Page 1

00809-0100-4022, Rev GA

Rosemount™ 4600 Oil & Gas Panel

Transmitter

Reference Manual

September 2016

Page 2

Page 3

Reference Manual

00809-0100-4022, Rev GA

Contents

1Section 1: Introduction

2Section 2: Configuration

Table of Contents

September 2016

1.1 Using this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.3 Commissioning on the bench with HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.4 Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.5 Review configuration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.6 Check output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7 Basic setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.8 Detailed setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.9 Diagnostics and service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.10 Advanced functions for HART protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.11 Multidrop communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3Section 3: Installation

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.3 General considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.4 Mechanical considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.5 Installation procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.6 Hazardous locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.7 Grounding the transmitter case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4Section 4: Operation and Maintenance

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

4.2 Calibration for HART

4.3 Sensor trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4.4 Recall factory trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.5 Analog output trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

®

protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table of Contents

5Section 5: Troubleshooting

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

5.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3

Page 4

Table of Contents

September 2016

AAppendix A: Specification and Reference Data

BAppendix B: Product Certifications

Reference Manual

00809-0100-4022, Rev GA

A.1 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

A.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

A.3 Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

B.1 European Directive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

B.2 Ordinary Location Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

B.3 Approval drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

4

Table of Contents

Page 5

Reference Manual

NOTICE

00809-0100-4022, Rev GA

Rosemount™ 4600

Oil & Gas Panel Transmitter

Read this manual before working with the product. For personal and system safety, and

for optimum product performance, make sure you thoroughly understand the

contents before installing, using, or maintaining this product.

Emerson

Customer Central

Technical support, quoting, and order-related questions.

United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

Asia Pacific- 65 777 8211

Europe/Middle East/Africa - 49 (8153) 9390

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of these areas, contact your local Emerson

representative.

™

Process Management has two toll-free assistance numbers:

Process Management

Title Page

September 2016

Title Page

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson

Process Management.

Apply torque only to the hex flat located at the process end of the transmitter. Do not

apply torque to the transmitter body or electrical connection - severe damage could

result. Do not exceed 100 ft-lbs.

Static electricity can damage sensitive components.

Observe safe handling precautions for static-sensitive components.

i

Page 6

Title Page

September 2016

Reference Manual

00809-0100-4022, Rev GA

Explosions can result in death or serious injury.

Transmitters located in hazardous areas should be installed in accordance with

local codes and requirements for that area.

Use appropriately rated Ex adapters, blanking elements, and glands during

installation.

Keep process insulation at least 1-in. [25 mm] from transmitter connection.

Electrical shock can result in death or serious injury.

Avoid contact with the exposed leads and terminals. High voltage that may be

present on leads can cause electrical shock.

Process leaks could result in death or serious injury.

Properly tighten process connections before applying pressure.

ii

Title Page

Page 7

Reference Manual

00809-01000-4022, Rev GA

Section 1 Introduction

1.1 Using this manual

The sections in this manual provides information on installing, operating, and maintaining

the Rosemount

Section 2: Configuration contains mechanical and electrical installation

Section 3: Installation provides instruction on commissioning and configuring the

Section 4: Operation and Maintenance contains operation and maintenance

Section 5: Troubleshooting provides troubleshooting techniques for the most

™

4600 Oil & Gas Pressure Transmitter. The sections are organized as follows:

instructions.

Rosemount 4600 Transmitter. Information on software functions, configuration

parameters, and online variables is also included.

instructions.

common operating problems.

Introduction

September 2016

Appendix A: Specification and Reference Data supplies reference and specification

data, as well as ordering information.

Appendix B: Product Certifications contains approval information

1.2 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation/regulations.

Introduction

1

Page 8

Introduction

September 2016

Reference Manual

00809-0100-4022, Rev GA

2

Introduction

Page 9

Reference Manual

00809-0100-4022, Rev GA

Section 2 Configuration

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Commissioning on the bench with HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Review configuration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Check output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Basic setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Detailed setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Diagnostics and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

Advanced functions for HART protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

Multidrop communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

2.1 Overview

Configuration

September 2016

This section contains information on commissioning and tasks that should be performed on the

bench prior to installation. This section contains the Rosemount

Transm itter HART

Field Communicator and AMS

functions. For convenience, Field Communicator Fast Key sequences are labeled “Fast Keys” for

each software function below the appropriate headings.

®

configuration information.

™

2.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a warning symbol ( ). Refer to the following safety messages before performing

an operation preceded by this symbol.

Explosions can result in death or serious injury.

Transmitters located in hazardous areas should be installed in accordance with local

codes and requirements for that area.

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

Electrical shock can result in death or serious injury.

Avoid contact with the exposed leads and terminals. High voltage that may be present

on leads can cause electrical shock.

™

4600 Oil & Gas Pressure

Device Manager instructions are given to perform configuration

Configuration

3

Page 10

Configuration

September 2016

Reference Manual

00809-0100-4022, Rev GA

2.3 Commissioning on the bench with HART

Commissioning consists of testing the Rosemount 4600 and verifying transmitter

configuration data. The transmitter can be commissioned either before or after installation.

Commissioning the transmitter on the bench before installation using a Field

Communicator or AMS Device Manager ensures that all transmitter components are in

working order.

To commission on the bench, connect the transmitter and the Field Communicator or AMS

Device Manager. Connect Field Communicator leads at any termination point in the signal

loop.

In order to commission the transmitter, the power supply must provide 11.25 to

42.4 V dc at the transmitter terminals. A current meter is also required to measure current

output. To enable communication, a resistance of at least 250 ohms must be present

between the Field Communicator loop connection and the power supply. Do not use

inductive-based transient protectors with more than 3 mH of inductance with the

Rosemount 4600.

When using a Field Communicator, any configuration changes made must be sent to the

transmitter by using the “Send” key (F2). AMS Device Manger configuration changes are

implemented when the “Apply” button is selected.

For more information on the Field Communicator, see 475 Field Communicator website for

the most up to date literature. AMS Device Manger help can be found in the AMS Device

Manager online guides within the AMS system.

2.3.1 Setting the loop to manual

Whenever sending or requesting data that would disrupt the loop or change the output of

the transmitter, set the process application loop to manual. The Field Communicator or

AMS Device Manager will prompt you to set the loop to manual when necessary.

Acknowledging this prompt does not set the loop to manual. The prompt is only a

reminder; set the loop to manual as a separate operation.

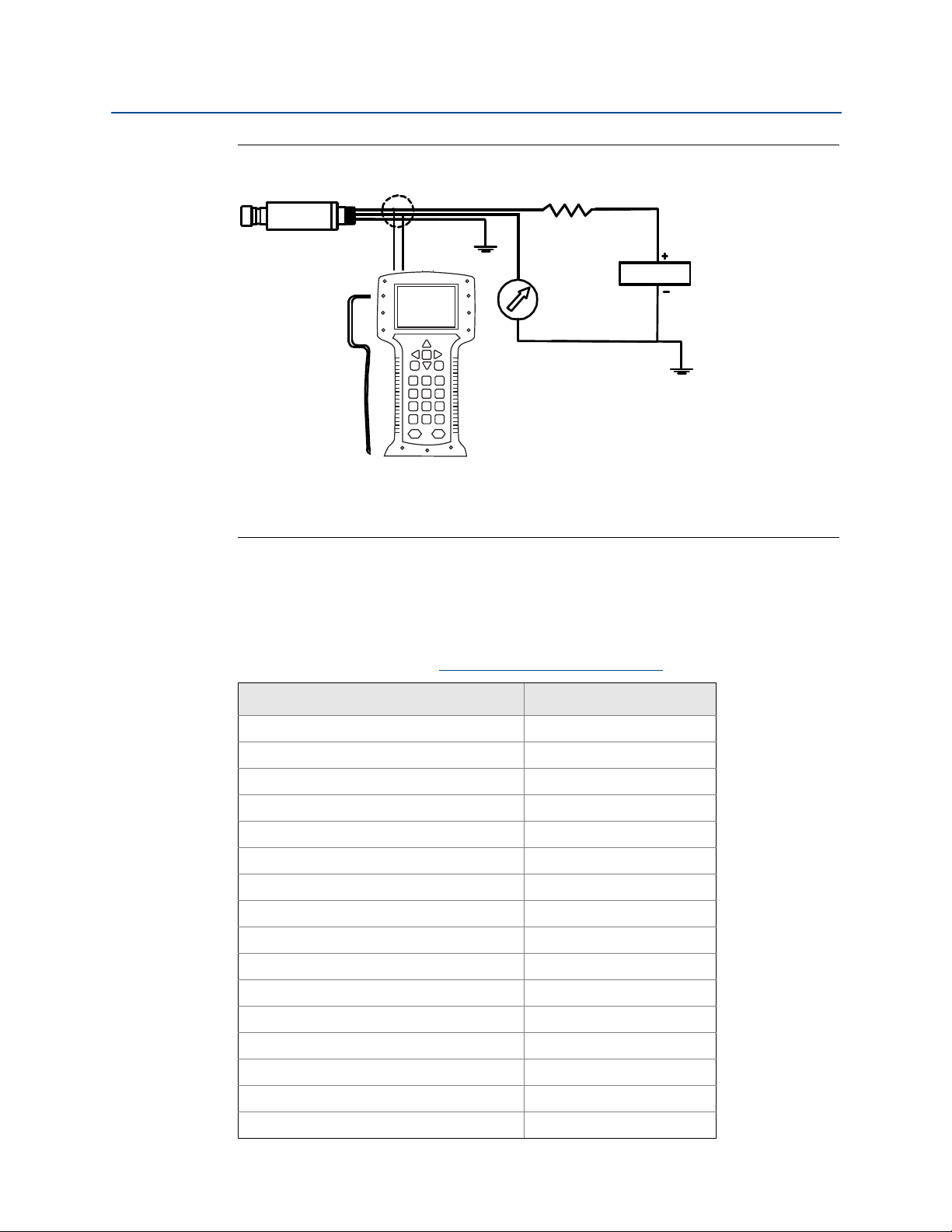

2.3.2 Wiring diagrams

Bench hook-up

Connect the bench equipment as shown in Figure 2-1 and turn on the Field Communicator

by pressing the ON/OFF key or log into AMS Device Manager. The Field Communicator or

AMS Device Manager will search for a HART-compatible device and indicate when the

connection is made. If the Field Communicator or AMS Device Manager fail to connect, it

indicates that no device was found. If this occurs, refer to Section 5: Troubleshooting.

4

Configuration

Page 11

Reference Manual

B

D

C

A

E

00809-0100-4022, Rev GA

Figure 2-1. Bench Wiring (4–20 mA)

Configuration

September 2016

A. Rosemount 4600

> 250 ohm

B. R

L

C. Power supply

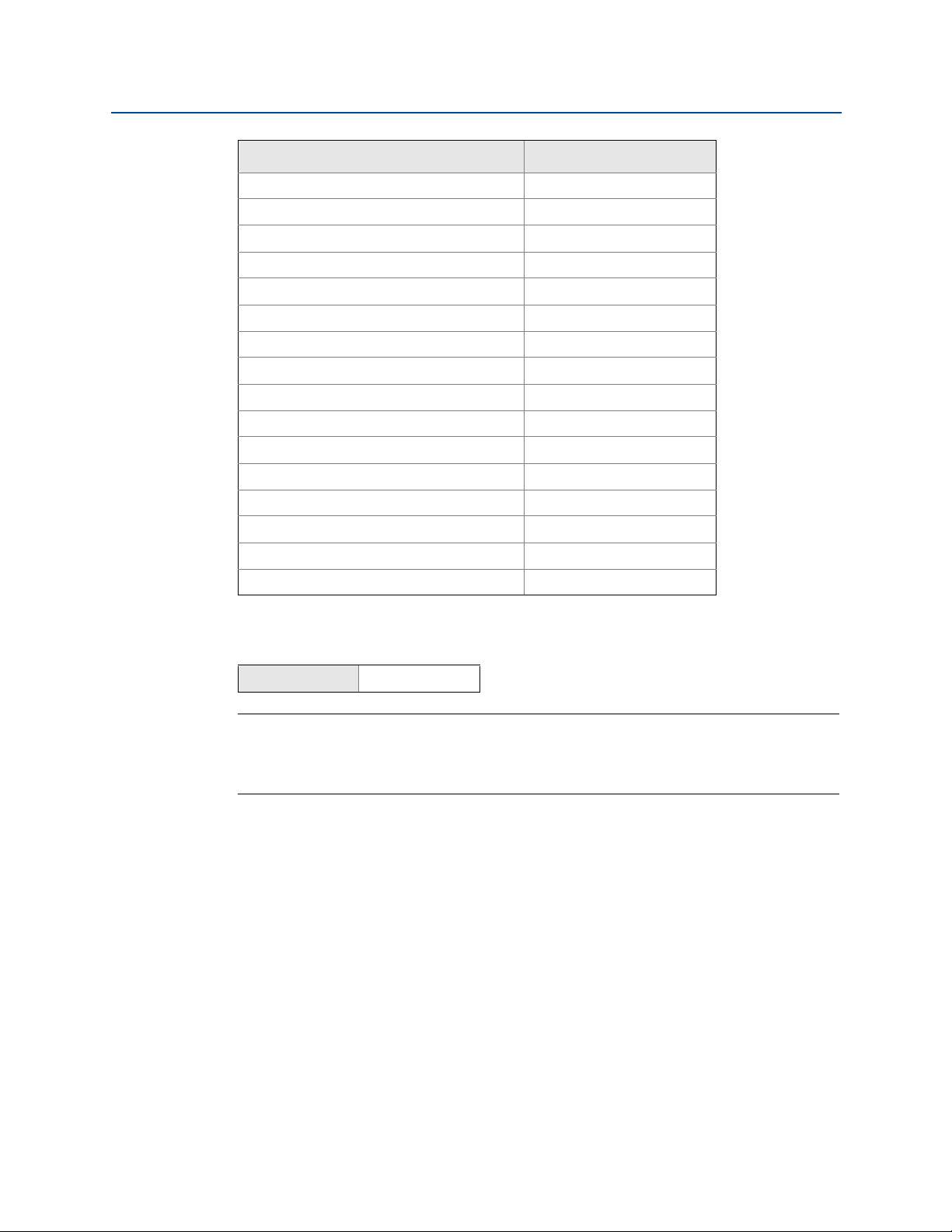

2.4 Field Communicator

The following menu indicates Fast Key sequences for common functions. For full Field

Communicator menu tree see EmersonProcess.com/Rosemount

Func tion HART Fast Key Sequence

Alarm Level Config. 1, 4, 2, 7, 7

Alarm and Saturation Levels 1, 4, 2, 7

Analog Output Alarm Direction 1, 4, 2, 7, 6

Analog Output Trim 1, 2, 3, 2

Burst Mode On/Off 1, 4, 3, 3, 3

Burst Options 1, 4, 3, 3, 4

Damping 1, 3, 6

Date 1, 3, 4, 1

D. Current meter

E. Field Communicator

.

Descriptor 1, 3, 4, 2

Digital To Analog Trim (4-20 mA Output) 1, 2, 3, 2, 1

Configuration

Field Device Information 1, 4, 4, 1

Loop Test 1, 2, 2

Lower Sensor Trim 1, 2, 3, 3, 1

Message 1, 3, 4, 3

Number of Requested Preambles 1, 4, 3, 3, 2

Pressure Alert Config. 1, 4, 3, 4, 3

5

Page 12

Configuration

September 2016

Reference Manual

00809-0100-4022, Rev GA

Func tion HART Fast Key Sequence

Poll Address 1, 4, 3, 3, 1

Poll a Multidropped Transmitter Left Arrow, 3, 1, 1

Rerange- Keypad Input 1, 2, 3, 1, 1

Saturation Level Config. 1, 4, 2, 7, 8

Scaled D/A Trim (4–20 mA Output) 1, 2, 3, 2, 2

Sensor Information 1, 4, 4, 2

Sensor Temperature 1, 1, 4

Sensor Trim 1, 2, 3, 3

Sensor Trim Points 1, 2, 3, 3, 4

Status 1, 2, 1

Ta g 1, 3, 1

Temperature Alert Config. 1, 4, 3, 4, 4

Transmitter Security (Write Protect) 1, 3, 4, 4

Units (Process Variable) 1, 3, 2

Upper Sensor Trim 1, 2, 3, 3, 2

Zero Trim 1, 2, 3, 3, 1

2.5 Review configuration data

Fast Keys

Note

Information and procedures in this section that make use of Field Communicator Fast Key

sequences and AMS Device Manager assume the transmitter and communication

equipment are connected, powered, and operating correctly.

1, 5

6

Configuration

Page 13

Reference Manual

00809-0100-4022, Rev GA

Field Communicator

Before placing the transmitter into operation, review the transmitter configuration data

below which was set by the factory.

PV Lower Sensor Limit (LSL) Ta g

PV Upper Sensor Limit (USL) Date

PV Lower Range Value (LRV) Descriptor

PV Upper Range Value (URV) Message

PV minimum span Write protect

Lower sensor trim point Local keys

Upper sensor trim point Universal revision

Sensor trim calibration type Field device revision

Damping Software revision

Alarm direction Hardware revision

High Alarm (Value) Physical signal code

Low Alarm (Value) Final assembly number

High saturation Device ID

Low saturation Burst mode

Alarm/Saturation type Burst option

Sensor S/N Poll address

Isolator material Number req preams

Fill fluid Distributor

Process connector

Process connector material

Configuration

September 2016

AMS Device Manger

Right click on the device and select Configuration Properties from the menu. Select the

tabs to review the transmitter configuration data.

2.6 Check output

Before performing other transmitter online operations, review the digital output

parameters to ensure the transmitter is operating properly and is configured to the

appropriate process variables.

2.6.1 Process variables

Fast Keys

The process variables for the Rosemount 4600 provide transmitter output, and are

continuously updated. The pressure reading in both engineering units and percent of range

will continue to track with pressures outside of the defined range from the lower to the

upper range limit.

1, 1

Configuration

7

Page 14

Configuration

September 2016

Reference Manual

00809-0100-4022, Rev GA

Field Communicator

The process variable menu displays the following process variables:

Pressure

Percent of range

Analog output

Sensor temperature

Note

Regardless of the range points, the Rosemount 4600 will measure and report all readings

within the digital limits of the sensor. For example, if the 4 and 20 mA points are set to

0 and 1,000 psi, and the transmitter detects a pressure of 2,500 psi, it digitally outputs the

2,500 psi reading and a 250% of span reading. However, there may be up to ±5.0% error

associated with output outside of the range points.

AMS Device Manger

Right click on the device and select Process Variables... from the menu.The process

variable screen displays the following process variables:

Pressure

Percent of range

Analog output

Sensor temperature

2.6.2 Sensor temperature

Fast Keys

The Rosemount 4600 contains a temperature sensor near the pressure sensor in the

transmitter. When reading this temperature, keep in mind this is not an accurate indicator

of process temperature.

Field Communicator

Enter the Fast Key sequence below Sensor Temperature to view the sensor temperature

reading.

AMS Device Manger

Right click on the device and select Process Variables... from the menu. Snsr Temp is the

sensor temperature reading.

1, 1, 4

8

Configuration

Page 15

Reference Manual

00809-0100-4022, Rev GA

2.7 Basic setup

2.7.1 Set process variable units

Configuration

September 2016

Fast Keys

The PV Unit command sets the process variable units to allow you to monitor your process

using the appropriate units of measure.

Field Communicator

Enter the Fast Key sequence shown. Select from the following engineering units:

inH

O bar torr

2

inHg mbar atm

ftH

O g/cm

2

mmH

mmHg Pa mmH

psi kPa

O kg/cm

2

AMS Device Manger

Right click on the device and select Configuration Properties from the menu. In the Basic

Setup tab, use Unit drop down menu to select units.

2.7.2 Rerange

The Range Values command sets the 4 and 20 mA points and digital lower (LRV) and upper

(URV) range values. In practice, you may reset the transmitter range values as often as

necessary to reflect changing process conditions. Changing the lower or upper range point

results in similar changes to the span.

1, 3, 2

2

2

MPa

inH2O at 4 °C

O at 4 °C

2

Configuration

Note

Transmitters are shipped from Emerson Process Management. fully calibrated per request

or by the factory default of full scale (span = upper range limit.)

Use one of the methods below to rerange the transmitter. Each method is unique; examine

all options closely before deciding which method works best for your process.

Rerange with a Field Communicator only.

Rerange with a pressure input source and a Field Communicator.

Rerange with a pressure input source and the local zero and span targets (option

D1).

Rerange with AMS Device Manger only.

Rerange with a pressure input source and AMS Device Manger.

9

Page 16

Configuration

September 2016

Reference Manual

00809-0100-4022, Rev GA

Rerange with a Field Communicator only

Fast Keys

The easiest and most popular way to rerange is to use the Field Communicator only. This

method changes the values of the analog 4 and 20 mA points independently without a

pressure input.

From the HOME screen, enter the Fast Key sequence shown.

1. At Keypad Input select 1 and use the keypad to enter lower range value.

2. From Keypad Input select 2 and use the keypad to enter upper range value.

1, 2, 3, 1, 1

Rerange with a pressure input source and Field

Communicator

Fast Keys

Reranging using the Field Communicator and a pressure source or process pressure is a way

of reranging the transmitter when specific 4 and 20 mA points are unknown.

Note

The span is maintained when the 4 mA point is set. The span changes when the 20 mA point

is set. If the lower range point is set to a value that causes the upper range point to exceed

the sensor limit, the upper range point is automatically set to the sensor limit, and the span

is adjusted accordingly.

1, 2, 3, 1, 2

1. From the HOME screen, enter the Fast Key sequence shown to configure lower and

upper range values and follow the online instructions.

Rerange with a pressure input source and the

local zero and span targets (option D1)

1. For Zero based lower range values (gauge only):

Vent the transmitter.

For Non-Zero based lower range values:

Using a pressure source with an accuracy 3 to 10 times the desired calibrated

accuracy, apply a pressure equivalent to the lower range value to the transmitter.

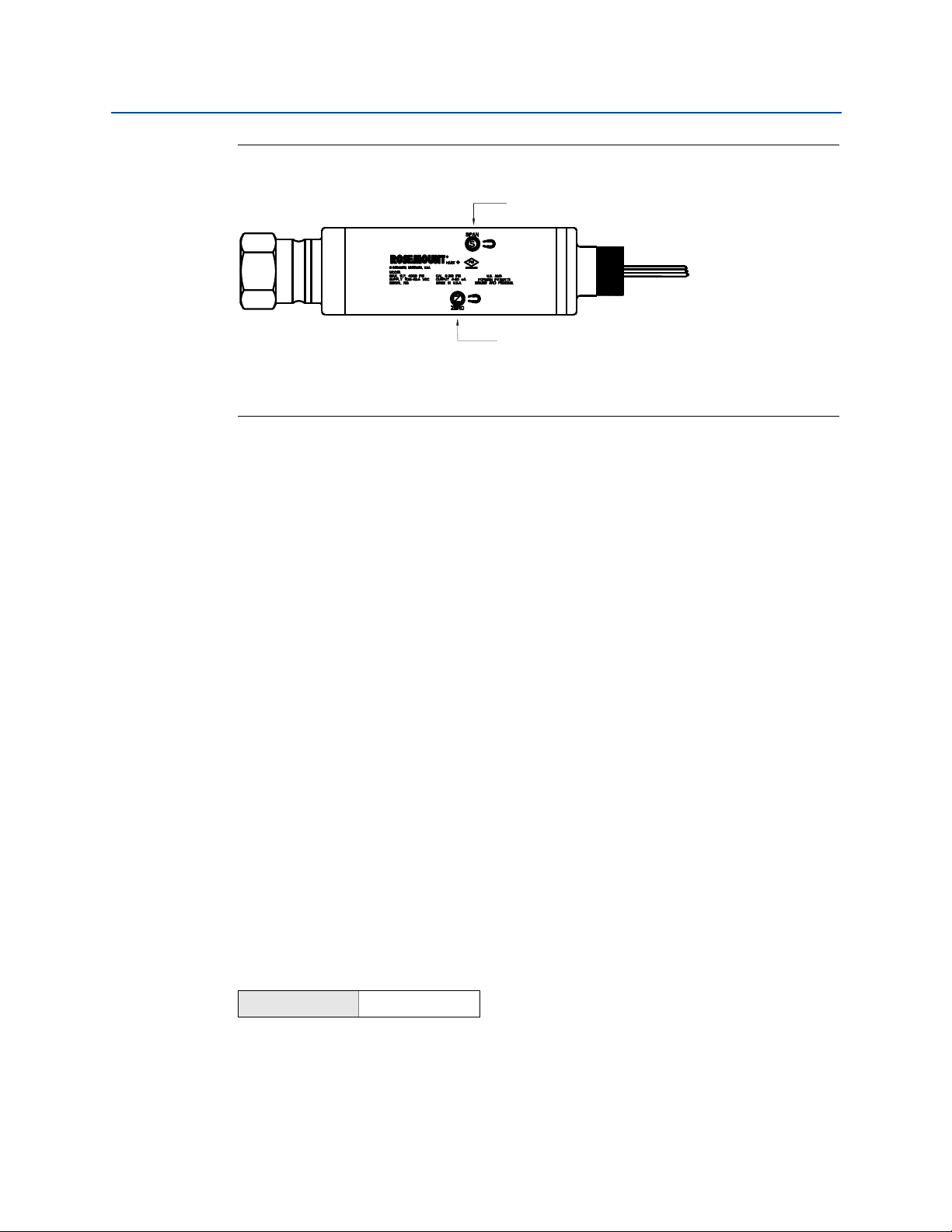

2. Using the supplied magnetic adjustment tool, touch and hold the magnetic end to

the zero adjustment target for at least two seconds, but no longer than ten

seconds.

3. Using a pressure source with an accuracy 3 to 10 times the desired calibrated

accuracy, apply a pressure equivalent to the upper range value to the transmitter.

4. Using the supplied magnetic adjustment tool, touch and hold the magnetic end to

the span adjustment target for at least two seconds, but no longer than ten

seconds.

10

Configuration

Page 17

Reference Manual

B

A

00809-0100-4022, Rev GA

Figure 2-2. Local Zero and Span Locations

A. Magnetic span target

B. Magnetic zero target

Rerange with AMS Device Manger only

Right click on the device and select Configuration Properties from the menu. In the Basic

Setup tab, locate the Analog Output box and perform the following procedure:

Configuration

September 2016

1. Enter the lower range value (LRV) and the upper range value (URV) in the fields

provided. Select Apply.

2. An Apply Parameter Modification screen appears, enter desired information and

select OK.

3. After carefully reading the warning provided, select OK.

Rerange with a pressure input source and AMS Device

Manger

Right click on the device, choose Calibrate, then Apply values from the menu.

1. Select Next after the control loop is set to manual.

2. From the Apply Values menu, follow the online instructions to configure lower and

upper range values.

3. Select Exit to leave the Apply Values screen.

4. Select Next to acknowledge the loop can be returned to automatic control.

5. Select Finish to acknowledge the method is complete.

2.7.3 Damping

Configuration

Fast Keys

The Damp command introduces a delay in processing which increases the response time of

the transmitter; smoothing variations in output readings caused by rapid input changes.

Determine the appropriate damp setting based on the necessary response time, signal

stability, and other requirements of the of loop dynamics of your system. The default

damping value is 0.4 seconds and is user-selectable from 0.3 to 60 seconds.

1, 3, 6

11

Page 18

Configuration

September 2016

AMS Device Manger

Right click on the device and select Configuration Properties from the menu.

1. In the Basic Setup tab, enter the damping value in the Damp field, select Apply.

2. An Apply Parameter Modification screen appears, enter desired information and

select OK.

3. After carefully reading the warning provided, select OK.

2.8 Detailed setup

2.8.1 Failure mode alarm and saturation

The Rosemount 4600 Transmitter automatically and continuously perform self-diagnostic

routines. If the self-diagnostic routines detect a failure, the transmitter drives the output to

configured alarm values. The transmitter will also drive the output to configured saturation

values if the applied pressure goes outside the 4-20 mA range values.

Reference Manual

00809-0100-4022, Rev GA

Note

The failure mode alarm direction can also be configured using the Field Communicator or

AMS Device Manager.

Note

Under some failure conditions, the transmitter will ignore user configured alarm conditions

and drive the transmitter to low alarm.

The Rosemount 4600 Transmitter have three configurable options for failure mode alarm

and saturation levels:

Rosemount (Standard), see Table 2- 1

Custom, see Tab le 2-2

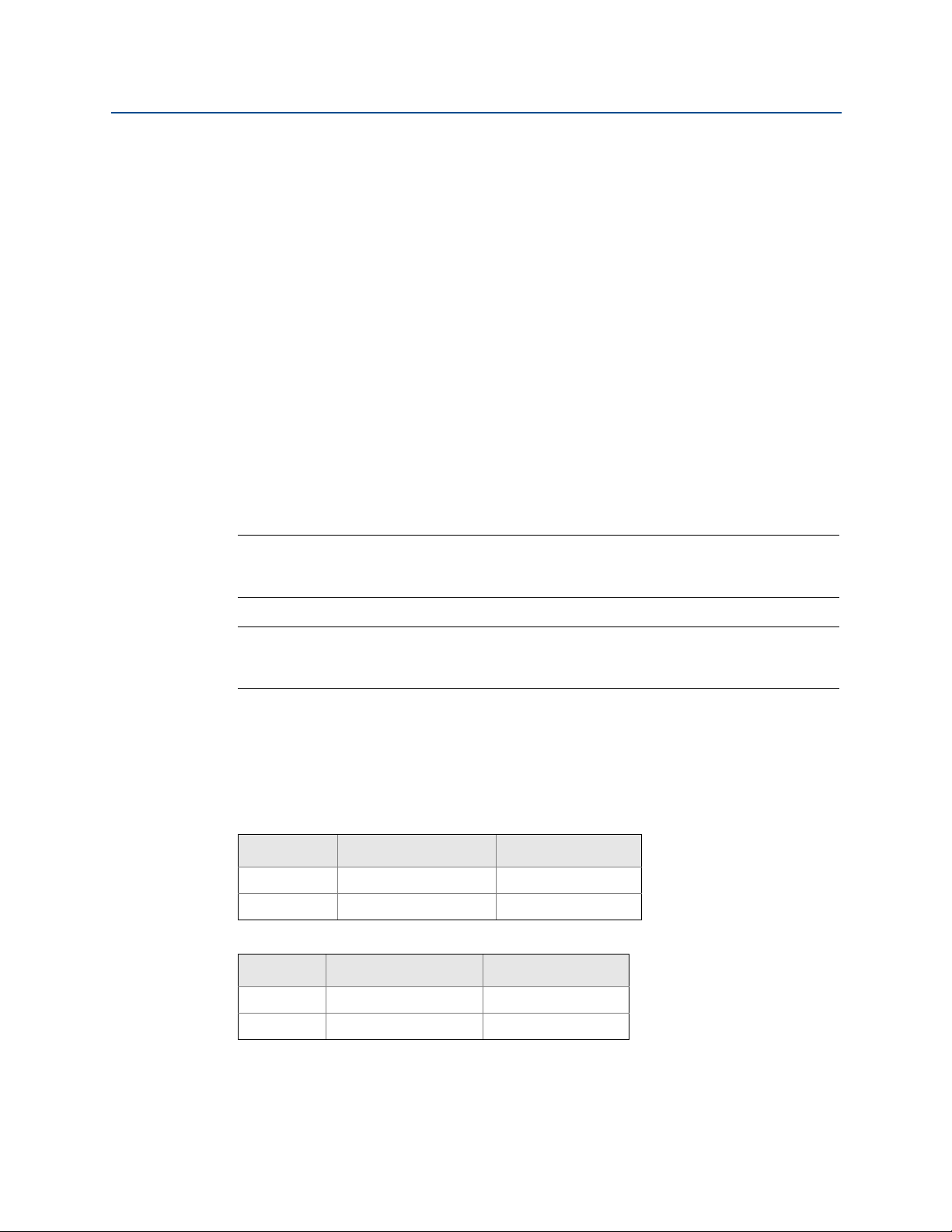

Table 2-1. Rosemount (Standard) Alarm and Saturation Values

Level 4–20 mA saturation 4–20 mA alarm

Low 3.9 mA ≤ 3.75 mA

High 20.8 mA ≥ 21.75 mA

Table 2-2. Custom Alarm and Saturation Values

Level 4–20 mA saturation 4–20 mA alarm

12

Low 3.7 mA — 3.9 mA 3.6 mA — 3.8 mA

High 20.1 mA — 21.5 mA 20.2 mA — 23.0 mA

Configuration

Page 19

Reference Manual

00809-0100-4022, Rev GA

Failure mode alarm and saturation levels can be configured using a Field Communicator or

AMS Device Manager, see “Alarm and saturation level configuration” on page 13. Per

Ta bl e 2 - 2, custom alarm and saturation levels can be configured between 3.6 mA and

3.9 mA for low values and between 20.1 mA and 23 mA for high values. The following

limitations exist for custom levels:

Low alarm level must be less than the low saturation level

High alarm level must be higher than the high saturation level

High saturation level must not exceed 21.5 mA

Alarm and saturation levels must be separated by at least 0.1 mA

The Field Communicator or AMS Device Manager will provide an error message if a

configuration rule is violated.

2.8.2 Alarm and saturation level configuration

Configuration

September 2016

Fast Keys

1, 4, 2, 7

To configure alarm and saturation levels with a Field Communicator or AMS Device Manager

perform the following procedure:

Field Communicator

1. From the HOME screen, follow the Fast Key sequence under Alarm and Saturation

Levels.

2. Select 7, Config. Alarm Level to configure alarm levels.

3. Select OK after setting the control loop to manual.

4. Select OK to acknowledge current settings.

5. Select desired setting, if OTHER is selected, enter HI and LO custom values.

6. Select OK to acknowledge the loop can be returned to automatic control.

7. Select 8, Config. Sat. Levels to configure saturation levels.

8. Repeat steps 3-6 to configure saturation levels.

Configuration

13

Page 20

Configuration

September 2016

Reference Manual

00809-0100-4022, Rev GA

AMS Device Manger

1. Right click on the device, select Device Configuration,

2. Select Alarm/Saturation Levels,

3. Select Alarm Levels from the menu

.

4. Select Next after setting the control loop to manual.

5. Select Next after acknowledging the current alarm levels.

6. Select the desired alarm settings: NAMUR, Rosemount, Other

7. If Other is selected, enter desired HI Value and LO Value custom values.

8. Select Next to acknowledge new alarm levels.

9. Select Next to acknowledge the loop can be returned to automatic control.

10. Select Finish to acknowledge the method is complete.

11. Right click on the device, select Device Configuration, then select

Alarm/Saturation Levels, then Alarm Levels from the menu

12. Select Saturation Levels.

13. Repeat Step 5 - 11 to configure saturation levels.

2.8.3 Alarm and saturation levels for burst mode

Transmitters set to burst mode handle saturation and alarm conditions differently.

.

14

Alarm conditions

Analog output switches to alarm value

Primary variable is burst with a status bit set

Percent of range follows primary variable

Temperature is burst with a status bit set

Saturation

Analog output switches to saturation value

Primary variable is burst normally

Tem perature is b urst normally

Configuration

Page 21

Reference Manual

00809-0100-4022, Rev GA

Configuration

September 2016

2.8.4 Alarm and saturation values for multidrop mode

Transmitters set to multidrop mode handle saturation and alarm conditions differently.

Alarm conditions

Primary variable is sent with a status bit set

Percent of range follows primary variable

Temperature is sent with a status bit set

Saturation

Primary variable is sent normally

Temperature is sent normally

2.8.5 Alarm level verification

To verify the transmitter alarm values, perform a loop test and set the transmitter output to

the alarm value (see Tables 2-1 and 2-2 on page 12, and “Advanced functions for HART

protocol” on page 18). This feature is also useful in testing the reaction of the control

system to a transmitter in an alarm state.

2.8.6 Process alerts

Fast Keys

Process alerts allow the user to configure the transmitter to output a HART message when

the configured data point is exceeded. Process alerts can be set for pressure, temperature,

or both. A process alert will be transmitted continuously if the pressure or temperature set

points are exceeded and the alert mode is ON. An alert will be displayed on a Field

Communicator, or AMS Device Manger status screen. The alert will reset once the value

returns within range.

Note

HI alert value must be higher than the LO alert value. Both alert values must be within the

pressure or temperature sensor limits.

Field Communicator

To configure the process alerts with a Field Communicator, perform the following

procedure:

1. From the HOME screen, follow the Fast Key sequence listed.

2. Select 3, Config Press Alert to configure the pressure alert.

Select 4, Config Temp Alert to configure the temperature alerts.

1, 4, 3, 4

Configuration

3. Use the right arrow key to configure the HI and LO alert values.

4. Use the left arrow to move back to the process alert menu.

Select 1, Press Alert Mode to turn on the pressure alert mode.

Select 2, Temp Alert Mode to turn on the temperature alert mode.

15

Page 22

Configuration

September 2016

AMS Device Manger

Right click on the device and select Configuration Properties from the menu.

1. In the Analog Output tab, locate the Configuration Pressure Alerts box, enter Press Hi Alert

Val and Press Lo Alert Val to configure the pressure alerts.

2. Configure Press Alert Mode to ON or OFF the drop down menu.

3. In the Configuration Temperature Alerts box, enter Temp Hi Alert Val and Temp Lo A lert Val

to configure the temperature alerts.

4. Configure Temp Alert Mode to ON or OFF using the drop down menu and select Apply.

5. An Apply Parameter Modification screen appears, enter desired information and select

OK.

6. After carefully reading the warning provided, select OK.

2.8.7 Sensor temperature unit

Reference Manual

00809-0100-4022, Rev GA

Fast Keys

The Sensor Temperature Unit command selects between Celsius and Fahrenheit units for the

sensor temperature. The sensor temperature output is accessible via HART only.

1, 4, 1, 2, 2

AMS Device Manger

Right click on the device and select Configuration Properties from the menu.

1. In the Process Input tab, use the drop down menu Snsr temp unit to select F (Farenheit)

or C (Celsius). Select Apply.

2. Select Next to acknowledge send warning.

3. Select Finish to acknowledge the method is complete.

4. An Apply Parameter Modification screen appears, enter desired information and select

OK.

5. After carefully reading the warning, select OK.

2.9 Diagnostics and service

Diagnostics and service functions listed below are primarily for use after field installation. The

Transmitter Test feature is designed to verify that the transmitter is operating properly, and can

be performed either on the bench or in the field. The Loop Test feature is designed to verify

proper loop wiring and transmitter output, and should only be performed after you install the

transmitter.

16

Configuration

Page 23

Reference Manual

00809-0100-4022, Rev GA

2.9.1 Loop Test

Configuration

September 2016

Fast Keys

The Loop Test command verifies the output of the transmitter, the integrity of the loop, and the

operations of any recorders or similar devices installed in the loop.

1, 2, 2

Field Communicator

To initiate a loop test, perform the following procedure:

1. Connect a reference meter to the transmitter by shunting transmitter power through

the meter at some point in the loop.

2. From the Home screen, enter the Fast Key sequence below Loop Test to verify the

output of the transmitter.

3. Select OK after the control loop is set to manual (see “Setting the loop to manual” on

page 4).

4. Select a discrete milliamp level for the transmitter to output. At the Choose Analog

Output prompt select 1: 4mA, select 2: 20mA, or select 3: Other to manually input a

value.

a. If you are performing a loop test to verify the output of a transmitter, enter a value

between 4 and 20 mA.

b. If you are performing a loop test to verify alarm levels, enter the milliamp value

representing an alarm state (see Tables 2-1and 2-2 on page 12).

5. Check the reference meter installed in the test loop to verify that it displays the

commanded output value.

a. If the values match, the transmitter and the loop are configured and functioning

properly.

b. If the values do not match, the current meter may be attached to the wrong loop, there

may be a fault in the wiring, the transmitter may require an output trim, or the

reference meter may be malfunctioning.

After completing the test procedure, the display returns to the loop test screen to select

another output value or to end loop testing.

Configuration

17

Page 24

Configuration

September 2016

Reference Manual

00809-0100-4022, Rev GA

AMS Device Manger

1. Right click on the device and select Diagnostics and Test then Loop test from the

menu.

2. Select Next after setting the control loop to manual.

3. Select desired analog output level. Select Next.

4. Select Next to acknowledge output being set to desired level.

5. Check the reference meter installed in the test loop to verify that it displays the

commanded output value.

a. If the values match, the transmitter and the loop are configured and functioning

properly.

b. If the values do not match, the current meter may be attached to the wrong loop, there

may be a fault in the wiring, the transmitter may require an output trim, or the

reference meter may be malfunctioning.

After completing the test procedure, the display returns to the loop test screen to select

another output value or to end loop testing.

6. Select End and select Next to end loop testing.

7. Select Next to acknowledge the loop can be returned to automatic control.

8. Select Finish to acknowledge the method is complete.

2.10 Advanced functions for HART protocol

2.10.1 Saving, recalling, and cloning configuration data

Fast Keys

Use the cloning feature of the Field Communicator or the AMS Device Manger “User

Configuration” feature to configure several Rosemount 4600 Transmitter similarly. Cloning

involves configuring a transmitter, saving the configuration data, then sending a copy of the

data to a separate transmitter. Several possible procedures exist when saving, recalling, and

cloning configuration data. For complete instructions refer to the Field Communicator

Reference Manual

Note

Do not clone an absolute pressure transmitter with sealed gauge pressure configuration data.

Do not clone a sealed gauge pressure transmitter with absolute pressure data.

left arrow, 1, 2

or AMS online guides. One common method is as follows:

18

Configuration

Page 25

Reference Manual

00809-0100-4022, Rev GA

Field Communicator

1. Confirm and apply configuration changes to the first transmitter.

Note

If transmitter configuration has not been modified, “SAVE” option in Step 2 will be disabled.

2. Save the configuration data:

a. Select SAVE from the bottom of the Field Communicator screen.

b. Select to save your configuration in either the “Internal Flash” (default) or the

c. Enter the name for this configuration file. The default name is the transmitter tag

d. Select SAVE.

3. Power the receiving transmitter and connect with Field Communicator.

4. Access the HART Application menu by pressing the LEFT ARROW from the

Configuration

September 2016

“Configuration EM” (Configuration Expansion Module).

number.

HOME/ONLINE screen.

5. Locate the saved transmitter configuration file.

a. Select Offline

b. Select Saved Configuration

c. Select either Internal Flash Contents or Configuration EM Content depending on

where the configuration was stored per Step 2b.

6. Use the DOWN ARROW to scroll through the list of configurations in the memory

module, and use the RIGHT ARROW to select and retrieve the desired

configuration.

7. Select Send to transfer the configuration to the receiving transmitter.

8. Select OK after the control loop is set to manual.

9. After the configuration has been sent, select OK to acknowledge that the loop can

be returned to automatic control. When finished, the Field Communicator informs

you of the status. Repeat Step 3 through Step 9 to configure another transmitter.

Note

The transmitter receiving cloned data must have the same software version (or later) as the

original transmitter.

Configuration

19

Page 26

Configuration

September 2016

Reference Manual

00809-0100-4022, Rev GA

AMS Device Manger creating a reusable copy

To create a reusable copy of a configuration perform the following procedure:

1. Select View then User Configuration View from the menu bar (or click the toolbar

button).

2. In the User Configuration window, right click and select New from the context

menu.

3. In the New window, select a device from the list of templates shown, and select OK.

4. The template is copied into the User Configurations window, with the tag name

highlighted; rename it as appropriate and select Enter.

Note

A device icon can also be copied by dragging and dropping a device template or any other

device icon from AMS Explorer or Device Connection View into the User Configurations

window.

The Compare Configurations window appears, showing the Current values of the copied

device on one side and mostly blank fields on the other (User Configuration) side.

5. Transfer values from the current configuration to the user configuration as

appropriate or enter values by typing them into the available fields.

6. Select Apply to apply the values, or select OK to apply the values and close the

window.

AMS Device Manger applying a user configuration

Any amount of user configurations can be created for the application. They can also be

saved, and applied to connected devices or to devices in the device list or plant database.

Note

When using AMS Revision 6.0 or later, the device to which the user configuration is applied,

bust be the same model type as the one created in the user configuration. When using AMS

Revision 5.0 or earlier, the same model type and revision number are required.

To apply a user configuration, perform the following procedure:

1. Select the desired user configuration in the User Configurations window.

2. Drag the icon onto a like device in AMS Explorer or Device Connection View. The

Compare Configurations window opens, showing the parameters of the target

device on one side and the parameters of the user configuration on the other.

20

3. Transfer parameters from the user configuration to the target device as desired.

Select OK to apply the configuration and close the window.

Configuration

Page 27

Reference Manual

00809-0100-4022, Rev GA

2.10.2 Burst mode

Configuration

September 2016

Fast Keys

When configured for burst mode, the Rosemount 4600 provides faster digital communication

from the transmitter to the control system by eliminating the time required for the control

system to request information from the transmitter. Burst mode is compatible with the analog

signal. Because the HART protocol features simultaneous digital and analog data transmission,

the analog value can drive other equipment in the loop while the control system is receiving the

digital information. Burst mode applies only to the transmission of dynamic data (pressure and

temperature in engineering units, pressure in percent of range, and/or analog output), and does

not affect the way other transmitter data is accessed.

Access to information other than dynamic transmitter data is obtained through the normal

poll/response method of HART communication. A Field Communicator, AMS Device Manger or

the control system may request any of the information that is normally available while the

transmitter is in burst mode. Between each message sent by the transmitter, a short pause

allows the Field communicator, AMS Device Manger or a control system to initiate a request.

The transmitter will receive the request, process the response message, and then continue

“bursting” the data approximately three times per second.

1, 4, 3, 3, 3

Field Communicator

To configure the transmitter for burst mode, perform the following step:

1. From the HOME screen, enter the Fast Key sequence below Burst Mode.

AMS Device Manger

Right click on the device and select Configuration Properties from the menu.

1. In the HART tab, use the drop down menu to select Burst Mode ON or OFF. For Burst

option select the desired properties from the drop down menu. Burst options are as

follows:

PV

% range/current

Process vars/crnt

Process variables

2. After selecting options, select Apply.

3. An Apply Parameter Modification screen appears, enter desired information and select

OK.

4. After carefully reading the warning provided, select OK.

Configuration

21

Page 28

Configuration

September 2016

2.11 Multidrop communication

Multidropping transmitters refers to the connection of several transmitters to a single

communications transmission line. Communication between the host and the transmitters

takes place digitally with the analog output of the transmitters deactivated. Up to 15

transmitters can be connected on a single twisted pair of wires.

Multidrop installation requires consideration of the update rate necessary from each

transmitter, the combination of transmitter models, and the length of the transmission line.

Communication with transmitters can be accomplished with Bell 202 modems and a host

implementing HART protocol. Each transmitter is identified by a unique address (1–15) and

responds to the commands defined in the HART protocol. Field Communicators and AMS

Device Manger can test, configure, and format a multidropped transmitter the same way as

a transmitter in a standard point-to-point installation.

Figure 2-3 shows a typical multidrop network. This figure is not intended as an installation

diagram.

Figure 2-3. Typical Multidrop Network

Reference Manual

00809-0100-4022, Rev GA

A

B

C

A. Bell 202 Modem

B. RS-232-C

C. Power supply

The Rosemount 4600 is set to address zero (0) at the factory, which allows operation in the

standard point-to-point manner with a 4–20 mA output signal. To activate multidrop

communication, the transmitter address must be changed to a number from 1 to 15. This

change deactivates the 4–20 mA analog output, sending it to 4 mA. It also disables the

failure mode alarm signal, which is controlled by the upscale/downscale alarm direction

configuration parameter. Failure signals in multidropped transmitters are communicated

through HART messages.

Note

A minimum loop resistance of 250 ohms is required to communicate with a Field

Communicator. If a single power supply is used to power more than one Rosemount 4600,

the power supply and circuitry common to the transmitter, should not have more than

20 ohms of impedance at 1200 Hz.

22

Configuration

Page 29

Reference Manual

00809-0100-4022, Rev GA

2.11.1 Changing a transmitter address

Configuration

September 2016

Fast Keys

To activate multidrop communication, the transmitter poll address must be assigned a

number from one to 15, and each transmitter in a multidropped loop must have a unique

poll address.

1, 4, 3, 3, 1

Field Communicator

1. From the HOME screen, enter the Fast Key sequence shown.

AMS Device Manger

Right click on the device and select Configuration Properties from the menu.

1. In the HART tab, in the ID box, enter the poll address located in the Poll addr box.

Select Apply.

2. An Apply Parameter Modification screen appears. Enter the desired information and

select OK.

3. After carefully reading the warning provided, select OK.

2.11.2 Communicating with a multidropped transmitter

Fast Keys

Lef t a rrow, 3, 1, 1

Field Communicator

To communicate with a multidropped transmitter, configure the Field Communicator to

poll for a non-zero address.

1. From the HOME screen, enter the Fast Key sequence shown.

2. On the polling menu, scroll down and select Polling Addresses and select the

appropriate polling range. In this mode, the Field Communicator automatically

polls for devices at addresses within the specified range upon start up.

AMS Device Manger

1. Select on the HART modem icon and select Scan All Devices.

2.11.3 Polling a multidropped transmitter

Fast Keys

Polling a multidropped loop determines the model, address, and number of transmitters on

the given loop.

Field Communicator

1. From the HOME screen, enter the Fast Key sequence shown.

Left arrow, 3, 1

Configuration

AMS Device Manger

1. Select on the HART modem icon and select Scan All Devices.

23

Page 30

Configuration

September 2016

Reference Manual

00809-0100-4022, Rev GA

24

Configuration

Page 31

Reference Manual

00809-0100-4022, Rev GA

Section 3 Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

General considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

Mechanical considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

Installation procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

Hazardous locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

Grounding the transmitter case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 33

3.1 Overview

The information in this section covers installation considerations. A Quick Start Guide

(document number 00825-0100-4022) is shipped with every transmitter to describe basic

mounting and wiring procedures for initial installation.

Installation

September 2016

Field Communicator and AMS

perform configuration functions. For convenience, Field Communicator Fast Key sequences

are provided and labeled “Fast Keys” for each software function below the appropriate

headings.

™

3.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operation. Information that raises potential safety

issues is indicated with a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

Explosions can result in death or serious injury.

Transmitters located in hazardous areas should be installed in accordance with

local codes and requirements for that area.

Use appropriately rated Ex adapters, blanking elements, and glands during

installation.

Keep process insulation at least 1-in. (25 mm) from transmitter connection.

Electrical shock can result in death or serious injury.

Avoid contact with the exposed leads and terminals. High voltage that may be

present on leads can cause electrical shock.

Process leaks could result in death or serious injury.

Properly tighten process connections before applying pressure.

Device Manager instructions are provided to allow users to

Installation

25

Page 32

Installation

September 2016

Apply torque only to the hex flat located at the process end of the transmitter. Do not

apply torque to the transmitter body or electrical connection - severe damage could

result. Do not exceed 100 ft-lbs.

3.3 General considerations

Measurement accuracy depends upon proper installation of the transmitter and impulse

piping. Mount the transmitter close to the process and use a minimum of piping to achieve

best accuracy. Also, consider the need for easy access, personnel safety, practical field

calibration, and a suitable transmitter environment. Install the transmitter to minimize

vibration, shock, and temperature fluctuation. Appendix A: Specification and Reference

Data lists temperature operating limits.

3.4 Mechanical considerations

Reference Manual

00809-0100-4022, Rev GA

Note

For applications with process temperatures greater than the limits of the transmitter, do not

blow down impulse piping through the transmitter. Flush lines with the blocking valves

closed and refill lines with water before resuming measurement.

26

Installation

Page 33

Reference Manual

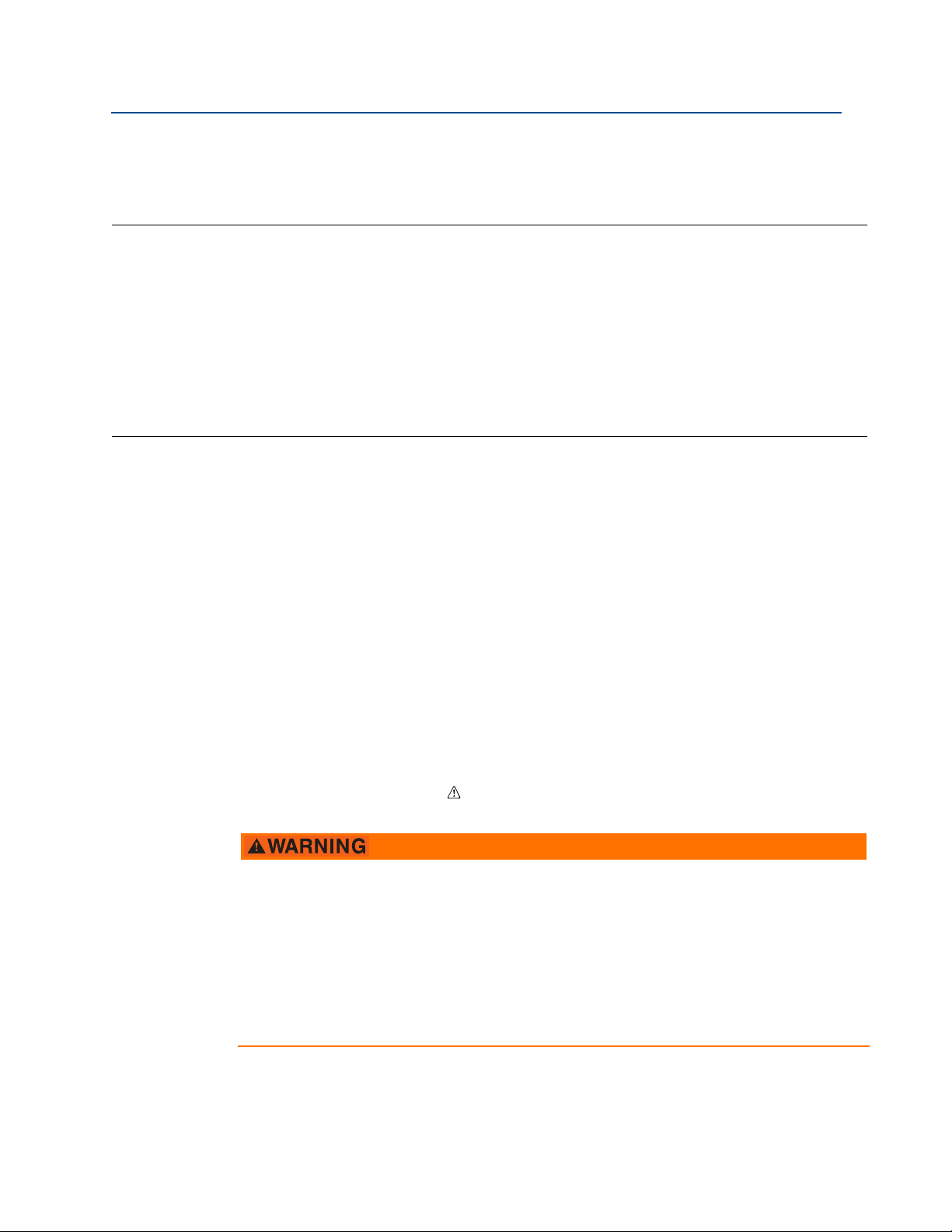

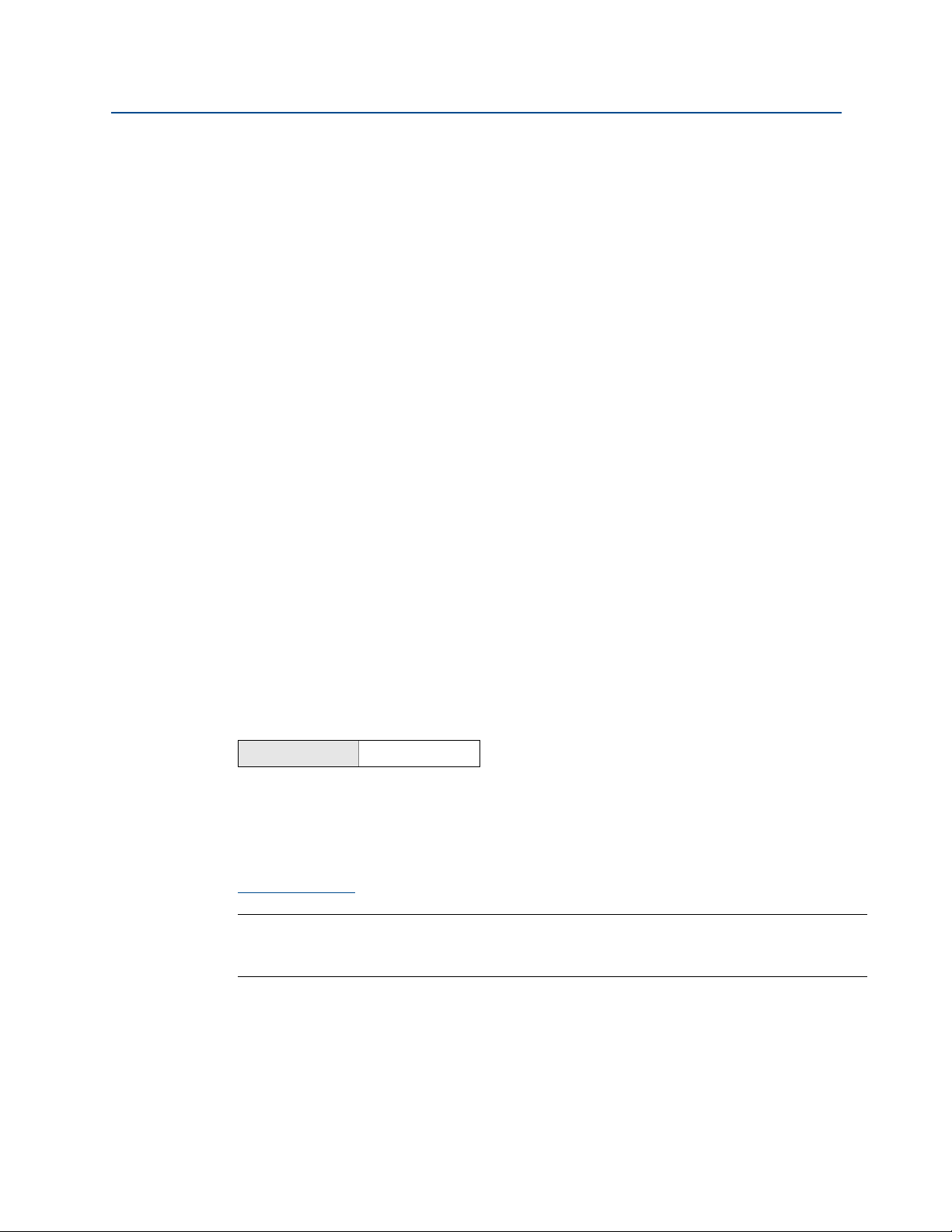

START HERE

Bench

Calibration?

Field Install

(Section 2: )

No

Configure

(Section 3)

Set Units

Set Range Points

Set Output Type

Set Damping

Veri fy

Apply Pressure

Yes

Within

Specifications?

Yes

No

Refer to

Section 5:

Troubleshooting

Mount Transmitter

(page 28)

Wire Transmitter

(pages 29–33)

Power Transmitter

(page 30)

Zero Out Sealed

Gauge Effects

(page 31)

Done

Confirm Transmitter

Configuration

(page 6)

Confirm Transmitter

Configuration

(page 6)

00809-0100-4022, Rev GA

Installation

September 2016

Figure 3-1. HART Installation Flowchart

Installation

27

Page 34

Installation

See “Safety messages” on page 25 for complete warning information.

September 2016

3.5 Installation procedures

For dimensional drawing information refer to Appendix A: Specification and Reference Data

on page 51.

3.5.1 Zero and span target orientation

Mount the transmitter with sufficient clearance so the zero and span targets are accessible.

3.5.2 Mount the transmitter

Panel mount

Electrical connection

1. Pull the leads through the threaded mounting hole in the panel wall.

2. Hand tighten the electrical connection into the mounting hole.

3. Using a wrench on the hex flat at the process connection, apply sufficient torque to

prevent transmitter vibration. Do not exceed 100 ft-lbs.

Reference Manual

00809-0100-4022, Rev GA

Process connection

1. Hand tighten the appropriate sized impulse piping into the process connection.

2. Using a wrench on the hex flat at the impulse piping connection, apply enough

torque to prevent the process fluid from leaking. Do not exceed 100 ft-lbs.

Note

Apply torque only to the hex flat located at the process end of the transmitter. Do not apply

torque to the transmitter body or electrical connection - severe damage could result. Do

not exceed 100 ft-lbs.

Note

Integral conduit seal meets the requirements of NEC

No additional conduit seal is required.

Note

The Rosemount

design which meets the requirements of NEC 2002 section 501:5 (F)(3) and API 14F 6.8.2.2.

No additional process sealing is required.

™

4600 Oil & Gas Pressure Transmitter features a reliable dual process seal

®

2002 section 501:5 (A) and 501.5 (B).

Impulse piping

The piping between the process and the transmitter must accurately transfer the pressure

to obtain accurate measurements. There are five possible sources of error: pressure

transfer, leaks, friction loss (particularly if purging is used), trapped gas in a liquid line and

liquid in a gas line.

28

Installation

Page 35

Reference Manual

00809-0100-4022, Rev GA

The best location for the transmitter in relation to the process pipe depends on the process

itself. Use the following guidelines to determine transmitter location and placement of

impulse piping:

Keep impulse piping as short as possible.

For liquid service, slope the impulse piping at least 1-in. per foot (8 cm per m)

For gas service, slope the impulse piping at least 1-in per foot (8 cm per m)

Avoid high points in liquid lines and low points in gas lines.

Use impulse piping large enough to avoid friction effects and blockage.

Vent all gas from liquid piping legs.

When purging, make the purge connection close to the process taps and purge

Keep corrosive or hot (above 200 °F [93.3 °C]) process material out of direct

Installation

September 2016

upward from the transmitter toward the process connection.

downward from the transmitter toward the process connection.

through equal lengths of the same size pipe. Avoid purging through the

transmitter.

contact with the transmitter.

Prevent sediment deposits in the impulse piping.

Avoid conditions that might allow process fluid to freeze within the process

connector.

3.5.3 Connect wiring and power up

Wiring

To make connections, connect the red lead to the positive terminal of the power supply and

the black lead to the positive terminal of the I/O card on the PLC. Connect the green wire to

panel ground. Keep green ground wire as short as possible to minimize the effects of Radio

Frequency Interference (RFI).

Inductive-based transient protectors with more than 3 mH of inductance can adversely

affect the output of the Rosemount 4600. If your application requires transient protection,

it is recommended that you order a transmitter with the transient protection option

specified.

Installation

29

Page 36

Installation

September 2016

Reference Manual

00809-0100-4022, Rev GA

Figure 3-2. Field Wiring

B

C

A

D

E

F

A. Rosemount 4600

L > 250 ohm

B. R

C. Power supply

D. I/O card

E. PLC

F. Field Communicator

Signal wiring grounding

Do not run signal wiring in conduit or open trays with power wiring, or near heavy electrical

equipment.

Power supply 4–20 mA transmitters

The dc power supply should provide power with less than two percent ripple. Total

resistance load is the sum of resistance from signal leads and the load resistance of the

controller, indicator, and related pieces. Note that the resistance of intrinsic safety barriers,

if used, must be included.

Note

A minimum loop resistance of 250 ohms is required to communicate with a Field

Communicator. If a single power supply is used to power more than one Rosemount 4600,

the power supply and circuitry common to the transmitter, should not have more than

20 ohms of impedance at 1200 Hz.

30

Installation

Page 37

Reference Manual

1355

11.25

1000

500

0

20

30

42.4

Operating

Regio n

Voltage (V dc)

00809-0100-4022, Rev GA

Figure 3-3. Power Supply Load Limitations, 4–20 mA Transmitters

Maximum field loop Resistance = 43.5 * (Power Supply Voltage - 11.25)

Load (Ohms)

*Communication requires a minimum loop resistance of 250 ohms.

Surges/transients

The transmitter will withstand electrical transients of the energy level usually encountered

in static discharges or induced switching transients. However, high-energy transients, such

as those induced in wiring from nearby lightning strikes, can damage the transmitter.

Installation

September 2016

Optional transient protection

Transient protection can be ordered as a factory installed option (Option Code T1 in the

transmitter model number). Transient protection can not be added to units ordered

without the T1 option.

3.5.4 Zero the transmitter

Performing a zero adjustment is a recommended step for sealed gauge transmitters.

Note

Do not re-zero absolute transmitters.

Re-zeroing the transmitter allows for a single point adjustment to compensate for any

mounting position and sealed gauge effects. This can be done with a zero trim (See “Sensor

trim” on page 40), 4-20 mA rerange or with the zero and span adjustments.

Installation

31

Page 38

Installation

September 2016

3.5.5 Re-zeroing

Reference Manual

00809-0100-4022, Rev GA

Fast Keys

1, 3, 3, 2

Field Communicator

4mA rerange

1. Vent the transmitter.

2. Follow the HART Fast Key sequence shown.

3. Select OK after the control is set to manual (see “Setting the loop to manual” on

page 4).

4. Select 1 to set the 4 mA point.

5. Select OK to set the new 4 mA point.

6. Select 1 to set the vented pressure as the new 4 mA point.

7. Select 3 to exit the screen.

8. Select OK to acknowledge that the loop can be returned to automatic control.

Using the transmitter zero adjustment target

1. Vent the transmitter.

2. Set the 4 mA point by touching the magnetic end of the provided adjustment tool

to the zero target (Z) on the transmitter. You must maintain contact for at least two

seconds, but no longer than ten seconds for the zero function to activate.

3. Verify that the output is 4 mA.

3.6 Hazardous locations

The Rosemount 4600 Transmitter has an explosion-proof housing. Individual transmitters

are clearly marked with a tag indicating the certifications they carry. See Appendix B:

Product Certifications for additional information.

Note

Once a device labeled with multiple approvals is installed, it should not be reinstalled using

any other approval type(s). Permanently mark the certification label to distinguish the

installed approval type from unused approval types.

32

Installation

Page 39

Reference Manual

00809-0100-4022, Rev GA

3.7 Grounding the transmitter case

Always ground the transmitter case in accordance with national and local electrical codes.

The most effective transmitter case grounding method is a direct connection to earth

ground with minimal impedance. Methods for grounding the transmitter case include:

Internal Ground Connection: The green lead provides the internal ground

connection, and is standard on all Rosemount 4600 Transmitters.

External Ground Assembly: This assembly is included with the optional transient

protection (Option Code T1). The External Ground Assembly can also be ordered

with the transmitter (Option Code D4), or as a spare part (4600-0113-0001).

Note

Grounding the transmitter case using the threaded electrical or process connections may

not provide a sufficient ground. The transient protection (Option Code T1) will not provide

transient protection unless the transmitter case is properly grounded. Use the above

guidelines to ground the transmitter case. Do not run transient protection ground wire with

signal wiring; the ground wire may carry excessive current if a lightning strike occurs.

Installation

September 2016

Installation

33

Page 40

Installation

September 2016

Reference Manual

00809-0100-4022, Rev GA

34

Installation

Page 41

Reference Manual

00809-0100-4022, Rev GA

Operation and Maintenance

September 2016

Section 4 Operation and Maintenance

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 35

Calibration for HART

Sensor trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 40

Recall factory trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 43

Analog output trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 44

®

protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 35

4.1 Overview

This section contains information on operation and maintenance of the Rosemount™ 4600

Oil & Gas Pressure Transmitter.

Field Communicator and AMS

maintenance functions. For convenience, Field Communicator Fast Key sequences are

labeled “Fast Keys” for each software function below the appropriate headings.

™

Device Manger instructions are given to perform

4.2 Calibration for HART® protocol

Calibrating a transmitter may include the following procedures:

Rerange: Sets the 4 and 20 mA points at required pressures.

Sensor Trim: Adjusts the position of the factory characterization curve to optimize

performance over a specified pressure range, or to adjust for mounting effects.

Analog Output Trim: Adjusts the analog output to match the plant standard or the

control loop.

The Rosemount 4600 uses a microprocessor that contains information about the sensor’s

specific characteristics in response to pressure and temperature inputs. A smart transmitter

compensates for these sensor variations. The process of generating the sensor performance

profile is called factory characterization. Factory characterization also provides the ability to

readjust the 4 and 20 mA points without applying pressure to the transmitter.

Trim and rerange functions differ significantly. Reranging sets analog output to the selected

upper and lower range points and can be done with or without an applied pressure.

Reranging does not change the factory characterization curve stored in the microprocessor.

Sensor trimming requires an accurate pressure input and adds additional compensation

that adjusts the position of the factory characterization curve to optimize performance over

a specific pressure range.

Note

Sensor trimming adjusts the position of the factory characterization curve. It is possible to

degrade performance of the transmitter if the trim is done improperly or with inaccurate

equipment.

Operation and Maintenance

35

Page 42

Operation and Maintenance

September 2016

Reference Manual

00809-0100-4022, Rev GA

Table 4-1. Recommended Calibration Tasks

Tra ns mitte r Bench calibration tasks Field calibration tasks

Rosemount 4600G

Rosemount 4600A

1.Set output configuration parameters:

a. Set the range points.

b. Set the output units.

c. Set the output type.

d. Set the damping value.

2.Optional: Perform a full sensor trim if

equipment available (accurate absolute

pressure source required), otherwise perform

the low trim value section of the full sensor trim

procedure.

3.Optional: Perform an analog output trim

(Accurate multimeter required).

1.Reconfigure parameters if necessary.

2.Perform low trim value section of the full

sensor trim procedure to correct for

mounting position effects.

4.2.1 Calibration overview

Complete calibration of the Rosemount 4600 involves the following tasks:

Configure the output parameters

Set Process Variable Units (page 9)

Rerange (page 9)

Set Damping (page 11)

Calibrate the sensor

Full Trim (page 42)

Zero Trim (page 41)

Calibrate the 4–20 mA output

4–20 mA Output Trim (page 44); or

4–20 mA Output Trim Using Other Scale (page 45)

Figure 4-1 on page 37 illustrates Rosemount 4600 data flow. Data flow can be summarized

in four major steps:

1. A change in pressure is measured by a change in the sensor output (Sensor Signal).

2. The sensor signal is converted to a digital format that is understood by the

microprocessor (Analog-to-Digital Signal Conversion).

3. Corrections are performed in the microprocessor to obtain a digital representation

of the process input (Digital PV).

36

4. The Digital PV is converted to an analog value (Digital-to-Analog Signal

Conversion).

Figure 4-1 also identifies the approximate transmitter location for each calibration task.

Data flows from left to right, and a parameter change affects all values to the right of the

changed parameter.

Operation and Maintenance

Page 43

Reference Manual

F

E

A

C

I

H

4600: PT-4763

1 á Device Setup

Online

2 PV 1000 PSI

3 AO 20.00 mA

4 LRV 0.00 PSI

5 URV 1000 PSI

B

G

D

TRANSMITTER RANGED 0 TO 1000 PSI

00809-0100-4022, Rev GA

Not all calibration procedures should be performed for each Rosemount 4600. Some

procedures are appropriate for bench calibration, but should not be performed during field

calibration. Ta b le 4 - 1 identifies the recommended calibration procedures for each type of

Rosemount 4600 transmitter for bench or field calibration.

Figure 4-1. Transmitter Data Flow with Calibration Options

Operation and Maintenance

September 2016

A. Sensor

B. Input pressure

C. Input device

D. Field Communicator

E. Microprocessor digital PV

F. Transmitter electronics module

G. Analog output

H.20 mA

I. Output device

Note

Value on PV line should equal the input pressure. Value on AO line should equal the output

device reading.

Operation and Maintenance

37

Page 44

1. Process Variable

2. Diagnostics and

Service

3. Basic Setup

4. Detailed Setup

5. Review Menus

1. Date

2. Descriptor

3. Message

4. Write protect

5. Conf Write Protect

6. Model

7. Model Number 1

8. Model Number II

9. Model Number III

1. Sensors

2. Signal

Condition

3. Output

Condition

4. Device

Information

1. # of diap. seals

2. Seal type

3. Seal fill fluid

4. RS isoltr matl

1.Field Device Info

2.Sensor Information

3.Self Test

4.Diaphragm Seal Info

1.Tag

2. Date

3. Descriptor

4. Message

5. Model

6. Model Number I

7. Model Number II

8. Model Number III

9. Write protect

1. Poll addr

2. Num req preams

3. Burst mode

4. Burst option

1.Press Alert

2.Temp Alert

3.Config Press Alert

4.Config Temp Alert

1. Meas typ

2. Module config type

3. Isoltr matl

4. Fill fluid

5. Process Connector

6. Process Conn Matl

7. O ring matl

8. Drain vent matl

1.Temp Hiu Alert Val

2.Temp Lo Alert Val

3.Snsr Temp USL

4.Snsr Temp LSL

1. Device Setup

2. PV

3. AO

4. PV URV

1.Temp Hi Alert Val

2.Temp Lo Alert Val

3. Snsr Temp USL

4. Snsr Temp LSL

1. Loop test

2. D/A trim

3. Scaled D/A trim

4. Alarm Direction

1. Press

2. % Range

3. AP

4. Snsr temp

1. Press

2. % Range

3. AO

4. Snsr temp

1. PVis

2. SVis

3. TVis

1. Process Variables

2. Analog Output

3. HART Output

4. Reserved

5. Process Alerts

6. Variable Remapping

1. Process Variables

2. Range Values

3. Unit

4. Xfer fnctn

5. Damp

6. Snsr temp Unit

1. Pressure Sensor

2. Device Temp Sensor

1.Keypad Input

2.Apply Values

1.Tag

2. Unit

3. Range Values

4. Device Information

5. Xfer fnctn

6. Damp

1. Keypad Input

2. Apply Values

1.Test Device

2. Loop Test

3. Calibration

1. Pressure

2. Percent of Range

3. Analog Output

4. Sensor Temp.

1.Status

1. Re-Range

2. Analog Input Trim

3. Sensor Trim

4. Recall fact trim

Operation and Maintenance

September 2016

Figure 4-2. HART Menu Tree

38

Reference Manual

00809-0100-4022, Rev GA

Operation and Maintenance

Page 45

Reference Manual

ReferenceAccuracy()

2

TemperatureEffect()

2

+

0.03 U RL×

Span

------------------------------

1.0+

pe r100 °F

2

-------------------------- -

±

= ±0.515% of span

Stability = ±0.5% of span for 3 years = ±0.0139% of span per month

Cal. Freq.

Req. Performance TPE–()

Stability per Month

------------------------------------------------------------ ---------- -

1.1% 0.57%–()

0.0139%

------------------------------------------

36 months===

00809-0100-4022, Rev GA

4.2.2 Determining calibration frequency

Calibration frequency can vary greatly depending on the application, performance

requirements, and process conditions. Use the following procedure to determine

calibration frequency that meets the needs of your application.

1. Determine the performance required for your application.

2. Determine the operating conditions.

3. Calculate the Total Probable Error (TPE).

4. Calculate the stability per month.

5. Calculate the calibration frequency.

Sample calculation

1. Determine the performance required for your application.

Required Performance: 1.1% of span

Operation and Maintenance

September 2016

2. Determine the operating conditions.

Transmitter: Rosemount 4600G, Range 4

Calibrated Span: 4000 psig

Ambient Temperature

50 °F

Change:

3. Calculate total probable error (TPE).

TPE = = 0.572% of span

Where:

Reference Accuracy = ± 0.25% of span

Ambient Temperature Effect =

Note

Temperature Effect is specified per 100 °F, divide by 2 for 50 °F temperature change.

4. Calculate the stability per month.

5. Calculate calibration frequency.

Operation and Maintenance

39

Page 46

Operation and Maintenance

September 2016

4.2.3 Selecting a trim procedure

To decide which trim procedure to use, you must first determine whether the analog-to-digital section or the digital-to-analog section of the transmitter electronics need

calibration. Refer to Figure 4-1 and perform the following procedure:

1. Connect a pressure source, a Field Communicator or AMS Device Manger, and a

digital readout device to the transmitter.

2. Establish communication between the transmitter and the Field Communicator.

3. Apply pressure equal to the upper range point pressure.

4. Compare the applied pressure to the Process Variable (PV) line on the Field

Communicator Online Menu or the Primary Variables screen in AMS Device

Manger.

a. If the PV reading does not match the applied pressure (with high-accuracy test

equipment), perform a sensor trim.

5. Compare the Analog Output (AO) line, on the Field Communicator or AMS Device

Manger, to the digital readout device.

Reference Manual

00809-0100-4022, Rev GA

a. If the AO reading does not match the digital readout device (with high-accuracy

test equipment), perform an output trim.

4.3 Sensor trim

Trim the sensor using either full or zero trim functions. Trim functions vary in complexity

and are application-dependent. Both trim functions alter the transmitter’s interpretation of

the input signal.

Zero trim is a single-point adjustment. It is useful for compensating for mounting position

and sealed gauge effects. Since this correction maintains the slope of the characterization

curve, it should not be used in place of a full trim over the full sensor range.

When performing a zero trim, ensure that the transmitter is vented to atmosphere.

Note

Do not perform a zero trim on Rosemount 4600 Absolute Pressure Transmitters. Zero trim

is zero based, and absolute pressure transmitters reference absolute zero. To correct

mounting position effects on a Rosemount 4600 Oil & Gas Transmitter, perform a low trim

within the full sensor trim function. The low trim function provides a “zero” correction

similar to the zero trim function, but it does not require zero-based input.

Full trim is a two-point sensor calibration where two end-point pressures are applied, and all