Page 1

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

Rosemount 3159 Nuclear Qualifi ed

Remote Diaphragm Seal

Page 2

This page intentionally left blank

Page 3

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

Title Page

iii

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum

Chan.RNII-CustomerFeedback@Emerson.com

Rosemount 3159 Remote Diaphragm Seal

performance, make sure you thoroughly understand the contents of this manual before installing, using

or maintaining this product.

For Assistance:

Within the United States, contact Rosemount Nuclear Instruments, Inc. (RNII) at

1-952-949-5210.

Outside the United States, contact the nearest Rosemount representative.

Customer Feedback:

Your feedback is important to us, please send comments or suggestions to:

Rosemount Nuclear Instruments, Inc. satisfies all obligations coming from legislation to

harmonize product requirements in the European Union

Page 4

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

iv

Title Page

RETURN OF MATERIAL

Authorization for return is required from Rosemount Nuclear Instruments, Inc. prior to shipment.

USA

IMPORTANT

The Nuclear Qualified Rosemount 3159 Remote Diaphragm Seal is designed for Nuclear Class 1E

for which the foregoing has not been complied with by the user.

Rosemount Nucl ear Instruments, I nc. Warranty and

Limitations of Remedy

The warranty and limitations of remedy applicable to this Rosemount equipment are as stated on the

reverse side of the current Rosemount quotation and customer acknowledgment forms.

Contact Rosemount Nuclear Instruments, Inc. (1-952-949-5210) for details on obtaining Return

Material Authorization (RMA). Rosemount Nuclear Instruments, Inc. will not accept any returned

material without a Return Material Authorization. Material returned without authorization is subject

to return to customer.

Material returned for repair, whether in or out of warranty, should be shipped prepaid to:

Rosemount Nuclear Instruments, Inc.

8200 Market Boulevard

Chanhassen, MN 55317

usage, and has been tested to the standards shown below:

• IEEE Std 323

• IEEE Std 344

Rosemount 3159 Remote Diaphragm Seals are manufactured under a quality system that meets the

requirements of ISO 9001, 10CFR50 Appendix B, ASME NQA-1, CSA Z299.1 and the applicable

portions of IAEA-50-C-Q. During qualification testing, interfaces were defined between

transmitter/remote seal system and the surrounding environment that are essential to meeting

requirements of the qualification standards listed above. Specifically, to ensure compliance with

10CFR Part 21, the transmitter/remote seal system must comply with the requirements herein and in

the applicable Rosemount qualification report(s) throughout its installation, opera t ion and m aintena nc e.

It is incumbent upon the user to ensure that Rosemount Nuclear Instruments, Inc.’s component

traceability program is continued throughout the life of the equipment.

In order to maintain the qualified status of the transmitter/remote seal system, the essential

environmental interfaces must not be compromised. Performance of any operations on the remote

seal system other than those specifically authorized in this manual has the potential for compromising

an essential environmental interface. Where the manual uses the terms requirement, man d atory,

must or required, the instructions so re fer enced must be carefully followed. Rosemount Nuclear

Instruments, Inc. expressly disclaims all responsibility and liability for transmitter/remote seal systems

TM

-1974/1983/2003

TM

-1975/1987/2004

Page 5

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

Title Page

v

Page

(Re v AA)

Page

(Rev AB)

Document revision change from October 2012 Rev AA to August 2017 Rev

regarding the 3159 Remote Seal qualification program.

2-2

4

Updated Figure 2-2 to depict current capillary support tube.

NA

5

Added Figure 2-3.

2-3

6

Added information on Temperature Head Effects.

3-4

11

Updated Figure 3-1 to depict current capillary support tube.

Updated Remote Seal / Lower Housing Assembly Procedure to include

instructions for installing Rosemount spares kit P/N 03159-5904-0003.

Updated Table 5-1 to include all current Rosemount Spares Kits for the 3159

Remote Seal.

NOTE

complete comparison deta il s .

Revision Status

Changes from October 2012 (Rev AA) to August 2017 (Rev. AB)

Changes

Cover,

throughout

3-3 – 3-4 10 – 13

5-1 19

The above Revision Status list summarizes the changes made. Please refer to both manuals for

Cover,

throughout

AB, updated document formatting, and removed outdated information

Page 6

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

vi

Title Page

This page intentionally left blank

Page 7

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

SECTION 1

Using this Manual.....................................................................................

1

Introduction

SECTION 2

Overview...................................................................................................

3

Performance

Remote Seal System................................................................................

3

Understanding Seal Syste m Performance........... .....................................

5

Temperature Effects....................................................................

6

System Time Response...............................................................

6

Static Head Effects......................................................................

6

Temperature Head Effects...........................................................

6

SECTION 3

Overview...................................................................................................

8

Installation

Safety Messages................ ......... ....... ...... ....... ...... ....... .. ......... .. ...............

8

Remote Seal Handling Considerations.....................................................

8

Remote Seal Installation Considerations..................................................

9

Remote Seal / Lower Housing Assembly Procedure................................

10

Installation of Capillary Clamps................................................................

13

SECTION 4

Overview...................................................................................................

15

Maintenance

Safety Messages................ ......... ....... ...... ....... ...... ....... .. ......... .................

15

General Considerations............................................................................

16

Metal Gasket Replacement......................................................................

15

SECTION 5

Overview...................................................................................................

18

Remote Seal

Spare Parts

Safety Messages................ ......... ....... ...... ....... ..................................... ....

18

18

Table of Contents

Spare Parts Ordering Information.............................................................

Page 8

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

viii

Contents

This page intentionally left blank

Page 9

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

SECTION 1:

Introduction

USING THIS MANUAL

This manual is designed to assist in installing, operating, and

leg reference is required.

NOTE

manual in conjunction with the transmitter reference manual.

maintaining the Rosemount 3159 Remote Diaphragm Seal.

The manual contains supplemental information about the

remote seal assemblies that are not covered in the

corresponding transmitter manuals.

The information is organized into the following categories:

Section 2: Performance

Explains key drivers of functional performance.

Section 3: Installation

Provides mechanical installation considerations of the remote

seal system.

Section 4: Maintenance

Provides basic hardware maintenance considerations for the

3159 remote seal.

Section 5: Spare Parts Ordering Information

Lists available spares kits.

The Rosemount 3159 Remote Diaphragm Seal is intended for

use in nuclear power stations where stringent quality control of

design and manufacturing processes is necessary to ensure

high reliability over an extended service life. The 3159 remote

seal can be supplied with all Rosemount 3150 Series nuclear

pressure transmitters.

Uses for the remote seal include applications where the

environment is unsuitable for instrumentation or where a wet

Refer to Rosemount Qualification/Test Reports and Product

Data Sheets for details on testing, performance specifications

and dimensional drawings.

Installation, operation, maintenance, and warranty information

for Rosemount 3150 Series nuclear pressure transmitters can

be found in the applicable reference manual. This

supplemental manual provides information regarding the use

of the Rosemount 3159 Remote Diaphragm Seal. Use this

Page 10

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

2

Introduction

This page intentionally left blank

Page 11

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

SECTION 2:

Performance

Overview................................................................

page 3

Remote Seal System.............................................

page 3

Understanding Seal System Performance..........

Page 5

OVERVIEW

This section contains the following considerations:

→ Temperature Head Effects

REMOTE SEAL SYSTEM

A remote seal system consists of a pressure transmitter, a

electronically to a 4-20 mA output signal.

Figure 2-1 Rosemount 3159 Exploded

View

• Remote Seal System

• Understanding Seal Syste m Performance

→ Temperature Effects

→ System Time Response

→ Static Head Effects

remote seal, and a capillary assembly filled with a secondary

fill fluid.

During operation, the thin, flexible diaphragm and remote seal

fill fluid separate the pressure sensor of the transmitter from

the process medium. The capillary tubing connects the

diaphragm to the transmitter.

When process pressure is applied, the diaphragm is

displaced, transferring the measured pressure through the

filled system, by way of the capillary tubing, to the transmitter.

This transferred pressure displaces the sensing diaphragm in

the pressure sensor of the transmitter. This displacement is

proportional to the process pressure and is converted

Page 12

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

4

Performance

Figure 2-2 – Rosemount 3159

Dimensions

NOTE: All dimensions are nominal in inches (millimeters)

Remote Seal / Lower Housing

Page 13

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

Performance

5

Figure 2-3 – Rosemount 3159

S0201 Special Option Dimensio ns

NOTE: All dimensions are nominal in inches (millimeters)

UNDERSTANDING SEAL

The performance of a remote diaphragm seal is determined by

Rosemount 3159 Product Data Sheet.

Remote Seal / Lower Housing with

SYSTEM PERFORMANCE

how accurately a pressure signal is transferred from the

remote seal isolator diaphragm to the transmitter sensor.

Remote seal performance is characterized by:

• Temperature Effects

• System Time Response

• Static Head Effects

• Temperature Head Effects

Remote seal performance specifications are published in the

Page 14

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

6

Performance

Temperature Effects

Changes in ambient temperature cause changes in fill fluid

(one-sided versus two-sided).

System Time Response

The time response of a system is dependent on the

requirement.

Static Head Effects

If the diaphragm seal and transmitter are installed at different

additional information.

Temperature Head Effects

Changes in ambient temperature also cause changes in the fill

by the transmitter as a change in pressure.

volume relative to the metallic capillary system. To an extent,

changes in fill fluid volume are accommodated by the remote

seal diaphragm, whose spring rate is much less than that of

the transmitter isolator diaphragm. However, some of the

temperature-induced vo lum e change is seen as back pressure

at the transmitter, which creates a shift in transmitter output.

Temperature effects errors are usually smaller for symmetric

systems, since the back pressure is more similar on high and

low sides.

Factors that affect remote seal temperature effects

performance include capillary length, fill fluid and configuration

transmitter model, its sensor range, the length and inner

diameter (ID) of the capillary, and the viscosity of the fill fluid

(which is directly affected by the process and ambient

temperatures). These factors all play a role in the overall

performance of any seal system.

For high viscosity fill fluids, capillary length should be kept to a

minimum if system time response is an important performance

elevations, a zero shift occurs due to static head effects. The

zero shift can be removed by re-zeroing the transmitter after

installation.

However, static head effects create restrictions on installation.

When the transmitter and remote seals are installed at

different heights, the limitations of the transmitter capability for

zero suppression and zero elevation must be considered. The

applicable 3150 Series Pressure Transmitter Product Data

Sheets define the zero suppression and zero elevation

capability of each pressure range. Please contact RNII for

fluid specific gravity. Changes in fill fluid specific gravity affect

the weight of the fill fluid column acting on the sensor.

At reference conditions, the weight of the fill fluid column will

produce a zero shift, which can be removed by re-zeroing the

transmitter (static head effect). As ambient temperature

changes, the fill fluid specific gravity changes which, in turn,

changes the weight of the fill fluid column. This will be seen

Page 15

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

Performance

7

This page intentionally left blank

Page 16

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

SECTION 3:

Installation

Overview.................................................................

page 8

Safety Messages....................................................

page 8

Remote Seal Handling Considerations................

page 8

Remote Seal Installation Considerations............

page 9

Remote Seal / Lower Housing Assembly

Procedure...............................................................

Page 10

Installation of Capillary Clamps............................

Page 13

OVERVIEW

This section contains the following installation considerations:

• Installation of Capillary Clamps

SAFETY MESSAGES

Procedures and instructions in this section may require special

performing an operation preceded by this symbol:

Warnings

WARNING

Never attempt to disconnect the remote seal flange from the

the product warranty.

REMOTE SEAL HANDLING

Diaphragm seals are relatively delicate and should be handled

false reading.

• Remote Seal Handling Considerations

• Remote Seal Installation Considerations

• Remote Seal / Lower Housing Assembly Procedure

precautions to ensure the safety of the personnel performing

the operation. Refer to the following safety messages before

transmitter. Doing so will result in loss of fill fluid and will void

CONSIDERATIONS

with care.

Do not lift the seal or transmitter by gripping the capillaries

when unpacking or handling a transmitter / remote seal

system. Avoid sharply bending or crimping capillary tubing.

The minimum bending radius of the capillary tubing is 3 in (8

cm).

The protective cover should remain on the seal until the

moment before installation. Avoid touching the diaphragm

with fingers or objects and refrain from setting the diaphragm

side of the seal down on a hard surface. Even minor dents or

scratches in the diaphragm material may impair the

performance of the remote seal system.

When installing the remote seal system, make sure the gasket

is aligned properly on the gasket sealing surface. Failure to

properly install the gasket may cause process leaks, which

can result in death or serious injury. In addition, make sure

the gasket does not press down upon the diaphragm face.

Anything pressing on the diaphragm will be read by the

transmitter as pressure. A misaligned gasket may cause a

Page 17

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

Installation

9

REMOTE SEAL

Rosemount 3159 remote seal is qualified for liquid and gas

a constant ambient temperature.

INSTALLATION

CONSIDERATIONS

service. As much as possible, the process medium should be

free of solids, since these could potentially clog the process

pipe connection or accumulate over time in the cavity on the

process side of the diaphragm. Care should be exercised in

making sure that the process fluid does not become overly

viscous or freeze in the process pipe connection or seal

cavity.

The maximum working pressure depends on the transmitter

pressure range, pressure measurement type, and remote seal

bolting option (B1 or B2). Use the applicable Rosemount

3150 Series Pressure Transmitter Product Data Sheet along

with the Rosemount 3159 Remot e Seal Product D ata She et to

determine maximum working pressure. Please contact RNII

for additional information.

The lower housing is available with four different process

connections: 1/4 inch NPT, 1/2 inch NPT, 1 inch NPT and 1

inch socket weld. The customer is responsible for making a

qualified connection to the process piping. The lower housing

includes one or two 1/4-18 NPT flushing connection(s) so that

the cavity under the diaphragm can be bled or flushed while

the unit is in service. See Figure 2-2 or Figure 2-3 for details.

Due to the many possible mounting configurations,

Rosemount does not provide a qualified remote seal mounting

bracket. Mounting of the remote seal is the responsibil it y of

the customer. The applicable Rosemount qualification report

describes the mounting configurations used during

qualification testing.

Due to pressure head effects, there are limits to the allowable

elevation difference between remote seals and 3150 Series

pressure transmitters. These limits are a function of the

remote seal fill fluid type, the fill fluid specific gravity and

transmitter range code. In no case should the difference in

height between a transmitter and seal or between two seals

exceed the upper range limit of the transmitter. Best practice

is to mount the transmitter at or below the lower process tap if

possible.

If the diaphragm seal and transmitter are installed at different

elevations, a zero shift occurs due to static head effects. The

zero shift can be removed by re-zeroing the transmitter after

installation.

Changes in process and ambient temperatures can result in

changes in transmitter zero output. Temperature-induced

errors can be minimized by heat tracing the capillary to ensure

Page 18

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

10

Installation

Special precautions must be taken to prevent damage to

from boiling. Refer to steam tables for required pressures.

IMPORTANT

Care must be taken under all circumstances to ensure the fill

fluid vapor pressure is not exceeded.

REMOTE SEAL / LOWER

PROCEDURE

IMPORTANT

Tools required for assembly of the 3159 Remote Seal / Lower

questions regarding the required tools.

Table 3-1 – Tools Required for

Assembly

Description

Rosemount Part Number

Photo

Vice or holding fixture

Customer Supplied

No photo available

capillary systems filled with distilled water. Distilled water

should not be exposed to operating temperatures below 40°F

(4.4°C); when exposed to operating temperatures above

180°F (82.2°C), application of static pressure to the remote

seal is conservatively recommended to prevent the fill fluid

HOUSING ASSEMBLY

Take care during the assembly process to prevent possible

damage to the isolator diaphragm or metal gasket.

Housing can be found in Table 3-1. If a Rosemount part

number is not specified, any general brand tool that meets the

specifications can be used. Please contact RNII with any

Remote Seal / Lower Housing

3/4-inch Open-ended Wrench Customer Supplied

3/4-inch Socket Adjustable

Torque Wrench

Customer Supplied

Page 19

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

Installation

11

1. Disassemble remote seal / lower housing if

NOTE

tight, then a new metal gasket must be installed.

NOTE

details.

NOTE

details.

NOTE

Table 3-2.

Figure 3-1 – B2 Option Bolt Detail

necessary.

If the metal gasket was installed between the remote seal

and lower housing and bolts were torqued beyond finger

2. Gently clean the remote seal isolator diaphragm,

lower housing and metal gasket with a clean cloth.

3. Center the metal gasket on the lower housing.

4. Carefully place the remote seal on top of the lower

housing and metal seal, taking care to align the bolt

holes.

5. Install eight bolts from the remote seal side.

For B2 option rotate bolts to ensure the heads are “locked”

against the remote seal center hub. See Figure 3-1 for

When installing bolts provided with Rosemount spare kit

P/N 03159-5904-0003, insert four 3.25-inch bolts from the

remote seal side and four 2.5-inch bolts from the lower

housing side in an alternating pattern. See Figure 3-2 for

6. Install eight nuts hand tight.

7. Tighten the eight nuts using the crossing pattern

shown in Figure 3-3 and according to the torque

sequence and values shown in Table 3-2.

When installing bolts provided with Rosemount spare kit

P/N 03159-5904-0003, tighten the eight nuts using the

crossing pattern shown in Figure 3-4 and according to the

torque sequence and values for the B2 Option shown in

Page 20

Rosemount 3159

Reference Manual

August 2017

12

Installation

Figure 3-2 – Rosemount Spares Kit

Detail

Figure 3-3 – Bolt Torqueing Pattern

Figure 3-4 – Torqueing Pattern for

Spares Kit P/N 03159-5904-0003

P/N 03159-5904-0003 Bo lt Inst allat ion

00809-0100-4859 Rev AB

Bolts Provided with Rosemount

Page 21

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

Installation

13

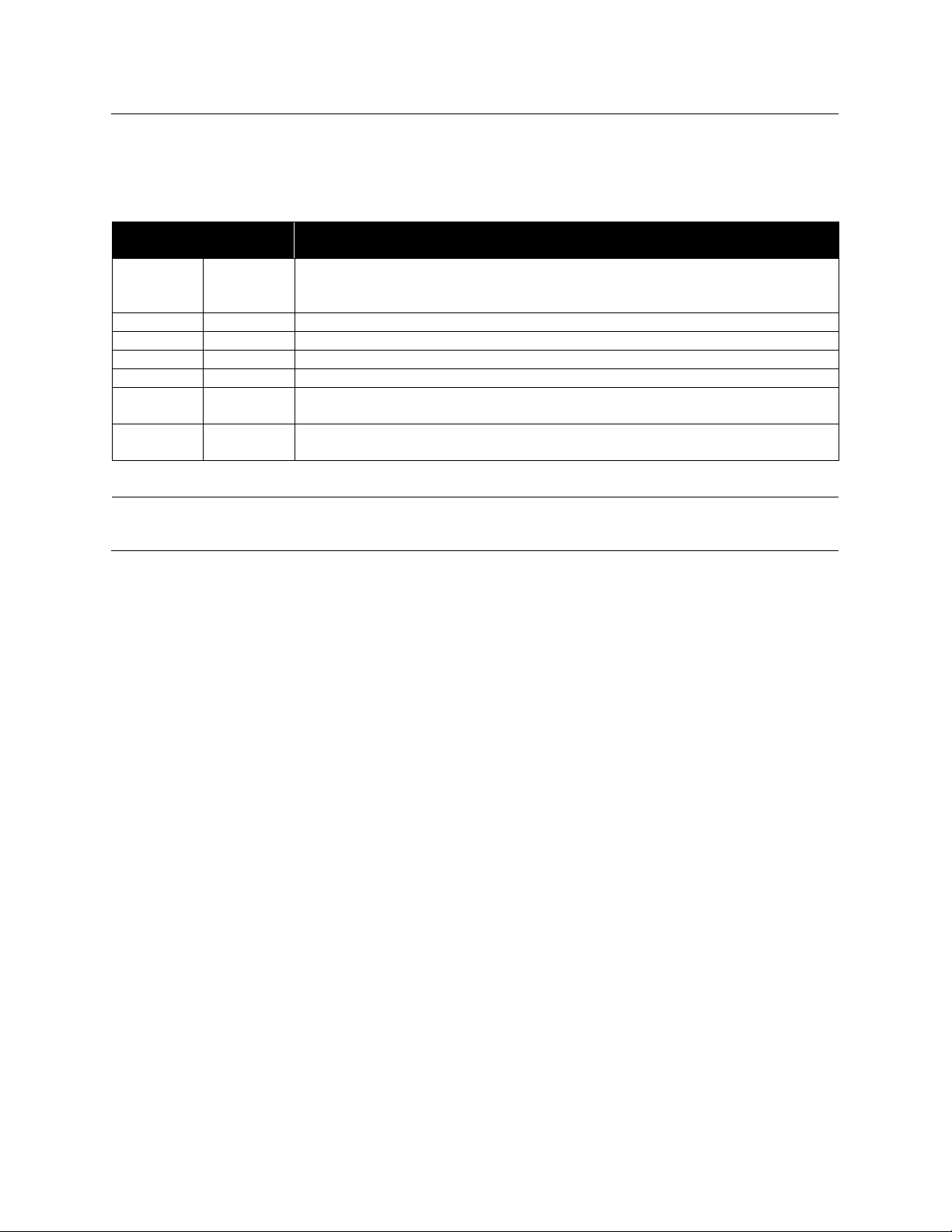

Table 3-2 – Torqueing Sequence for

B1 and B2 Options

Torque Value

B1

B2

(1)

1

150 in-lb (16.9 N-m)

220 in-lb (24.9 N-m)

2

300 in-lb (33.9 N-m)

440 in-lb (49.7 N-m)

3

450 in-lb (50.8 N-m)

660 in-lb (74.6 N-m)

4

600 in-lb (67.8 N-m)

875 in-lb (98.9 N-m)

5

600 in-lb (67.8 N-m)

875 in-lb (98.9 N-m)

(2)

6

600 in-lb (67.8 N-m)

(2)

--

Notes:

(2) T orque tolerance for this step is ±5%.

INSTALLATION OF

Clamps (Rosemount spare kit P/N 03159-5902-0001 or

(8 cm).

Step

(1) Use B2 torque sequence and values when installing bolts provided with Rosemount spares kit P/N 03159-5904-0003.

CAPILLARY CLAMPS

equivalent) should be placed approximately 18 inches (46 cm)

apart to hold the capillary tubing in place, using any standard

grade 1/4-20 screw.

The minimum bending radius of the capillary tubing is 3 inches

Page 22

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

14

Installation

This page intentionally left blank

Page 23

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

SECTION 4:

Maintenance

Overview.................................................................

page 15

Safety Messages....................................................

page 15

General Considerations.........................................

page 16

Metal Gasket Replacement....................................

page 16

OVERVIEW

This section contains the following maintenance

• Metal Gasket Replacement

SAFETY MESSAGES

Procedures and instructions in this section may require special

performing an operation preceded by this symbol:

Warnings

WARNING

Replacement equipment or spare parts not approved by

Instruments, Inc. as spare parts for the 3159.

WARNING

Remote seal systems are factory filled systems that cannot be

seal system assembly and voids the product warranty.

WARNING

Residual process fluid may remain after disassembly of lower

appropriate safety measures.

WARNING

Process leaks could result in death or serious injury.

while the remote seal is in service.

NOTE

beginning of this manual preceding Section 1).

considerations:

• General Considerations

precautions to ensure the safety of the personnel performing

the operation. Refer to the following safety messages before

Rosemount Nuclear Instruments, Inc. for use could reduce the

performance capabilities of the remote seal system and may

render the instrument dangerous or adversely impact its

qualified status.

• Use only components supplied with the 3159 Remote

Seal or designated by Rosem ount Nucle ar

refilled in the field. Do not attempt to disconnect the seals or

capillaries from the transmitter. Doing so can damage the

housing. If this fluid is potentially contaminated, take

• Install and tighten all eight remote seal bolts before

applying pressure

• Do not attempt to loosen or remove remote seal bolts

Maintenance of traceability of any replacement parts is the

responsibility of the user (see Important Notice at the

Page 24

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

16

Maintenance

GENERAL

Once installed, the Rosemount 3159 Remote Seal is generally

guidance.

METAL GASKET

Use the following steps to replace the metal gasket:

procedure shown in Section 3: Installation.

NOTE

followed whenever the remote seal is disassembled.

CONSIDERATIONS

REPLACEMENT

considered to be a maintenance-free component. In cases

where maintenance is required, this section provides

1. Remove the remote seal from service.

2. Disassemble the remote seal / lower housing and

discard metal gasket.

3. Follow the remote seal / lower housing assembly

The procedure for replacement of the metal gasket must be

Page 25

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

Maintenance

17

his page intentionally left blank

T

Page 26

Rosemount 3159

Reference Manual

00809-0100-4859 Rev AB

August 2017

SECTION 5:

Remote Seal Spare Par ts

Overview.................................................................

page 18

Safety Messages....................................................

page 18

Spare Parts Ordering Information........................

page 18

OVERVIEW

This section contains the following topics:

• Spare Parts Ordering Information

SAFETY MESSAGES

Procedures and instructions in this section may require special

performing an operation preceded by this symbol:

WARNING

Replacement equipment or spare parts not approved by

Instruments, Inc. as spare parts for the 3159.

NOTE

beginning of this manual preceding Section 1).

SPARE PARTS ORDERING

INFORMATION

Table 5-1 contains part numbers used for ordering spare parts

precautions to ensure the safety of the personnel performing

the operation. Refer to the following safety messages before

Rosemount Nuclear Instruments, Inc. for use could reduce the

performance capabilities of the remote seal system and may

render the instrument dangerous or adversely impact its

qualified status.

• Use only components supplied with the 3159 Remote

Seal or designated by Rosem ount Nucle ar

Maintenance of traceability of any replacement parts is the

responsibility of the user (see Important Notice at the

for the 3159 Remote Seal.

Page 27

Reference Manual

00809-0100-4859 Rev AB

August 2017

Rosemount 3159

Remote Seal Spare Parts

19

Table 5-1 – Rosemount 3159 Spare

Parts

Rosemount

Part Number

03159-5901-0001

Metal Gasket (Remote Seal / Lower Housing Interface) (Qty=1)

--

03159-5902-0001

Capillary Clamp (Qty=1)

--

03159-5903-0001

Lower Housing, 1/4-inch NPT, One Flushing Connection (Qty=1)

P1

03159-5903-0002

Lower Housing, 1/2-inch NPT, One Flushing Connection (Qty=1)

P2

03159-5903-0003

Lower Housing, 1-inch NPT, One Flushing C onn ec tio n (Q t y=1)

P3

Lower Housing, 1-inch Socket Weld, One Flushing Connection

(Qty=1)

03159-5903-0005

Lower Housing,1/4-inch NPT, Two Flushing Connections (Qty=1)

P5

03159-5903-0006

Lower Housing, 1/2-inch NPT, Two Flushing Connections (Qty=1)

P6

03159-5903-0007

Lower Housing, 1-inch NPT, Two Flushing Connections (Qty=1)

P7

Lower Housing, 1-inch Socket Weld, Two Flushing Connections

(Qty=1)

03159-5904-0001

Nut & Bolt, 2.5-inch, Standard Head (Qty=8)

B1

03159-5904-0002

Nut & Bolt, 2.5-inch, Heavy Hex Head (Qty=8)

B2

03159-5904-0003

Nut & Bolt, 2.5-inch & 3.25-inch, Heavy Hex Head (Qty=4 ea.)

--

Spares Kit

03159-5903-0004

03159-5903-0008

Description

3159 Model

Code Option

P4

P8

Page 28

Rosemount 3159

Global Headquarters

RNII.info@Emerson.com

Standard Terms and Conditions of Sale can be found at:

© 2017 Emerson Automation Solutions. All rights reserved.

Std 323 and Std 344 are registered trademarks of IEEE

Rosemount Nuclear Instruments, Inc. satisfies

European Union.

Reference Manual

00809-0100-4859 Rev AB

August 2017

Emerson Automation Solutions

Rosemount Nuclear Instruments, Inc.

8200 Market Blvd.

Chanhassen, MN 55317, USA

P +1 952 949-5210

F +1 952 949-5201

www.Emerson.com/en-us/pages/Terms-of-Use.aspx

merson logo is a trademark and service mark of

The E

Emerson Electric Co.

Rosemount and Rosemount logotype are trademarks of

Rosemount Inc.

All other marks are the property of their respective owners

all obligations coming from legislation to

harmonize product requirements in the

Loading...

Loading...