Page 1

Quick Start Guide

00825-0100-4810, Rev HA

Rosemount™ 405 Compact Primary

Element

June 2016

Page 2

Quick Start Guide

June 2016

NOTICE

This guide provides basic guidelines for Rosemount 405. It does not provide instructions for configuration,

diagnostics, maintenance, service, troubleshooting, Explosion-pr oof, Flameproof, or intrinsically safe (I.S.)

installations. Refer to the Rosemount 405 Reference Manual (document number 00809-0100-4810) for

more instruction. This manual is also available electronically on www.rosemount.com.

If the Rosemount 405 was ordered assembled to a Rosemount

Rosemount 3051SFC Compact Flowmeter. See the following Quick Start Guide for information on

configuration and hazardous locations certifications: Rosemount 3051S Series Pressure Transmitter

(document number 00825-0100-4801).

If the Rosemount 405 was ordered assembled to a Rosemount 3051S MultiVariable™ Tra nsm itt er, th e ne w

assembly is the Rosemount 3051SFC Compact Flowmeter. See the following Quick Start Guide for

information on configuration and hazardous locations certifications: 3051S MultiVariable Transmitter

(document number 00825-0100-4803).

Process leaks may cause harm or result in death.

To avoid process leaks, use only gaskets designed to seal with the corresponding flange and O-rings to seal

process connections.

To ensure correct operation download the most current version of the Engineering Assistant software at:

EmersonProcess.com/en-US/brands/rosemount/Pressure/Pressure-Transmitters/MultiVariable-Transmitters/

3051S-MultiVariable/engineering-assistant6/Pages/index.aspx.

3051S Transmitter, the new assembly is the

Contents

Primary element location . . . . . . . . . . . . . 3

Primary element orientation . . . . . . . . . . 5

2

Primary element installation . . . . . . . . . 10

Product certifications . . . . . . . . . . . . . . . 13

Page 3

June 2016

1.0 Primary element location

Quick Start Guide

Install the Rosemount 405 in the correct location within the piping branch to

prevent inaccurate measurement caused by flow disturbances.

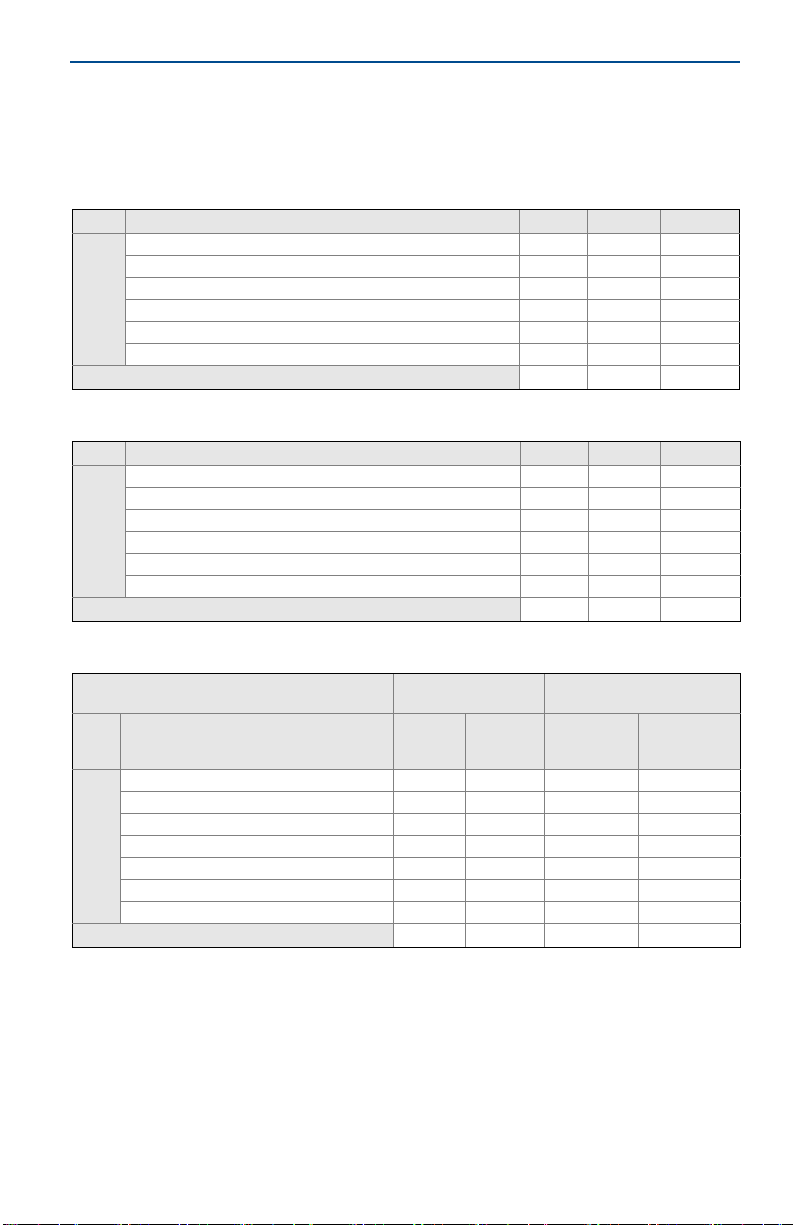

Table 1. 405C Straight Pipe Requirements

Beta 0.40 0.50 0.65

Reducer 2 2 2

Single 90° bend or tee 2 2 2

Two or more 90° bends in the same plane 2 2 2

Two or more 90° bends in different planes 2 2 2

Up to 10° of swirl 2 2 2

side of primary

Upstream (inlet)

Butterfly valve (75% to 100% open) 2 5 5

Downstream (outlet) side of primary

Table 2. 405P Straight Pipe Requirements

Beta 0.40 0.50 0.65

Reducer 5 8 12

Single 90° bend or tee 16 22 44

Two or more 90° bends in the same plane 10 18 44

Two or more 90° bends in different planes 50 75 60

Expander 12 20 28

side of primary

Upstream (inlet)

Ball/gate valve fully open 12 12 18

Downstream (outlet) side of primary

1

Table 3. 405 Straight Run Requirements

Annubar™ averaging pitot tube - sensor

size 1

Reducer 12 12 8 4

Expander 18 18 8 4

Single 90° bend or tee 8 10 8 4

Two or more 90° bends in the same plane 11 16 8 4

Two or more 90° bends in different planes 23 28 8 4

side of primary

Butterfly Valve (75–100% open) 30 30 8 4

Upstream (inlet)

Ball/Gate Valve fully open 8 10 8 4

Downstream (outlet) side of primary

(1)

(1)(2)

(1)

Without

straightening vane

In

plane

Out of

(4)

4 4 4 4

plane

(4)

(1)(2)(3) (4)

2 2 2

6 6 7

With straightening vane

From

disturbance

(3)

From

straightening

vane

1. Consult an Emerson™ Process Management representative if a disturbance is not listed.

2. If using flow straighteners, refer to ISO 5167 for recommended links.

3. Use straightening vane to reduce the required straight run length.

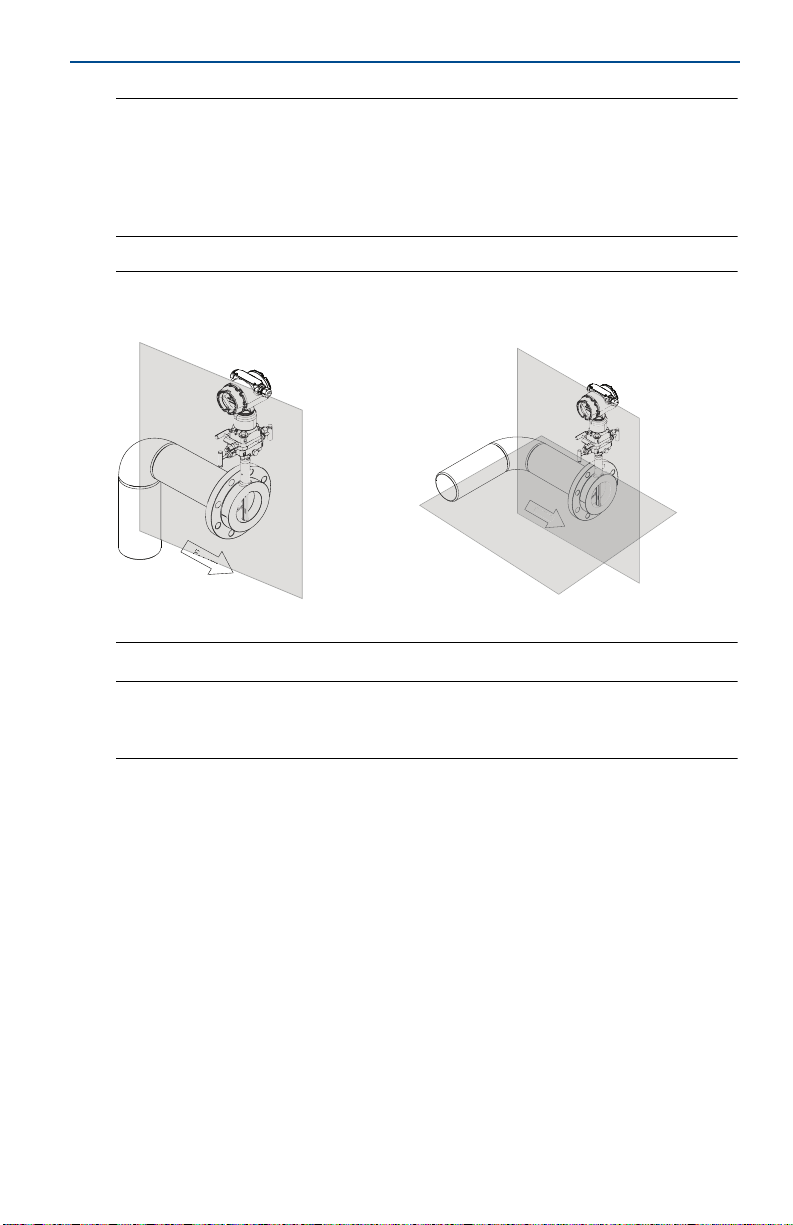

4. In plane means the Rosemount 405 is in the same plane as the elbow. Out of plane means the bar is

perpendicular to the plane of the upstream elbow. Refer to Figure 1 on page 4

.

3

Page 4

Quick Start Guide

FLOW

FLOW

In plane

Out of plane

Note

Recommended lengths are represented in pipe diameters. If longer lengths of straight run

are available, position the Rosemount 405 so 80% of the pipe run is upstream and 20% is

downstream.

Flow conditioners may be used to reduce the required straight run length, improving

performance.

Figure 1. Compact Annubar Flowmeter In Plane and Out of Plane

June 2016

Note

The above figure depicts in plane and out of plane orientations only. Refer to Tab le 3 on

page 3 for recommended straight run requirements.

1.1 Vibration limits for Rosemount 405 products

Qualified per IEC61298-3 (2008) for field with general application or pipeline with

low vibration level (10–1000 Hz test frequency range, 0,15 mm displacement

peak amplitude, 20 m/s

The weight and length of the transmitter assembly shall not exceed 9.8 lb

(4,45 kg) and 8.60-in. (218,44 mm).

1. Stainless steel temperature housing is not recommended with primary element technology A in appl ications with

mechanical vibration.

4

2

acceleration amplitude)

(1).(1)

Page 5

June 2016

FLOW

Quick Start Guide

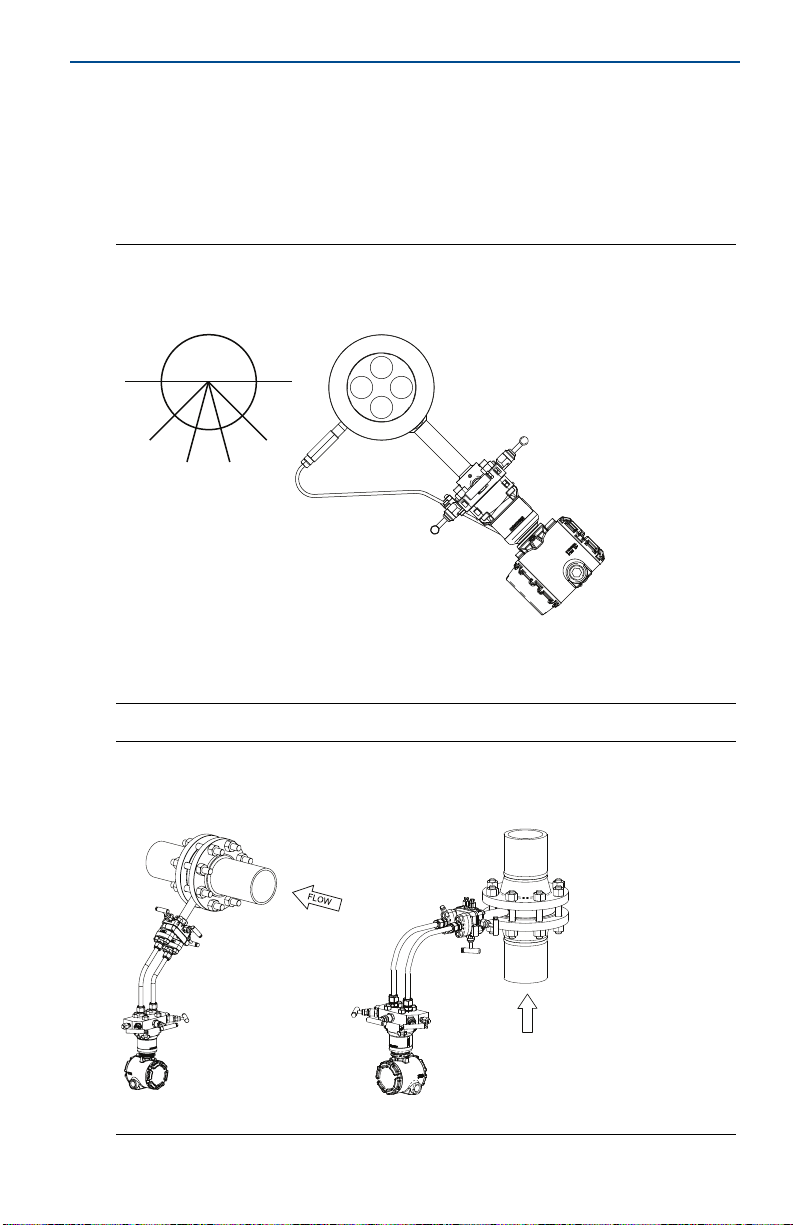

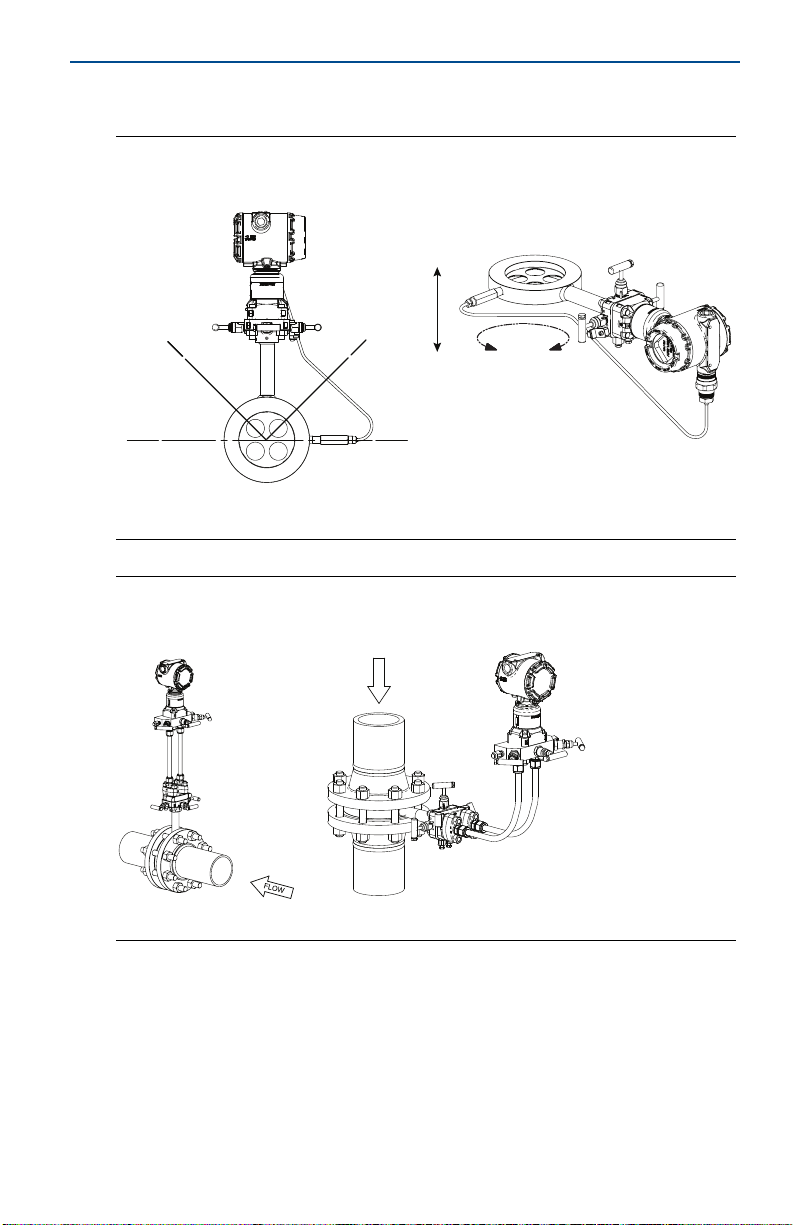

2.0 Primary element orientation

The primary element can be installed in any position around the circumference of

the pipe, provided the vents are positioned properly for bleeding or venting.

Optimal results for liquid or steam in a vertical line are obtained when flow is up.

Liquid - 405C, 405P, and 405A

Figure 2. Direct Mount

Horizontal liquid

45°

AA

30°

A. Recommended zone 30°

Figure 3. Remote Mount

Horizontal liquid Vertical liquid

45°

5

Page 6

Quick Start Guide

Gas - 405C, 405P, and 405A

Figure 4. Direct Mount

Horizontal gas Vertical gas

June 2016

Flow

A

45° 45°

A. Recommended zone 90°

Figure 5. Remote Mount

Horizontal gas Vertical gas

FLOW

360°

6

Page 7

June 2016

45°

45°

30°

AA

Steam - 405C, 405P, and 405A

Figure 6. Direct Mount

A. Recommended zone 30°

Figure 7. Remote Mount

Horizontal steam Vertical steam

Quick Start Guide

Horizontal steam

FLOW

Note

For the Rosemount 405A model in steam applications, with DP readings in a low flow

condition as low as 0.75 inH

element/flowmeter in the top mounting for steam configuration.

O in horizontal pipes consider installing the primary

2

7

Page 8

Quick Start Guide

60° 60°

A

Top mounting for steam

Top mounting in steam is an alternative mounting method for steam installations

that can be used if there are space restrictions or other concerns. This installation

method is intended for applications that run with limited interruptions or

shutdowns. Also, for outdoor applications, top mounting can eliminate the need

for heat tracing, if steam is flowing.

Figure 8. Direct mount — 405C, 405P, and 405A

Horizontal top mounting for steam up to 400 °F (204 °C)

A. Recommended zone 60°

June 2016

Note

For the Rosemount 405A Model in wet steam applications, do not mount the flowmeter at

the direct vertical position. Mounting at an angle will avoid measurement inaccuracy due to

water running along the bottom of the pipe.

8

Page 9

June 2016

Figure 9. Remote mount up to 850 °F (454 °C) – 405C, 405P, and 405A

Note

When top mounting with a remote mount transmitter, use enough impulse piping to

dissipate the process heat to avoid damaging the transmitter.

Quick Start Guide

Suggested top mounting orientations:

For steam up to 400 °F (204 °C) use direct mount orientation and for steam up

to 850 °F (454 °C) use remote mount orientation.

For direct mounting, ambient temperature should be less than 100 °F (38 °C).

For remote mount installations, the impulse piping should slope up slightly

from the instrument connections on the Rosemount 405A Model to the cross

fittings, allowing condensate to drain back into the pipe.

From the cross fittings, the impulse piping should be routed downward to the

transmitter and the drain legs. The transmitter should be located below the

instrument connections of the Rosemount 405A Model.

For technologies C, P, and A, depending on the environmental conditions, it may

be necessary to insulate the mounting hardware.

9

Page 10

Quick Start Guide

3.0 Primary element installation

1. Orient the assembly according to the guidelines provided in “Primary element

orientation” on page 5. Ensure the flow arrow stamped on the

405 Primary Element is pointing in the same direction as the process flow.

Note

ANSI 150 - 600# alignment ring is included as standard when ordering for up to 8-in. line

sizes. For the 10-in. and 12-in. line size, the alignment ring must be ordered (Installation

Accessories). If a DIN or JIS alignment ring is required, it must be ordered as an option.

Contact an Emerson Process Management sales representative for additional information.

Note

For ease of installation, the gasket may be secured to the flange face with small pieces of

tape. Be sure the gasket or tape does not protrude into the pipe.

2. If using an alignment ring with through holes, proceed to Step 9.

3. Insert two studs through the flange holes located opposite the head of the

Rosemount 405.

4. Place the alignment ring on the Rosemount 405 body (see Figure 10 ).

5. Insert gaskets.

6. Insert the Rosemount 405 between the flanges so the indentations on the

alignment ring contact the installed studs. The studs must contact the

alignment ring in the indentation marked with the appropriate flange rating

to ensure proper alignment.

7. Install remaining studs and nuts (hand tight). Ensure three of the studs are in

contact with the alignment ring.

8. Lubricate studs and tighten nuts in a cross pattern to the appropriate torque

per local standards.

Step 9 through Step 12 are for use with alignment rings that have through holes.

9. Place the alignment ring on the Rosemount 405 body (see “Horizontal gas” on

page 6).

10. Insert the Rosemount 405 between the flanges.

a. Starting on the side opposite the Rosemount 405 head, rotate the

alignment ring such that the radius corresponding to the alignment ring

marking matches that of the application flange rating.

b. Insert one stud through both the upstream and downstream flanges and

allow the ring to rest on the bolt. This will ensure proper alignment.

11. Repeat Step 10 for the installation of the remaining bolts that will contact the

alignment ring.

12. Insert gaskets.

13. Install remaining studs and nuts (hand tight). Ensure three of the studs are in

contact with the alignment ring.

14. Lubricate studs and tighten nuts in a cross pattern to the appropriate torque

per local standards.

June 2016

10

Page 11

June 2016

Quick Start Guide

Note

Standa rd 1/16-in. gaskets are recommended for use with the Rosemount 405. Using other

gaskets could potentially cause a bias shift in the measurement.

3.1 Recommended insulation guidelines

For flowmeters with integral temperature assembly:

It is recommended that the meter be insulated when the difference between

process and ambient temperature is greater than 30 °F (16.6 °C).

1. For line sizes

4-in. (100 mm) of insulation of at least a 4.35 R-factor.

2. For line sizes 6-in. (150 mm) to 12-in. (300 mm), it is recommended to have

5-in. (125 mm) of insulation of at least a 4.35 R-factor.

The full thickness stated above may not be necessary for the entire flowmeter,

but is required for the temperature sensor area at a minimum. Insulation is

needed to ensure meeting our specified temperature measurement accuracy.

Insulation should only be placed up to the neck and not cover the transmitter.

1

/2-in. (15 mm) to 4-in. (100 mm), it is recommended to have

11

Page 12

Quick Start Guide

A

B

G

A

F

C

D

B

E

Figure 10. Rosemount 405 Installation

June 2016

A. Rosemount 405

(1)

B. Alignment ring

C. Existing pipe assembly with flange

E. Gasket

F. St ud

G. Transmitter

(2)

(2)

D. Nut

1. This installation drawing applies to the 405C, 405P, and 405A.

2. The installation drawing applies when using the Rosemount 3051S, Rosemount 3051S

MultiVariable, Rosemount 3051, and Rosemount 2051 Transmitter. See the following documents

for quick installation instruction of the transmitter:

Rosemount 3051S MultiVariable Transmitter: document number 00825-0100-4803

Rosemount 3051S: document number 00825-0100-4801

Rosemount 3051: document number 00825-0100-4001

Rosemount 2051: document number 00825-0100-4101

12

Page 13

June 2016

Quick Start Guide

4.0 Product certifications

4.1 Approved Manufacturing Locations

Rosemount Inc. – Chanhassen, Minnesota USA

Rosemount DP Flow Design and Operations – Boulder, Colorado USA

Emerson Process Management GmbH & Co. OHG – Wessling, Germany

Emerson Process Management Asia Pacific Private Limited – Singapore

Emerson Beijing Instrument Co., Ltd – Beijing, China

4.2 European Directive Information

The EC declaration of conformity for all applicable European directives for this

product can be found on the website at EmersonProcess.com/Rosemount. A

hard copy may be obtained by contacting our local sales office.

European Pressure Equipment Directive (PED) (97/23/EC)

Rosemount 405 Compact Primary Element — Sound Engineering Practice (SEP)

Pressure Transmitter — See appropriate Pressure Transmitter QSG.

4.3 Hazardous Locations Certifications

For information regarding the electronics product certification, see the

appropriate transmitter Quick Start Guide:

Rosemount 3051SMV: (document number 00825-0100-4803)

Rosemount 3051S: (document number 00825-0100-4801)

Rosemount 3051: (document number 00825-0100-4001)

Rosemount 2051: (document number 00825-0100-4101)

13

Page 14

Quick Start Guide

Figure 11. Rosemount 405 Declaration of Conformity

June 2016

14

Page 15

June 2016

Quick Start Guide

15

Page 16

Quick Start Guide

June 2016

16

Page 17

June 2016

表表格

1B: 含有China RoHS

管控物峐超彯㚨⣏㳻⹎旸ῤ的部件型号列表

Rosemount 405

Table 1B: List of Rosemount 405 Parts with China RoHS Concentration above MCVs

部件名称

Part Name

有害物峐ġİġHazardous Substances

摭

Lead

(Pb)

汞

Mercury

(Hg)

擱

Cadmium

(Cd)

六价撔

Hexavalent

Chromium

(Cr +6)

多ⓤ俼劗

Polybrominated

biphenyls

(PBB)

多ⓤ俼劗慂

Polybrominated

diphenyl ethers

多ⓤ俼劗慂

(PBDE)

䬍ࡦᓖՐ

ᝏಘཆ༣㓴

Ԧ

Aluminum

RTD

Housing

Assembly

O O O X O O

本表格系依据

SJ/T11364

的奬⭂侴⇞ἄįġ

This table is proposed in accordance with the provision of SJ/T11364

O:

意宍悐ẞ䘬㚱⛯峐㛸㕁宍㚱⭛䈑峐䘬⏓慷⛯ỶḶ

GB/T 26572

所奬⭂䘬旸慷天㯪įġ

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

意⛐宍悐ẞἧ䓐䘬㚱⛯峐㛸㕁慴炻军⮹㚱ᶨ䰣⛯峐㛸㕁宍㚱⭛䈑峐䘬⏓慷檀Ḷ

GB/T 26572

所奬⭂䘬旸慷天㯪įġ

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

к䘠⭣᰾ӵ䘲⭘Ҿ䘹ᤙ䬍ࡦཆ༣㓴ԦⲴӗ૱DŽަԆᡰᴹᐞ⍱䟿а⅑ݳԦⲴ㓴ԦᡰᴹⲴ China RoHS ㇑᧗⢙䍘⎃

ᓖ൷վҾ GB/T 26572 ᡰ㿴ᇊⲴ䲀䟿㾱≲DŽޣҾᐞ⍱䟿䇑䘱ಘ㓴ԦⲴ㇑᧗⢙䍘⎃ᓖⲴ⭣᰾ˈ䈧৲ⴻ䘱ಘⲴᘛ

䙏ᆹ㻵ᤷইDŽ

The disclosure above applies to units supplied with aluminum connection heads. No other components supplied

with DP Flow primary elements contain any restricted substances. Please consult the transmitter Quick Start

Guide (QIG) for disclosure information on transmitter components.

Quick Start Guide

17

Page 18

Global Headquarters

Emerson Process Management

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@EmersonProcess.com

North America Regional Office

Emerson Process Management

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Process Management

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@EmersonProcess.com

Europe Regional Office

Emerson Process Management Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@EmersonProcess.com

Asia Pacific Regional Office

Emerson Process Management Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.EmersonProcess.com

Middle East and Africa Regional Office

Emerson Process Management

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emi rates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

*00825-0100-4810*

Quick Start Guide

00825-0100-4810, Rev HA

Linkedin.com/company/Emerson-Process-Management

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/us er/RosemountMeasur ement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found at

www.Emerson.com/en-us/pages/Terms-of-Use.aspx

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Annubar, Rosemount and Rosemount logotype are trademarks of

Emerson Process Management.

All other marks are the property of their respective owners.

© 2016 Emerson Process Management. All rights reserved.

June 2016

Loading...

Loading...