Page 1

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series Nuclear Pressure

Transmitters including the Rosemount

3152, 3153 and 3154

Page 2

Page 3

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

NOTICE

Rosemount Nuclear Instruments, Inc. satisfies all obligations

Rosemount 3150 Series Nuclear Pressur e Transmitters

including the Rosemount 3152, 3153 and 3154

Read this manual before working with the product. For personal and system

safety, and for optimum performance, make sure you thoroughly understand the

contents of this manual before installing, using or maintaining this product.

For Assistance:

Within the United States, contact Rosemount Nuclear Instruments, Inc. at

1-952-949-5210.

Outside the United States, contact the nearest Rosemount representative.

Customer Feedback:

Your feedback is important to us, please send comments or suggestions to:

Chan.RNII-CustomerFeedback@emersonprocess.com

coming from legislation to harmonize product requirements in

the European Union.

i

Page 4

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount Nucl ear Instruments, I nc. Warranty and

Limitations of Remedy

The warranty and limitations of remedy applicable to this Rosemount equipment are as stated on the reverse

side of the current Rosemount quotation and customer acknowledgment forms.

RETURN OF MATERIAL

Authorization for return is required from Rosemount Nuclear Instruments, Inc. prior to shipment. Contact

Rosemount Nuclear Instruments, Inc. (1-952-949-5210) for details on obtaining Return Material Authorization

(RMA). Rosemount Nuclear Instruments will not accept any returned materi al without a Return

Material Authorization. Material returned without authorization is subject to return to customer.

Material returned for repair, whether in or out of warranty, should be shipped prepaid to:

Rosemount Nuclear Instruments, Inc.

8200 Market Boulevard

Chanhassen, MN 55317

USA

IMPORTANT

Rosemount 3152, 3153 and 3154 Series Pressure Transmitters are designed for Nuclear Class 1E usage, and

have been tested to the standards shown below:

• IEEE Std 323™-1974, -1983 and -2003

• IEEE Std 344™-1975, -1987 and -2004

These transmitters are manufactured under a quality system that meets the requirements of 10CFR50

Appendix B, 10CFR Part 21, ISO 9001, NQA-1, KTA 1401, KTA 3507, CSA N285.0, CSA Z299 and the

applicable portions of IAEA-50-C-Q. During qualification testing, interfaces were defined between the

transmitter and its environment that are essential to meeting requirements of the qualification standards listed

above. Specifically, to ensure compliance with 10CFR Part 21, the transmitter must comply with the

requirements herein and in the applicable Rosemount qualification report(s) throughout its installation,

operation and maintenance. It is incumbent upon the user to ensure that the Rosemount Nuclear Instruments,

Inc.’s component traceability program is continued throughout the life of the transmitter.

In order to maintain the qualified status of the transmitter, the essential environmental interfaces must not be

compromised. Performance of any operations on the transmitter other than those specifically authorized in

this manual has the potential for compromising an essential environmental interface. Where the manual

uses the terms requirement, mandatory, must or required, the instructions so referenced must be

carefully followed. Rosemount Nuclear Instruments, Inc. expressly disclaims all responsibility and liability for

transmitters for which the foregoing has not been complied with by the user.

• RCC-E-2002

• KTA 3505-2005

ii

Page 5

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

Cover,

throughout

Cover,

throughout

Throughout

Throughout

Updated references and terminology for consistency throughout document.

Minimum time constant for damping adjustment set to maximum position for

3153 and 3154 transmitters (output code T) changed from 0.8 sec to 1.2 sec.

Relocated step 2 in the Preliminary Electric al Housing Reassembly Section to

the Electronics Housing Cover Installation Section and revised for clarity.

Updated Electronics Assembly Installation procedure to include additional

instruction for installing the connector plug.

Added Figure 5-7 – Connector Plug Detail and updated subsequent figure and

page numbers accordingly.

NOTE

The above Revision Status list summarizes the changes made. Please refer to both manuals for complete

comparison details.

Revision Status

Changes from March 2015 (Rev BC) to July 2016 (Rev BD)

Page

(Rev BC)

3-11 3-11

5-11 & 5-13 5-11 & 5-14

5-12 5-12

5-12 to 5-18 5-12 to 5-19

Page

(Rev BD)

Changes

Document revision change from March 2015 to July 2016, Rev BC to Rev BD

iii

Page 6

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

iv

Page 7

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

SECTION 1

Using this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .1-1

SECTION 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . 2-1

SECTION 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Messages. . . . . . . . . . . .

Calibration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Procedures

Zero DP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

Code 4 and 5 DP Transmitters. . . . . . . . . . . . . . . . . .

Transmitters (All Ranges). . . . . . . . . . . . . . . . . . . . . .

. . .3-1

1

Introduction

Table of Contents

Installation

Process Connections and Interfaces . . . . . . . . . . . . . . . . . . .

Impulse Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical – Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical – Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration

Calibration Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Span Adjustment Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zero Adjustment Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Span and Zero Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Procedure for Zero Based Span (LRV is

Damping Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Correction for High Static Line Pressure. . . .

Linearity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Procedure for Elevated or Suppressed

Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coarse Zero Select Jumper Position Selection

High Static Pressure Span Effect on Range Codes

1, 2 and 3 DP Transmitters . . . . . . . . . . . . . . . . . . . .

High Static Pressure Span Correction for Range

High Static Line Pressure Zero Correction for DP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

. . .2-1

. . . 2-2

. . . 2-2

. . . 2-3

. . . 2-4

. . . 2-5

. . . 2-6

. . . 2-6

. . . 2-7

. . 2-10

. . 2-10

. . 2-14

. . 2-14

. . . 3. . . 3-2

. . . 3-2

. . . 3-3

. . . 3-5

. . . 3-5

. . .3-6

. . .3-6

. . .3-6

. . . 3-7

. . 3-10

. . 3-11

. . 3-12

. . 3-12

. . 3-12

. . 3-17

. . 3-17

Page 8

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

SECTION 4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Sensor Cell. . . . . . . . . . . . . . . . . . . . . . . .

Demodulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Reg

Current Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reverse Polarity Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . 4-1

SECTION 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Considerations. . . . . . . .

Test Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronics Assembly Checkout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensor

Disassembly Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Post Assembly Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . 5-1

SECTION 6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . .

General Considerations

Spare Parts Shelf Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impact on

Transmitter Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . 6-1

. . . 6-4

Operation

Maintenance and

Troubleshooting

Transmitter Spare Parts

. . . . . . . . . . . . . . . . . .

ulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Checkout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Process Flange Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Housing Disassembly . . . . . . . . . . . . . . . . . . . . . . .

Electrical Housing Reassembly . . . . . . . . . . . . . . . . . . . . . . .

Process Flange Reassembly . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Qualified Life . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . 4-2

. . . 4-3

. . . 4-4

. . . 4-5

. . . 4-5

. . . 4-5

. . . 4-5

. . . 4-5

. . . 5-1

. . . 5-3

. . . 5-5

. . . 5-5

. . . 5-6

. . . 5-7

. . . 5-7

. . . 5-8

. .5-11

. . 5-11

. . 5-14

. . 5-16

. . . 6-1

. . . 6-3

. . . 6-3

. . . 6-3

TOC-2

Page 9

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

USING THIS MANUAL

This manual is designed to assist in installing, operating and

NOTE

Refer to the applicable Rosemount Qualification/Test Reports, Product

performance specifications and dimensional drawings for each model.

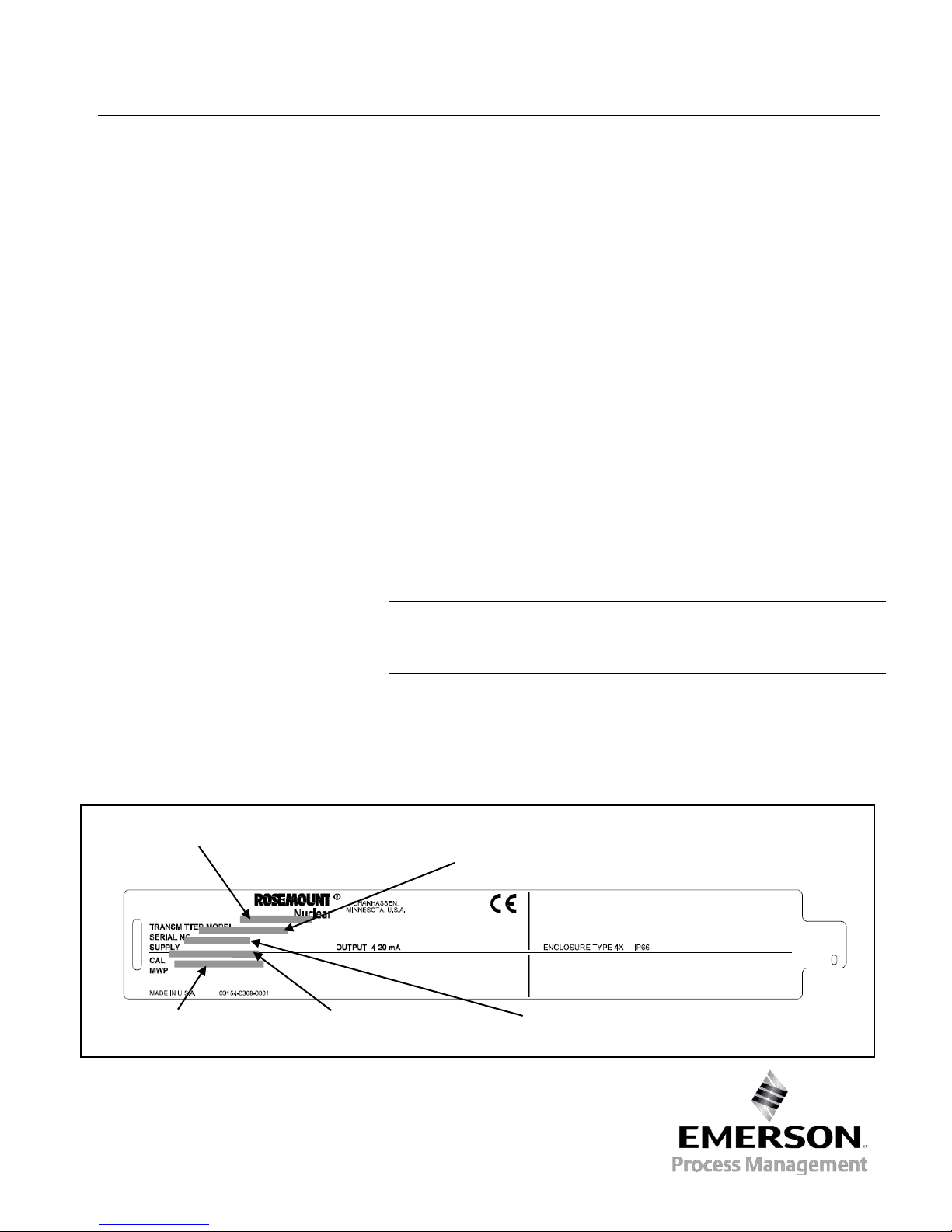

Unique Transmitter Serial Number

is stamped here

Transmitter Model Number is

stamped here

Factory Calibrated Span

is stamped here

Transmitter Maximum Power

Maximum Working

Pressure is stamped here

SECTION 1: INTRODUCTION

maintaining the Rosemount 3150 Series Pressure Transmitters.

Instructions for the 3152, 3 153 and 3154 models are included in this

manual. Where differences in instructions between the models occur

they shall be noted within those instructions. The manual is organized

into the following sections:

Data Sheets and/or Specification Drawings for details on testing,

Figure 1-1 shows the standard transmitter nameplate and where

transmitter information is stamped onto the nameplate. Nameplate

material is stainless steel.

Figure 1-1 – Standard Transmitter

Nameplate

Section 2: Installation

Provides general, mechanical, and electrical installation

considerations.

Section 3: Calibration

Provides transmitter calibration procedures.

Section 4: Operation

Provides a description of how the transmitter operates.

Section 5: Maintenance and Troubleshooting

Provides basic hardware troubleshooting considerations including

disassembly and reassembly procedures and post assembly tests.

Section 6: Transmitter Spare Pa rts

Provides order information for transmitter spare parts.

Supply Limit is stamped here

Page 10

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

1-2

Page 11

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . .

page 2-1

page 2-10

SAFETY MESSAGES

Procedures and instructions in this section may require special

an operation preceded by this symbol .

Warnings

WARNING

OVERVIEW

This section contains the following installation considerations:

o Electrical

SECTION 2: INSTALLATION

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Considerations. . . . . . . . . . . . . . . . . . . . . . . .

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . .

page 2-1

page 2-2

page 2-2

page 2-7

• General Considerations

• Mechanical Considerations

o Process Connections

o Impulse Piping

o Mounting Configurations

o Conduit

o Electrical Housing

• Electrical Considerations

• Installation Procedures

o Mechanical

precautions to ensure the safety of the personnel performing the

operation. Refer to the following safety messages before performing

Explosions can result in death or injury.

• Do not remove the transmitter covers in explosive

• Verify that the operating atmosphere of the transmitter is

environments when the circuit is live.

consistent with the appropriate qualification parameters.

Page 12

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

WARNING

GENERAL

CONSIDERATIONS

Measurement accuracy depends upon proper installation of the

MECHANICAL

CONSIDERATIONS

This section contains information you should consider when preparing

WARNING

NOTE

For steam service, do not blow down impulse piping through the

lines with water before resuming measurement.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and terminals.

Process leaks could result in death or serious injury.

• Install and tighten all four flange bolts before applying

pressure.

• Do not attempt to loosen or remove flange bolts while the

transmitter is in service.

Replacement equipment or spare parts not approved by

Rosemount Nuclear Instruments, Inc. for use could reduce the

pressure retaining capabilities of the transmitter and may render

the instrument dangerous or adversely impact i ts qualified

status.

• Use only components supplied with the Rosemount 3152,

3153 or 3154 transmitter or designated by Rosemount

Nuclear Instruments, Inc. as spare parts for the 3152,

3153 or 3154.

Improper assembly of mounting bracket to traditional process

flange can damage sensor module.

• For safe assembly of bracket to transmitter traditional

process flange, bolts must break back plane of flange

web (i.e. bolt hole), but must not contact module housing.

Use only the RNII approved bolts supplied with the

bracket.

transmitter and its associated impulse piping and valves. Mount the

transmitter close to the process and use a minimum of piping to

achieve best accuracy. For flow measurement, proper installation of

the primary element is also critical to accuracy. Also, consider the

need for easy access, personnel safety, practical field calibration and a

suitable transmitter environment. Transmitter installation should

minimize the effects of temperature gradients and fluctuations, and

avoid vibration and shock during normal operation.

to mount the transmitter. Read this section carefully before

proceeding to the mechanical installation procedure. Proper

installation is mandatory to assure seismic qualification.

Do not attempt to loosen or remove flange bolts while the transmitter

is in service.

transmitter. Flush the lines with the transmitter isolated and refill the

2-2

Page 13

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

NOTE

When the transmitter is mounted on its side, position the traditional

liquid service.

Mount the Rosemount 3150 Series transmitter to a rigid support (i.e.

position.

NOTE

The transmitter is calibrated in an upright position at the factory.

Calibration.

process flanges to ensure proper venting or draining. Keep drain/vent

connections oriented on the bottom for gas service and on the top for

one with a fundamental mechanical resonant frequency of 40 Hz or

greater). Two mounting options are qualified for the transmitter: panel

mount or 2-inch pipe mount. A stainless steel panel bracket is

provided with the 3154. For the 3152 and 3153 series, the user has

the option of specifying either the stamped carbon steel panel bracket

or the stainless steel panel bracket.

Refer to Figure 2-5 for qualified mounting configurations for both the

panel and pipe mount options.

Orientation with respect to gravity is not critical to qualification. For

maximum accuracy, zero the transmitter after installation to cancel any

zero shift that may occur due to liquid head effect caused by mounting

Mounting the transmitter in another position may cause the zero po int to

shift by an amount equivalent to the internal liquid head within the

sensor module induced by the varied mounting position. For maximum

accuracy, zero the transmitter to cancel this effect per Section 3:

2-3

Page 14

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

Process Connections and

Interfaces

Mount the process flanges with sufficient clearance for process

thickness for the pressure involved.

connections. For safety reasons, place the drain/vent valves so the

process fluid is directed away from possible human contact when the

vents are used. Also consider that access to the vent/drain valve(s)

and process connection(s) may be required for plant specific

operations (i.e. calibration, draining, etc.)

Process tubing must be installed to prevent any added mechanical

stress on the transmitter under seismic conditions. Use stress-relief

loops in the process tubing or separately support the process tubing

close to the transmitter.

Typical connections on the transmitter flanges are ¼ - 18 NPT or 3/8

inch Swagelok ™. Use your plant-approved, qualified thread sealant

when making threaded connections. The end-user is responsible for

the qualification of the threaded seal interface on all ¼ - 18 NPT

interfaces.

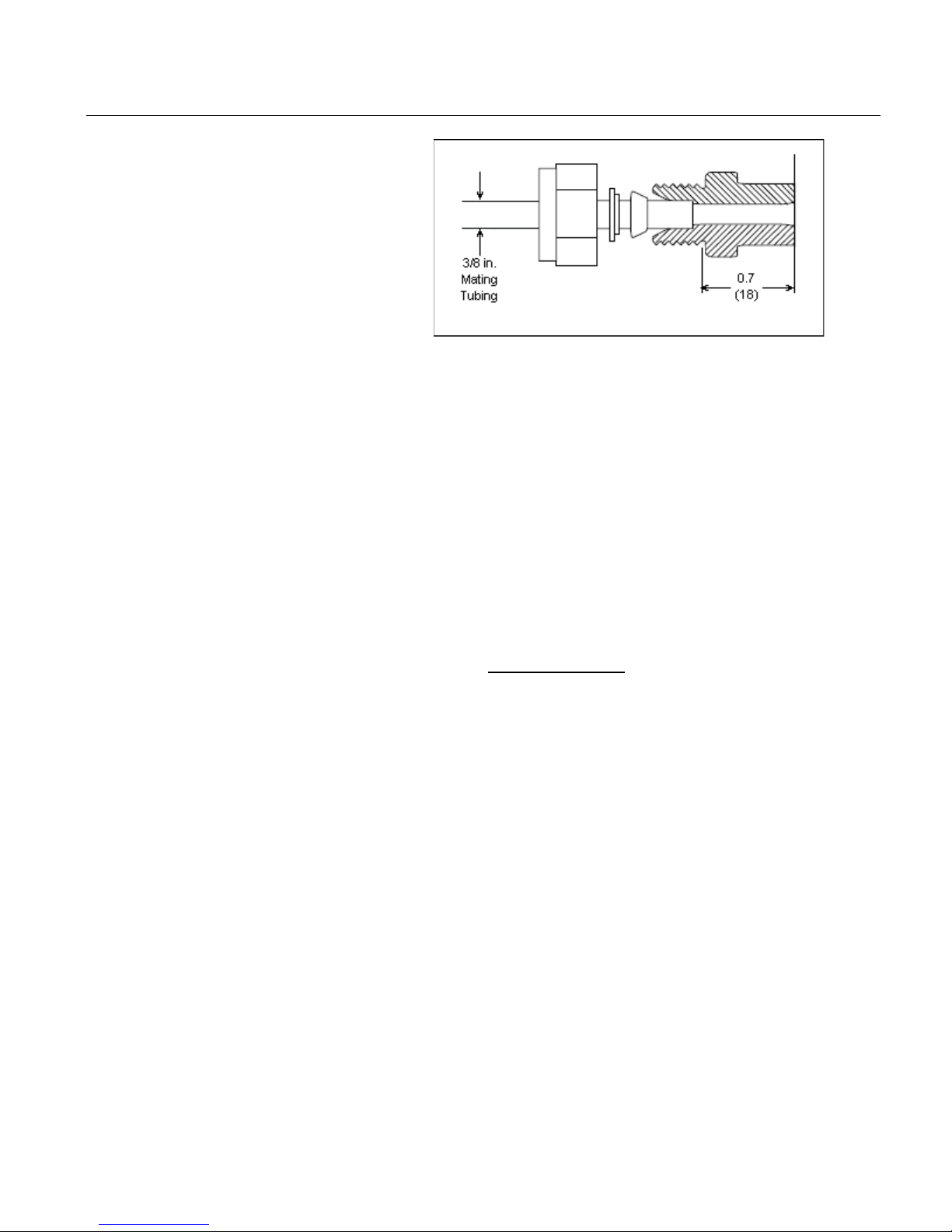

Transmitters with options including 3/8 inch Swagelok™ are shipped

with front ferrule, rear ferrule and nut. Place these fittings on the

tubing with the orientation and relative position shown in Figure 2-1.

Use process tubing with 3/8 inch outside diameter and of suitable

2-4

Page 15

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

Figure 2-1 – Swagelok™

Compression Fitting Detail

Impulse Piping

The Swagelok™ tube fittings come completely assembled and are

ready for immediate use.

because dirt or foreign materials may get into the fitting and cause

le

tubing rests firmly on the shoulder of the fitting and the nut is finger

tight. Tighten the nut one

To reconnect, insert the tubing with p

until the front ferrule sits in the fitting. Tighten the nut by hand, then

rotate one

position. Then snug it slightly with a wrench.

For more detailed i

Swagelok™ tube fittings, refer to:

If drain/vent valves are opened to

the value in Table 5

when closing.

The piping between the process and the transmitter must accurately

transfer the pressure to obtain accurate measurements. There are fi

possible sources of error: pressure transfer (such as obstruction), leaks,

friction loss (particularly if purging is used), trapped gas in a liquid line

or liquid in a gas line and density variations between the legs.

The best location for the transmit

depends on the process itself. Use the following guidelines to

determine transmitter location and placement of impulse piping:

• Make sure both impulse legs are the same temperature

Dimensions are nominal in inches (mm)

aks. Insert the tubing into the Swagelok™ tube fitting, make sure the

-quarter turn more or to the original one-and-one-quarter tight

• Keep impulse piping as short as possible

• For liquid service, slope the impulse piping at least 1 inch per

foot (8 cm per m) upward from the transmitter toward the

process connection

• For gas service, slope the impulse piping at least 1 inch per foot

(8 cm per m) downward from the transmitter toward the process

connection

• Avoid high points in liquid lines and low points in gas lines

Do not disassemble them before use

-and-one-quarter turns. Do not over-tighten.

re-swaged ferrules into the fitting

nformation regarding the specifications and use of

Fittings Catalog MS-01-140

“Gaugeable Tube Fittings and Adapter Fittings”

www.swagelok.com

-2 in Section 5 Maintenance and Troubleshooting

bleed process lines, torque stems to

ter in relation to the process pipe

ve

2-5

Page 16

Rosemount 3150 Series

Reference Manual

July 2016

Mounting Configurations

• Use impulse piping of large enough diameter to avoid friction

l out of direct contact with

Refer to Figure 2

configurations:

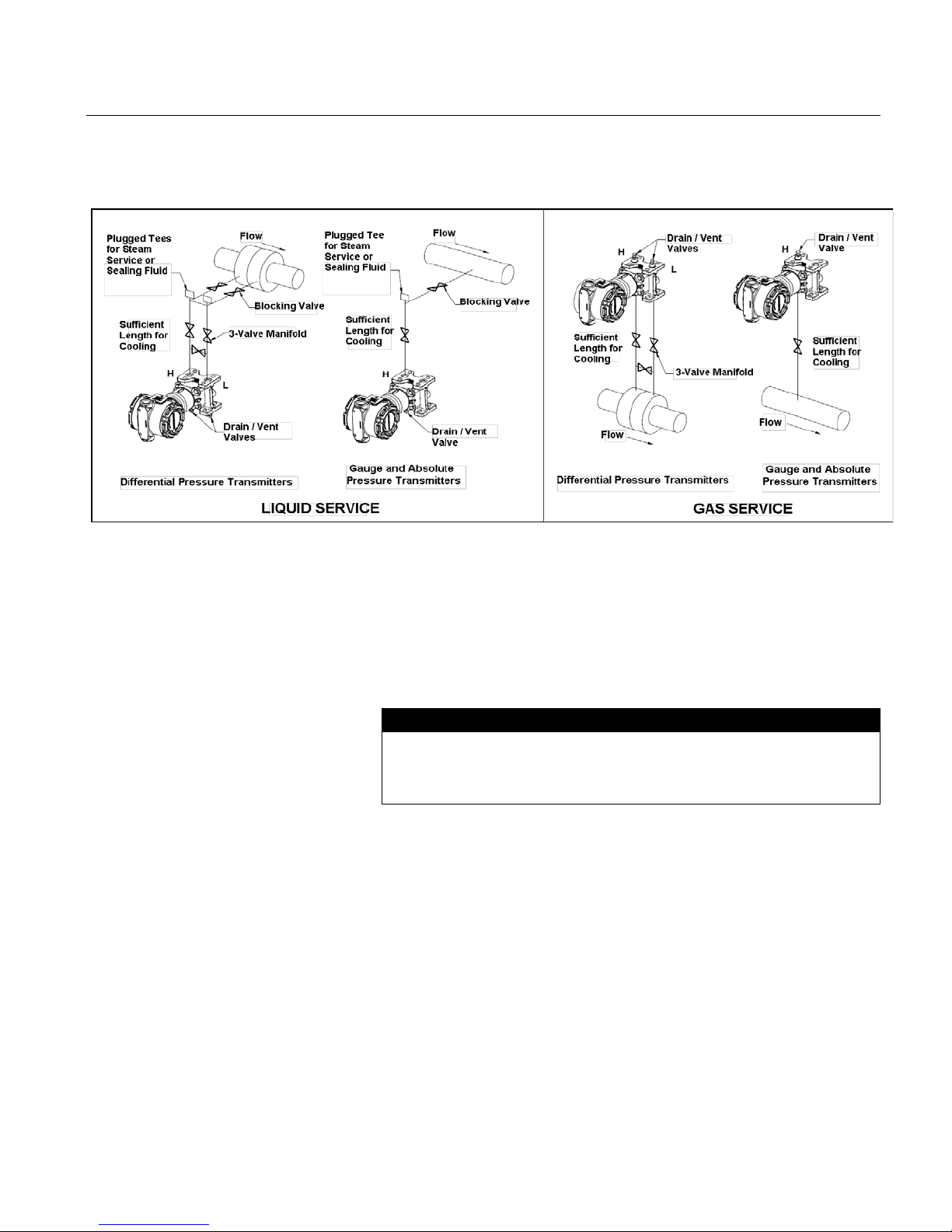

Liquid Flow Measurement

Gas Flow Measurement

Stea

negligible.

NOTE

The mounting configurations described above and depicted in Figure 22 are based on general

Where applicable, specific plant approved installation practices should

be used.

NOTE

In steam or other elevated temperature services, it is important that

temperatures at the process flanges not exceed 25

vacuum service, these limits are reduced to 220oF (104oC).

• Vent all gas from liquid piping legs

• Vent all liquid from gas piping legs

• When using a sealing fluid, fill both piping legs to the same level

• When purging, make the purge connection close to the process

• Keep corrosive or hot process materia

• Prevent sediment deposits in the impulse piping

• Keep the liquid balanced on both legs of the impulse piping

• Avoid conditions that might allow process fluid to freeze within

• Make sure the impulse piping is of adequate strength to be

• Place taps to the side of the line to prevent sediment deposits

• Mount the transmitter beside or below the taps so gases vent

00809-0100-4835 Rev BD

effects and blockage

taps and purge through equal lengths of the same size pipe –

avoid purging through the transmitter

the transmitter

the process flange

compatible with anticipated pressure.

-2 for examples of the following mounting

on the process isolators.

into the process lines.

• Place taps in the top or side of the line.

• Mount the transmitter beside or above the taps to drain liquid

into the process line.

m Flow Measurement

• Place taps to the side of the line.

• Mount the transmitter below the taps to ensure that impulse

piping will remain filled with condensate.

• Fill impulse lines with water to prevent steam from contacting

the transmitter directly and to ensure accurate measurement

start-up. Condensate chambers are not typically necessary

since the volumetric displacement of the transmitter is

industry “best practice” recommendations.

0oF (121oC). In

2-6

Page 17

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

Conduit

Electrical Housing

The conduit connections to the transmitter are threaded. Options

f the unused opening with a compatible thread type

IMPORTANT

For all 3152 and 3153 transmitters, install the conduit plug (provided

with

values outlined in

Table 5-2.

Rosemount Nuclear Instruments, Inc.

Figure 2-2 Transmitter Installation

Examples (liquid, gas or steam)

Please note that transmitters depicted in Figure 2-2 are intended for reference only.

available are ½ -14 ANPT, M20, PG 13.5 and G1/2. Two openings are

available on the 3152 and 3153 transmitter housings for convenient

installation. Close of

stainless steel pipe plug. Use your plant-approved, qualified thread

sealant on the conduit connection threads.

the transmitter) in the unused conduit opening per the torque

The 3154 has one conduit connection.

Use a qualified conduit seal at the conduit entry to prevent moisture

from accumulating in the terminal side of the housing during accident

conditions. Certain option codes provide a qualified connector with the

connector factory assembled to the transmitter. To prevent the conduit

from adding mechanical stress to the transmitter during seismic

disturbances, use flexible conduit or support the conduit near the

transmitter. Install the conduit seal in accordance with the

manufacturer’s instructions or use the procedure in this section.

The standard transmitter orientation is shown in dimensional drawings

found in this manual (see Figure 2-6). The electronics housing

cannot be rotated in the field. For more information, please contact

Section 5: Maintenance and Troubleshooting,

2-7

Page 18

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

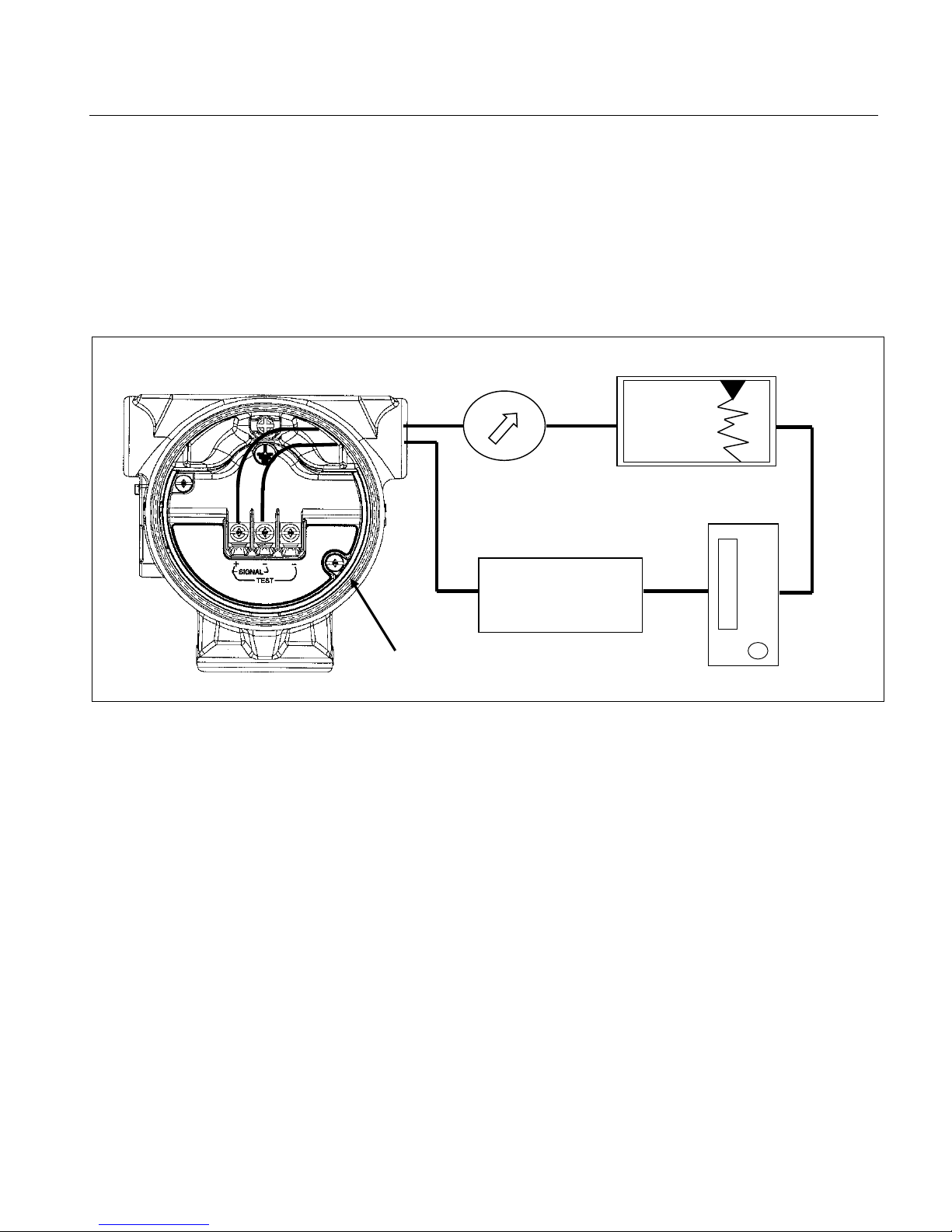

ELECTRICAL

CONSIDERATIONS

This section contains information you should consider when preparing

receivers (controller, indicator, computer).

The power supply must supply at least 12 volts to the transmitter

Terminal Side (cover removed)

-

+

Power

Figure 2-3 – Typical transmitter

Wiring connection

to make electrical connections to the transmitter. Read this section

carefully before proceeding to the electrical installation procedure.

Rosemount 3150 Series transmitters provide a 4-20 mA signal when

connected to a suitable dc power source. Figure 2-3 illustrates a typical

signal loop consisting of a transmitter, power supply, and various

Supply

terminals at 20 mA signal, or the maximum output current required for

proper system operation. Any power supply ripple appears in the

output load. The power supply versus load limitation relationship is

shown in Figure 2-4. See qualification reports for additional details.

The loop load is the sum of the resistance of the signal leads and the

load resistance of the receivers.

2-8

Page 19

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

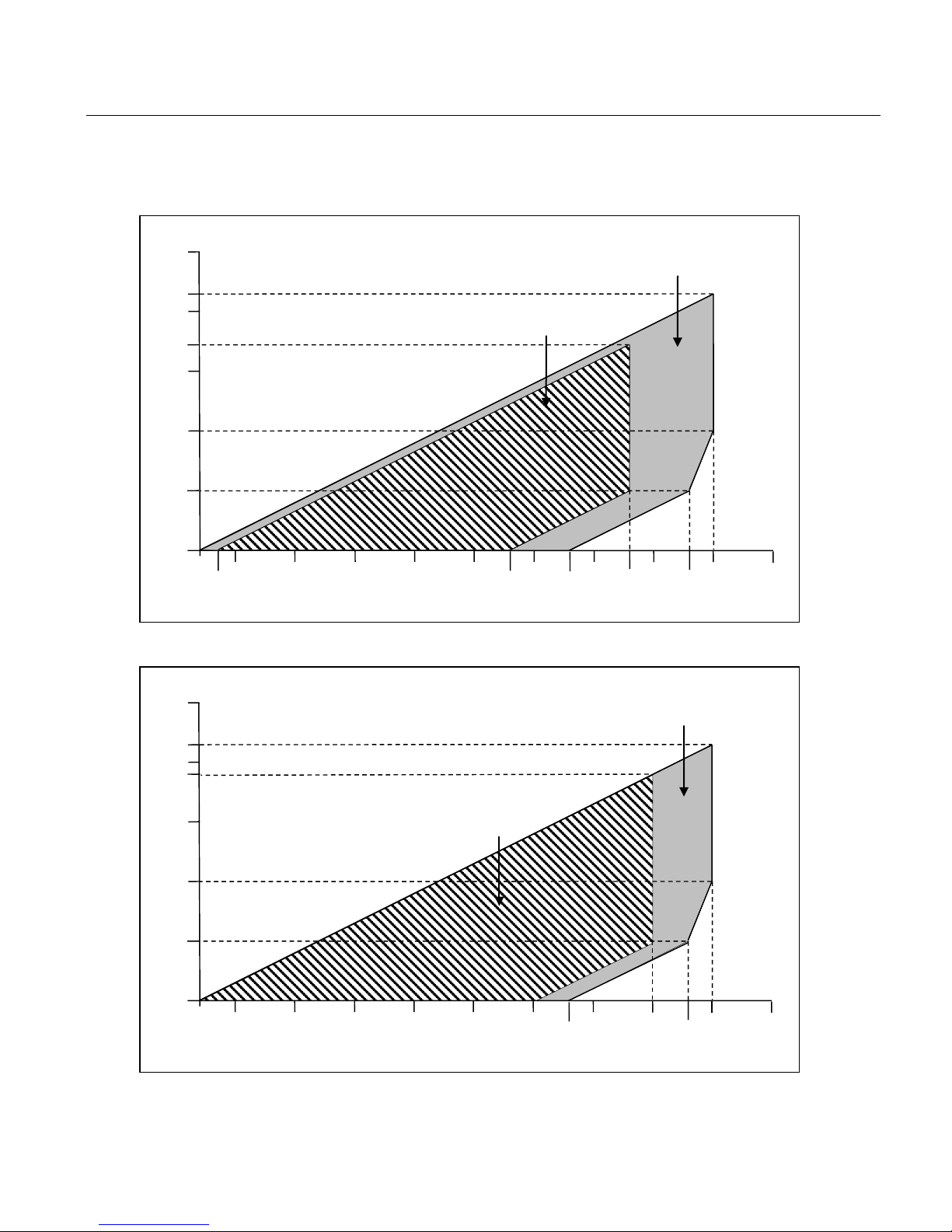

POWER SUPPLY (VDC)

2500

1500

2000

500

1000

12

20

25

30

35

40

45

50

48

13.5

15

38

55

IEEE

REGION

DESIGN

REGION

LOAD (OHMS)

53

2150

1725

60

43

0

2150

POWER SUPPLY (VDC)

2500

1500

500

12

1000

20

25

30

35

40

45

50

15

55

KTA

DESIGN

REGION

LOAD (OHMS)

53

60

43

0

1900

2000

Figure 2-4 – Transmitter Supply

Voltage vs. Load

Figure 2-4a – IEEE Qualified and Design Regions

(applicable to 3152N, 3153N and 3154N models only)

QUALIFIED

Figure 2-4b – KTA Qualified and Design Regions

(applicable to 3152K and 3154K models only)

QUALIFIED

REGION

2-9

Page 20

Rosemount 3150 Series

Reference Manual

July 2016

Signal wiring need not be shielded, but twis ted pairs yi eld the best

in the signal

), and

45

43

POWER SUPPLY (VDC)

2500

2000

1500

500

12

1000

20

25

30

35

40

50

15 55

RCC

DESIGN

REGION

LOAD (OHMS)

53

2150

2050

60

0

38

750

Figure 2-4c – RCC-E Qualified and Design Regions

(applicable to 3153K and 3154K models only)

00809-0100-4835 Rev BD

QUALIFIED

REGION

results. Shielded cable should be used for best results in electrically

noisy environments. Do not run signal wiring in conduit or open trays

with AC power wiring, or near heavy electrical equipment. Signal wiring

may be ungrounded (floating) or grounded at any one point

loop.

For installations with EMC performance requirements, consult the

Rosemount Nuclear Instruments, Inc. EMC test reports for additional

details regarding recommended practices for electrical wiring per

various national and international codes and regulations.

The transmitter case may be grounded or ungrounded. Grounding

should be completed in accordance with national and local electrical

codes. Transmitter case can be grounded using either the internal or

external ground connection.

• Internal Ground Connection: The Internal Ground

• External Ground Assembly: The External Ground location is

Connection screw is inside the terminal side of the electronics

housing. The screw is identified by a ground symbol (

is standard on all 3150 Series transmitters.

indicated by the ground symbol ( ) on the module. An

External Ground Assem bl y kit can be ordered as an option on

the 3150 Series transmitter. This kit can also be ordered as a

spare part. Please contact RNII for ordering information.

2-10

Page 21

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

The capacitance sensing element uses alternating current to generate a

rough the

INSTALLATION

PROCEDURES

Mechanical

Installation consists of mounting the transmitter and conduit and making

WARNING

Improper assembly of mounting bracket to transmitter traditional

process

supplied with the bracket.

.

see

Troubleshooting.

capacitance signal. This alternating current is developed in an oscillator

circuit with a nominal frequency of 110 kHz +/- 11 kHz. This 110 kHz

signal is capacitively-coupled to the transmitter case ground th

sensing element. Because of this coupling, a voltage may be imposed

across the load, depending on choice of grounding.

This impressed voltage, which is seen as high frequency noise, has no

effect on most instruments. Computers with short sampling times in a

circuit where the negative transmitter terminal is grounded detect a

significant noise signal. Filter this signal out by using a large capacitor

(1 uf) or a 110 kHz LC filter across the load. Signal loops at any other

point are negligibly affected by this noise and do not need filtering.

electrical and process connections. The procedures for each operation

follow.

– Transmitter

flange can damage sensor module.

• For safe assembly of bracket to traditional flange, bolts must

break back plane of flange web (i.e. bolt hole), but must not

contact module housing. Use only the RNII approved bolts

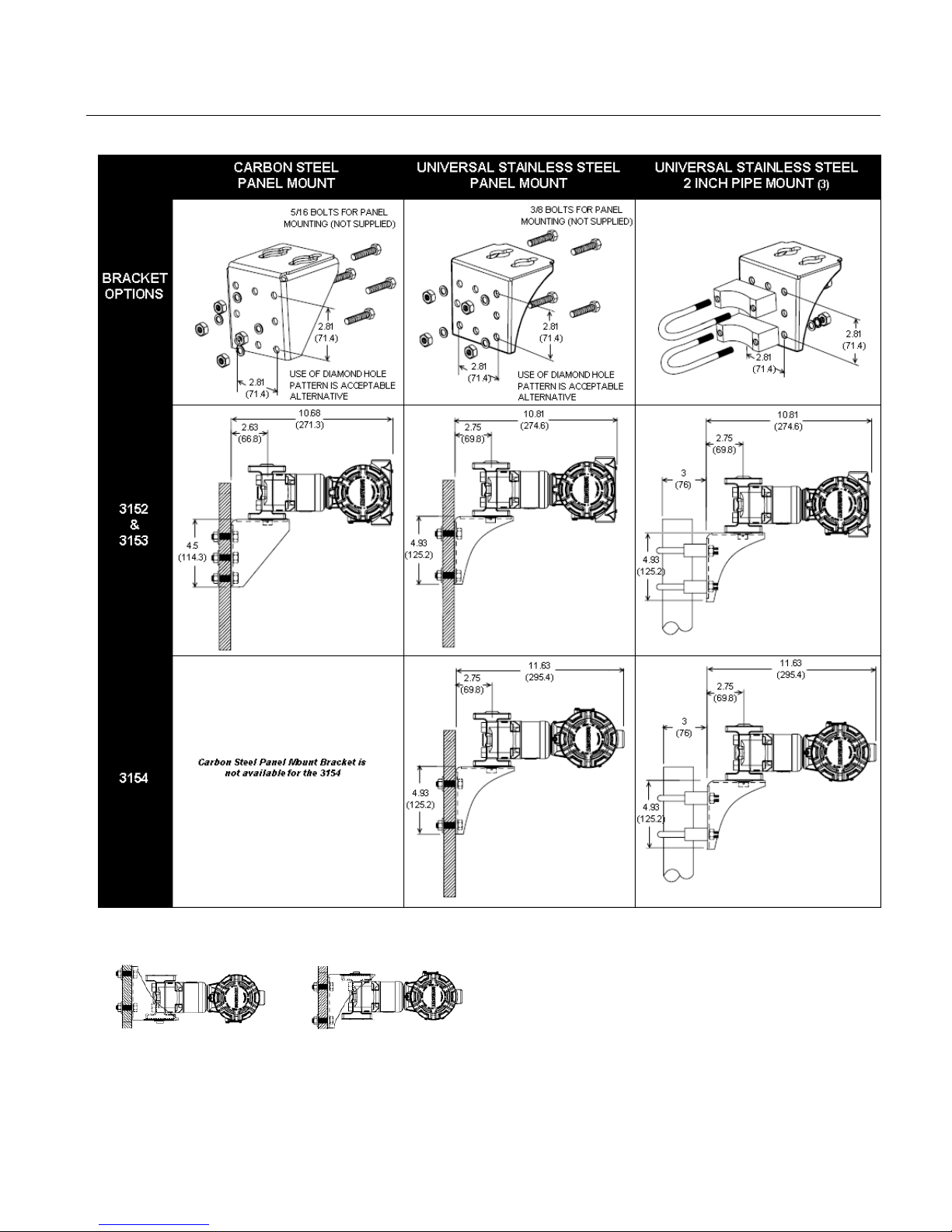

1. Attach the mounting bracket to the mounting location as follows:

Panel Mount

Mount the bracket to a panel or other flat surface (for

illustration see Figur e 2-5). Please note that the bolts

required for this step are customer supplied hardware.

Based on qualification tests performed by Rosemount, the

bolts listed in Table 2-1 are recommended for the bracketto-customer interface. Torque each bolt to value shown in

Table 5-2 in Section 5 Maintenance and

Troubleshooting

Pipe Mount

Assemble the bracket kit to a 2-inch pipe (for illustration

Figure 2-5). Torque each bolt to value shown in Table 5-2

in Section 5 Maintenance and Troubleshooting.

2. Attach the transmitter to the mounting bracket (for illustration

see Figure 2-5). Use the four 7/16-20 x ¾ inch bolts with

washers supplied with the transmitter. Torque each bolt to

value shown in Table 5-2 in Section 5 Maintenance and

2-11

Page 22

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

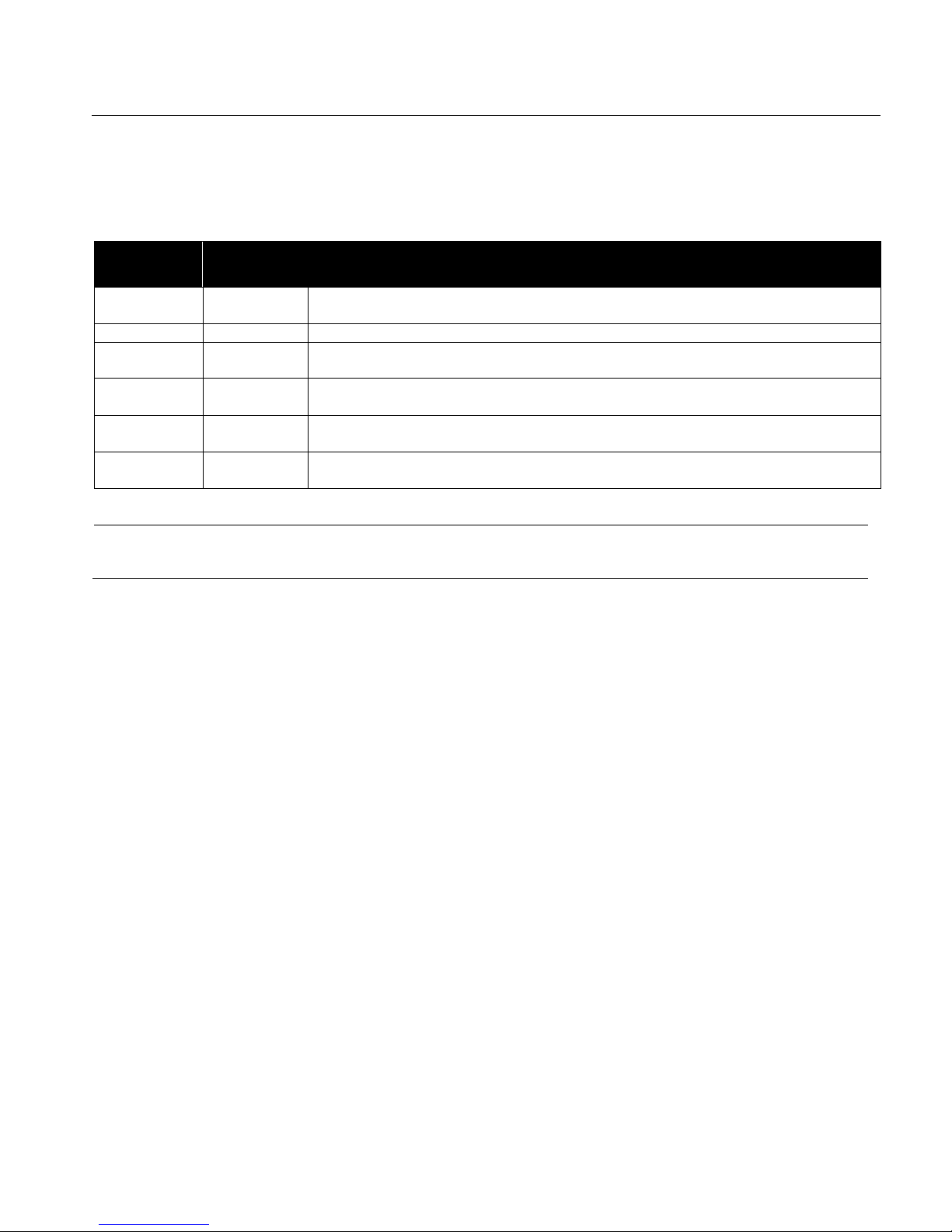

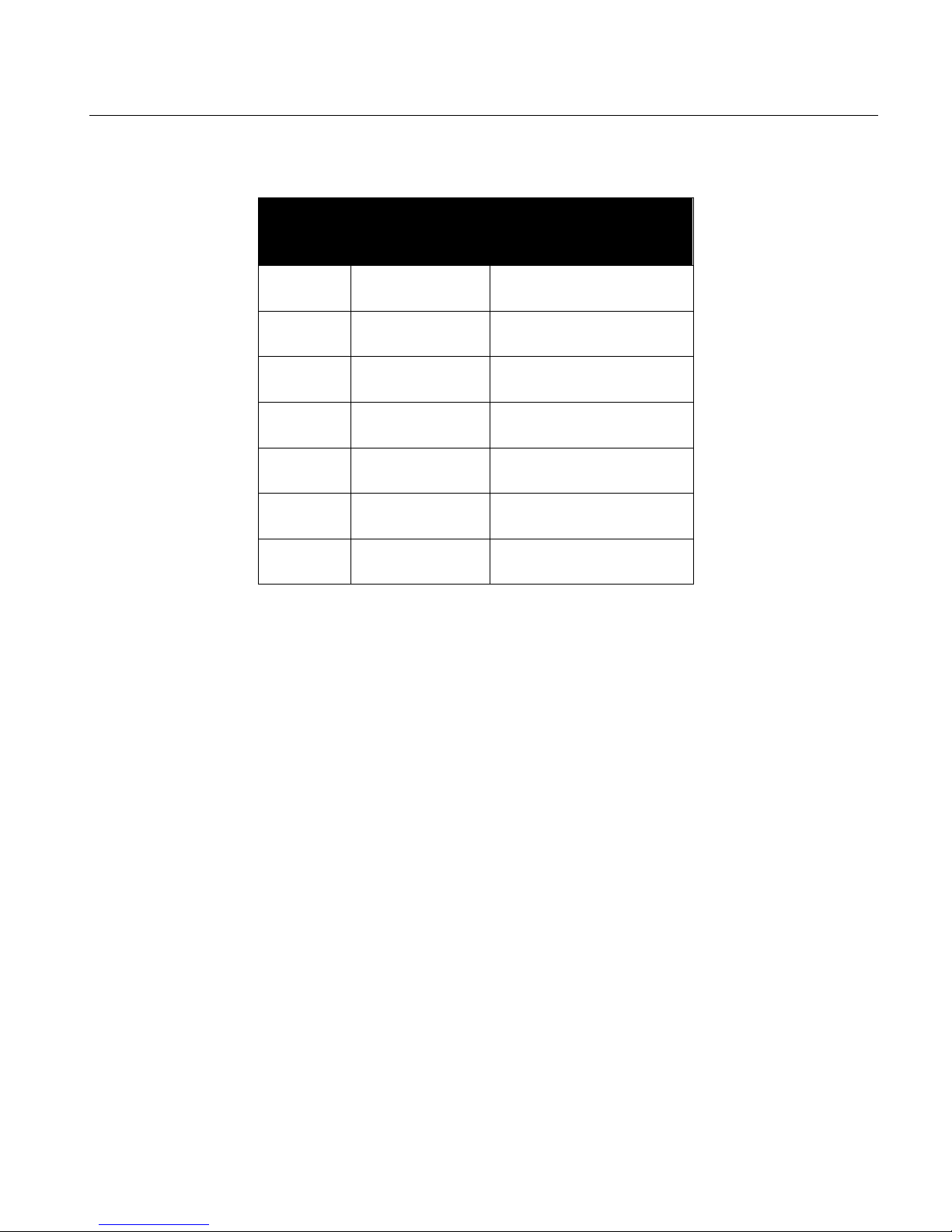

Table 2-1 – Recommended bolts for

bracket-to-customer interface

(1) The Bracket Code can be found in the 13

(2) Bracket Codes 1 and 5 are available on the 3152 and 3153-series only

(3) Bracket Codes 2 and 7 are available on the 3152, 3153 and 3154-series

(4) Bracket Codes 3 and 8 are available on the 3152, 3153 and 3154-series; this bracket code includes the listed bracket along

with the pipe mount hardware (Rosemount P/N 01154-0044-0001)

BRACKET

CODE

(1)

0

(2)

1

(3)

2

(4)

3

(2)

5

(3)

7

(4)

8

BRACKET TYPE

No Bracket

Supplied

Carbon Steel

Panel Bracket

SST Panel

Bracket

SST 2” Pipe

Mount Bracket

Carbon Steel

Panel Bracket

SST Panel

Bracket

SST 2” Pipe

Mount Bracket

th

position of the 3152, 3153 and 3154 model strings

RECOMMENDED BOLT

FOR BRACKET TO

CUSTOMER INTERFACE

N/A

5/16-18 UNC 2A Grade 2

3/8-24 UNF 2A Grade 2

3/8-24 UNF 2A Grade 2

5/16-18 UNC 2A Grade 2

3/8-24 UNF 2A Grade 2

3/8-24 UNF 2A Grade 2

2-12

Page 23

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

NOTE: All dimensions are nominal in

inches (millimeters)

Figure 2-5 – Typical Transmitter Mounting Bracket Configuration, Traditional Flange

(1) (2)

(1) Transmitter and bracket orientation with respect to gravity will not impact qualification.

(2) Transmitters can alternatively be mounted inside bracket (as shown below) or with process connection posit i oned adj acent to bracket

(not shown).

(3) A pipe-mount kit with three (3) U-bolts (not shown) is also available. The use of a third U-bolt is necessary to meet KTA seismic

requirements in installations where the KTA Airplane Crash (APC) value of 8g is applicable,. Please consult the applicable RNII Product

Data Sheet (PDS) for ordering information.

2-13

Page 24

Rosemount 3150 Series

Reference Manual

July 2016

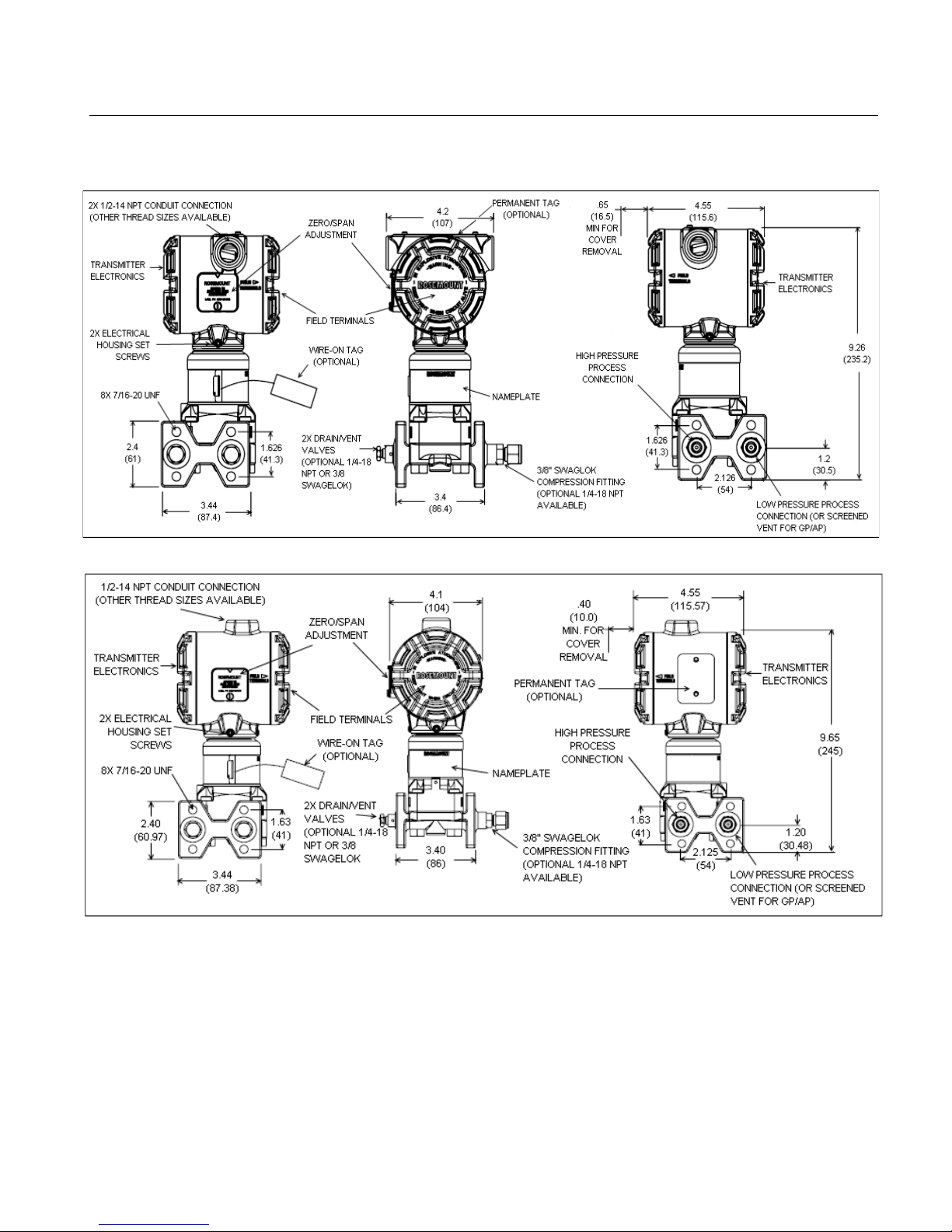

NOTE: All dimensions are nominal in inches (millimeters)

NOTE: All dimensions are nominal in inches (millimeters)

Figure 2-6 – Transmitter Dimensional

Drawings

00809-0100-4835 Rev BD

3152, 3153 Traditional Flange

3154 Traditional Flange

2-14

Page 25

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

Mechanical – Conduit

Electrical

CAUTION

Be careful not to damage the set screw interface between the sensor

module and the electronics housing.

NOTE

Install the conduit seal in accordance with the manufacturer’s

instructions or use the procedure in this section.

housing conduit hub has two flat surfaces that allow the housing

CAUTION

Do not connect signal leads to the ‘TEST’ terminals.

WARNING

Electrical shock can result in death or serious injury. Avoid contact with

the leads and terminals. High voltage that may be present on leads can

cause electrical shock.

Recheck connections for proper polarity. Position excess wiring

NOTE

Once the cover is installed metal-to-metal, do not torque the cover

further.

1. Seal conduit threads with your plant-approved qualified thread

sealant.

2. Install conduit to the manufacturer’s recommended thread

engagement or torque level. For conduit connectors, refer to

the appropriate manufacturer’s installation manuals. Hold the

electronics housing securely to avoid damaging the set screw

interface between the sensor module and the electronics

housing during conduit installation. The 3154 electronics

to be held securely with open end wrench or other suitable tool

during conduit installation.

3. Provide separate support for the conduit if necessary.

1. Remove the cover from the terminal side of the transmitter.

2. Connect the power leads to the ‘SIGNAL’ terminals on the

transmitter terminal block (see Figure 2-7). Avoid contact with

the leads and terminals. Do not connect the powered signal

wiring to the test terminals, power could damage the test diode.

Torque the terminal screws to the value shown in Table 5-2 in

Section 5 Maintenance and Troubleshooting or hand-tight.

Signal wiring supplies all power to the transmitter. If a 3 wire

connector is utilized or loop groundi ng is requ ired, us e the

ground screw shown in Figure 2-8.

3.

inside the housing so cover installation avoids damage to the

wiring.

4. Carefully replace cover. Caution should be taken that electrical

wires do not interfere with cover installati on so wire da mage

does not occur. Tighten until cover and housing are fully

engaged metal-to-metal (see Figure 2-9). Covers come prelubricated from the factory and should not require additional

lubrication during initial installation.

2-15

Page 26

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

Figure 2-7 – Terminal Block

Assembly

Figure 2-8 – Ground Screw

Location

Figure 2-9 – Cover and

Housing Metal

Installation

Ground Screw

3152 & 3153

3154

3152 & 3153

3154

Metal-to-Metal Contact

-to-Metal

2-16

Page 27

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

2-17

Page 28

Rosemount 3150 Series

Reference Manual

July 2016

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Procedures. . . . . . . . . . . . . . . . . . . . . . . . . .

page 3-1

page 3-6

WARNING

consistent with the appropriate qualification parameters.

WARNING

OVERVIEW

This section contains the following transmitter calibration information:

o Linearity

SAFETY MESSAGES

Procedures and instructions in this section may require special

operation preceded by this symbol .

SECTION 3: CALIBRATION

00809-0100-4835 Rev BD

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . .

• Calibration Overview

o Calibration Considerations

o Definitions

o Span Adjustment Range

o Zero Adjustment Range

• Calibration Procedures

o Span and Zero Adjustment

Calibration Procedure for Zero Based Span (LRV is

Zero DP)

Calibration Procedure for Elevated or Suppressed

Zero

Coarse Zero Select Jumper Position Selection

Procedure

o Damping Adjustment

o Correction for High Static Line Pressure

High Static Pressure Span Effect on Range Codes

1, 2 and 3 DP Transmitters

High Static Pressure Span Correction for Range

Code 4 and 5 DP Transmitters

High Static Line Pressure Zero Correction for DP

Transmitters (All Ranges)

page 3-1

page 3-2

precautions to ensure the safety of the personnel performing the

operation. Refer to the following safety messages before performing an

Explosions can result in death or injury.

• Do not remove the transmitter covers in explosive

environments when the circuit is live.

• Verify that the operating atmosphere of the transmitter is

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and terminals when the circuit is

live.

Page 29

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

WARNING

transmitter is in service. WARNING

Inc. as spare parts for the 3152, 3153 or 3154.

NOTE

The pressure unit “inches H2O @ 68ºF (20ºC)” is used throughout this

unit will be abbreviated to “inH2O”.

CALIBRATION OVERVIEW

Calibration Considerations

section.

Process leaks could result in death or serious injury.

• Install and tighten all four flange bolts before applying

pressure.

• Do not attempt to loosen or remove flange bolts while the

Replacement equipment or spare parts not approved by Rosemount

Nuclear Instruments, Inc. for use could reduce the pressure retaining

capabilities of the transmitter and may render the instrument

dangerous or adversely impact its qualified status.

• Use only components supplied with the 3152, 3153 or 3154

transmitter or designated by Rosemount Nuclear Instruments,

section. For ease of reading and to conserve space, this pressure

Review this section to become familiar with the fundamentals of

calibrating the Rosemount 3150 Series transmitter. Contact

Rosemount Nuclear Instruments, Inc. with questions regarding

calibrations that are not explained in this manual.

Rosemount 3150 Series transmitters are factory calibrated to the range

shown on the nameplate (see Figure 1-1). This range may be changed

within the limits of the transmitter. Zero may also be adjusted to elevate

(for all models except absolute pressure reference) or suppress (for all

models). Calibrations that hav e a lower rang e va lue b elow zero are

termed zero elevated while calibrations that have a lower range value

above zero are termed zero suppressed.

The zero and span are adjusted during calibration using zero and span

adjustment screws. The adjustment screws are accessible externally

and are located behind the access cover plate on the side of the

electronics housing (see Figure 3-1). Transmitter output increases with

clockwise rotation of the adjustment screws. For normal calibration

adjustments, the zero adjustment screw has negligible effect on the

span and the span adjustment has negligible effect on the zero.

For large amounts of zero adjustment, a course zero selection jumper is

provided. The jumper is located on the electronics assembly,

accessible within the electronics hous in g as shown in F igures 3-1 and

3-2. Models ordered with optional output damping will have a damping

adjustment potentiometer located on the amplifier board (see Figure 3-

2).

Procedures for calibration, including setting the course zero selection

jumper and optional damping adjustment, are provided later in this

3-2

Page 30

Rosemount 3150 Series

Reference Manual

July 2016

Definitions

The following definitions and descriptions are provided to aid in

pressure side of

module by an “L”.

calibration:

DP

Differential pressure between the high pressure “H” and low pressure

“L” process inputs, as marked on the transmitter module.

Upper Range Limit (URL)

The highest pressure the transmitter can be adjusted to measure,

specified in the model ordering information by pressure range code.

Upper Range Value (URV)

The highest pressure the transmitter is adjusted to measure. This

pressure corresponds to 20mA output point.

Lower Range Value (LRV)

The lowest pressure the transmitter is adjusted to measure. This

pressure corresponds to the 4mA output point.

Span = |URV - LRV|

Zero Based Calibration

Calibration where the LRV is zero DP (see Figure 3-3)

Elevated Zero Calibration

Calibration where the LRV is less than zero DP (i.e. the LRV is

achieved when a positive pressure is applied to the low

the DP cell or a vacuum is applied to the high pressure side of the DP

cell – see Figure 3-3).

Suppressed Zero Calibration

Calibration where the LRV is greater than zero DP (i.e. the LRV is

achieved when a positive pressure is applied to the high pressure side

of the DP cell or a vacuum is applied to the low pressure side of the DP

cell – see Figure 3-3).

% Zero Offset

= (LRV/URL) X 100

Note: % Zero Offset is used when making coarse zero adjustments and

replaces the traditional % Zero Elevation and % Zero Suppression

terms. This concept is used due to the limited interaction between zero

and span adjustments on the 3150 series pressure transmitter.

Sign Convention

Positive numbers indicate positive pressure is applied to the high

pressure side of the DP cell or a vacuum is applied to the low pressure

side of the DP cell. The high pressure side is indicated on the sensor

module by an “H”.

Negative numbers indicate positive pressure is applied to the low

pressure side of the DP cell or a vacuum is applied to the high pressure

side of the DP cell. The low pressure side is indicated on the sensor

00809-0100-4835 Rev BD

3-3

Page 31

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

Damping Adjustment

Coarse Zero

Electronics

housing

Zero and Span

Figure 3-1 – Zero and Span

Figure 3-2 – Electronics Assembly

Assembly located

inside electronics

Select Jumper

Adjustment Screws

(optional)

3-4

Page 32

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

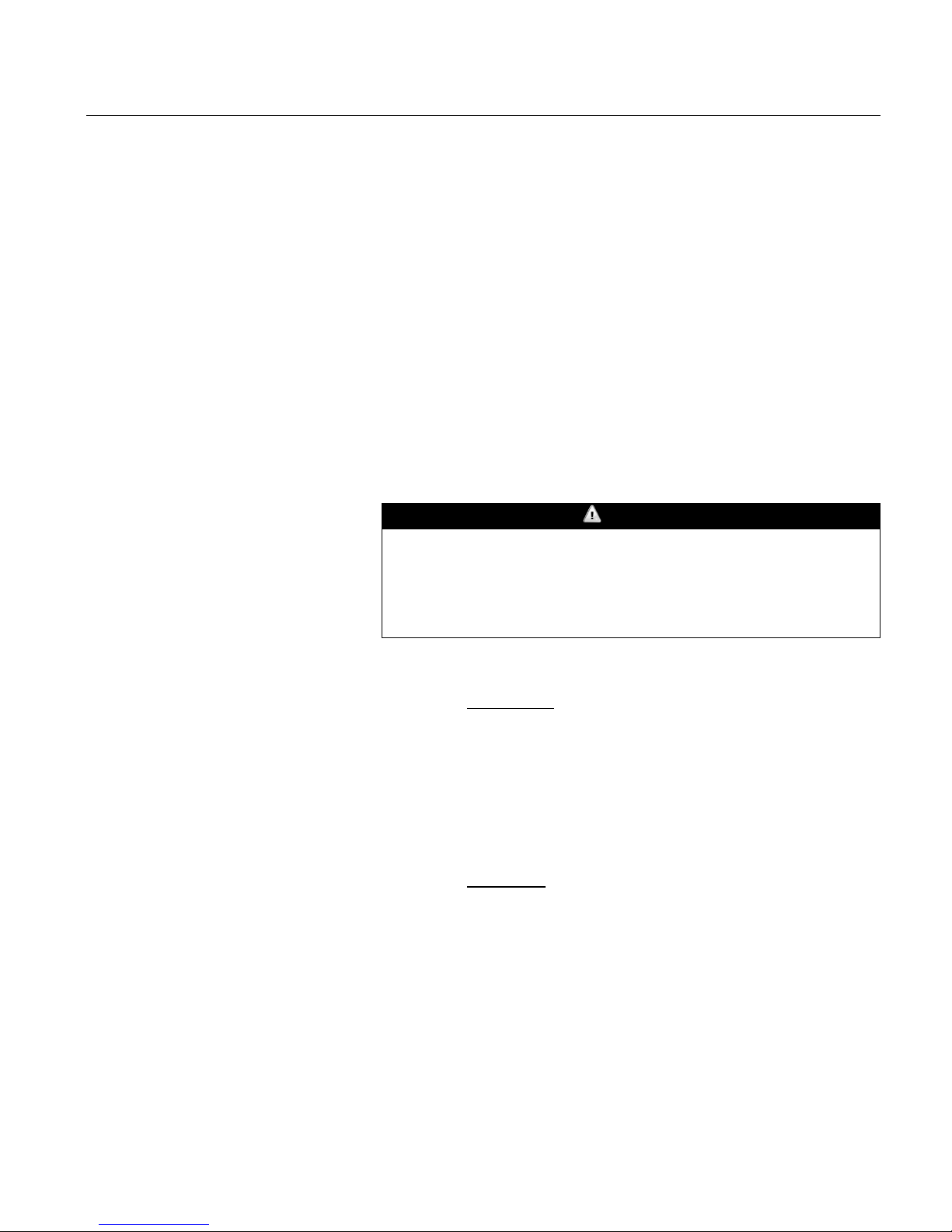

Span Adjustment Range

For transmitter ranges 2 to 6, the span is continuously adjustable to

Zero Adjustment Range

The transmitter zero can be adjusted to achieve a maximum 90%

75 inH2O (-18,6 kPa to 18,6 kPa).

0

4

8

12

16

20

-250

-200

(-49,8)

-100

(

24,9)

-50

(

0

50

(12,4)

100

(24,9)

150

(37,3)

200

(49,8)

250

(62,2)

Differential Pressure Input

(kPa)

Analog Output (mA)

Elevated Zero

Calibration

-250 to -150 inH2O

(

(-100% Zero Offset)

Zero Based

Calibration

0 to 100 inH2O

(0 to 24,9 k Pa)

Suppressed Zero

Calibration

150 to 250 inH2O

(37,3 to 62,2 kPa)

Zero

Adjust

Span Adjust

LRV

URV

URV

LRV

LRV

-150

URV

LRL

URL

(+60% Zero Offset)

allow calibration anywhere between the transmitter URL and 1/10 of

URL. For example, the span on a Range 2 transmitter can be

continuously adjusted bet w een 25 and 250 inH

O (6,22 kPa and 62,2

2

kPa).

For Range 1 transmitters, the span is continuously adjustable to allow

calibration anywhere between the transmitter URL and 1/5 of URL.

For example, the span on a Range 1 transmitter can be continuously

adjusted between 5 and 25 inH

O (1,25 kPa and 6,22 k Pa).

2

Zero Offset for suppressed zero calibrations and -100% Zero Offset

for elevated zero calibrations. To achieve these levels of zero

elevation and zero suppression, the 3150 Series is equipped with a

“Coarse Zero Select Jumper” located on the Electronics Assembly in

the electronics housing (see Figure 3-2).

A graphical representation of three calibrations is shown in Figure 3-

3. Procedures for setting the “Coarse Zero Select Jumper” are

provided in the Calibration Procedure section. The zero may be

elevated or suppressed with the limitation that no applied pressure

within the calibrated range exceeds the URL or LRL. During zero

elevation the transmitter may be calibrated to cross zero, ex. -75 to

Figure 3-3 – Graphical Representation of Elevated Zero, Zero Based, and

Suppressed Zero Calibrations for a Range 2 Transmitter

-62,2 to -37,3 kPa)

(-62,2)

(-37,3)

-

-12,4)

3-5

inH2O

Page 33

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

CALIBRATION PROCEDURES

The following calibration procedures describe the recommended

Span and Zero Adjustment

CAUTION

The 3150 Series pressure transmitters contain electronic circuit

boards which may be static sensitive.

NOTE

zero and span adjustment screws.

NOTE

pressure unit will be abbreviated to “inH2O”.

Zero Based Calibration Procedure

The adjustment screws are accessible externally and are located

Figure 3-4b uses SI Units (kPa).

steps necessary to calibrate the Rosemount 3150 Series pressure

transmitters.

Electronics housing covers do not need to be removed to access the

The pressure unit “inches H2O @ 68ºF (20ºC)” is used throughout

this section. For ease of reading and to conserve space, this

(LRV is zero DP)

behind the access cover plate on the side of the electronics housing

(see Figure 3-1). The transmitter output increases with clockwise

rotation of the adjustment screw. The Coarse Zero Select jumper is

in the Nominal position for all zero based calibrations.

1. Apply a pressure equivalent to the LRV to the high side

pressure connection and turn Zero adjustment until output

reads 4 mA.

2. Apply a pressure equivalent to the URV to the high side

process connection and turn Span adj us tment until output

reads 20 mA.

3. Check to assure desired outputs are achieved and repeat

steps 1 and 2 if necessary.

Figure 3-4 contains an example of calibrating a transmitter with a zero

based calibration. Figure 3-4a uses English Units (inH

O) while

2

3-6

Page 34

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

Figure 3-4a – Example for Zero Based

Range 2 for a calibration of 0 to 100 inH2O (100 inH2O span)

and 2 if necessary.

Figure 3-4b – Example for Zero Based

Range 2 for a calibration of 0 to 24,9 kPa (24,9 kPa span)

and 2 if necessary.

Elevated or Suppressed Zero

The easiest way to calibrate a 3150 Series pressure transmitter with

adjustment screw and, if necessary, the Coarse Zero Select Jumper.

NOTE

Jumper Position Selection Procedure.

English units (inH2O) while Figures 3-5b and 3-6b use SI units (kPa)

Calibration (English Units)

Calibration (SI Units)

Calibration Procedure

1. Adjust the zero: With 0 inH2O applied to the transmitter, turn the

Zero adjustment until the transmitter reads 4 mA.

2. Adjust the span: Apply 100 inH

connection. Turn the Span adjustment until the transmitter output

reads 20 mA.

3. Check to assure desired outputs are achieved and repeat steps 1

O to the transmitter high side

2

1. Adjust the zero: With 0 kPa applied to the transmitter, turn the Zero

adjustment until the transmitter reads 4 mA.

2. Adjust the span: Apply 24,9 kPa to the transmitter high side

connection. Turn the Span adjustment until the transmitter output

reads 20 mA.

3. Check to assure desired outputs are achieved and repeat steps 1

an elevated or suppressed zero is to perform a zero-based calibration

and then elevate or suppress the zero by adjusting the zero

For large amounts of elevation or suppression, it may be necessary to

reposition the Coarse Zero Select Jumper. Procedures for repositioning the jumper are described in the Coarse Zero Select

Figures 3-5 and 3-6 contain examples of calibrating a transmitter with

Zero Elevated and Suppressed zeros. Figures 3-5a and 3-6a us e

3-7

Page 35

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

Figure 3-5a – Example for Elevated

Range 2 with Zero Elevation for a calibration of –120 to –20

transmitter output reads 4mA. Do not use the span adjustment.

NOTE

marked on the transmitter module) will give the same result

4. Apply -20 inH

O to the high side process connection (as marked on

adjustment.

NOTE

on the transmitter module) will give the same result.

Figure 3-5b – Example for Elevated

Range 2 with Zero Elevation for a calibration of –29,9 to –5,0 kPa

transmitter output reads 4mA. Do not use the span adjustment.

NOTE

on the transmitter module) will give the same result.

4.

adjustment.

NOTE

on the transmitter module) will give the same result.

Zero Calibration (English Units)

inH2O (100 inH2O span)

1. Calibrate the transmitter to 0 to 100 inH2O as descri bed in the Zero

Based Calibration Procedure.

2. Consult Table 3-1 to determine appropriate Course Zero Select

Jumper position. If necessary, reposition jumper using the Coarse

Zero Select Jumper Position Selection Procedure.

For this example:

% Zero Offset = (-120 inH

Position the jumper to the MID ZE position.

3. Apply -120 inH

the transmitter sensor module) and adjust the zero until the

Applying 120 inH2O to the low side process connection (as

the transmitter sensor module). Verify the output reads 20mA. If

necessary, adjust the span. Recheck the zero after any span

Applying 20 inH2O to the low side process connection (as marked

O to the high side process connection (as marked on

2

2

O /250 inH2O)*100 = -48%

2

Zero Calibration (SI Units)

(24,9 kPa span)

1. Calibrate the transmitter to 0 to 24,9 kPa as described in the Zero

Based Calibration Procedure.

2. Consult Table 3-1 to determine appropriate Course Zero Select

Jumper position. If necessary, reposition jumper using the Coarse

Zero Select Jumper Position Selection Procedure.

For this example:

% Zero Offset = (-29,9 kPa /62,2 kPa)*100 = -48%

Position the jumper to the MID ZE position.

3. Apply -29,9 kPa to the high side process connection (as marked on

the transmitter sensor module) and adjust the zero until the

Applying 29,9 kPa to the low side process connection (as marked

Apply -5,0 kPa to the high side process connection (as marked on

the transmitter sensor module). Verify the output reads 20 mA. If

necessary, adjust the span. Recheck the zero after any span

Applying 5,0 kPa to the low side process connection (as marked

3-8

Page 36

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

Figure 3-6a – Example for Suppressed

Range 2 with Zero Suppression for a calibration of 20 to 120

zero after any span adjustment.

Figure 3-6b – Example for Suppressed

Range 2 with Zero Suppression for a calibration of 5,0 to 29,9

zero after any span adjustment.

Zero Calibration (English Units)

Zero Calibration (SI Units)

inH2O (100 inH2O span)

1. Calibrate the transmitter to 0 to 100 inH2O as descri bed in the Zero

Based Calibration Procedure.

2. Consult Table 3-1 to determine appropriate Course Zero Select

Jumper position. If necessary, reposition jumper using the Coarse

Zero Select Jumper Position Selection Procedure.

For this example:

% Zero Offset = (20 inH

Position the jumper to the NOMINAL position.

3. Apply 20 inH

zero until the transmitter output reads 4 mA. Do not use the span

adjustment.

4. Apply 120 inH2O to the high side process connection. Verify the

output reads 20 mA. If necessary, adjust the span. Recheck the

O to the high side process connection, and adjust the

2

O /250 inH2O)*100 = 8%

2

kPa (24,9 kPa span)

1. Calibrate the transmitter to 0 to 24,9 kPa as described in the Zero

Based Calibration Procedure.

2. Consult Table 3-1 to determine appropriate Course Zero Select

Jumper position. If necessary, reposition jumper using the Coarse

Zero Select Jumper Position Selection Procedure.

For this example:

% Zero Offset = (5,0 kPa /62,2 kPa)*100 = 8%

Position the jumper to the NOMINAL position.

3. Apply 5,0 kPa to the high side process connection, and adjust the

zero until the transmitter output reads 4 mA. Do not use the span

adjustment.

4. Apply 29,9 kPa to the high side process connection. Verify the

output reads 20 mA. If necessary, adjust the span. Recheck the

3-9

Page 37

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

Coarse Zero Select Jumper

The Coarse Zero Select Jumper (see Figure 3-2) is shipped from the

Figure 3-7a – Example for Coarse

Range 2 for a calibration of -175 to -125 inH2O

From Table 3-1, the recommended jumper position is MAX ZE.

Figure 3-7b – Example for Coarse

Range 2 for a calibration of –43,6 to –31,1 kPa

From Table 3-1, the recommended jumper position is MAX ZE.

NOTE

reinstall the cover.

Table 3-1 – Coarse Zero Select

(1)

% Zero Offset

Range 1

% Zero Offset

Ranges 2-6

Recommended

Jumper Position

-

60% to 90%

MAX ZS

30% to 90%

20% to 60%

MID ZS

-30% to 30 %

-20% to 20 %

Nominal

-100% to -30%

-60% to -20%

MID ZE

-

-100% to -60%

MAX ZE

desired calibration.

Position Selection Procedure

factory in either the Nominal position or the position required to obtain

the calibration specified when ordered. Changes to the factory

calibration may require repositioning of the jumper. To do this, follow

the procedure below:

1. Calculate the % zero offset using the following formula:

% Zero Offset = (LRV/URV) X 100

Where:

LRV = Lower Range Value of desired calibration

URL = Transmitter Upper Range Limit

2. Consult Table 3-1 to determine recommended jumper

position.

3. If the jumper requires re-positioning, remove the electronics

housing cover opposite the “Field Terminals” label. Remove

the jumper by squeezing the sides and pulling out.

Reposition the jumper with the arrow pointing to the

recommended position and carefully push in. Ensure both

jumper clips are fully engaged and return to calibration

If no change is required, return to calibration procedure.

procedure.

Figure 3-7 contains an example of determining the recommended

position of the Coarse Zero Select Jumper. Figure 3-7a uses English

Units (inH

O) while 3-7b uses SI Units (kPa).

2

Zero Adjustment (English Units)

Zero Adjustment (SI Units)

LRV = -175 inH

% Zero Offset = (-175 inH

LRV = -43,6 kPa

% Zero Offset = (-43,6 kPa /62,2 kPa)*100 = -70%

If you remove either cover during the above procedures, follow the

instructions in Section 5 Maintenance and Troubleshooting to

(1) % Zero Offset values and jumper positions indicated are

approximations. Select jumper position as needed to achieve the

O

2

O /250 inH2O)*100 = -70%

2

3-10

Page 38

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

Damping Adjustment

The 3150 Series amplifier boards for transmitter output code options

CAUTION

permanent damage and require electronics assembly replacement.

NOTE

If you remove either electronics housing cover during the above

Troubleshooting to reinstall the cover.

B (3152) and T (3153 and 3154) are designed to permit damping of

rapid pulsations in the pressure source through adjustment of the

single turn damping adjustment potentiometer (see Figure 3-2).

When adjusted to the maximum position (clockwise stop), timeconstant values of at least 1.20 seconds are available for 3152, 3153,

and 3154 transmitters. Transmitters with the electronics damping

option are calibrated and shipped with the adjustment set at the

counterclockwise stop, giving the minimum time constant.

Damping adjustment should be made with the transmitter calibrated

to the intended application calibration. To adjust the damping, turn

the damping adjustment potentiometer until the desired time constant

is obtained. It is best to set the damping to the shortest possible time

constant. Since transmitter calibration is not affected by the damping

setting, damping may be adjusted with the transmitter installed on the

process.

The damping adjustment potentiometer has positive stops at both

ends. Forcing the potentiometer beyond the stops may cause

procedures, follow the instruc tions in Section 5 Maintenance and

3-11

Page 39

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

Correction for High Static

High Static Line Pressure Span

Rosemount 3150 Series Range 1, 2, and 3 differential pressure

High Static Line Pressure Span

Rosemount 3150 series Range 4 and 5 pressure transmitters

Table 3-2 – Range 4 and 5 Correc tion

Range 4 and 5 Span Correction Factor

% Input Reading per 1000 psi (6,90 MPa)

Range 4

1.00%

(1)

Range 5

1.25%

(1)

NOTE

procedure described in Method 2 (see pg. 3-14) is recommended.

Line Pressure

Effect on Range Codes 1, 2 and 3

DP Transmitters

Correction for Range Code 4 and 5

DP Transmitters

Factors

transmitters do not require correction for high static pressure span

effect. The correction for these ranges occurs within the sensor.

experience a systematic span shift when operated at high static line

pressure. It is linear and correctable during calibration.

The correction factor for span shift caused by the application of static

line pressure is shown in Table 3-2

(1) Correction factors have an uncertainty of ±0.20% of

input reading per 1000 psi (6,90 MPa)

The following illustrates two methods of correcting for the high static

pressure span shift. Examples follow each method.

Method 1 for High Static Line Pressure, Ranges 4 and 5

Adjust transmitter output while leaving the input pressure at desired in

service differential pressures. Use on of the following formula sets

(depending on the pressure units being used to calibrate):

If using English Units (psi):

Corrected output reading (at LRV) =

4 mA + ((S X P/1000 X LRV)/Span) X 16 mA

Corrected output reading (at URV) =

20 mA + ((S X P/1000 X URV)/Span) X 16 mA

If using SI Units (MPa):

Corrected output reading (at LRV) =

4 mA + ((S X P/6,90 X LRV)/Span) X 16 mA

Corrected output reading (at URV) =

20 mA + ((S X P/6,90 X URV)/Span) X 16 mA

Where:

S = Value from Table 3-2 divided by 100

LRV = Lower Range Value

URV = Upper Range Value

P = Static Line Pressure

Span = Calibrated Span

For corrections where the calculated output adjustment exceeds the

output high or low adjustment limits, the pressure input adjust

3-12

Page 40

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

Figure 3-8 outlines examples of calculating a High Static Line

Figure 3-8a – Example for High Static

Range 4; for a calibration of –10 to 45 psi corrected for 1,500 psi static

psi.

Figure 3-8b – Example for High Static

Range 4; for a calibration of –0,07 to 0,31 MPa corrected for 10,34 MPa

0,31 MPa.

Pressure Span Correction using Method 1. Figure 3-8a uses English

units (psi) while Figure 3-8b uses SI units (MPa).

Line Pressure, Span Correction using

Method 1 (English Units)

line pressure:

1. Calculate the corrected output reading (at LRV)

= 4 mA + ((0.01 X 1500 psi/1000 psi X (-10 psi))/55 psi) X 16 mA

= 3.956 mA

2. Calculate the corrected output reading (at URV)

= 20 mA + ((0.01 X 1500 pis/1000 psi X 45 psi)/55 psi) X 16 mA

= 20.196 mA

3. At atmospheric static line pressure, apply 10 psi to the low side

process connection (-10 psi), and adjust the zero until the

transmitter output reads 3.956 mA.

4. Remaining at atmospheric static line pressure, apply 45 psi to the

high side process co nnection and adjust the span until the

transmitter output reads 20.196 mA.

5. Check to assure desired outputs are achieved and repeat steps 3

and 4 if necessary.

When the transmitter is exposed to 1,500 psi static line pressure, within

specified uncertainties, the output will be 4 mA at -10 psi and 20 mA at 45

Line Pressure, Span Correction using

Method 1 (SI Units)

static line pressure:

1. Calculate the corrected output reading (at LRV)

= 4 mA + ((0,01 X 10,34 MPa/6,90 MPa X (-0,07 MPa))/0,38 MPa) X 16 mA

= 3,956 mA

2. Calculate the corrected output reading (at URV)

= 20 mA + ((0,01 X 10,34 MPa/6,90 MPa X 0,31 MPa)/0,38 MPa) X 16 mA

= 20,196 mA

3. At atmospheric static line pressure, apply 0,07 MPa to the low side

process connection (-0,07MPa), and adjust the zero until the

transmitter output reads 3,956 mA.

4. Remaining at atmospheric static line pressure, apply 0,31 MPa to

the high side process connection and adjust the span until the

transmitter output reads 20,196 mA.

5. Check to assure desired outputs are achieved and repeat steps 3

and 4 if necessary.

When the transmitter is exposed to 10,34 MPa static line pressure, within

specified uncertainties, the output will be 4 mA at -0,07 MPa and 20 mA at

3-13

Page 41

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

High Static Line Pressure Span

Method 2 for High Static Line Pressure, Ranges 4 and 5

units (psi) while Figure 3-10b uses SI units (MPa).

Correction for Range Code 4 and 5

DP Transmitters (continued)

Adjust transmitter pressure input while leaving the output at 4 mA and

20 mA. Use one of the following formula sets (depending on the

pressure units being used to calibrate):

If using English Units (psi):

Corrected LRV pressure input =

Corrected URV pressure input =

If using SI Units (MPa):

Corrected LRV pressure input =

Corrected URV pressure input =

Where:

Figures 3-9 and 3-10 outline two examples of calculating a High

Static Line Pressure Span Correction using Method 2.

“Example 1” in Figure 3-9 contains a calculation for a Zero Based

Calibration Range. Figure 3-9a uses English units (psi) for the

calculation while Figure 3-9b uses SI units (MPa)

“Example 2” in Figure 3-10 demonstrates the calculation for a Zero

Elevated Calibration Range. “Example 2” can also be followed for

Zero Suppressed Calibration Ranges. Figure 3-10a uses English

Desired LRV – ((S X LRV) X (P/1000))

Desired URV – ((S X URV) X (P/1000))

Desired LRV – ((S X LRV) X (P/6,90))

Desired URV – ((S X URV) X (P/6,90))

S = Value from Table 3-2 divided by 100

LRV = Lower Range Value

URV = Upper Range Value

P = Static Line Pressure

Span = Calibrated Span

3-14

Page 42

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

Figure 3-9a – Example 1 for High

Range 4 for a calibration of 0 to 45 psi corrected for 1,500 psi static line

specified uncertainties, the output will be 4 mA at 0 psi and 20 mA at 45 psi.

Figure 3-9b – Example 1 for High

Range 4 for a calibration of 0 to 0,31 MPa corrected for 10,34

MPa.

Static Line Pressure, Span Corr ection

using Method 2 (English Units)

Static Line Pressure, Span Corr ection

using Method 2 (SI Units)

pressure

1. In this example LRV is 0 psid. Zero differential pressure points

require no span correction.

2. Calculate the corrected URV pressure input

= 45 psi – ((0.01 X 45 psi) X (1500 psi/1000 psi))

= 44.325 psi

3. At atmospheric static line pressure, with zero differential pressure

applied, adjust the zero until the transmitter output reads 4 mA.

4. Remaining at atmospheric static line pressure, apply 44.325 psi to

the high side process connection and adjust the span until the

transmitter output reads 20 mA.

5. Check to assure desired outputs are achieved and repeat steps 3

and 4 if necessary.

When the transmitter is exposed to 1,500 psi stat ic line pres sure, withi n

MPa static line pressure

1. In this example LRV is 0 MPa. Zero differential pressure points

require no span correction.

2. Calculate the corrected URV pressure input

= 0,31 MPa – ((0,01 X 0,31 MPa) X (10,34 MPa/6,90 MPa))

= 0,305 MPa

3. At atmospheric static line pressure, with zero differential pressure

applied, adjust the zero until the transmitter output reads 4 mA.

4. Remaining at atmospheric static line pressure, apply 0,305 MPa to

the high side process connection and adjust the span until the

transmitter output reads 20 mA.

5. Check to assure desired outputs are achieved and repeat steps 3

and 4 if necessary.

When the transmitter is exposed to 10,34 MPa static line pressure, within

specified uncertainties, the output will be 4 mA at 0 MPa and 20 mA at 0,305

3-15

Page 43

Reference Manual

00809-0100-4835 Rev BD

July 2016

Rosemount 3150 Series

Figure 3-10a – Example 2 for High

Range 5 for a calibration of –250 to 750 psi corrected for 1,500 psi static

psi.

Figure 3-10b – Example 2 for High

Range 5 for a calibration of –1,72 to 5,17 MPa corrected for 10,34 MPa

5,17 MPa.

Static Line Pressure, Span Corr ection

using Method 2 (English Units)

Static Line Pressure, Span Corr ection

using Method 2 (SI Units)

line pressure

1. Calculate the corrected LRV pressure input

= -250 psi – ((0.0125 X -250 psi) X (1500 psi/1000 psi))

= -245.31 psi

2. Calculate the corrected URV pressure input

= 750 psi – ((0.0125 X 750 psi) X (1500 psi/1000 psi))

= 735.94 psi

3. At atmospheric static line pressure, apply 245.31 psi to the low side

process connection (-245.31 psi) and adjust the zero until the

transmitter output reads 4 mA.

4. Remaining at atmospheric static line pressure, apply 735.94 psi to

the high side process connection and adjust the span until the

transmitter output reads 20 mA.

5. Check to assure desired outputs are achieved and repeat steps 3

and 4 if necessary.

When the transmitter is exposed to 1,500 psi static line pressure, within

specified uncertainties, the output will be 4 mA at -250 psi and 20 mA at 750

static line pressure

1. Calculate the corrected LRV pressure input

= -1,72 MPa – ((0,0125 X -1,72 MPa) X (10,34 MPa/6,90 MPa))

= -1,69 MPa

2. Calculate the corrected URV pressure input

= 5,17 MPa – ((0,0125 X 5,17 MPa) X (10,34 MPa/6,90 MPa))

= 5,07 MPa

3. At atmospheric static line pressure, apply 1,69 MPa to the low side

process connection (-1,69 MPa) and adjust the zero until the

transmitter output reads 4 mA.

4. Remaining at atmospheric static line pressure, apply 5,07 MPa to

the high side process connection and adjust the span until the

transmitter output reads 20 mA.

5. Check to assure desired outputs are achieved and repeat steps 3

and 4 if necessary.

When the transmitter is exposed to 10,34 MPa static line pressure, within

specified uncertainties, the output will be 4 mA at -1,72 MPa and 20 mA at

3-16

Page 44

Rosemount 3150 Series

Reference Manual

00809-0100-4835 Rev BD

July 2016

High Static Line Pressure Zero

Zero shift with static pressure is not systematic. However, the effect

Line Pressure for a transmitter with a non-zero based c alibr ati on.

Figure 3-11 – High Static Line

If -0.007 mA was calculated in step f and the LRV reads 4.002 mA,

4.002 mA.

Linearity

Linearity is factory optimized and requires no field adjustment.

Correction for Differential Pressure

Transmitters (All Ranges)

can be eliminated during calibration. To trim out the zero error at high

static line pressure, perform the following:

1. If the calibrated range contains zero differential pressure:

a. Calibrate the pressure transmitter according to the

b. Apply atmospheric line pressure with zero differential

c. Record the output reading.

d. Apply the intended line pressure at zero differential

e. Adjust the zero to match the reading obtained in step c.

2. If the calibrated range does not contain zero differentia l

pressure:

a. Calibrate the pressure transmitter to the intended span

b. Apply atmospheric line pressure with zero differential

c. Record the output reading.

d. Apply the intended line pressure at zero differential

e. Record the output reading.

f. Subtract the reading in step e from the reading in step

g. Calibrate the transmitter to the zero elevated or zero