Page 1

Reference Manual

00809-0100-4088, Rev DB

April 2018

Rosemount™ 4088 MultiVariable™ Transmitter

Page 2

Reference Manual

00809-0100-4088, Rev DB

Section Title

April 2018

ii

Page 3

Reference Manual

00809-0100-4088, Rev DB

Contents

1Section 1: Introduction

2Section 2: Configuration

Contents

April 2018

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Models covered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Product recycling/disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Software installation and initial setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 RTIS part numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.3 Installing the RTIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.4 Getting started with RTIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.5 Connecting to a personal computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Launching the configuration process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Basic device configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4.1 Units of measure and damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4.2 Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Detailed device configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.2 Device information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5.3 Overview variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5.4 Alert setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6 Variable configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6.1 Differential pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6.2 Static pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6.3 Process temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6.4 Module temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.7 Menu trees and Field Communicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7.1 Rosemount 4088A menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.7.2 Rosemount 4088B menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.7.3 Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.8 Rosemount 4088A configuration with legacy tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Contents

iii

Page 4

Contents

April 2018

Reference Manual

00809-0100-4088, Rev DB

3Section 3: Installation

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.3 Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.3.2 Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.3.3 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.4 Steps required for quick installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.4.1 Mount the transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.4.2 Consider housing rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.4.3 Set the switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.4.4 Wiring and power up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.5 Verify device configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.4.6 Trim the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.5 Rosemount 305, 306, and 304 Manifolds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.5.1 Rosemount 305 Integral Manifold installation procedure . . . . . . . . . . . . . . . . . . . . . . . . 49

3.5.2 Rosemount 306 In-line Manifold installation procedure. . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.5.3 Rosemount 304 Conventional Manifold installation procedure . . . . . . . . . . . . . . . . . . . 50

3.5.4 Rosemount 305 and 304 Manifold styles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.5.5 Manifold operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4Section 4: Communication

4.1 Rosemount 4088A Modbus communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.1.1 Modbus communication overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.1.2 Modbus data types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.1.3 Modbus function codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.1.4 Registers for process variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.1.5 Process variable integer scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.1.6 Floating point formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.1.7 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.1.8 Implementing calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.1.9 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.1.10 Transmitter register maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.2 Rosemount 4088B ROC communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.3 Rosemount 4088B BSAP communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.3.1 Rosemount 4088B BSAP communications signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

iv

Contents

Page 5

Reference Manual

00809-0100-4088, Rev DB

5Section 5: Operation and Maintenance

6Section 6: Troubleshooting

Contents

April 2018

5.1 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.1.1 Sensor trim overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

5.1.2 Differential pressure sensor calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.1.3 Static pressure sensor calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.1.4 Process temperature sensor calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.1.5 Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.1.6 Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

5.1.7 Legacy calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

5.2 Simulate device variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

6.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

6.3 Communications troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

6.4 Alarms and conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6.5 Field upgrades and replacements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

6.5.1 Disassembly considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

6.5.2 Housing assembly including electronics board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

6.5.3 Terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

6.5.4 LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6.5.5 Flange and drain vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

6.6 Service support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

AAppendix A: Reference Data

A.1 Product Certifications and Installation Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

A.2 Ordering Information, Specifications, and Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . 123

A.3 Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Contents

v

Page 6

Contents

April 2018

Reference Manual

00809-0100-4088, Rev DB

vi

Contents

Page 7

Reference Manual

NOTICE

00809-0100-4088, Rev DB

Rosemount™ 4088 MultiVariable™

Transmitter

Read this manual before working with the product. For personal and system safety, and for optimum

product performance, make sure the contents are fully understood before installing, using, or

maintaining this product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions

United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

Asia Pacific- 65 777 8211

Europe/Middle East/Africa - 49 (8153) 9390

North American Response Center

Equipment service needs

1-800-654-7768 (24 hours—includes Canada)

Outside of these areas, contact your local Emerson

™

representative.

Title Page

April 2018

To view current Rosemount 4088 Product Certifications and EC Declarations of Conformity, follow these

steps:

1. Go to Emerson.com/Rosemount/4088

2. Scroll as needed to the green menu bar and click Documents & Drawings.

3. Click Certificates & Approvals.

The manual and this guide are also available electronically on Emerson.com/Rosemount

.

.

Title Page

vii

Page 8

Title Page

April 2018

Reference Manual

00809-0100-4088, Rev DB

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

Do not remove the transmitter cover in explosive atmospheres when the circuit is live.

Before connecting a communicator in an explosive atmosphere, make sure the instruments in the

loop are installed in accordance with intrinsically safe or non-incendive field wiring practices.

Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Verify the operating atmosphere of the transmitter is consistent with the appropriate hazardous

locations certifications.

Electrical shock could cause death or serious injury.

If the sensor is installed in a high-voltage environment and a fault or installation error occurs, high

voltage may be present on the transmitter leads and terminals.

Use extreme caution when making contact with the leads and terminals.

Process leaks could result in death or serious injury.

Install and tighten all four flange bolts before applying pressure.

Do not attempt to loosen or remove flange bolts while the transmitter is in service.

Replacement equipment or spare parts not approved by Emerson for use as spare parts could reduce

the pressure retaining capabilities of the transmitter and may render the instrument dangerous.

Use only bolts supplied or sold by Emerson as spare parts.

Improper assembly of manifolds to traditional flange can damage sensor module.

For safe assembly of manifold to traditional flange, bolts must break back plane of flange web (i.e., bolt

hole) but must not contact module housing.

Sensor module and electronics housing must have equivalent approval labeling in order to

maintain hazardous location approvals.

When upgrading, verify sensor module and electronics housing certifications are equivalent.

Differences in temperature class ratings may exist, in which case the complete assembly takes the

lowest of the individual component temperature classes (for example, a T4/T5 rated electronics housing

assembled to a T4 rated sensor module is a T4 rated transmitter.)

viii

The products described in this document are NOT designed for nuclear-qualified applications. Using

non-nuclear qualified products in applications that require nuclear-qualified hardware or products may

cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson Sales

Representative.

Individuals who handle products exposed to a hazardous substance can avoid injury if they are informed

of and understand the hazard. If the product being returned was exposed to a hazardous substance as

defined by OSHA, a copy of the required Material Safety Data Sheet (MSDS) for each hazardous

substance identified must be included with the returned goods.

Title Page

Page 9

Reference Manual

00809-0100-4088, Rev DB

Section 1 Introduction

1.1 Using this manual

The sections in this manual provide information on installing, operating, and maintaining the

Rosemount

Section 2: Configuration contains mechanical and electrical installation instructions.

Section 3: Installation provides details about the communication protocols supported by the

transmitter.

Section 4: Communication contains information on software functions, configuration parameters,

and online variables.

Section 5: Operation and Maintenance provides techniques for calibrating the transmitter.

Section 6: Troubleshooting contains troubleshooting techniques for the most common operating

problems.

Appendix A: Reference Data provides links to product certifications, installation drawings, ordering

information, specifications, and dimensional drawings.

™

4088 MultiVariable™ Transmitter. The sections are organized as follows:

Introduction

April 2018

1.1.1 Models covered

The following Rosemount 4088 Transmitters are covered in this manual.

Table 1-1. Rosemount 4088 Coplanar

Measurement type Description

1 Differential pressure, static pressure, temperature

2 Differential pressure and static pressure

3 Differential pressure and temperature

4 Differential pressure

5 Static pressure and temperature

7 Static pressure

Table 1-2. Rosemount 4088 In-line Transmitter

Measurement type Description

6 Static pressure and temperature

8 Static pressure

™

Transmitter

1.2 Product recycling/disposal

Introduction

Recycling of equipment and packaging should be taken into consideration and disposed of in accordance

with local and national legislation/regulations.

1

Page 10

Introduction

April 2018

Reference Manual

00809-0100-4088, Rev DB

2

Introduction

Page 11

Reference Manual

00809-0100-4088, Rev DB

Section 2 Configuration

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Software installation and initial setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Launching the configuration process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Basic device configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Detailed device configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Variable configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

Menu trees and Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Rosemount 4088A configuration with legacy tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

Configuration

April 2018

The Rosemount

configuration and maintenance functions for the Rosemount 4088 MultiVariable

Instructions for performing configuration functions are given for the RTIS. Field Communicator Fast Key

sequences are labeled “Field Communicator” for each software function below the appropriate

headings.

Note

Coplanar transmitter configurations measuring gage pressure with optional process temperature

(measurement type 5 and 7) will report the pressure as differential pressure. This will be reflected on the

LCD display nameplate, digital interfaces, and other user interfaces.

™

Transmitter Interface Software (RTIS) is a PC-based application that performs

2.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety of the

personnel performing the operations. Refer to the following safety messages before performing an

operation.

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

Do not remove the transmitter cover in explosive atmospheres when the circuit is live.

Verify the operating atmosphere of the transmitter is consistent with the appropriate hazardous

locations certifications.

Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Electrical shock could cause death or serious injury.

If the sensor is installed in a high-voltage environment and a fault or installation error occurs, high

voltage may be present on the transmitter leads and terminals.

Use extreme caution when making contact with the leads and terminals.

™

Transmitter.

Config uration

3

Page 12

Configuration

April 2018

2.2 Software installation and initial setup

2.2.1 System requirements

The following are the minimum system requirements to install the RTIS:

Microsoft

Recommended hardware driver for USB modem option

MACTek

2.2.2 RTIS part numbers

The Rosemount 4088 MultiVariable Transmitter is not shipped with RTIS; the RTIS can be ordered

separately using the part numbers below.

RTIS CD only: 04088-9000-0001

RTIS CD with HART

2.2.3 Installing the RTIS

®

Windows™ 7 Operating System (32- bit or 64-bit)

®

VIATOR® Modem Driver (included)

®

USB modem and cables: 04088-9000-0002

Reference Manual

00809-0100-4088, Rev DB

Multiple DTMs™ are available on the RTIS, however the following FDT® frame and DTMs are required for

this installation:

RTIS

Rosemount HART Comm DTM (Communications driver)

Rosemount 4088 Device DTM (Rosemount 4088 User interface Configuration application)

1. Right click the setup.exe file and select Run as administrator.

4

Configuration

Page 13

Reference Manual

00809-0100-4088, Rev DB

2. Follow the installation wizard. Select all desired DTMs (the first three are required).

Configuration

April 2018

Note

The MACTek modem install will also be automatically selected to run. If the MACTek VIATOR Utility is

already installed, this install will allow you to repair or update.

For each additional DTM selected, you will be prompted for individual installation options. Once

installation has started, the next prompt would be for any optionally-selected HART Device DTMs.

3. Run a complete installation for the HART Modem driver and each additional selected DTM.

This completes the installation.

2.2.4 Getting started with RTIS

1. Ensure the modem is connected.

2. Launch RTIS from the desktop or All Programs menu option.

Config uration

5

Page 14

Configuration

April 2018

Reference Manual

00809-0100-4088, Rev DB

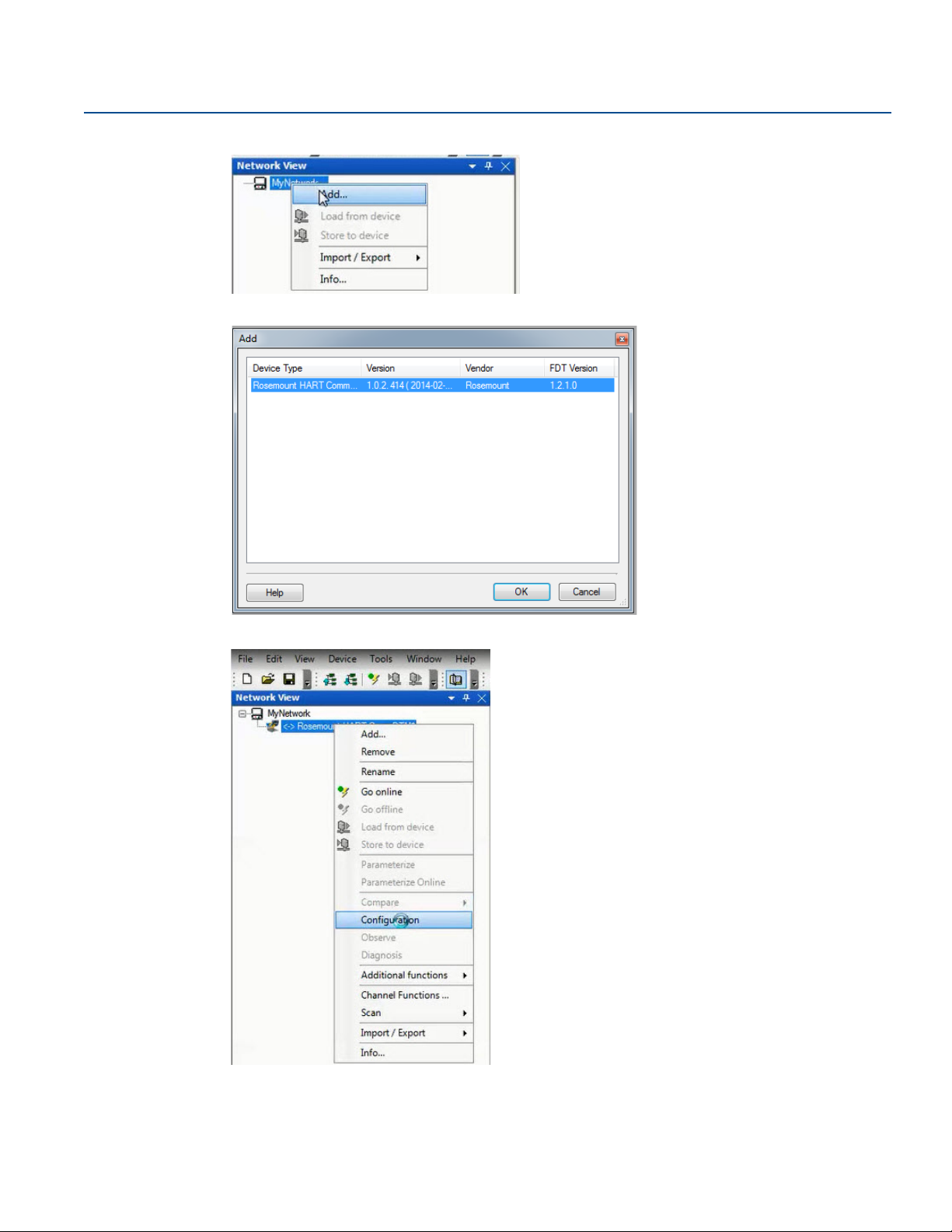

3. Right click My Network, and then select Add....

4. Select Rosemount HART CommDTM for Device Type and select OK.

5. Under MyNetwork, right click Rosemount HART CommDTM, then select Configuration.

6. Select the correct COM Port.

7. Select the Access Mode dropdown and set to Emulated.

6

Configuration

Page 15

Reference Manual

A

B

C

D

OR

00809-0100-4088, Rev DB

8. Select Self Test to check the connection.

Configuration

April 2018

9. Select OK.

2.2.5 Connecting to a personal computer

Figure 2-1 shows how to connect a device to either a computer with the RTIS or a handheld

communicator.

Figure 2-1. Connecting a Personal Computer to a Transmitter

A. RTIS

B. HART modem

C. Field Communicator

D. User-provided power supply

Config uration

7

Page 16

Configuration

April 2018

1. Wire the device as detailed in Section 3: Installation.

2. Connect the MACTek HART modem to the correct USB communications port on the PC as set up in

“Getting started with RTIS” on page 5.

3. Remove the cover of the transmitter above the side marked “FIELD TERMINALS.”

4. Connect the mini-grabber connectors to the “LOCAL (HART)” terminals.

Explosions can cause death or serious injury.

Do not remove the instrument cover in explosive atmospheres when the circuit is live.

2.3 Launching the configuration process

This section outlines how to configure the transmitter using the RTIS.

1. Right click Rosemount HART CommDTM, select Scan, then select Create Network.

Reference Manual

00809-0100-4088, Rev DB

8

Configuration

Page 17

Reference Manual

00809-0100-4088, Rev DB

The DTM setup is complete.

2. Right click on the transmitter, then select Go Online. Your device is now online.

Configuration

April 2018

3. Right click on the transmitter again, select Parameterize Online, then select Configure/Setup.

Config uration

9

Page 18

Configuration

April 2018

2.4 Basic device configuration

The Guided Setup section provides procedures to commission the transmitter. The Basic Setup button

can be used to perform all of the required transmitter configuration. See Table 2-2 on page 33 for the

complete list of Field Communicator for basic setup.

Figure 2-2. Guided Setup Tab

Reference Manual

00809-0100-4088, Rev DB

All screens in this section are shown for measurement type 1 (differential pressure, static pressure

[absolute], and process temperature) with LCD display. Field Communicator are given for a transmitter

with Measurement type 1. Field Communicator and screens for other multivariable types and

measurement types may vary.

Note

All screens in this section are shown using the RTIS. Edited information is not sent to the transmitter until

the Send button is selected.

2.4.1 Units of measure and damping

Fast Keys

The damping command changes the response time of the transmitter; higher values can smooth

variations in output readings caused by rapid input changes. Determine the appropriate damping setting

based on the necessary response time, signal stability, and other requirements. The damping command

utilizes floating point configuration allowing the user to input any damping value between 0 and 60

seconds.

The units and damping for each process variable may be edited by selecting Manual Setup in the menu

tree and then the appropriate tab as detailed below:

Under the Differential Pressure tab, the Units and Damping for the Differential Pressure may be edited.

Under the Static Pressure tab, the Units and Damping for the Static Pressure may be edited.

Units: 2, 1, 1, 2

Damping: 2, 1, 1, 3

10

Configuration

Page 19

Reference Manual

00809-0100-4088, Rev DB

Note

Both absolute and gage pressure are available as variables. The type of transmitter ordered will

determine which variable is measured and which is calculated based on the user defined atmospheric

pressure. For more information on configuring the atmospheric pressure, see “Static pressure” on

page 16. Since only one of the static pressures is actually being measured, there is a single damping

setting for both variables which may be edited under the Static Pressure tab.

Under the Process Temperature tab, the Units and Damping for the Process Temperature may be edited.

Under the Module Temperature tab, the Units for the Module Temperature may be set. The sensor

module temperature measurement is taken within the module, near the differential pressure and/or

static pressure sensors and can be used to control heat tracing or diagnose device overheating.

2.4.2 Network

Configuration

April 2018

Fast Keys

2, 2, 6, 1

Device address

In the Network tab, the Device Address field can be used to set the device's address under the Modbus®

Configuration heading.

Figure 2-3. Network Tab

Config uration

Baud rates

The baud rate is user selectable under the Modbus Configuration heading.

For default and available baud rates, see “Baud rate (software configurable)” on page 57.

Turn around delay

The Turnaround Delay Time (ms) field can be used to configure the device’s turnaround delay time. For

more information, reference “Communications” on page 62.

11

Page 20

Configuration

April 2018

2.5 Detailed device configuration

2.5.1 Display

Reference Manual

00809-0100-4088, Rev DB

Fast Keys

The LCD display features a four-line display. The first line of five characters displays the output

description, the second line of seven digits displays the actual value, and the third line of six characters

displays engineering units. The fourth line displays “Error” when there is a problem detected within the

transmitter. The LCD display can also display diagnostic messages. These diagnostic messages are listed

in “Alarms and conditions” on page 115.

The Display tab allows the user to configure which variables will be shown on the LCD display. Click the

check box next to each variable to select a variable for display. The transmitter will scroll through the

selected variables, showing each for three seconds as a default setting.

Figure 2-4. Display Tab

2, 2, 5

12

The Display tab includes three types of display options (information that appears on the LCD display)

including Device Variables, User-Defined Parameters, or User-Defined Variables.

Device variables

The device variables include Differential Pressure, Absolute Temperature, Gage Pressure, Process

Temperature, Module Temperature, Device Address or Baud Rate. These display variables can be selected

or deselected on the left column of the Display Options heading.

User-defined parameters

The User-Defined Parameters fields are for pieces of information the device can store for reference. The

device will not modify or update these parameters but they can be written by the user or a host system to

be displayed on the LCD display and include Beta Ratio, Pipe Schedule, or Orifice Bore. If the device loses

power at any point during operation, these values are stored in memory and will not be lost.

Configuration

Page 21

Reference Manual

00809-0100-4088, Rev DB

To configure User-Defined Parameters, select Configure User-Defined Parameters.

A screen will appear as shown below:

Each parameter can be given a label, value and unit to be stored inside the device.

Configuration

April 2018

User-defined variables

Note

Only the value of the user-defined variables should be written on a periodic basis. Regular writes to the

other parameters may cause the device memory to fail.

The User-Defined Variable fields are for pieces of information that the device can store for a live reference

of the application status or production levels, via Modbus. The device itself will not modify or update

these variables; rather this is intended to be a live value sent to the device from a host, such as a flow

computer or Remote Terminal Unit (RTU). This information can then be displayed on the device's LCD

display and include variables such as Last 24-Hours of Gas Volume or Instantaneous Flow Rate.

To configure User-Defined Variables, select Configure User-Defined Variables. A screen will appear as

shown below:

Config uration

13

Page 22

Configuration

April 2018

Similar to the User-Defined Parameters screen, you can input a label and unit for each variable, however

the value will be written by the flow computer or host. The user must program the flow computer or host

separately to write the value to the device. If the device loses power at any point during operation, the

value will be lost, but the Label and Units will not be lost.

Note

If the transmitter is ordered without an LCD display, the User-Defined Parameters and User-Defined

Variables are still available but are configured through the User-Defined Data tab in Manual Setup rather

than accessing them through the Display tab.

LCD display scroll time

The LCD display scroll time controls the amount of time each variable is displayed on the LCD display.

2.5.2 Device information

Reference Manual

00809-0100-4088, Rev DB

Fast Keys

The Device Information tab displays the device identification information on one screen including tags,

model numbers and assembly information.

Figure 2-5. Device Information Tab

2, 2, 7

2.5.3 Overview variables

Fast Keys

The Overview Variables tab allows the user to set which variables are displayed on the RTIS Overview

screen.

14

2, 2, 8

Configuration

Page 23

Reference Manual

00809-0100-4088, Rev DB

Figure 2-6. Overview Variables Tab

2.5.4 Alert setup

Configuration

April 2018

Fast Keys

The Alert Configuration tab is found under the Alert Setup menu of the device’s configuration menu. From

this tab, the user can configure upper and lower alert levels for each of the measured variables. This

includes the Differential Pressure, Static Pressure (Absolute or Gage), Module Temperature, or Process

Tem p er at ur e.

Figure 2-7. Alert Configuration Tab

2, 3

Config uration

15

Page 24

Configuration

April 2018

2.6 Variable configuration

2.6.1 Differential pressure

Reference Manual

00809-0100-4088, Rev DB

Fast Keys

Note

For Differential pressure sensor calibration , see page 106.

Figure 2-8. Differential Pressure Tab

2, 2, 1

1. Under the Setup heading, edit the Units, Damping, and Low DP Cutoff as needed.

2. Under the Reading heading, view the Differential Pressure and status.

3. Under the Sensor Limits heading, view the Upper, Lower, and Minimum Span.

2.6.2 Static pressure

Fast Keys

Note

For Static pressure sensor calibration , see page 109.

16

2, 2, 2

Configuration

Page 25

Reference Manual

00809-0100-4088, Rev DB

Figure 2-9. Static Pressure Tab

Configuration

April 2018

1. Under the Sensor Type heading, view whether the sensor is an Absolute Pressure Sensor or a Gage

Pressure Sensor.

2. Under the Setup heading for Static Pressure, edit the Units, Damping, and User-Defined Atmospheric

Pressure as needed.

3. Under the Absolute Pressure Setup and Gage Pressure Setup heading, view the Pressure, Status, Upper,

Lower, and Minimum Span for both Absolute and Gage Pressure respectively.

2.6.3 Process temperature

Fast Keys

Note

For Process temperature sensor calibration , see page 109.

2, 2, 3

Config uration

17

Page 26

Configuration

April 2018

Reference Manual

00809-0100-4088, Rev DB

Figure 2-10. Process Temperature Tab

1. Under the Setup heading for Process Temperature, edit the Units, Damping, and Sensor Type as

needed.

Note

The Rosemount 4088 accepts either a 3-wire or 4-wire RTD sensor, which can be selected under Sensor

Type. Ensure the type of sensor being used is selected or an RTD Sensor Type Mismatch will occur. For

more information about wiring the RTD, see “Install optional process temperature input (Pt 100 RTD

Sensor)” on page 47.

2. Under the Reading heading, view the Process Temperature and status.

3. Select the Tem per at ur e Mode under the Mode Setup heading. See Ta bl e 2 -1 for mode types and

descriptions.

Table 2-1. Temperature Modes

Temperature mode Description

Normal

Backup

Fixed

The transmitter will only use the actual measured Process Temperature value. If the

temperature sensor fails, the transmitter process temperature will be NAN (not a

number).

The transmitter will use the actual measured Process Temperature value. If the

temperature sensor fails, the transmitter will use the value shown in the Fixed/Backup

Tem pera ture field.

The transmitter will always use the temperature value shown in the Fixed/Backup

Tem pera ture field.

18

The Rosemount 4088 accepts Callendar-Van Dusen constants from a calibrated RTD schedule and

generates a special custom curve to match that specific sensor resistance vs. temperature performance.

Configuration

Page 27

Reference Manual

00809-0100-4088, Rev DB

Matching the specific sensor curve with the transmitter configuration enhances the temperature

measurement accuracy.

4. Under the Sensor Matching heading, view the Callendar-Van Dusen constants R0, A, B, and C. If the

Callendar-Van Dusen constants are known for the user’s specific Pt 100 RTD sensor, the constants R0,

A, B, and C may be edited by selecting the Callendar-Van Dusen Setup button and following the

on-screen prompts.

The user may also view the α, β, and d coefficients by selecting the View Alpha, Beta, Delta button. The

constants R0, α, β, and d may be edited by selecting the Callendar-Van Dusen Setup button and

following the on-screen prompts. To reset the transmitter to the IEC 751 Defaults, select the Reset to IEC

751 Defaults button.

5. Under the Process Temperature Sensor Limits heading, view and edit the Upper and Lower Sensor

Limits. Process Temperature Sensor Limits allow for early detection of RTD failures or abnormal

process conditions.

2.6.4 Module temperature

Configuration

April 2018

Fast Keys

The sensor module temperature variable is the measured temperature of the sensors and electronics

within the sensor module assembly. The module temperature value can be used to control heat tracing

or diagnose device overheating.

Figure 2-11. Module Temperature Tab

2, 2, 4

Config uration

1. Under the Setup heading, edit the Units as needed.

2. Under the Reading heading, view the Module Temperature and status.

3. After the Sensor Limits heading, view the Upper and Lower Module Temperature Limits.

19

Page 28

Configuration

April 2018

2.7 Menu trees and Field Communicator

Based on the configuration ordered, some measurements (i.e. static pressure, process temperature) may

not be available. Available measurements are determined by the Multivariable Type and Measurement

Type codes ordered. See ordering information in the Product Data Sheet for more information.

The menu trees and Field Communicator in this section are shown for the following model code:

Measurement type 1 (differential pressure, static pressure [absolute], process temperature) with LCD

display

The menu trees and Field Communicator for other model codes will vary.

Reference Manual

00809-0100-4088, Rev DB

20

Configuration

Page 29

Reference Manual

00809-0100-4088, Rev DB

2.7.1 Rosemount 4088A menu tree

Figure 2-12. Overview

Configuration

April 2018

Config uration

21

Page 30

Configuration

April 2018

Figure 2-13. Configure – Guided Setup

Reference Manual

00809-0100-4088, Rev DB

22

Configuration

Page 31

Reference Manual

00809-0100-4088, Rev DB

Figure 2-14. Configure – Manual Setup

Configuration

April 2018

Config uration

23

Page 32

Configuration

April 2018

Figure 2-15. Configure – Manual Setup (Continued)

Reference Manual

00809-0100-4088, Rev DB

24

Configuration

Page 33

Reference Manual

00809-0100-4088, Rev DB

Figure 2-16. Service Tools

Configuration

April 2018

Config uration

25

Page 34

Configuration

April 2018

Figure 2-17. Service Tools (continued)

Reference Manual

00809-0100-4088, Rev DB

26

Configuration

Page 35

Reference Manual

00809-0100-4088, Rev DB

2.7.2 Rosemount 4088B menu tree

Figure 2-18. Overview

Configuration

April 2018

Config uration

27

Page 36

Configuration

April 2018

Figure 2-19. Configure – Guided Setup

Reference Manual

00809-0100-4088, Rev DB

28

Configuration

Page 37

Reference Manual

00809-0100-4088, Rev DB

Figure 2-20. Configure – Manual Setup

Configuration

April 2018

Config uration

29

Page 38

Configuration

April 2018

Figure 2-21. Configure – Manual Setup (Continued)

Reference Manual

00809-0100-4088, Rev DB

30

Configuration

Page 39

Reference Manual

00809-0100-4088, Rev DB

Figure 2-22. Service Tools

Configuration

April 2018

Config uration

31

Page 40

Configuration

April 2018

Figure 2-23. Service Tools (Continued)

Reference Manual

00809-0100-4088, Rev DB

32

Configuration

Page 41

Reference Manual

00809-0100-4088, Rev DB

2.7.3 Field Communicator

A check () indicates the basic configuration parameters. At a minimum, these parameters should be

verified as part of the configuration and startup procedure.

Table 2-2. Field Communication Fast Keys

Category Function Sequence

Device Available Measurements 1, 9, 4

Device Display 2, 2, 5

Device Sensor Module Temperature 2, 2, 4

Device Sensor Module Temperature Units 2, 2, 4, 3

Device Sensor Module Temperature Upper Alert Limit 2, 2, 4, 4

Device Sensor Module Temperature Lower Alert Limit 2, 2, 4, 5

Device Device Address 2, 2, 6, 1, 1

Device Device Status 1, 1

Device Baud Rate 2, 2, 6, 1, 2

Device Turnaround Delay 2, 2, 6, 1, 3

Device Ta g 2, 2, 7, 1, 1

Configuration

April 2018

Device Long Tag 2, 2, 7, 1, 2

Device Transmitter S/N 2, 2, 7, 1, 7

Device Security Switch 1, 9, 5, 1

DP Sensor DP 2, 2, 1

DP Sensor Calibration 3, 4, 1, 8

DP Sensor DP Units 2, 2, 1, 3

DP Sensor DP Damping 2, 2, 1, 4

DP Sensor Veri fic atio n 3, 4, 1, 9

DP Sensor Upper Alert Limit 2, 2, 1, 6

DP Sensor Lower Alert Limit 2, 2, 1, 7

PT Sensor Sensor Matching 2, 2, 3, 8

PT Sensor PT 2, 2, 3

PT Sensor Calibration 3, 4, 3, 8

PT Sensor PT Units 2, 2, 3, 3

PT Sensor PT Damping 2, 2, 3, 4

PT Sensor Sensor Type 2, 2, 3, 5

PT Sensor Veri fic atio n 3, 4, 3, 9

PT Sensor Upper Alert Limit 2, 2, 3, 6, 1

Config uration

PT Sensor Lower Alert Limit 2, 2, 3, 6, 2

PT Sensor Temp Mode Setup 2, 2, 3, 7

33

Page 42

Configuration

D

C

B

A

D

E

F

G

April 2018

Reference Manual

00809-0100-4088, Rev DB

Table 2-2. Field Communication Fast Keys

Category Function Sequence

SP Sensor AP 2, 2, 2, 7

SP Sensor SP Units 2, 2, 2, 3

SP Sensor GP 2, 2, 2, 6

SP Sensor SP Damping 2, 2, 2, 4

SP Sensor Calibration 3, 4, 2, 8

SP Sensor Veri fic atio n 3, 4, 2, 9

SP Sensor Upper Alert Limit 2, 2, 2, 6, 3

SP Sensor Lower Alert Limit 2, 2, 2, 6, 4

2.8 Rosemount 4088A configuration with legacy tool

The Rosemount 4088A may be configured with the Rosemount 3095FB Configuration Software. When

using this legacy tool, only functionality that was available with the Rosemount 3095FB can be accessed.

The device must be removed from the Modbus network prior to communicating over the RS-485 bus.

Figure 2-24. Transmitter Configuration via RS-485 Network Port

A. RS- 485 (A)

B. RS-485 (B)

C. RS-485 bus, twisted pair required

D. Bus Termination: AC termination on Rosemount 4088 (see “Set the switches” on page 43) or 120 Ω resistor

E. User-provided power supply

F. Rosemount 3095FB configuration software

G. RS 232/RS 485 converter

34

Configuration

Page 43

Reference Manual

00809-0100-4088, Rev DB

Section 3 Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 35

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 35

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

Steps required for quick installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 37

Rosemount 305, 306, and 304 Manifolds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 49

3.1 Overview

Installation

April 2018

The information in this section covers installation considerations for the Rosemount™ 4088

MultiVariable

describe basic installation, wiring, and startup procedures. Dimensional drawings for each transmitter

variation and mounting configuration are included in Appendix A: Reference Data.

™

Transmitter. The Rosemount 4088 Quick Start Guide is shipped with every transmitter to

3.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety of the

personnel performing the operation. Information that raises potential safety issues is indicated with a

warning symbol ( ). Refer to the following safety messages before performing an operation preceded

by this symbol.

Installation

35

Page 44

Installation

April 2018

Reference Manual

00809-0100-4088, Rev DB

Explosions can result in death or serious injury.

Do not remove the transmitter covers in explosive environments when the circuit is live.

Fully engage both transmitter covers to meet explosion-proof requirements.

Before connecting a communicator in an explosive atmosphere, make sure the instruments in the

loop are installed in accordance with intrinsically safe or non-incendive field wiring practices.

Verify the operating atmosphere of the transmitter is consistent with the appropriate hazardous

locations certifications.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals.

Process leaks could result in death or serious injury.

Install and tighten all four flange bolts before applying pressure.

Do not attempt to loosen or remove flange bolts while the transmitter is in service.

Replacement equipment or spare parts not approved by Emerson

reduce the pressure retaining capabilities of the transmitter and may render the instrument

dangerous.

Use only bolts supplied or sold by Emerson as spare parts.

Improper assembly of manifolds to traditional flange can damage sensor module.

For safe assembly of manifold to traditional flange, bolts must break back plane of flange web (i.e., bolt

hole) but must not contact module housing.

Sensor module and electronics housing must have equivalent approval labeling in order to

maintain hazardous location approvals.

When upgrading, verify sensor module and electronics housing certifications are equivalent.

Differences in temperature class ratings may exist, in which case the complete assembly takes the

lowest of the individual component temperature classes (for example, a T4/T5 rated electronics

housing assembled to a T4 rated sensor module is a T4 rated transmitter).

™

for use as spare parts could

3.3 Considerations

3.3.1 General

Measurement performance depends upon proper installation of the transmitter and impulse piping.

Mount the transmitter close to the process and use minimum piping to achieve best performance. Also,

consider the need for easy access, personnel safety, practical field calibration, and a suitable transmitter

environment. Install the transmitter to minimize vibration, shock, and temperature fluctuation.

Important

Install the enclosed pipe plug (found in the box) in the unused conduit opening. For straight threads, a

minimum of six threads must be engaged. For tapered threads, install the plug wrench-tight.

For material compatibility considerations, see the Material Selection Tech n ical Note.

36

Installation

Page 45

Reference Manual

00809-0100-4088, Rev DB

3.3.2 Mechanical

Steam service

For steam service or for applications with process temperatures greater than the limits of the

transmitter, do not blow down impulse piping through the transmitter. Flush lines with the blocking

valves closed and refill lines with water before resuming measurement.

Side mounting

When the transmitter is mounted on its side, position the coplanar flange to ensure proper venting or

draining. Mount the flange as shown in Figure 3-5 on page 41, keeping drain/vent connections on the

bottom for gas service and on the top for liquid service.

3.3.3 Environmental

Best practice is to mount the transmitter in an environment that has minimal ambient temperature

change. The transmitter electronics temperature operating limits are –40 to 185 °F (–40 to 85 °C).

Appendix A: Reference Data lists the sensing element operating limits. Mount the transmitter so it is not

susceptible to vibration and mechanical shock and does not have external contact with corrosive

materials.

Installation

April 2018

3.4 Steps required for quick installation

Start >

Mount the transmitter

Consider housing rotation

Set the switches

Wiring and power up

Verify device configuration

Trim the transmitter

> Finish

Installation

37

Page 46

Installation

Flow

April 2018

3.4.1 Mount the transmitter

Liquid flow applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Mount the transmitter so that the drain/vent

valves are oriented upward.

Gas flow applications

1. Place taps in the top or side of the line.

2. Mount beside or above the taps.

Reference Manual

00809-0100-4088, Rev DB

Flow

Steam flow applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Fill impulse lines with water.

Flow

Flow

38

Installation

Page 47

Reference Manual

00809-0100-4088, Rev DB

Figure 3-1. Mounting Bracket – Coplanar Flange

Figure 3-2. Mounting Brackets – Traditional Flange

Installation

April 2018

Panel mount Pipe mount

Panel mount Pipe mount

Installation

Figure 3-3. Mounting Brackets – In-line

Panel mount Pipe mount

39

Page 48

Installation

April 2018

Reference Manual

00809-0100-4088, Rev DB

Bolting considerations

If the transmitter installation requires assembly of a process flange, manifold, or flange adapters, follow

these assembly guidelines to ensure a tight seal for optimal performance characteristics of the

transmitter. Only use bolts supplied with the transmitter or sold by Emerson as spare parts. Figure 3-4

illustrates common transmitter assemblies with the bolt length required for proper transmitter

assembly.

Figure 3-4. Common Transmitter Assemblies

A

4 × 1.75-in.

(44 mm)

B

C

4 × 1.75-in.

(44 mm)

D

4 × 2.25-in.

(57 mm)

4 × 1.50-in.

(38 mm)

4 × 1.75-in.

(44 mm)

4 × 2.88-in.

(73 mm)

A. Transmitter with coplanar flange

B. Transmitter with coplanar flange and optional flange adapters

C. Transmitter with traditional flange and optional flange adapters

D. Transmitter with coplanar flange and optional manifold and flange adapters

Note

For all other manifolds, contact Customer Central technical support.

Bolts are typically carbon steel or stainless steel. Confirm the material by viewing the markings on the

head of the bolt and referencing Table 3-1 on page 41. If bolt material is not shown in Tab l e 3- 1 , contact

the local Emerson representative for more information.

Use the following bolt installation procedure:

1. Carbon steel bolts do not require lubrication and the stainless steel bolts are coated with a lubricant

to ease installation. However, no additional lubricant should be applied when installing either type of

bolt.

2. Finger-tighten the bolts.

3. Torque the bolts to the initial torque value using a crossing pattern. See Ta b le 3 - 1 for initial torque

value.

4. Torque the bolts to the final torque value using the same crossing pattern.

See Ta bl e 3 -1 for final torque value.

40

5. Verify the flange bolts are protruding through the sensor module before applying pressure (see

Figure 3-5 on page 41).

Installation

Page 49

Reference Manual

A

B

A

B

C

D

00809-0100-4088, Rev DB

Table 3-1. Torque Values for the Flange and Flange Adapter Bolts

Bolt material Head markings Initial torque Final torque

Installation

April 2018

B8M

B7M

316

Carbon Steel (CS) 300 in-lb 650 in-lb

316

Stainless Steel (SST) 150 in-lb 300 in-lb

316

STM

R

316

SW

316

Figure 3-5. Proper Bolt Installation

A. Bolt

B. Sensor module

O-rings with flange adapters

Failure to install proper flange adapter O-rings may cause process leaks, which can result in death or

serious injury. Only use the O-ring that is designed for its specific flange adapter.

A. Flange adapter

B. O-ring

C. PTFE-based profile (square)

D. Elastomer profile (round)

Whenever the flange or adapters are removed, visually inspect the O-rings. Replace them if there are

any signs of damage, such as nicks or cuts. If the O-rings are replaced, re-torque the flange bolts and

alignment screws after installation to compensate for seating of the O-rings.

In-line gage transmitter orientation

The low side pressure port (atmospheric reference) on the in-line gage transmitter is located under the

sensor module neck label. (See Figure 3-6 on page 42)

Keep the vent path free of any obstruction, including but not limited to paint, dust, and lubrication by

mounting the transmitter so that any contaminants can drain away.

Installation

41

Page 50

Installation

A

A

B

April 2018

Figure 3-6. In-line Gage Transmitter

A. Low side pressure port (under neck label)

3.4.2 Consider housing rotation

To improve field access to wiring or to better view the optional LCD display:

Reference Manual

00809-0100-4088, Rev DB

1. Loosen the housing rotation set screw.

2. Turn the housing up to 180° left or right of its original (as shipped) position.

3. Re-tighten the housing rotation set screw.

Figure 3-7. Transmitter Housing Set Screw

A. LCD display

B. Housing rotation set screw (

3

/32-in.)

Note

Do not rotate the housing more than 180° without first performing a disassembly procedure (refer to

Section 6: Troubleshooting for more information). Over-rotation may sever the electrical connection

between the sensor module and the electronics.

Rotate the LCD display

Transmitters ordered with the LCD display will be shipped with the display installed.

In addition to housing rotation, the optional LCD display can be rotated in 90° increments by squeezing

the two tabs, pulling out, rotating and snapping back into place.

If LCD display pins are inadvertently removed from the electronics board, carefully re-insert the pins

before snapping the LCD display back into place.

Use the following procedure and Figure 3-8 on page 43 to install the LCD display:

42

Installation

Page 51

Reference Manual

AB

00809-0100-4088, Rev DB

1. If the transmitter is installed in a loop, then secure the loop and disconnect power.

2. Remove the transmitter cover on the electronics board side (opposite the field terminals side). Do not

remove instrument covers in explosive environments when circuit is live.

3. Engage the four-pin connector into the electronics board and snap LCD display into place.

4. In order to meet explosion-proof requirements, reinstall the housing cover and tighten so the cover is

fully seated with metal to metal contact between the housing and cover. After the cover is seated

properly, replace the flathead screw located on the bottom of the housing cover.

Figure 3-8. Optional LCD Display

A. Electronics board

B. LCD display

C. Display cover

Installation

April 2018

A

B

C

3.4.3 Set the switches

The transmitter’s default configuration for the AC Termination is in the off position. The transmitter’s

electronics board default configuration for the Security switch is in the off position.

1. If the transmitter is installed, secure the bus and remove power.

2. Remove the transmitter cover opposite the field terminal side. Do not remove the instrument covers

in explosive environments when the circuit is live.

3. Slide the Security and AC Termination switches into the preferred position by using a small

screwdriver.

Note

The Security switch will need to be in the off position in order to make any configuration changes.

4. In order to meet explosion-proof requirements, reinstall the housing cover and tighten so the cover is

fully seated with metal to metal contact between the housing and cover. After the cover is seated

properly, replace the flathead screw located on the bottom of the housing cover.

Figure 3-9. Transmitter Switch Configuration

A. Security

B. AC termination

Installation

43

Page 52

Installation

April 2018

3.4.4 Wiring and power up

Use the following steps to wire the transmitter:

1. Remove the cover on the field terminals side of the housing.

2. Set up based on optional process temperature input.

a. If the optional process temperature input is being utilized, follow the procedure “Install optional

process temperature input (Pt 100 RTD Sensor)” on page 47.

b. If there will not be an optional process temperature input, plug and seal the unused conduit

connection.

Note

When the enclosed threaded plug is utilized in the conduit opening, it must be installed with a minimum

engagement of five threads in order to comply with explosion-proof requirements. For straight threads,

a minimum of six threads must be engaged. For tapered threads, install the plug wrench-tight.

3. Connect the Rosemount 4088A to the RS-485 bus as shown in Figure 3-10 (for Rosemount 4088B

wiring and power up instructions, reference the ROC and FloBoss Manuals outlined in “Rosemount

4088B ROC communications” on page 77 or the ControlWave Manual outlined in “Rosemount 4088B

BSAP communications”).

a. Connect the A lead to the “A” terminal.

b. Connect the B lead to the “B” terminal.

Reference Manual

00809-0100-4088, Rev DB

4. Connect the positive lead from the power source to the “PWR +” terminal, and the negative lead to

the “PWR –” terminal (for power requirements, reference the Product Data Sheet).

Note

The Rosemount 4088A uses RS-485 Modbus

baud rate is 9600.

Note

Twisted pair wiring is required for RS-485 bus wiring. Wiring runs under 1000 ft (305 m) should be AWG

22 or larger. Wiring runs from 1000 to 4000 ft. (305 to 1219 m) should be AWG 20 or larger. Wiring

should not exceed AWG 16.

5. Reinstall the housing cover and tighten so the cover is fully seated with metal to metal contact

between the housing and cover in order to meet explosion-proof requirements.

Note

Installation of the transient protection terminal block does not provide transient protection unless the

transmitter housing is properly grounded.

®

with eight data bits, one stop bit and no parity. The default

44

Installation

Page 53

Reference Manual

D

D

B

A

C

E

00809-0100-4088, Rev DB

Transmitter wiring

Figure 3-10. Transmitter Wiring for RS-485 Bus

Installation

April 2018

A. RS- 485 (A)

B. RS-485 (B)

C. RS-485 bus, twisted pair required

D. Bus Termination: AC Termination on Rosemount 4088

(see “Set the switches” on page 43) or 120 Ω resistor

E. User-provided power supply

To co nfigure tr ansmitter via H A RT® port, reference Figure 2-1 on page 7 for the wiring diagram.

To configure using RS-485 network port, reference Figure 2-24 on page 34 for the wiring diagram.

Grounding

Signal wire grounding

Do not run signal wiring in conduit or open trays with power wiring, or near heavy electrical equipment.

If shielded wiring is used, ground the shield of the signal wiring at any one point on the signal loop.

Device must be properly grounded or earthed according to local electric codes.

Transmitter case

Always ground the transmitter case in accordance with national and local electrical codes. The most

effective transmitter case grounding method is a direct connection to earth ground with minimal

impedance (< 1 Ω). Methods for grounding the transmitter case include:

Internal ground connection

The internal ground connection screw is inside the terminal side of the electronics housing. The screw is

identified by a ground symbol ( ).

Figure 3-11. Internal Ground Connection

A

Installation

A. Ground lug

45

Page 54

Installation

April 2018

Reference Manual

00809-0100-4088, Rev DB

External ground connection

The external ground connection is on the outside of the sensor module housing. The connection is

identified by a ground symbol ( ). An external ground assembly is included with the option codes

shown in Table 3-2 on page 46 or is available as a spare part (03151-9060-0001).

Figure 3-12. External Ground Connection

B

A

A. External ground lug

B. External ground assembly (03151-9060-0001)

Table 3-2. External Ground Screw Approval Option Codes

Option code Description

E1 AT EX Flamep roo f

I1 ATEX Intrinsic Safety

N1 ATE X Type n

ND ATE X Dus t

K1 ATEX Flameproof, Intrinsic Safety, Type n, Dust (combination of E1, I1, N1, and ND)

E7 IECEx Flameproof, Dust Ignition-proof

N7 IECEx Type n

K7 IECEx Flameproof, Dust Ignition-proof, Intrinsic Safety, and Type n (combination of E7, I7, and N7)

KA ATEX and CSA Explosion-proof, Intrinsically Safe, Division 2 (combination of E1, E6, I1, and I6)

KC FM and ATEX Explosion-proof, Intrinsically Safe, Division 2 (combination of E5, E1, I5, and I1)

T1 Transient terminal block

D4 External ground screw assembly

Surges/transients

The transmitter will withstand electrical transients of the energy level usually encountered in static

discharges or induced switching transients. However, high-energy transients, such as those induced in

wiring from nearby lightning strikes, can damage the transmitter.

Optional transient protection terminal block

The transient protection terminal block can be ordered as an installed option (option code T1 in the

transmitter model number) or as a spare part to retrofit existing Rosemount 4088 MultiVariable

Transmitters in the field. For a complete listing of spare part numbers for transient protection terminal

blocks, refer to “Spare parts list” on page 123. A lightning bolt symbol on a terminal block identifies it as

having transient protection.

46

Installation

Page 55

Reference Manual

00809-0100-4088, Rev DB

Note

Grounding the transmitter case using the threaded conduit connection may not provide a sufficient

ground. The transient protection terminal block (option code T1) will not provide transient protection

unless the transmitter case is properly grounded. See “Grounding” on page 45 to ground the transmitter

case. Do not run transient protection ground wire with signal wiring; the ground wire may carry

excessive current if a lightning strike occurs.

Optional extended cover

The Rosemount 4088 can also be ordered with an aluminum or SST extended cover. The extended cover

option is beneficial in applications where more space is needed to wire the transmitter. The extended

cover can be ordered as an installed option (option code HX under housing cover extension) or as a spare

part to retrofit existing Rosemount 4088 MultiVariable Transmitters in the field. For a complete list of the

spare part numbers for covers, refer to “Spare parts list” on page 123.

Install optional process temperature input

(Pt 100 RTD Sensor)

Note

To meet ATEX/IECEx Flameproof certification, only ATEX/IECEx Flameproof cables (temperature input

code C30, C32, C33, or C34) may be used.

Installation

April 2018

1. Mount the Pt 100 RTD Sensor in the appropriate location.

Note

Use shielded 4- or 3-wire cable for the process temperature connection.

2. Connect the RTD cable to the transmitter by inserting the cable wires through the unused housing

conduit and connect to the screws on the transmitter terminal block. An appropriate cable gland

should be used to seal the conduit opening around the cable.

Note

If power is already connected to the Rosemount 4088, power should be removed prior to connecting the

RTD wires. This will allow the Rosemount 4088 to detect the RTD type at startup. Once the RTD is

installed, reconnect power.

Installation

47

Page 56

Installation

April 2018

3. Connect the RTD cable shield wire to the ground lug in the housing.

Figure 3-13. Transmitter RTD Wiring Connection

3-wire 4-wire

A

A

Reference Manual

00809-0100-4088, Rev DB

Red

B

A. Ground lug

B. Pt 100 RTD sensor

C. Connection head

White

C

B

Red

Note

Verify the installed PT sensor type (3-wire or 4-wire) matches the device setting.

3.4.5 Verify device configuration

For Rosemount 4088A, use Rosemount Transmitter Interface Software with the Rosemount 4088 DTM

or a HART Field Communicator with the Rosemount 4088 Device Descriptor to communicate with and

verify configuration of the transmitter.

For Rosemount 4088B, use ROCLINK

and verify configuration of the transmitter.

™

, TechView, or HART Field Communicator to communicate with

White

C

Note

A list of parameters to verify during commissioning is listed in “Field Communicator” on page 33.

3.4.6 Trim the transmitter

Transmitters are shipped fully calibrated per request or by the factory default.

Zero trim

A zero trim is a single-point adjustment used for compensating mounting position and line pressure

effects on static and differential pressure sensors. When performing a zero trim, ensure that the

equalizing valve is open and all wet legs are filled to the correct level.

If zero offset is less than 5 percent of USL, follow the user interface software instructions below to

perform a zero trim on a Field Communicator or see the “Zero trim” on page 105 for PC configuration.

Performing a zero trim using the Field Communicator

1. Block, equalize, and vent the transmitter and connect the Field Communicator (for more information

on connecting the Field Communicator, see Figure 2-1 on page 7).

2. If the device is equipped with a static pressure sensor, trim the sensor by inputting the following Fast

48

Installation

Page 57

Reference Manual

00809-0100-4088, Rev DB

Key sequence at the transmitter menu:

Installation

April 2018

Field Communicator

3. Follow the appropriate static pressure trim procedure.

Zero trim for gage pressure sensors

or

Lower sensor trim for absolute pressure sensors

Note

It is possible to degrade the performance of the transmitter if the full sensor trim is done improperly or

with inaccurate calibration equipment. Use a pressure input source that is at least three times more

accurate than the transmitter and allow the pressure input to stabilize for ten seconds before entering

any values.

4. Zero the differential pressure sensor by inputting the following Fast Key sequence at the transmitter

menu:

Field Communicator

5. Follow the zero DP trim procedure.

3, 4, 2, 8

3, 4, 1, 8, 5

3.5 Rosemount 305, 306, and 304 Manifolds

The Rosemount 305 Integral Manifold mounts directly to the transmitter and is available in two styles:

traditional and coplanar. The traditional Rosemount 305 can be mounted to most primary elements in

the market today using mounting adapters.

The Rosemount 306 Integral Manifold is used with in-line transmitters to provide block-and-bleed valve

capabilities of up to 10000 psi (690 bar).

The Rosemount 304 conventional manifold combines a traditional flange and manifold that can be

mounted to most primary elements.

3.5.1 Rosemount 305 Integral Manifold installation procedure

To install a Rosemount 305 to a Rosemount 4088:

1. Inspect the PTFE sensor module O-rings. If the O-rings are undamaged, reusing them is

recommended. If the O-rings are damaged (if they have nicks or cuts, for example), replace them with

new O-rings.

Important

If replacing the O-rings, be careful not to scratch or deface the O-ring grooves or the surface of the

isolating diaphragm when removing the damaged O-rings.

2. Install the integral manifold on the sensor module. Finger tighten the bolts, then tighten the bolts

incrementally in a cross pattern (see Figure 3-14) to final torque value. See Table 6-4 on page 122 for

complete bolt installation information and for torque values. When fully tightened, the bolts should

extend through the top of the module housing plane of the flange web (i.e. bolt hole) but must not

contact the module housing.

Installation

49

Page 58

Installation

April 2018

3. If the PTFE sensor module O-rings have been replaced, the flange bolts should be re-tightened after

installation to compensate for cold flow of the O-rings.

4. If applicable, install flange adapters on the process end of the manifold using the 1.75-in. flange bolts

supplied with the transmitter.

Note

Always perform a zero trim on the transmitter/manifold assembly after installation to eliminate

mounting effects. See “Zero trim” on page 48.

Reference Manual

00809-0100-4088, Rev DB

3.5.2 Rosemount 306 In-line Manifold installation procedure

The Rosemount 306 is for use only with a Rosemount 4088 In-line Transmitter.

Assemble the Rosemount 306 to the Rosemount 4088 with a thread sealant.

1. Place transmitter into holding fixture.

2. Apply appropriate thread paste or tape to threaded instrument end of the manifold.

3. Count total threads on the manifold before starting assembly.

4. Start turning the manifold by hand into the process connection on the transmitter.

Note

If using thread tape, be sure the thread tape does not strip when the manifold assembly is started.

5. Wrench tighten manifold into process connection.

Note

Minimum torque value is 425 in-lb.

6. Count how many threads are still showing.

Note

Minimum engagement is three revolutions.

7. Subtract the number of threads showing (after tightening) from the total threads to calculate the

revolutions engaged. Further tighten until a minimum of three rotations is achieved.

8. For block and bleed manifold, verify the bleed screw is installed and tightened. For 2-valve manifold,

verify the vent plug is installed and tightened.

9. Leak-check assembly to maximum pressure range of transmitter.

3.5.3 Rosemount 304 Conventional Manifold installation procedure

To install a Rosemount 304 to a Rosemount 4088:

1. Align the conventional manifold with the transmitter flange. Use the four manifold bolts for

alignment.

50

2. Finger tighten the bolts, then tighten the bolts incrementally in a cross pattern (see Figure 3-14) to

final torque value. See Table 6-4 on page 122 for complete bolt installation information and for

torque values. When fully tightened, the bolts should extend through the top of the module housing

plane of the flange web (i.e. bolt hole) but must not contact the module housing.

3. If applicable, install flange adapters on the process end of the manifold using the 1.75-in. flange bolts

supplied with the transmitter.

Installation

Page 59

Reference Manual

00809-0100-4088, Rev DB

Figure 3-14. Bolt Tightening Pattern

3.5.4 Rosemount 305 and 304 Manifold styles

The Rosemount 305 Integral Manifold is available in two styles: coplanar and traditional. The traditional

Rosemount 305 can be mounted to most primary elements with mounting adapters.

Figure 3-15. Rosemount 305 Manifold Styles

Integral coplanar Integral traditional

Installation

April 2018

The Rosemount 304 comes in two basic styles: traditional (flange + flange and flange + pipe) and wafer.

The Rosemount 304 traditional manifold comes in 2-, 3-, and 5-valve configurations. The Rosemount

304 wafer manifold comes in 3- and 5-valve configurations.

Figure 3-16. Rosemount 304 Manifold Styles

Traditiona l Wafer

Installation

51

Page 60

Installation

HL

Drain/Vent

valve

Isolate

(open)

Drain/Vent

valve

Isolate

(closed)

Process

Equalize

(closed)

April 2018

3.5.5 Manifold operation

Improper installation or operation of manifolds may result in process leaks, which may cause death or

serious injury.

Always perform a zero trim on the transmitter/manifold assembly after installation to eliminate any shift

due to mounting effects. See Section 5: Operation and Maintenance, “Sensor trim overview” on

page 105.

Coplanar transmitters

3-valve and 5-valve manifolds

Performing zero trim at static line pressure

In normal operation the two isolate (block) valves

between the process ports and transmitter will be open

and the equalize valve will be closed.

Drain/Vent

valve

Isolate

(open)

Reference Manual

00809-0100-4088, Rev DB

HL

Drain/Vent

Equalize

(closed)

valve

Isolate