Page 1

Rosemount™ 326L Level Transmitter

Quick Start Guide

00825-0100-4326, Rev 01

January 2019

Page 2

2

Page 3

Quick Start Guide Contents

00825-0100-4326 January 2019

Contents

Chapter 1 Introduction.................................................................................................................. 5

1.1 Safety instructions............................................................................................................................5

1.2 Applications..................................................................................................................................... 5

1.3 Measuring principle..........................................................................................................................6

1.4 Outputs............................................................................................................................................7

1.5 IO-Link..............................................................................................................................................8

1.6 Functions..........................................................................................................................................8

Chapter 2 Installation...................................................................................................................13

2.1 Installation considerations..............................................................................................................13

2.2 Installing the level transmitter........................................................................................................17

2.3 Wire the transmitter.......................................................................................................................22

Chapter 3 Operation.................................................................................................................... 25

3.1 Display elements............................................................................................................................ 25

3.2 Menu structure...............................................................................................................................26

3.3 Parameter settings......................................................................................................................... 29

3.4 Setup the level transmitter............................................................................................................. 30

3.5 Using the transmitter..................................................................................................................... 38

3.6 Setting parameters with IO-Link..................................................................................................... 40

Chapter 4 Troubleshooting and maintenance...............................................................................43

4.1 Error indicators...............................................................................................................................43

4.2 Output response in different operating states................................................................................ 43

4.3 Maintenance.................................................................................................................................. 44

Chapter 5 Setting ranges..............................................................................................................47

Chapter 6 Product certifications...................................................................................................49

6.1 European directive information...................................................................................................... 49

6.2 Ordinary location information........................................................................................................ 49

6.3 3-A® certification............................................................................................................................49

6.4 Other industry certifications...........................................................................................................49

Chapter 7 Factory settings........................................................................................................... 51

Quick Start Guide 3

Page 4

Contents Quick Start Guide

January 2019 00825-0100-4326

4 Quick Start Guide

Page 5

Quick Start Guide

00825-0100-4326 January 2019

Introduction

1 Introduction

The level transmitter continuously detects level of a media and reports the level of the

media in multiple selectable units of measurements and values.

1.1 Safety instructions

Follow these safety guidelines when installing and using the level transmitter.

CAUTION

• Read this document before installing the level transmitter and keep it for the life of the

level transmitter.

• The level transmitter must be suitable for the corresponding applications and

environmental conditions without any restrictions.

• Use the level transmitter only for its intended purpose.

• Use the level transmitter only with permissible media.

• If you do not adhere to the operating instructions and technical data, personal injury

and/or damage to property might occur.

• The manufacturer assumes no liability or warranty for any consequences caused by

tampering with the product or incorrect use by the operator.

• Installation, electrical connection, set-up, operation and maintenance of the product

must be performed by qualified personnel authorized by the machine operator.

• Protect units and cables against damage.

1.2 Applications

The level transmitter is intended to be used in food and beverage applications or

applications with significant hygienic requirements.

The level transmitter complies with the standard EN 61000-6-4 and is a class A product.

The level transmitter may cause radio interference in domestic areas. If interference

occurs, the user must take appropriate actions.

Note

The level transmitter emits less microwave energy than mobile phones. The operation of

the level transmitter is harmless to human health if used as intended.

1.2.1

Quick Start Guide 5

Application area restrictions

Measurements made by the level transmitter can be impacted by the environment and

the type of media it is measuring.

The following media characteristics can cause incorrect measurements:

Page 6

Introduction Quick Start Guide

January 2019 00825-0100-4326

• Highly absorbing surfaces (foam)

• Intensely bubbling surfaces

• Media which are very inhomogeneous, separate from each other thus forming

separation layers (oil layer on water)

To prevent this, follow these guidelines:

• Check the function by performing an application test.

• Install the level transmitter in a steady environment.

In case of signal loss, the level transmitter displays SEnS and switches the outputs to a

defined state. See Output response in different operating states for more information.

The level transmitter is not suitable for:

• Bulk materials like plastic granulates and media with a very low dielectric constant like

oils.

• Applications where the probe is subjected to permanent and high mechanical stress.

For example, fast moving viscous medium or fast flowing medium.

Use the level transmitter preferably with metal tanks. When used with plastic tanks,

deterioration caused by electromagnetic interference might occur (noise immunity to

EN61000-6-2).

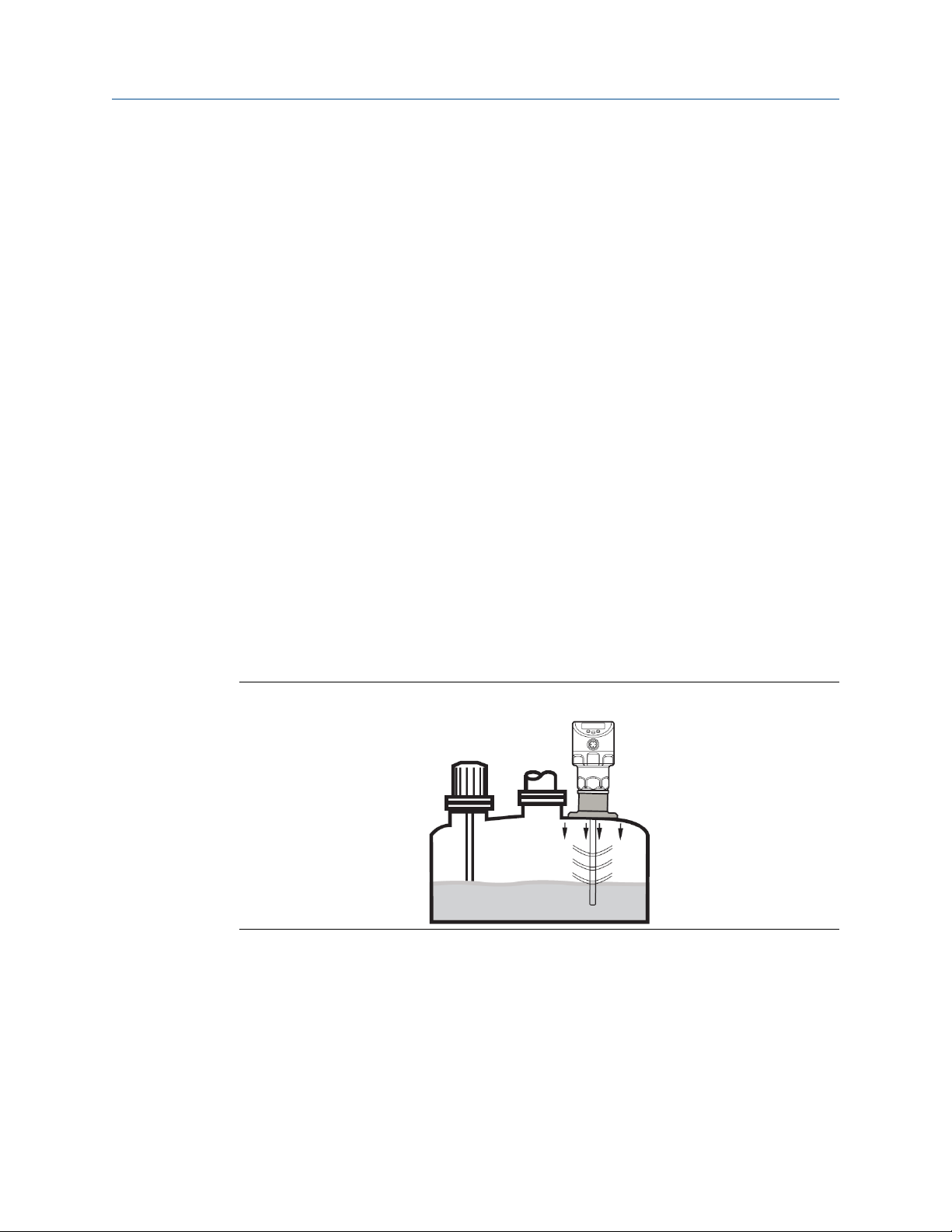

1.3 Measuring principle

The level transmitter uses guided wave radar to measure media level. It emits

electromagnetic pulses every nanosecond to measure the level.

Figure 1-1: Transmitting Pulses

6 Quick Start Guide

Page 7

Quick Start Guide

00825-0100-4326 January 2019

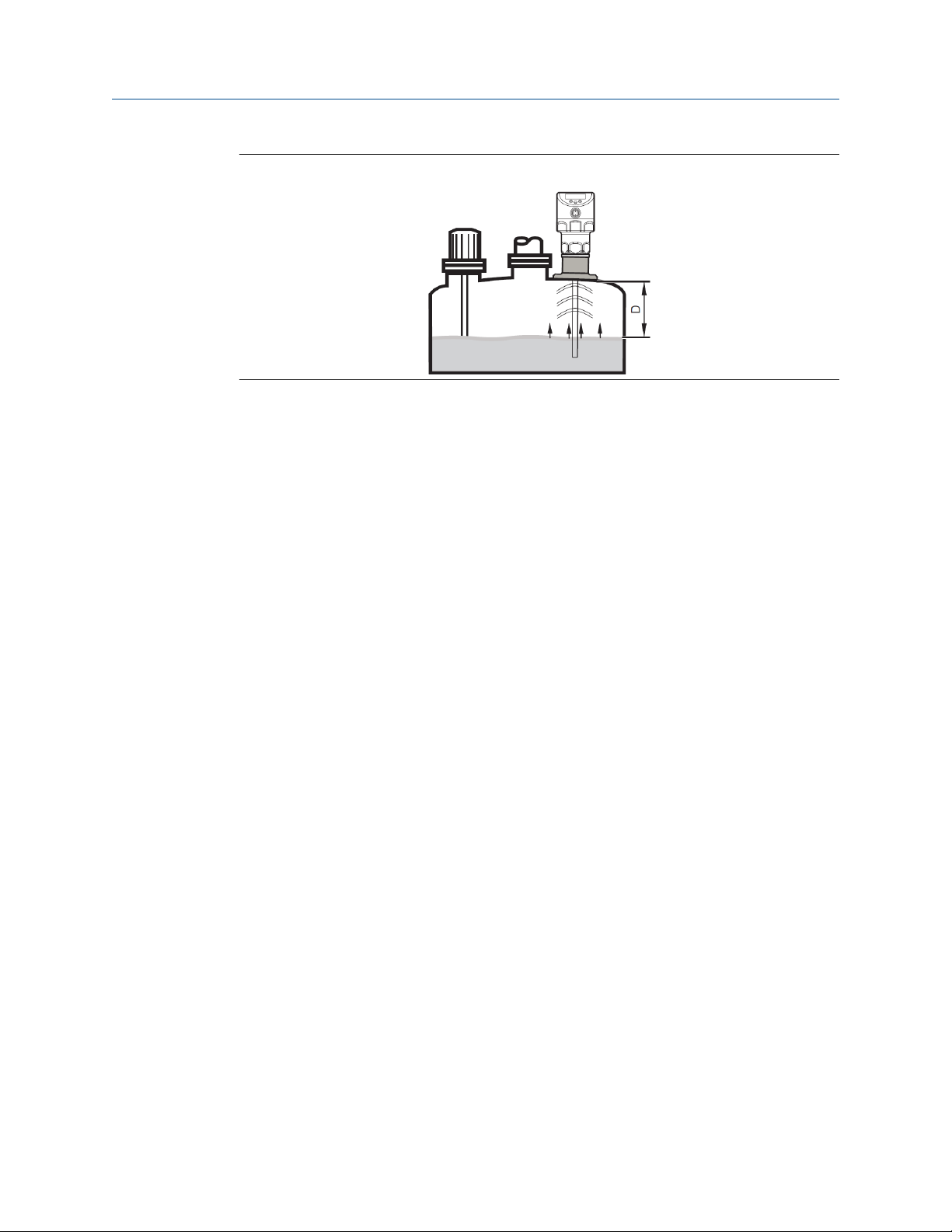

Figure 1-2: Receiving Pulses

The transmitter head transmits pulses that are guided along the probe towards the media

(Figure 1-2). When the pulses hit the media they are reflected and guided back to the

transmitter (Figure 1-2). The time between transmitting and receiving the pulse

determines the traveled distance (D) and the current level. The reference for distance

measurement is the lower edge of the process connection.

Introduction

1.3.1

Probes for different tank heights

The height of the probe must be adjusted to accommodate the height of the tank. Probes

at different heights are available to order. The minimum probe length is 1.18 inches (150

mm). The maximum probe length 78.74 in (2000 mm).

1.4 Outputs

The level transmitter generates output signals based on the output parameter settings.

Two outputs are available and they can be set separately.

OUT1

OUT1 provides a switching signal for level limit or IO-Link communication. See IO-Link for

more information.

OUT2

OUT2 can perform one of these functions:

• An analog signal proportional to the level 4 - 20 mA or 20 - 4 mA

• Switching signal for level limit

1.4.1

Fault states

Defined states for each output prepare the output for fault conditions. If the level

transmitter detects a fault or if the signal quality is below a minimum value, the

transmitter outputs change to the defined fault state.

Use FOU1 and FOU2 to configure fault states for the respective outputs. Fault states for

the analog output follow Namur recommendation (NE43). For more information, see Set

response of the outputs in case of fault.

Quick Start Guide 7

Page 8

Introduction

January 2019 00825-0100-4326

Setting a delay time prevents the level transmitter from erroneously falling into a fault

state. For more information, see Set delay time in case of a fault. During the delay time,

the level transmitter retains the last measured value. If the measured signal is received

again in sufficient strength within the delay time, the unit continues to work in normal

operation. If it is not received again in sufficient strength within the delay time, the

outputs change to the defined state.

Note

In case of heavy foam build-up or turbulence, create a steady environment for the level

transmitter. For more information, see Minimum distances and connection piece

diameter.

Quick Start Guide

1.5 IO-Link

The level transmitter has an IO-Link communication interface which requires an IO-Linkcapable module (IO-Link master) for operation.

The IO-Link interface enables direct access to the process and diagnostic data and provides

the possibility to set the parameters of the unit during operation.

Point-to-point connection is possible with a USB adapter cable.

Detailed information about process data structure (IODDs) necessary for the configuration

of the level transmitter, diagnostic information, parameter addresses, and the necessary

information about the required IO-Link hardware and software can be found at

Emerson.com/Rosemount.

1.6 Functions

The level transmitter performs the functions detailed in this section.

1.6.1

Display functions

The level transmitter displays the current level, either in millimeters, inches, or percentage

of the scaled measuring range. The default factory setting is inches.

For more information on changing the displayed unit of measurement, see Configure the

display.

In the operating mode, you can switch between length display (mm, inch) and

percentage. For more information, see Change display between length and percentage.

The LEDs indicate the set unit of measurement and the switching status of the outputs. For

more information, see Display elements.

1.6.2

8 Quick Start Guide

Analog signal

The level transmitter can provide an analog signal proportional to level.

The parameter ou2 defines the output function for the analog output:

• 4-20 mA (ou2 = I)

• 20-4 mA (ou2 = InEG)

Page 9

Quick Start Guide

00825-0100-4326 January 2019

For more information, see Set output function for OUT2.

The analog start point ASP2 defines the measured value at which the analog start value is

provided. The analog start value is 4 mA with ou2 = I or 20 mA with ou2 = InEG. For more

information, see Scale analog signal.

The analog end point AEP2 defines the measured value at which the analog end value is

provided. The analog end value is 20 mA with ou2 = I or 4 mA with ou2 = InEG. For more

information, see Scale analog signal.

The minimum distance between ASP2 and AEP2 is 20 percent of the active zone.

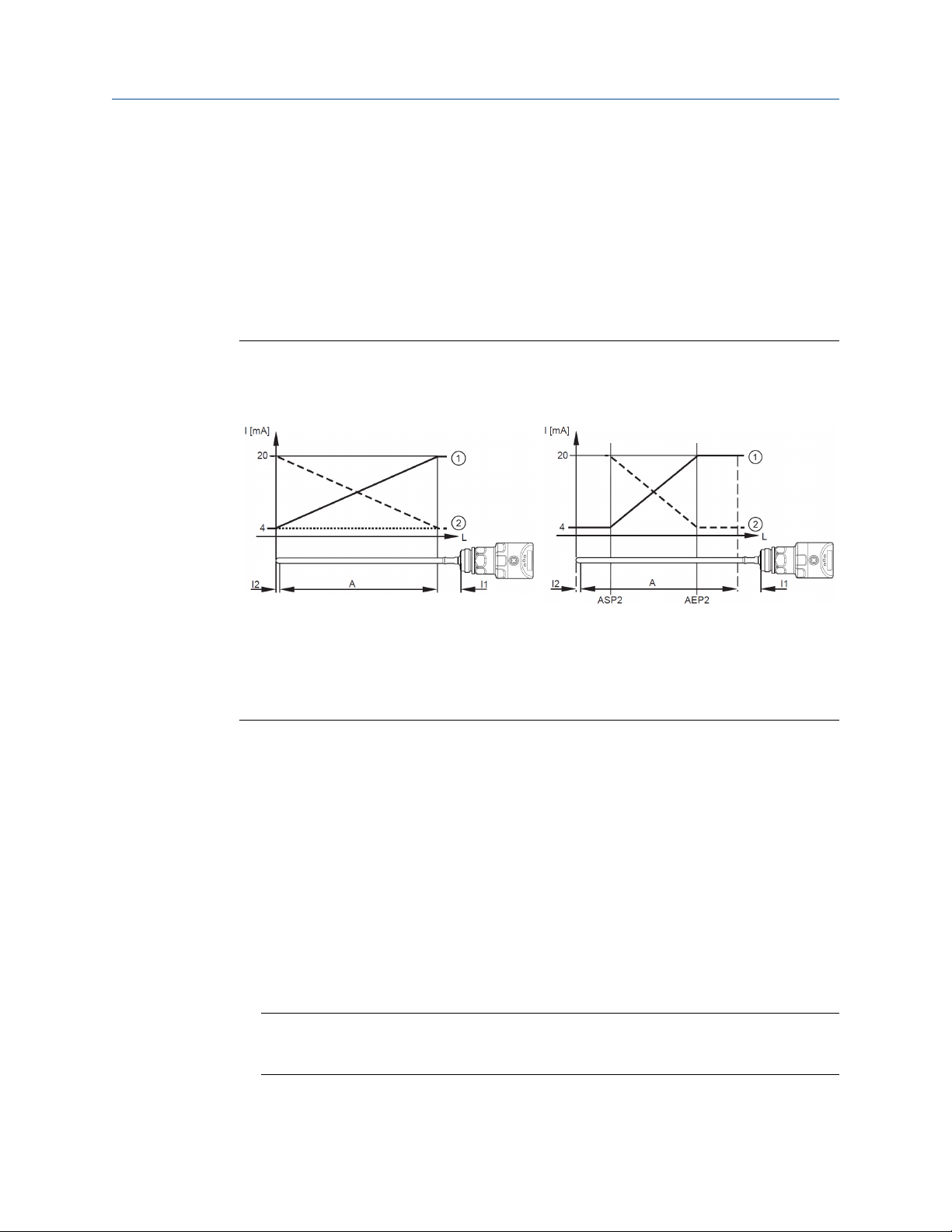

Figure 1-3: Analog signal

The default factory curve of the analog signal: A scaled measuring range curve of the analog

signal:

Introduction

1.6.3

L: Level

A: Active zone = L - (I1 + I2)

I1: Inactive zone 1

I2: Inactive zone 2

For more information about the analog output, see Output response in different operating

states.

Take note of the tolerances and accuracy limits during the evaluation of the analog signal.

For more information, see the Product Data Sheet.

1: ou2 = I (factory setting)

2: ou2 = InEG

ASP2: Analog start point

AEP2: Analog end point

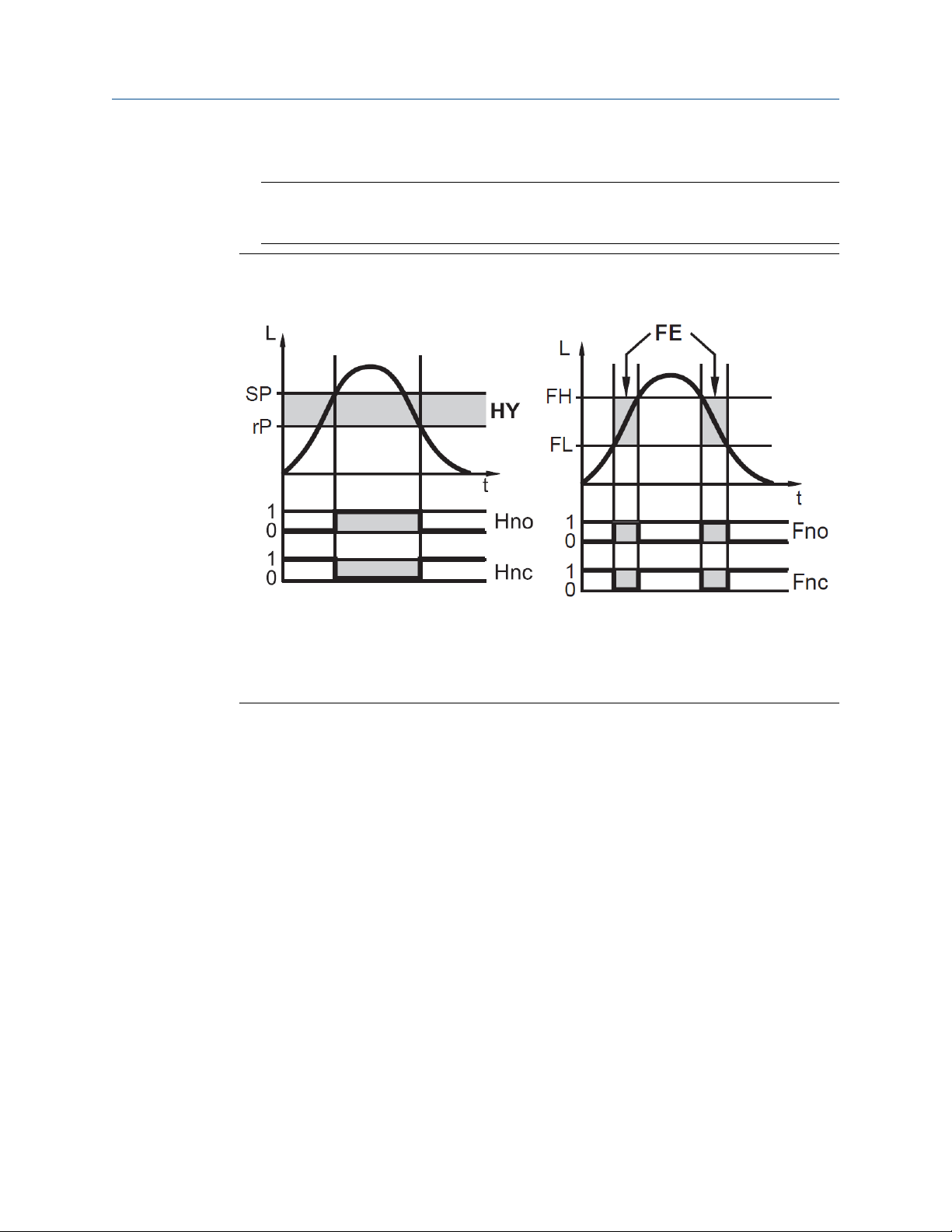

Switching functions

When using a switching output (OUT1 or OUT2), the level transmitter indicates when the

level reaches a set limit or that the level is below the limit.

Select one of the following switching functions for the outputs:

• Hysteresis function/normally open: oux = Hno

• Hysteresis function/normally closed: oux = Hnc

Note

When configuring a switching function, set the set point (SPx) first, then set the reset

point (rPx) with the requested difference.

• Window function/normally open: oux = Fno

Quick Start Guide 9

Page 10

Introduction

January 2019 00825-0100-4326

• Window function/normally closed: oux = Fnc

Note

The difference between FHx and FLx sets the width of the window. FHx is the upper

value and FLx is the lower value.

Figure 1-4: Switching function

Hysteresis function Window function

Quick Start Guide

1.6.4

L: Level

HY: Hysteresis

FE: Window

• The adjustable limits (SP and rP) always refer to the lower edge of the probe.

• The maximum switch-on and switch-off delay for the switching output is 60 seconds.

For more information, see Set switch-on delay for switching outputs and Set switch off

delay for switching outputs.

Damping function

If the medium conditions are unsteady, dampen the transmitter response. The level

transmitter uses a filter to smooth the values into a steady curve when the display and

output response is dampened.

You can configure the damping using dAP. For more information, see Set damping for

measured signal.

In the event of a sudden jump in level, dAP indicates the time in seconds for the output to

reach 63 percent of the final value. After five times dAP, the output should reach 100

percent of the final value.

10 Quick Start Guide

Page 11

Quick Start Guide Introduction

00825-0100-4326 January 2019

1.6.5 Simulation functions

To assist in maintenance, reducing interference, or setting up the level transmitter,

simulate error scenarios and levels.

The duration of a simulation can be between one minute and one hour. The simulation is

started manually and runs until the set duration elapses. During the simulation, the

outputs respond according to the simulated process values. For more information, see

Simulation.

Quick Start Guide 11

Page 12

Introduction Quick Start Guide

January 2019 00825-0100-4326

12 Quick Start Guide

Page 13

Quick Start Guide Installation

00825-0100-4326 January 2019

2 Installation

This section includes instructions for installing and wiring the level transmitter.

These procedures are required to setup the level transmitter:

1. Installing the level transmitter

2. Wire the transmitter

3. Adjust the probe length

To modify the factory default settings, perform these procedures.

• Set parameters

• Perform a tank adjustment

• Change basic settings

To view the factory default settings, see Factory settings. Test that the level transmitter is

working correctly before using.

2.1 Installation considerations

Follow these installation guidelines to ensure more effective operation of the level

transmitter.

• For more effective level measurement, install the level transmitter vertically on the top

of the tank or pipe.

• To reduce signal interference, perform a tank adjustment (see Tank adjustment).

• For more effective level measurement, install the level transmitter in closed, metal

tanks or bypass pipes.

— For installation instructions for open tanks, see Installing in an open tank.

— For installation instructions for plastic containers, see Installing in a plastic tank.

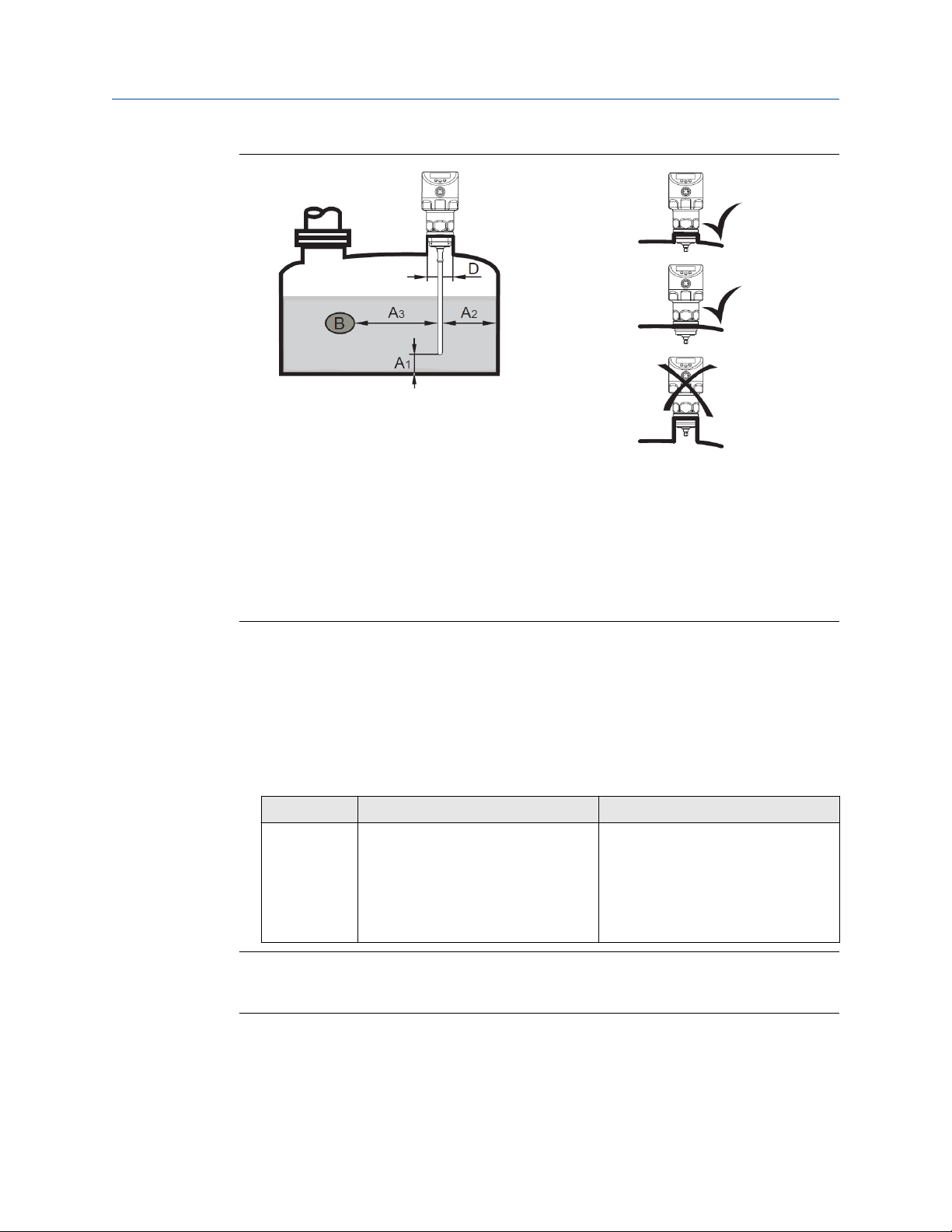

2.1.1

Minimum distances and connection piece diameter

For more effective operation, follow these guidelines for the connection piece diameter

and the distances between the level transmitter and the tank.

Select a connection piece height that is smaller than the connection piece diameter.

Quick Start Guide 13

Page 14

Installation Quick Start Guide

January 2019 00825-0100-4326

Installation distances with adjustment

A1: 0.39 in (10 mm)

A2: 0.79 in (20 mm)

A3: 0.79 in (20 mm) to tank structures (B) 1.97

in (50 mm) to other transmitters type LR

D: ø 1.18 in (30 mm) if installed in a connection

piece

2.1.2 Installation in pipes

If installing the level transmitter in a pipe, the conditions must meet these requirements.

• Hygienic requirements

• Install only in metal pipes

• The internal diameter of the pipe (d) must meet these requirements:

With adjustment

d ø 1.18 in (30 mm) ø 3.94 in (100 mm) with [MEdI] =

Installation distances without adjustment

A1: 0.39 in (10 mm)

A2: 1.97 in (50 mm)

A3: 1.97 in (50 mm) to tank structures (B) 1.97

in (50 mm) to other transmitters type LR

D: No connection piece allowed (see above

image)

Without adjustment

[HIGH]

ø 7.87 in (250 mm) with [MEdI] =

[MId]

For more information, see Set to

another medium.

Note

Using a centering piece can prevent damage caused by turbulent media by stabilizing the

probe.

14 Quick Start Guide

Page 15

Quick Start Guide

00825-0100-4326 January 2019

Installation

2.1.3 Applications with viscous or fast-flowing media

The installation of the level transmitter must meet the following requirements if installed

in conditions with viscous or fast-flowing media and/or agitators.

• The probe cannot contact the tank walls or structures.

• Expect an increase in the minimum lateral distances according to probe length and the

lateral deflection.

• If possible, use a sleeve or a similar device to fix the probe at the lower end so that it is

electrically conductive. See Figure 2-1

Figure 2-1: Installation with Viscous or Fast-Flowing Media

2.1.4

2.1.5

2.1.6

• Ensure the correct function is set. (Especially in use with an empty tank)

Fill openings

Do not install the level transmitter near or in contact with a fill opening.

Highly polluted medium

If the medium is highly polluted, there is a risk that a bridge forms between the probe and

the tank wall or structures in the tank.

To avoid this, increase minimum distance between the probe and the tank walls

depending on the pollution intensity.

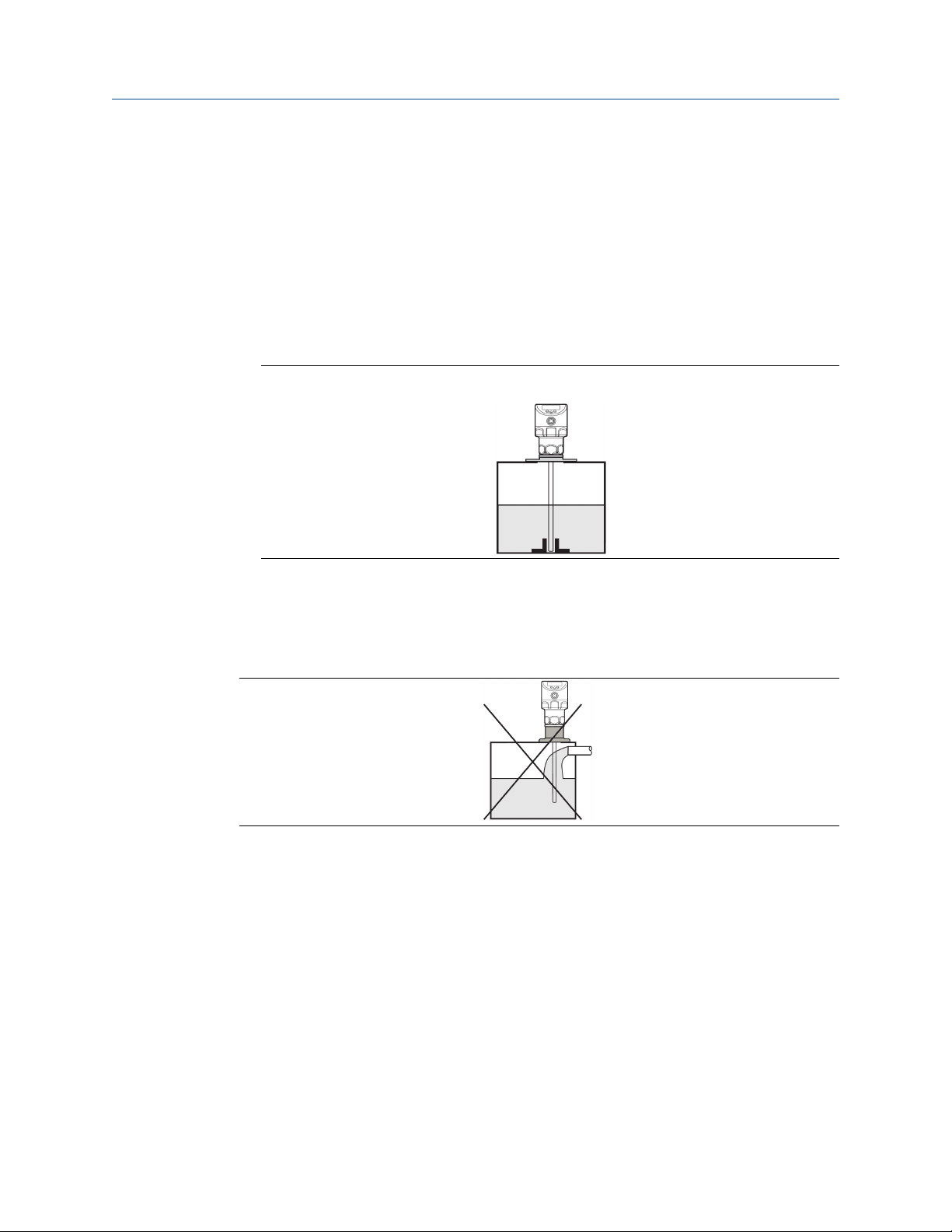

Heavy foam build-up and turbulence

Heavy foam build-up or turbulence in the tank might cause incorrect measurements.

To avoid this, install the transmitter in a steady area that meets hygienic requirements.

Examples of how to create a steady environment include:

Quick Start Guide 15

Page 16

Installation

January 2019 00825-0100-4326

• Install the level transmitter in a metal bypass or a metal still pipe.

• Separate the level transmitter location with metal sheets or perforated sheets.

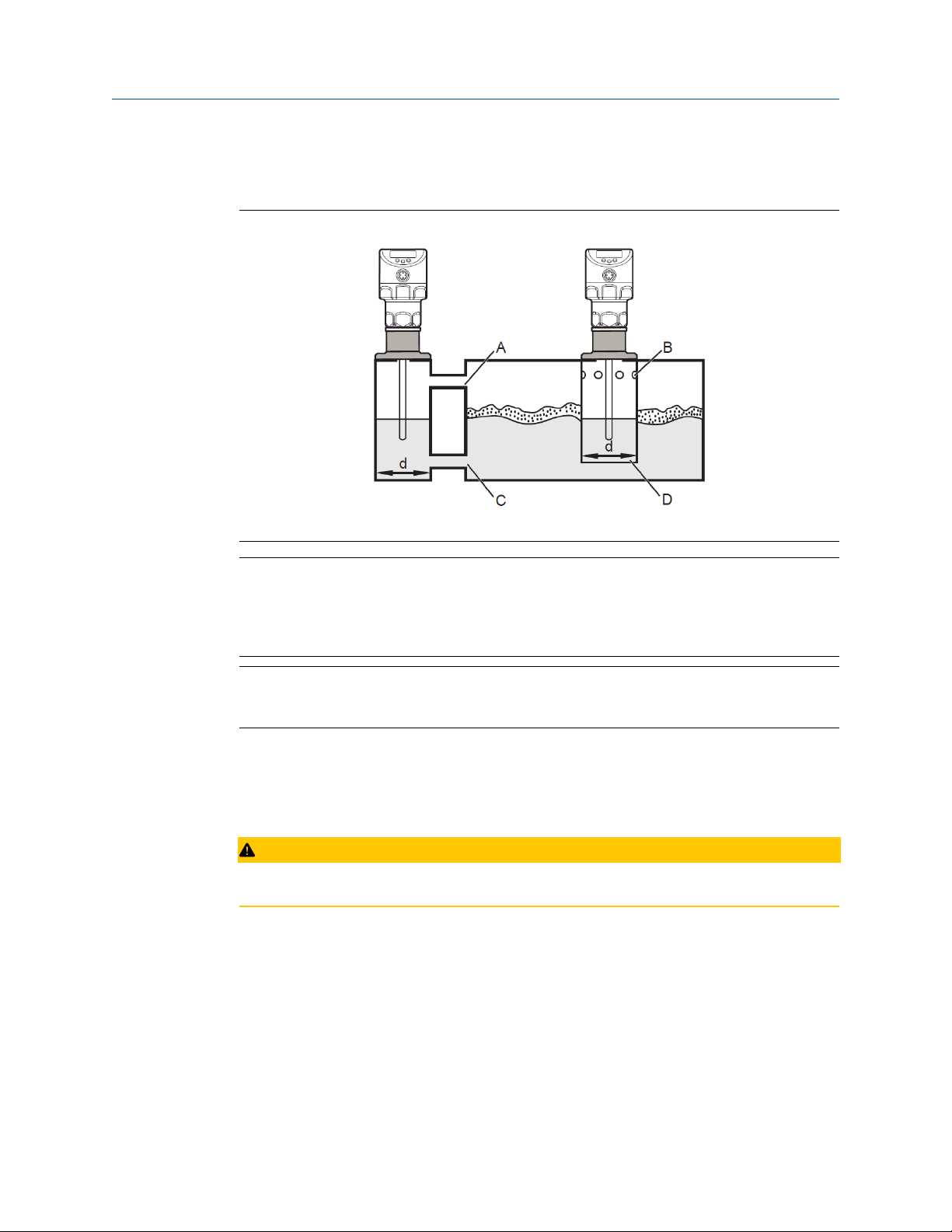

Figure 2-2: Installing in foam build-up and turbulence

Quick Start Guide

2.1.7

d: Minimum diameter (See Installation in pipes)

Note

The upper access to the steady area (A, B) must be above the maximum level. The lower

access (C, D) or the area with perforated sheet must be below the minimum level. This

ensures that neither foam nor turbulence impact the transmitter zone. To avoid

interference from solids in the medium, use perforated sheets or something similar.

Note

With increased foam build-up set the medium parameter [MEdI] to [MId]. For instructions,

see Set to another medium.

Tank adjustment

Tank adjustment reduces interference and ensures a higher excess gain in difficult

application conditions.

CAUTION

Perform a tank adjustment only after installing the level transmitter.

• When performing a tank adjustment, enter an adjustment distance first. Starting from

the process connection, use the adjustment distance to compensate for interfering

reflections.

• Select an adjustment distance (a) so the level transmitter can detect the connection

piece (S) and structures in the tank (B).

• Observe safety distance (b ≥ 9.84 in (250 mm)) to the level or the probe end.

16 Quick Start Guide

Page 17

Quick Start Guide

00825-0100-4326 January 2019

a: Minimum adjustment distance is 0.39 in (10 mm); maximum is L - 9.84 in (250 mm)

b: Safety distance to the level or probe end: b ≥ 9.84 in (250 mm)

S: Connection piece

B: Structures in the tank

Installation

• For probe lengths L < 10.24 in (260 mm), tank adjustment is not possible. tREF is then

not available. In this case, adhere to all installation distances in Installation

considerations.

• If the installation meets all distance guidelines, a tank adjustment is not necessary.

• If possible, perform the tank adjustment on an empty tank to detect any possible

sources of interference. In this case, select the maximum adjustment distance (L - 9.84

in or L - 250 mm).

• Tank adjustment information is not saved with IO-Link. After a replacement, perform a

tank adjustment again. For more information on data storage, see Unit locking and

data storage.

2.2 Installing the level transmitter

Follow these instructions to install the level transmitter.

2.2.1

Adjust the probe length

If needed, modify the standard probe length to accommodate the height of the tank.

Note

• The level transmitter does not support probe lengths less than 5.91 in (150 mm).

• Tank adjustment is not possible with probe lengths of less than 10.24 in (260 mm). For

more information, see Tank adjustment.

Procedure

1. Screw the probe to the level transmitter.

Quick Start Guide 17

Page 18

Installation

January 2019 00825-0100-4326

2. Mark the desired length (L) on the probe. The reference point is the lower edge of

the process connection.

3. Remove the probe from the unit. Do not lose the O-ring between the probe

attachment piece and the probe.

4. Shorten the probe at the mark.

5. Remove all burrs and sharp edges. For hygienic requirements: Restore the required

surface quality. If necessary, polish the probe.

Quick Start Guide

2.2.2

Note

In cases with strong vibrations or moving viscous medium, it may be necessary to

secure the probe connection using screw retaining compound. In this case, ensure

that the compound is harmless because it might migrate into the medium.

Postrequisites

Reinstall the probe by following the steps in Install the probe.

Install the probe

Install the probe onto the level transmitter to ensure accurate level readings.

For more information, see Measuring principle.

Note

The probe is not included with the level transmitter.

CAUTION

Do not damage the surfaces of the process connection and probe. Use tools suitable for

use with plastic surfaces.

Procedure

1. Remove the protective cover and protective devices from the unit and the probe.

18 Quick Start Guide

Page 19

Quick Start Guide

00825-0100-4326 January 2019

2. Slip the supplied O-ring onto the probe connection of the unit and check its

position.

3. Screw the probe to the unit and tighten it.

Note

Recommended tightening torque: 4.79 ft/lbs (6.5 Nm).

Installation

2.2.3

4. Ensure that the O-ring has not moved from its original position. Replace the O-ring

if necessary.

Note

In cases with strong vibrations or moving viscous medium, it might be necessary to

secure the probe connection using screw retaining compound. In this case, ensure

that the compound is harmless because it might migrate into the medium.

5. If the probe length was modified, measure and record the probe length.

a) Precisely measure the length of the probe starting from the lower edge of

the process connection.

b) Record the length of the probe. It is needed for setting up the device

parameters.

For more information on setting the length of the probe in the device parameters,

see Enter probe length.

Install the level transmitter

Install the level transmitter using these steps. Take note of the different process

connections.

CAUTION

Consider the potential dangers related to extreme machine and medium temperatures.

Quick Start Guide 19

Page 20

Installation

January 2019 00825-0100-4326

Prerequisites

Note

Before installing or removing the level transmitter, ensure that no pressure is applied to

the system. Also ensure that there is no medium in the tank that might leak during

installation.

The level transmitter can be installed using a mounting or welding adapter with a sealing

ring. The adapters are supplied with an EPDM o-ring. Further sealing ring materials (FKM)

are available. For ordering information, see the transmitter Product Data Sheet. For

installation instructions, refer to the instructions included with the mounting adapter.

Note

Certain configurations do not allow alignment of the transmitter housing. With process

connections that cannot be aligned, like welding adapters, take into account the final

position of the transmitter housing (readability of the display, cable entry). Observe marks

on adapters. If needed, screw in the unit and mark the requested alignment.

Procedure

1. Lightly grease the thread of the transmitter using a lubricating paste suitable and

approved for the application.

2. Insert the unit into the process connection.

3. Tighten it using a spanner to a torque of 25.8 ft/lbs (35 Nm).

Quick Start Guide

2.2.4

Installing in an open tank

Follow these guidelines when installing the level transmitter in an open tank.

• Use a metal fixture to install the level transmitter to the side of the open tank. It serves

as a launching plate (R) for the level transmitter. The minimum size for a square fixture

is 5.91 by 5.91 in (150 by 150 mm). The minimum size for a circular fixture is 5.91 in

(150 mm) diameter. For more information, see Operation with a single probe.

• If possible, mount the level transmitter in the middle of the fixture. Adhere to the

specified installation distances according to Installation considerations. If necessary,

perform a tank adjustment.

D1: Minimum 5.91 in (150 mm)

R: Launching plate

20 Quick Start Guide

Page 21

Quick Start Guide

00825-0100-4326 January 2019

Installation

2.2.5 Installing in a plastic tank

Follow these guidelines when installing the level transmitter in a plastic tank or in a metal

tank with a plastic lid.

D1: Minimum 5.91 in (150 mm)

R: Launching plate

• The plastic lid must have a drill hole with a minimum diameter of 5.91 in (150 mm).

2.2.6

• Use a metal flange plate or launching plate (R) that sufficiently covers the drill hole. For

more information, see Operation with a single probe.

• Ensure that the distance between the probe and the tank wall is at least 3.15 in (80

mm). Adhere to the installation instructions in Installation considerations. If necessary,

perform a tank adjustment.

CAUTION

When installed in plastic tanks, there may be deterioration caused by electromagnetic

interference from other devices. Follow these guidelines to avoid deterioration:

• Apply a metal foil to the outside of the tank.

• Apply a shielding screen between the level transmitter and other electronic units.

• Install in a metal pipe only if hygienic requirements are met. For more information, see

Installation considerations.

Installing with 3-A® standards

The level transmitter is authorized to display the 3-A symbol. Follow these guidelines to

ensure 3-A compliance when installing the level transmitter.

• Ensure that the transmitter is installed according to 3-A standards.

• Use the level transmitter only with 3-A certified adapters marked with the 3-A symbol.

• The process connection must have a self-draining leakage port. 3-A certified adapters

all have self-draining leakage ports.

• Choose an installation position where the probe and process connection can be

cleaned with a spray ball.

Quick Start Guide 21

Page 22

Installation Quick Start Guide

January 2019 00825-0100-4326

Note

According to 3-A standards, special regulations apply for cleaning and maintenance. For

more information, see Cleaning and maintenance in 3-A® applications. Not suitable for

systems which must meet the criteria of paragraph E1.2 / 63-03 of the 3-A standard 63-03.

2.3 Wire the transmitter

Wire the transmitter according the instructions and illustrations in this topic.

CAUTION

The level transmitter must be connected by a qualified electrician. Adhere to national and

international regulations for the installation of electrical equipment.

Voltage supply according to EN 50178, SELV, PELV.

CAUTION

This devices requires additional surge protection for marine applications (if approval is

available for this device).

Procedure

1. Disconnect power to the level transmitter.

2. Connect the unit according to these diagrams (colors to DIN EN 60947-5-2):

OUT1: switching output / IO-Link

OUT2: analog output / switching output

BK: Black

BN: Brown

BU: Blue

WH: White

Note

After applying operating voltage to the level transmitter for the first time, enter the

probe length into the device parameters. After that, the level transmitter is ready

for operation. For more information, see Enter probe length.

22 Quick Start Guide

Page 23

Quick Start Guide Installation

00825-0100-4326 January 2019

Example circuits

2 x positive switching 2 x negative switching

1 x positive switching / 1 x analog 1 x negative switching / 1 x analog

Quick Start Guide 23

Page 24

Installation Quick Start Guide

January 2019 00825-0100-4326

24 Quick Start Guide

Page 25

Quick Start Guide Operation

00825-0100-4326 January 2019

3 Operation

The procedures in this section provide instructions for setting parameters and settings on

the level transmitter.

3.1 Display elements

The front of the level transmitter includes LED indicators, buttons, and an alphanumeric

display.

1 to 8: Indicator LEDs

LEDs 1 - 3 Selected unit of measurement.

LEDs 4 - 6 Not used.

LED 7 Active only if the switching output ou2 = I or InEG is selected; then:

switching status OUT2 (on when output 2 is switched).

LED 8 Switching status OUT1 (on when output 1 is switched).

9: Enter button

Open the user menu, edit and confirm the parameter values.

10 to 11: Arrow keys up [▲] and down [▼]

• Selection of the parameters

• Setting of the parameter values (continuously by holding pressed; incrementally by pressing

once).

12: Alphanumeric display, four digits

• Display of the current level.

• Display of the parameters and parameter values.

Quick Start Guide 25

Page 26

Operation Quick Start Guide

January 2019 00825-0100-4326

3.2 Menu structure

The menu provides options for configuring parameters and viewing settings.

Note

Menu items highlighted in gray are active only after setting assigned parameters.

• I: Main Menu (See Main menu options)

• II: Menu level EF (See Extended functions menu options (EF))

26 Quick Start Guide

Page 27

Quick Start Guide Operation

00825-0100-4326 January 2019

3.2.1

Note

Menu items highlighted in gray are active only after setting assigned parameters.

• III: Level CFG (See Configuration menu options (CFG))

• IV: Level ENV (See Environment menu options (ENV))

• V: Level SIM (See Simulation menu options (SIM))

Main menu options

The main menu includes these options.

Option

tREF Carry out tank adjustment.

SP1/rP1 Set point 1 / reset point 1 at which OUT1 switches.

FH1/FL1 Upper / lower limit for the acceptable range within which OUT1 switches.

ASP2 Analog start point 2: measured value at which the analog start value is

AEP2 Analog end point 2: measured value at which the analog end value is

Description

Visible only if LEnG ≥ 10.24 (260 mm).

Visible only after selecting hysteresis function (ou1 = H..)

Visible only after selecting window function (ou1 = F..)

provided. The analog start value is set with parameter ou2.

Visible only after selecting analog output (ou2 = I or InEG)

provided. The analog end value is set with parameter ou2.

Visible only after selecting the analog output (ou2 = I or InEG)

Quick Start Guide 27

Page 28

Operation Quick Start Guide

January 2019 00825-0100-4326

Option Description

SP2/rP2 Set point 2 / reset point 2 at which OUT2 switches.

Visible only after selecting the hysteresis function (ou2 = H..)

FH2/FL2 Upper / lower limit for the acceptable range within which OUT2 switches.

Visible only after selecting the window function (ou2 = F..)

EF Extended functions / opening of menu level 2

3.2.2 Extended functions menu options (EF)

The extended functions menu includes these options.

Option Description

rES Restore factory settings (all parameters including tank adjustment)

CFG Open the configuration menu (CFG)

ENV Open the environment menu (ENV)

SIM Open the simulation menu (SIM)

3.2.3 Configuration menu options (CFG)

The configuration menu includes these options.

Option

ou1 Output configuration for OUT1: switching signal for level limit value.

ou2 Output configuration for OUT2:

dS1 Switch-on delay for OUT1

dr1 Switch-off delay for OUT1

(1)

dS2

(1)

dr2

uni Selection of the unit of measurement on the transmitter display; mm or

P-n Output polarity of the switching outputs; positive or negative switching

FOU1 Response of OUT1 in case of a fault

FOU2 Response of OUT2 in case of a fault

Description

Hysteresis or window function, normally closed or normally open

• analog signal for current level, 4 - 20 mA or 20 - 4 mA

• Switching signal for level limit. Hysteresis or window function,

normally closed or normally open

Switch-on delay for OUT2

Switch-off delay for OUT2

inch

SELd Selection of display options

dAP Damping of the measured signal (mean filter)

28 Quick Start Guide

Page 29

Quick Start Guide

00825-0100-4326 January 2019

Option Description

dFo Delay time for the outputs to pass into the state defined with FOUx; only

effective in case of a fault

(1) Visible only after selecting hysteresis or window function (ou2 = H.. or F..).

Operation

3.2.4 Environment menu options (ENV)

The environment menu includes these options.

Option Description

LEnG Input of the probe length

MEdI Medium selection

3.2.5 Simulation menu options (SIM)

The simulation menu includes these options.

Option Description

S.LvL Simulation of a level or an error state

S.Tim Simulation duration 1 - 60 minutes

S.On Simulation start/stop

3.3 Parameter settings

The level transmitter remains in operating mode while setting new parameters. It

continues to monitor using the existing parameters until new parameters are set.

3.3.1

Read set parameters

Perform these steps to view the parameters set on the level transmitter.

Procedure

1. Press Enter to open the menu.

2. Press the up or down button to scroll through the set parameters.

3. Press Enter again to view the parameter value. The transmitter displays the value

for 30 seconds then returns to the process value display.

3.3.2

Quick Start Guide 29

Set parameters

Follow these steps to modify parameters values.

Procedure

1. Press Enter to open the menu.

2. Press the up or down buttons to navigate to a parameter.

Page 30

Operation

January 2019 00825-0100-4326

3. Press Enter to select a parameter.

4. Press the up or down buttons for at least one second.

After one second the parameter value changes. Press and hold the button to

change the value continuously.

5. Press Enter.

The level transmitter saves the new value.

6. Repeat steps 2 - 5 to modify other parameters.

After 30 seconds of inactivity, the menu returns to the process view display.

Quick Start Guide

3.3.3 Change menu level

Perform these steps to move to the next menu level.

Procedure

1. Press Enter to get to the menu.

2. Press up or down until the menu displays EF.

3. Press Enter.

The display shows the next menu.

3.3.4

Lock or unlock the menu

Lock the menu to prevent unintentional changes to the parameters. By default, the menu

is unlocked. When the menu is locked, it briefly displays Loc when you attempt to change

a parameter value.

Prerequisites

The level transmitter must be in normal operating mode.

Procedure

1. Press and hold the up and down buttons simultaneously for 10 seconds.

The menu is locked and it displays Loc.

2. To unlock the menu, press and hold the up and down buttons for 10 seconds.

The menu is unlocked and it displays uLoc.

3.4 Setup the level transmitter

Procedures in this section provide instructions for configuring the settings and parameters

of the level transmitter.

3.4.1

Enter probe length

Enter the length of the probe into the parameters to ensure accurate level measurements.

Procedure

1. Apply operating voltage.

30 Quick Start Guide

Page 31

Quick Start Guide

00825-0100-4326 January 2019

The display shows the initial display.

2. Select LEnG from the menu.

If the parameter does not contain a value, the display shows nonE.

3. Press and hold up or down for at least one second. The display shows the detected

probe length.

4. If the detected probe length is incorrect, press up or down to change the probe

length to the correct value.

5. Press Enter.

The level transmitter proceeds to operating mode.

Notes

The level transmitter can automatically detect the length of the probe if:

• The tank is empty

• The level transmitter is mounted on a sufficiently large launching plate

For instructions on manually determining the length of the probe, see Record probe

length.

Operation

3.4.2

3.4.3

Perform a tank adjustment

Tank adjustment reduces the effect of interference and ensures a higher excess gain in

difficult application conditions.

For more information on tank adjustments, see Tank adjustment.

Prerequisites

The tank adjustment menu option tREF appears only if the set probe length is greater than

or equal to 10.24 in (260 mm).

Procedure

1. Select tREF from the menu.

The display shows nonE or the value set by a previous tank adjustment.

2. Press and hold up or down for at least one second.

The display shows the distance value. The default value is 0.39 in (10 mm).

3. If necessary, correct the value using the up and down buttons.

4. Press Enter.

The display shows donE.

5. Press Enter again.

The level transmitter reboots and returns to operating mode.

Configure the display

Modify how the level transmitter displays information.

Procedure

1. Change the unit of measurement.

Quick Start Guide 31

Page 32

Operation

January 2019 00825-0100-4326

a) Select uni from the menu.

b) Select mm for millimeters or inch for inches.

c) Press Enter.

2. Change the indicator.

a) Select SELd from the menu.

b) Set the type of indicator.

• L: The level indicated in millimeters or inches.

• %: The level indicated as a percentage. ASP2 corresponds to 0% and AEP2

corresponds to 100%.

• OFF: The display is off by default. When a button is pressed, the display

turns on for 30 seconds.

Quick Start Guide

Change display between length and percentage

3.4.4

While the level transmitter is in operating mode, it displays the set unit of measurement. It

can display the level measurement in a different unit of measurement during operation

mode.

For more information on setting the default unit, see Configure the display.

Procedure

1. Press up or down.

The display shows the level measurement in a different unit of measurement.

2. Press up or down again to return it to the default unit of measurement or wait for 30

seconds.

Set output signals

The procedures in this section provide instructions for modifying the output signals.

Set output function for OUT1

Follow these steps to set the function for the output 1 (OUT1).

Procedure

1. Select ou1 from the menu.

2. Select a switching function.

• Hno: Hysteresis function / normally open

• Hnc: Hysteresis function / normally closed

• Fno: Window function / normally open

• Fnc: Window function / normally closed

32 Quick Start Guide

Page 33

Quick Start Guide

00825-0100-4326 January 2019

Note

Use the Hnc switching function if the switching output is used as an overflow

prevention. The principle of normally closed operation ensures that the level

transmitter also detects wire breaks or cable breaks.

Operation

Set switching limits (hysteresis)

Use these steps to set the hysteresis limits for the switching output.

Procedure

1. Ensure that the function Hno or Hnc is set for ou1 or ou2.

2. Select SP1 or SP2 then set the value at which the output is set.

3. Select rP1 or rP2 then set the value at which the output is reset.

Note

rPx is always smaller than SPx. The level transmitter accepts only values which are

lower than the value for SPx. If SPx changes, rPx also changes provided that the

lower end of the setting range is not reached.

Set switching limits (window)

Use these steps to set the limits for the window switching output.

Procedure

1. Ensure that the function Fno or Fnc is set for ou1 or ou2.

2. Select FH1 or FH2 then set the upper limit of the acceptable range.

3. Select FL1 or FL2 then set the lower limit of the acceptable range.

Note

FLx is always lower than FHx. The level transmitter accepts only values which are

lower than the value for FHx. If FHx changes, FLx also changes provided that the

lower end of the setting range is not reached.

Set switch-on delay for switching outputs

Follow these steps to set the switch-on delay for switching outputs.

Procedure

1. Select dS1 or dS2 from the menu.

2. Set the value between 0.0 and 60 seconds.

Note

The switch-on delay reacts according to VDMA. According to VDMA, the switch-on

delay always effects SP and the switch-off delay always effects rP irrespective of

whether the level transmitter uses the normally open or normally closed function.

Quick Start Guide 33

Page 34

Operation

January 2019 00825-0100-4326

Quick Start Guide

Set switch off delay for switching outputs

Follow these steps to set the switch-off delay for switching outputs.

Procedure

1. Select dr1 or dr2 from the menu.

2. Set the value between 0.0 and 60 seconds.

Note

The switch-on delay reacts according to VDMA. According to VDMA, the switch-on

delay always effects SP and the switch-off delay always effects rP irrespective of

whether the level transmitter uses the normally open or normally closed function.

Set output function for OUT2

Follow these steps to set the function for the output 2 (OUT2).

Procedure

1. Select ou2 from the menu.

2. Set the switching function:

• I: Current output 4-20 mA

• InEG: Current output 20-4 mA

• Hno: Hysteresis function/normally open

• Hnc: Hysteresis function/normally closed

• Fno: Window function/normally open

• Fnc: Window function/normally closed

Note

If using the output to prevent overflow, set ou2 = Hnc (NC function). The principle

of normally closed operation ensures that wire break or cable break is also detected.

Scale analog signal

Follow these steps to modify the start and end points of the analog signal.

Procedure

1. Select ASP2 and set the analog start point.

2. Select AEP2 and set the analog end point.

Note

Setting these parameters with IO-Link is possible only if parameter ou2 = I or InEG.

For more information, see Analog signal.

34 Quick Start Guide

Page 35

Quick Start Guide

00825-0100-4326 January 2019

Operation

Set output logic for switching outputs

Follow these steps to set the output logic for switching outputs.

Procedure

1. Select P-n from the menu.

2. Set PnP or nPn.

Set response of the outputs in case of fault

Follow these steps to modify how an output responds to faults.

Procedure

1. Select FOU1 to modify the response for output 1 or FOU2 to modify the response

for output 2 from the menu.

2. Set a value:

• On: Output switches ON in case of a fault.

The analog output switches to a value of greater than 21 mA in case of a fault.

• OFF: Switching output switches OFF in case of a fault.

The analog output switches to a value of less than 3.6 mA in case of a fault.

Fault examples

• Defective hardware

• Signal quality too low

Note

The level transmitter does not consider overflow to be a fault.

Set damping for measured signal

Follow these steps to set the damping time for a measured signal.

Procedure

1. Select dAP from the menu.

2. Set damping in seconds.

The setting range is between 0.0 to 60.0 seconds.

For more information, see Damping function.

Set delay time in case of a fault

Follow these steps to set the delay time after which the level transmitter identifies a fault.

Procedure

1. Select dFo from the menu.

2. Set a value between 0.0 and 10.0 seconds.

Quick Start Guide 35

Page 36

Operation

January 2019 00825-0100-4326

Note

The parameter dFo is effective only in the case of a fault. Mind the dynamics of your

application. In case of fast level changes, change the value step by step. For more

information, see Fault states.

Quick Start Guide

3.4.5 Reset all parameters to factory default settings

Follow these steps to reset all of the parameter values to the default factory settings.

Procedure

1. Select rES from the menu.

2. Press Enter until rES is aligned right.

3. Press and hold up or down until the display shows ----.

4. Press Enter.

The level transmitter reboots and resets the parameter values to the default factory

settings.

3.4.6

Note

The level transmitter is operational only after entering basic settings. For more

information, see Menu structure.

Change basic settings

Set these parameters after making any changes to the probe length or medium type.

Change the probe length

Modify the probe length parameter value after changing the length of the probe.

Procedure

1. Select LEnG from the menu.

2. Enter the probe length (L).

Note the set unit of measurement uni.

3. Press Enter.

Note

After changing the probe length, review or modify the values for the switching

limits. For more information, see Enter probe length.

Note

After changing the probe length, the unit deletes any existing tank adjustment. If

necessary, perform a tank adjustment again. For more information, see Perform a

tank adjustment.

36 Quick Start Guide

Page 37

Quick Start Guide Operation

00825-0100-4326 January 2019

Set to another medium

If the medium in the tank has changed, modify the parameters for the medium to match

the new medium.

Procedure

1. Select MEdI from the menu.

2. Set the medium type.

• HIGH: For water and water-based media.

Operating mode is optimized for suppression of deposits on the probe.

• MId: For water-based media and media with a medium dielectric constant value

(oil-in-water emulsions).

Operating mode optimized for the detection of media with increased foam

build-up.

3. Press Enter.

Note

In case of doubt, perform an application test to ensure that the setting is best suited

for the medium.

3.4.7

Simulation

Simulation mode allows you to perform tests on the level transmitter while it simulates

levels and error scenarios.

Set simulation value

The simulation value determines what error scenario the simulation shows.

Procedure

1. Select S.LvL from the menu.

2. Set the simulation value:

• Numerical value: level in millimeters or inches (depending on the basic setting)

• FULL: full state

• SEnS: weak measured signal

• Err: electronic fault found

• EPTY: empty state

3. Press Enter.

Quick Start Guide 37

Page 38

Operation

January 2019 00825-0100-4326

Quick Start Guide

Set simulation duration

The simulation duration parameter sets the length in time of the simulation.

Procedure

1. Select S.Tim from the menu.

2. Set time span for simulation.

Setting range: 1, 2, 3, 4, 5, 10, 15, 20, 30, 45, 60 minutes

Factory setting: three minutes

3. Press Enter.

Switch simulation on or off

Switching the simulation on starts the simulation and switching it off cancels the

simulation.

Procedure

1. Select S.On from the menu.

2. Select On or OFF.

3. Press Enter.

Note

The simulation is active until Enter is pressed again or the time set via S.Tim

elapses. During the simulation, the level transmitter displays SIM every three

seconds. After the simulation, the level transmitter goes again to the parameter

S.On and internally the level transmitter goes again to the operating mode (and the

process value transmission).

After another 30 seconds the display goes again to the process value display.

Note

If using IO-Link to start and configure a simulation, it can be canceled only using IOLink. The level transmitter displays C.Loc if the simulation is attempted to be

canceled with the function buttons.

3.5 Using the transmitter

The procedures in this section provide instructions for operating the level transmitter.

3.5.1

38 Quick Start Guide

Operation with a single probe

Using the level transmitter with a single probe is suited for the detection of aqueous

media, especially heavily soiled aqueous media.

Note

The level transmitter is intended only for operation with a single probe. A coaxial probe is

not available for this unit.

Page 39

Quick Start Guide Operation

00825-0100-4326 January 2019

To correctly transfer the microwave pulse to the tank with optimum transmission power,

the level transmitter needs a sufficiently large metal launching surface or launching plate.

For installation in closed metal tanks or metal bypass pipes, the tank lid or upper pipe

section serves as a launching surface. Use a sufficiently large fixing plate, metal plate or

something similar when installing in open metal tanks, plastic tanks, or metal tanks with

plastic lids. For more information, see Installing in an open tank or Installing in a plastic

tank.

3.5.2 Operation with a bypass or still pipe

Use a bypass or a still pipe in applications like heavy foam build-up.

For more information about heavy foam build-up and turbulence, see Heavy foam build-

up and turbulence.

For more information about the minimum internal pipe diameter, see Installation in pipes.

For general installation instructions, see Installation.

3.5.3

3.5.4

Function check

After turning on the level transmitter, it is in operating mode. It measures and evaluates

level and generates output signals according to the set parameters.

Check that the level transmitter is operating correctly before using it in a production

environment.

Operation indication

These indicators show how the level transmitter is operating.

Indicator

---- continuous Initialization phase after power on

---- Level below the active zone

Numerical value + LED1Current level in millimeters

Numerical value + LED2Current level in inches

Numerical value + LED3Current level in percent of the scaled measuring range

Definition

Initially the level transmitter is not operational. Configure basic settings

to enable the level transmitter (see Change basic settings).

LED 7 / LED 8 Switching status OUT2/OUT1

FULL + numerical value

alternately

SIM + XXX Simulation active. XXX = state to be simulated (See Simulation)

S.On Simulation stopped (See Simulation)

Quick Start Guide 39

Level has reached or exceeded the maximum measuring range (=

overflow warning).

Page 40

Operation

January 2019 00825-0100-4326

Indicator Definition

Loc The level transmitter is locked using the function buttons. Setting

parameter values is not possible without unlocking the level transmitter.

To unlock the level transmitter, press and hold up and down for 10

seconds.

uLoc The level transmitter is unlocked or the parameter setting is possible

again.

C.Loc The level transmitter is temporarily locked. Parameter setting via IO-Link

is active.

S.Loc The level transmitter permanently locked via IO-Link. Unlocking is

possible only via IO-Link.

Quick Start Guide

3.6 Setting parameters with IO-Link

During setup, send valid basic settings to the device even if the default settings

correspond to the connected device. Enter the basic settings correctly according to the

attached probe and the medium to be detected.

3.6.1

Set parameters using IO-Link

Use IO-Link software to set parameter settings on the level transmitter using a computer.

Procedure

1. Enter probe length (LEnG). Example: LEnG = 1000 mm.

2. Scale analog output (ASP2 and AEP2; AEP2 must at least be 20 % greater than

ASP2). Example: AEP2 = 970 mm.

3. Alternatively: Set parameter ou2 to H.. or F...

4. Select the medium (MEdI). Example: MEdI = MId.

• HIGH = For water and water-based media. Operating mode is optimized for

suppression of deposits on the probe.

• MId = For water-based media and media with a mean dielectric constant value.

Operating mode is optimized for media with increased foam build-up.

5. Transfer the transmitter data to the unit.

6. Carry out tank adjustment depending on the installation (tREF or button

"TEACH_TANK_REF".

To change the adjustment distance (RefDist), send this individual parameter to the

transmitter first. Then, perform a tank adjustment. Select the adjustment distance

according to, for example, the height of connection pieces or the position of

structures in the tank. Within the adjustment distance, starting from the process

connection, interfering reflections are compensated. Example: RefDist = 50 mm.

7. Modify any other parameter values.

Note

Only if data storage is required in an IO-Link application:

40 Quick Start Guide

Page 41

Quick Start Guide Operation

00825-0100-4326 January 2019

IO-Link does not save tank adjustment information. After the level transmitter fails,

perform another tank adjustment. The level transmitter reverts to the cyclical

process data transmission after performing a tank adjustment successfully.

After a factory reset, the device reboots and the factory settings are restored.

3.6.2 Unit locking and data storage

The IO-Link master saves all parameters of the connected transmitter (except tank

adjustment) if configured in the master (data storage). When a transmitter is replaced by a

transmitter of the same type, the parameters of the old transmitter are automatically

written to the new transmitter if configured in the master and if the transmitter allows

this.

For safety reasons, the level transmitter can refuse the parameter download.

Factory default setting: Open

Data storage

• Open: the transmitter allows parameter download from the master

• Locked: the transmitter refuses parameter download from the master

Quick Start Guide 41

Page 42

Operation Quick Start Guide

January 2019 00825-0100-4326

42 Quick Start Guide

Page 43

Quick Start Guide Troubleshooting and maintenance

00825-0100-4326 January 2019

4 Troubleshooting and maintenance

The topics in this section provide information on identifying and resolving issues and

maintaining the level transmitter.

4.1 Error indicators

This table describes error scenarios for the level transmitter and possible solutions.

Indicator Possible cause Recommended fix

Err Fault in the electronics. Replace the unit.

nPrb Probe detached from the unit; possibly

incorrect setting of the probe length.

SEnS Measurement disturbed by heavy foam

build-up or turbulence.

Measurement disturbed by separation

layers (e.g. oil layer on water).

Probe or process connection soiled. Clean the probe and the process

Installation conditions not adhered to. • Observe the notes in Installation.

Probe length or sensitivity (setting to

the medium) incorrect.

SCx + LED 7

SCx + LED 8

SC + LED 7

+ LED 8

Flashing: short circuit in switching

output OUT1 or OUT2.

Flashing: short circuit in both switching

outputs

Check whether the probe is still

attached to the unit. Check the

parameter LEnG.

• Install the unit in a still pipe or

bypass (Installation)

• Set or increment dFo (Set delay

time in case of a fault)

Remove the oil layer by suction, stir the

medium, verify the composition.

connection.

• Repeat or perform a tank

adjustment. (Tank adjustment)

Correct settings then perform a tank

adjustment (Tank adjustment).

Remove the short circuit.

Remove the short circuit.

PArA Faulty data set Restore factory default settings (See

Reset all parameters to factory default

settings)

4.2 Output response in different operating states

These tables provide information on the response of outputs for different operating

states.

Operating state

Initialization OFF OFF

Quick Start Guide 43

OUT1 OUT2

(1)

Page 44

Troubleshooting and maintenance Quick Start Guide

January 2019 00825-0100-4326

Operating state OUT1 OUT2

Normal operation According to the level and ou1

Fault OFF with FOU1 = OFF;

(1) If the analog function ou2 = I has been selected. If the switching function has been selected: see

column OUT1.

Additions to the analog output

Full signal With ou2 = I: 20 - 20.5 mA

Empty signal With ou2 = I: 4 - 3.8 mA

4.3 Maintenance

This section includes notes on maintaining the level transmitter.

• Keep the process connection free of deposits and foreign bodies.

• In case of heavy soiling: clean the process connection and probe. For cleaning

purposes, the level transmitter can be removed from the adapter and the probe can be

screwed off the unit.

(1)

According to the level 4 - 20

setting

ON with FOU1 = On

With ou2 = InEG: 4 - 3.8 mA

With ou2 = InEG: 20 - 20.5 mA

mA

< 3.6 mA with FOU2 = OFF

> 21 mA with FOU2 = On

CAUTION

Before installing or removing the unit:

— Ensure no pressure is applied to the system and there is no medium in the tank that

could leak.

— Note the potential dangers related to extreme machine and medium temperatures.

• Use only tools suitable for plastic surfaces for wetted surfaces.

• Ensure gasketed connections (probe or process connection adapter) are not soiled or

damaged. Check sealing rings for damage.

• Replace any damaged parts.

• After changing the medium, it may be necessary to change the settings of the level

transmitter. (See Set to another medium)

• IO-Link does not save tank adjustment information. After replacing the transmitter,

perform another tank adjustment. (See Perform a tank adjustment)

• It is not possible to repair the level transmitter.

• After use, dispose of the unit in an environmentally friendly way in accordance with the

applicable national regulations.

44 Quick Start Guide

Page 45

Quick Start Guide Troubleshooting and maintenance

00825-0100-4326 January 2019

• In case of returns, ensure that the unit is free from soiling, especially dangerous and

toxic substances.

4.3.1 Cleaning and maintenance in 3-A® applications

Follow these steps when cleaning the level transmitter in a 3-A compliant environment.

Regularly perform clean out of place (COP) cleaning on the level transmitter to conform to

3-A standards.

Prerequisites

Before installing the level transmitter:

• Ensure that no pressure is applied to the system and that there is no media in the tank

that could leak.

• Note the potential dangers related to extreme machine and medium temperatures.

Procedure

1. Remove the probe from the unit.

2. Remove O-ring from the transmitter.

3. Remove O-ring from the groove and clean it.

4. Check O-ring and groove.

5. Reassemble the level transmitter.

4.3.2

Transport

When transporting the level transmitter, follow these guidelines to avoid damage.

• Use only appropriate packaging.

• If installed in a tank or pipe, protect the tank or pipe and the level transmitter against

shock and vibration. Protect the probe against deflections and vibrations. If necessary,

fix at several points to prevent movement of unstable areas.

Quick Start Guide 45

Page 46

Troubleshooting and maintenance Quick Start Guide

January 2019 00825-0100-4326

46 Quick Start Guide

Page 47

Quick Start Guide Setting ranges

00825-0100-4326 January 2019

5 Setting ranges

These tables show the setting ranges for the level transmitter parameters.

LEnG inch mm

Setting range 6.0 - 78.8 150 - 2000

Step increment 0.2 5

The setting ranges for the switching limits (SPx, rPx, FHx, FLx) depend on the probe length

(L). In general the following applies:

Parameters inch mm

min max min max

SPx/FHx 0.6 L - 1.2 15 L - 30

rPx/FLx 0.4 L - 1.4 10 L - 35

Step increment 0.05 1

rPx/FLx is always smaller than SPx / FHx. If SPx / FHx is shifted, rPx / FLx also shifts provided

that the lower end of the setting range is not reached. Always set SPx / FHx first, then rPx/

FLx.

The setting ranges for analog start point ASP2 and analog end point AEP2 depend on the

probe length (L). In general the following applies:

Parameters

ASP2 0 N/A 0 N/A

AEP2 N/A L - 1.2 N/A L - 30

Step increment 0.05 1

inch mm

min max min max

Minimum distance between ASP2 and AEP2 is 20 percent of the active zone.

Quick Start Guide 47

Page 48

Setting ranges Quick Start Guide

January 2019 00825-0100-4326

48 Quick Start Guide

Page 49

Quick Start Guide Product certifications

00825-0100-4326 January 2019

6 Product certifications

6.1 European directive information

The most recent revision of the EC Declaration of Conformity can be found at

Emerson.com/Rosemount.

6.2 Ordinary location information

As standard, this product has been examined and tested to determine that the design

meets the basic electrical, mechanical, and fire protection requirements by a nationally

recognized test laboratory (NRTL) as accredited by the Federal Occupational Safety and

Health Administration (OSHA).

6.3 3-A® certification

This product is authorized to display the 3-A symbol. Ensure gaskets and process

connection accessories selected for installation meet both the application and 3-A

requirements. A certificate of compliance is available at Emerson.com/Rosemount.

6.4 Other industry certifications

All Rosemount 326L transmitter surfaces and materials which come into contact with

process medium comply with the following regulations:

Quick Start Guide 49

Page 50

Product certifications Quick Start Guide

January 2019 00825-0100-4326

50 Quick Start Guide

Page 51

Quick Start Guide Factory settings

00825-0100-4326 January 2019

7 Factory settings

Use this worksheet to record modified parameter settings.

Parameter Factory default setting User-defined setting

tREF nonE

SP1 50% VMR

rP1 0.2 in (5 mm) below SP1

ASP2 0 % VMR

AEP2 100 % VMR

dS1 0.0

dr1 0.0

ou1 Hno

ou2 I

(1)

(1)

(1)

uni inch

P-n PnP

FOU1 OFF

FOU2 OFF

SELd L

dAP 0.0

dFo 3.0

LEnG nonE

MEdl MID

S.LVL 50 % LEnG

S.Tim 3

S.On OFF

(1) VMR = final value of the measuring range = LEnG value minus 1.18 in (30 mm). When the LEnG

value is entered, the unit calculates the basic setting.

Quick Start Guide 51

Page 52

*00825-0100-4326*

00825-0100-4326

Rev. 01

2019

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRF@Emerson.com

©

2019 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric Co. Rosemount is mark of one of the

Emerson family of companies. All other marks are the property of their respective owners.

Loading...

Loading...