angle.

• The flat tank wall can be located within the antenna beam angle as long

as there is a minimum distance from the transmitter to the tank wall

(see Figure 3-2 for preferred installation).

Figure 3-4. Beam width at

various distances from the

flange.

5401

(low frequency)

5402

(high frequency)

Table 3-2. Beamwidth for the

Rosemount 5401 model.

Table 3-3. Beamwidth for the

Rosemount 5402 model.

Distance

Antenna

Distance

16 ft (5 m) 11.5 (3.5) 6.6 (2.0) 4.9 (1.5)

33 ft (10 m) 23.0 (7.0) 13.1 (4.0) 9.8 (3.0)

49 ft (15 m) 32.8 (10) 19.7 (6.0) 14.8 (4.5)

66 ft (20 m) 42.7 (13) 26.2 (8.0) 19.7 (6.0)

Distance

16 ft (5 m) 4.9 (1.5) 3.3 (1.0) 3.3 (1.0)

33 ft (10 m) 9.8 (3.0) 6.6 (2.0) 4.9 (1.5)

49 ft (15 m) 14.8 (4.5) 9.8 (3.0) 8.2 (2.5)

66 ft (20 m) 19.7 (6.0) 13.1 (4.0) 9.8 (3.0)

4 in. (DN 100) Cone

/Rod

2 in. (DN 50) Cone 3 in. (DN 80) Cone 4 in. (DN 100) Cone

6 in. (DN 150) Cone 8 in. (DN 200) Cone

Beam Diameter, ft (m)

Antenna

Beam Diameter, ft (m)

BEAM_DIAMETER_2.EPS

3-6

Page 27

Reference Manual

00809-0100-4032, Rev AA

November 2005

Figure 3-5. Beam angle.

Rosemount 5400 Series

Beam Angle

BEAMWIDTH2.EPSS

Table 3-4. Beam Angle for the

Rosemount 5401 model.

Table 3-5. Beam Angle for the

Rosemount 5402 model.

Antenna Half Power Beam Width

3 in. Cone (Still Pipe)

4 in. Cone / Rod 37°

6 in. Cone 23°

8 in. Cone 17°

Antenna Half Power Beam Width

2 in. Cone 19°

3 in. Cone 14°

4 in. Cone 9°

3-7

Page 28

Reference Manual

00809-0100-4032, Rev AA

Rosemount 5400 Series

November 2005

Vessel Characteristics Heating coils, agitators and other objects in the tank may lead to disturbing

echoes and noise in the measurement signal. Vertical structures cause

minimal effect since the radar signal is scattered rather than directed back to

the antenna.

The shape of the tank bottom affects the measurement signal when the

product surface is close to the tank bottom. The Rosemount 5400 Series has

built-in functions which optimize measurement performance for various

bottom shapes (see Tank Type and Tank Bottom Type on page 4-7).

Disturbing objects The Rosemount 5400 Series transmitter should be mounted so that objects

such as heating coils, ladders etc. are not within the radar signal path. These

objects may cause false echoes resulting in reduced measurement

performance. However, the transmitter has built-in functions designed to

reduce the influence of disturbing objects in case such objects can not be

totally avoided.

The Rosemount 5402 with its more narrow radar beam is particularly suitable

in installations that have tall or narrow nozzles or nozzles close to the tank

wall. It may also be used to avoid disturbing objects in the tank.

3-8

Page 29

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

MECHANICAL INSTALLATION

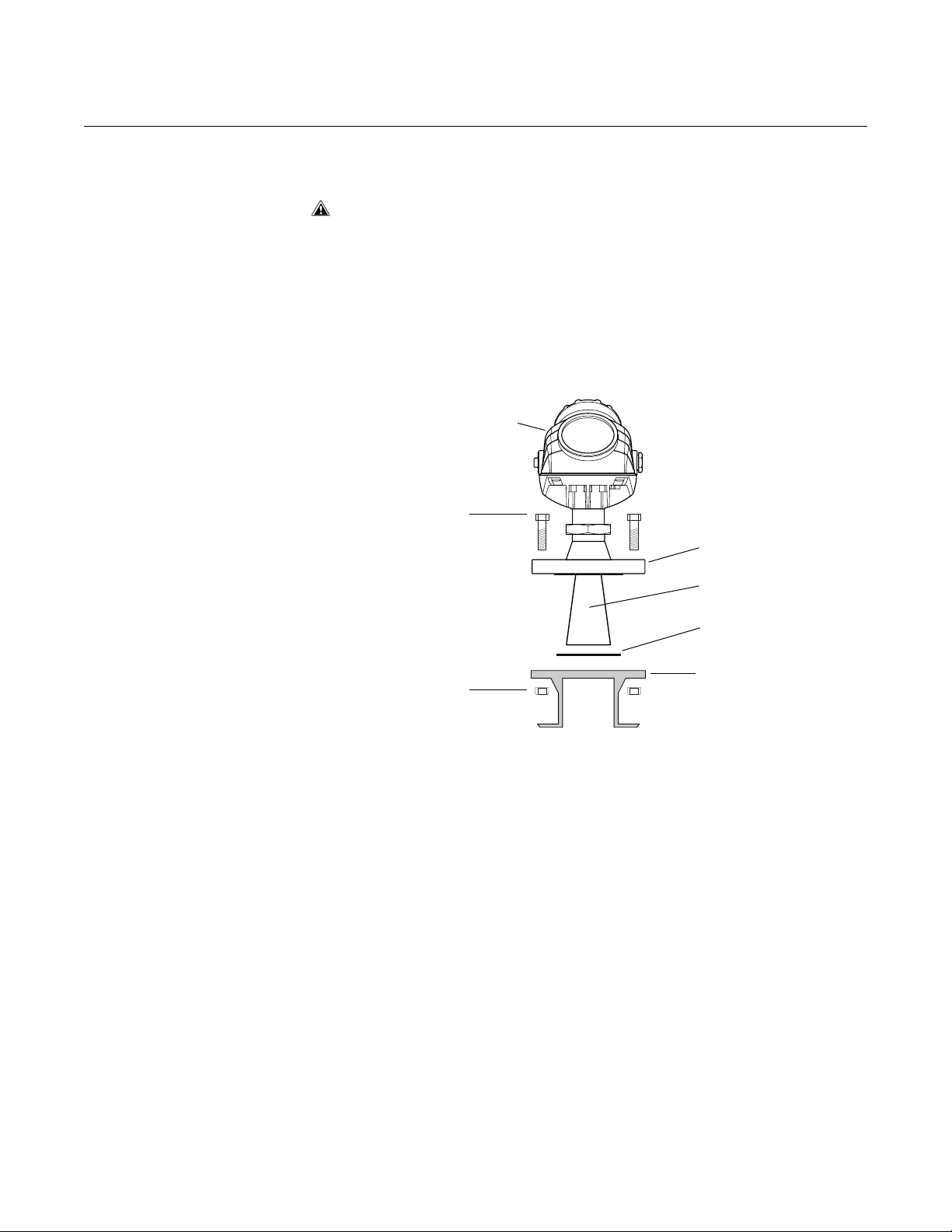

Figure 3-6. Mounting the 5400

with cone antenna.

Mount the transmitter on a nozzle on top of the tank. Make sure only qualified

personnel perform the installation.

The transmitter housing must not be opened. If a software update or other

service action is required that involves opening the housing, it must be done

by a suitably trained service technician. Maintenance work that involves

opening the housing must not be done when the transmitter is mounted on the

tank.

If the transmitter housing must be removed for service, make sure that the

®

Te fl o n

sealing is carefully protected against dust and water.

Transmitter housing

Bolt

Flange

Cone antenna

Gasket

Tan k f lange

Nut

1. Place a gasket with thickness and of material suitable to the process on

top of the tank flange.

2. Lower the transmitter with antenna and flange into the tank nozzle.

3. Tighten the bolts and nuts with sufficient torque regarding flange and

gasket choice. See also Process Temperature and Pressure Rating on

page A-4.

MOUNT_TH_FLANGE.EPS

3-9

Page 30

Rosemount 5400 Series

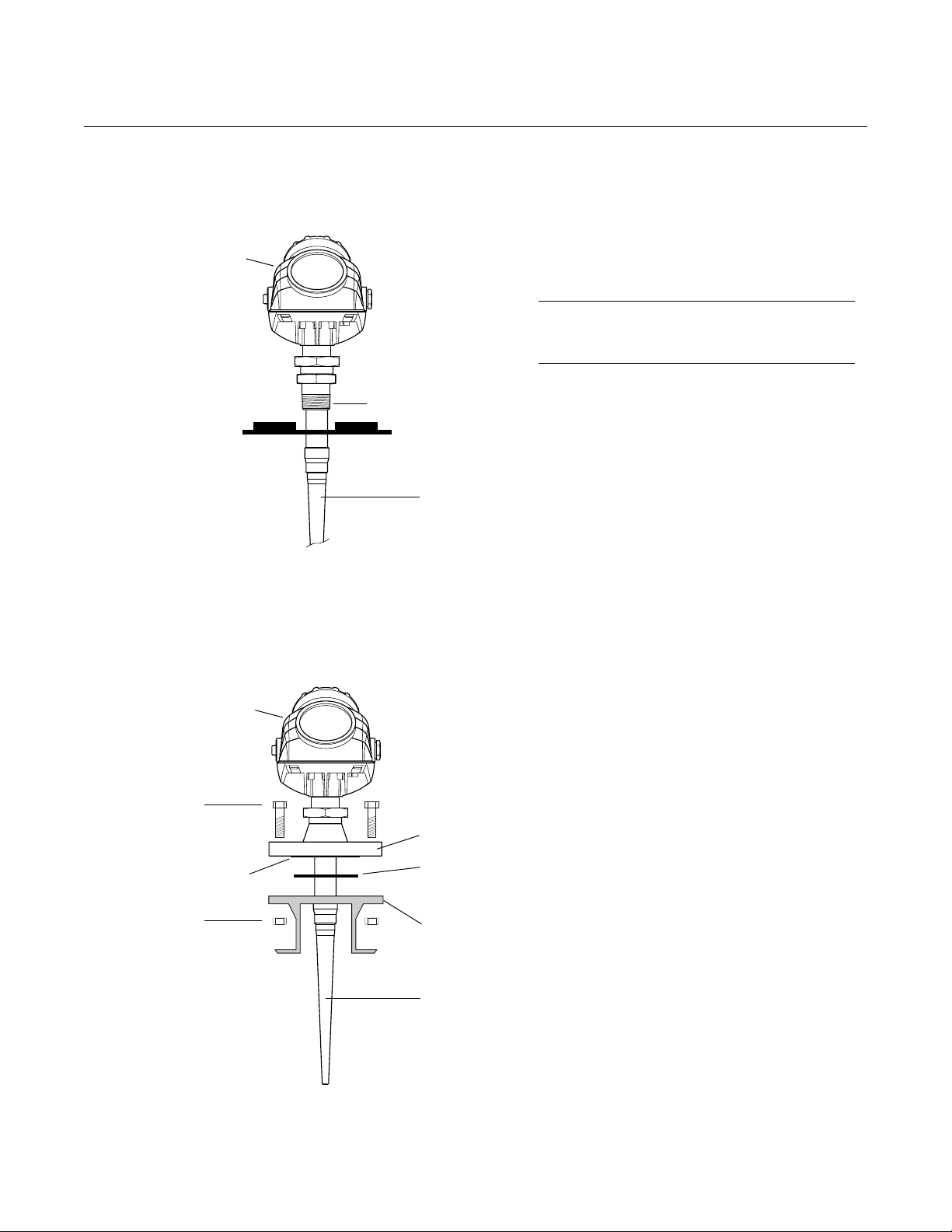

Figure 3-7. Mounting the 5400

transmitter with rod antenna and

threaded tank connection.

Transmitter housing

Reference Manual

00809-0100-4032, Rev AA

November 2005

1. Lower the transmitter and antenna into

the tank.

2. Screw the transmitter into the process

connection.

NOTE!

Tank connections with NPT threads require a

sealant for pressure-tight joints.

Sealant on threadsSealant on threads

Antenna

MOUNT_TH_ROD_THREADED.EPS

Figure 3-8. Mounting the 5400

transmitter with rod antenna and

flange connection.

Transmitter housing

Optional PFA plate

Bolt

Nut

Flange

Gasket (not for

the All PFA

version)

Tank flan ge

1. Place a gasket with thickness and of

material suitable to the process on top of

the tank flange.

Note: For the All PFA version (tank

sealing model code=PD) no gasket is

used.

2. Lower the transmitter with antenna and

flange into the tank nozzle.

3. Tighten the bolts and nuts with sufficient

torque regarding flange and gasket

choice. See also Process Temperature

and Pressure Rating on page A-4.

3-10

MOUNT_ROD_FLANGE.EPS

Rod antenna

Page 31

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Mounting in Pipes Still Pipe mounting is recommended for tanks where surface conditions are

extremely turbulent. All cone antenna sizes for the 5400 Series transmitter

can be used for Still Pipe installations. The 2 and 3 inch antennas for 5401 are

designed for use in Still Pipes and Bypass Pipes only.

When the transmitter is mounted in a Still Pipe the inclination should be

within 1° of vertical. The gap between the antenna and the Still Pipe may be

up to 0.2 inch (5 mm).

Figure 3-9. Mount the

transmitter vertically.

max. 0.2 inch

(5 mm)

Figure 3-10. Recommended

hole size for pipe installations.

max. 1 °

STILLPIPE_REQS.EPS / STILLPIPE_TANK_V2.EPS

Recommendations for pipe installations

• The pipe must be smooth on the inside.

• Not suitable for adhesive products.

• Make sure that at least one hole is above the product surface.

• The hole diameter Ø should not exceed 10% of the pipe diameter D.

• Holes should be drilled on one side.

min. 6 inch (150 mm)

max. Ø: D/10.

STILLPIPE_HOLEREQ.EPS

D

3-11

Page 32

Rosemount 5400 Series

Reference Manual

00809-0100-4032, Rev AA

November 2005

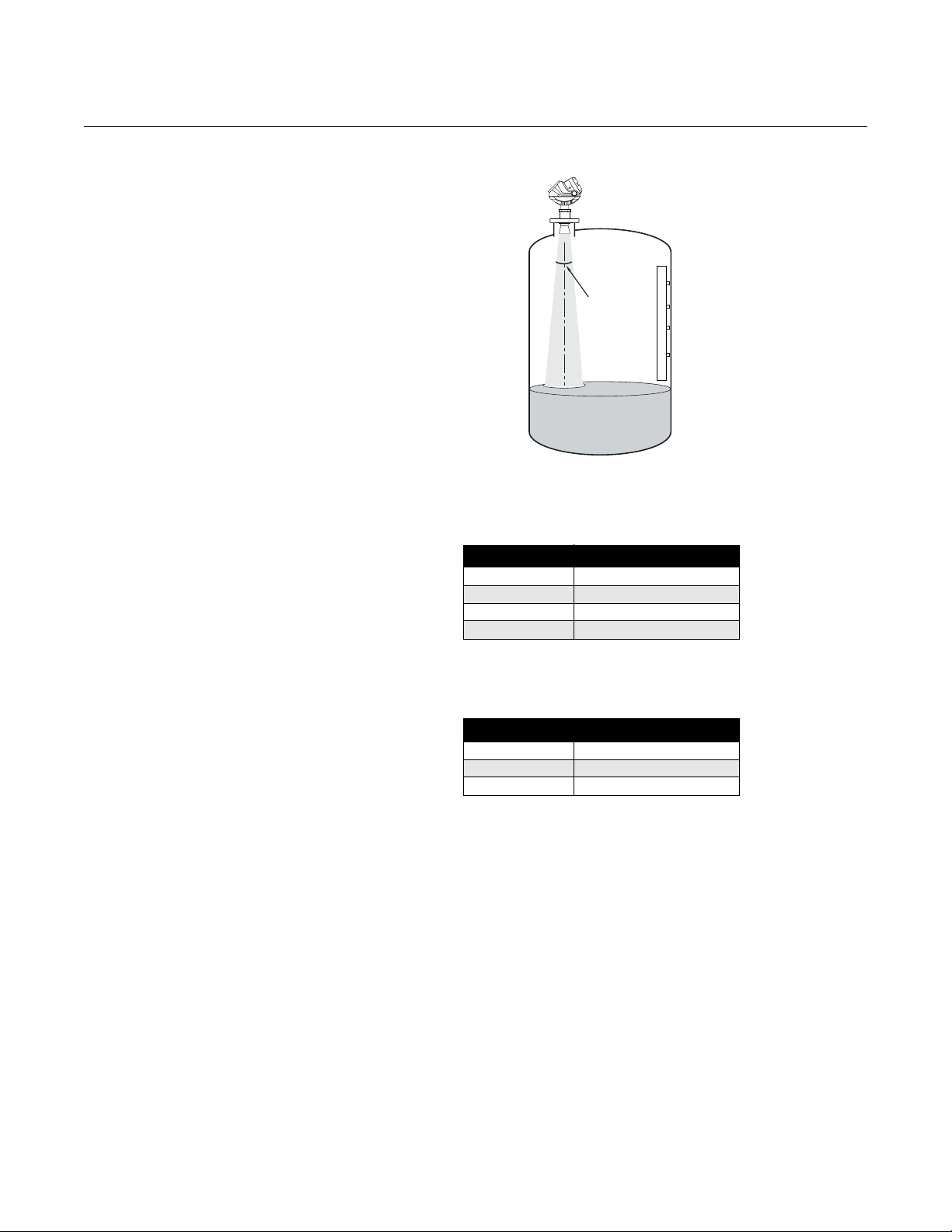

Mounting in Bypass Pipes

Figure 3-11. Bridle mounting is

recommended for tanks with

extremely turbulent surface

conditions.

In tanks with turbulent conditions it is recommended to mount the transmitter

on a bridle pipe.

BRIDLE_V2.EPS

max. 1 °

Minimum 12 in. (300 mm)

In pipes with inlet pipe diameter Ø<2 inch (51 mm) the gap D between pipe

and antenna should be less than 0.2 inch (5 mm).

Figure 3-12. Recommended

specifications for bridles with

pipe inlets.

If the inlet pipe diameter Ø>2 inch (51 mm) the gap D between pipe and

antenna should be less than 0.04 inch (1 mm).

The distance A between the antenna and the nearest inlet pipe should be at

least 2 inches (50 mm).

Ø (in./mm) D (in./mm)

<2/51 <0.2/5

>2/51 <0.04/1

A > 2 in./50 mm

D

Ø

BRIDLE_REQUIREMENTS.EPS

3-12

Page 33

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

ELECTRICAL INSTALLATION

Cable/conduit entries The electronics housing has two entries with ½ - 14 NPT threads. Optional

M20×1.5 adapters are also available. The connections are made in

accordance with national, local and plant electrical codes.

Make sure that unused ports are properly sealed to prevent moisture or other

contamination from entering the terminal compartment of the electronics

housing. Install wiring with a drip loop. The bottom of the loop must be lower

than the cable/conduit entry.

NOTE!

Use the enclosed metal plug to seal any unused port.

Grounding The housing should always be grounded in accordance with national and

local electrical codes. Failure to do so may impair the protection provided by

the equipment. The most effective grounding method is direct connection to

earth ground with minimal impedance. There are two grounding screw

connections provided. One is inside the Terminal compartment of the housing

and the other is located on one of the cooling fins below the housing. The

internal ground screw is identified by a ground symbol: .

NOTE!

Grounding the transmitter via threaded conduit connection may not provide

sufficient ground.

NOTE!

After installation and commissioning make sure that no ground currents exist

due to high ground potential differences in the installation.

Cable Selection For best installation practices use a fieldbus type A cable. All power to the

transmitter is supplied over the signal wiring. For the Rosemount 5400 Series

signal wiring should be shielded, twisted pair for best results in electrically

noisy environments. Do not use unshielded signal wiring in open trays with

power wiring or near heavy electrical equipment. The cables must be suitable

for the supply voltage and approved for use in hazardous areas, where

applicable. For instance, in the U.S., explosionproof conduits must be used in

the vicinity of the vessel. For the ATEX flameproof approval version of the

Rosemount 5400 Series, suitable conduits with sealing device or flameproof

(EEx d) cable glands must be used depending on local requirements.

Use 18 AWG to 12 AWG wiring in order to minimize the voltage drop to the

transmitter.

Do not remove the transmitter cover in explosive atmospheres when the

circuit is alive.

Hazardous Areas When the Rosemount 5400 Series transmitter is installed in hazardous area,

national and local regulations and specifications in applicable certificates

must be observed.

3-13

Page 34

Reference Manual

00809-0100-4032, Rev AA

Rosemount 5400 Series

November 2005

External Circuit Breaker For complicance with Low Voltage Directive 73/23/EEG an external circuit

breaker should be installed.

Power Requirements Terminals in the transmitter housing provide connections for signal wiring.

The 5400 transmitter is powered over F

fielbus power supplies.

The transmitter operates with the following power supplies:

Approval Type Power Supply (V dc)

IS 9 - 30

Explosion Proof/Flame Proof 16 - 32

None 9 - 32

OUNDATION fieldbus with standard

3-14

Page 35

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Connecting the Transmitter

Figure 3-13. Terminal

compartment and external

ground screw.

The Rosemount 5400 Series with Foundation Fieldbus accepts power

supplies ranging from 9 V dc to 32 V dc.

To connect the transmitter:

1. Make sure that the power supply is switched off.

2. Remove the terminal block cover.

3. Pull the cable through the cable gland/conduit. Install wiring with a drip

loop. The bottom of the loop must be lower than the cable/conduit entry.

4. Connect wires according to Figure 3-15 for non-intrinsically safe power

supplies and according to Figure 3-16 for Intrinsically safe power

supplies.

5. Use the enclosed metal plug to seal any unused port.

6. Mount the cover and tighten the cable gland. Make sure that the cover is

fully engaged to meet explosion-proof requirements.

Note that adapters are required if M20 glands are used.

7. Tighten the Locking Screw (ATEX Flameproof version).

8. Switch on the power supply.

NOTE!

Use Teflon® tape or other sealant at the NPT threads in the Cable Entries.

3

5

11

4

2

GROUNDINGSCREW.EPS/JUNCTION_BOX.EPS

Cable entries.

Internal Ground screw.

Terminals for signal and power supply.

Locking screw.

External Ground screw

3-15

Page 36

Rosemount 5400 Series

Grounding

Signal wiring of the fieldbus segment can not be grounded. Grounding out

one of the signal wires will shut down the entire fieldbus segment.

Shield Wire Ground

To protect the fieldbus segment from noise, grounding techniques for shield

wire usually require a single grounding point for shield wire to avoid creating a

ground loop. The ground point is typically at the power supply.

Connecting Fieldbus Devices

Figure 3-14. Rosemount 5400

Radar Transmitter field wiring

Integrated Power

Conditioner

and Filter

Power

Supply

Reference Manual

00809-0100-4032, Rev AA

November 2005

6234 ft (1900 m) max

(depending upon cable

characteristics)

Ter minator s

fieldbus

Segment

(Trunk)

(The power supply,

filter, first

terminator, and

configuration tool

are typically located

in the control room.)

*Intrinsically safe installations

may allow fewer devices per I.S.

barrier due to current

limitations.

Configuration

(Spur)

OUNDATION

F

fieldbus

Too l

fieldbus

devices on

segment

Configuration with Rosemount RadarMaster

(in a fieldbus system hooked up on Fieldbus

segment).

(Spur)

Signal

Wiring

FF_FIELD_WIRING_5400_V2.EPS

3-16

Page 37

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Non-Intrinsically Safe Power Supply

Figure 3-15. Wiring for

non-intrinsically safe power

supply.

5400 Series Radar Transmitter

With non-intrinsically safe power supply in Non-hazardous installations or

Explosion-proof/Flameproof installations, wire the transmitter as shown in

Figure 3-15.

NOTE!

Make sure that the power supply is off when connecting the transmitter.

Power

supply

Umax=250 V

Fieldbus Modem

PC

375 Field Communicator

NOTE!

For Explosion Proof/Flame Proof installations make sure that the transmitter

is grounded to the I.S. ground terminal inside the terminal compartment in

accordance with national and local electrical codes.

WIRING_NON_IS_FF.EPS

3-17

Page 38

Rosemount 5400 Series

Reference Manual

00809-0100-4032, Rev AA

November 2005

Intrinsically Safe Power Supply

Figure 3-16. Wiring diagram for

intrinsically safe power supply.

5400 Series Radar Transmitter

When your power supply is intrinsically safe, wire the transmitter as shown in

Figure 3-16.

NOTE!

Make sure that the instruments in the loop are installed in accordance with

intrinsically safe field wiring practices.

Approved IS Barrier

Power

supply

Fieldbus Modem

PC

375 Field Communicator

WIRING_IS_FF.EPS

For information on I.S. parameters see Section B: Product Certifications.

3-18

Page 39

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Section 4 Configuration/Start-Up

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-2

Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-6

Echo Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-10

Configuration Using DeltaV . . . . . . . . . . . . . . . . . . . . . . . . page 4-13

Configuration Using Rosemount Radar Master . . . . . . . . page 4-18

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the safety messages listed at the beginning of each section before performing

an operation preceded by this symbol.

Explosions could result in death or serious injury:

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before powering a F

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit

is alive.

All connection head covers must be fully engaged to meet explosion-proof

requirements.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

OUNDATION fieldbus segment in an explosive atmosphere, make

www.rosemount.com

Page 40

Reference Manual

00809-0100-4032, Rev AA

Rosemount 5400 Series

November 2005

OVERVIEW Configuration of a Rosemount 5400 transmitter is normally a simple and

straight-forward task. If the transmitter is pre-configured at the factory

according to the ordering specifications in the Configuration Data Sheet, no

further Basic Configuration is required unless tank conditions have changed.

The 5400 Series supports a set of advanced configuration options as well,

which can be used to handle special tank conditions and applications.

Figure 4-1 illustrates how the signals are channeled through the gauge.

Figure 4-1. Function Block

Diagram for the Rosemount

5400 Series Radar Level

Transmitters with F

fieldbus.

OUNDATION

FOUNDATION

Fieldbus

Compliant

Communications

Stack

Level

Transducer

Block

Register

Transducer

Block

Advanced

Configuration

Block

Resource Block

physical device

information

FF_FUNCTIONBLOCKS_5400.EPS

It is highly recommended that you limit the number of periodic writes to all static or non-volatile

parameters such as HI_HI_LIM, LOW_CUT, SP, TRACK_IN_D, OUT, IO_OPTS, BIAS,

STATUS_OPTS, SP_HI_LIM, and so on. Static parameter writes increment the static revision

counter, ST_REV, and are written to the device's non-volatile memory. Fieldbus devices have a

non-volatile memory write limit. If a static or non-volatile parameter is configured to be written

periodically, the device can stop its normal operation after it reaches its limit or fail to accept new

values.

Each F

OUNDATION fieldbus configuration tool or host device has a different

way of displaying and performing configurations. Some will use Device

Descriptions (DD) and DD Methods to make configuration and displaying of

data consistent across host platforms. Since there is no requirement that a

configuration tool or host support these features, this section will describe

how to reconfigure the device manually. Appendix H: Operation with Delta V

shows the Delta V implementation of these common functions.

This section covers basic operation, software functionality, and basic

configuration procedures for the Rosemount 5400 Series Level Transmitter

with F

OUNDATION fieldbus (Device Revision 1). For detailed information about

F

OUNDATION fieldbus technology and function blocks used in the Rosemount

5400 Series, refer to the F

OUNDATION fieldbus Block manual (Ref. no.

00809-0100-4783).

4-2

Page 41

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Assigning Device Tag and Node Address

FOUNDATION Fieldbus Block Operation

A Saab Rosemount 5400 Series transmitter is shipped with a blank tag and a

temporary address (unless specifically ordered with both) to allow a host to

automatically assign an address and a tag. If the tag or address need to be

changed, use the features of the configuration tool. The tool basically does

the following:

1. Changes the address to a temporary address (248-251).

2. Changes the tag to new value.

3. Changes the address to a new address.

When the transmitter is at a temporary address, only the tag and address can

be changed or written to. The resource, transducer, and function blocks are all

disabled.

Function blocks within the fieldbus device perform the various functions

required for process control. Function blocks perform process control

functions, such as analog input (AI) functions, as well as

proportional-integralderivative (PID) functions. The standard function blocks

provide a common structure for defining function block inputs, outputs, control

parameters, events, alarms, and modes, and combining them into a process

that can be implemented within a single device or over the fieldbus network.

This simplifies the identification of characteristics that are common to function

blocks.

In addition to function blocks, fieldbus devices contain two other block types

to support the function blocks. These are the Resource block and the

Transducer block.

Resource blocks contain the hardware specific characteristics associated with

a device; they have no input or output parameters. The algorithm within a

resource block monitors and controls the general operation of the physical

device hardware. There is only one resource block defined for a device.

Transducer blocks connect function blocks to local input/output functions.

They read sensor hardware and write to effector (actuator) hardware.

Level Transducer Block

The Level Transducer block contains transmitter information including

diagnostics and the ability to configure, set to factory defaults and restarting

the transmitter.

Register Transducer Block

The Register Transducer Block allows a service engineer to access all

database registers in the device.

Advanced ConfigurationTransducer Block

The Advanced Configuration Transducer Block contains functions such as

amplitude threshold settings for filtering of disturbing echoes and noise,

simulation of measurement values and strapping table for volume

measurements.

Resource Block

The Resource block contains diagnostic, hardware, electronics, and mode

handling information. There are no linkable inputs or outputs to the Resource

Block.

4-3

Page 42

Rosemount 5400 Series

Analog Input Block

Figure 4-2. Analog-Input Block

Reference Manual

00809-0100-4032, Rev AA

November 2005

OUT_D

AI

OUT=The block output value and status

OUT_D=Discrete output that signals a selected

alarm condition

OUT

The Analog Input (AI) function block processes field device measurements

and makes them available to other function blocks. The output value from the

AI block is in engineering units and contains a status indicating the quality of

the measurement. The measuring device may have several measurements or

derived values available in different channels. Use the channel number to

define the variable that the AI block processes and passes on to linked

blocks. For further information refer to Appendix E: Analog-Input Block.

For more information on the different function blocks refer to Appendix D:

Level Transducer Block, Appendix E: Register Transducer Block, Appendix F:

Advanced Configuration Transducer Block, Appendix G: Resource

Transducer Block and Appendix H: Analog-Input Block.

Function Blocks

The following function blocks are available for the Rosemount 5400 Series:

• Proportional/Integral/Derivative (PID)

• Input Selector (ISEL)

• Signal Characterizer (SGCR)

• Arithmetic (ARTH)

• Output Splitter (OS)

FF_AIBLOCK

4-4

For detailed information about F

OUNDATION fieldbus technology and function

blocks used in the Rosemount 5400 Series, refer to the F

Block manual (Ref. no. 00809-0100-4783).

OUNDATION fieldbus

Page 43

Reference Manual

00809-0100-4032, Rev AA

November 2005

Rosemount 5400 Series

Basic Configuration The Basic Configuration includes parameters for a standard configuration

which is sufficient in most cases. The Basic Configuration comprises the

following items:

• Measurement Units

• Tank Configuration

- Tank Geometry

- Environment

- Volume

Echo Tuning Echo Tuning is used to handle special situations when there are objects in the

tank which cause disturbing echoes that are stronger than the surface echo.

The following tools are available to handle such situations:

• Amplitude Threshold Curve (ATC)

• False Echo registration

Advanced Configuration For some applications further configuration is needed in addition to the Basic

Configuration. This may be due to the properties of the product or the shape

of the tank. Disturbing objects and turbulent conditions in the tank may also

require that advanced measures are taken. See Appendix C: Advanced

Configuration for more information.

Configuration Tools There are several tools available for basic configuration of a 5400 transmitter:

• Rosemount Radar Master (RRM). Note that RRM is required for

advanced configuration features.

See Configuration Using Rosemount Radar Master on page 4-18 for

information on how to use RRM for configuration of the 5400 Series.

• Rosemount 375 Field Communicator.

•DeltaV.

RRM is a user-friendly, Windows based software package including waveform

plots, off-line/on-line configuration Wizard, logging, and extensive on-line

help.

4-5

Page 44

Reference Manual

00809-0100-4032, Rev AA

Rosemount 5400 Series

November 2005

BASIC CONFIGURATION This chapter describes the basic parameters that need to be configured for a

Rosemount 5400 transmitter. If the transmitter is pre-configured at factory

according to the ordering specifications in the Configuration Data Sheet, no

further basic configuration is needed unless conditions have changed since

the ordering date.

At the end of this section different configuration tools are described.

Measurement Units Measurement units can be specified for presentation of Level, Level Rate,

Volume and Temperature values.

Tank Geometry Tank Height

The Tank Height is the distance between the Upper Reference Point at the

underside of the transmitter flange or the threaded adapter, and the Lower

Reference Point close to or at the bottom of the tank (see Figure 4-4 for

further information on Upper Reference Points for various tank connections).

The transmitter measures the distance to the product surface and subtracts

this value from the Tank Height to determine the product level.

Figure 4-3. Tank Geometry

Product Level

Upper Reference Point

Dead Zone

Tank Height (R)

Lower Reference Point

(Level=0)

TANKGEOMETRY_STANDARD.EPS

4-6

Page 45

Reference Manual

00809-0100-4032, Rev AA

November 2005

Figure 4-4. Upper Reference

Point

Upper

Reference Point

Rosemount 5400 Series

Adapter Flange

Cone antenna

Figure 4-5. The transmitter can

be optimized for different tank

types and bottom shapes.

Rod antenna with

threaded tank

connection

Rod antenna

with flange

Tank Type and Tank Bottom Type

The 5400 transmitter is optimized according to the Tank Type and Tank

Bottom Type configuration by automatically setting some parameters to

pre-defined default values.

Select Tank Bottom Type Flat Inclined if the bottom inclination is between 10

and 30 degrees. If the inclination is less than 10 degrees but there are

disturbing objects on the tank floor (like heating coils) within the radar beam,

this selection should also be used. If inclination is greater than 30 degrees

use Tank Bottom Type Cone.

Table 4-1. Tank Type and Tank Bottom Type

Tan k Ty p e Tank Bottom Type

Vertical Cylinder Flat, Dome, Cone, Flat inclined

Horizontal Cylinder Not used

Spherical Not used

Cubical Flat, Dome, Cone, Flat inclined

5400_UPPERREFERENCE.EPS

Flat Dome ConeFlat inclined Spherical

TANKTYPE.EPS

4-7

Page 46

Reference Manual

00809-0100-4032, Rev AA

Rosemount 5400 Series

Pipe Diameter

When the transmitter is mounted in a still pipe the inner diameter of the pipe

must be specified. The Pipe Diameter is used to compensate for the lower