Page 1

Model 4081 pH/ORP

Remote Controlled FOUNDATION

Fieldbus

Two-Wire pH/ORP Transmitter

Instruction Manual

PN 51-4081pH/rev.D

August 2002

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests its products to meet

many national and international standards. Because these instruments are

sophisticated technical products, you must properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The

following instructions must be adhered to and integrated into your safety

program when installing, using, and maintaining Rosemount Analytical

products. Failure to follow the proper instructions may cause any one of the

following situations to occur: Loss of life; personal injury; property damage;

damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

If this Instruction Manual is not the correct manual, telephone 949-757-8500

or (toll free) 800-654-7768 and the requested manual will be provided. Save

this Instruction Manual for future reference.

• If you do not understand any of the instructions, contact your Rosemount

representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with

the product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate,

update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use

replacement parts specified by Rosemount. Unauthorized parts and

procedures can affect the product’s performance and place the safe

operation of your process at risk. Look alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in

place, except when maintenance is being performed by qualified persons, to

prevent electrical shock and personal injury.

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.RAuniloc.com

© Rosemount Analytical Inc. 2001

Page 3

WHAT YOU NEED TO KNOW

BEFORE INSTALLING AND WIRING A ROSEMOUNT ANALYTICAL

SENSOR TO THE MODEL 4081 pH/ORP TRANSMITTER

1. THE MODEL NUMBER OF THE SENSOR

• Look on the label.

• Also note the model option string.

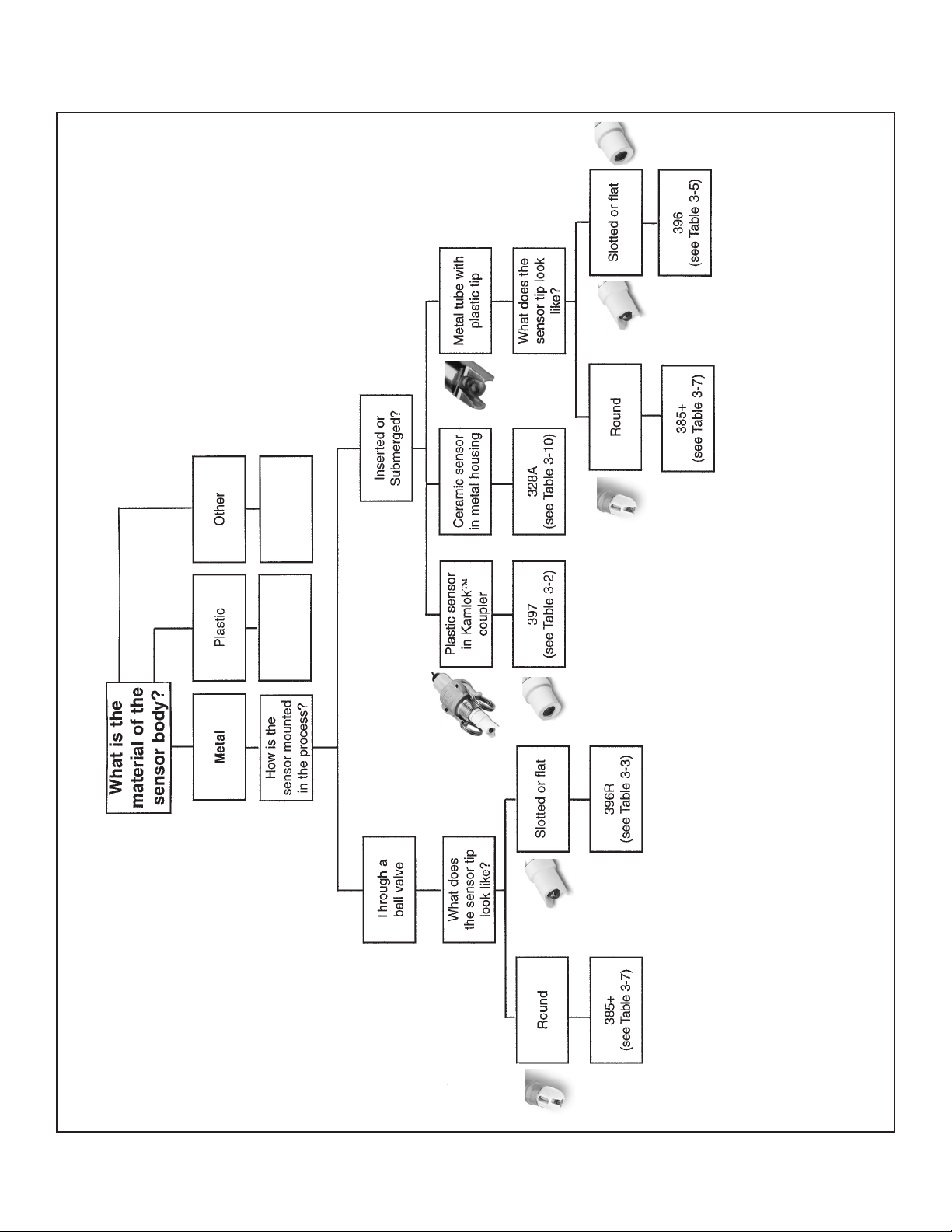

• If the label is missing or unreadable, see the

flowcharts on pages 28 through 30.

Write the sensor model number here

2. THE TYPE OF TEMPERATURE ELEMENT

• Look on the label.

• If the label is missing or unreadable, measure the resistance between the RTD leads.

Write the temperature element RTD here

3. THE LOCATION OF THE PREAMPLIFIER: INSIDE OR OUTSIDE THE TRANSMITTER?

• If the sensor is wired through a junction box, the preamplifier is ALWAYS in the junction box or the

sensor.

If resistance is . . . the RTD is . . .

about 110 ohms Pt 100

about 3000 ohms Balco 3K

Page 4

• If the sensor is wired directly to the transmitter, the preamplifier can be in either the sensor

or the transmitter.

• Look at the wires in the sensor cable. A GREEN wire means the preamplifier is in the sensor. An coaxial cable means the preamplifier is in the transmitter. A coaxial cable is an

insulated wire surrounded by a braided metal shield. The wire terminates in either a BNC

connector or an ORANGE wire with a CLEAR shield.

Write the preamplifier location here

CAN YOU USE THE QUICK START GUIDE

ON THE FOLLOWING PAGE?

Use the Quick Start Guide if . . .

1. you do NOT require an intrinsically safe or explosion-proof installation,

2. you are NOT measuring ORP,

3. you are NOT using a a sensor-mounted junction box or a remote junction box,

4. you are NOT using a sensor made by another manufacturer,

5. you are using one of the following sensors:

Note: Only the model option numbers needed to select the correct wiring diagram in the

Quick Start Guide are shown. Other model option numbers are not shown.

If you cannot use the Quick Start Guide, turn to Section 2.0 of the instruction manual.

Base Model RTD Preamplifier located Model Option (note)

381+ Pt 100 in sensor (green wire) 381+ -55

381+ Pt 100 in transmitter (orange wire) 381+ -52

385+ Pt 100 in sensor (green wire) 385+ -03

385+ Pt 100 in transmitter (orange wire) 385+ -04

396P Pt 100 in transmitter (orange wire) 396P-02-54

396P Pt 100 in sensor (green wire) 396P-01-55

396P Pt 100 in transmitter (orange wire) 396P-02-55

396R Pt 100 in transmitter (orange wire) 396R-54

Page 5

QUICK START GUIDE FOR MODEL 4081pH/ORP

Before using this Quick Start Guide, please read “WHAT YOU NEED TO KNOW BEFORE

INSTALLING AND WIRING A ROSEMOUNT ANALYTICAL SENSOR TO THE MODEL 4081

pH/ORP TRANSMITTER” on the preceding page.

Section 1.1 Setup for the Models 381+-52, 385+-04, 396P-02-54, 396P-02-55 and 396R-54 without a junction box

A. The factory setting of the preamplifier switch is in the appropriate location, so no adjustment is necessary.

B. Mount the transmitter in the desired location. Most installations use PN 2002577, pipe mounting bracket.

C. Continue the start up with Section 2 Wiring.

Section 1.2 Setup for Sensor Models 381+-55, 385+-03, and 396P-01-55 without a junction box

A. This section shows how to set the preamplifier switch and should be done prior to installation of the transmitter.

B. Loosen the cover lock nut on the Model 4081pH/ORP transmitter until the tab disengages from the circuit end cap.

Unscrew and remove the cap. Unscrew the three bolts holding the circuit board stack in the enclosure.

C. Pull up on the display board. Do not disconnect the ribbon cable between it and the CPU board. The CPU and analog

boards are joined by a pin and socket connector along the bottom edge of the boards. Carefully pull the boards apart and

remove the CPU board. The analog board is on the bottom and remains in the enclosure. See Figure 1 below.

D. The analog board is shaped like a circle with an arc missing. Directly opposite the straight side is a slide switch. Change

the switch position to the "sensor or j-box" setting by sliding the switch closer to the edge of the board. See Figure 2 below.

E. To reassemble the stack, place the display board on the CPU board. Be sure the display board is properly oriented. The

small square window (the infrared detector for the remote controller) marks the top of the board. Insert the three bolts

through the holes. Align the bolts with the standoffs on the analog board and position the display and CPU boards on the

analog board. If the boards are properly aligned, the bolts will drop in place. Press along the bottom of the stack to seat the

pin and socket connector. Tighten the bolts, replace the cap and cover lock nut.

F. Mount the transmitter in the desired location. Most installations use PN 2002577, pipe mounting bracket.

FIGURE 2

FIGURE 1

Page 6

Section 2 Wiring

A. Wire sensor Model 381+-55, 385+-03, or 396P-01-55 directly to the transmitter as shown in Figure 3.

B. Wire sensor Model 381+-52, 385+-04, 396P-02-55, 396P-02-55, or 396R-54 as shown in Figure 4.

C. Wire the 12 - 42.4 Vdc power supply to TB-15 and TB-16.

Section 3 Power up and Calibration

A. Apply dc power to the transmitter.

B. Remove the red protective "boot" from the sensor end. Rinse with deionized water and gently pat dry with a tissue (don't

wipe or rub). Place the pH sensor in the first buffer. Install the batteries in the remote controller.

Note: A pH measurement is only as good as the calibration, and the calibration is only as good as the buffers

used. A careful buffer calibration is the first step in making an accurate pH measurement. For best results, calibrate with buffers having the same temperature as the process. Allow time for the sensor and buffers to reach the

same temperature. If the process temperature is more than 10 C different from the buffer, allow at least 20 minutes. Be careful using buffers at high temperatures because the pH of many buffers is undefined above 60 C.

See the main instruction manual for further information.

C. Aim the infrared remote controller (IRC) at the LCD display.

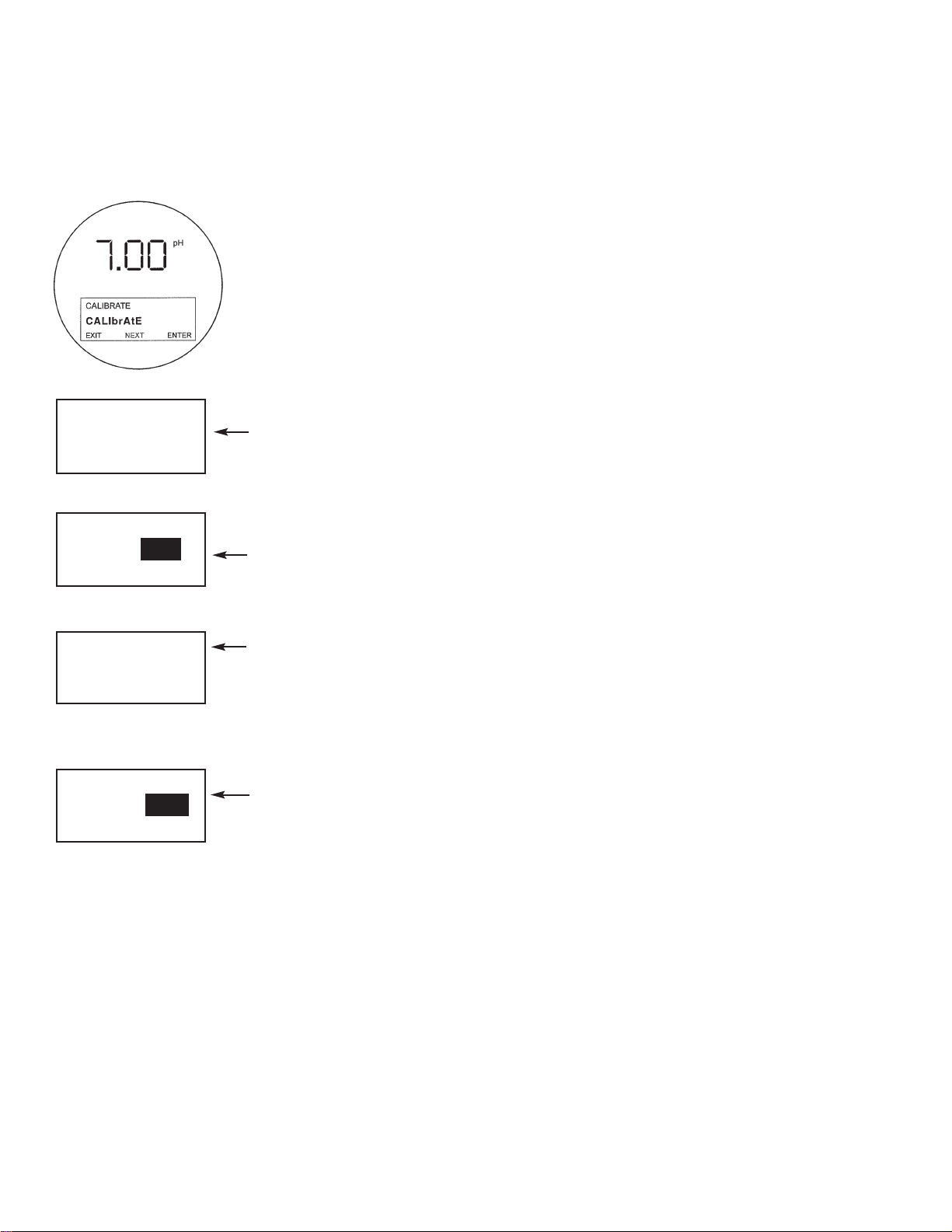

Press CAL. CALIbrAtE will appear.

Press ENTER. CAL bF1 will appear.

D. With the sensor in the first buffer, be sure the glass bulb and the temperature element are completely submerged (i.e. 3

inches). Do not let the weight of the sensor rest on the glass bulb. Swirl the sensor to dislodge trapped bubbles.

Press ENTER. bF1 will flash until reading is stable. The measured pH value will appear in the main display.

Press éor êuntil the small number next to bF1 matches the nominal pH buffer value (i.e. 4.01 pH).

Press ENTER to save the first calibration point. CAL bF2 will appear.

E. Remove the sensor from the first buffer, rinse, and place in the second buffer.

Press ENTER. bF2 will flash until the reading is stable. The measured pH value will appear in the main display.

Press éor êuntil the small number next to bF2 matches the nominal pH buffer value (i.e. 10.00 pH).

Press ENTER to save the second calibration point.

F. Press RESET to return to the process display. The calibration is complete.

G. Place the sensor in the process. The start up is complete, although the following optional procedure may be useful.

NOTE: Diagnostics is turned OFF. See menu tree, Figure 5-4.

NOTES:

1. INSTRUMENT JUMPER SUPPLIED BY CUSTOMER.

2. DO NOT CONNECT BLUE WIRE INSIDE TRANSMITTER. INSULATE STRIPPED

END OF BLUE WIRE.

FIGURE 3 FIGURE 4

-VDC

-VDC

+VDC

+VDC

Page 7

QUICK REFERENCE GUIDE

MODEL 4081PH/ORP

Automatic Buffer Calibration

Note: A pH measurement is only as good as the calibration, and the calibration is only as good as the buffers used. For best

results, calibrate with buffers having the same temperature as the process. Allow time for the sensor and buffers to reach the

same temperature. If the process temperature is more than 10°C different from the buffer, allow at least 20 minutes. Be careful

using buffers at high temperatures. The pH of many buffers is undefined above 60°C. See the main instruction manual for further information.

A. Aim the infrared remote controller (IRC) at the LCD display.

Press HOLD on the IRC. HoLd OFF will appear.

Press êto toggle the display to HoLd On.

Press ENTER to engage hold mode. The HOLD indicator will appear to the left of the pH value.

B. Press CAL. CALIbrAtE will appear.

Press ENTER. CAL bF1 will appear.

C. With the sensor in the first buffer, be sure the glass bulb and the temperature element are completely submerged (about 3

inches deep). Do not let the weight of the sensor rest on the glass bulb. Swirl the sensor to dislodge trapped bubbles.

Press ENTER. bF1 will flash until reading is stable. The measured pH value will appear in the main display.

Press é or êuntil the small number next to bF1 matches the nominal pH buffer value (i.e., 4.01 pH).

Press ENTER to save the first calibration point. CAL bF2 will appear.

D. Remove the sensor from the first buffer, rinse and place in the second buffer.

Press ENTER. bF2 will flash until the reading is stable.

Press éor êuntil the small number next to bF2 matches the nominal pH buffer value (i.e., 10.00 pH).

Press ENTER to save the second calibration point.

E. The calibration is complete, but the transmitter remains in the CALIbrAtE sub-menu for two minutes after ENTER is

pressed. Press RESET to return to the process display immediately.

F. Place sensor in the process.

G. (Optional) For maintenance purposes, track the slope of the pH electrode. The slope value of a new electrode is 59mV

per pH unit, and this value falls over time. The sensor should be changed when the slope nears 47.5 mV per pH. To view

the slope value, use the following steps.

Press CAL. CALIbrAtE will appear.

Press NEXT. Std will appear.

Press ENTER. The current pH value will appear next to Std.

Press ENTER. SLOPE and the current slope value will appear. Record this number as your slope value.

Press RESET to return to the process display.

H. After calibration, press HOLD. HoLd On will display.

Press êto toggle the display to HoLd Off. Press ENTER to save this into memory.

The HOLD indicator on the display will turn off.

Standardizing to Match a Reference Instrument

Note: Standardization does not perform a true calibration. Regular buffer calibrations are still needed to update the sensor

slope value. For best results take your grab sample from a point as close as possible to the pH sensor and measure the sample at the same temperature as the process.

A. Aim the infrared remote controller (IRC) at the LCD display.

Press HOLD on the IRC. HoLd OFF will appear.

Press êto toggle the display to HoLd On.

Press ENTER to engage the hold mode. The HOLD indicator will appear to the left of the pH value.

B. Press CAL. CALIbrAtE will appear.

Press NEXT. Std will appear.

Press ENTER. The measured value will appear.

C. Take a grab sample of the process and measure it with your reference instrument. Use the editing keys to adjust the value

on the Model 4081pH/ORP to match the reference instrument. Press ENTER to save the corrected pH value.

D. If the value is acceptable, the sensor slope is displayed. The slope has not been changed.

E. Press RESET to return to the process display.

F. After calibration, press HOLD. HoLd On will display.

Press êto toggle the display to HoLd Off. Press ENTER to save this into memory.

The HOLD indicator on the display will turn off.

Page 8

Technical Support Hotline:

For assistance with any technical problems, please contact our Customer Support Center (CSC) The CSC is staffed

from 5:00am to 5:00pm PST.

Phone (US only): 800-854-8257 Phone: 949-757-8500

Fax: 949-863-9159 Email: uniloc.csc@frco.com

World Wide Web: www.RAuniloc.com

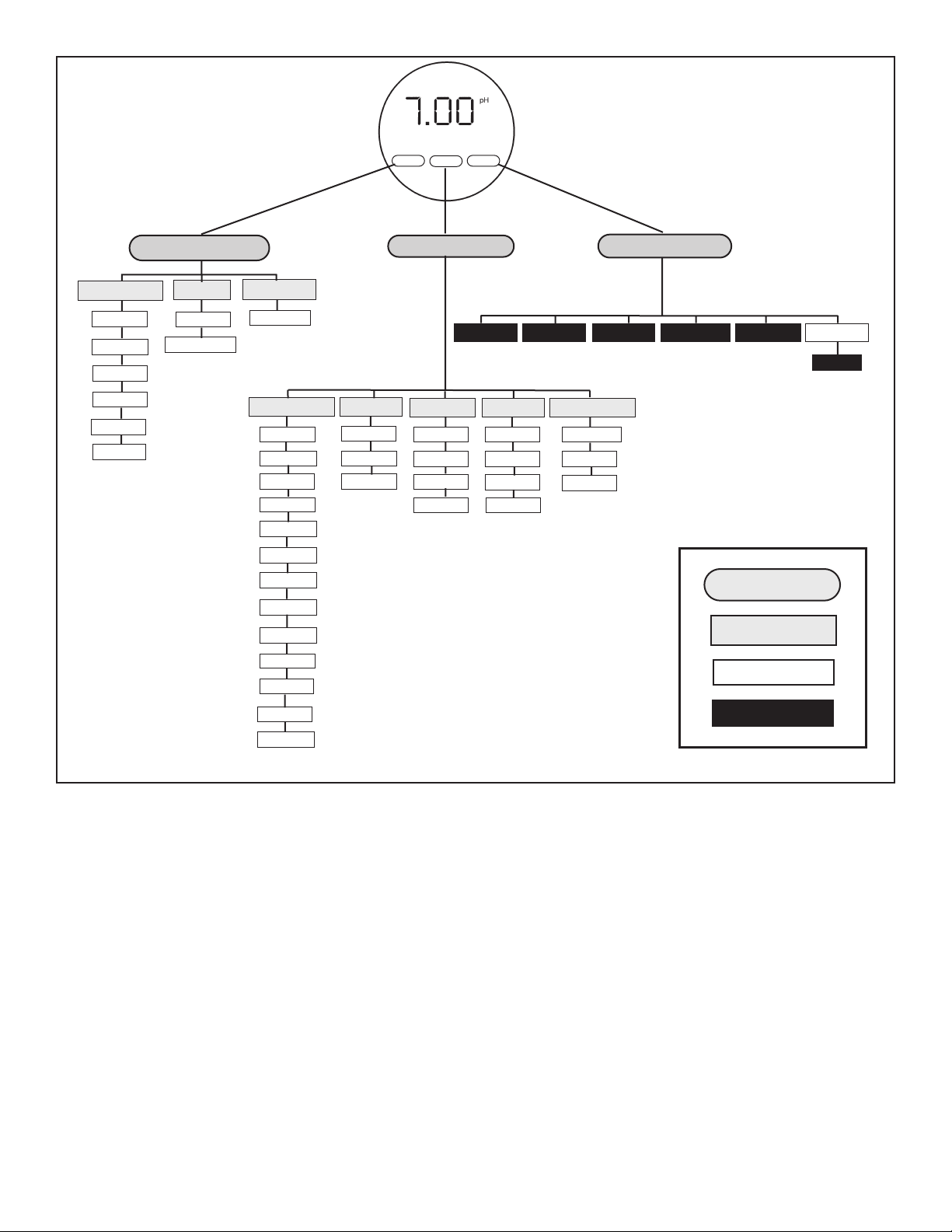

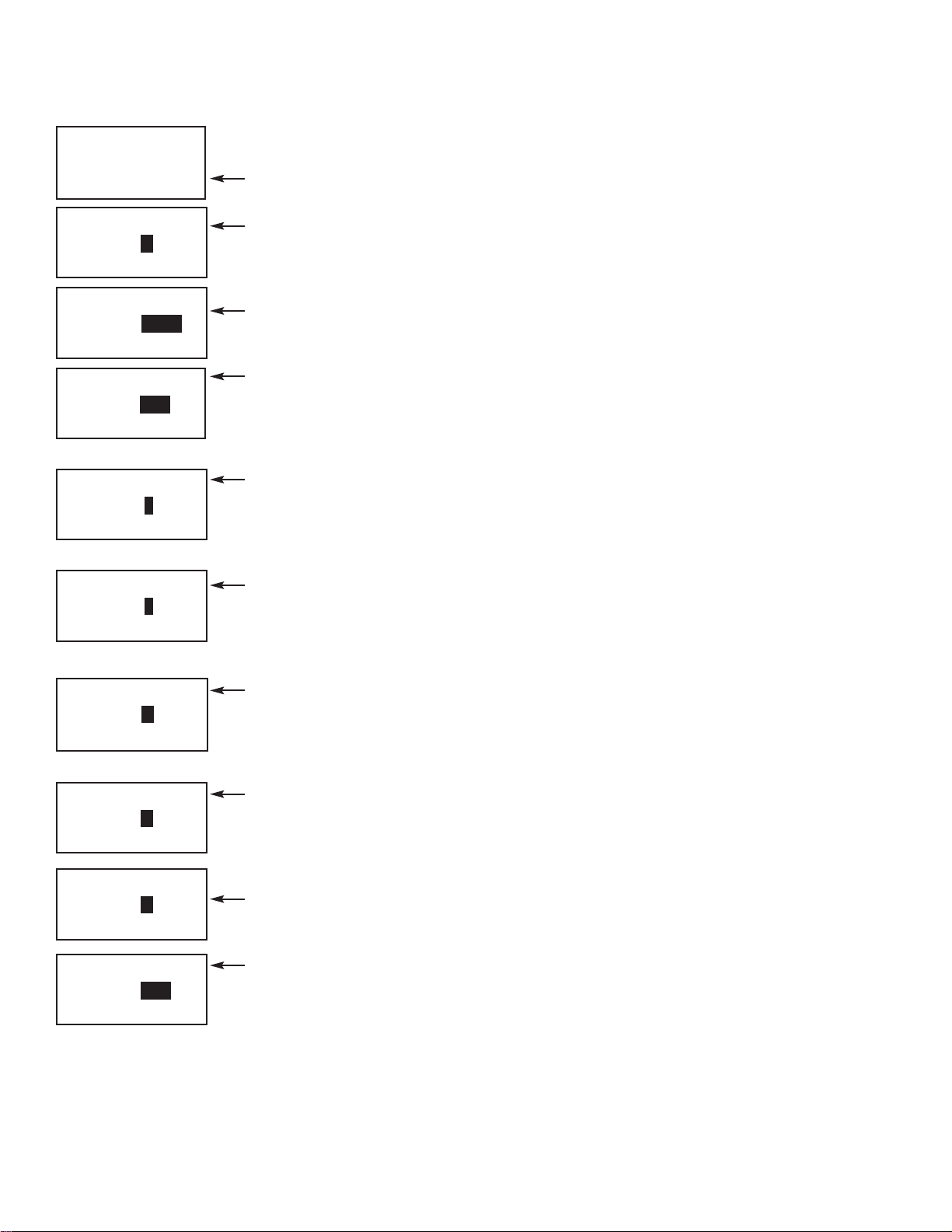

PROGRAM

CALIBRATE

GIMP 1000 V Er 4081

tEMP 25 C

InPut 58.9 ShoW FLt

nonE

rIMP 10

dIAGnOStIC tEMP

bUFFErdISPLAY ISOPOtntAL

CALIbrAtE

Std

tEMP AdJ

tEMP 25.0

tAUtO On

tMAn 25.0

tC 100-3

tYPE PH

tEMP C

OUtPUt Cur

COdE 000

bAUtO On

bUFFEr Std

tIME 04

PH 00.02

tCOEF 00.00

ISO 07.00

Snr 07.00

rOFFSt 060

dIAG OFF

IMPtC OFF

GWH 1000

GFH 1500

GWL 020

GFL 010

CAL 200

rEF LO

rFH 140

rWH 040

rWL 000

rFL 000

CAL bF1

bF 1

bF1 4.01

CAL bF2

bF 2

bF2 10.01

DIAGNOSE

Std 7.00

SLOPE 59.01

MENU

Sub-menu

PROMPT

Diag Message

Menu Tree for pH

Page 9

i

MODEL 4081 pH/ORP TABLE OF CONTENTS

MODEL 4081 PH/ORP

MICROPROCESSOR ANALYZER

TABLE OF CONTENTS

Section Title Page

1.0 DESCRIPTION AND SPECIFICATIONS ................................................................ 1

1.1 Features................................................................................................................... 1

1.2 FOUNDATION Fieldbus Technology........................................................................ 2

1.3 Specifications - General for Model 4081 pH/ORP ................................................... 3

1.4 Specifications - pH ................................................................................................... 4

1.5 Specifications - ORP................................................................................................ 4

1.6 Ordering Information ............................................................................................... 4

2.0 INSTALLATION ....................................................................................................... 7

2.1 Unpacking and Inspection........................................................................................ 7

2.2 Pre-Installation Set Up ............................................................................................. 7

2.3 Orienting the Display Board ..................................................................................... 10

2.4 Mechanical Installation............................................................................................. 10

2.5 Power Supply Wiring................................................................................................ 13

3.0 WIRING.................................................................................................................... 14

3.1 General Information ................................................................................................. 14

3.2 Wiring Diagrams ...................................................................................................... 15

4.0 INTRINSICALLY SAFE AND EXPLOSION PROOF ............................................... 31

4.1 Intrinsically Safe and Non-Incendive Installations.................................................... 31

4.2 Explosion Proof Installations.................................................................................... 31

5.0 OPERATION WITH REMOTE CONTROLLER ....................................................... 33

5.1 Overview .................................................................................................................. 33

5.2 Displays ................................................................................................................... 34

5.3 Infrared Remote Controller (IRC)............................................................................. 35

5.4 Menu Tree - pH........................................................................................................ 36

5.5 Diagnostic Messages - pH ....................................................................................... 36

5.6 Menu Tree -ORP...................................................................................................... 37

5.7 Diagnostic Messages - ORP.................................................................................... 37

5.8 Security .................................................................................................................... 38

6.0 CALIBRATION OF pH MEASUREMENTS ............................................................. 39

6.1 General .................................................................................................................... 39

6.2 Entering and Leaving the Calibrate Menu................................................................ 39

6.3 Using the Hold Function........................................................................................... 39

6.4 Temperature Calibration........................................................................................... 40

6.5 Auto Calibration ....................................................................................................... 41

6.6 Manual Calibration ................................................................................................... 43

6.7 Making the Transmitter Reading Match a Second pH Meter (Standardization)....... 45

Page 10

MODEL 4081 pH/ORP TABLE OF CONTENTS

TABLE OF CONTENTS CONT’D

ii

7.0 PROGRAMMING FOR pH MEASUREMENTS....................................................... 47

7.1 General .................................................................................................................... 47

7.2 Entering and Leaving the Program Menu ................................................................ 47

7.3 Diagnostic Parameters............................................................................................. 49

7.4 Temperature Related Settings ................................................................................. 53

7.5 Display Units ............................................................................................................ 55

7.6 Buffer Calibration Parameters.................................................................................. 56

7.7 Isopotential Parameters ........................................................................................... 58

8.0 CALIBRATION OF ORP MEASUREMENTS .......................................................... 60

8.1 General .................................................................................................................... 60

8.2 Entering and Leaving the Calibrate Menu................................................................ 60

8.3 Using the Hold Function........................................................................................... 60

8.4 Temperature Calibration........................................................................................... 61

8.5 Standardization ........................................................................................................ 62

9.0 PROGRAMMING FOR ORP MEASUREMENTS.................................................... 63

9.1 General .................................................................................................................... 63

9.2 Entering and Leaving the Program Menu ................................................................ 63

9.3 Temperature Element............................................................................................... 64

9.4 Display Units ............................................................................................................ 65

9.5 Diagnostic Parameters............................................................................................. 66

10.0 MAINTENANCE ...................................................................................................... 69

10.1 Overview .................................................................................................................. 69

10.2 Transmitter Maintenance ......................................................................................... 69

10.3 pH Sensor Maintenance .......................................................................................... 70

10.4 ORP Sensor Maintenance ....................................................................................... 72

10.5 Calibration................................................................................................................ 72

11.0 TROUBLESHOOTING ........................................................................................... 73

11.1 Warning and Fault Messages .................................................................................. 73

11.2 Calibration Errors ..................................................................................................... 74

11.3 Troubleshooting - General ....................................................................................... 74

11.4 Troubleshooting When a Diagnostic Message is Showing ...................................... 74

11.5 Troubleshooting When No Diagnostic Message is Showing.................................... 86

11.6 Systematic Troubleshooting..................................................................................... 91

11.7 Displaying Diagnostic Variables............................................................................... 93

11.8 Testing the Transmitter by Simulating pH ................................................................ 93

11.9 Factory Assistance and Repairs .............................................................................. 96

Page 11

iii

MODEL 4081 pH/ORP TABLE OF CONTENTS

TABLE OF CONTENTS CONT’D

12.0 pH MEASUREMENTS............................................................................................. 97

12.1 General .................................................................................................................... 97

12.2 Measuring Electrode ................................................................................................ 98

12.3 Reference Electrode ................................................................................................ 98

12.4 Liquid Junction Potential .......................................................................................... 99

12.5 Converting Voltage to pH......................................................................................... 99

12.6 Glass Electrode Slope ............................................................................................. 100

12.7 Buffers and Calibration ............................................................................................ 100

12.8 Isopotential pH ......................................................................................................... 101

12.9 Junction Potential Mismatch .................................................................................... 101

12.10 Sensor Diagnostics .................................................................................................. 102

12.11 Shields, Insulation, and Preamplifiers...................................................................... 102

13.0 ORP MEASUREMENTS.......................................................................................... 103

13.1 General .................................................................................................................... 103

13.2 Measuring Electrode ................................................................................................ 104

13.3 Reference Electrode ................................................................................................ 104

13.4 Liquid Junction Potential .......................................................................................... 104

13.5 Relating Cell Voltage to ORP................................................................................... 105

13.6 ORP, Concentration, and pH.................................................................................... 105

13.7 Interpreting ORP Measurements ............................................................................. 106

13.8 Calibration................................................................................................................ 107

14.0 GLOSSARY............................................................................................................. 109

15.0 RETURN OF MATERIAL......................................................................................... 115

INDEX ...................................................................................................................... 116

Appendix Title Page

A 4081 pH RESOURCE AND TRANSDUCER BLOCK PARAMETERS .................. 118

B 4081 ORP RESOURCE AND TRANSDUCER BLOCK PARAMETERS ................ 125

Page 12

iv

MODEL 4081 pH/ORP TABLE OF CONTENTS

TABLE OF CONTENTS CONT’D

LIST OF FIGURES

Number Title Page

2-1 Model 4081 pH/ORP Transmitter - Exploded Drawing of Circuit Board Stack ......... 8

2-2 Model 4081 pH/ORP Transmitter - Analog Board .................................................... 9

2-3 Model 4081 pH/ORP Transmitter - CPU Board........................................................ 10

2-4 Mounting the Model 4081 pH/ORP Transmitter on a Flat Surface ........................... 11

2-5 Using the Pipe Mounting Kit to Attach the Model 4081 pH/ORP to a pipe ............... 12

2-6 Power Supply Wiring ................................................................................................ 13

2-7 Typical Fieldbus Network Electrical Wiring Configuration ........................................ 13

3-1 Wiring and Preamplifier Configurations for pH and ORP Sensors ........................... 14

3-2 Wire Functions for Models 399-02, 399-09, 381pH-30-41, and 381pHE-31-41 .......

before removing BNC and terminating cable ........................................................... 18

3-3 Wire Functions for Models 399-02, 399-09, 381pH-30-41, and 381pHE-31-41 .......

after removing BNC and terminating cable. Wire Functions for Models ..................

399-09-10-62, 381pH-30-42, and 381pHE-31-42 as received ................................. 18

3-4 Wiring Diagram for Models 399-02, 399-09, 381pH-30-41, and 381pHE-31-41 ......

after removing BNC and terminating cable. Wiring Diagram for Models 399-09-10-62,

381pH-30-42, and 381pHE-31-42 as received. Wiring directly to the transmitter .... 18

3-5 Wiring Diagram for Models 399-02, 399-09, 381pH-30-41 after removing BNC .....

and terminating cable. Wiring Diagram for Model 399-09-10-62, 381pH-30-42, and

381pH-31-42 as received. Wiring through a remote junction box to the transmitter 18

3-6 Wire Functions for Models 397-50, 397-54, 396-50, 396-54, 396R-50-60, 396R-54-60,

389-02-50, and 389-02-54 before removing BNC and terminating cable................. 19

3-7 Wire Functions for Models 397-50, 397-54, 369-50, 396-54, 396R-50-60, 396R-54-60,

389-02-50, and 389-02-54 after removing BNC and terminating cable. Wire .........

Functions for Models 397-54-62, 396-02-62, and 389-02-54-62 as received .......... 19

3-8 Wiring Diagram for Models 397-50, 397-54, 369-50, 396-54, 389-02-50, and.........

389-02-54 after removing BNC and terminating cable. Wiring Diagram for Models

397-54-62, 396-02-62, and 389-02-54-62 as received. Wiring Directly to the ........

Transmitter .................................................................................................... 19

3-9 Wiring Diagram for Models 397-50, 397-54, 369-50, 396-54, 396R-50-60, 396R-54-60,

389-02-50, and 389-02-54 after removing BNC and terminating cable. Wiring ......

Diagram for Models 397-54-62, 396-02-62, and 389-02-54-62 as received. ..........

Wiring Through a Remote Junction Box to the Transmitter ..................................... 19

3-10 Wire Functions for Models 396R-50, 396R-54, 396R-50-61, 396P-02-50, 396P-02-54,

396P-05-55, 385+-04, and 385+-41-52.................................................................... 20

3-11 Wiring Diagram for Models 396R-50, 396R-54, 396R-50-61, 396P-02-50, 396P-02-54,

396P-05-55, 385+-04, and 385+-41-52. Wiring Directly to the Transmitter ............ 20

3-12 Wiring Diagram for Models 396R-50, 396R-54, 396R-54-61, 396P-02-50, 396P-02-54,

396P-02-55, 385+-04, and 385+-41-52. Wiring Through a Sensor-Mounted ..........

Junction Box to the Transmitter ............................................................................... 20

3-13 Wire Functions for Models 396P-01-55, 385+-03, 381+-40-55, and 381+-43-55 .... 21

3-14 Wiring Diagram for Models 396P-01-55, 385+-03, 381+-40-55, and 381+-43-55.... 21

3-15 Wire Functions for Model 385+-02 ........................................................................... 22

3-16 Wiring Diagram for Model 385+-02 .......................................................................... 22

3-17 Wire Functions for Model 328A-07........................................................................... 23

3-18 Wiring Diagram for Model 328A ............................................................................... 23

3-19 Wiring Diagram for Model 320HP-10-55 .................................................................. 24

3-20 Wiring Diagram for Model 320HP-10-58 .................................................................. 24

3-21 Wire Functions for Model 399-33 ............................................................................. 25

Page 13

v

MODEL 4081 pH/ORP TABLE OF CONTENTS

TABLE OF CONTENTS - CONT’D

LIST OF FIGURES - CONT’D

Number Title Page

3-22 Wiring Diagram for Model 399-33 ............................................................................ 25

3-23 Procedure for Removing BNC Connector and Preparing Coaxial Cable for ............

Connection to the Model 4081 pH/ORP Transmitter................................................ 26

3-24 Preparation of Raw Connecting Cable ..................................................................... 27

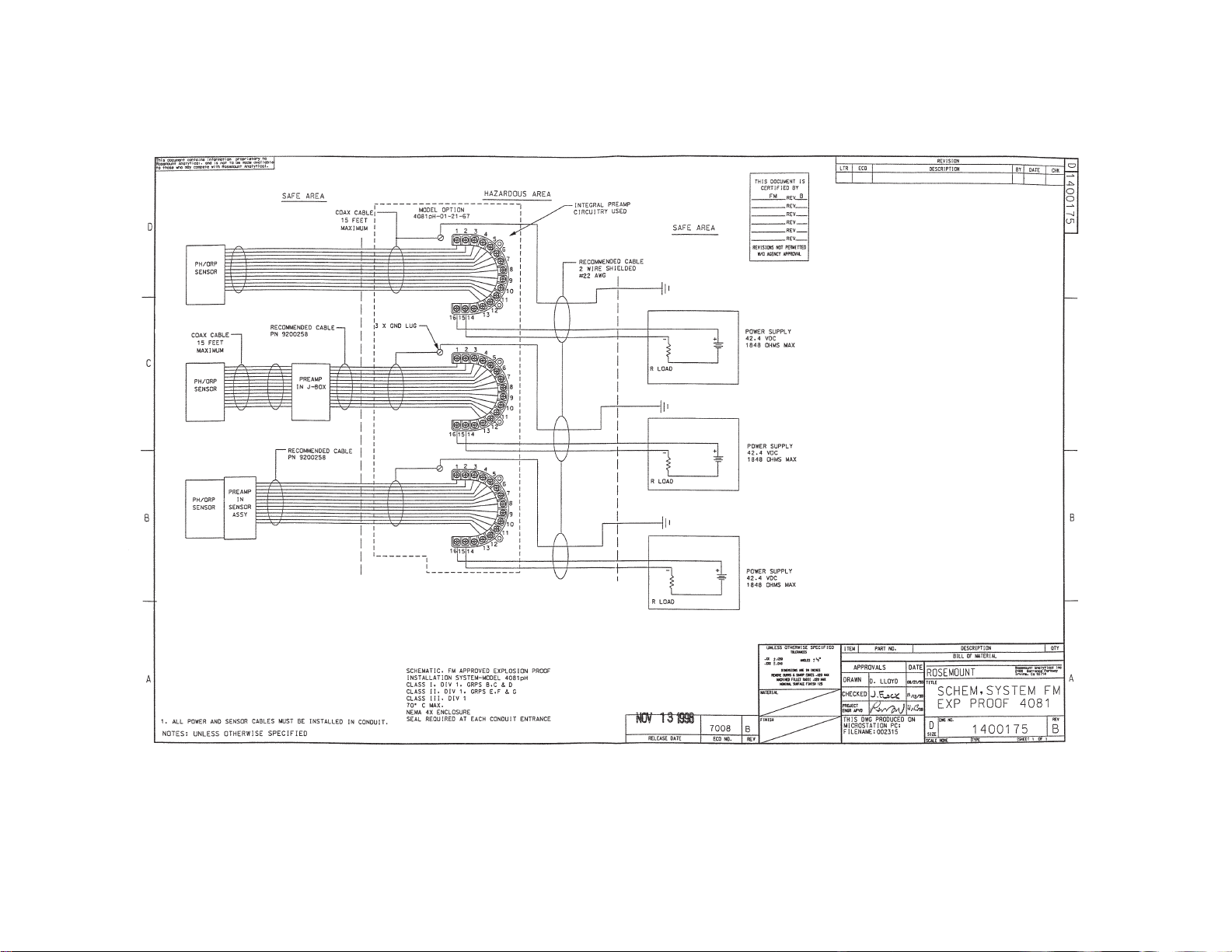

4-1 CSA I.S. Label .......................................................................................................... 31

4-2 FM Explosion-Proof Installation for Model 4081 pH/ORP Transmitter ..................... 32A

4-3 CSA Intrinsically Safe Installation for Model 4081 pH/ORP Transmitter .................. 32B

4-4 FMRC Intrinsically Safe Installation for Model 4081 pH/ORP Transmitter ............... 32C

5-1 Functional Block Diagram for the Model 4081 pH/ORP Transmitter with.................

FOUNDATION Fieldbus ............................................................................................. 33

5-2 Process Display Screen ........................................................................................... 34

5-3 Program Display Screen .......................................................................................... 34

5-4 Infrared Remote Controller ....................................................................................... 35

5-5 Menu Tree for pH ..................................................................................................... 36

5-6 Menu Tree for ORP ................................................................................................. 37

7-1 Suggested Glass Impedance Warning and Failure Limits ....................................... 49

7-2 Suggested Warning and Failure Limits for Low Impedance Reference Electrodes . 50

7-3 Suggested Warning and Failure Limits for High Impedance Glass Reference Electrodes 50

9-1 Suggested Warning and Failure Limits for Low Impedance Reference Electrodes . 66

9-2 Suggested Glass Impedance Warning and Failure Limits for a Glass Reference ...

Electrode .................................................................................................................. 66

10-1 Exploded View of Model 4081 pH/ORP Transmitter ................................................ 69

10-2 Checking the Potential of the Reference Electrode.................................................. 71

11-1 Warning Annunciation .............................................................................................. 73

11-2 Fault Annunciation.................................................................................................... 73

11-3 Three-Wire RTD .................................................................................................... 80

11-4 Temperature Simulation into the Model 4081 pH/ORP Transmitter ......................... 81

11-5 Troubleshooting Flow Chart/Preamplifier in Sensor-Mounted Junction Box or........

Remote Junction Box ............................................................................................... 91

11-6 Troubleshooting Flow Chart/Preamplifier in Transmitter or Built into Sensor........... 92

11-7 pH Simulation When the Preamplifier is Located in the Transmitter ........................ 94

11-8 pH Simulation When the Preamplifier is Located in a Remote Junction Box or.......

in a Sensor-Mounted Junction Box .......................................................................... 94

11-9 Simulate pH Through Model 381+ Sensor Preamplifier........................................... 95

12-1 pH Measurement Cell............................................................................................... 97

12-2 Measuring Electrode (pH) ........................................................................................ 98

12-3 Cross-Section Through the pH Glass....................................................................... 98

12-4 Reference Electrode................................................................................................. 99

12-5 The Origin of Liquid Junction Potential..................................................................... 99

12-6 Glass Electrode Slope.............................................................................................. 100

12-7 Two-Point Buffer Calibration..................................................................................... 101

12-8 Liquid Junction Potential Mismatch .......................................................................... 102

13-1 ORP Measurement Cell ........................................................................................... 103

13-2 Measuring Electrode (ORP) ..................................................................................... 104

13-3 Reference Electrode................................................................................................. 104

13-4 The Origin of Liquid Junction Potential..................................................................... 105

13-5 Electrode Potential ................................................................................................... 105

13-6 ORP Measurement Interpretation ............................................................................ 106

Page 14

vi

MODEL 4081 pH/ORP TABLE OF CONTENTS

TABLE OF CONTENTS CONT’D

LIST OF TABLES

Number Title Page

3-1 Wiring Diagrams for Model 399 Sensors.................................................................. 15

3-2 Wiring Diagrams for Model 397 Sensors.................................................................. 15

3-3 Wiring Diagrams for Model 396R Sensors ............................................................... 15

3-4 Wiring Diagrams for Model 396P Sensors ............................................................... 16

3-5 Wiring Diagrams for Model 396 Sensors.................................................................. 16

3-6 Wiring Diagrams for Model 389 Sensors.................................................................. 16

3-7 Wiring Diagrams for Model 385+ Sensors................................................................ 17

3-8 Wiring Diagrams for Model 381+ Sensors................................................................ 17

3-9 Wiring Diagrams for Model 381pHE and 381pH Sensors ........................................ 17

3-10 Wiring Diagrams for Model 328A Sensors ............................................................... 17

3-11 Wiring Diagrams for Model 320HP Sensors............................................................. 17

7-1 pH Settings List ....................................................................................................... 48

7-2 pH Values of Standard Buffer Solutions and the Temperature Range over which ...

pH Values are Defined ............................................................................................. 56

7-3 pH Values of Commercial (technical) Buffers and the Temperature Range over .....

which pH Values are Defined .................................................................................. 57

7-4 Standard and Technical Buffers Recognized by the Model 4081 pH Transmitter ... 57

9-1 ORP Settings List .................................................................................................... 63

10-1 Replacement Parts for Model 4081 pH Transmitter ................................................ 70

11-1 RTD Resistance Values ........................................................................................... 80

Page 15

1

MODEL 4081 pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.1 Features

1.2

FOUNDATION Fieldbus Technology

1.3 Specifications - General for Model 4081 pH/ORP

1.4 Specifications - pH

1.5 Specifications - ORP

1.6 Ordering Information

• REMOTE COMMUNICATION IS SIMPLE; use the handheld infrared remote controller,

DeltaV

1

, or FOUNDATION2Fieldbus host.

• LARGE TWO LINE DISPLAY shows pH or ORP, temperature, and output signal.

• SIMPLE, INTUITIVE menus make programming and calibrating easy.

• AUTOMATIC TWO-POINT BUFFER CALIBRATION reduces errors.

• SOLUTION TEMPERATURE COMPENSATION converts the pH measured at any temperature to the pH at 25°C.

• CONTINUOUS DIAGNOSTICS monitor sensor performance and warn the user of impending problems.

• ROBUST NEMA 4X and NEMA 7 ENCLOSURE protects the transmitter from harsh plant

environments.

• SOLUTION TEMPERATURE COEFFICIENT allows pH adjustment for actual pH changes

with temperature.

• NON-VOLATILE EEPROM MEMORY retains program settings and calibration data during

power failures.

1.1 FEATURES

APPLICATION: The Model 4081pH/ORP Transmitter

with the appropriate pH or ORP sensor measures pH

between 0 and 14 and ORP between -1400 and 1400

millivolts. Converting the transmitter from a pH instrument to an ORP instrument takes only seconds.

REMOTE COMMUNICATIONS: Remote communications with the Model 4081 pH/ORP transmitter is easy.

The handheld, push button infrared remote controller

works from as far away as six feet. The transmitter also

communicates via any FOUNDATION fieldbus host,

such as the Fisher Rosemount DeltaV system.

DISPLAY: The 0.8-inch high LCD main display means

pH and ORP values are easy to read even at a distance.

Temperature reading also appears in a 0.3 inch high display.

MENUS: Menu formats for calibration and programming

are simple and intuitive. Prompts guide the user through

the basic procedures. Diagnostic and error messages

appear in plain language. There are no annoying error

codes to look up.

1. DeltaV is a trademark of Fisher-Rosemount.

2. FOUNDATION is a registered trademark of Fieldbus Foundation.

Page 16

2

CALIBRATION: Two-point, temperature-corrected buffer

calibration is standard. To reduce errors caused by impatient operators, the Model 4081 transmitter does not

accept calibration data until programmed stability limits

have been met. If data are not acceptable, the transmitter

displays an error message and does not update the calibration. The transmitter recognizes buffer values commonly used in the world today. Manual two-point and one-point

calibration is also available.

AUTOMATIC TEMPERATURE COMPENSATION:

External 3 or 4 wire PT100 RTD, PT1000 RTD, or 3K

Balco thermistor located in the sensor compensates the

pH reading for temperature fluctuations. Compensation

covers the range -15 to 130°C (5 to 270°F). Manual temperature compensation is program selectable.

SOLUTION TEMPERATURE COMPENSATION: The

Model 4081 pH transmitter features solution temperature

compensation. The transmitter calculates and displays the

pH at 25°C from the pH measured at any temperature.

The temperature coefficient of the liquid being measured

must be known.

SENSOR DIAGNOSTICS: Continuous diagnostics alert

the user to impending or existing sensor failure. Diagnostic

messages in plain language aid in troubleshooting. The

manual contains a thorough, step-by-step troubleshooting

guide.

HOUSING: The Model 4081 pH/ORP transmitter housing

meets NEMA 4X standards. The transmitter tolerates outdoor and harsh plant environments. The housing also

meets NEMA 7B explosion-proof standards.

HAZARDOUS AREA INSTALLATION: Circuits in the

Model 4081 pH/ORP transmitter are designed and built to

be intrinsically safe when used with the appropriate safety

barrier.

OUTPUT: The digital FOUNDATION fieldbus output signal

is fully adjustable between 0 and 14 pH and between 1400 and 1400 mV.

1.2 FOUNDATION FIELDBUS TECHNOLOGY

F

OUNDATION fieldbus is an all digital, serial, two-way

communication system that interconnects field equipment

such as sensors, actuators, and controllers. Fieldbus is a

Local Area Network (LAN) for instruments used in both

process and manufacturing automation with built-in capability to distribute the control application across the network. The fieldbus environment is the base level group of

digital networks in the hierarchy of plant networks.

The fieldbus retains the desirable features of the 4 - 20

mA analog system, but uses a digital signal. Fieldbus

transmitters include a standardized physical interface to

the wire, bus powered devices on a single pair of wires,

and intrinsic safety options, and enables additional capabilities, such as:

* increased capabilities due to full digital communica-

tions,

* reduced wiring and wire terminations due to multiple

devices on one pair of wires,

* increased selection of suppliers due to interoperability,

* reduced loading on control room equipment with the

distribution of some control and input/output functions

to field devices.

* speed options for process control and manufacturing

applications.

MODEL 4081 pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

Page 17

3

MODEL 4081 pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.3 SPECIFICATIONS -GENERAL

FOR MODEL 4081 pH/ORP

Case: Cast aluminum containing less than 6% magnesium.

NEMA 4X (IP65), NEMA 7 (explosion-proof)

Epoxy-polyester painted over low-copper aluminum.

Neoprene O-rings on cover.

Dimensions: 6.3 in. x 6.9 in. x 6.4 in. (160 mm x 175 mm x

161 mm); diameter 6.1 in (155 mm)

Conduit Openings: 2 X 3/4 in. FNPT

Reference Impedance: Transmitter accepts high impedance

(i.e. glass) reference electrodes as well as low impedance

(i.e. silver-silver chloride) reference electrodes.

Output: Digital FOUNDATION fieldbus

Response Time: Display reaches 95% of final reading within

10 seconds.

Temperature Sensors: The following RTDs can be used with

the Model 4081 pH/ORP transmitter:

3 and 4 wire Pt 100 RTDs

3 and 4 wire Pt 1000 RTDs

3000 ohm Balco RTD

Transmitter can also be used with two-wire RTDs.

Temperature Range: 5°F to 248°F (-15°C to 120°C)

Local Display: Two line LCD; first line shows process vari-

able (pH or ORP), second line shows temperature and

output signal. When triggered, fault and warning messages alternate with temperature and output readings.

Process variable: 7 segment LCD, 0.8 in. (20 mm) high

Temperature/output: 7 segment LCD, 0.3 in. (7 mm) high

Display board can be rotated 90 degrees clockwise or

counterclockwise.

During calibration and programming, messages and

prompts appear in the temperature/output area.

Power Supply and Load Requirements: A minimum power

supply voltage of 9 Vdc to 32 Vdc is required; Intrinsically

Safe installations may be limited to a maximum of 2-3

transmitters per node, depending on the barrier used.

Security: User selected security code prevents

accidental changes to program settings.

Ambient Temperature: -4 to 149°F (-20 to 65°C)

Relative Humidity: 0 to 95% (with covers sealed)

Storage Temperature: -22 to 176°F (-30 to 80°C)

F

OUNDATION

Fieldbus:

Two AI Function Blocks: pH and temperature

Execution time: 75 milliseconds

Hazardous Area Protection: The Model 4081 pH/ORP is

certified to the following:

NEMA 7B: Explosion proof housing

CE: EMI/RFI Certification

EN50081-1

EN50082-2

Hazardous Area Classification:

Explosion Proof:

FM: Class I, Div. 1, Groups B, C & D

Class II, Div. 1, Groups E, F, & G

Class III, Div. 1

CSA: Class I, Div. 1, Groups C& D

Class I, Div. 2, Groups A, B, C & D

Class II, Div. 2, Groups E, F & G

Class III, Div. 1

Intrinsic Safety:

FM: Class I, II & III, Div. 1

T4 T AMB= 40°C; T3AT AMB= 70°C

CSA: Class I, Div. 1

T 3C T AMB=40°C; T3 T AMB=80°C

CENELEC: EEx ia IIC

T5 Tamb=40°C; T4 Tamb=60°C

Non-Incendive:

FM: Class I, Div. 2, Groups A, B, C & D

CSA: Class I, Div. 2, Groups A, B, C & D T5

(Tamb=40°C)

Weight/Shipping Weight: 10 lb/10 lb (4.5 kg/4.5 kg).

Weights and shipping weights are rounded to the nearest

whole pound.

Page 18

4

MODEL 4081 pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.6 ORDERING INFORMATION

The Model 4081 pH/ORP two-wire microprocessor transmitter is housed in a NEMA 4X and NEMA 7 case.

Communication with the transmitter is through a hand-held infrared remote controller, DeltaV, or FOUNDATION fieldbus

host. Automatic temperature compensation is standard, and the transmitter can be programmed to convert measured pH

to pH at 25°C. Continuous sensor diagnostics are standard.

MODEL

4081pH/ORP FOUNDATION FIELDBUS TWO-WIRE MICROPROCESSOR TRANSMITTER

Code REQUIRED SELECTION

01-20 LCD (Infrared Remote Control - included), 9.4 lb/4.3 kg

01-21 LCD (Infrared Remote Control - not included)

1.4 SPECIFICATIONS - pH

pH Input Range: 0 to 14 pH

Temperature Input Range: 5°F to 248°F (-15°C to 120°C)

Output Scale Expansion: Continuously expandable

between pH 0 and 14

Accuracy at 25°C: ±0.01 pH

Repeatability at 25°C: ±0.01 pH

Resolution: 0.01 pH and 0.1°C or °F

Stability at 25°C: 0.25% per year

Temperature Compensation: Automatic or manual

between 5°F to 248°F (-15°C to 120°C)

Solution Temperature Compensation: Transmitter will

convert pH measured at any temperature to the pH at

25°C. Temperature coefficient is programmable

between -0.044 pH/°C and 0.028 pH/°C

Calibration: Automatic two-point and manual two-point

buffer calibration. For automatic calibration, the transmitter recognizes NIST, DIN 19266 and 19267,

JIS 8802, BSM, Merck, and Ingold buffers.

1.5 SPECIFICATIONS - ORP

ORP Input Range: -1400 to 1400 mV

Temperature Input Range: 5°F to 248°F (-15°C to 120°C)

Accuracy at 25°C: ±1 mV

Repeatability at 25°C: ±1 mV

Resolution: 1 mV and 0.1°C or °F

Stability at 25°C: 0.25% per year

Code AGENCY APPROVALS (no selection required)

67 FM approved, Intrinsically Safe (when used with approved sensor and safety barrier) and Explosion Proof

69 CSA approved, Intrinsically Safe (when used with approved sensor and safety barrier) and Explosion Proof

73 CENELEC approved, Intrinsically Safe (safety barrier required)

4081pH - 01 - 20 - 67 EXAMPLE

Page 19

5

MODEL 4081 pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

MODEL 4081 pH/ORP TRANSMITTER-SENSOR COMPATIBILITY CHART

PREAMPLIFIER LOCATION

Sensor-mounted Remote

MODEL pH ORP Sensor junction box junction box Transmitter

320B x see note

320HP x see note x

330B x see note

328A x x x

370 x x x x

371 x x x x

381pH x x x x

381pHE x x x x

381 x x x

381+ x x x x

385 x x x x

385+ x x x x x x

389 x x x x

396 x x x

396P x x x x x

396R x x x x x

397 x x x

398 x x x x

398R x x x x x

399 x x x x

399-33 x x

GP1 x x x x

NOTE: Preamplifier installed in junction box attached to sensor mounting plate.

Notes: 1. Special Quotation No. SQ5856 2. Remote J-box/Preamplifier assembly PN 23555-00 3. Sensor Head J-box PN 23709-00

pH SENSOR PREAMP LOCATION DIAGNOSTIC CAPABILITY

320B-99

1

Sensor junction box only Glass only

320HP-55

1

Transmitter only or remote junction box Glass only

328A Transmitter or remote junction box

2

Glass only

381 pHE-31-41-52 Transmitter or remote junction box

2

Glass only

381+ Transmitter, sensor or remote junction box Glass and Reference

385-53 Transmitter or remote junction box

2

Glass only

385+ Transmitter, Sensor or remote junction box

2

Glass and Reference

389-02-54 Transmitter or remote junction box

2

Glass only

396 TUpH Transmitter, Sensor or remote junction box

2

Glass only

396P TUpH Transmitter, Sensor or remote junction box

2

Glass and Reference

399-09 Transmitter or remote junction box

2

Glass only

396R Transmitter or remote j-box

2

sensor head

3

Glass and Reference

ORP SENSOR PREAMP LOCATION DIAGNOSTIC CAPABILITY

330B-99

1

Sensor None

381pHE-31-41-52 Transmitter or remote junction box

2

None

381+ Transmitter, sensor or remote junction box Reference only

385-53 Transmitter or remote junction box

2

None

385+ Transmitter Sensor or remote junction box

2

Reference only

389-02-12-54 Transmitter or remote junction box

2

None

396P Transmitter Sensor or remote junction box

2

Reference only

396R Transmitter or remote junction box

2

sensor head

3

Reference only

399-33 Transmitter or remote junction box None

Page 20

6

MODEL 4081 pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

MODEL/PN DESCRIPTION SHIPPING WEIGHT

23572-00 Infrared remote controller, includes two 1.5 V AAA alkaline batteries 1 lb/0.5 kg

23555-00 Remote junction box, includes preamplifier (PN 23557-00), 10 terminals on 2 lb/1.0 kg

sensor side and 12 terminals on transmitter side (additional two terminals

supply power from transmitter to the preamplifier)

23557-00 Preamplifier for remote junction box (PN 23555-00) 1 lb/0.5 kg

23550-00 Remote junction box without preamplifier, 12 terminals on sensor side and 2 lb/1.0 kg

12 terminals on transmitter side

23646-01 Extension cable for connecting transmitter to junction box, 10 conductors with 1 lb per 10 ft

1 internal drain wire, cable is terminated and ready for use, specify length 1.0 kg per 10 m

(in feet) when ordering

9200273 Extension cable for connecting transmitter to junction box, 10 conductors with 1 lb per 10 ft

1 internal drain wire, cable is not terminated, customer must prepare cable 1.0 kg per 10 m

ends, specify length (in feet) when ordering

2002577 Pipe mounting kit for 2-inch pipe, complete, includes mounting bracket, 2 lb/1.0 kg

U bolts, and all necessary fasteners

9241178-00 Stainless steel tag, specify marking, shipped loose 1 lb/0.5 kg

9120531 BNC adapter, BNC female to two leads 1 lb/0.5 kg

9210012 Buffer solution, 4.01 pH at 25°C, potassium hydrogen phthalate solution, NIST 2 lb/1.0 kg

pH scale buffer, 16 oz (473 mL)

9210013 Buffer solution, 6.86 pH at 25°C, potassium dihydrogen phosphate and 2 lb/1.0 kg

sodium hydrogen phosphate solution, NIST pH scale buffer, 16 oz (473 mL)

9210014 Buffer solution, 9.18 pH at 25°C, sodium tetraborate solution, NIST pH scale 2 lb/1.0 kg

buffer, 16 oz (473 mL)

R508-16OZ ORP standard, 475 ± 20 mV at 25°C, iron (II) ammonium sulfate and iron (III) 2 lb/1.0 kg

ammonium sulfate in 1 M sulfuric acid, 16 oz (473 mL)

5104081P Instruction manual 1 lb/0.5 kg

ACCESSORIES

* Weights rounded up to nearest pound or nearest 0.5 kg.

Page 21

MODEL 4081 pH/ORP SECTION 2.0

INSTALLATION

SECTION 2.0

INSTALLATION

2.1 Unpacking and Inspection

2.2 Pre-Installation Set Up

2.3 Orienting the Display Board

2.4 Mechanical Installation

2.5 Power Supply Wiring

2.1 UNPACKING AND INSPECTION

Inspect the shipping container. If it is damaged, contact the shipper immediately for instructions. Save the box. If there is

no apparent damage, remove the transmitter. Be sure all items shown on the packing list are present. If items are missing, immediately notify Rosemount Analytical.

Save the shipping container and packaging. They can be reused if it is later necessary to return the transmitter to the factory.

2.2 PRE-INSTALLATION SETUP

2.2.1 Transmitter Default Settings

Two jumpers and a switch may need to be changed from the factory default settings before installing the transmitter. The

settings tell the transmitter the type of temperature element in the sensor, whether the reference electrode is high or low

impedance, and the location of the preamplifier. The factory default settings are given below.

default setting

temperature element Pt 100 RTD

reference impedance low

preamplifier location in transmitter

If your sensor or system is different, the transmitter settings must be changed. If you do not know the type of temperature

element in the sensor, whether the reference electrode impedance is high or low, or the location of the preamplifier, refer

to Sections 2.2.2, 2.2.3, and 2.2.4.

2.2.2 Temperature Element

The Model 4081 pH/ORP transmitter is compatible with sensors having Pt 100, Pt 1000, or 3K Balco RTDs. pH and ORP

sensors manufactured by Rosemount Analytical contain either a Pt 100 or a 3K Balco RTD. Sensors from other manufacturers may have a Pt 1000 RTD. For Rosemount Analytical sensors, the type of temperature element in the sensor is printed on the metalized tag attached to the sensor cable. If the label is missing or unreadable, determine the type of RTD by

measuring the resistance across the RTD IN and RTD RTN leads. For the majority of sensors manufactured by Rosemount

Analytical, the RTD IN lead is red and the RTD RTN lead is white. For the Model 399-33 ORP sensor, the leads are black

and white. The Model 328A sensor has no RTD. The Model 320HP system has a readily identifiable separate temperature

element. Resistance at room temperature for common RTDs is given in the table.

If the resistance is... the temperature element is a

about 110 ohms Pt 100 RTD

about 1100 ohms Pt 1000 RTD

about 3000 ohms 3K Balco RTD

2.2.3 Reference Electrode Impedance

The standard silver-silver chloride reference electrode used in most industrial and laboratory pH electrodes is low impedance. EVERY pH and ORP sensor manufactured by Rosemount Analytical has a low impedance reference. Certain specialized applications require a high impedance reference electrode. The transmitter must be programmed to recognize the

high impedance reference.

7

Page 22

MODEL 4081 pH/ORP SECTION 2.0

INSTALLATION

8

FIGURE 2-1. Model 4081 pH/ORP Transmitter - Exploded Drawing of Circuit Board Stack

2.2.4 Preamplifier Location

pH sensors produce a high impedance voltage signal that must be preamplified before use. The signal can be preamplified before it reaches the transmitter or it can be preamplified in the transmitter. To work properly, the transmitter must know

where preamplification occurs. Although ORP sensors produce a low impedance signal, the voltage from an ORP sensor

is amplified the same way as a pH signal.

If the sensor is wired to the transmitter through a junction box, the preamplifier is ALWAYS in either the junction box or the

sensor. Junction boxes can be attached to the sensor or installed some distance away. If the junction box is not attached

to the sensor, it is called a remote junction box. In most junction boxes used with the Model 4081 pH/ORP, a flat, black

plastic box attached to the same circuit board as the terminal strips houses the preamplifier. The preamplifier housing in

the 381+ sensor is crescent shaped.

If the sensor is wired directly to the transmitter, the preamplifier can be in the sensor or in the transmitter. If the sensor

cable has a GREEN wire, the preamplifier is in the sensor. If there is no green wire, the sensor cable will contain a coaxial cable. A coaxial cable is an insulated wire surrounded by a braided metal shield. Depending on the sensor model, the

coaxial cable terminates in either a BNC connector or in a separate ORANGE wire and CLEAR shield.

2.2.5 Changing Switch and Jumper Positions

If the sensor and installation does not match the transmitter default settings in Section 2.2.1, change the settings to the

correct values.

1. Refer to Figure 2-1.

2. Loosen the cover lock nut until the tab disengages from the front cover. Unscrew the cover.

3. Remove the three bolts holding the circuit board stack.

4. Lift out the display board. Do not disconnect the ribbon cable between it and the CPU board. The CPU and analog

boards are joined by a pin and socket connector along the bottom edge of the boards. Carefully disengage the CPU

board from the analog board. The analog board will remain attached to the transmitter body.

Page 23

MODEL 4081 pH/ORP SECTION 2.0

INSTALLATION

9

5. Set the jumpers and the slide switch on the analog board. Refer to Figure 2-2.

a. Temperature element jumper.

Jumper position Temperature element

JP-1 Pt 1000 RTD

JP-2 Pt 100 RTD

JP-3 3K Balco RTD

b. Reference impedance jumper.

Jumper position Reference impedance

JP-6 low

JP-7 high

c. Preamplifier location selection switch.

Move slider toward Preamplifier location

edge of board sensor or junction box

center of board transmitter

FIGURE 2-2. Model 4081 pH/ORP Transmitter Analog Board

DWG. NO. REV.

40308110 H

The transmitter must also be programmed to recognize the

RTD. If pH is being measured, see Section 7.4.3. If ORP is

being measured, see Section 9.3.2.

If sensor diagnostics are to be used with a high impedance

reference electrode, the high impedance must be identified

in the diagnostics setup program. See Section 7.3.3.

Page 24

10

MODEL 4081 pH/ORP SECTION 2.0

INSTALLATION

6. Verify the settings on the CPU board.

Refer to Figure 2-3.

Verify that jumpers JP-1, JP-3, and JP-4

on the CPU board are in the positions

shown in Figure 2-3. The jumpers are

factory set and should not need moving.

For installations where 50 Hz ac power is

present, closing JP-3 may improve immunity of the transmitter to noise.

7. To reassemble the stack, place the display board on the CPU board. Be sure

the display board is properly oriented.

The small window (the infrared detector

for the remote controller) marks the top of

the board. Insert the three bolts through

the holes. Align the bolts with the standoffs on the analog board and position the

display and CPU boards on the analog

board. If the boards are properly aligned,

the bolts will drop in place. Press along

the bottom of the stack to seat the pin

and socket connector. Tighten the bolts.

8. Replace the end cap and lock nut.

2.3 ORIENTING THE DISPLAY BOARD

The display board can be rotated 90 degrees, clockwise or counterclockwise, from the original position. To reposition the

display:

1. Loosen the cover lock nut until the tab disengages from the circuit end cap. Unscrew the cap.

2. Remove the three bolts holding the circuit board stack.

3. Lift and rotate the display board 90 degrees, clockwise or counterclockwise, into the desired position.

4. Position the display board on the stand offs. Replace and tighten the bolts.

5. Replace the circuit end cap.

2.4 MECHANICAL INSTALLATION

2.4.1 General information

1. The transmitter tolerates harsh environments. For best results, install the transmitter in an area where temperature

extremes, vibrations, and electromagnetic and radio frequency interference are minimized or absent.

2. To prevent unintentional exposure of the transmitter circuitry to the plant environment, keep the security lock in place

over the circuit end cap. To remove the circuit end cap, loosen the lock nut until the tab disengages from the end cap,

then unscrew the cover.

3. The transmitter has two 3/4-inch conduit openings, one on each side of the housing. Run sensor cable through the left

side opening (as viewed from the wiring terminal end of the transmitter) and run power wiring through the right side

opening.

FIGURE 2-3. Model 4081 pH/ORP Transmitter CPU Board

DWG. NO. REV.

40008125 A

Page 25

11

MODEL 4081 pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-4. Mounting the Model 4081 pH/ORP Transmitter on a Flat Surface

MILLIMETER

INCH

4. Use weathertight cable glands to keep moisture out of the transmitter.

5. If conduit is used, plug and seal the connections at the transmitter housing to prevent moisture from getting inside the

transmitter.

NOTE

Moisture accumulating in the transmitter housing can affect the performance of the transmitter and may void the warranty.

6. If the transmitter is installed some distance from the sensor, a remote junction box with preamplifier in the junction box

or in the sensor may be necessary. Consult the sensor instruction manual for maximum cable lengths.

2.4.2 Mounting on a Flat Surface.

See Figure 2-4.

Page 26

12

MODEL 4081 pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-5. Using the Pipe Mounting Kit to Attach the Model 4081 pH/ORP Transmitter to a Pipe

MILLIMETER

INCH

2.4.3 Pipe Mounting.

See Figure 2-5. The pipe mounting kit (PN 2002577) accommodates 1-1/2 to 2 in. pipe.

DWG. NO. REV.

40308104 G

DWG. NO. REV.

40308103 C

Page 27

13

MODEL 4081 pH/ORP SECTION 2.0

INSTALLATION

2.5 POWER SUPPLY WIRING

2.5.1 Power Supply Wiring. Refer to

Figures 2-6 and 2-7.

Run the power/signal wiring through the

opening nearest terminals 15 and 16.

Use shielded cable and ground the

shield at the power supply. To ground the

transmitter, attach the shield to the

grounding screw on the inside of the

transmitter case. A third wire can also be

used to connect the transmitter case to

earth ground.

NOTE

For optimum EMI/RFI immunity,

the power supply/output cable

should be shielded and

enclosed in an earth-grounded

metal conduit.

Do not run power supply/signal wiring in

the same conduit or cable tray with AC

power lines or with relay actuated signal

cables. Keep power supply/signal wiring

at least 6 ft (2 m) away from heavy electrical equipment.

FIGURE 2-6. Power Supply Wiring

DWG. NO. REV.

40408117 A

FIGURE 2-7. Typical Fieldbus Network Electrical Wiring Configuration

4081 pH/ORP

Transmitter

4081 pH/ORP

Transmitter

Page 28

14

MODEL 4081 pH/ORP SECTION 3.0

WIRING

SECTION 3.0

WIRING

3.1 GENERAL INFORMATION

pH and ORP sensors manufactured by Rosemount Analytical can be wired to the Model 4081 pH/ORP transmitter in three

ways:

1. directly to the transmitter,

2. to a sensor-mounted junction box and then to the transmitter,

3. to a remote junction box and then from the remote junction box to the transmitter.

The pH (or ORP) signal can also be preamplified in one of four places.

1. in the sensor,

2. in a junction box mounted on the sensor,

3. in a remote junction box.

4. at the transmitter.

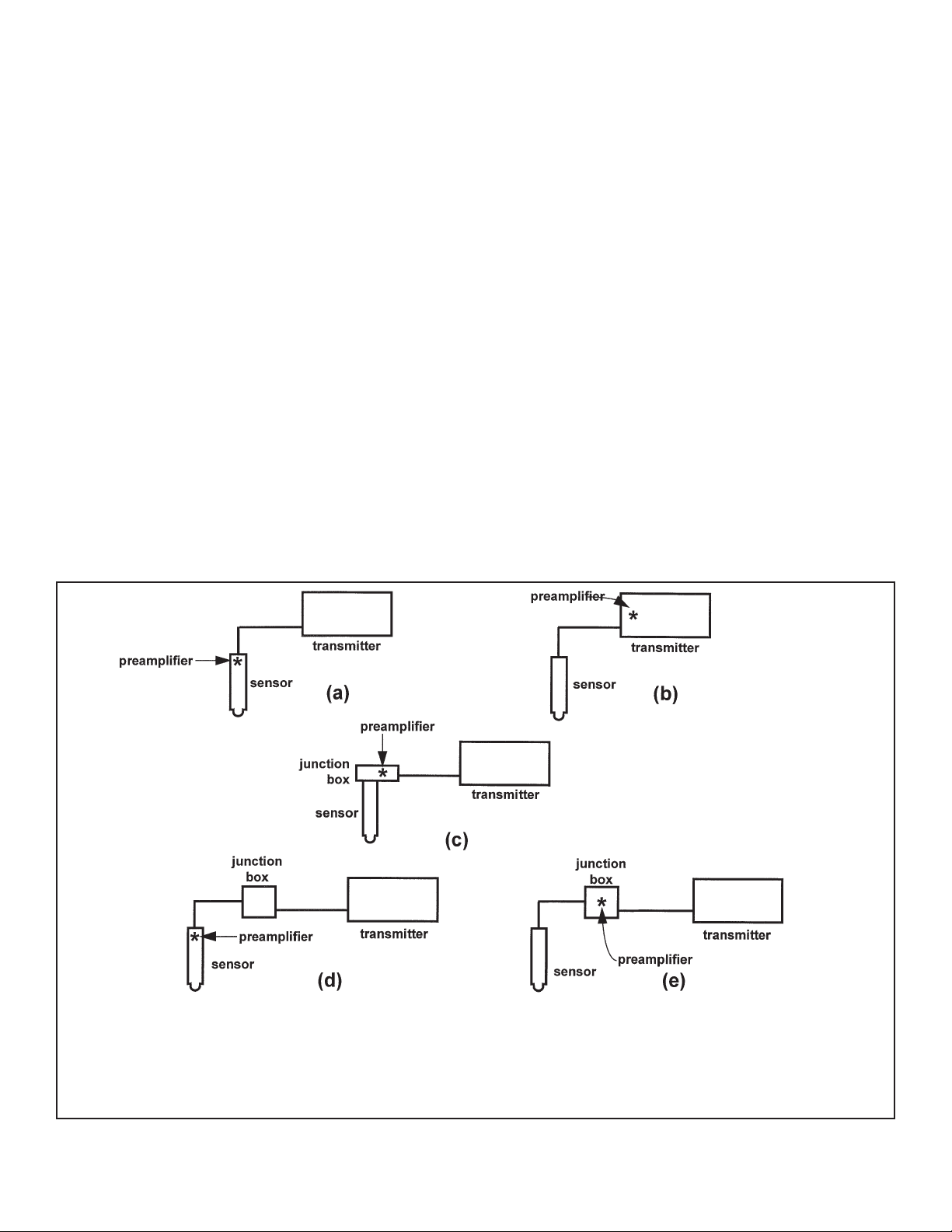

Figure 3-1 illustrates the various arrangements.

3.1 General Information

3.2 Wiring Diagrams

FIGURE 3-1. Wiring and Preamplifier Configurations for pH and ORP Sensors.

The asterisk identifies the location of the preamplifier. In (a) and (b) the sensor is wired directly to the transmitter. The signal is amplified at the sensor (a) or at the transmitter (b). In (c) the sensor is wired through a sensor-mounted junction box to the transmitter.

The preamplifier is in the sensor-mounted junction box. In (d) and (e) the sensor is wired through a remote junction box to the transmitter. The preamplifier is located in the sensor (d) or the junction box (e).

Page 29

15

MODEL 4081 pH/ORP SECTION 3.0

WIRING

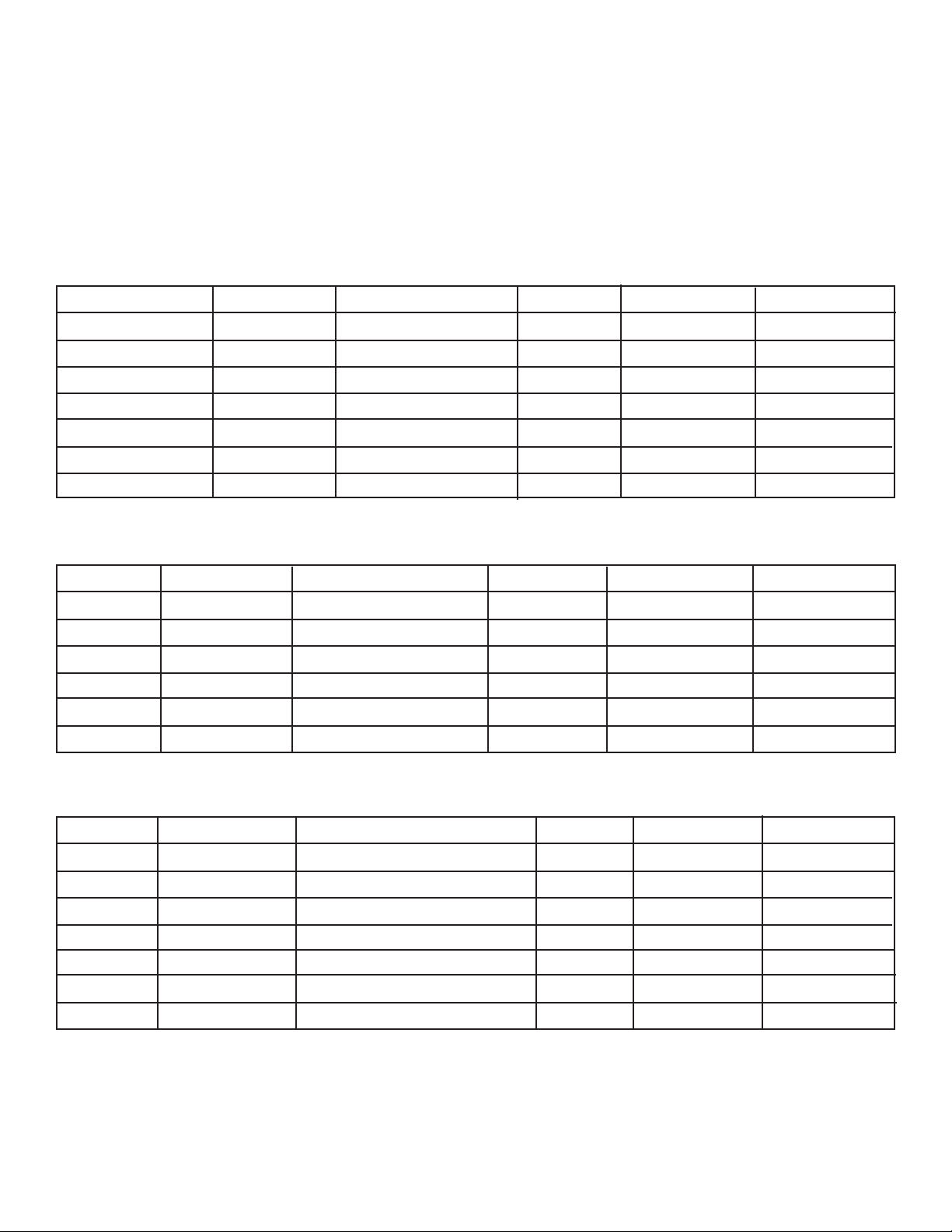

3.2 WIRING DIAGRAMS

Refer to Tables 3-1 through 3-11 to locate the appropriate wire function and wiring diagram. There is a separate table for

each model. The sensor models having the highest number appear first. If you do not know the model number of the

sensor, refer to the flow charts on pages 28 through 30. Only the model option numbers needed to select the cor-

rect wiring diagram are shown. Other numbers are not shown. For all other sensors, see sensor manual.

Table 3-1. Wiring Diagrams for Model 399 sensors

Sensor Junction Box Preamplifier RTD Wire Function Wiring Diagram

399-02 none in transmitter 3K Balco** Figure 3-2 Figure 3-4

399-02 remote in remote junction box 3K Balco** Figure 3-2 Figure 3-5

399-09* none in transmitter Pt 100 Figure 3-2 Figure 3-4

399-09* remote in remote junction box Pt 100 Figure 3-2 Figure 3-5

399-09-62 none in transmitter Pt 100 Figure 3-3 Figure 3-4

399-09-62 remote in remote junction box Pt 100 Figure 3-3 Figure 3-5

399-33 (ORP only) none in transmitter Pt 100 Figure 3-21 Figure 3-22

Table 3-2 Wiring Diagrams for Model 397 Sensors

Sensor Junction Box Preamplifier RTD Wire Function Wiring Diagram

397-50 none in transmitter 3K Balco** Figure 3-6 Figure 3-8

397-50 remote in remote junction box 3K Balco** Figure 3-6 Figure 3-9

397-54* none in transmitter Pt 100 Figure 3-6 Figure 3-8

397-54* remote in remote junction box Pt 100 Figure 3-6 Figure 3-9

397-54-62 none in transmitter Pt 100 Figure 3-7 Figure 3-8

397-54-62 remote in remote junction box Pt 100 Figure 3-7 Figure 3-9

Table 3-3 Wiring Diagrams for Model 396R Sensors

Sensor Junction Box Preamplifier RTD Wire Function Wiring Diagram

396R-50 remote in remote junction box 3K Balco** Figure 3-10 Figure 3-12

396R-50 none in transmitter 3K Balco** Figure 3-10 Figure 3-11

396R-50-60 sensor-mounted in sensor-mounted junction box 3K Balco** Figure 3-6 Figure 3-9

396R-54 none in transmitter Pt 100 Figure 3-10 Figure 3-11

396R-54 remote in remote junction box Pt 100 Figure 3-10 Figure 3-12

396R-54-60 sensor-mounted in sensor-mounted junction box Pt 100 Figure 3-7 Figure 3-9

396R-54-61 sensor-mounted in sensor-mounted junction box Pt 100 Figure 3-10 Figure 3-12

* Sensors have a BNC connector that the Model 4081 pH/ORP transmitter does not accept. Cut off the BNC and terminate

the coaxial cable as shown in Figure 3-23. Alternatively, use a BNC adapter.

** Set the RTD jumper to the 3K position (see Section 2.2). Also, program the transmitter to recognize the 3K RTD (see

Section 7.4.3 for pH or 9.3.2 for ORP).

Page 30

16

MODEL 4081 pH/ORP SECTION 3.0

WIRING

Table 3-4 Wiring Diagrams for Model 396P Sensors

Sensor Junction Box Preamplifier RTD Wire Function Wiring Diagram

396P-01-55 none in sensor Pt 100 Figure 3-13 Figure 3-14

396P-01-55 remote in sensor Pt 100 Figure 3-13 Figure 3-14

396P-02-50 none in transmitter 3K Balco** Figure 3-10 Figure 3-11

396P-02-50 remote in remote junction box 3K Balco** Figure 3-10 Figure 3-12

396P-02-54 none in transmitter Pt 100 Figure 3-10 Figure 3-11

396P-02-54 remote in remote junction box Pt 100 Figure 3-10 Figure 3-12

396P-02-55 none in transmitter Pt 100 Figure 3-10 Figure 3-11

396P-02-55 remote in remote junction box Pt 100 Figure 3-10 Figure 3-12

Table 3-5 Wiring Diagrams for Model 396 Sensor

Sensor Junction Box Preamplifier RTD Wire Function Wiring Diagram

396-50* none in transmitter 3K Balco** Figure 3-6 Figure 3-8

396-50* remote in remote junction box 3K Balco** Figure 3-6 Figure 3-9

396-54* none in transmitter Pt 100 Figure 3-6 Figure 3-8

396-54* remote in remote junction box Pt 100 Figure 3-6 Figure 3-9

396-54-62 none in transmitter Pt 100 Figure 3-7 Figure 3-8

396-54-62 remote in remote junction box Pt 100 Figure 3-7 Figure 3-9

Table 3-6 Wiring Diagrams for Model 389 Sensors

Sensor Junction Box Preamplifier RTD Wire Function Wiring Diagram

389-02-50* none in transmitter 3K Balco** Figure 3-6 Figure 3-8

389-02-50* remote in remote junction box 3K Balco** Figure 3-6 Figure 3-9

389-02-54* none in transmitter Pt 100 Figure 3-6 Figure 3-8

389-02-54* remote in remote junction box Pt 100 Figure 3-6 Figure 3-9

389-02-54-62 none in transmitter Pt 100 Figure 3-7 Figure 3-8

389-02-54-62 remote in remote junction box Pt 100 Figure 3-7 Figure 3-9

* Sensors have a BNC connector that the Model 4081 pH/ORP transmitter does not accept. Cut off the BNC and terminate

the coaxial cable as shown in Figure 3-23. Alternatively, use a BNC adapter (PN 9120531).

** Set the RTD jumper to the 3K position (see Section 2.2). Also, program the transmitter to recognize the 3K RTD (see

Section 7.4.3 for pH or 9.3.2 for ORP).

Page 31

17

MODEL 4081 pH/ORP SECTION 3.0

WIRING

Table 3-7 Wiring Diagrams for Model 385+ Sensors

Sensor Junction Box Preamplifier RTD Wire Functions Wiring Diagram

385+ -02 sensor-mounted in sensor-mounted junction box Pt 100 Figure 3-15 Figure 3-16

385+ -03 none in sensor Pt 100 Figure 3-13 Figure 3-14

385+ -03 remote in sensor Pt 100 Figure 3-13 Figure 3-14

385+ -04 none in transmitter Pt 100 Figure 3-10 Figure 3-11

385+ -04 remote in remote junction box Pt 100 Figure 3-10 Figure 3-12

Table 3-8 Wiring Diagrams for Model 381+ Sensors

Sensor Junction Box Preamplifier RTD Wire Functions Wiring Diagram

381+ -40-55 none in sensor Pt 100 Figure 3-13 Figure 3-14

381+ -43-55 none in sensor Pt 100 Figure 3-13 Figure 3-14

381+ -40-55 remote in sensor Pt 100 Figure 3-13 Figure 3-14

381+ -43-55 remote in sensor Pt 100 Figure 3-13 Figure 3-14

381+ -41-52 none in transmitter Pt 100 Figure 3-10 Figure 3-11

381+ -41-52 remote in remote junction box Pt 100 Figure 3-10 Figure 3-12

Table 3-9 Wiring Diagrams for Model 381pHE and 381pH Sensors

Sensor Junction Box Preamplifier RTD Wire Functions Wiring Diagram

381pHE-30-41-52* none in transmitter 3K Balco** Figure 3-2 Figure 3-4

381pHE-30-41-52* remote in remote junction box 3K Balco** Figure 3-2 Figure 3-5

381pHE-30-42-52 none in transmitter 3K Balco** Figure 3-3 Figure 3-4

381pHE-30-42-52 remote in remote junction box 3K Balco** Figure 3-3 Figure 3-5

381pH-31-41-52* none in transmitter Pt 100 Figure 3-2 Figure 3-4

381pH-31-41-52* remote in remote junction box Pt 100 Figure 3-2 Figure 3-5

381pH-31-42-52 none in transmitter Pt 100 Figure 3-3 Figure 3-4

381pH-31-42-52 remote in remote junction box Pt 100 Figure 3-3 Figure 3-5

Table 3-10 Wiring Diagrams for Model 328A Sensor

Sensor Junction Box Preamplifier RTD Wire Functions Wiring Diagram

328A none in transmitter none Figure 3-17 Figure 3-18

Table 3-11 Wiring Diagrams for Model 320HP Sensor

Sensor Junction Box Preamplifier RTD Wiring Diagram

320-10-55 on mounting plate in transmitter Pt 100 Figure 3-19

320-10-58 on mounting plate in junction box attached to mounting plate Pt 100 Figure 3-20

* Sensors have a BNC connector that the Model 4081 pH/ORP transmitter does not accept. Cut off the BNC and terminate the coax-

ial cable as shown in Figure 3-23. Alternatively, use a BNC adapter (PN 9120531).

** Set the RTD jumper to the 3K position (see Section 2.2). Also, program the transmitter to recognize the 3K RTD (see Section 7.4.3

for pH or 9.3.2 for ORP).

Page 32

18

MODEL 4081 pH/ORP SECTION 3.0

WIRING

REMOVE BNC AND TERMINATE COAXIAL CABLE BEFORE WIRING SENSOR TO

TRANSMITTER. SEE FIGURE 3-23. ALTERNATIVELY, USE A BNC ADAPTER OR

ORDER MODEL OPTION -62 (SENSOR WITH BNC REMOVED AND TERMINATIONS

COMPATIBLE WITH 4081 pH/ORP). IF USING A BNC ADAPTER, THE RED WIRE IS

MV OR pH IN AND THE BLACK WIRE IS REFERENCE IN. TO PREVENT SHORT CIRCUITS TO THE TRANSMITTER HOUSING, INSULATE THE BNC BY WRAPPING IT

WITH ELECTRICAL TAPE.

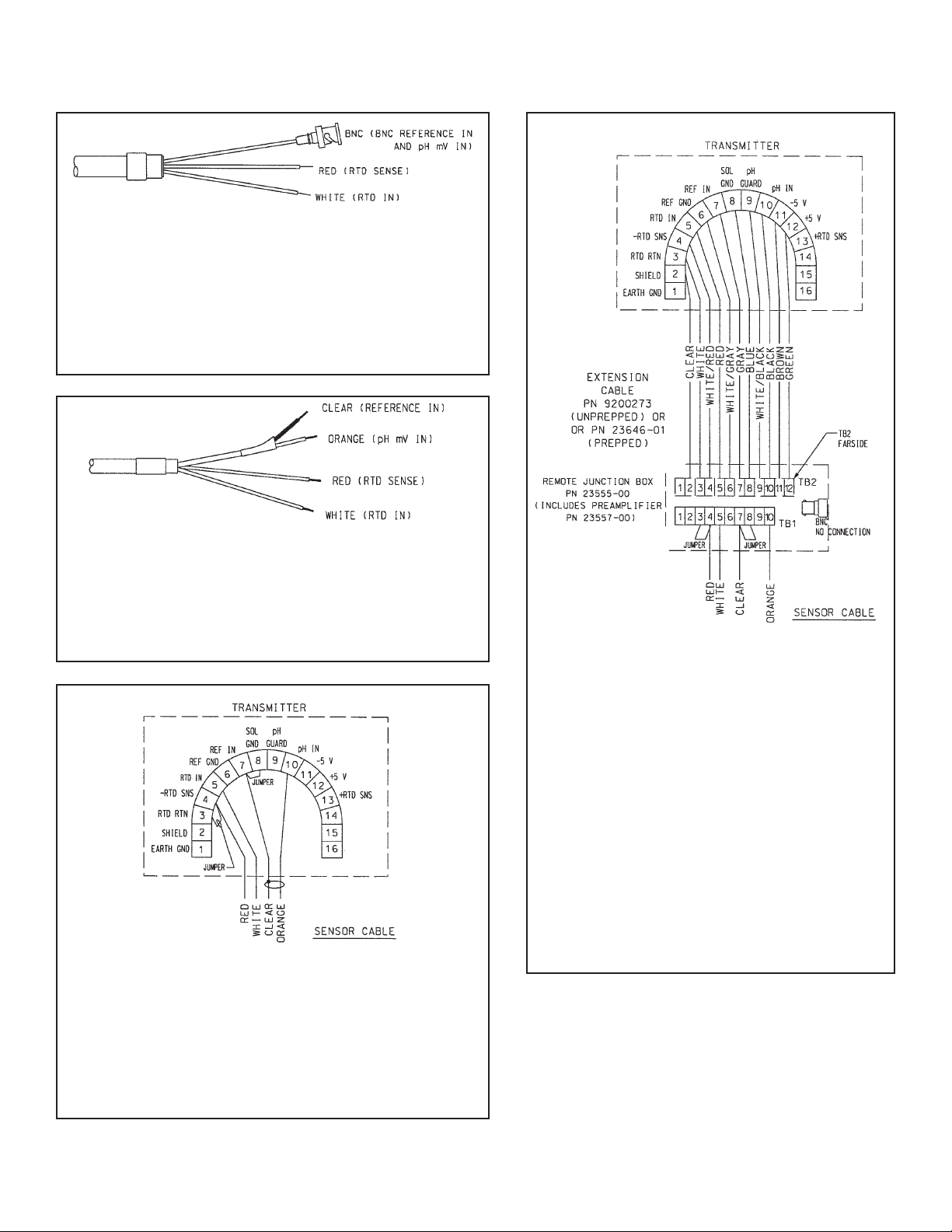

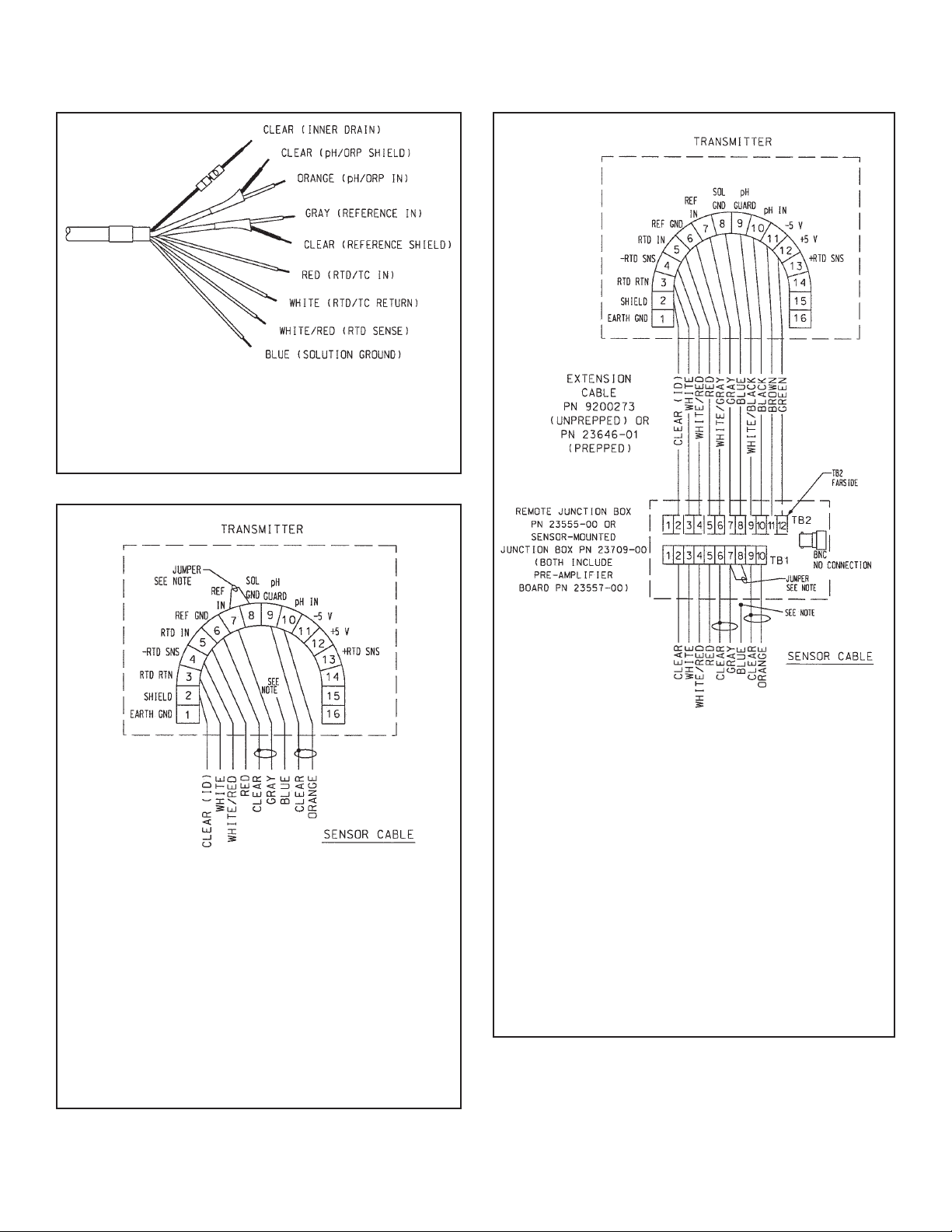

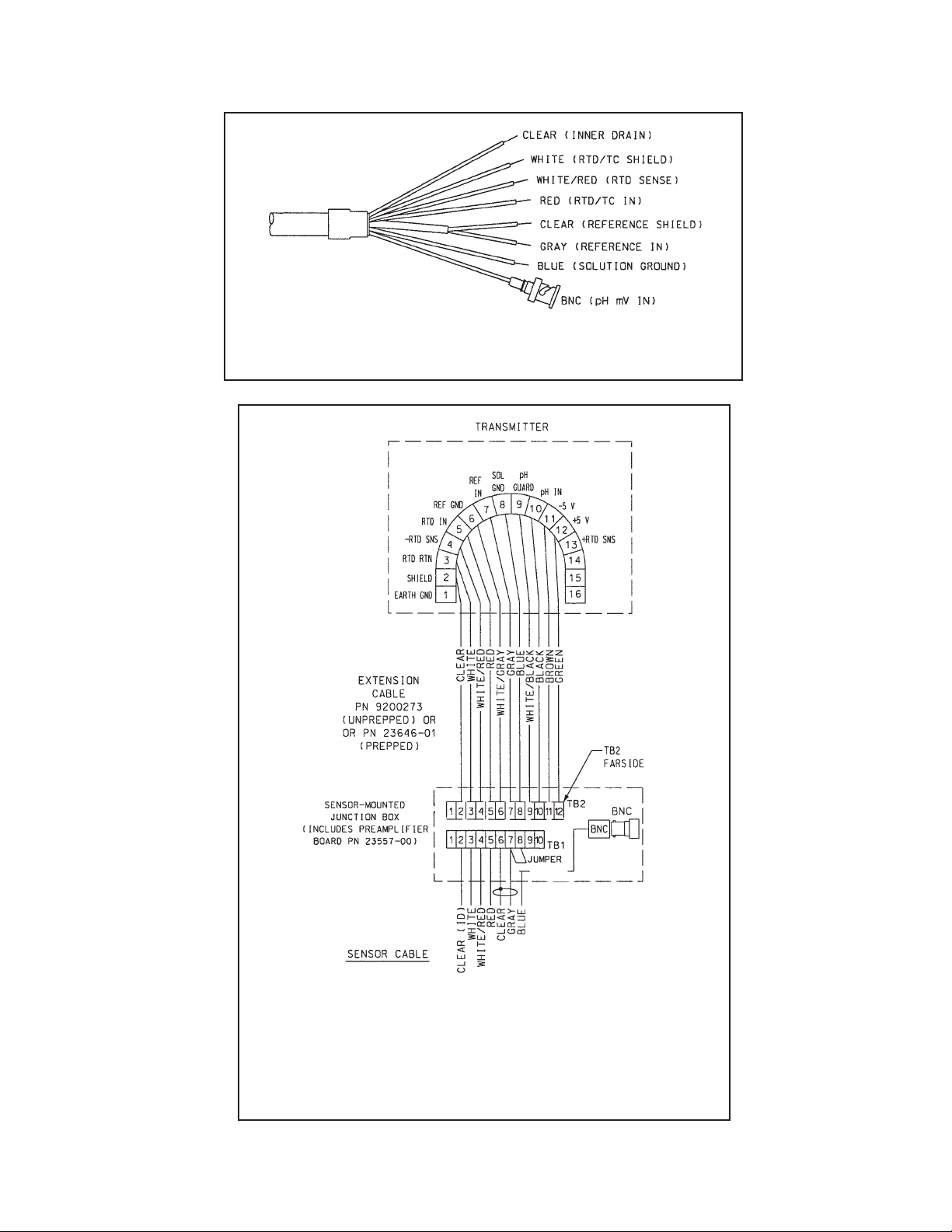

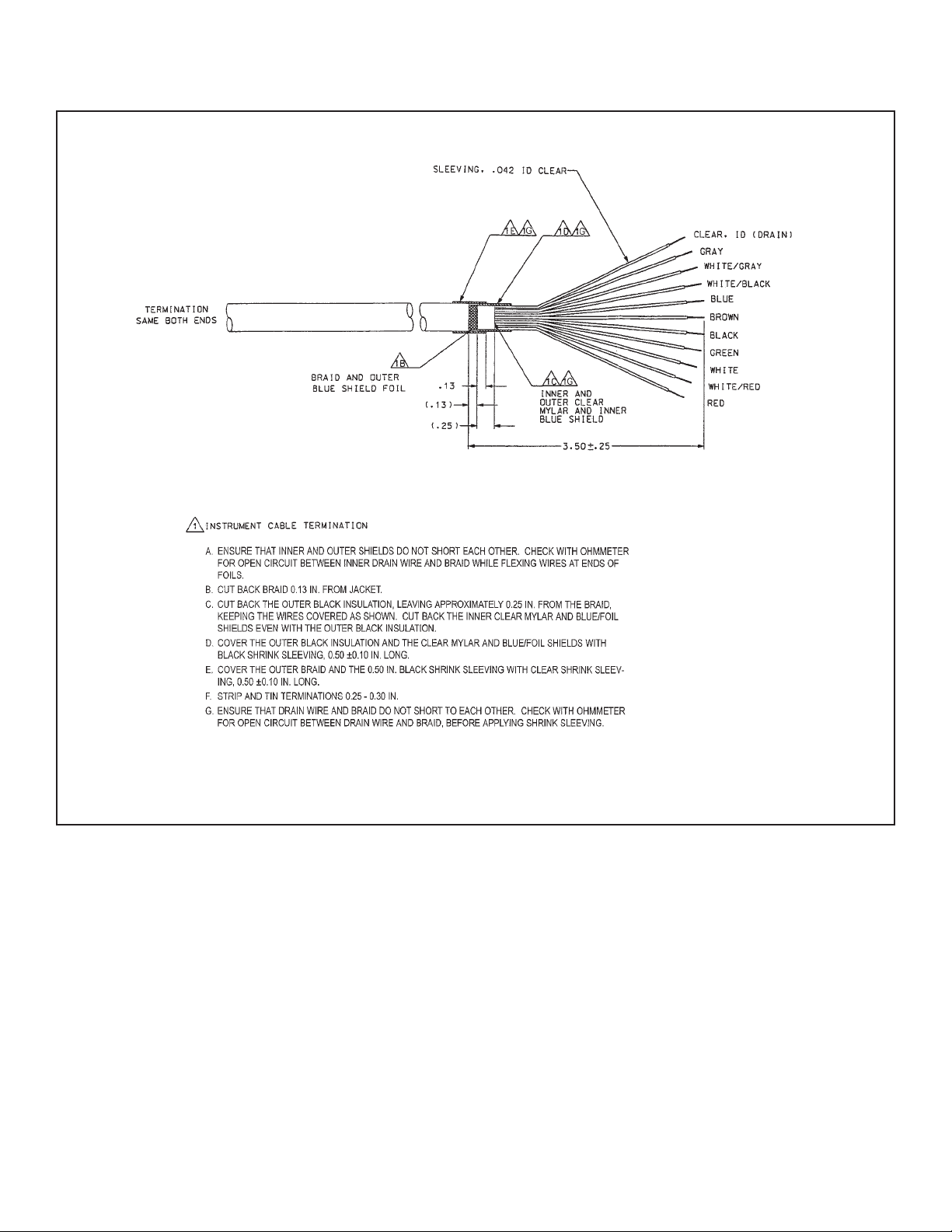

FIGURE 3-2. Wire functions for Models 399-02, 399-09,

381pH-30-41, and 381pHE-31-41 before removing BNC

and terminating cable.