Rosemount 4081FG 2-Wire In Situ O2 Analyzer (550° to 1600°C) with FOUNDATION Fieldbus Communications-Rev 1.2 Manuals & Guides

Page 1

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

Two-Wire In Situ Oxygen Analyzer

(550° to 1600°C) with F

OUNDATION

Fieldbus Communications

http://www.processanalytic.com

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical repre-

sentative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and mainte-

nance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate In-

struction Manual and per applicable local and national codes. Connect all products to the

proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical shock

and personal injury.

The information contained in this document is subject to change without notice.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

Page 3

HIGHLIGHTS OF CHANGES

Effective April, 2001 Rev. 1.0

Page Summary

Throughout Changed all references of 38 in. (965 mm) probe to 34.625 in. (880 mm).

Page 11-2 Added drawing 1400175.

Effective December, 2001 Rev. 1.1

Page Summary

Page 1-3 Updated Product Matrix.

Effective September, 2002 Rev. 1.2

Page Summary

Page 1-8 Updated process temperature limits specification.

Page 4

Page 5

Model 4081FG

PREFACE........................................................................................................................ P-1

Definitions ........................................................................................................................P-1

Safety Instructions .......................................................................................................... P-2

1-0 DESCRIPTION AND SPECIFICATIONS........................................................................ 1-1

1-1 Component Checklist of Typical System (Package Contents) .................................. 1-1

1-2 System Overview............................................................................................................ 1-1

1-3 Specifications................................................................................................................... 1-8

2-0 INSTALLATION .............................................................................................................. 2-1

2-1 Pre-Installation................................................................................................................. 2-1

2-2 Mechanical Installation ................................................................................................... 2-1

2-3 Electrical Installation.....................................................................................................2-10

2-4 Pneumatic Installation .................................................................................................. 2-11

3-0 STARTUP........................................................................................................................ 3-1

3-1 General ............................................................................................................................ 3-1

3-2 Power Up........................................................................................................................ 3-1

3-3 Reestablishing Proper Calibration Check Gas Flow Rate......................................... 3-2

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

TABLE OF CONTENTS

4-0 OPERATION ...................................................................................................................4-1

4-1 General ............................................................................................................................ 4-1

4-2 Program Menu ................................................................................................................4-4

4-3 Diagnostics Menu ........................................................................................................... 4-8

4-4 CALCHECK MENU ...................................................................................................... 4-12

4-5 SIMULATE SWITCH .................................................................................................... 4-15

4-6 SECURITY SWITCH .................................................................................................... 4-15

5-0 MAINTENANCE AND SERVICE .................................................................................. 5-1

5-1 MODEL 4081 ELECTRONICS REPLACEMENT ........................................................... 5-1

5-2 OXYGEN PROBE REPLACEMENT ............................................................................. 5-2

6-0 TROUBLESHOOTING .................................................................................................... 6-1

6-1 GENERAL........................................................................................................................ 6-1

6-2 PROBE LIFE.................................................................................................................... 6-1

6-3 FAULT INDICATIONS .................................................................................................... 6-2

6-4 IDENTIFYING AND CORRECTING FAULT INDICATIONS ....................................... 6-3

7-0 RETURN OF MATERIAL .............................................................................................. 7-1

8-0 REPLACEMENT PARTS ............................................................................................... 8-1

9-0 APPENDICES ................................................................................................................. 9-1

10-0 INDEX............................................................................................................................ 10-1

11-0 DRAWINGS AND SCHEMATICS............................................................................... 11-1

Rosemount Analytical Inc. A Division of Emerson Process Management i

Page 6

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

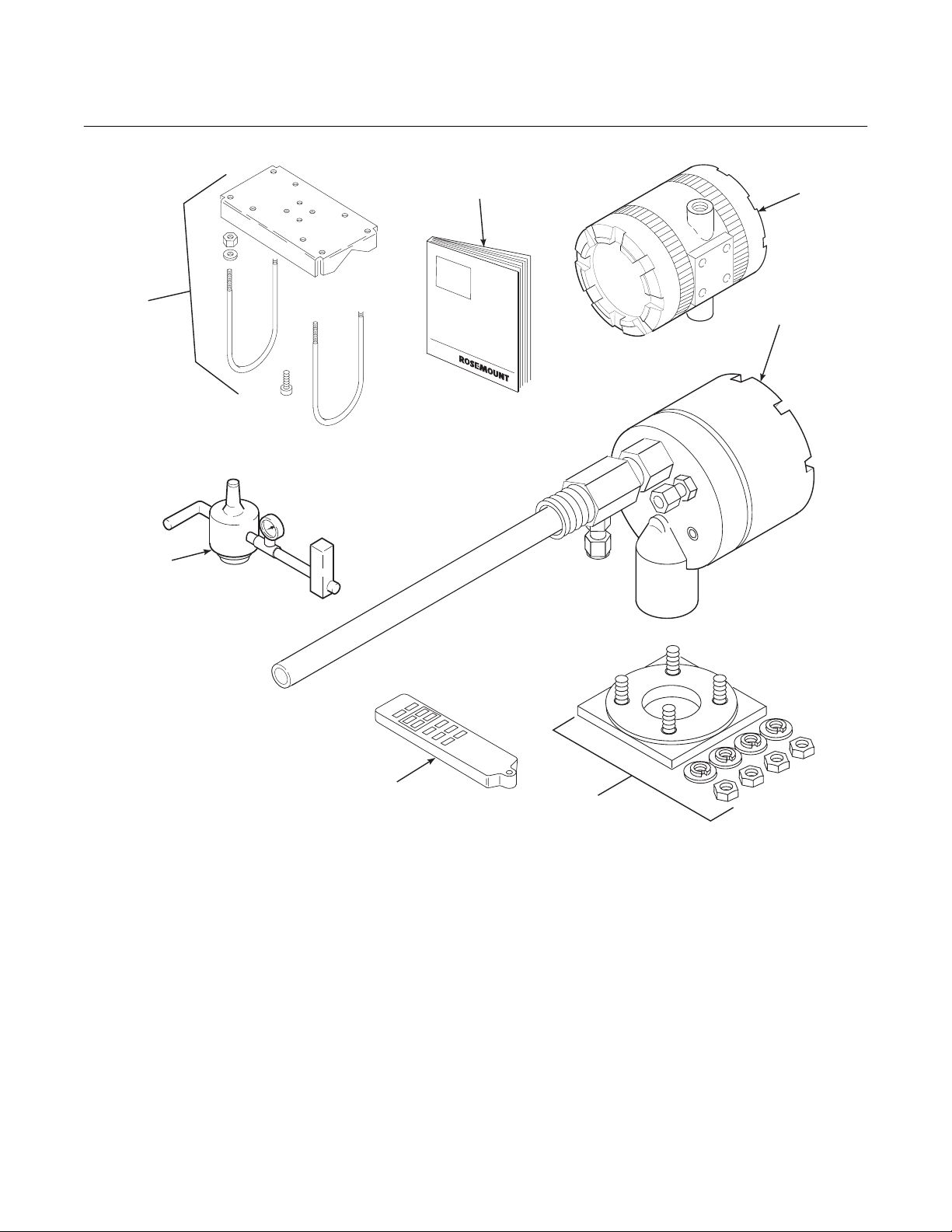

Figure 1-1. Typical System Package ....................................................................................... 1-2

Figure 1-2. Two-Wire In Situ Oxygen Analyzer Fieldbus Connections .................................... 1-7

Figure 1-3. Typical System Installation .................................................................................... 1-7

Figure 2-1. Probe Installation Details ....................................................................................... 2-2

Figure 2-2. Optional Adapter Plate........................................................................................... 2-2

Figure 2-3. Optional Probe Mounting Flange ........................................................................... 2-3

Figure 2-4. Horizontal Probe Installation .................................................................................. 2-4

Figure 2-5. Adjusting Probe Insertion Depth ............................................................................ 2-5

Figure 2-6. Flat Surface Mounting Dimensional Information.................................................... 2-7

Figure 2-7. Pipe Mounting Dimensional Information................................................................ 2-8

Figure 2-8. Display Positioning Assembly................................................................................ 2-9

Figure 2-9. Oxygen Probe Terminal Block ............................................................................. 2-11

Figure 2-10. Model 4081 Transmitter Terminal Block.............................................................. 2-11

Figure 2-11. Oxygen Probe Gas Connections ......................................................................... 2-12

Figure 2-12. Air Set, Plant Air Connection ............................................................................... 2-12

Figure 3-1. Normal Operation Display...................................................................................... 3-1

Figure 3-2. Faulted Operation Display ..................................................................................... 3-1

Figure 3-3. Proper Calibration Check Gas Flow Rate.............................................................. 3-2

Figure 4-1. Normal Operation Display...................................................................................... 4-1

Figure 4-2. Model 4081 Transmitter Menu Tree ...................................................................... 4-2

Figure 4-3. Infrared Remote Control (IRC)............................................................................... 4-3

Figure 4-4. CODE..................................................................................................................... 4-4

Figure 4-5. DISPLAY CODE ................................................................................................... 4-5

Figure 4-6. CELL T HI ............................................................................................................ 4-5

Figure 4-7. RESET MAX CELL T.......................................................................................... 4-6

Figure 4-8. SET O

Figure 4-9. SET HI BOTTLE O

Figure 4-10. SET LO BOTTLE O

Figure 4-11. SET CODE............................................................................................................ 4-8

Figure 4-12. SHOW FAULT ...................................................................................................... 4-8

Figure 4-13. T/C mV................................................................................................................... 4-9

Figure 4-14. O

Figure 4-15. CELL IMPEDANCE............................................................................................. 4-10

Figure 4-16. PREVIOUS SLOPE ............................................................................................ 4-10

Figure 4-17. PREVIOUS CONSTANT .................................................................................... 4-11

Figure 4-18. MAX CELL T ...................................................................................................... 4-11

Figure 4-19. IN MANUAL? ...................................................................................................... 4-12

Figure 4-20. ACCEPT HIGH O

Figure 4-21. ACCEPT LOW O

Figure 4-22. PURGING ............................................................................................................ 4-14

Figure 4-23. SLOPE ................................................................................................................. 4-14

Figure 4-24. CONSTANT ......................................................................................................... 4-14

Figure 4-25. Simulate and Security Switch Positions .............................................................. 4-15

Figure 5-1. Two-Wire In Situ Oxygen Analyzer Exploded View............................................... 5-0

Figure 5-2. Oxygen Probe Terminal Block ............................................................................... 5-3

Figure 6-1. Slope vs. Impedance ............................................................................................. 6-1

Figure 6-2. Speed of Response ............................................................................................... 6-2

Figure 6-3. Faulted Operation Display ..................................................................................... 6-2

Figure 6-4. Model 4081 Transmitter Terminal Block ................................................................ 6-3

Figure 6-5. Fault 1, Open Thermocouple ................................................................................. 6-4

Model 4081FG

LIST OF ILLUSTRATIONS

FILTER TIME......................................................................................... 4-6

2

CELL mV ........................................................................................................ 4-9

2

............................................................................................ 4-7

2

........................................................................................... 4-7

2

............................................................................................. 4-13

2

.............................................................................................. 4-13

2

ii Rosemount Analytical Inc. A Division of Emerson Process Management

Page 7

Model 4081FG

LIST OF ILLUSTRATIONS (CONTINUED)

Figure 6-6. Fault 2, Reversed Thermocouple .......................................................................... 6-4

Figure 6-7. Fault 3, Shorted Thermocouple ............................................................................. 6-5

Figure 6-8. Fault 4, High Probe Temperature .......................................................................... 6-5

Figure 6-9. Fault 5, O

Figure 6-10. Fault 6, Cell Impedance Too High ......................................................................... 6-6

Figure 6-11. Fault 7, Reversed O

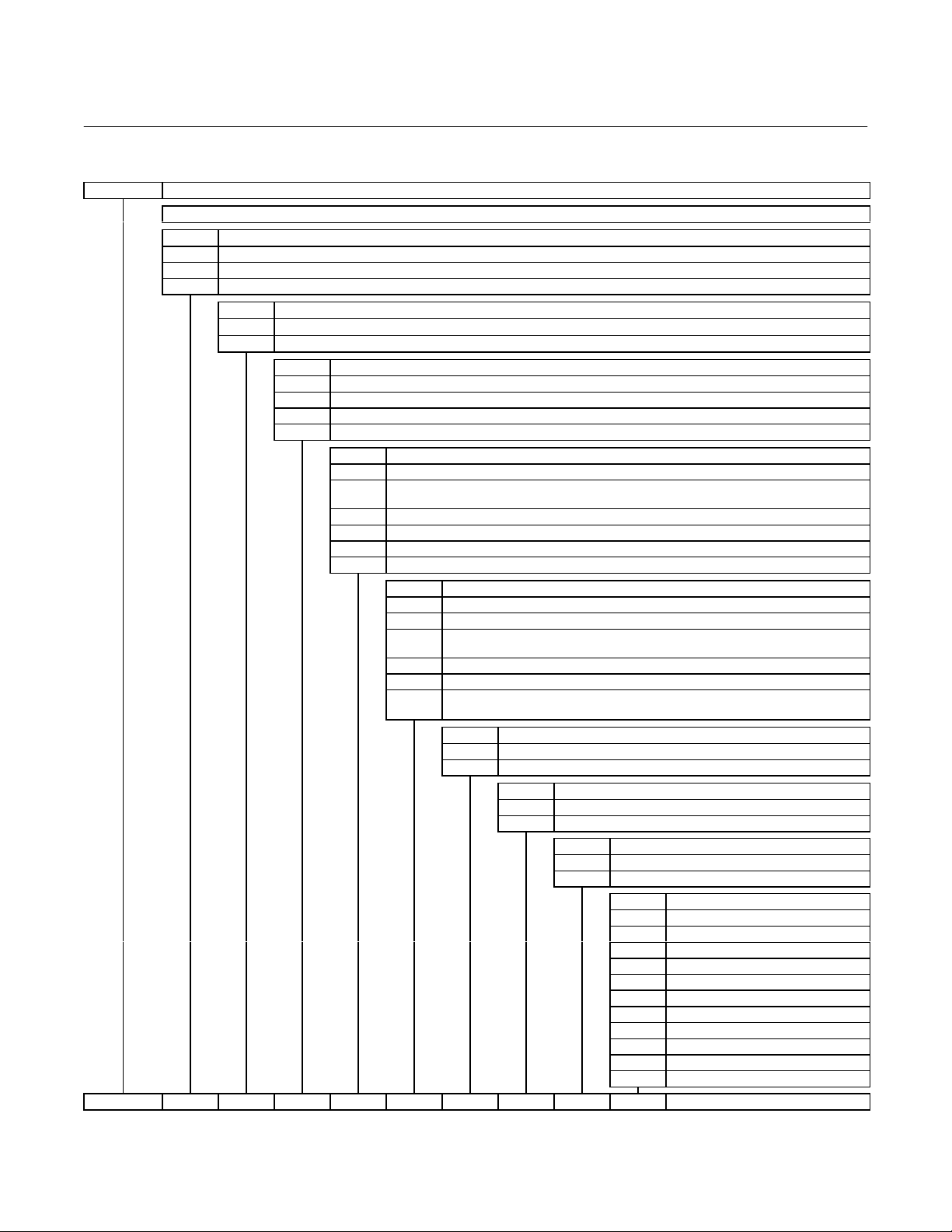

Table 1-1. Product Matrix........................................................................................................ 1-3

Table 1-2. Accessories............................................................................................................ 1-4

Table 1-3. Mounting Adapter................................................................................................... 1-4

Table 4-1. Model 4081 Transmitter Parameters ..................................................................... 4-8

Table 8-1. Replacement Parts List.......................................................................................... 8-1

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Cell Open............................................................................................. 6-6

2

Cell ...................................................................................... 6-7

2

LIST OF TABLES

Rosemount Analytical Inc. A Division of Emerson Process Management iii

Page 8

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

iv Rosemount Analytical Inc. A Division of Emerson Process Management

Page 9

Model 4081FG

The purpose of this manual is to provide information concerning the components, functions, installation and maintenance of this particular NGA 2000 module.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly familiar with the operation of this module before operating it. Read

this instruction manual completely.

The following definitions apply to WARNINGS, CAUTIONS, and NOTES found throughout this

publication.

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

PREFACE

DEFINITIONS

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in injury, death, or long-term

health hazards of personnel.

Highlights an essential operating procedure,

condition, or statement.

: EARTH (GROUND) TERMINAL

: PROTECTIVE CONDUCTOR TERMINAL

: RISK OF ELECTRICAL SHOCK

: WARNING: REFER TO INSTRUCTION BULLETIN

NOTE TO USERS

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in damage to or destruction of

equipment, or loss of effectiveness.

NOTE

The number in the lower right corner of each illustration in this publication is a manual illustration number. It is not a part number, and is not related to the illustration in any technical

manner.

Rosemount Analytical Inc. A Division of Emerson Process Management P-1

Page 10

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

FOR THE WIRING AND INSTALLATION

The following safety instructions apply specifically to all EU member states. They should

be strictly adhered to in order to assure compliance with the Low Voltage Directive. NonEU states should also comply with the following unless superseded by local or National

Standards.

1. Adequate earth connections should be made to all earthing points, internal and external,

where provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced.

The integrity of all earth terminals must be maintained at all times.

3. Mains supply cords should comply with the requirements of IEC227 or IEC245.

Model 4081FG

IMPORTANT

SAFETY INSTRUCTIONS

OF THIS APPARATUS

4. All wiring shall be suitable for use in an ambient temperature of greater than 75°C.

5. All cable glands used should be of such internal dimensions as to provide adequate cable

anchorage.

6. To ensure safe operation of this equipment, connection to the mains supply should only be

made through a circuit breaker which will disconnect all circuits carrying conductors during a

fault situation. The circuit breaker may also include a mechanically operated isolating switch.

If not, then another means of disconnecting the equipment from the supply must be provided

and clearly marked as such. Circuit breakers or switches must comply with a recognized

standard such as IEC947. All wiring must conform with any local standards.

7. Where equipment or covers are marked with the symbol to the right, hazard-

ous voltages are likely to be present beneath. These covers should only be

removed when power is removed from the equipment — and then only by

trained service personnel.

8. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain surfaces may remain hot to the touch.

9. Where equipment or covers are marked with the symbol to the right, refer to

the Operator Manual for instructions.

10. All graphical symbols used in this product are from one or more of the follow-

ing standards: EN61010-1, IEC417, and ISO3864.

P-2 Rosemount Analytical Inc. A Division of Emerson Process Management

Page 11

Model 4081FG

1

DESCRIPTION AND SPECIFICATIONS

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

SECTION 1

1-1 COMPONENT CHECKLIST OF TYPICAL

SYSTEM (PACKAGE CONTENTS)

A typical Rosemount Two-Wire In Situ Oxygen

Analyzer should contain the items shown in

Figure 1-1. Record the part number, serial number, and order number for each component of

your system in the table located on the first

page of this manual. Also, use the product matrix in Table 1-1 to compare your order number

against your unit. The first part of the matrix defines the model. The last part defines the various options and features of the analyzer.

Ensure the features and options specified by

your order number are on or included with the

unit.

1-2 SYSTEM OVERVIEW

a. Scope

This Instruction Bulletin is designed to supply details needed to install, start up, operate, and maintain the Rosemount Two-Wire

In Situ Oxygen Analyzer. The analyzer consists of an oxygen probe and Model 4081

Transmitter. Integral signal conditioning

electronics outputs a digital F

fieldbus signal representing an O2 value. An

infrared remote control (IRC) allows access

to setup, calibration, and diagnostics. This

same information, plus additional details,

can be accessed via fieldbus digital

communications.

OUNDATION

OUNDATION

b. F

FOUNDATION fieldbus is an all digital, serial, two-way communication system that

inter-connects field equipment such as sensors, actuators, and controllers. Fieldbus is

a Local Area Network (LAN) for instruments

used in both process and manufacturing

automation with built-in capacity to distribute the control application across the network. The fieldbus environment is the base

level group of digital networks in the hierarchy of planet networks.

The fieldbus retains the desirable features

of the 4-20 mA analog system, including a

standardized physical interface to the wire,

bus powered devices on a single wire, and

intrinsic safety options, and enables additional capabilities, such as:

• Increased capabilities due to full digital

communications

• Reduced wiring and wire terminations

due to multiple devices on one set of

wires

• Increased selection of suppliers due to

inter-operability

• Reduced loading on control room

equipment with the distribution of some

control and input/output functions to field

devices

• Speed options for process control and

manufacturing applications

Fieldbus Technology

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

Page 12

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

1

7

6

2

3

5

1. Instruction Bulletin

2. Model 4081 Transmitter

3. Oxygen Probe

4. Adapter Plate with Mounting Hardware

and Gasket (Optional)

5. Infrared Remote Control (IRC) (Optional)

6. Reference Air Set (Optional)

7. Pipe Mounting Kit (Optional)

4

29760001

Figure 1-1. Typical System Package

1-2 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 13

Instruction Manual

1

IB-106-4081 Rev. 1.2

Model 4081FG

Table 1-1. Product Matrix

4081FG Model 4081FG In Situ Oxygen Analyzer with FOUNDATION Fieldbus Communications

Model 4081FG Oxygen Analyzer - Instruction Book

Code Sensing Probe Length

1 20 in. (508 mm) probe, 1/4 in. tube fittings

2 26 in. (660 mm) probe, 1/4 in. tube fittings

3 38 in. (965 mm) probe, 1/4 in. tube fittings

Code Probe Outer Tube Material - Maximum Operating Temperature

1 Alumina - 2912°F (1600°C) maximum - 1.25 NPT mounting

2 Inconel 600 - 1832°F (1000°C) maximum - 1.25 NPT mounting

Code Mounting Adapter - Stack Side

0 No adapter plate required uses 1.25 NPT (“0” must also be chosen under “Mounting Adapter” probe side)

1 New flanged installation - Square weld plate with studs (matches “Mounting Adapter” probe side)

2 Model 450 mounting (“4” must also be chosen under “Mounting Adapter” probe side)

3 Competitor's Mount (“5” must also be chosen under “Mounting Adapter” probe side)

Code Mounting Adapter - Probe Side

0 No adapter plate

1 ANSI 2 in. 150 lb flange to 1.25 NPT adapter

(6 in. dia. Flange, 4.75 in. BC with 4 x 0.75 in. dia. holes)

2 DIN to 1.25 NPT adapter (184 mm flange, 145 mm BC with 4 x 18 mm dia. holes)

3 JIS to 1.25 NPT adapter (155 mm flange, 130 mm BC with 4 x 13 mm dia. holes)

4 Model 450 to 1.25 NPT adapter

5 Competitor’s mounting flange

Code Electronics & Housing - Intrinsically Safe, NEMA 4X, IP65

1 4081 F

2 4081 F

3

4 4081 F

5 4081 F

6

4081FG2100111211 Example

OUNDATION

OUNDATION

OUNDATION

4081 F

Suite

OUNDATION

OUNDATION

4081 F

OUNDATION

Control Suite

Code Housing Mounting

0 Surface or wall mounting

1 1/2 to 2 in. pipe mounting

Fieldbus Electronics - CENELEC EEx ia IIC T5 with Control Suite

Fieldbus Electronics - CSA pending, with Control Suite

Fieldbus Electronics-FM Class I, Div. I, Groups B,C,D with Control

Fieldbus Electronics - CENELEC EEx ia IIC T5 without Control Suite

Fieldbus Electronics - CSA pending, without Control Suite

Fieldbus Electronics-FM Class I, Div. I, Groups B,C,D without

Code Communications

0 No remote control

1 Infrared Remote Control (IRC) (LCD display through cover)

Code Calibration Accessories

1 No hardware

2 Reference air flowmeters and pressure regulator

Code Armored Cable Length

00 No cable

11 20 ft (6 m)

12 40 ft (12 m)

13 60 ft (18 m)

14 80 ft (24 m)

15 100 ft (30 m)

16 150 ft (45 m)

17 200 ft (61 m)

18 300 ft (91 m)

19 400 ft (122 m)

20 500 ft (152 m)

September, 2002

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-3

Page 14

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Table 1-2. Accessories

Part No. Description

1A99135H01 Armored cable, bulk, uncut, no connectors 100’ minimum.

1A99135H02 Unarmored cable, bulk, uncut, no connectors 100’ minimum.

Order as separate items.

Table 1-3. Mounting Adapter

Type Description

Plate with studs Bolt circle diameter, number and arrangement of studs, stud thread, stud height

above mounting plate.

Plate without studs Bolt circle diameter, number and arrangement of holes, thread, depth of stud

mounting plate with accessories.

Where possible specify SPS number; otherwise provide details of the existing mounting plate.

Model 4081FG

c. System Description

The Rosemount Two-Wire In Situ Oxygen

Analyzer is designed to measure the net

concentration of oxygen in an industrial process; i.e., the oxygen remaining after all fuels have been oxidized. The oxygen probe

is permanently positioned within an exhaust

duct or stack and performs its task without

the use of a sampling system. The Model

4081 Transmitter is mounted remotely and

conditions the oxygen probe outputs.

The equipment measures oxygen percentage by reading the voltage developed

across an electrochemical cell, which consists of a small yttria-stabilized, zirconia

disc. Both sides of the disc are coated with

porous metal electrodes. The millivolt output

voltage of the cell is given by the following

Nernst equation:

EMF = KT log

10(P1/P2

) + C

Where:

1. P

is the partial pressure of the oxygen

2

in the measured gas on one side of the

cell.

2. P

is the partial pressure of the oxygen

1

in the reference air on the opposite side

of the cell.

3. T is the absolute temperature.

4. C is the cell constant.

5. K is an arithmetic constant.

NOTE

For best results, use clean, dry, instrument air (20.95% oxygen) as the

reference air.

NOTE

The probe uses a Type B thermocouple to measure the cell temperature.

When the cell is at 550°C to 1600°C

(1022°F to 2912°F) and there are unequal

oxygen concentrations across the cell, oxygen ions will travel from the high oxygen

partial pressure side to the low oxygen partial pressure side of the cell. The resulting

logarithmic output voltage is approximately

50 mV per decade.

The output is proportional to the inverse

logarithm of the oxygen concentration.

Therefore, the output signal increases as

the oxygen concentration of the sample gas

decreases. This characteristic enables the

Rosemount Two-Wire In Situ Oxygen Analyzer to provide exceptional sensitivity and

accuracy at low oxygen concentrations.

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 15

Model 4081FG

1

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Oxygen analyzer equipment measures net

oxygen concentration in the presence of all

the products of combustion, including water

vapor. Therefore, it may be considered an

analysis on a “wet” basis. In comparison

with older methods, such as the portable

apparatus, which provides an analysis on a

“dry” gas basis, the “wet” analysis will, in

general, indicate a lower percentage of

oxygen. The difference will be proportional

to the water content of the sampled gas

stream.

d. System Configuration

The equipment discussed in this manual

consists of two major components: the oxygen probe and the Model 4081 Transmitter.

Oxygen probes are available in three length

options, providing in situ penetration appropriate to the size of the stack or duct. The

options on length are 20 in. (508 mm), 26

in. (660 mm), or 38 in. (965 mm).

The Model 4081 Transmitter is a two-wire

transmitter providing an output proportional

to the measured oxygen concentration. A

customer-supplied 24 VDC power source is

required to provide power to the electronics.

The transmitter accepts millivolt signals

generated by the probe and produces the

outputs to be used by other remotely connected devices. The output is a FOUNDATION fieldbus digital communication signal.

e. System Features

1. The cell output voltage and sensitivity

increase as the oxygen concentration

decreases.

2. High process temperatures eliminate

the need for external cell heating and

increase cell accuracy.

3. FOUNDATION fieldbus is standard.

4. Easy probe replacement due to the

lightweight, compact probe design.

5. Remote location of the Model 4081

Transmitter removes the electronics

from high temperature or corrosive

environments.

6. Power is supplied to the electronics

through the FOUNDATION fieldbus

digital signal line for intrinsic safety (IS)

purposes.

7. Infrared remote control (IRC) allows

inter-facing without exposing the

electronics.

8. An operator can operate and diagnostically troubleshoot the Two-Wire In

Situ Oxygen Analyzer in one of two

ways:

(a) Infrared Remote Control. The IRC

allows access to fault indication

menus on the Model 4081 Transmitter LCD display. Calibration can

be performed from the IRC keypad.

(b) FOUNDATION fieldbus Interface.

The transmitter’s output carries a

signal containing the oxygen level

encoded in digital format. This

digital output can also be used to

communicate with the oxygen

analyzer and access all of the oxygen analyzer status information.

9. Selected Distributed Control Systems The use of distributed control systems

requires input/output (I/O) hardware

and AMS Security codes are provided

(by infrared remote control) to prevent

unintended changes to analyzers adjacent to the one being accessed.

10. A calibration check procedure is provided to determine if the Rosemount

Two-Wire In Situ Oxygen Analyzer is

correctly measuring the net oxygen

concentration in the industrial process.

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-5

Page 16

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

f. Handling the Analyzer

The probe was specially packaged to prevent breakage due to handling. Do not remove the padding material from the probe

until immediately before installation.

It is important that printed circuit

boards and integrated circuits are

handled only when adequate antistatic

precautions have been taken to prevent possible equipment damage.

The oxygen probe is designed for industrial applications. Treat with care

to avoid physical damage. The probe

contains components made from ceramic, which are susceptible to shock

when mishandled. THE WARRANTY

DOES NOT COVER DAMAGE FROM

MISHANDLING.

temperatures, environmental considerations, convenience, and serviceability

Figure 1-2 shows the FOUNDATION Fieldbus communications interface. A typical

system installation is illustrated in Figure

1-3.

A source of instrument air is required at the

oxygen probe for reference air use. Since

the Two-Wire In Situ Oxygen Analyzer is

equipped with an in-place calibration feature, provisions should be made for connecting calibration check gas tanks to the

oxygen probe during calibration.

If the calibration check gas bottles are to be

permanently connected, a check valve is

required next to the calibration fittings on

the integral electronics.

This check valve is to prevent breathing of

calibration check gas line and subsequent

flue gas condensation and corrosion. The

check valve is in addition to the stop valve

in the calibration check gas kit.

g. System Considerations

Prior to installing your Rosemount Two-Wire

In Situ Oxygen Analyzer, make sure you

have all the components necessary to make

the system installation. Ensure all the components are properly integrated to make the

system functional.

After verifying that you have all the components, select mounting locations and determine how each component will be placed in

terms of available line voltage, ambient

NOTE

The electronics of the Model 4081

Transmitter is rated NEMA 4X (IP65)

and is capable of operating at temperatures up to 65°C (149°F).

NOTE

Retain the packaging in which the

Rosemount Two-Wire In Situ Oxygen

Analyzer arrived from the factory in

case any components are to be

shipped to another site. This packaging has been designed to protect the

product.

1-6 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 17

Model 4081FG

1

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

TWO-WIRE IN SITU

OXYGEN ANALYZER

CALIBRATION CHECK

GAS LINE

Figure 1-2. Two-Wire In Situ Oxygen Analyzer Fieldbus Connections

GASES

STACK

REFERENCE

AIR LINE

OmV

2

SIGNAL

MODEL 4081

TRANSMITTER

TEMPERATURE

mV SIGNAL

DUCT

DIGITAL OUTPUT

FIELDBUS

(TWISTED PAIR)

INTRINSIC

SAFETY

BARRIER

(OPTIONAL)

FIELDBUS

COMPUTER TERMINAL

29760002

OXYGEN

PROBE

MODEL 4081

TRANSMITTER

OPTIONAL

ADAPTER

PLATE

FLOWMETER

FIELDBUS

DIGITAL SIGNAL

PRESSURE

REGULATOR

Figure 1-3. Typical System Installation

INSTRUMENT

AIR SUPPLY

(REFERENCE AIR)

29760003

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-7

Page 18

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

1-3 SPECIFICATIONS

Net O

Range ...................................................... 0 to 25% O2 Fully Field Selectable via the FOUNDATION

2

Fieldbus Interface

Lowest Limit................................................... 0.05% O

Highest Limit.................................................. 25.00% O

2

2

Accuracy.............................................................. ±1.5% of reading or 0.05% O2, whichever is greater

System Response to Calibration Check Gas...... Initial response in less than 3 seconds

T90 in less than 10 seconds

Probe

Lengths................................................................ 20 in. (508 mm)

26 in. (660 mm)

34.625 in. (880 mm)

Temperature Limits

Process Temperature Limits ......................... 550° to 1400°C (1022° to 2552°F)

Operation to 1600°C (2912°F) with reduced cell life.

Ambient ......................................................... -40° to 149°C (-40° to 300°F) Ambient

Mounting and Mounting Position......................... Vertical or Horizontal

Materials of Construction - Process Wetted Parts

Inner Probe ............................................. Zirconia

Outer Protection Tube............................. Alumina [1600°C (2912°F) limit]

Inconel 600 [1000°C (1832°F) limit]

Probe Junction Box................................. Cast aluminum

Speed of Installation/Withdrawal......................... 1 in. (25.4 mm) per minute

Hazardous Area Certification .............................. Intrinsically safe per EN50 014 (1977), clause 1.3

(pending)

Reference Air Requirement................................. 100 ml per minute (0.2 scfh) of clean, dry instrument air;

1/4 in. tube fittings

Calibration Check Gas Fittings............................ 1/4 in. tube fittings

Cabling ................................................................ Two twisted pairs, shielded

Electronics

Enclosure ............................................................ IP65 (NEMA 4X), weatherproof, and corrosion-resistant

Materials of Construction .................................... Low copper aluminum

Ambient Temperature Limits ............................... -20° to 65°C (-4° to 149°F)

Relative Humidity ................................................ 95% with covers sealed

Inputs (from O

Probe) ........................................ Two wires - O2 signal, Two wires - type B thermocouple

2

Output ................................................................ FOUNDATION Fieldbus digital signal

Fieldbus Logic Function Blocks

Two AI Blocks: Execution Rate .................... 75mS

PID Block: Execution Rate ........................... 150mS

Fieldbus Segment Power Consumption ............. 30mA max, 30VDC max

Hazardous Area Certification .............................. Cenelec EEx ia IIC T4 or T5(2) (pending)

NEC Class I Div.I Group B,C,D (pending)

Fisher-Rosemount has satisfied all obligations coming from the

European legislation to harmonize the product requirements in Europe.

Power Transient Protection ................................. IEC 801-4

Shipping Weight .................................................. 10 lbs (4.5 kg)

Infrared Remote Control

Power Requirements........................................... Three AAA batteries

Hazardous Area Certification .............................. Cenelec EEx ia IIC Class I, Div. I, Group A, B, C, D

(1)

Thermocouple and O2 probe cell are both unpowered, developing a millivolt emf, and are considered a “simple apparatus” by certifying agencies.

(2)

Dependent on ambient temperature limits.

Model 4081FG

(1)

1-8 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 19

Model 4081FG

2

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

SECTION 2

INSTALLATION

2-1 PRE-INSTALLATION

a. Inspect

Carefully inspect the shipping container for

any evidence of damage. If the container is

damaged, notify the carrier immediately.

b. Packing List

Confirm all items shown on the packing list

are present. Notify Rosemount Analytical

immediately if items are missing.

Before installing this equipment, read

the “Safety instructions for the wiring

and installation of this apparatus” at

the front of this Instruction Bulletin.

Failure to follow the safety instructions could result in serious injury or

death.

2-2 MECHANICAL INSTALLATION

Avoid installation locations near

steam soot blowers.

the process gas temperature falls within

a range of 550° to 1600°C (1022° to

2912°F). Figure 2-1 provides mechanical installation references.

2. Check the flue or stack for holes and

air leakage. The presence of this condition will substantially affect the accuracy of the oxygen reading. Therefore,

either make the necessary repairs or

install the probe up-stream of any

leakage.

3. Ensure the area is clear of internal and

external obstructions that will interfere

with installation and maintenance access to the probe. Allow adequate

clearance for probe removal (Figure

2-1).

b. Installing Oxygen Probe

The probe was specially packaged to

prevent breakage due to handling. Do

not remove the padding material from

the probe until immediately before installation.

1. Ensure all components are available to

a. Locating Oxygen Probe

1. The location of the oxygen probe in the

stack or flue is important for maximum

accuracy in the oxygen analyzing process. The probe must be positioned so

the gas it measures is representative of

the process. Best results are normally

obtained if the probe is positioned near

the center of the duct (40-60% insertion).

Longer ducts may require several analyzers since the O

stratification. A point too near the wall of

the duct, or the inside radius of a bend,

may not provide a representative sample

because of the very low flow conditions.

The sensing point should be selected so

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-1

can vary due to

2

Leave the probe inner protective cover

in place until installation. This is required to protect the ceramic cell during movement.

install the probe.

NOTE

2. If using an optional adapter plate

(Figure 2-2) or an optional mounting

flange (Figure 2-3), weld or bolt the

component onto the duct. The through

hole in the stack or duct wall and refractory material must be 2 in. (50.8

mm) diameter, minimum.

Page 20

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

Figure 2-1. Probe Installation Details

A

B

C

NOTE: DIMENSIONS ARE

IN INCHES WITH

MILLIMETERS IN

PARENTHESES.

DIMENSION

“B” THREAD 0.625-11 M-16x2 M-12x1.75

“C” DIA. 4.75 (121) 5.71 (145) 5.12 (130)

METAL WALL

STACK OR DUCT

A

WELD OR BOLT ADAPTER

PLATE TO STACK OR DUCT.

JOINT MUST BE AIR TIGHT.

PLATE DIMENSIONS

ANSI

4512C34G01

“A” 6.00 (153) 7.5 (191) 6.50 (165)

2.50 (63.5)

MIN. DIA.

JOINT MUST

BE AIR TIGHT

DIN

4512C36G01

MASONRY WALL

STACK

3.00 SCHEDULE 40

PIPE SLEEVE

SUPPLIED BY CUSTOMER

JIS

4512C35G01

WELD PIPE TO

ADAPTER PLATE

3.50 (89)

O.D. REF

29750002

Figure 2-2. Optional Adapter Plate

2-2 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 21

Model 4081FG

2

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

TAP 1.25 NPT

B

A

C

FLANGE DIMENSIONS

ANSI

DIMENSION

“A” DIA. 6.00 (153) 7.28 (185) 6.10 (155) 9.00 (229)

“B” DIA. 0.75 (20) 0.71 (18) 0.59 (15) 0.50 (13)

“C” DIA. 4.75 (121) 5.71 (145) 5.12 (130) 7.68 (195)

5R10158H01

DIN

5R10158H02

0.50 (12.7)

NOTE: DIMENSIONS ARE IN

INCHES WITH MILLIMETERS

IN PARENTHESES.

JIS

5R10158H03

MODEL 450

5R10158H04

29750003

Figure 2-3. Optional Probe Mounting Flange

3. If the optional adapter plates are not

used, a 2 in. NPT, schedule 40, pipe

nipple (Figure 2-4) should be welded to

the stack or duct wall.

When a 2 in. NPT to 1.25 NPT adapter

is threaded to the welded pipe nipple,

the adapter provides the pipe threads

needed for the probe’s process fitting.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-3

Page 22

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

STACK OR DUCT

METAL WALL

WELD PIPE TO

METAL WALL

2.0 IN. (51 mm)

MIN. DIA.

REFRACTORY

SCHEDULE 40

STACK OR DUCT

METAL WALL

ADAPTER

2 IN. NPT

PIPE

1.25 NPT

CUSTOMER

SUPPLIED

ADAPTER

INSULATE IF EXPOSED

TO AMBIENT WEATHER

CONDITIONS

2 IN. NPT

SCHEDULE 40

PIPE

CALIBRATION

CHECK

GAS LINE

REFERENCE

AIR LINE

SYSTEM

CABLE

29750004

Figure 2-4. Horizontal Probe Installation

2-4 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 23

Model 4081FG

2

REFRACTORY

STACK OR

DUCT METAL

PROBE LENGTH

A

WAL L

1.5 + A

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

DIMENSION A -- 1-5/8, 2-1/2, 3, OR

4 IN. 1.25 NPT SCHEDULE 40

PIPE NIPPLE

2 IN., 1.25 NPT

PIPE COUPLING

29750005

Figure 2-5. Adjusting Probe Insertion Depth

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-5

Page 24

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

4. Where high particulate or slag is in the

flue gas stream, it may be desirable to

inset the probe in the refractory as

shown in Figure 2-5. Use pipe couplings and nipples to adjust the probe

insertion depth.

5. Use rags or other material to seal

around the probe during insertion. This

prevents hot gases from escaping or

cold air from entering the stack or duct.

6. Initially insert the probe to a depth of 3

in. (76.2 mm) or ½ the depth of the

stack or duct refractory, whichever is

greater.

After initial insertion, do not insert the

probe at a rate exceeding 1 in. per minute (25.4 mm per minute) or damage

to the probe may result due to thermal

shock.

the probe. Ensure the electrical conduit

is routed below the level of the terminal

block housing. This drip loop minimizes

the possibility that moisture will accumulate in the housing.

9. If insulation was removed to access the

duct work for probe mounting, make

sure the insulation is replaced afterward. See Figure 2-4.

If the ducts will be washed down during outage, MAKE SURE to power

down the probes and remove them

from the wash area.

c. Locating Model 4081 Transmitter

1. Ensure the Model 4081 Transmitter is

easily accessible for maintenance and

service and for using the infrared remote control (if applicable).

7. After initial insertion, insert the probe at

a rate of 1 in. (25.4 mm) per minute

until the probe is fully inserted.

8. Install anti-seize compound on the pipe

threads and screw the probe into the

process flange or adapter.

NOTE

Use anti-seize compound on threads

to ease future removal of probe.

The electrical conduit port should be

facing down for a horizontal probe installation. See Figure 2-4. In vertical

probe installations, orient the probe so

the system cable drops vertically from

Do not allow the temperature of the

Model 4081 Transmitter to exceed

65°C (149°F) or damage to the unit

may result.

2. The ambient temperature of the transmitter housing must not exceed 65°C

(149°F). Locate the electronics in an

area where temperature extremes, vibration, and electromagnetic and radio

frequency interference are minimal.

3. Locate the Model 4081 Transmitter

within 150 ft (45.7 m) of the oxygen

probe due to wiring and signal

considerations.

2-6 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 25

Model 4081FG

2

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

d. Installing Model 4081 Transmitter

1. Ensure all components are available to

install the Model 4081 Transmitter.

2. Choose a method or location to mount

the transmitter.

(a) Flat Surface Mounting. The trans-

mitter may be mounted on a flat

COVER

LOCK

CIRCUIT

END

6.32

(160.5)

6.35

(161.3)

TERMINAL

END

THREADED CAP

(2 PLACES)

surface using the threaded mounting holes located on the bottom of

the transmitter housing. Refer to

Figure 2-6 for installation references.

(b) Pipe Mounting. An optional pipe

mounting bracket is available for

this type of installation. Refer to

Figure 2-7 for installation

references.

TERMINAL BLOCK (TB)

TERMINAL END

CAP OMITTED

FOR CLARITY

(THIS VIEW)

1.32

(33.5)

O-RING

(2 PLACES)

NOTE: DIMENSIONS ARE IN INCHES

WITH MILLIMETERS IN

PARENTHESES.

3.68

(93.5)

Figure 2-6. Flat Surface Mounting Dimensional Information

3/4-14 NPT

(2 PLACES)

SURFACE

BY OTHERS

0.839

(21.31)

FLAT SURFACE MOUNTING

PAD HOLE PATTERN

1/4-20 THREADS

(4 PLACES)

0.839

(21.31)

26020003

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-7

Page 26

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

6.35

(161.3)

COVER LOCK

6.9

(175.3)

Model 4081FG

TERMINAL

BLOCK (TB)

CIRCUIT

6.32

(160.5)

1.00

(25.4)

0.375 (9.525) DIA.

(4 MOUNTING

HOLES)

1.405

(35.687)

2.81

(71.374)

END

1.32

(33.5)

C

L

3.87

(98.3)

3.25

(82.55)

7.5

(190.5)

6.5

(165.1)

C

L

TERMINAL

END

3/4 -14 NPT

2 PLACES

3/4-14 FNPT

(2 PLACES)

5/16-18 NUT

4.00

(101.6)

TERMINAL END CAP

OMITTED FOR CLARITY

IN THIS VIEW.

2 IN. PIPE/WALL

MOUNTING BRACKET

(OPTION)

U-BOLT

(2 PLACES)

%

1/4-20 THREADS

BRACKET HOLE PATTERN

FOR WALL MOUNTING

NOTE:

DIMENSIONS ARE IN INCHES WITH

MILLIMETERS IN PARENTHESES.

*SCREWS FURNISHED WITH

Figure 2-7. Pipe Mounting Dimensional Information

5/16 WASHER

U-BOLT

MOUNTING KIT ONLY. NOT

FURNISHED WITH

ANALYZER/TRANSMITTER.

BOTTOM VIEW

1/4-20 SCREW*

29760016

2-8 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 27

Model 4081FG

2

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

3. For correct viewing orientation, the display may be changed 90 degrees, using the following procedure:

(a) Refer to Figure 2-8. Loosen the

cover lock screw until the cover

lock is disengaged from the

knurled surface on the threaded

circuit end cap.

(b) Remove the circuit end cap.

(c) Remove the three screws retaining

the display board in place.

(d) Lift and rotate the display board 90

degrees either way.

(e) Reposition the display board on

the standoffs. Install and tighten all

three screws.

(f) Install the circuit end cap and

tighten the cover lock screw to secure the cover lock in place.

CIRCUIT

END CAP

SCREW

COVER LOCK

SCREW

DISPLAY

BOARD

90

O

90

O

Figure 2-8. Display Positioning Assembly

HOUSING

29760004

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-9

Page 28

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

2-3 ELECTRICAL INSTALLATION

All wiring must conform to local and national

codes.

Disconnect and lock out power before

connecting the unit to the power

supply.

Install all protective equipment covers

and safety ground leads after installation. Failure to install covers and

ground leads could result in serious

injury or death.

To meet the Safety Requirements of

IEC 1010 (EC requirement), and ensure

safe operation of this equipment, connection to the main electrical power

supply must be made through a circuit

breaker (min 10 A) which will disconnect all current-carrying conductors

during a fault situation. This circuit

breaker should also include a mechanically operated isolating switch. If

not, then another external means of

disconnecting the supply from the

equipment should be located close by.

Circuit breakers or switches must

comply with a recognized standard

such as IEC 947.

a. General

The power supply and signal wiring should

be shielded. Also, make sure the signal

wiring is grounded at the Model 4081

Transmitter end only. Do not ground the

signal loop at more than one point. Twisted

pairs are recommended. Ground the transmitter housing to an earth ground to prevent

unwanted electromagnetic interference

(EMI) or radio frequency interference (RFI).

NOTE

For optimum EMI/RFI immunity, shield

the FOUNDATION fieldbus signal cable and enclose in an earth grounded

metal conduit.

Never run signal or sensor wiring in

the same conduit, or open tray, with

power cables. Keep signal or sensor

wiring at least 12 in. (0.3 m) away from

other electrical equipment and 6.5 ft (2

m) from heavy electrical equipment.

It is necessary to prevent moisture from

entering the Model 4081 Transmitter housing. The use of weather-tight cable glands is

required. If conduit is used, plug and seal

connections on the transmitter housing to

prevent moisture accumulation in the terminal side of the housing.

Moisture accumulation in the transmitter housing can affect its performance

and may void its warranty.

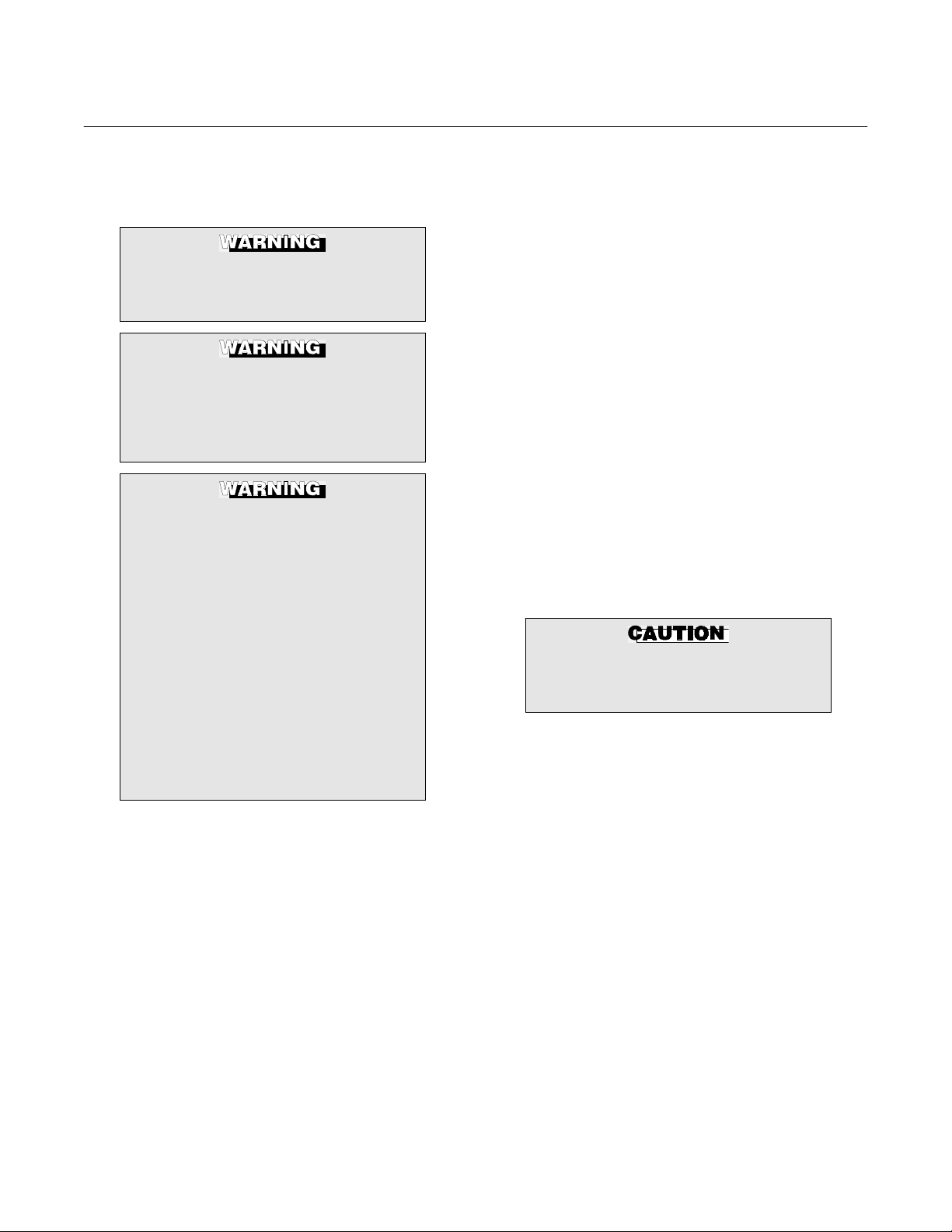

b. Oxygen Probe Signal Connections

1. Two signals represent the O

and the cell temperature. The probe

provides these values to the Model

4081 Transmitter for processing and

signal conditioning.

2. Wiring connections for the probe are

shown in Figure 2-9.

value

2

2-10 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 29

Model 4081FG

2

TERMINAL

BLOCK

CONDUIT

FACTORY-INSTALLED

JUMPER

TERMINAL

BLOCK (TB1)

PROBE

CABLE

SHIELD

GROUND

4

3

12

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

CELL - (WH)

THERMOCOUPLE - (RD)

CELL + (BK)

7

6

5

THERMOCOUPLE + (GY)

EARTH

GROUND

11

12

TERMINALS

FIELDBUS

13

DIGITAL (-)

14

15

FIELDBUS

16

DIGITAL (+)

8

9

10

THERMOCOUPLE + (GY)

THERMOCOUPLE - (RD)

CELL - (WH)

CELL + (BK)

26020004

Figure 2-9. Oxygen Probe Terminal Block

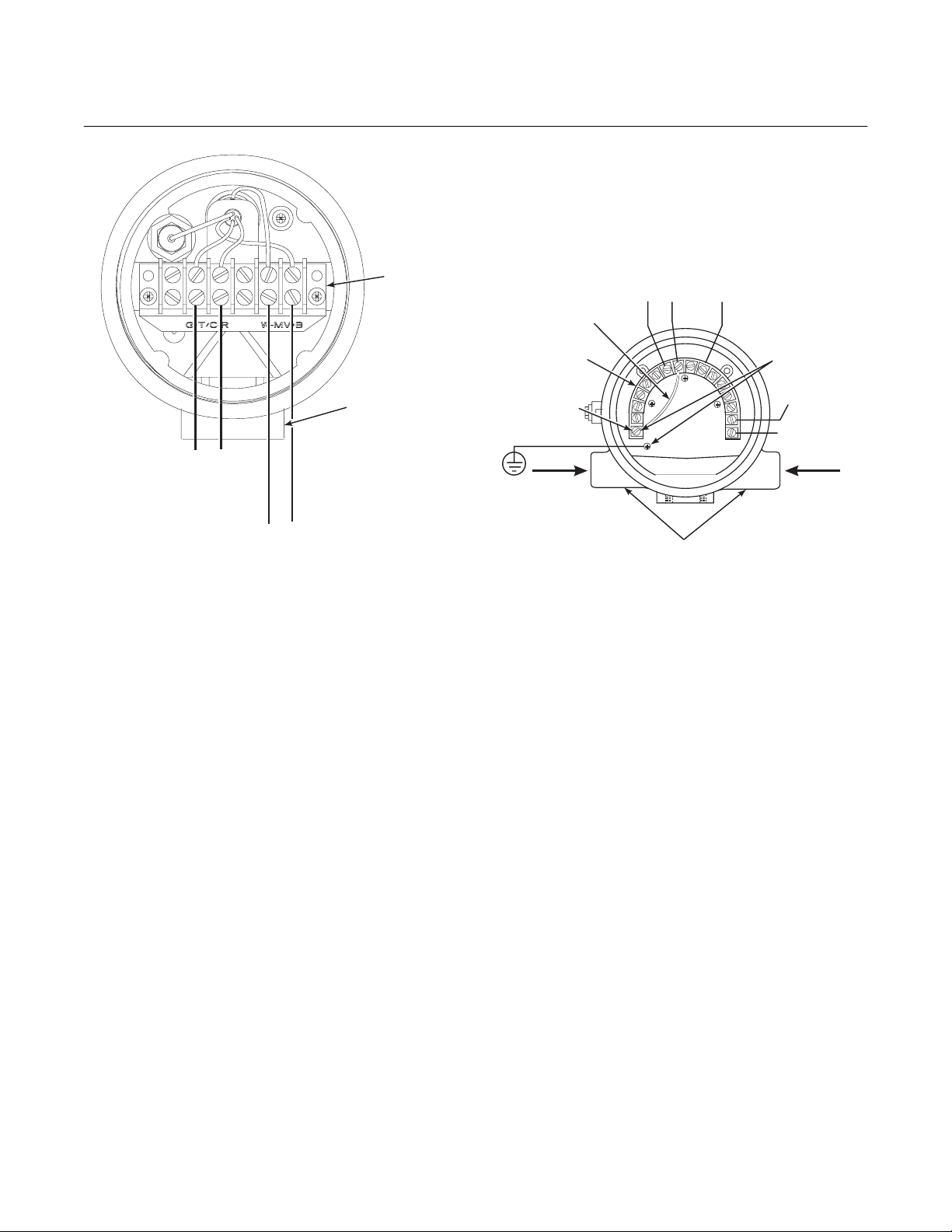

c. Model 4081 Transmitter and F

OUNDATION

Fieldbus Signal Connections

1. Two signals representing the O

value

2

and the cell temperature are supplied

to the Model 4081 Transmitter from the

oxygen probe.

2. Wiring connections for the Model 4081

Transmitter are shown in Figure 2-10.

NOTE

The ground arrangement shown in

Figure 2-10 limits the amount of noise

introduced into the electronics.

3. Connect wire shields to terminal 1.

Connect earth ground as shown.

CELL AND

THERMOCOUPLE

CONDUITS

NOTE:

RUN CELL AND THERMOCOUPLE SIGNALS IN

SEPARATE CONDUIT FROM .FIELDBUS

Figure 2-10. Model 4081 Transmitter

Terminal Block

2-4 PNEUMATIC INSTALLATION

a. General

Reference air is required for O

and calibration check gas is required during

a calibration check. Refer to Figure 2-11 for

the gas connections on the oxygen probe.

b. Reference Air Package

After the oxygen probe is installed, connect

the reference air set. Install the reference

air set according to Figure 2-12.

c. Instrument Air (Reference Air)

Instrument air is required for reference. Use

10 psig (68.95 kPa gage) minimum,

FIELDBUS

DIGITAL

29760005

calculation,

2

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-11

Page 30

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

225 psig (1551.38 kPa gage) at 0.2 scfh

(100 ml/min.); less than 40 parts-per-million

total hydrocarbons. Regulator outlet pressure should be set at 5 psi (35 kPa).

d. Calibration Check Gas

Two calibration check gas concentrations

are used with the Two-Wire In Situ Oxygen

Analyzer: Low Gas - 0.4% O

- 8% O

Do not use 100% nitrogen. See Figure 2-11

for the probe connections. Set both calibration check gases at the same flow rate:

5 scfh (2.5 L/min).

, each with the balance in nitrogen.

2

and High Gas

2

Model 4081FG

1/4 TUBE FITTING

(REFERENCE AIR PORT)

1/4 TUBE FITTING

(CALIBRATION CHECK

Figure 2-11. Oxygen Probe Gas Connections

GAS PORT)

REFERENCE

AIR VENT

26020006

4.81 (122.17)

FLOW SET

POINT KNOB

0.125-27 NPT FEMALE

OUTLET CONNECTION

1

2

1.19

(30.22)

DRAIN VALVE

OUTLET

10.0

(254)

REF

3.12 (79.25) MAX

3

(SUPPLIED BY CUSTOMER)

1/4” TUBE

2.250 (57.15)

2.0

(50.80)

1.50

(38.10)

1 FLOWMETER 0.2-2.0 SCFH 771B635H08

2 2" PRESSURE GAGE 0-15 PSIG 275431-006

3 COMBINATION FILTER-REG. 0-30 PSIG 4505C21G01

TO PROBE

NOTE: DIMENSIONS ARE IN INCHES WITH

0.25-18 NPT FEMALE

INLET CONNECTION

2 MOUNTING HOLES

3.19 (81.03) LG

THROUGH BODY FOR

0.312 (7.92) DIA BOLTS

REF AIR SET

263C152G05

MILLIMETERS IN PARENTHESES.

8.50

(215.90)

MAX

INSTRUMENT

AIR SUPPLY

10-225 PSIG

MAX PRESSURE

SCHEMATIC HOOKUP FOR REFERENCE AIR SUPPLY ON OXYGEN PROBE.

26020034

Figure 2-12. Air Set, Plant Air Connection

2-12 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 31

Model 4081FG

3

Install all protective equipment covers

and safety ground leads before

equipment startup. Failure to install

covers and ground leads could result

in serious injury or death.

3-1 GENERAL

a. Verify Mechanical Installation

SECTION 3

STARTUP

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

play should look similar to Figure 3-1. The

display will now track the O

and cell temperature.

concentration

2

O CONCENTRATION

2

Ensure the Oxygen Analyzer is installed

correctly. See paragraph 2-2 for mechanical

installation information.

b. Verify Terminal Block Wiring

Ensure the wiring of both the oxygen probe

terminal block and Model 4081 Transmitter

terminal block is correct. Refer to paragraph

2-3 for electrical installation and wiring

information.

3-2 POWER UP

a. General

The Two-Wire In Situ Oxygen Analyzer displays the current oxygen reading on the

LCD face of the Model 4081 Transmitter.

The O

concentration and cell temperature

2

are displayed as shown in Figure 3-1. This

and other in-formation may also be accessed using the FOUNDATION Fieldbus.

b. Startup Display

When the probe is first inserted into the

stack, some time is required until minimum

operating temperatures [550°C (1022°F)]

are reached. Some time is also required for

the electronics to reach an operating state.

Therefore, when the unit is first powered up,

a faulted operation display as shown in

Figure 3-2 may be displayed by the transmitter until the probe operating temperatures are reached and the electronics are

working properly (approximately 5 minutes).

c. Operating Display

CELL

TEMPERATURE

Figure 3-1. Normal Operation Display

%

29760006

%

29760007

After the probe has reached operating tem-

Figure 3-2. Faulted Operation Display

peratures, the Model 4081 Transmitter dis-

Rosemount Analytical Inc. A Division of Emerson Process Management Startup 3-1

Page 32

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

3-3 REESTABLISHING PROPER CALIBRATION

CHECK GAS FLOW RATE

The calibration check gas flow must be enough

to ensure no combustion flue gases mix with the

calibration check gases and only clean, good

calibration check gas surrounds the cell without

expending excess gas (Figure 3-3). Monitor the

O

concentration using an IRC or F

2

OUNDATION

fieldbus. Set the calibration check gas flow rate

as follows:

NOTE

Only set the calibration check gas flow

rate at startup. It is not necessary to

perform this procedure for each calibration check.

FLUE GAS

PROTECTIVE

TUBE

CELL

a. Adjust the calibration check gas flow to 5

scfh (2.5 L/min) to ensure the cell is surrounded by calibration check gas. Due to

the cooling effect of the gas, the cell temperature will decrease slightly, causing the

O

concentration to drop. Once the elec-

2

tronics compensates for this effect, the O

concentration will stabilize.

b. Next, slowly reduce the calibration check

gas flow until the O

concentration changes,

2

which indicates that the calibration check

and flue gases are mixing. Increase the flow

rate until this effect is eliminated.

STACK OR DUCT

METAL WALL

2

CALIBRATION

GAS

Figure 3-3. Proper Calibration Check Gas Flow Rate

REFRACTORY

CHECK GAS LINE

CALIBRATION

REFERENCE

AIR LINE

26020062

3-2 Startup Rosemount Analytical Inc. A Division of Emerson Process Management

Page 33

Model 4081FG

4

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

SECTION 4

OPERATION

4-1 GENERAL

a. Overview

This section explains the operator controls

and displays of the Two-Wire In Situ Oxygen Analyzer. The use of the Infrared Remote Control (IRC) and the Model 4081

Transmitter Liquid Crystal Display (LCD) are

described in detail.

CIRCUIT

END

b. Display

The Model 4081 Transmitter LCD displays

the O

concentration and cell temperature

2

during normal operation (see Figure 4-1).

The LCD will also display fault conditions

when they occur. To interact with the transmitter, use the IRC and navigate through a

series of menus displayed on the LCD.

TERMINAL

END

MODEL 4081 TRANSMITTER

ELECTRONICS HOUSING

%

Figure 4-1. Normal Operation Display

29760008

Rosemount Analytical Inc. A Division of Emerson Process Management Operation 4-1

Page 34

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

ON STARTUP

RESET

OR ON

FROM ANY

SCREEN

PROCESS DISPLAY

NORMAL

OPERATION

EXIT

ON FROM

ANY SCREEN

EXIT

WITHOUT

EXPLICITY

STATED

Model 4081FG

1 - USER ENTERS DISPLAY

ANALYZER CODE

2 - USER ENTERS ANALYZER

ACCESS CODE

CAL

NEXT

PROG

2

CODE

1

DISPLAY

CODE

CELL T HI

RESET MAX

CELL T

SET O2 FILTER

TIME

SET HI BOTTLE

O2

SET LO BOTTLE

O2

555 ENTER

NEXT

NEXT

NEXT

NEXT

NEXT

PROCESS DISPLAY

FAULTED

OPERATION

EXIT

PROGRAM

MENU

DIAG

SHOW FAULT IN MANUAL?

T/C mV ACCEPT HIGH O2

O2 CELL mV ACCEPT LOW O2

CELL

IMPEDANCE

PREVIOUS

SLOPE

PREVIOUS

CONSTANT

MAX CELL T

ENTER

NEXT ENTER

NEXT NEXT

NEXT NEXT

NEXT

NEXT

EXIT

EXIT

DIAGNOSTICS

NEXT

NEXT

FAULT

(IF PRESENT)

FAULT

(IF PRESENT)

MENU

PURGING

NEXT

SLOPE

NEXT

CONSTANT

RESET OR EXIT

CALCHECK

MENU

SET CODE

NEXT

SW VER

NEXT

UNIT SER #

NEXT

SW BUILD

NUMBER

NEXT

SW BUILD DATE

29760009

Figure 4-2. Model 4081 Transmitter Menu Tree

4-2 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management

Page 35

Model 4081FG

4

c. Menu Tree

The screens that can be displayed are

shown in the menu tree of Figure 4-2.

These screens are displayed on the LCD

and are accessed using the IRC keypad.

d. Navigation

The IRC in Figure 4-3 is used to interact

with the Model 4081 Transmitter and navigate through the screens on the LCD.

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

RESET HOLD

ENTERCAL

1. Hold the IRC within 6 ft (1.8 m) of the

Model 4081 Transmitter and within 15

degrees from the centerline of the

transmitter LCD. The amount of ambient light may also affect IRC

performance.

NOTE

The LCD may react slowly to IRC

commands. Allow sufficient time between key presses to avoid undesired

or repeated commands from accumulating in the command queue.

2. Use the keys on the IRC to navigate

through the menu screens. Refer to

Figure 4-3. General usage is as

follows:

(a) RESET. Returns to the PROCESS

DISPLAY screen at the top of the

menu tree. Any non-entered number in the exited state will be ignored, and the previous data will

be used.

(b) HOLD. Not used.

(c) Left/Right Arrow. Moves left and

right among editable digits on the

display.

(d) Up/Down Arrow. Increases or de-

creases the value of the currently

selected digit on the display.

PROG

DIAG EXIT

REMOTE CONTROL

ROSEMOUNT

NEXT

MODEL 3081

FISHER-ROSEMOUNT

29760010

Figure 4-3. Infrared Remote Control (IRC)

(e) CAL. Accesses the CALCHECK

MENU branch of the menu tree.

Only works from the PROCESS

DISPLAY screen.

(f) PROG. Accesses the PROGRAM

MENU branch of the menu tree.

Only works from the PROCESS

DISPLAY screen.

(g) DIAG. Accesses the DIAGNOS-

TICS MENU branch of the menu

tree. Only works from the PROCESS DISPLAY screen.

Rosemount Analytical Inc. A Division of Emerson Process Management Operation 4-3

Page 36

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

(h) ENTER. Initiates the editing proc-

ess and causes the most significant digit of the edited item to start

flashing. Also processes the entry

so the previous value updates to

the new value entered using the

arrow keys. Failure to press ENTER before exiting a screen will

cancel the input value and revert to

the previous value.

(i) NEXT. Accesses the next user

screen as shown in the menu tree.

Any non-entered number in the exited state will be ignored, and the

previous data will be used.

(j) EXIT. Exits from sub-branches of

the menu tree where an exit option

is explicitly shown. Otherwise, returns to the PROCESS DISPLAY

screen at the top of the menu tree.

Any non-entered number in the exited state will be ignored, and the

previous data will be used.

4-2 PROGRAM MENU

a. CODE

Refer to Figure 4-4. After pressing the

PROG key, this screen will display. Use this

screen to identify a specific analyzer in a

process to prevent accessing an adjacent

analyzer when using the IRC.

Press ENTER to begin editing. At this point,

you can either specify the analyzer by its

access code or view its code if it is unknown.

1. To gain further access to the screens

in the PROGRAM MENU branch, enter the correct three-digit analyzer access code using the arrow keys and

press ENTER. If security is disabled,

this screen does not appear and the

system displays the FAULT VAL

screen.

2. If the analyzer access code is unknown, enter 555 and press ENTER to

access the DISPLAY CODE screen. In

that screen, you will be able to view the

analyzer access code.

The PROGRAM MENU branch of the menu

tree allows you to program and edit some process parameters, faults, outputs, and security

codes. To access this branch of the menu tree,

press the PROG key on the IRC when in the

PROCESS DISPLAY screen (Normal or

Faulted). You must enter the analyzer code to

gain further access to the screens in this

branch. Each screen in this branch is accessed

sequentially using the NEXT key. Refer to

Figure 4-2 during the following menu and

screen descriptions.

NOTE

To edit a screen value, press ENTER

to access the data field. Use the left

and right arrow keys to move among

the digits in the data field. Note that

the editable position will be flashing.

To change the value of a digit, use the

up and down arrow keys to increase or

decrease the value. When finished editing, press ENTER to accept the

value. To go to the next screen in the

menu, press NEXT.

O CONCENTRATION

2

%

Figure 4-4. CODE

ANALYZER

ACCESS CODE

OR SECURITY

ACCESS CODE

26020009

4-4 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management

Page 37

Model 4081FG

4

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

b. DISPLAY CODE

Refer to Figure 4-5. This screen is accessible from the CODE screen by entering 555

and pressing ENTER. The DISPLAY CODE

screen identifies the analyzer access code

so you can return to the CODE screen and

enter the code as described in paragraph 42a. To return to the Process Display screen,

press EXIT.

O CONCENTRATION

2

%

c. CELL T HI

Refer to Figure 4-6. Use this screen to set

the value of the upper cell temperature fault

condition. This value is the maximum allowed cell temperature before a fault condition is indicated. Press ENTER to begin

editing. Use the arrow keys to select and

change the value. The value must be between 550° and 1600°C. Press ENTER to

accept the value. Pressing NEXT displays

the RESET MAX CELL T screen.

O CONCENTRATION

2

%

ACCESS CODE

Figure 4-5. DISPLAY CODE

ANALYZER

26020047

UPPER CELL

TEMPERATURE

FAULT VALUE

26020012

Figure 4-6. CELL T HI

Rosemount Analytical Inc. A Division of Emerson Process Management Operation 4-5

Page 38

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Model 4081FG

d. RESET MAX CELL T

Refer to Figure 4-7. The transmitter tracks

the maximum cell temperature obtained.

Use this screen to reset the maximum cell

temperature attained value to the current

cell temperature. Press ENTER to begin

editing. Use the arrow keys to select and

change the value (Y/N). Then, press ENTER to accept the value. Pressing NEXT

displays the SET O

FILTER TIME screen.

2

O CONCENTRATION

2

%

e. SET O

FILTER TIME

2

Refer to Figure 4-8. In some applications, it

is beneficial to dampen the raw O

2

coming from the cell. Use this screen to

enter the amount of time it will take the O

to reach 90% of the new reading. Press

ENTER to begin editing. Use the arrow keys

to select and change the screen value to

the O

filter value (in seconds). Enter a

2

value between 0 and 300 seconds and

press ENTER to accept the value. Press

NEXT to access the SET HI BOTTLE O

screen.

O CONCENTRATION

2

%

signal

2

2

Y/N (TO RESET

MAXIMUM CELL

TEMPERATURE)

Figure 4-7. RESET MAX CELL T

26020013

O FILTER

2

VALUE (IN SECONDS)

Figure 4-8. SET O2 FILTER TIME

26020048

4-6 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management

Page 39

Model 4081FG

4

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

f. SET HI BOTTLE O

2

Refer to Figure 4-9. Use this screen to

identify, within the electronics, the percentage of O

used as the high calibration check

2

gas. Press ENTER to begin editing. Use the

arrow keys to select and change the screen

value to the O

percentage of the high cali-

2

bration check gas. Press ENTER to accept

the value. Press NEXT to display the SET

LO BOTTLE O

screen.

2

O CONCENTRATION

2

%

g. SET LO BOTTLE O

2

Refer to Figure 4-10. Use this screen to

identify, within the electronics, the percentage of O

used as the low calibration check

2

gas. Press ENTER to begin editing. Use the

arrow keys to select and change the screen

value to the O

percentage of the low cali-

2

bration check gas. Press ENTER to accept

the value. Press NEXT to display the SET

CODE screen.

O CONCENTRATION

2

%

HIGH CALIBRATION

CHECK GAS O

PERCENTAGE

Figure 4-9. SET HI BOTTLE O

LOW CALIBRATION

2

26020049

2

Figure 4-10. SET LO BOTTLE O

CHECK GAS O

PERCENTAGE

26020050

2

2

Rosemount Analytical Inc. A Division of Emerson Process Management Operation 4-7

Page 40

Instruction Manual

IB-106-4081 Rev. 1.2

September, 2002

Figure 4-11. SET CODE

h. SET CODE

Refer to Figure 4-11. Use this screen to set

the security code for the Model 4081

Transmitter. Press ENTER to begin editing.