Page 1

Model 430 DO

Dissolved Oxygen Sensor

Instruction Manual

PN 51-430/rev.A

May 1996

Page 2

CAUTION

SENSOR/PROCESS

APPLICA

TION COMPATIBILITY

The wetted sensor materials may not be

compatible with process composition

and operating conditions. Application

compatibility is entirely the responsibility of the user.

DANGER

HAZARDOUS AREA INSTALLATION

Installations near flammable liquids or in hazardous

area locations must be carefully evaluated by qualified on site safety personnel. This sensor is not

Intrinsically Safe or Explosion Proof.

To secure and maintain an intrinsically safe installation, the certified safety barrier, transmitter, and

sensor combination must be used. The installation system must comply with the governing

approval agency (FM, CSA or BASEEFA/CENELEC) hazardous area classification requirements. Consult your analyzer/transmitter instruction manual for details.

Proper installation, operation and servicing of this

sensor in a Hazardous Area Installation is entirely

the responsibility of the user.

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests its products to

meet many national and international standards. Because these instruments are sophisticated technical products, you must properly install, use,

and maintain them to ensure they continue to operate within their normal

specifications. The following instructions must be adhered to and integrated

into your safety program when installing, using, and maintaining Rosemount

Analytical products. Failure to follow the proper instructions may cause any

one of the following situations to occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product. If this Instruction Manual is not the correct manual, telephone 1-800654-7768 and the requested manual will be provided. Save this

Instruction Manual for future reference.

• If you do not understand any of the instructions, contact your Rosemount

representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied

with the product.

• Inform and educate your personnel in the proper installation, operation,

and maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national

codes. Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate,

update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use

replacement parts specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance and place the safe operation of your process at risk. Look alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in

place, except when maintenance is being performed by qualified persons,

to prevent electrical shock and personal injury.

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2003

About This Document

This manual contains instructions for installation and operation of the Model 430 Dissolved Oxygen

Sensor. The following list provides notes concerning all revisions of this document.

Rev. Level Date Notes

A 5/96 This is the initial release of the product manual. The manual has been refor-

matted to reflect the Emerson documentation style and updated to reflect any

changes in the product offering.

Page 3

MODEL 430 DO TABLE OF CONTENTS

MODEL 430

DISSOLVED OXYGEN

TABLE OF CONTENTS

Section Title Page

1.0 DESCRIPTION AND SPECIFICATIONS................................................................. 1

1.0 Features and Applications ...................................................................................... 1

1.2 Operation ................................................................................................................ 1

1.3 Available Models...................................................................................................... 2

1.4 Specifications........................................................................................................... 2

1.5 Ordering Information ............................................................................................... 4

2.0 INSTALLATION ....................................................................................................... 5

2.1 General.................................................................................................................... 5

2.2 Unpacking and Inspection ...................................................................................... 5

2.3 Mechanical Installation ........................................................................................... 5

2.4 Electrical Installation................................................................................................ 5

3.0 MAINTENANCE ...................................................................................................... 9

3.1 General.................................................................................................................... 9

3.2 Recharging the Sensor............................................................................................ 9

4.0 TROUBLESHOOTING............................................................................................. 10

4.1 General.................................................................................................................... 10

4.2 Troubleshooting....................................................................................................... 10

4.3 Bench Testing .......................................................................................................... 10

5.0 PARTS LIST ........................................................................................................... 11

5.1 General.................................................................................................................... 11

6.0 RETURN OF MATERIAL ......................................................................................... 15

6.1 General.................................................................................................................... 15

6.2 Warranty Repair....................................................................................................... 15

6.3 Non Warranty Repair............................................................................................... 15

i

Page 4

TABLE OF CONTENTS CONTINUED

LIST OF FIGURES

Number Title Page

1-1 Flow Through Senson Assemblies ......................................................................... 2

1-2 Optional Mounting Bracket ..................................................................................... 3

2-1 Code 01 and 02 Flow Through Installation ........................................................... 6

2-2 Sensor Dimensions ................................................................................................ 7

5-1 Model 430 (Codes 01 and 02) Dissolved Oxygen Sensor ..................................... 11

5-2 Model 430 Sensor Assembly .................................................................................. 12

5-3 Model 430 (Code 03) Dissolved Oxygen Sensor ................................................... 13

5-4 Model 430 (Code 04) Dissolved Oxygen Sensor .................................................... 14

LIST OF TABLES

Number Title Page

2-1 Electrical Connections ........................................................................................... 5

ii

MODEL 430 DO TABLE OF CONTENTS

Page 5

1

•

LARGE ELECTROLYTE RESERVOIR allows up to twelve months and often longer

between refills.

•

OPTIONAL MOUNTING BRACKET allows easy removal of the sensor from an aeration

basin without the use of tools.

•

MODULAR PRESSURE COMPENSATOR AND MEMBRANE RETAINER simplify recharging and membrane replacement.

• MEMBRANE RETAINER REPLACEMENT AND RECHARGING require no tools.

MODEL 430 DO SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SECTION 1.0

GENERAL DESCRIPTION AND SPECIFICATIONS

1.1 FEATURES AND APPLICATIONS

The Rosemount Analytical®Model 430 Dissolved

Oxygen Sensor, used with the Model 1181 Dissolved

Oxygen Transmitter, measures oxygen levels in a variety of applications. The most widely used application is

the secondary phase of the waste treatment process

where a critical dissolved oxygen level must be maintained for the digestive process to occur. Other applications include water quality monitoring in natural bodies of water such as rivers and streams, or any location

where adequate oxygen content is important to sustain

aquatic life.

The Model 430 Dissolved Oxygen Sensor is constructed of PVC with an oxygen permeable Teflon1membrane .

1.2 OPERATION

As oxygen passes through the Teflon membrane an

oxygen dependent electrochemical reaction takes

place between the gold cathode and silver anode in the

presence of the electrolyte. The resultant current flow

between these elements is proportional to the quantity

of oxygen which has entered the sensor.

Temperature and pressure compensation are both

standard features on the Model 430. Temperature compensation is necessary for two reasons: First, the solubility of oxygen in water decreases with an increase in

temperature; secondly, the permeability of the Teflon

membrane and the oxygen diffusion rate increase as

the temperature increases. For these reasons, it is

important for a dissolved oxygen measurement to be

accompanied by an accurate temperature measurement. Temperature compensation is accomplished by

means of a thermistor located in the sensor housing,

and its associated circuitry in the analyzer.

Pressure compensation is a mechanical rather than

electronic correction. It is important for the tension on

the Teflon membrane to remain constant at all times,

even with sample pressure changes. Fluctuations in

membrane tension affect its diffusion characteristics.

By means of a pressure compensator the pressure on

the sample side of the compensator membrane is

transmitted to the electrolyte reservoir so the pressure

on both sides of the membrane remains equal. In this

manner, sample pressure changes do not affect the diffusion rate of oxygen through the membrane.

The Teflon membrane is held in place by a retainer. A

water-tight seal is made with an O-ring between the

membrane and sensor reservoir. Membrane replacement is rarely required, but in those situations when it

is necessary, the procedure can be performed quickly

and easily.

Since oxygen diffuses through the Teflon membrane at

a faster rate than through the sample, it is necessary to

continuously maintain a fresh sample in front of the

membrane. A stream velocity of approximately 1.5 feet

per second (0.5 m/s) is required to ensure that a fresh

sample is in contact with the membrane at all times.

1

Reg. U.S. Pat. Office for du Pont’s fluorocarbon resins.

Page 6

2

MODEL 430 DO SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.3 AVAILABLE MODELS

The Model 430-01 and -02 Sensor is a flow through

assembly. The sensor is supplied in a 1-1/2 inch PVC

tee for installation into a process line.

The Model 430-03 Submersible Sensor is for use in

those applications where the required flow velocity can

be maintained without the use of an agitator. When the

measurement is being made in a stagnant pond or

other media where the minimum flow rate of 1.5 FPS

cannot be obtained, the Model 430-04 must be selected. This model is designed for submersible use and is

provided with its own agitator to ensure adequate flow

velocity at the membrane.

The Models 430-03 and 04 may be provided with an

optional mounting bracket assembly. This bracket is

constructed of light weight aluminum and can be

adjusted to satisfy virtually any aeration basin mounting requirement. Once installed, the probe can be

removed without the use of tools. A single locking pin

holds the assembly rigidly in place but allows it to be

easily removed for inspection or cleaning.

1.4 SPECIFICATIONS

Process Connection:

430-00/01 1-1/2 inch socket fitting

Wetted Materials: HOUSING - PVC

MEMBRANE - Teflon

PRESSURE COMPENSATOR - Neoprene

Temperature Compensation:

0 to 50°C (32 to 122°F) Automatic

Sample Pressure: 0-50 psig (345 kPa abs)

Submersible to 200 ft. (61 m).

Agitator Power Requirement: Model 430-04 only)

115 Vac, ±10 60 Hz (0.2 amp)

Cable Length (standard):

6.1 meters (20 ft) on sensor and agitator

Maximum Cable Length:

305 meters (1000 ft)

Operating Time Between Electrolyte Recharge:

Approximately 12 months or longer, depending upon

application

Sample Flow Requirements for Models 430-01-02-03:

1.5 feet per seconds (0.5 m/s)

FIGURE 1-1 Flow Through Assemblies

DWG. NO. REV.

40043019 A

MILLIMETER

INCH

Page 7

3

MODEL 430 DO SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

FIGURE 1-2 Optional Mounting Bracket

DWG. NO. REV.

40043018 B

MILLIMETER

INCH

Page 8

4

MODEL 430 DO SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.5 ORDERING INFORMATION. The Model 430 Dissolved Oxygen Sensor: Includes PVC body with integral,

oxygen-permeable membrane of Teflon1. Temperature and pressure compensators included. Compatible with

Model1181DO.

MODEL

430 DO DISSOLVED OXYGEN SENSOR

CODE MOUNTING HARDWARE

01 1-1/2” PVC flow cell, 90° flow

02 1-1/2” PVC flow cell, 180° flow

03 PVC union with 3/4” FNPT for submersion service

04 PVC union with 1” FNPT and agitator with 20 foot cable for submersion. Agitator motor requires

115 VAC power only.

499 DO 01 16 EXAMPLE

CODE MOUNTING HARDWARE

11 Stainless steel tag (specify marking)

14 Handrail mounting bracket (P/N 1000857) for use with junction box (see Code 17 below).

15 Handrail mounting bracket (P/N 1000856) for use with Model 803

17 Weatherproof, NEMA 4X junction box (P/N 22719-02)

NOTES:

Recommended interconnecting cable from sensor to transmitter is Belden 8434 or equivalent, available from Rosemount Analytical as P/N

9200074. Specify length.

1

Reg. U.S. Pat. Office for du Pont's fluorocarbon resins.

Page 9

5

MODEL 430 DO SECTION 2.0

INSTALLATION

SECTION 2.0

INSTALLATION

2.1 GENERAL. This section provides instructions for

the Model 430 Dissolved Oxygen Sensor.

2.2 UNPACKING AND INSPECTION. Inspect the shipping container and remove the sensor. Carefully check

the sensor and its associated hardware for any damage. Report any damage to the carrier immediately.

2.3 MECHANICAL INSTALLATION. The sensor

comes in four different configurations. Follow the

instruction for the configuration being installed. See

Figure 2-2 for dimensions. Figure 1-2 illustrates

optional bracket assembly for sensor installation in

tanks or ponds.

2.4 Electrical Installation. Connect the sensor to the

transmitter as shown in Table 2-1.

2.3.1 Codes 01 and 02 (see Figure 2-1). These configurations are for flow through measurements. Install the

tee using 1-1/2 inch PVC. For the angle flow (Code

01), make sure the flow enters at the opening opposite

the sensor, so that the sample flows directly into the

membrane.

2.3.2 Codes 03 and 04 (see Figure 5-3 and Figure 5-

4). These configurations are for submersion into a tank

or pond. The Code 03 configuration requires a flow

past the sensor of 1.5 feet per second (0.5 m/s). The

Code 04 configuration is for stagnant or still tanks and

ponds.

Sensor Lead

Model 1181DO

1. (Red) silver anode TB2-4

2. Shield TB2-2

3. (White) T.C. element TB2-1

4. (Green) T.C. element TB2-3

5. (Black) gold cathode TB2-3

TABLE 2-1 Electrode Connections

Page 10

6

MODEL 430 DO SECTION 2.0

INSTALLATION

FIGURE 2-1. Codes and 01 and 02 Flow Through Installation

DWG. NO. REV.

40043001 G

MILLIMETER

INCH

Page 11

7

MODEL 430 DO SECTION 2.0

INSTALLATION

FIGURE 2-2. Code 03 Sensor Dimensions

DWG. NO. REV.

40043002 D

MILLIMETER

INCH

Page 12

Page 13

9

MODEL 430 DO SECTION 3.0

MAINTENANCE

SECTION 3.0

MAINTENANCE

3.1 GENERAL. Sensor maintenance consists of keep-

ing the sensor clean, recharging the sensor and

replacing the membrane. The sensor should be

cleaned with clean water and a soft cloth. Make sure

the membrane area is kept clean and free of any

accumulation of dirt, algae, fungus, hair, etc.

3.2 RECHARGING THE SENSOR. A recharge kit

(Rosemount analytical P/N 2002473) is required to

service the sensor.

Recharge the sensor as follows (see Figure 5-2):

1. Remove the sensor from its mounting.

2. Loosen the vent screw approximately 1-1/2 turns.

DO NOT REMOVE IT

3. Unscrew and remove the reservoir retainer from

the base. Use a strap wrench if the retainer is to

tight to remove by hand.

4. Pull the reservoir housing assembly from the base

WITHOUT rotating it. Hold sensor in a base-up

position to keep electrolyte from spilling out. If the

reservoir housing assembly is locked onto the

base, use a screwdriver at the parting lines to dislodge the base from the reservoir housing assembly. Do not damage the mating surfaces with the

screwdriver while separating the base from the

reservoir housing assembly.

CAUTION

The electrolyte (KCI) is a corrosive liquid

which could damage some materials and

may irritate the skin or eyes. If the electrolyte

comes in contact with the skin or eyes, wash

immediately with clean water.

5. Discard the O-ring, electrolyte, and reservoir

housing assembly.

6. Prepare the electrolyte solution as follows:

a. Pour electrolyte crystals into a beaker containing

100 milliliters of distilled or demineralizer water.

Stir until crystals are dissolved.

b. If it is desired to forego the stabilization period of

two hours, a dilution of the electrolyte may be

done by adding NaOH or KOH to adjust the pH of

the solution to 12 or greater.

c. The unused electrolyte solution can be saved for

future use. The pH should be rechecked prior to

use if the solution has been stored.

7. Fill the new reservoir housing assembly with electrolyte to the hole in the inner wall of the reservoir

(approximately 3/4 full). Tap the reservoir lightly to

remove any air bubbles.

8. Rinse all parts of the base in distilled or deionized

water. To remove silver chloride from the silver

anode, use a fine grit sandpaper or a pencil eraser and rub lightly until the coating is removed.

Rinse the silver anode in distilled water until all

traces of grit are removed.

9. Lightly lubricate the O-rings with O-ring lube and

install the O-ring in the groove of the base.

10. Hold the reservoir housing assembly in an upright

position and carefully slide the base into the reservoir housing assembly, making sure the tip of the

post enters the membrane retainer. Some electrolyte should seep out through the vent screw

while the reservoir housing assembly is being

pushed onto the base. Do not grip the pressure

compensator while pushing the reservoir housing

assembly onto the base.

CAUTION

In the following step, do not push the reservoir housing assembly onto the base too fast.

The orifices in the base vent screw are very

small and a quick surge of pressure could

damage the membrane. A stream of electrolyte solution could be forced through the

vent screw while the reservoir housing

assembly is being installed.

11. Push the reservoir housing assembly onto the

base until the threads of the base and the reservoir retainer can be engaged. After the threads are

engaged, turn the reservoir retainer until it is finger-tight. Caution, over finger-tight may damage

membrane or base post.

NOTE

Do not touch or apply pressure to the membrane.

12. Tighten the vent screw. Rinse the sensor with

clean water and dry with a lint-free cloth or towel.

13. The sensor is now ready for use.

Page 14

10

4.1 GENERAL. This section contains troubleshooting

data for the Model 430 Sensor Assembly.

4.2 TROUBLESHOOTING THE MODEL 430

DISSOLVED OXYGEN SENSOR. The majority of

problems encountered in DO systems are because the

sensor is either improperly maintained or has an internal leakage causing improper temperature compensator resistance and high impedance current paths

between elements of the sensor.

Disassemble the sensor completely by unscrewing the

reservoir retainer and pulling the reservoir housing

assembly straight out (refer to Figure 5-2). The membrane may have dried onto the gold cathode. Soak this

loose with water as scraping will damage the gold tip.

Clean all the parts with clean water and dry them.

Check for visible damage (i.e., cracks, deep cuts, broken silver wires). Perform the following checks with an

ohmmeter. Check T.C. resistance between the green

and white wires. It should be 100K ohms at 25°C or per

the Temperature/Resistance Chart. Check continuity

between the red wire and the silver anode, and

between the black wire and the gold cathode (be careful not to scratch the gold). Perform a high meg check

between the following (100 meg ohms minimum):

Shield to Black or Red or Green. If everything checks

O.K., the sensor should function after a proper

recharge. If the silver anode appears oxidized, it may

be cleaned with wet or dry 400 sandpaper. Also brush

the gold tip two or three times with the 400 sandpaper

in one direction only. Follow the recharge directions in

Section 3.2.

4.3 BENCH TESTING. Soak the electrode for 24 hours

with polarizing voltage applied (instrument), then air

calibrate to check for a response.

CAUTION

Care should be taken not to damage the

membrane made of “Teflon”.

1. Low readings and inability to calibrate are

generally the result of a coated membrane

and usually can be restored to service by

cleaning the sensor. Clean a coated membrane by gently wiping the membrane with a

soft cloth or tissue.

1

Reg. U.S. Pat. Office for du Pont’s fluorocarbon resins.

2. Readings offscale and inability to calibrate

are usually caused by a damaged membrane. If this is the case, replace the membrane.

3. To check the membrane made of “Teflon”,

connect the negative (—) lead of an ohmmeter to the cathode (black) lead and

place water saturated with salt on the

membrane. Touch the positive (+) lead to

the water. The meter should read open

(100 megohms or more). If the meter indicates a short (less than 100 megohms),

replace the membrane (refer to Section

3.2).

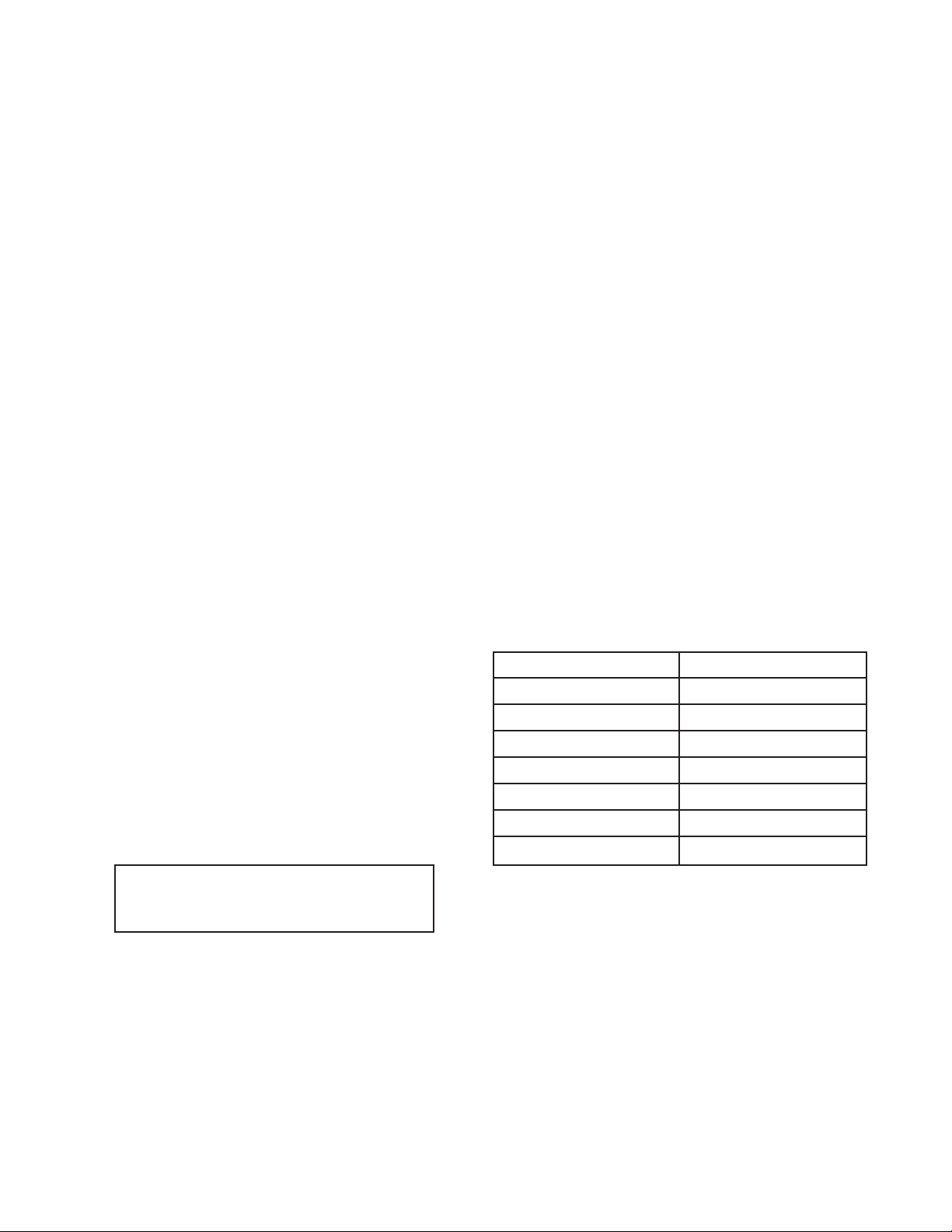

4. To check the resistance of the temperature

compensator, connect an ohmmeter to the

green and white leads of the sensor. The

resistance should be as indicated at the

temperature listed below: If the resistance

as specified above cannot be achieved,

replace the sensor (Figure 5-2).

Temperature Resistance Chart

5. To check for shorted sensor leads, measure the resistance between one temperature compensator wire (green or white) and

the cathode (black) lead and anode (red)

lead. The meter should indicate an open

circuit (100 megohms or more). Repeat the

measurement using the other temperature

compensator wire. If the sensor shows a

short circuit, the sensor is defective and

should be replaced.

MODEL 430 DO SECTION 4.0

TROUBLESHOOTING

SECTION 4.0

TROUBLESHOOTING

TEMPERATURE RESISTANCE (ohms)

0°C 371.40K

10°C 214.50K

20°C 128 00K

25°C 100.00K

30°C 78.00K

40°C 49.80K

50°C 32.36K

Page 15

11

MODEL 430 DO SECTION 5.0

PARTS LISTS

SECTION 5.0

PARTS LISTS

5.1 GENERAL. This section contains the replacement parts lists and illustrations for the Model 430 Sensor Assembly.

Parts are keyed with an item number. Use the illustration to locate the item number for the part in question. Then refer

to the accompanying parts list for the part number, description and quantity needed. The Usage Code column, where

used, identifies parts used on more than one assembly. If there is no code letter, the item is used on all assemblies

in that parts list.

Figure & Part Usage

Item No. Number Description Code Qty.

5-1 A SENSOR ASSY, Model 430 Dissolved Oxygen, angle flow (Code 01 ) A RF

B SENSOR ASSY, Model 430 Dissolved Oxygen, straight flow (Code 02) B RF

3 2002566 Tee Assy, angle flow A

4 2002567 Tee Assy, straight flow B

5 Union, 1” NPT

7 9550090 O-ring (Buna-N, 2-029)

8 1001021 Sensor Assy (see Figure 5-2 for details)

9 3001197 Gasket

FIGURE 5-1. Model 430 (Codes 01 and 02) Dissolved Oxygen Sensor

DWG. NO. REV.

40045052 A

Page 16

12

MODEL 430 DO SECTION 5.0

PARTS LISTS

Part Number Description Qty.

3002384 Base 1

9550116 O-ring (2-018)* 1

2002572 Reservoir housing assembly with membrane* 1

3002385 Retainer ,reservoir 1

9550133 O-ring (2-004) 1

3002382 Screw, vent 1

2002473 Recharge Kit 1

FIGURE 5-2. Model 430 Sensor Assembly

DWG. NO. REV.

40043016 A

Page 17

13

MODEL 430 DO SECTION 5.0

PARTS LISTS

FIGURE 5-3. Model 430 (Code 03) Dissolved Oxygen Sensor

DWG. NO. REV.

40043015 A

Figure & Part

Item No. Number Description Qty.

5-3 SENSOR ASSY, Model 430 Dissolved Oxygen, submersion (Code 13) RF

2 9330020 Union, 3/4” NPT RF

3 3001617 Gasket 1

4 1001021 Sensor Assy (see Figure 5-2 for details) 1

Page 18

14

MODEL 430 DO SECTION 5.0

PARTS LISTS

FIGURE 5-4. Model 430 (Code 04) Dissolved Oxygen Sensor

DWG. NO. REV.

40043017 A

Figure & Part

Item No. Number Description Qty.

5-4 SENSOR ASSY, Model 430 Dissolved Oxygen, with agitator (Code 04) 1

2 9380053 Pump, submersible Attaching parts for item 2: 1

3 Screw, SPH SS (#8-32x3/8) 4

4 Screw, SPH SS (#8-32x3/8) 2

5 3001150 Holder Assy 1

6 9320057 Union, 1” NPT 1

7 3001197 Gasket 1

8 1001021 Sensor assy (see Figure 5-2 for details) 1

Page 19

15

Model 430 DO SECTION 6.0

RETURN OF MATERIAL

SECTION 6.0

RETURN OF MATERIAL

6.1 GENERAL. To expedite the repair and return of

instruments, proper communication between the customer and the factory is important. A return material

authorization (RMA) number is required. Call (949)

757-8500. The "Return of Materials Request" form is

provided for you to copy and use in case the situation

arises. The accuracy and completeness of this form

will affect the processing time of your materials.

6.2 WARRANTY REPAIR. The following is the procedure for returning instruments still under warranty.

1. Contact the factory for authorization.

2. Complete a copy of the “Return of Materials

Request” form as completely and accurately as

possible.

3. To verify warranty, supply the factory sales order

number or the original purchase order number. In

the case of individual parts or sub-assemblies, the

serial number on the mother unit must be supplied.

4. Carefully package the materials and enclose your

“Letter of Transmittal” and the completed copy of

the “Return of Materials Request” form. If possible, pack the materials in the same manner as it

was received.

IMPORTANT

Please see second section of “Return of

Materials Request Form”. Compliance to

the OSHA requirements is mandatory for

the safety of all personnel. MSDS forms

and a certification that the instruments

have been disinfected or detoxified are

required.

5. Send the package prepaid to:

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606

Attn: Factory Repair

Mark the package: Returned for Repair RMA#

Model No. ____

6.3 NON WARRANTY REPAIR. Contact Factory For

Authorization

1. Contact the factory for authorization.

2. Fill out a copy of the “Return of Materials Request”

form as completely and accurately as possible.

3. Include a purchase order number and make sure

to include the name and telephone number of the

right individual to be contacted should additional

information be needed.

4. Do Steps 4 and 5 of Section 6.2.

NOTE

Consult the factory for additional information regarding service or repair.

Page 20

MODEL CFA 3000 RETURN OF MATERIAL

RETURN OF MATERIAL

GENERAL.

To expedite the repair and return of instruments, proper communication between the customer and the factory is

important. Before returning a product for repair, call 1-949-757-8500 for a Return Materials Authorization (RMA)

number.

WARRANTY REPAIR.

The following is the procedure for returning instruments still under warranty:

1. Call Emerson Process Management for authorization.

2. To verify warranty, supply the factory sales order number or the original purchase order number. In the case

of individual parts or sub-assemblies, the serial number on the unit must be supplied.

3. Carefully package the materials and enclose your “Letter of Transmittal” (see Warranty). If possible, pack the

materials in the same manner as they were received.

4. Send the package prepaid to:

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606

Attn: Factory Repair

RMA No. ____________

Mark the package: Returned for Repair

Model No. ____

NON-WARRANTY REPAIR.

The following is the procedure for returning for repair instruments that are no longer under warranty:

1. Call Emerson Process Management for authorization.

2. Supply the purchase order number, and make sure to provide the name and telephone number of the individual to be contacted should additional information be needed.

3. Do Steps 3 and 4 of the Warranty Repair section above.

NOTE

Consult the factory for additional information regarding service or repair.

Page 21

A Worldwide Network of Sales and Service

Emerson Process Management’s field sales offices are your source for more information on the fill line of Rosemount Analytical

products. Field sales personnel will work closely with you to supply technical data and application information.

For more information, please contact your nearest Emerson Process Management sales office.

Immediate, Reliable Analytical Support

Now there’s a way to quickly get the right answers for your liquid analytical instrumentation questions: the Analytical Customer Support Center.

Our staff of trained professionals is ready to provide the information you need. If you are placing an

order, verifying delivery, requesting application information, or just want to contact a Rosemount

Analytical representative, a call to the Customer Support Center will provide you with the right people, the right answers, right now.

The right people, the right answers, right now.

THE AMERICAS HEADQUARTERS

Emerson Process Management

Rosemount Analytical Inc.

Liquid Center of Excellence

2400 Barranca Parkway

Irvine, CA 92606

Phone: +1.949.757.8500

Toll Free: +1.800.854.8257

Fax: +1.949.474.7250

ASIA-PACIFIC

Emerson Process Management

Asia Pacific Private Ltd.

1 Pandan Crescent

Singapore 0512

Republic of Singapore

Phone: 65.777.8211

Fax: 65.777.0947

EUROPE

Emerson Process Management AG

Blegistrasse 21

CH-6341 Baar-Walterswil

Switzerland

T 41.41.768.6111

T 41.41.761.8740

VISIT OUR WEBSITE AT

www.rosemountanalytical.com

GERMANY

Emerson Process Management Process

Gas Analyzer Center of Excellence

GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T 49.6055.884.0

F 49.6055.884.20

LATIN AMERICA

Emerson Process Management

Rosemount Analytical

10241 West Little York, Suite #200

Houston, TX 77040 USA

T 713.467.6000

F 713.827.3328

MIDDLE EAST AND AFRICA

Emerson Process Management

EPM Building

P. O. Box 17033

Jebe Ali Free Zone

Dubai, United Arab Emirates

T 971.4.8835235

F 971.4.8835312

Page 22

FROM: RETURN BILL TO:

_____________________________ _____________________________ _____________________________

_____________________________ _____________________________ _____________________________

_____________________________ _____________________________ _____________________________

CUSTOMER/USER MUST SUBMIT MATERIAL SAFETY SHEET (MSDS) OR COMPLETE STREAM COMPOSITION, AND/OR

LETTER CERTIFYING THE MATERIALS HAVE BEEN DISINFECTED AND/OR DETOXIFIED WHEN RETURNING ANY

PRODUCT, SAMPLE OR MATERIAL THAT HAVE BEEN EXPOSED TO OR USED IN AN ENVIRONMENT OR PROCESS THAT

CONTAINS A HAZARDOUS MATERIAL ANY OF THE ABOVE THAT IS SUBMITTED TO ROSEMOUNT ANALYTICAL WITH-

OUT THE MSDS WILL BE RETURNED TO SENDER C.O.D. FOR THE SAFETY AND HEALTH OF OUR EMPLOYEES. WE

THANK YOU IN ADVANCE FOR COMPLIANCE TO THIS SUBJECT.

SENSOR OR CIRCUIT BOARD ONLY:

(Please reference where from in MODEL / SER. NO. Column)

1. PART NO.__________________________1. MODEL_________________________________1. SER. NO. ________________

2. PART NO.__________________________2. MODEL_________________________________2. SER. NO. ________________

3. PART NO.__________________________3. MODEL_________________________________3. SER. NO. ________________

4. PART NO.__________________________4. MODEL_________________________________4. SER. NO. ________________

PLEASE CHECK ONE:

n REPAIR AND CALIBRATE n DEMO EQUIPMENT NO. __________________________

n EVALUATION n OTHER (EXPLAIN) _______________________________

n REPLACEMENT REQUIRED? n YES n NO _________________________________________________

DESCRIPTION OF MALFUNCTION:

______________________________________________________________________________________________________

______________________________________________________________________________________________________

______________________________________________________________________________________________________

WARRANTY REPAIR REQUESTED:

n YES-REFERENCE ORIGINAL ROSEMOUNT ANALYTICAL ORDER NO. ________________________________________

CUSTOMER PURCHASE ORDER NO. _________________________________________________

n NO-PROCEED WITH REPAIRS-INVOICE AGAINST P.O. NO. _________________________________________________

n NO-CONTACT WITH ESTIMATE OF REPAIR CHARGES: LETTER n __________________________________________

PHONE n ___________________________________________

NAME ____________________________________________________ PHONE _________________________________________

ADDRESS ___________________________________________________________________________________________________

______________________________________________________________ ZIP _________________________________________

RETURN AUTHORITY FOR CREDIT ADJUSTMENT [Please check appropriate box(s)]

n WRONG PART RECEIVED n REPLACEMENT RECEIVED

n DUPLICATE SHIPMENT REFERENCE ROSEMOUNT ANALYTICAL SALES ORDER NO. _________

n RETURN FOR CREDIT RETURN AUTHORIZED BY: ______________________________________

WARRANTY DEFECT____________________________________________________________________________________

_____________________________________________________________________________________________________

24-6047

RETURN OF MATERIALS REQUEST

•IMPORTANT!

This form must be completed to ensure expedient factory service.

R

E

P

A

I

R

S

T

A

T

U

S

R

E

A

S

O

N

F

O

R

R

E

T

U

R

N

C

U

S

T

O

M

E

R

N

O

T

I

C

E

T

O

S

E

N

D

E

R

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.RAuniloc.com

© Rosemount Analytical Inc. 2001

Page 23

Page 24

WARRANTY

Seller warrants that the firmware will execute the programming instructions provided by Seller, and that the Goods manufactured

or Services provided by Seller will be free from defects in materials or workmanship under normal use and care until the expiration of the applicable warranty period. Goods are warranted for twelve (12) months from the date of initial installation or eighteen

(18) months from the date of shipment by Seller, whichever period expires first. Consumables, such as glass electrodes,

membranes, liquid junctions, electrolyte, o-rings, catalytic beads, etc., and Services are warranted for a period of 90

days from the date of shipment or provision.

Products purchased by Seller from a third party for resale to Buyer ("Resale Products") shall carry only the warranty extended by

the original manufacturer. Buyer agrees that Seller has no liability for Resale Products beyond making a reasonable commercial

effort to arrange for procurement and shipping of the Resale Products.

If Buyer discovers any warranty defects and notifies Seller thereof in writing during the applicable warranty period, Seller shall, at

its option, promptly correct any errors that are found by Seller in the firmware or Services, or repair or replace F.O.B. point of manufacture that portion of the Goods or firmware found by Seller to be defective, or refund the purchase price of the defective portion of the Goods/Services.

All replacements or repairs necessitated by inadequate maintenance, normal wear and usage, unsuitable power sources, unsuitable environmental conditions, accident, misuse, improper installation, modification, repair, storage or handling, or any other

cause not the fault of Seller are not covered by this limited warranty, and shall be at Buyer's expense. Seller shall not be obligated to pay any costs or charges incurred by Buyer or any other party except as may be agreed upon in writing in advance by an

authorized Seller representative. All costs of dismantling, reinstallation and freight and the time and expenses of Seller's personnel for site travel and diagnosis under this warranty clause shall be borne by Buyer unless accepted in writing by Seller.

Goods repaired and parts replaced during the warranty period shall be in warranty for the remainder of the original warranty period or ninety (90) days, whichever is longer. This limited warranty is the only warranty made by Seller and can be amended only

in a writing signed by an authorized representative of Seller. Except as otherwise expressly provided in the Agreement, THERE

ARE NO REPRESENTATIONS OR WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, OR ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES.

RETURN OF MATERIAL

Material returned for repair, whether in or out of warranty, should be shipped prepaid to:

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606

The shipping container should be marked:

Return for Repair

Model

_______________________________

The returned material should be accompanied by a letter of transmittal which should include the following information (make a

copy of the "Return of Materials Request" found on the last page of the Manual and provide the following thereon):

1. Location type of service, and length of time of service of the device.

2. Description of the faulty operation of the device and the circumstances of the failure.

3. Name and telephone number of the person to contact if there are questions about the returned material.

4. Statement as to whether warranty or non-warranty service is requested.

5. Complete shipping instructions for return of the material.

Adherence to these procedures will expedite handling of the returned material and will prevent unnecessary additional charges

for inspection and testing to determine the problem with the device.

If the material is returned for out-of-warranty repairs, a purchase order for repairs should be enclosed.

Page 25

Credit Cards for U.S. Purchases Only.

The right people,

the right answers,

right now.

ON-LINE ORDERING NOW AVAILABLE ON OUR WEB SITE

http://www.raihome.com

Specifications subject to change without notice.

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2005

Loading...

Loading...