Page 1

Model 4081C

Remote Controlled FOUNDATION

™

Fieldbus

Two-Wire Conductivity Transmitter

Instruction Manual

PN 51-4081C/rev.C

June 2002

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests its products to meet

many national and international standards. Because these instruments are

sophisticated technical products, you must properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The

following instructions must be adhered to and integrated into your safety

program when installing, using, and maintaining Rosemount Analytical

products. Failure to follow the proper instructions may cause any one of the

following situations to occur: Loss of life; personal injury; property damage;

damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

If this Instruction Manual is not the correct manual, telephone 1-800-6547768 and the requested manual will be provided. Save this Instruction

Manual for future reference.

• If you do not understand any of the instructions, contact your Rosemount

representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with

the product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate,

update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use

replacement parts specified by Rosemount. Unauthorized parts and

procedures can affect the product’s performance and place the safe

operation of your process at risk. Look alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in

place, except when maintenance is being performed by qualified persons, to

prevent electrical shock and personal injury.

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.RAuniloc.com

© Rosemount Analytical Inc. 2001

Page 3

TABLE OF CONTENTS

Section Title Page

1.0 INSTALLATION................................................................................................................. 1-1

1.1 Overview .................................................................................................................. 1-1

1.2 Mechanical Installation............................................................................................. 1-2

1.3 Electrical Installation ................................................................................................ 1-4

2.0 OPERATION OVERVIEW ................................................................................................. 2-1

2.1 General .................................................................................................................... 2-1

2.2 Display ..................................................................................................................... 2-1

2.3 Infrared Remote Control (IRC)................................................................................. 2-2

2.4 Diagnostic Messages............................................................................................... 2-2

2.5 Menu Program Tree................................................................................................. 2-3

3.0 FACTORY PROGRAMMED SETTINGS ........................................................................... 3-1

4.0 TRANSMITTER PROGRAM SET-UP ............................................................................... 4-1

4.1 Program Menu ......................................................................................................... 4-1

4.2 Temperature Parameters ......................................................................................... 4-2

4.3 Display Units ............................................................................................................ 4-3

5.0 START-UP AND CALIBRATION....................................................................................... 5-1

5.1 Accessing The Calibrate Menu ................................................................................ 5-1

5.2 Calibrate Menu ........................................................................................................ 5-2

5.3 Calibrate Menu (Contacting) .................................................................................... 5-3

5.4 Branch Calibration Initial Start-Up............................................................................ 5-4

5.5 Calibrate Menu (Low Conductivity/Resistivity)......................................................... 5-5

5.6 On-line Calibration ................................................................................................... 5-6

6.0 DIAGNOSIS AND TROUBLESHOOTING ........................................................................ 6-1

6.1 Overview .................................................................................................................. 6-1

6.2 Fault Conditions ....................................................................................................... 6-3

6.3 Diagnostic Messages............................................................................................... 6-4

6.4 Quick Troubleshooting Guide................................................................................... 6-5

6.5 Systematic Troubleshooting..................................................................................... 6-6

6.6 RTD Resistance Values ........................................................................................... 6-7

7.0 MAINTENANCE ................................................................................................................ 7-1

7.1 Overview .................................................................................................................. 7-1

7.2 Preventative Maintenance ....................................................................................... 7-1

7.3 Corrective Maintenance ........................................................................................... 7-1

8.0 PRODUCT DATA............................................................................................................... 8-1

8.1 Features................................................................................................................... 8-1

8.2 Specifications........................................................................................................... 8-2

8.3 Transmitter Display .................................................................................................. 8-3

8.4 Infrared Remote Control Functions.......................................................................... 8-3

8.5 Ordering Information ................................................................................................ 8-4

9.0 OPERATION WITH REMOTE CONTROLLER ................................................................. 9-1

10.0 RETURN OF MATERIALS ................................................................................................ 10-1

i

MODELS 4081C TABLE OF CONTENTS

MODEL 4081C

MICROPROCESSOR ANALYZERS

Page 4

ii

LIST OF FIGURES

Figure No. Title Page

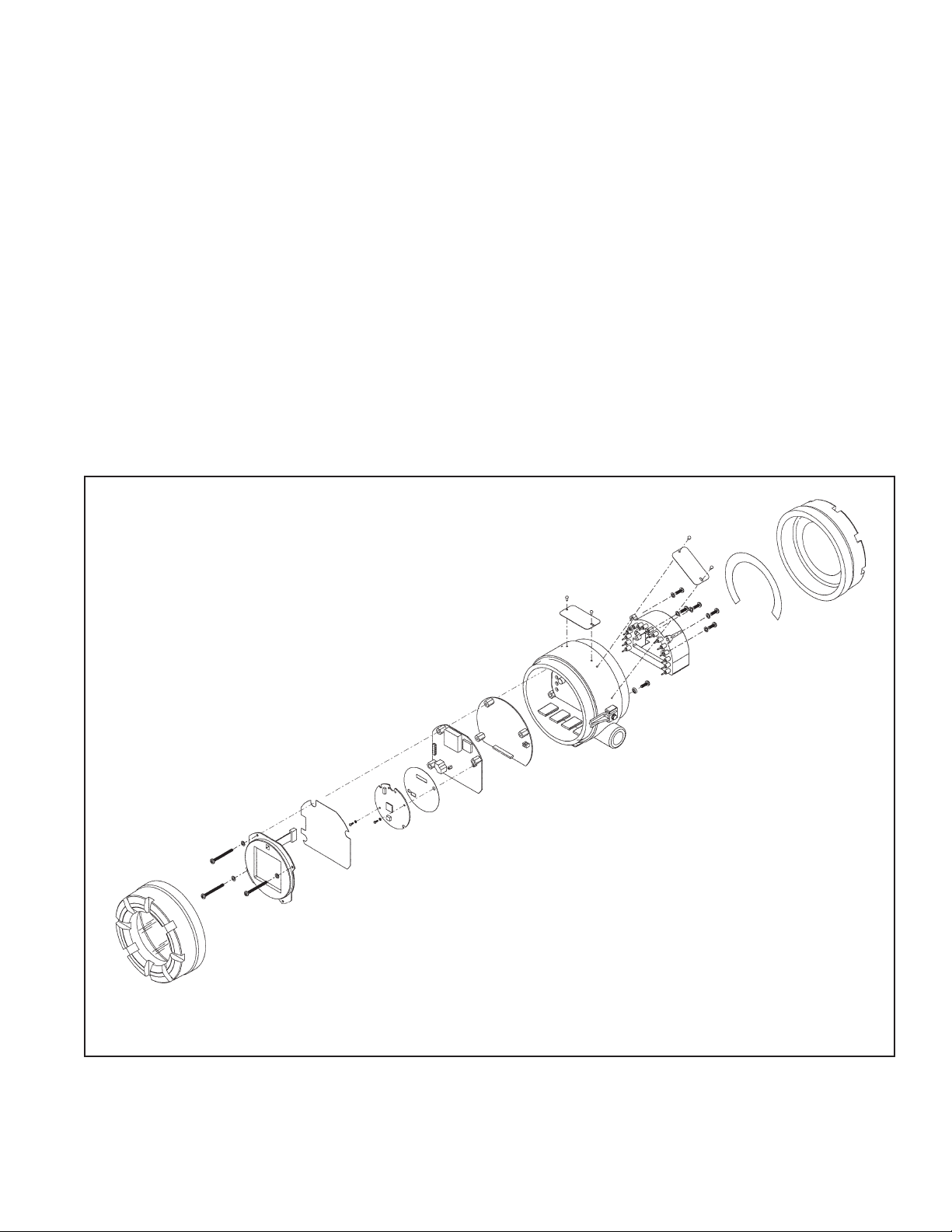

1-1 Exploded Drawing of Circuit Board Stack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

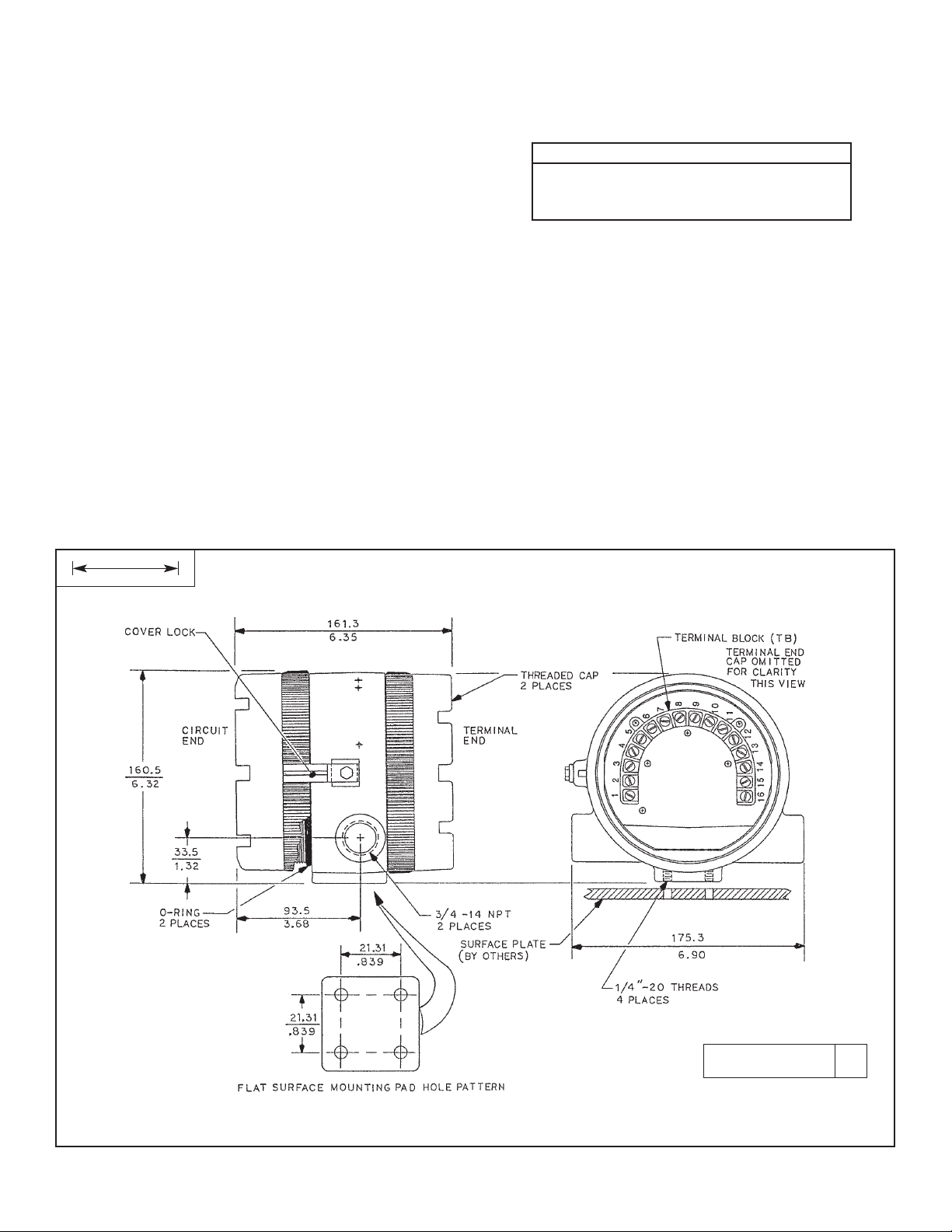

1-2 Dimensional Information - Model 4081C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-3 Mounting Information - Model 4081C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-4 Contacting Conductivity Sensor Wiring to Model 4081C Transmitter . . . . . . . . . . . . 1-6

1-5 Sensor Wiring with Pre-existing Conductivity Sensors . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-6 Model 4081C Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-7 Typical Fieldbus Network Electrical Wiring Configuration . . . . . . . . . . . . . . . . . . . . . 1-8

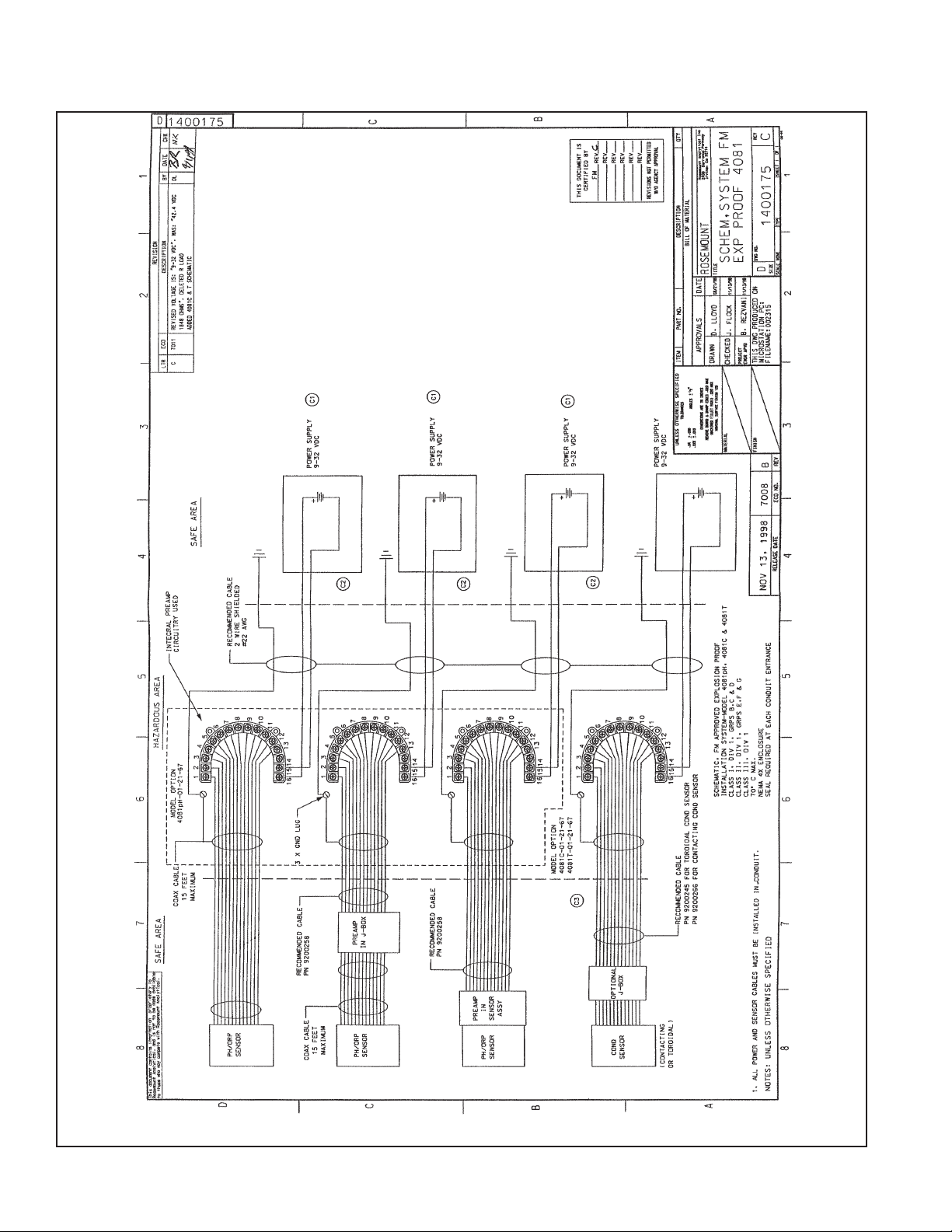

1-8 FM Explosion Proof Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

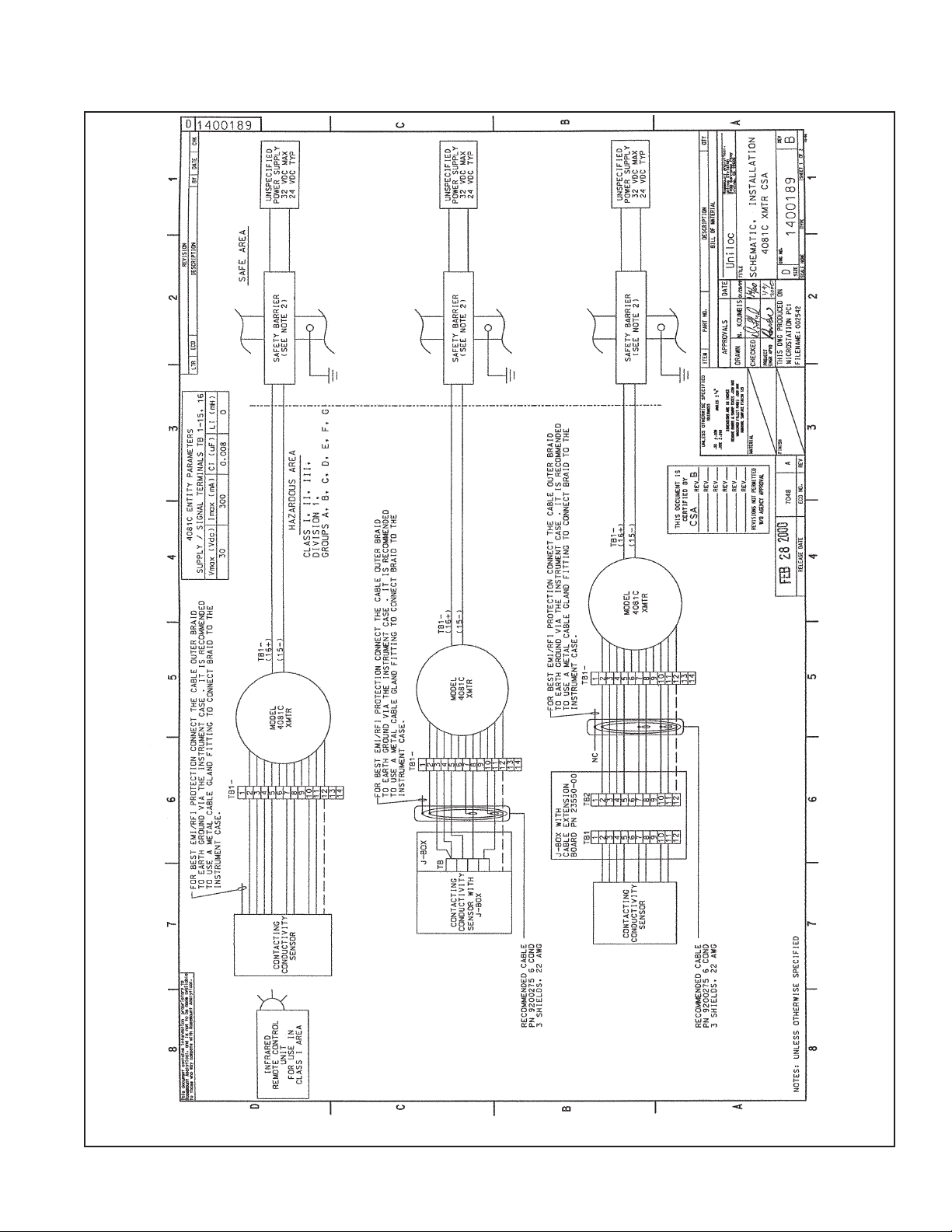

1-9 CSA Intrinsically Safe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-10 FMRC Intrinsically Safe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

2-1 Process Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Program Mode Display Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3 Infrared Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-4 Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

4-1 Program Menu and Menu Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 RTD Sensor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-3 Security Code Prompt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5-1 Calibration Menu Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6-1 Diagnose Menu Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 Diagnose Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-3 Disabling Fault Annunciation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-4 Non-disabling Warning Annunciation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-5 Troubleshooting Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

7-1 Hold Annunciation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2 Exploded View of Model 4081C Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

8-1 Transmitter Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8-2 Infrared Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8-3 Functional Block Diagram for Model 4081C Transmitter with F

OUNDATION Fieldbus . 8-3

9-1 Functional Block Diagram for Model 4081C Transmitter with FOUNDATION Fieldbus . 9-1

LIST OF TABLES

Table No. Title Page

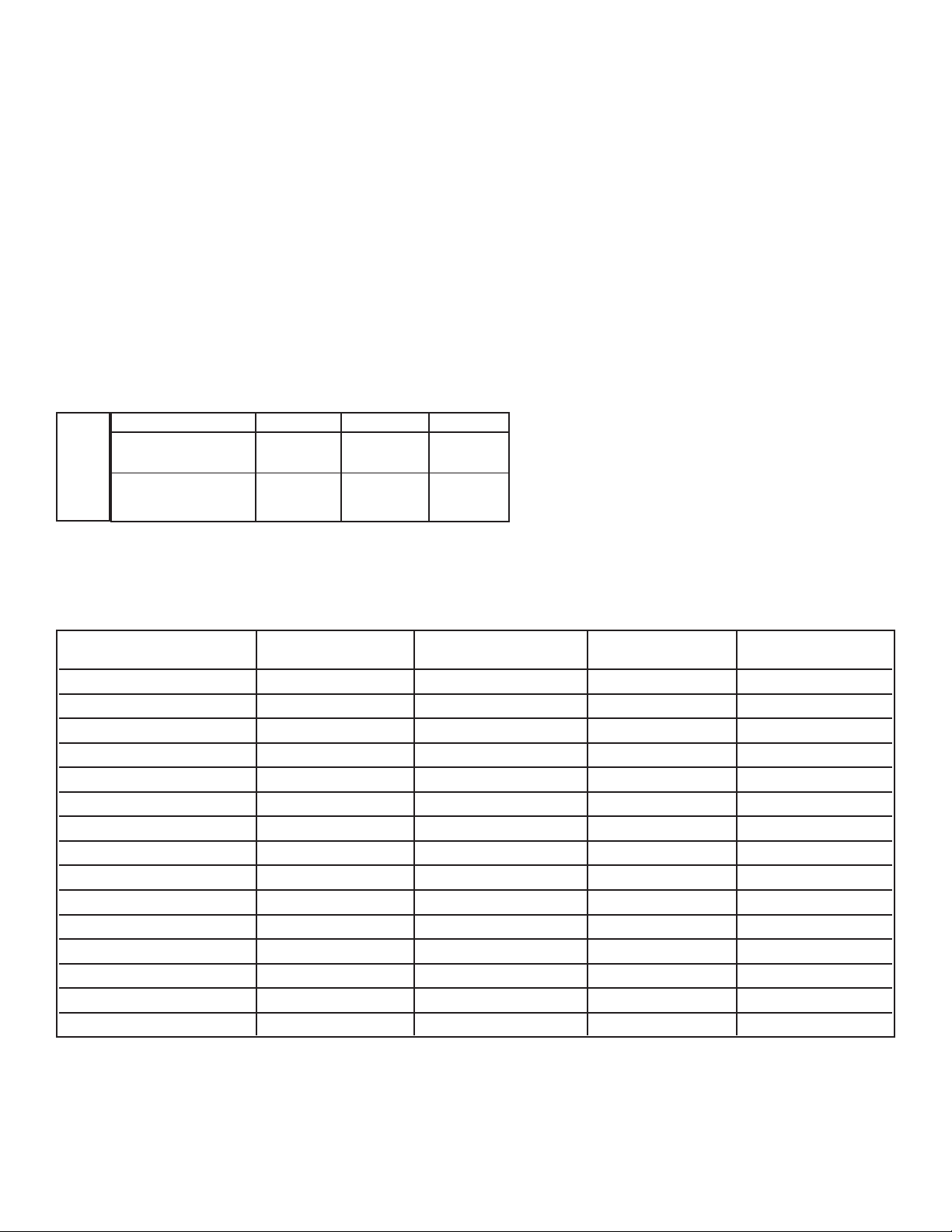

1-1 Measurement Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2 Transmitter Range Limits (Ultra Pure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 Transmitter Range Limits (Resistivity) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-4 Transmitter Range Limits (Conductivity) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3-1 Program Variables with Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

4-1 Transmitter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2 Program Menu Mnemonics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5-1 Calibrate Menu Mnemonics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

6-1 Diagnostics Variables Mnemonics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2 Diagnostic Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-3 Quick Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-4 RTD Resistance Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-5 Conductivity Determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

7-1 Replacement Parts for Model 4081C Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

LIST OF APPENDICES

Section Title Page

A Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

B 4081C Resource and Transducer Block Parameters. . . . . . . . . . . . . . . . . . . . . . . . . B-1

MODELS 4081C TABLE OF CONTENTS

Page 5

MODELS 4081C SECTION 1.0

INSTALLATION

SECTION 1.0

INSTALLATION

FIGURE 1-1. Model 4081C Transmitter - Exploded Drawing of Circuit Board Stack

1.1 OVERVIEW

This conductivity transmitter has been designed for

easy installation and shipment. The purpose of this

section is to provide information on the electrical configurations and the physical mountings available. Prior

to discarding the packing case:

If it is damaged, the transmitter may have also

sustained damage. Contact the carrier at once.

Remove all items shown on the packing list and

note any exceptions.

1-1

The Model 4081C conductivity transmitter is designed

to make accurate measurements while the sensor is

submersed in the process stream. Measurements can

also be tailored to high temperature and/or high pressure streams. The specific ranges covered are controlled by both hardware and software.

Page 6

1-2

FIGURE 1-2. Dimensional Information – Model 4081C

DWG. NO. REV.

44081C01 A

MILLIMETER

INCH

MODELS 4081C SECTION 1.0

INSTALLATION

1.2 MECHANICAL INSTALLATION

The Model 4081C Transmitter is suitable for installation in

harsh environments.

• For best operation, locate in an area where temperature extremes, vibrations, electromagnetic, and radio

frequency interferences are minimized or absent.

The transmitter is equipped with two 3/4 in. FNPT conduit

openings, one on each side of the transmitter housing.

• Remove the terminal end cap.

• With the transmitter positioned with the wiring terminal

side of the enclosure opened (as seen in Figure 1-2),

use the left conduit opening to bring in the sensor

wiring, and the right side conduit opening for power

supply/current loop wiring.

• To prevent moisture from entering the transmitter

housing, use weathertight cable glands supplied by

others.

NOTE

Moisture accumulation in the transmitter

housing can affect transmitter performance

and may void its warranty.

• If conduit is used, connections on the transmitter housing should be plugged and sealed (with tape, pipe compound, or sealant) to prevent moisture accumulation in

the terminal side of the housing.

• The transmitter must be installed so that the conduit

openings are not on the top, because moisture can

accumulate in that position.

• The transmitter should be easily accessed by operating

and maintenance personnel.

1.2.1 Flat Surface Mounting. The transmitter may be

mounted on a flat surface (see Figure 1-2) using the threaded mounting holes on the bottom of the transmitter.

1.2.2 Pipe Mounting Bracket. An optional pipe mounting

bracket is available. See Figure 1-3 for mounting information.

Page 7

1-3

MODELS 4081C SECTION 1.0

INSTALLATION

FIGURE 1-3. Mounting Information - Model 4081C

DWG. NO. REV.

40408103 B

DWG. NO. REV.

40408104 F

MILLIMETER

INCH

Page 8

1-4

MODELS 4081C SECTION 1.0

INSTALLATION

1.3 ELECTRICAL INSTALLATION

1.3.1 Conductivity Sensors

All Rosemount Analytical Inc.’s contacting conductivity

sensors with Pt100 RTD or Pt1000 RTD are compatible

with the Model 4081C transmitter.

NOTE

Optimum EMI/RFI immunity may be achieved on

sensors whose interconnecting cable has an outer

braided shield by utilizing a cable gland fitting that

provides for continuity between the braided shield

and the transmitter enclosure. An equivalent conduit connector may also be used if the sensor

cable is to be enclosed in conduit.

1.3.2 Contacting Loops.

The Model 4081C conductivity transmitter is designed to

make accurate measurements while in contact with the

process stream. Measurements can also be tailored to high

temperature and/or high pressure streams. The following

table shows the measurement ranges and linearity available for each range and cell constant.

TABLE 1-1. Measurement Ranges (µs/cm)

TABLE 1-2. Transmitter Range Limits (Ultra Pure [PV_HIGH_LOW_RANGE = Low])

CELL CONSTANT 0.01 0.10 1.0

Low Range 0-20 0-200 0-2,000

(linearity: ± 1.0%)

High Range 0-200 0-2,000 0-20,000

(linearity: ± 5.0%)

Wire Terminal

Connection

(11) or (12)

*NOTE: Values shown are the 25°C conductivity with a tem-

perature slope of 2% per degree C. The maximum

range value will be higher for solutions with a lower

temperature slope, and lower for solutions with a

higher temperature slope.

NOTE: Connect grey (or black) wire of sensor to TB-11 for

high conductivity ranges or to TB-12 for low conductivity ranges.

MANUAL_AUTO_RANGE RANGE_VALUE CELL_CONSTANT (0% FS) (100% FS)

Manrng (1/cm) EU0% µS/cm EU100% µS/cm

Auto N/A 0.01 0 20

Auto N/A 0.1 0 200

Auto N/A 1.0 0 2,000

Manual 1 0.01 0 0.0975

Manual 1 0.1 0 0.975

Manual 1 1.0 0 9.75

Manual 2 0.01 0 0.64

Manual 2 0.1 0 6.4

Manual 2 1.0 0 64

Manual 3 0.01 0 4.05

Manual 3 0.1 0 40.5

Manual 3 1.0 0 405

Manual 4 0.01 0 20

Manual 4 0.1 0 200

Manual 4 1.0 0 2,000

Page 9

MODELS 4081C SECTION 1.0

INSTALLATION

1-5

TABLE 1-3. Transmitter Range Limits (Resistivity [PV_HIGH_LOW_RANGE = Low])

MANUAL_AUTO_RANGE RANGE_VALUE CELL_CONSTANT (0% FS) (100% FS)

Manrng (1/cm) EU0% (MΩ-cm) EU100% (MΩ-cm)

Auto N/A 0.01 0.05 50

Auto N/A 0.1 0.005 50

Auto N/A 1.0 0.0005 50

Manual 1 0.01 10.3 50

Manual 1 0.1 1.03 50

Manual 1 1.0 0.103 50

Manual 2 0.01 1.56 50

Manual 2 0.1 0.156 50

Manual 2 1.0 0.0156 50

Manual 3 0.01 0.247 50

Manual 3 0.1 0.0247 50

Manual 3 1.0 0.00247 50

Manual 4 0.01 0.05 50

Manual 4 0.1 0.005 50

Manual 4 1.0 0.0005 50

TABLE 1-4. Transmitter Range Limits (Linear Conductivity)

PV_HIGH_LOW_RANGE MANUAL_AUTO_RANGE RANGE_VALUE CELL_CONSTANT (0% FS) (100% FS)

Manrng

(1/cm) EU0% µS/cm EU100% µS/cm

Low Auto N/A 0.01 0 20

Low Auto N/A 0.1 0 200

Low Auto N/A 1.0 0 2,000

High Auto N/A 0.01 0 200

High Auto N/A 0.1 0 2,000

High Auto N/A 1.0 0 20,000

Low Manual 1 0.01 0 0.0975

Low Manual 1 0.1 0 0.975

Low Manual 1 1.0 0 9.75

Low Manual 2 0.01 0 0.64

Low Manual 2 0.1 0 6.40

Low Manual 2 1.0 0 64

Low Manual 3 0.01 0 4.05

Low Manual 3 0.1 0 40.5

Low Manual 3 1.0 0 405

Low Manual 4 0.01 0 20

Low Manual 4 0.1 0 200

Low Manual 4 1.0 0 2,000

High Manual 1 0.01 0 8

High Manual 1 0.1 0 80

High Manual 1 1.0 0 800

High Manual 2 0.01 0 52

High Manual 2 0.1 0 520

High Manual 2 1.0 0 5,200

High Manual 3 0.01 0 200

High Manual 3 0.1 0 2,000

High Manual 3 1.0 0 20,000

Page 10

1-6

MODELS 4081C SECTION 1.0

INSTALLATION

*

Note: Connect grey wire of sensor to TB-11 for high conductivity ranges or to TB-12 for low conductivity ranges. See

Table 1-2 for range selection.

FIGURE 1-4. Contacting Conductivity Sensor to Model 4081C Transmitter

Page 11

1-7

MODELS 4081C SECTION 1.0

INSTALLATION

FIGURE 1-5. Sensor Wiring with Pre-existing Conductivity Sensors

Page 12

1-8

MODELS 4081C SECTION 1.0

INSTALLATION

FIGURE 1-6. MODEL 4081C TERMINAL BLOCKS

MODEL 4081C

FIGURE 1-7. TYPICAL FIELDBUS NETWORK ELECTRICAL WIRING CONFIGURATION

Page 13

MODELS 4081C SECTION 1.0

INSTALLATION

LABEL, I.S. N.I. & EX CSA APPROVED FOR MODEL 4081C

1-9

1.3.3 Hazardous Area Installation

In order to maintain the hazardous area rating for installed transmitter, the following drawings must be used:

Figure 1-8. Wiring for FM Explosion-Proof Installation for Model 4081C (Drawing Number 1400175)

Figure 1-9. Wiring for CSA Intrinsic Safety for Model 4081C (Drawing Number 1400189). See also label below.

Figure 1-10. Wiring for FMRC Instrinsically Safe Installation for Model 4081C (Drawing Number 1400186).

Page 14

1-10

MODELS 4081C SECTION 1.0

INSTALLATION

FIGURE 1-8. EXPLOSION-PROOF INSTALLATION

Page 15

MODELS 4081C SECTION 1.0

INSTALLATION

FIGURE 1-9. CSA INTRINSICALLY SAFE INSTALLATION (1 of 2)

1-11

Page 16

1-12

MODELS 4081C SECTION 1.0

INSTALLATION

FIGURE 1-9. CSA INTRINSICALLY SAFE INSTALLATION (2 of 2)

Page 17

MODELS 4081C SECTION 1.0

INSTALLATION

FIGURE 1-10. FMRC INTRINSICALLY SAFE INSTALLATION (1 of 2)

1-13

Page 18

1-14

MODELS 4081C SECTION 1.0

INSTALLATION

FIGURE 1-10. FMRC INTRINSICALLY SAFE INSTALLATION (2 of 2)

Page 19

2-1

2.1 GENERAL

The Model 4081C transmitter operates in either the

Process or Program modes. The process mode screen

is illustrated in Figure 2-1 and the program mode screen

is illustrated in Figure 2-2.

2.2 DISPLAY

2.2.1 Process Mode (normal operating mode). When

operating in this mode:

• The primary process variable (the conductivity) is

continuously displayed (see 1 in Figure 2-1)

• Engineering units are determined by the process

display mode

• Temperature output is in °F or °C (see 2 in Figure 2-1)

2.2.2 Program Mode (programming or calibrating

mode — step-by-step instructions for programming

and calibrating the transmitter are given in Sections

4.0 and 5.0, respectively). When operating in this mode

the following information is provided on the instrument

display:

• Continuous display of the primary process variable

is still available.

• Menus are displayed below the process variable.

The active subset title is in bold print (see 1 in

Figure 2-2).

CALIBRATE PROGRAM DIAGNOSE

CALIbrAtE

EXIT NEXT ENTER

1000

mS/cm

F

A

U

L

T

H

O

L

D

5

4

1

3

MODELS 4081C SECTION 2.0

OPERATION OVERVIEW

SECTION 2.0

OPERATION OVERVIEW

2

FIGURE 2-1. Process Display Screen

11000000

mS/cm

25.0C

FIGURE 2-2. Program Mode Display Areas

• Security ID (see Section 4.3, step 10) and prompts

are displayed below the segments (see 2 and 3 in

Figure 2-2).

• FAULT is displayed (see 4 in Figure 2-2) when a

transmitter disabling condition occurs. When in the

fault mode, the fault indicator lights up and the

process variable flashes. The program mode must

be entered to see the descriptive fault message.

• HOLD (see 5 in Figure 2-2) becomes visible when-

ever the transmitter is placed in the hold, test, or

multidrop function. Hold is most often used when

servicing/cleaning the sensor.

2

1

Page 20

2-2

2.3 INFRARED REMOTE CONTROL (IRC)

The IRC is the most convenient way to calibrate, program, or access the diagnostics in the transmitter. It

operates the same as other remote controllers.

For best operation, the IRC should be within ten feet of

the transmitter and aimed directly at the infrared sensor

window (small square window at top of display) at an

angle of no more than fifteen degrees. The amount of

ambient light may also affect IRC communication.

2.3.1. The overall menu structure is shown in Figure 2-4.

The top level functions available to the IRC (CAL,

PROG, and DIAG) are shown on the display with the

active menu segment highlighted as described in

Section 2.2.

2.3.2. Menu Keys. The three primary menu structures

are Calibrate (CAL), Program (PROG), and Diagnose

(DIAG). They are shown horizontally on the screen and

have separate keys on the IRC (see 1, 2, and 3 in Figure

2-3). Pressing the labeled key will provide access to that

menu.

2.3.3. Program Command Keys. The three program

command keys are labeled ENTER, NEXT, and EXIT

(see 4, 5, and 6 in Figure 2-3). These keys are used as

follows:

ENTER: This advances down through the submenus to the prompts, will save the new value,

and activate NEXT.

NEXT: This advances the program to the next

sub-menu.

EXIT: This key is used to abort the current submenu operation and return to the previous

menu segment.

2.3.4. Editing Keys. These keys are used to edit input

variables (see Figure 2-3). The left/right arrows change

the location of the prompt and causes the integer to

flash. These also allow access to the measurement unit

and decimal place location. When a flashing mnemonic

appears on the display, the UP and DOWN arrow keys

scroll up or down through the list. When numbers are

shown, the UP and DOWN keys change the value of

the digit.

MODELS 4081C SECTION 2.0

OPERATION OVERVIEW

9

8

6

5

4

3

2

1

Editing

keys

FIGURE 2-3. Infrared Remote Control

2.3.5. Special Entry Keys. These keys provide system

level operations.

RESET: Aborts the current operation and

returns to the process display screen (see 8 in

Figure 2-3).

HOLD: Accesses prompt to toggle between

enable and disabling of this function (see 9 in

Figure 2-3).

2.4 DIAGNOSTIC MESSAGES

Whenever a warning or fault has been triggered, diagnostic messages are displayed to aid in problem solving. These messages flash alternately with the

temperature reading.

If more than one message has been generated, the

warning or fault messages will alternate with the regular

readings.

See Section 6.0 Diagnosis and Troubleshooting for

message meaning and possible causes.

Page 21

2-3

MODELS 4081C SECTION 2.0

OPERATION OVERVIEW

CALIBRATION

AdJ SLOPEtEMP SLOPE

AbS C

CELL 0

FActor

UEr 4081C

tSLOPE

Shouu FLt

1000

25.0C

Model 4081C

Process Display

Screen

mS/cm

CALIbrAtE

CELL COnSt SEnSOr 0

tEMP AdJ

tEMP

dISPLAY

PROGRAM

Process Display

FIGURE 2-4. Menu Tree

DIAGNOSTICS

2.5 MENU PROGRAM TREE

The software has been designed with the user in mind. It uses a simple three layer setup to calibrate and program (configure)

the instrument and display instrument diagnostic conditions (see Figure 2-4).

Page 22

2-4

Page 23

3-1

MODELS 4081C SECTION 3.0

FACTORY PROGRAMMED SETTINGS

SECTION 3.0

FACTORY PROGRAMMED SETTINGS

GENERAL

The Models 4081C transmitter is shipped with factory programmed settings.

This table is useful in several ways:

1. It gives an overview of variables that can be changed, the mnemonics, and the factory settings.

2. It identifies more detailed sections for each menu.

3. It shows the factory settings.

4. It provides space to input specific values.

VARIABLE NAME

MNEMONIC FACT

ORY SETTINGS CUSTOMER SETTINGS

Temperature (Section 4.2)

ttEEMMPP

Auto temperature compensation tAUtO on

Manual temperature tMAn 25.0° C (overridden by auto)

Temperature sensor type tC 100-3

Display (Section 4.3)

ddIISSPPLLAAYY

Measurement type

LLIInnEEAArr,nn SSAALLtt

, Linear

rrSSttvvttYY

, or

nn CCAAttiioonn

Range rAnGE Lo

Temperature (°C or °F) tEMP C

Code COdE 000

Calibrate (Section 5.0)

Calibration constant Cal 500 500

1.0

Cell constant CELL Const (sensor specific)

Sensor 0 Sensor O 0

Temperature setting Temp Adj 025.0

Temperature slope (if already known) adj slope 2.000

Diagnose (Section 6.1)

(Each segment displays the current value in the transmitter.)

Absolute conductivity Abs C 1000 µS

Cell constant cell 1.00

Temperature slope tslope 2.000

Software version

Show fault warnings Showj Flt (enter) none

Table 3-1. Program Variables with Factory Settings*

*Press ENTER after each command to get entry field.

NOTE: Software version is on the serial tag and should match what is in the diagnose segment.

Page 24

3-2

Page 25

4-1

4.1 PROGRAM MENU

The program menu allows configuration of the transmitter values for the display shown on the LCD.

Changes to the operating parameters are made through

the Program menu.

Press the Program menu key, while pointing the Infrared

Remote Control (IRC) at the transmitter to initiate communication. To avoid communicating with more than one

transmitter at a time, each one must have a unique 3

digit code. Entering the “Id” CODE (see Section 4.3,

step 9) of a transmitter will permit access to

programming menus of only that transmitter. For the

MODELS 4081C SECTION 4.0

TRANSMITTER PROGRAM SET-UP

SECTION 4.0

PROGRAM SET-UP

Calibrate Menu

Segments/Commands

Program Menu

Segments/Commands

DIAGNOSE MENU

Segments/Commands

CURRENT OPERATING MENU

FACtOr

EXIT NEXT ENTER

CELL

EXIT NEXT ENTER

AbSC

EXIT NEXT ENTER

FIGURE 4-1. Program Menu and Menu Segments

SEnSOr

EXIT NEXT ENTER

CALIbrAtE

EXIT NEXT ENTER

CELL COnSt

EXIT NEXT ENTER

tSLOPE EXIT

NEXT ENTER

UEr 4081t

EXIT NEXT ENTER

KEYPRESS COMMANDS

CalibrateProgram Diagnose

IIdd 000000

Exit Enter

Menu Segment/Prompt

Area

sequence to enter this code, press the PROG key and

go to the last (display) element of the sub-menu.

The sub-menus are shown in the message display area.

These define which prompts are shown (See Figure 2-2).

The prompts have fields that are used to edit the parameters of the menu currently active. Editing is accomplished by scrolling through a predetermined list of

responses. See Figure 4-1 for the sub-menus available

under the program menu.

See Table 4-1 for Program Menu sequence/ commands

and mnemonics.

dISPLAY

EXIT NEXT ENTER

tEMP

EXIT NEXT ENTER

AdJ SLOPE

EXIT NEXT ENTER

tE

M

P AdJ

EXIT NEXT ENTER

tEMP SLOPE

EXIT NEXT ENTER

ShoWjFLt

EXIT NEXT ENTER

Page 26

4-2

MODELS 4081C SECTION 4.0

TRANSMITTER PROGRAM SET-UP

4.2 TEMPERATURE PARAMETERS

1. Press the Program key (PROG) on the IRC, enter the security code if

necessary, and press NEXT.

While tEMP is displayed, press ENTER to get the first prompt of the

tEMP menu segment.

2. The tAUtO prompt is used to enable (ON) or disable (OFF) auto temperature compensation for all conductivity process measurements. If

On is selected, an equation is used to temperature compensate all

process measurements to 25 °C and will be the reported temperature

on the process display. The default value is On. Press ENTER.

3. The tMAn prompt is used to enter a temperature value that the com-

pensation equation will use (overrides auto). The actual process temperature, however, will be shown on the main screen. The temperature

display mode determines the units used. Absolute conductivity is measured using the default value of 025.0 °C. Use the IRC editing keys to

change the value only if some determination other than absolute conductivity is required. Press ENTER.

4. The tC prompt matches the instrument to the type of temperature sensor being used. Listed type available is 100-3 (3-wire Pt100 RTD). The

IRC editing keys scroll through the listing. The default value is 100-3.

Press ENTER.

NOTE

4-wire Pt100 is displayed but is not available in

toroidal sensors.

5. Press EXIT to return to normal operation or NEXT to go to the display

sub-menu.

tEMP

EXIT NEXT ENTER

Return

to Main

Screen

To display

menu segment.

R

T

D

3 Wire RTD - Connected to an instrument designed to accept three wire

input. Compensation is achieved for lead resistance (cable wire resistance

is affected by cable length and temperature change). This is the most commonly used configuration.

+

-

The following procedures are used to select between automatic temperature compensation, absolute conductivity, manual

temperature compensation, and RTD sensor type. To access the temperature parameters, do the following:

tAUt

O On

EXIT ENTER

t

C 1 00-3

EXIT ENTER

t

M

An 0 25.0

EXIT ENTER

Sense

FIGURE 4-2. RTD Sensor Connections

Page 27

4-3

MODELS 4081C SECTION 4.0

TRANSMITTER PROGRAM SET-UP

4.3 DISPLAY UNITS

The following procedures are used to select the display menus, calculation formulas, process variable and temperature

display units. The factory settings are shown with each variable. To access the display sub-menu, do the following:

t

EM P

EXIT NEXT ENTER

dISPLAY

EXIT NEXT ENTER

Manrng “1”

EXIT ENTER

tYP “LInEAr”

EXIT ENTER

Autorng

“On”

EXIT ENTER

COdE “000”

EXIT ENTER

t

EMP “C”

EXIT ENTER

rAngE “Lo”

EXIT ENTER

1. Press PROG key on remote control.

2. Enter ID Code number (if necessary). See step 7.

Press NEXT twice to scroll through the tEMP menu segment

to the dISPLAY menu segment.

3. When the dISPLAY menu is displayed, press ENTER to

access the first prompt in the display sequence.

4. The tYP prompt determines how conductivity is displayed:

“LInEAr” = linear conductivity; “n SALt” = neutral salt (ultrapure water); “rStvtY” = resistivity; and “CAtion” = cation conductivity. The IRC editing keys are used to scroll through the

list. Choose the desired type and press ENTER.

5. The rAnGE prompt is used to determine the measurement

range limit (High or Low). The IRC editing keys are used to

scroll between these. The default is LO. Press ENTER.

6. The Autorng (auto range) is a toggle (or increment between

On and Off) that enables or disables the auto range function.

Press the up or down arrow to select On or Off as desired.

The On setting turns on the auto range function and preempts Manrng. Press ENTER.

NOTE

The transmitter is shipped with range=Lo since

this is the most frequently used setting. Others

are shown in Table 4-1 below.

Return to

Menu

Screen

Continued on page 4-4.

TABLE 4-1. Transmitter Settings*

* Assumes 1.0 cell constant.

Software Settings

Process Stream Type Range

Contacting Conductivity in the range

20-2,000 µs/cm (default) LInEAr Low

Contacting Conductivity

in the range 2,000 to 20,000 µs/cm LInEAr High

Ultrapure water up to 20µs/cm n SALt Low

Ultrapure water Resistivity

to 50 MΩ-cm rStvtY Low

Page 28

4-4

MODELS 4081C SECTION 4.0

TRANSMITTER PROGRAM SET-UP

7. The Manrng (manual range) prompt asks for the fixed

range used by the process measurement. Autorng

must be Off to enable.

For the “Hi” range setting, use Table 1-4 for range limits in the conductivity mode (C).

For the “lo” range, use Table 1-4 for the linear conductivity mode, Table 1-2 for the neutral salt mode, or

Table 1-3 for the resistivity mode.

Select the desired range using the up and down arrow

keys. Press ENTER.

8. The tEMP prompt is used to determine which units will

be used with the temperature reading displays. Units

available are °C or °F. The IRC editing keys are used to

scroll between these. The default value is °C. Choose

the appropriate units and press ENTER.

9. The COdE prompt is used to identify the security “Id”

Code number of the unit (see Figure 4-3). The number

entered here determines the “Id” code number used to

unlock the security feature and allow access to the

menu programs and program segments. The limits are

between 000 and 999. New transmitters are shipped

with the code set to 000 which disables the feature,

(allows access to all menus). If no key is pressed for

two minutes the code will need to be entered again.

Use the IRC editing keys to set the desired security

code. Press ENTER.

NOTE

If this code has been changed or the number misplaced, entering 555 at the “Id” prompt and press-

ing ENTER will display the current code. Access

will not be granted, however, until you EXIT to the

process display, select program to enter (CALI-

BRATE, PROGRAM, or DIAGNOSE), press

ENTER again, and enter CODE # just displayed.

10. Press EXIT to return to normal operation.

FIGURE 4-3. Security Code prompt.

CALIBRATE PROGRAM DIAGNOSE

IIdd 00 00 00

EXIT NEXT ENTER

TABLE 4-2. Program Menu Mnemonics

HoLd

Transmitter on hold

FAULt

System disability fault condition

tE

M

P

Temperature menu header

tAUtO

Automatic temperature compensation

t

M

An

Manual temperature compensation

tC

Temperature sensor type

dISPLAY

Display menu header

tYP

Conductivity measurement type

rAnGE

LO/HI measurement range

Autorn

Autorange on or off toggle

Manrng

Manual ranges used for narrow, higher linearity

Associated with range

When range = Hi, Manrng = 1, 2, 3

When range = Lo, Manrng = 1, 2, 3, 4

(see Table 1-2)

tE

M

P

°C / °F toggle selection

COdE

Security code

Page 29

5-1

CURRENT OPERATING MENU

KEYPRESS COMMANDS

Menu Segment/Prompt

Area

MODELS 4081C SECTION 5.0

START-UP AND CALIBRATION

5.1 ACCESSING THE CALIBRATE MENU

The “Calibrate” menu allows the transmitter and sensor

loop to be calibrated to known temperature and conductivity values. This menu also accesses two-point temperature calibration operation to establish the temperature

slope.

Calibrating the Transmitter/Sensor loop may proceed

after proper power and sensor wiring.

Figure 5-1 illustrates the relationship between the

Calibrate Menu and its sub-menus. Each sub-menu

leads to a series of prompts that are used to edit transmitter parameters.

Calibration may be successfully accomplished if the factory settings identified in Table 3-1 of Section 3.0 are satisfactory or if the transmitter has been properly programmed per Section 4.0 to match the intended process

application requirements.

Calibrate Menu

Segments/Commands

Program Menu

Segments/Commands

DIAGNOSE MENU

Segments/Commands

fACtOr

EXIT NEXT ENTER

CELL

EXIT NEXT ENTER

AbSC 1000

EXIT NEXT ENTER

FIGURE 5-1. Calibration Menu Segments

SEnSOr O

EXIT NEXT ENTER

CALIbrAtE

EXIT NEXT ENTER

CELL COnSt

EXIT NEXT ENTER

tSLOPE

EXIT NEXT ENTER

UEr 4081C

EXIT NEXT ENTER

dISPLAY

EXIT NEXT ENTER

tEMP

EXIT NEXT ENTER

AdJ SLOPE

EXIT NEXT ENTER

tE

M

P AdJ

EXIT NEXT ENTER

tEMP SLOPE

EXIT NEXT ENTER

Sho

Wj

FLt

EXIT NEXT ENTER

Calibrate Program Diagnose

IIdd 000000

Exit Enter

SECTION 5.0

START-UP AND CALIBRATION

Page 30

MODELS 4081C SECTION 5.0

START-UP AND CALIBRATION

5.2 CALIBRATE MENU

There are three separate calibration procedures, depending on the measurement needs and the situation. These are general calibration, low conductivity calibration, and standardization.

CALIbrAtE

EXIT NEXT ENTER

CELL COnSt

EXIT NEXT ENTER

Return

to Main

Screen

tEMP Adj

menu segment

CAL 1000

EXIT ENTER

CELL 1 .000

EXIT NEXT ENTER

CALIbrAtE

EXIT NEXT ENTER

Return

to Main

Screen

CELL COnST

menu segment

CAL 1000

EXIT ENTER

CALIbrAtE

EXIT NEXT ENTER

CELL COnSt

EXIT NEXT ENTER

Return

to Main

Screen

SEnSOR0

menu segment

CELL 1 .000

EXIT NEXT ENTER

5.2.1. General Calibration. This calibration menu is used for all conductivity

applications. At the Cell Const prompt,

ENTER will access the step to allow

entry of the cell constant for the sensor

you are using. Temperature compensation is input further down in the menu

(see Section 5.3).

5.2.2. Low Conductivity. This calibration method is used to enter the calibration constant (if available) for the sensor

you are using (see Section 5.5). You

must be in the “L” or “r” display mode

(see Section 4.3).

5.2.3. Calibration Adjustments (Standardization). Once the transmitter is ini-

tially calibrated, it may be necessary to

fine tune it over time. This can be done

using either a standard solution (see

Section 5.4) or an on-line sample (see

Section 5.6). In either case pressing

ENTER at the calibrate prompt will

access the CAL prompt where the

adjustment can be made.

Section 5.2.2 Menu

Section 5.2.3 Menu

Section 5.2.1 Menu

5-2

Page 31

5-3

MODELS 4081C SECTION 5.0

START-UP AND CALIBRATION

SEnSOr 0

EXIT NEXT ENTER

CALIbrAtE

EXIT NEXT ENTER

CELL COnSt

EXIT NEXT ENTER

AdJ SLOPE

EXIT NEXT ENTER

tEMP AdJ

EXIT NEXT ENTER

tE

M

P SLOPE

EXIT NEXT ENTER

Return

to Main

Screen

SEnSOr 0

EXIT ENTER

CELL “1” 000

EXIT NEXT ENTER

tSLOPE 2000

EXIT ENTER

tEMP 0 250

EXIT ENTER

t1 2000

EXIT NEXT ENTER

t2 2000

EXIT NEXT ENTER

5.3 CALIBRATE MENU (Contacting)

For calibration using solutions of known conductivity, see

Section 5.4.

For low conductivity (L) and resistivity (r) measurements,

see Section 5.5.

Figure 5-1 illustrates the Calibrate Menu.

1. To access the “Calibrate” menu, press the Cal key on

the Infrared Remote Control. If security has been

enabled, the secondary process display will be

replaced with a prompt asking for the “Id”. Using the

IRC editing keys, enter the “Id”. If the correct “Id” is

entered, the CALibrAtE sub-menu will appear when

ENTER is pressed.

2. If the calibrate sub-menu does not appear when

ENTER is pressed, see Section 4.3 (step 8) for procedure to find correct code.

3. When the calibrate sub-menu has been accessed,

press the NEXT and then ENTER to access the

CELL menu segment with the flashing cell constant

prompt.

4. Using the arrow keys on the IRC, enter your sensor’s

cell constant.

5. Press ENTER to install the cell constant into the

transmitter memory and return to the CELL COnSt

sub-menu.

Page 32

MODELS 4081C SECTION 5.0

START-UP AND CALIBRATION

5-4

6. Press NEXT to enter the SEnSOr 0 menu and press

ENTER to access the SEnSOr 0 sub-menu. With the

sensor attached and in air, press ENTER again to zero

the sensor and return to the SEnSOr 0 sub-menu.

7. Press NEXT and then ENTER to access the tEMP

sub-menu with flashing prompt. With the sensor in any

solution of known temperature, allow the temperature

of the sensor to stabilize. Use the editing keys of the

IRC to change the displayed value as needed.

8. Press ENTER to standardize the temperature reading

and return to the tEMP AdJ sub-menu.

9. Press NEXT to enter the tEMP SLOPE menu.

The correct temperature slope must be entered into

the transmitter to ensure an acceptable process variable measurement under fluctuating process temperature conditions. This can either be done using a twopoint calibration (see Section 5.3.1) or by inputting the

slope if it is known.

10. If the temperature slope of the process is not known

but you wish to approximate it, refer to the following

guide and press ENTER to proceed on to tSLOPE

sub-menu with flashing prompt. Utilize the IRC editing

keys to generate the desired slope value. Press

ENTER then EXIT to return to the main screen.

Acids: 1.0 to 1.6% per °C

Bases: 1.8 to 2.2% per °C

Salts: 2.2 to 3.0% per °C

Water: 2.0% per °C

5.3.1 Two Point Temperature Calibration.

[Available in “C” type setting only]

1. Press ENTER to access the t1 temperature prompt.

• obtain a grab sample of the actual process to be

measured.

• immerse the sensor in the process solution. The

sensor body must be held away from the bottom and

the sides of the sample's container at a distance at

least equal to the diameter of the sensor, and the

sensor cable must not be allowed to contact the

solution. Shake the sensor to ensure that no air

bubbles are present.

• allow the sensor to acclimate to the temperature of

the process solution (10 min.). The process solution

temperature must be stable

. Record the conductivity at t1. Press ENTER to enter t1 conductivity and to

move to t2 prompt.

2. Using a hotplate with a stirrer, change the temperature of the process solution by at least 20°C. Allow

the sensor to acclimate to the new temperature (10

min.). The new reading must be stable.

NOTE

You can also allow a hot sample to cool

down for this step.

3. Using the editing keys of the IRC, adjust the t2 con-

ductivity to equal t1 conductivity. Press ENTER .

4. Press EXIT twice to return to the main screen.

5. Proceed to Section 5.4 for Bench Calibration.

5.4 BENCH CALIBRATION FOR INITIAL

START-UP

1. With the sensor in a standard solution of known conductivity value, allow the temperature of the sensor to

stabilize (10 min).

2. To access the CALIbrAtE menu, press the CAL but-

ton on the IRC.

3. Press ENTER to access the CAL segment with flashing prompt.

4. Use the IRC editing keys to indicate the conductivity

values of the standard solution on the screen.

5. Press ENTER then EXIT to enter the standard solution

value and exit again return to the main screen.

CALIbrAtE

EXIT NEXT ENTER

CAL 1000

EXIT ENTER

Return

to Menu

Screen

CELL COnSt

menu segment

Page 33

MODELS 4081C SECTION 5.0

START-UP AND CALIBRATION

5-5

5.5 CALIBRATE MENU

(Low Conductivity/Resistivity)

5.5.1 INITIAL SET-UP AND CALIBRATION

Follow these calibration instructions for initial set-up where

Type “L” low conductivity and Type “r” resistivity measurements are being made.

Low conductivity instruments are difficult to calibrate

using standard solutions. The interferences of carbon

dioxide in air and surface contamination in sample containers lead to substantial errors.

To prevent these errors, Rosemount low-conductivity

cells are pre-calibrated and are marked with a calibration

constant on their cables.

Once this calibration constant number is entered into the

instrument and a temperature calibration is performed,

then the loop is calibrated and ready to be placed on-line.

1. To access the Calibrate menu, press the Cal key on

the Infrared Remote Control. If security has been

enabled, the secondary process display will be

replaced with a prompt asking for the “Id”. Using the

IRC editing keys, enter the “Id”. If the correct “Id” is

entered, the calibrate menu will appear when ENTER

is pressed.

2. If calibrate menu does not appear when ENTER is

pressed, see Section 4.3 (step 8) for procedure to find

correct code.

3. When the calibrate menu has been accessed, press

the NEXT and then ENTER to access the CELL menu

with the flashing cell constant prompt.

4. Utilizing the edit keys on the IRC, generate the correct

cell constant of the sensor being used (for example,

.01, .10, 1.00, 10.0).

5. Press ENTER to install the cell constant and access

the CAL sub-menu with flashing calibration constant

prompt. Use the IRC edit keys to select the sensor's

calibration constant. This is a value between 0 and

999 found on the sensor cable.

6. Press ENTER to install the calibration constant and

return to the CELLCOnSt menu.

7. Continue with the SEnSOr 0 and tEMP AdJ sub-

menus from Section 5.3, steps 6 - 8. Note that the

tEMP SLOPE prompt will not appear in “L” or “r”

modes.

tE

M

P AdJ

EXIT NEXT ENTER

CALIbrAtE

EXIT NEXT ENTER

CELL COnSt

EXIT NEXT ENTER

Return

to Main

Screen

tE

M

P 025. 0

EXIT ENTER

CELL 1000

EXIT NEXT ENTER

CAL1000

EXIT ENTER

Page 34

MODELS 4081C SECTION 5.0

START-UP AND CALIBRATION

5-6

CALIbrAtE

EXIT NEXT ENTER

Return

to Main

Screen

CAL 1000

EXIT NEXT ENTER

to next

menu

segment

TABLE 5-1. CALIBRATE MENU MNEMONICS

CALIbrAtE Calibrate menu header

CAL Sensor calibration

tE

M

P SLOPE Sub-menu header

t1 First temperature conductivity value for slope calculation

t2 Second temperature conductivity value for slope calculation

Adj SLOPE Sub-menu header

tSLOPE Slope adjustment %/°C

CELL COnSt Sub-menu header

CELL Cell constant value

CAL Cell constant correction value (L/r)

SEnSOr Sub-menu header

SEnSOr 0 Sensor "0" (performed in air)

tE

M

P AdJ Sub-menu header

tE

M

P Temperature adjustment °C/°F

5.6 ON-LINE CALIBRATION

For maximum accuracy, calibrate the sensor in the

process. This should be done after the initial transmitter

calibration and periodically thereafter as required.

Refer to Section 5.4 for the procedure.

On-line calibration is well-suited for most conductivity

measurements except ultra pure conductivity and resistivity measurements. These special applications require specialized tools to perform an accurate on-line comparison. A

certified conductivity instrument with a certified flowthrough conductivity cell, like the Rosemount Portable

Validation Instrument, can be used for this purpose.

Type “C” only

Type “L” or “r”

Page 35

6-1

6.1 OVERVIEW

The Model 4081C transmitter automatically monitors for

fault conditions. The Diagnose Menu allows the current

variable settings to be reviewed and shows fault messages indicating problems detected. Figure 6-1 illustrates

the relationship between the Diagnose Menu and its

sub-menus. The factory-set diagnose values are illustrated in Figure 6-2. The mnemonics are defined in

Table 6-1.

6.1.1 TROUBLESHOOTING

Step 1 Look for a diagnostic fault message on the

display to help pinpoint the problem. Refer to

Table 6-2 for an explanation of the message and

a list of the possible problems that triggered it.

Step 2 Refer to the Quick Troubleshooting Guide, Table

6-3, for common loop problems and the

recommended actions to resolve them.

MODELS 4081C SECTION 6.0

DIAGNOSIS AND TROUBLESHOOTING

SECTION 6.0

DIAGNOSIS AND TROUBLESHOOTING

Step 3 Follow the step by step troubleshooting flow

chart, offered in Figure 6-6, to diagnose less

common or more complex problems.

6.1.2 DISPLAYING DIAGNOSTIC VALUES

The DIAG key on the IRC is used to access the

Diagnosis Menu. The menu flow is shown in Figure 6-2

and the mnemonics are defined in Table 6-1.

The ShoW FLT sub-menu can be entered to show the

last three faults/warnings. The most recent is displayed

first; NEXT scrolls through the remaining faults. Pressing

EXIT clears all fault/warnings and returns the SHoW FLT

segment. Disconnecting power removes all fault messages from memory. The nonE is displayed when no

faults/warnings have occurred.

CURRENT OPERATING MENU

KEYPRESS COMMANDS

Menu Segment/Prompt

Area

Calibrate Menu

Segments/Commands

Program Menu

Segments/Commands

DIAGNOSE MENU

Segments/Commands

fACtOr

EXIT NEXT ENTER

AbSC

EXIT NEXT ENTER

FIGURE 6-1. Diagnose Menu Segments

tSLOPE

EXIT NEXT ENTER

dISPLAY

EXIT NEXT ENTER

tE

M

P

EXIT NEXT ENTER

AdJ SLOPE

EXIT NEXT ENTER

tE

M

P SLOPE

EXIT NEXT ENTER

ShoWJFLt

EXIT NEXT ENTER

SEnSOr O

EXIT NEXT ENTER

CELL

EXIT NEXT ENTER

UEr 4081C

EXIT NEXT ENTER

CALIbrAtE

EXIT NEXT ENTER

CELL COnSt

EXIT NEXT ENTER

tEMP AdJ

EXIT NEXT ENTER

CalibrateProgram Diagnose

IIdd 000000

Exit Enter

Page 36

6-2

MODELS 4081C SECTION 6.0

DIAGNOSIS AND TROUBLESHOOTING

AbSC Absolute conductivity (µS/cm or mS/cm)

CELL Sensor cell constant (used in C mode)

CAL Calibration constant (used in “L” or “r” mode)

FActOr Calibration factor

nonE No fault messages in memory

Sho

WJ

FLt

Show fault messages

tSLOPE Temperature slope in %/ °C

UEr Software version

Calibrate Program Diagnose

Exit Enter

Return to

Main

Screen

TABLE 6-1. Diagnostic Variables Mnemonics

AbS C 1000

EXIT NEXT

CELLCOnST

EXIT NEXT

UEr 4081C

EXIT NEXT

ShoWjFLt

EXIT NEXT ENTER

nonE

EXIT NEXT

FActor 1.000

EXIT NEXT

tSLOPE 2.000

EXIT NEXT

CAL 500

EXIT NEXT

CELL 1.000

EXIT NEXT

µS

(L & r)

(C)

(C)

(L, r)

FIGURE 6-2. Diagnose Values

Page 37

6-3

MODELS 4081C SECTION 6.0

DIAGNOSIS AND TROUBLESHOOTING

6.2 FAULT CONDITIONS

Three classes of error conditions/problems can be

detected and are differentiated by the diagnostic program. System disabling problems are faults caused by

failures in the loop or significant variations in the

process. System non-disabling problems are warnings

and deal with inputted signals/values or Analog to

Digital conversion settings. The third class of detected

problems are error messages and occur when the calibration limits are exceeded.

6.2.1 DISABLING FAULTS

1. Both FAULT and HOLD annunciation fields will

become active (see Figure 6-3).

2. The process variable will flash at the rate of 1 second ON and 1 second OFF.

3. The appropriate fault message alternates with the

normal Temperature display (see Figure 6-3).

CALIBRATE PROGRAM DIAGNOSE

“ LInE FAIL”

EXIT NEXT ENTER

1000

µS/cm

F

A

U

L

T

H

O

L

D

FIGURE 6-3. Disabling Fault Annunciation

CALIBRATE PROGRAM DIAGNOSE

“ InPut WJArn”

EXIT NEXT ENTER

1000

µS/cm

FIGURE 6-4. Non-Disabling Warning Annunciation

6.2.2 NON-DISABLING WARNINGS

When a non-system disabling condition occurs, a

warning message is displayed. The Process variable

does not flash. The appropriate message alternates with

the Temperature display (see Figure 6-4).

If more than one fault exists, the display will sequence

through the diagnostic messages. This will continue until

the cause of the fault has been corrected.

F

A

U

L

T

H

O

L

D

Page 38

6-4

MODELS 4081C SECTION 6.0

DIAGNOSIS AND TROUBLESHOOTING

6.3 DIAGNOSTIC MESSAGES

The Model 4081C transmitter’s diagnostics constantly monitor the system for possible problems. If an operational problem is encountered, check the display for a fault or error message. These are displayed in the Temperature segment of

the display. Note the message and refer to Table 6-2 for a description of possible problems that may have triggered the

diagnostic message.

Message Description Action

Faults

tE

M

P LO Low temperature limit of 0.0° C is exceeded (too low). Check wiring or sensor/process temp.

Check RTD

tE

M

P HI High temperature limit of 100.0° C is exceeded (too high). Check wiring or sensor/process temp.

Check RTD

LInE FAIL The RTD sense line fault limits have been exceeded Check wiring or Check Program/Temp

for the sensor. menu setting to verify the 100-3

sensor type connected.

CPU FAIL The CPU has failed during RAM or EEPROM Recycle the power. If persistent contact

verification. the factory.

FACt FAIL The transmitter has not been accurately factory calibrated. Contact factory.

rO

M

FAIL The PROM failed the check-sum test. Contact factory.

CYCLE P

W

r A wrong value was detected during power-up. Recycle the power.

Sensor fail Conductivity too low or open Verify the solution type setting

Simulate sensor (Figure 6.5) to check

transmitter

Replace sensor

Warnings

InPut WArn The compensated conductivity limit of 9999 mS/cm is Verify the conductivity range setting.

exceeded.

AdC WArn An analog to digital conversion error has occurred. Recycle the power.

Errors

CAL Err A calibration error has occurred between the standard Press RESET and repeat.

and process.

tSLOPE Err The limit for t2 in a two point calibration has been Press RESET and repeat the

exceeded ( > 5%). calibrate/temp slope menu setting.

-0- Err Sensor Zero limit has been exceeded. Press RESET and repeat the cali-

brate/sensor menu setting.

WRITE Err An attempt to write on the EEPROM has failed. The jumper JP-1 on the CPU board

has been removed.

TABLE 6-2. Diagnostic Fault Messages.

Page 39

6-5

MODELS 4081C SECTION 6.0

DIAGNOSIS AND TROUBLESHOOTING

SYMPTOM ACTION

Wrong temperature reading. Perform a temperature standardization. Verify sensor's RTD.

Suspected temp. compensation problem. Resistance vs. temp.; see Table 6.4; temperature may be out of range of sensor.

Check wiring. Check jumpers and RTD configuration on display

Display segments missing. Display inoperable. Replace Display board. If fault continues, check CPU board.

Analyzer locks up; won't respond. Replace PCB stack.

Press Reset on IRC.

Check batteries in IRC.

Erratic displays. Check sensors in process.

Transmitter won't respond to IRC key presses. Verify and clean ribbon cable connection on CPU board.

Check batteries in IRC

Key press gives wrong selection. Replace IRC. Check ribbon cable connection on CPU board.

No display or indicators. Check power connections. Replace PCB stack.

”Excess Input” Check sensor wiring.

“Reverse Input” Perform sensor zero.

“Check sensor zero” Analyzer will not zero; place sensor in air and perform zero routine (see Section 5.2).

Table 6-3 identifies some of the more common symptoms and suggests actions to help resolve a problem. In general,

wiring is most commonly at fault.

6.4 QUICK TROUBLESHOOTING GUIDE

TABLE 6-3. Quick Troubleshooting Guide.

When it is apparent by grab sample analysis that the

transmitter is giving inaccurate readings, the following procedure should be followed.

A. A quick visual inspection of the installation may identify

the problem. Check to be sure that the transmitter is

mounted securely and that its internal parts are properly connected.

B. Recheck to ensure the power supply is connected to

the correct pins in the transmitter and that power is

being received.

C. Check the sensor to transmitter terminal wiring and that

all connections are tight. Most error messages are generated by incorrect wiring and will indicate if the RTD or

the toroid are connected incorrectly.

D. The sensor must be immersed into the process stream

to the top of the toroid.

E. Verify that the sensor is clean and the process is flow-

ing through and around the toroid.

6.4.1 FIELD TROUBLESHOOTING

Page 40

6-6

6.5 SYSTEMATIC TROUBLESHOOTING

Not all the problems encountered will be typical. If the

Quick Troubleshooting Guide will not resolve the error,

then try the step-by-step approach offered in this section.

Conductivity Measurement

Problem (in the process)

Remove the sensor from process

and place sensor in air. Zero transmitter.

Refer to Section 5.2 and 5.3.

OK?

Consult

Service Center

YES

NO

YES

YES

NO

NO

Does problem

still exist?

NOTE:

Before starting this procedure

make sure that all wiring is correct.

FIGURE 6-5. Troubleshooting Flow Chart

Step 1 Follow the applicable troubleshooting flow chart

below:

Step 2 Refer to the tests and instructions indicated by

the flow chart to diagnose the problem.

Place sensor in process and

standardize. Refer to Section 5.2.

OK?

Restart

Transmitter

Remove sensor from process and

test in known conductivity solution

OK?

Check wiring

for short and check

jumpers for correct

configuration

Check diagnostic

messages

Refer to Table 6-2

Check for ground

loops and/or

improper installation

YES

NO

MODELS 4081C SECTION 6.0

DIAGNOSIS AND TROUBLESHOOTING

Page 41

MODELS 4081C SECTION 6.0

DIAGNOSIS AND TROUBLESHOOTING

6.6 RTD RESISTANCE VALUES

Table 6-4 is a ready reference of RTD resistance values

at various temperatures. These are used for test and

evaluation of the sensor.

NOTE

Ohmic values are read across the RTD

element and are based on the manufacturer’s stated values (±1%). Allow

enough time for the RTD element in the

sensor to stabilize to the surrounding

temperature (10 min).

Table 6-4. RTD Resistance Values.

Table 6-5. Conductivity Determination.

FORMULA:

EXAMPLE:

cell constant value x 1,000,000

desired simulated conductivity in µs/cm

.01 x 1,000,000

10 µs/cm

Use the following formula to determine the appropriate resistance value to use to simulate a

conductivity value:

= resistance in ohms

= use 1,000 ohm resistance

6-7

Temperature Pt-100 Pt-1000

(°C) Resistance (ohms) Resistance (ohms)

0 100.00 1000

10 103.90 1039

20 107.79 1078

25 109.62 1096

30 111.67 1117

40 115.54 1155

50 119.40 1194

60 123.24 1232

70 127.07 1271

80 130.89 1309

90 134.70 1347

100 138.50 1385

Page 42

6-8

Page 43

7-1

MODELS 4081C SECTION 7.0

MAINTENANCE

SECTION 7.0

MAINTENANCE

7.1 OVERVIEW

Maintenance consists of "Preventative" and "Corrective"

measures.

7.2 PREVENTATIVE MAINTENANCE

7.2.1 Sensor Maintenance. Sensor maintenance

consists of periodic cleaning of the electrode. If the sensor is coated either mechanically or chemically, the sensor must be cleaned.

A weekly cleaning is a good starting maintenance

schedule. This schedule can then be fine tuned to the

site process.

7.2.2 Transmitter Maintenance. Transmitter maintenance consists of periodic calibration. A monthly calibration is a good starting maintenance schedule. This

schedule can then be fine tuned to the site process.

7.2.3 Initiating HOLD Function For Maintenance. To

place the transmitter into the Hold operational mode prior

to servicing the sensor, press the HOLD key on the IRC.

The message field will respond with a message concerning the present hold condition. Press the IRC editing key

to toggle to the On condition. Press ENTER to activate

HOLD output.

Hold Mode will maintain the operating parameters

regardless of process changes.

The section of the LCD reserved for hold annunciation

(Refer to Figure 7-1) will display HOLD when the transmitter is in the Hold Mode.

Always calibrate after cleaning or replacing the sensor.

To return transmitter to normal operation, press HOLD

on the IRC.

Press the IRC editing key to toggle to the OFF condition.

Press ENTER to disengage the HOLD output function.

1000

µS/cm

F

A

U

L

T

H

O

L

D

FIGURE 7-1. Hold Annunciation

Hold field Illuminated

CALIBRATE PROGRAM DIAGNOSE

22 550CC

EXIT NEXT ENTER

7.3 CORRECTIVE MAINTENANCE

Refer to Figure 7-2 for an exploded view of the 4081C

Transmitter.

Table 7-1 lists suggested spare parts along with part

numbers. Sales and service locations are located on

the back pages of this manual.

Page 44

7-2

FIGURE 7-2. Exploded View of Model 4081C Transmitter

MODELS 4081C SECTION 7.0

MAINTENANCE

}

1

2

6

13

13

9

7

5

8

12

TABLE 7-1. Replacement Parts for Model 4081C Transmitter

Location in Shipping

Figure 7-1 PN Description Weight

1 23811-01 PCB stack consisting of the CPU, communication, and analog boards; 1 lb/0.5 kg

display board is not included; CPU, communication, and analog boards

are factory-calibrated as a unit and cannot be ordered separately

2 23652-01 LCD display PCB 1 lb/0.5 kg

5 33337-02 Terminal block 1 lb/0.5 kg

6 23593-01 Enclosure cover, front with glass window 3 lb/1.5 kg

7 33360-00 Enclosure, center housing 4 lb/1.5 kg

8 33362-00 Enclosure cover, rear 3 lb/1.0 kg

9 6560135 Desiccant in bag, one each 1 lb/0.5 kg

9550187 O-ring (2-252), one, front and rear covers each require an O-ring 1 lb/0.5 kg

12 note Screw, 8-32 x 0.5 inch, for attaching terminal block to center housing *

13 note Screw, 8-32 x 1.75 inch, for attaching circuit board stack to center *

housing

14 33342-00 Cover lock 1 lb/0.5 kg

33343-00 Locking bracket nut 1 lb/0.5 kg

note Screw, 10-24 x 0.38 inch, for attaching cover lock and locking bracket *

nut to center housing

NOTE: For information only. Screws cannot be purchased from Rosemount Analytical.

* Weights are rounded up to the nearest whole pound or 0.5 kg.

Page 45

8-1

MODELS 4081C SECTION 8.0

PRODUCT DATA

SECTION 8.0

PRODUCT DATA

• REMOTE COMMUNICATION IS SIMPLE; use the hand-held infrared

remote controller, DeltaV

1

, or FOUNDATION2Fieldbus host.

• LARGE TWO LINE DISPLAY shows conductivity and temperature.

• SIMPLE, INTUITIVE menus make programming and calibrating easy.

• HIGH ACCURACY (within ±1% of actual conductivity and resistivity

measurement).

• ROBUST NEMA 4X and NEMA 7 ENCLOSURE protects the transmitter from harsh plant environments.

• INTRINSICALLY SAFE DESIGN allows the transmitter to be used in

hazardous environments (with appropriate safety barriers).

• NON-VOLATILE EEPROM MEMORY retains program settings and calibration data during

power failures.

8.1 FEATURES

REMOTE COMMUNICATIONS: Remote communica-

tions with the Model 4081C transmitter is easy. The

hand-held, push button infrared remote controller

works from as far away as six feet. The transmitter

also communicates via any F

OUNDATION fieldbus host,

such as the Fisher Rosemount DeltaV system.

DISPLAY: The 0.8-inch high LCD main display means

conductivity values are easy to read even at a distance. Temperature reading also appears in a 0.3

inch high display.

MENUS: Menu formats for calibration and programming are simple and intuitive. Prompts guide the user

through the basic procedures. Diagnostic and error

messages appear in plain language. There are no

annoying error codes to look up.

Remote Control and Digital Communication

Capability Make Interface Convenient, Regardless

of Transmitter Location: Direct user interface is

achieved via an infrared remote controller that provides access to a self-prompting menu for programming, calibration, standardization, and interrogation.

Digital communication capability through FOUNDATION

fieldbus or AMS (Asset Management Solutions) software stretches the user’s access from anywhere in

the factory to anywhere outside the factory.

1. DeltaV is a trademark of Fisher-Rosemount.

2.

FOUNDATION is a registered trademark of Fieldbus Foundation.

Page 46

MODELS 4081C SECTION 8.0

PRODUCT DATA

8-2

FUNCTIONAL SPECIFICATIONS

Calibration: Calibration is easily accomplished by

immersing the sensor in a known solution and entering its value or entering the cell calibration constant for

ultra pure applications.

Power Supply and Load Requirements: A power

supply voltage of 9 Vdc to 32 Vdc at 22 mA is

required; Intrinsically Safe installations may be limited

to a maximum of 2-3 transmitters per node, depending on the barrier used.

Automatic Temperature Compensation:

3-wire Pt 100 or Pt 1000 RTD

Conductivity: 0 to 200°C (32 to 392°F)

Resistivity: 0 to 100°C (32 to 212°F)

Low Conductivity: 0 to 100°C (32 to 212°F)

Local Readout: LCD display may be set in one of

three positions at 90° increments for optimum legibility independent of mounting. Main display is 4

digits, 20 mm (0.8 in.) tall. Message display is ten

digits 7 mm (0.3 in.) tall

Diagnostics: The internal diagnostics can detect:

Calibration Error Zero Error

Temperature Slope Error Low Temperature Error

High Temperature Error Sensor Failure

Line Failure CPU Failure

ROM Failure Input Warning

Once one of the above is diagnosed, the LCD will display a message describing the failure/default detected.

FOUNDATION Fieldbus:

3 AI Function Blocks: conductivity, temperature,

and absolute conductivity

Execution time: 75 milliseconds

PID Block (optional)

Execution time: 100 milliseconds

Ambient Temperature: – 20 to 65°C. (– 4 to 149°F)

Failure Mode Alarm: When a fault is detected, the

display will indicate a fault.

Configuration Security: Access to the transmitter

configuration and reconfiguration modes may be

restricted via user selected security codes.

Enclosure: NEMA 4X (IP65), weatherproof and corro-

sion resistant; NEMA 7, explosion-proof

CE: EMI/RFI Certification

EN50081-1

EN50082-2

Hazardous Area Classification:

Explosion Proof:

FM: Class I, Div. 1, Groups B, C & D

Class II, Div. 1, Groups E, F, & G

Class III, Div. 1

CSA: Class I, Div. 1, Groups C& D

Class I, Div. 2, Groups A, B, C & D

Class II, Div. 2, Groups E, F & G

Class III, Div. 1

Intrinsic Safety:

FM: Class I, II & III, Div. 1

T4 T AMB= 40°C; T3AT AMB= 70°C

CSA: Class I, Div. 1

T 3C T AMB=40°C; T3 T AMB=80°C

CENELEC: EEx ia IIC

T5 Tamb=40°C; T4 Tamb=60°C

Non-Incendive:

FM: Class I, Div. 2, Groups A, B, C & D

CSA: Class I, Div. 2, Groups A, B, C & D T5

(Tamb=40°C)

PHYSICAL SPECIFICATIONS - General

Housing: Epoxy-polyester painted over low-copper

aluminum. Neoprene O-rings on cover. 160.5 mm

x 175.3 mm x 161.3 mm (6.3 in. x 6.9 in. x 6.4 in.)

Diameter: 155.4 mm (6.1 in.)

Electrical Conduit Openings: 2 X 3/4 in. FNPT

Weight/Shipping Weight: 4.18 kg/4.27 kg (9.2/9.4 lb)

TRANSMITTER SPECIFICATIONS @ 25°C

Measured Range: 0 to 20,000 µS/cm

Accuracy: ± 0.5% of reading

Repeatability: ± 0.25% of reading

Stability: 0.25% of output range/month, non-cumula-

tive

Ambient Temperature Coefficient: ± 0.2% of FS/°C

Temperature Slope Adjustment: 0-5%/° C

LOOP SPECIFICATIONS (see table below)

Accuracy: ± 1.0% of reading ± 2 least significant digit

Linearity: ± 1.0% in low range, ± 5.0% in high range

CELL CONSTANT 0.01 0.10 1.0

Low Range 0-20 0-200 0-2,000

(linearity: ± 1.0%)

High Range 0-200 0-2,000 0-20,000

(linearity: ± 5.0%)

*NOTE: Values shown are for the 25°C conductivity with a temperature slope of 2% per degree C. The maximum range value will be

higher for solutions with a lower temperature slope, and lower for solutions with a higher temperature slope.

Measurement Range*

Page 47

MODELS 4081C SECTION 8.0

PRODUCT DATA

8-3

FIGURE 8-2. Infrared Remote Control

8.3 TRANSMITTER DISPLAY

The liquid crystal display (LCD) provides valuable user

information clearly identified as follows:

1. Continuous process display.

2. Process temperature displayed during process

operation mode.

3. Options within sub-menus become visible when in

each selected menu.

4. Selected menu becomes visible after the appropriate “Menu key” on the IRC is activated.

5. “Hold” is displayed when the analyzer is in hold,

test or fault mode. Pressing the “HOLD” key on

the IRC will place the transmitter in a hold mode.

6. “Fault” is displayed should a system disabling

fault occur.

8.4 INFRARED REMOTE CONTROL

FUNCTIONS

All operating functions of the Model 4081C are

accessed and activated through the hand-held Infrared

Remote Control (IRC).

1. MENU KEYS: Allow access to calibrate, program

and diagnose menus.

2. VARIABLE ENTRY KEYS: Allow the operator to

enter data, move between sub-menus and edit.

3. EDITING KEYS: Allow navigation through the

pre-programmed variables or editable digits.

These arrow keys scroll across digit fields when

entering numbers.

4. SPECIAL ENTRY KEYS:“Hold” key activation

drives the reading to a preprogrammed level.

“Reset” key activation aborts the current function

and exits to the on-line process display mode.

1.

4.

3.

2.

FIGURE 8-1. Transmitter Display

6

5

4

2

1

3

-00.00

F

A

U

L

T

H

O

L

D

µS

CALIBRATE PROGRAM DIAGNOSE

EXIT NEXT ENTER

088.000

FIGURE 8-3. Functional Block Diagram for the Model 4081C Transmitter with FOUNDATION Fieldbus

Page 48

MODELS 4081C SECTION 8.0

PRODUCT DATA

8-4

MODEL / PN DESCRIPTION

2002188 Junction Box, Two Wire Transmitter

2002577 Two Inch Pipe Mounting Kit

23572-00 Infrared Remote Controller

8.5 ORDERING INFORMATION