Rosemount 3051S MultiVariable Transmitter and 3051SF Series Flowmeter MultiVariable Transmitter with HART Protocol Quick Start Guide

Quick Start Guide

00825-0100-4803, Rev GA

October 2021

Rosemount™ 3051S and 3051SF Series

Flow Meter MultiVariable™ Transmitters

Quick Start Guide October 2021

Contents

About this guide...........................................................................................................................3

Mount the transmitter..................................................................................................................5

Consider housing rotation..........................................................................................................11

Set the switches......................................................................................................................... 12

Connect wiring and power up.....................................................................................................13

Engineering Assistant installation...............................................................................................17

Flow configuration..................................................................................................................... 19

Verifying device configuration....................................................................................................28

Trimming the transmitter...........................................................................................................32

Safety instrumented systems installation................................................................................... 33

Product certifications................................................................................................................. 34

2 Rosemount 3051SMV

October 2021 Quick Start Guide

1 About this guide

This guide provides basic guidelines to install the Rosemount 3051S

MultiVariable Transmitter. It also provides the basic Rosemount 3051SMV

configuration guidelines for the Rosemount 3051SFA, Rosemount 3051SFC,

and Rosemount 3051SFP. It does not provide instructions for detailed

configuration, diagnostics, maintenance, service, troubleshooting, or

installations. Refer to the Rosemount 3051SMV Reference Manual for more

instruction. The manual and this guide are also available electronically at

Emerson.com/Rosemount.

1.1 Safety messages

WARNING

Failure to follow these installation guidelines could result in death or

serious injury.

Ensure only qualified personnel perform the installation.

Explosions

Explosions could result in death or serious injury.

Installation of device in an explosive environment must be in accordance

with appropriate local, national, and international standards, codes, and

practices.

Review the Hazardous Locations Certifications for any restrictions

associated with a safe installation.

Process leaks

Process leaks could result in death or serious injury.

Install and tighten thermowells and sensors before applying pressure.

Do not remove the thermowell while in operation.

Conduit/cable entries

Unless marked, the conduit/cable entries in the transmitter housing use

a ½–14 NPT thread form. Entries marked “M20” are M20 × 1.5 thread

form. On devices with multiple conduit entries, all entries will have the

same thread form. Only use plugs, adapters, glands, or conduit with a

compatible thread form when closing these entries.

When installing in a hazardous location, use only appropriately listed or

Ex certified plugs, glands, or adapters in cable/conduit entries.

Quick Start Guide 3

Quick Start Guide October 2021

WARNING

Electrical shock

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

Unless marked, the conduit/cable entries in the housing use a ½–14 NPT

thread form. Entries marked “M20” are M20 × 1.5 thread form. On

devices with multiple conduit entries, all entries will have the same

thread form. Only use plugs, adapters, glands, or conduit with a

compatible thread form when closing these entries.

When installing in a hazardous location, use only appropriately listed or

Ex certified plugs, glands, or adapters in cable/conduit entries.

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

4 Rosemount 3051SMV

A

A

October 2021 Quick Start Guide

2 Mount the transmitter

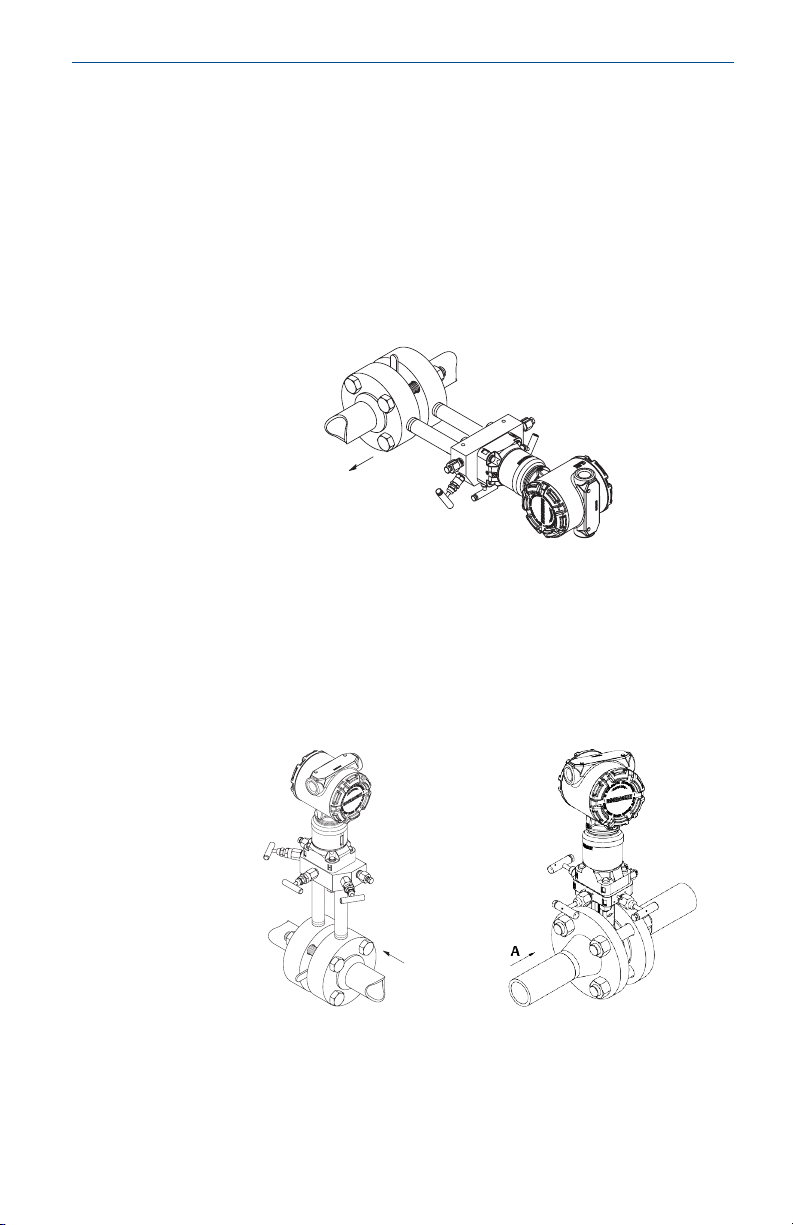

2.1 Liquid flow applications

Procedure

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Mount the transmitter so that the drain/vent valves are oriented

upward.

A. Direction of flow

2.2 Gas flow applications

Procedure

1. Place taps in the top or side of the line.

2. Mount beside or above the taps.

A. Direction of flow

Quick Start Guide 5

A

Quick Start Guide October 2021

2.3 Steam flow applications

Procedure

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Fill impulse lines with water.

A. Direction of flow

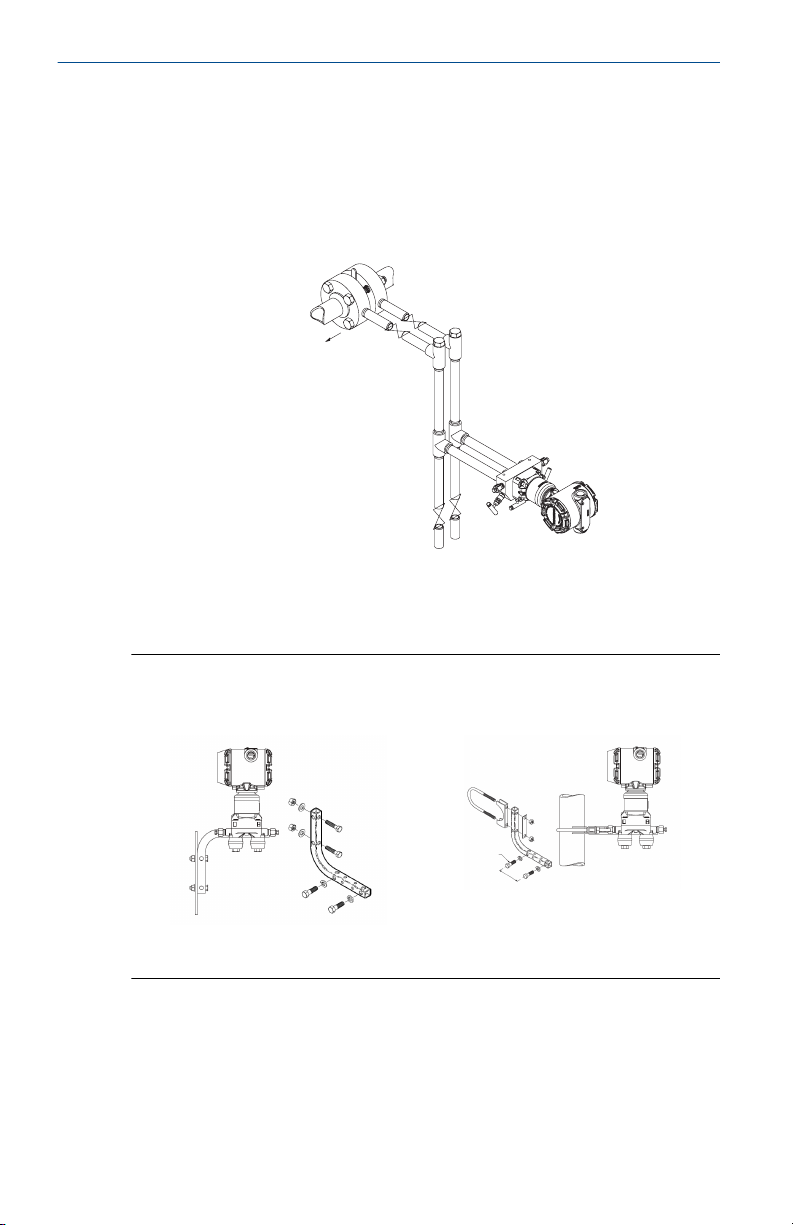

2.4 Mounting brackets

Figure 2-1: Mounting Bracket – Coplanar Flange

Panel mount

6 Rosemount 3051SMV

Pipe mount

October 2021 Quick Start Guide

Figure 2-2: Mounting Brackets – Traditional Flange

Panel mount Pipe mount

Figure 2-3: Mounting Brackets – In-line

Panel mount Pipe mount

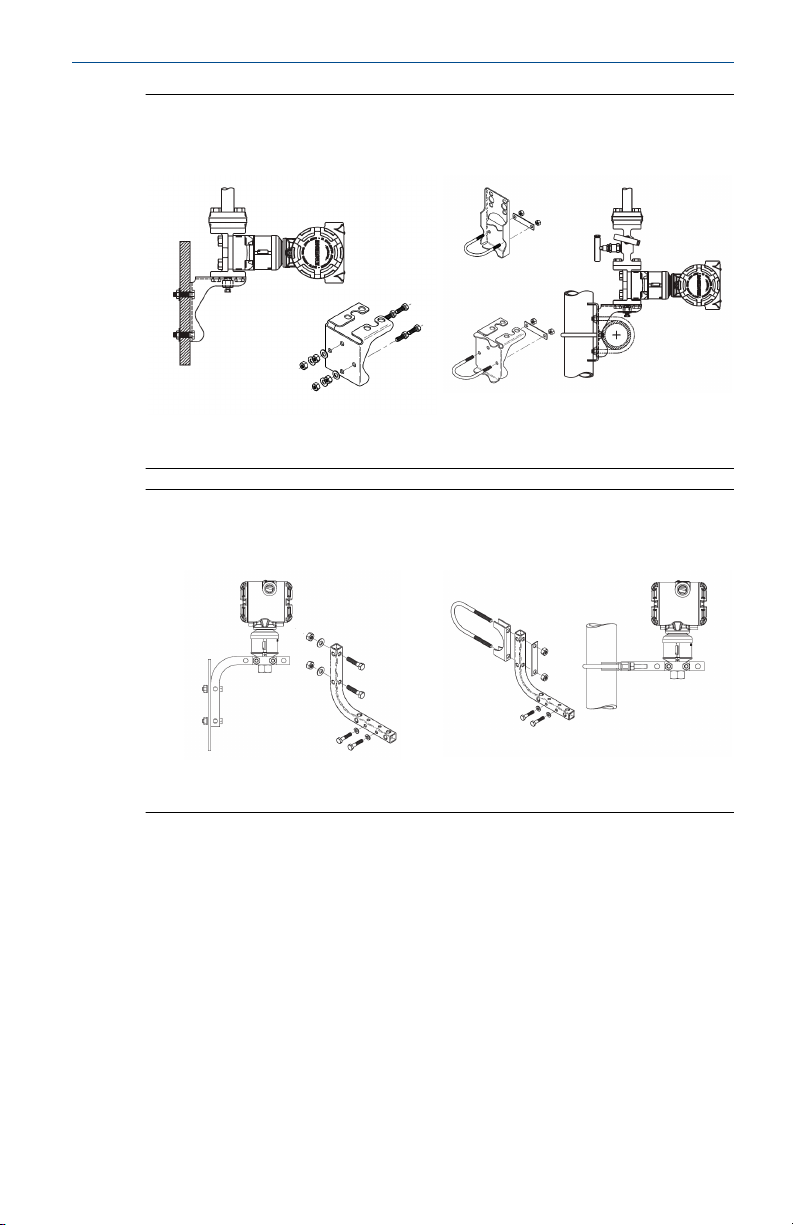

2.5 Bolting considerations

If the transmitter installation requires assembly of a process flange,

manifold, or flange adapters, follow these assembly guidelines to ensure a

tight seal for optimal performance characteristics of the transmitter. Only

use bolts supplied with the transmitter or sold by Emerson as spare parts.

Figure 2-4 illustrates common transmitter assemblies with the bolt length

required for proper transmitter assembly.

Quick Start Guide 7

A

4 × 1.75-in.

(44 mm)

D

4 × 1.75-in.

(44 mm)

4 × 2.25-in.

(57 mm)

C

4 × 1.75-in.

(44 mm)

4

× 1.50-in.

(38 mm)

B

4 × 2.88-in.

(73 mm)

Quick Start Guide October 2021

Figure 2-4: Common Transmitter Assemblies

A. Transmitter with coplanar flange

B. Transmitter with coplanar flange and optional flange adapters

C. Transmitter with traditional flange and optional flange adapters

D. Transmitter with coplanar flange and optional Rosemount Conventional

Manifold and flange adapters

Note

For all other manifolds, contact Customer Central technical support.

Bolts are typically carbon steel or stainless steel. Confirm the material by

viewing the markings on the head of the bolt and referencing Table 2-1 . If

bolt material is not shown in Table 2-1, contact the local Emerson

representative for more information.

Use the following bolt installation procedure:

Procedure

1. Carbon steel bolts do not require lubrication and the stainless steel

bolts are coated with a lubricant to ease installation. However, no

additional lubricant should be applied when installing either type of

bolt.

2. Finger-tighten the bolts.

3. Torque the bolts to the initial torque value using a crossing pattern.

See Table 2-1 for initial torque value.

4. Torque the bolts to the final torque value using the same crossing

pattern. See Table 2-1 for final torque value.

8 Rosemount 3051SMV

B7M

316

316

316

SW

316

STM

316

R

B8M

A

B

October 2021 Quick Start Guide

5. Verify the flange bolts are protruding through the sensor module

before applying pressure (see Figure 2-5).

Example

Table 2-1: Torque Values for the Flange and Flange Adapter Bolts

Bolt material Head markings Initial torque Final torque

Carbon Steel

300 in-lb 650 in-lb

(CS)

Stainless Steel

150 in-lb 300 in-lb

(SST)

Figure 2-5: Proper Bolt Installation

A. Bolt

B. Sensor module

Quick Start Guide 9

A

B

C

D

Quick Start Guide October 2021

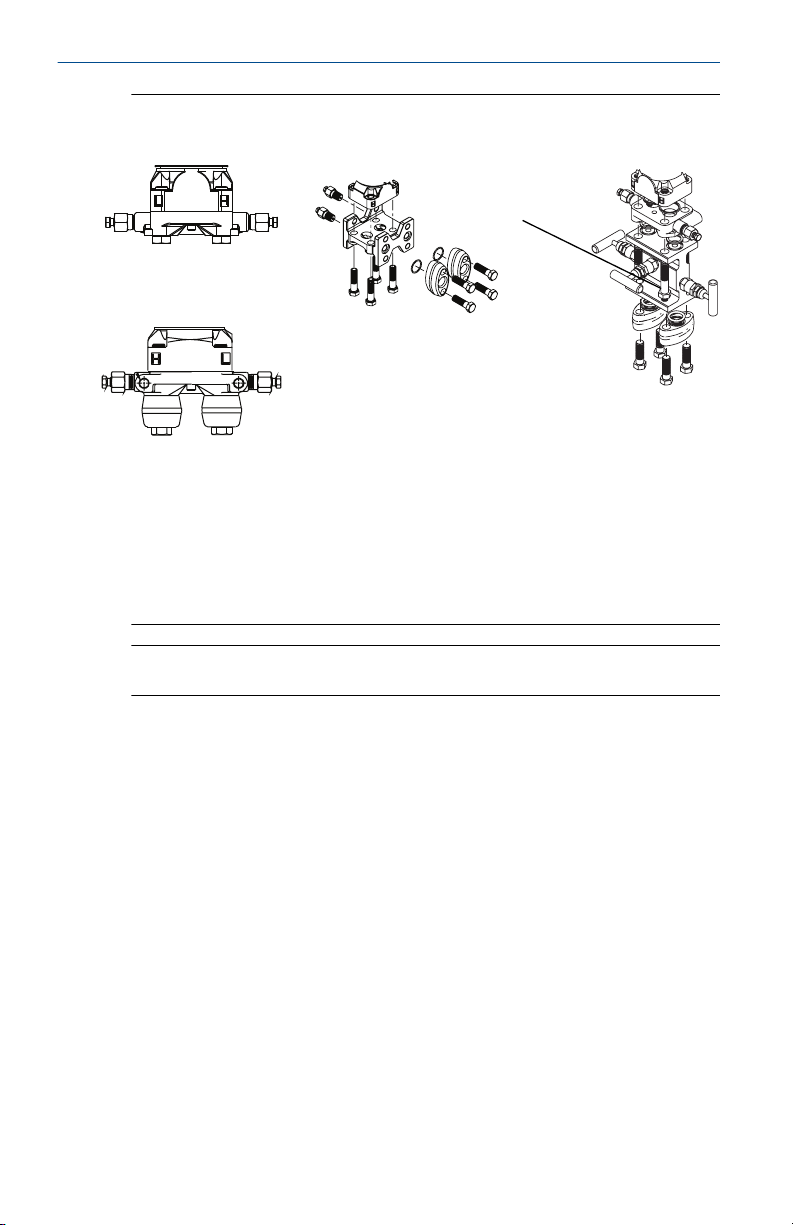

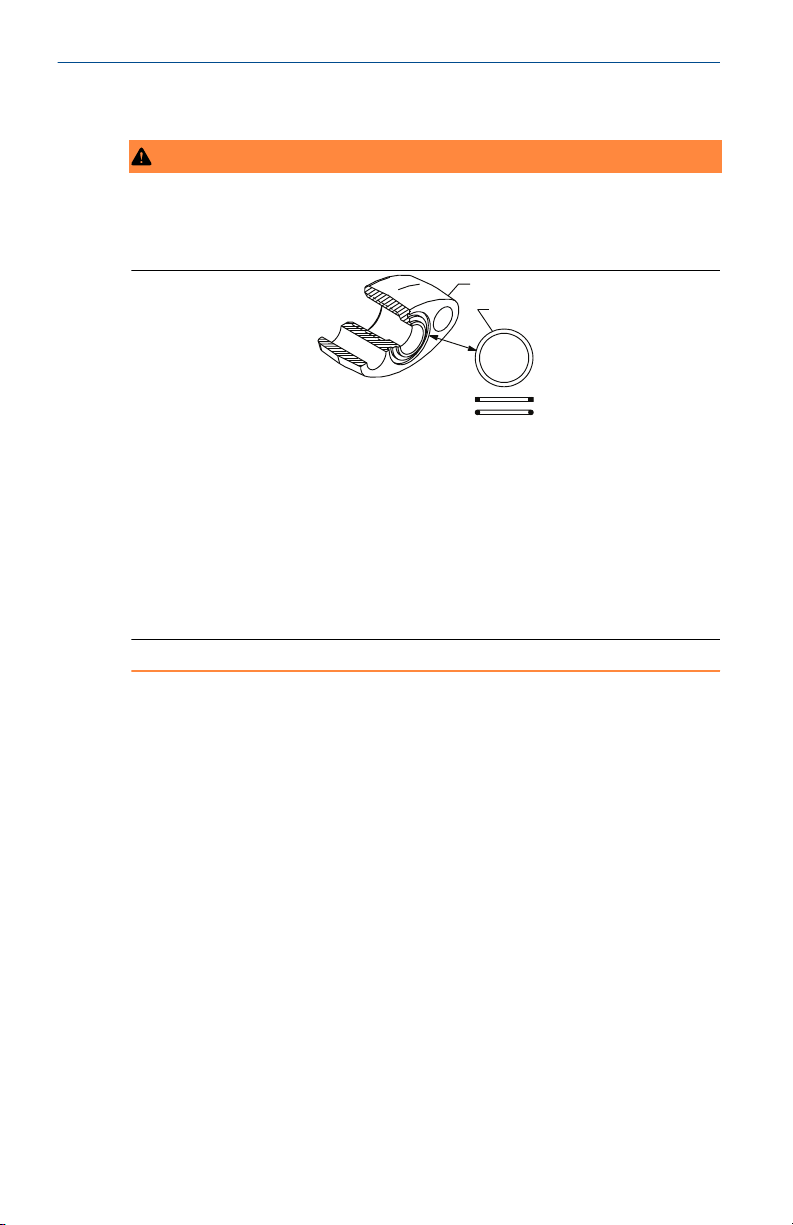

2.6 O-rings with flange adapters

WARNING

Failure to install proper flange adapter O-rings may cause process leaks,

which can result in death or serious injury. Only use the O-ring that is

designed for its specific flange adapter.

A. Flange adapter

B. O-ring

C. PTFE-based profile (square)

D. Elastomer profile (round)

Whenever the flange or adapters are removed, visually inspect the O-rings.

Replace them if there are any signs of damage, such as nicks or cuts. If the Orings are replaced, re-torque the flange bolts and alignment screws after

installation to compensate for seating of the O-rings.

10 Rosemount 3051SMV

October 2021 Quick Start Guide

3 Consider housing rotation

To improve field access to wiring or to better view the optional LCD display:

Procedure

1. Loosen the housing rotation set screw.

2. Turn the housing up to 180° left or right of its original (as shipped)

position.

3. Re-tighten the housing rotation set screw.

Figure 3-1: Transmitter Housing Set Screw

A. LCD display

B. Housing rotation set screw (3/32-in.)

CAUTION

Do not rotate the housing more than 180° without first performing a

disassembly procedure. Over-rotation may sever the electrical

connection between the sensor module and the electronics.

Quick Start Guide 11

A B

Quick Start Guide October 2021

4 Set the switches

The transmitter’s default configuration sets the alarm condition to high (HI)

and the security to off.

Procedure

1. If the transmitter is installed, secure the bus and remove power.

2. Required: Remove the transmitter cover opposite the field terminal

side. Do not remove the instrument covers in explosive

environments when the circuit is live.

3. Slide the Security and Alarm switches into the preferred position by

using a small screwdriver.

Note

The Security switch will need to be in the off position in order to make

any configuration changes.

4. Required: In order to meet explosion-proof requirements, reinstall

the housing cover and tighten so the cover is fully seated with metal

to metal contact between the housing and cover. After the cover is

seated properly, replace the flathead screw located on the bottom of

the housing cover.

Figure 4-1: Transmitter Switch Configuration

A. Security

B. AC Termination

12 Rosemount 3051SMV

October 2021 Quick Start Guide

5 Connect wiring and power up

CAUTION

Do not connect the power across the test terminals. Power could damage

the test diode in the test connection. Twisted pairs yield best results. Use 24

to 14 AWG wire and do not exceed 5,000 ft. (1500 m).

Use the following steps to wire the transmitter:

Procedure

1. Remove the cover on the field terminals side of the housing.

2. Connect the positive lead to the “PWR/COMM +” terminal, and the

negative lead to the “PWR/COMM –” terminal.

3. If the optional process temperature input is not installed, plug and

seal the unused conduit connection. If the input is being utilized, see

Install optional process temperature input (Pt 100 RTD sensor) for

more information.

NOTICE

When the enclosed pipe plug is utilized in the conduit opening, it

must be installed with a minimum engagement of five threads to

comply with explosion-proof requirements. Refer to the Rosemount

3051SMV Reference Manual for more information.

™

4. If applicable, install wiring with a drip loop. Arrange the drip loop

so the bottom is lower than the conduit connections and the

transmitter housing.

5. Reinstall the housing cover and tighten so that metal contacts metal

to meet explosion-proof requirements.

Figure 5-1 shows the wiring connections necessary to power a

Rosemount 3051SMV and enable communications with a hand-held

Field Communicator.

Quick Start Guide 13

A

RL ≥ 250Ω

A

RL ≥ 250Ω

Quick Start Guide October 2021

Figure 5-1: Transmitter Wiring

Without optional process temperature

connection

With optional process temperature

connection

A. Power supply

Note

Installation of the transient protection terminal block does not

provide transient protection unless the Rosemount 3051SMV

housing is properly grounded.

5.1 Conduit electrical connector wiring (option GE or GM)

For Rosemount 3051SMV with conduit electrical connectors GE or GM, refer

to the cordset manufacturer’s installation instructions for wiring details. For

FM Intrinsically Safe, Division 2 hazardous locations, install in accordance

with Rosemount drawing 03151-1009 to maintain outdoor rating (NEMA

4X and IP66). See the Rosemount 3051SMV Reference Manual.

5.2

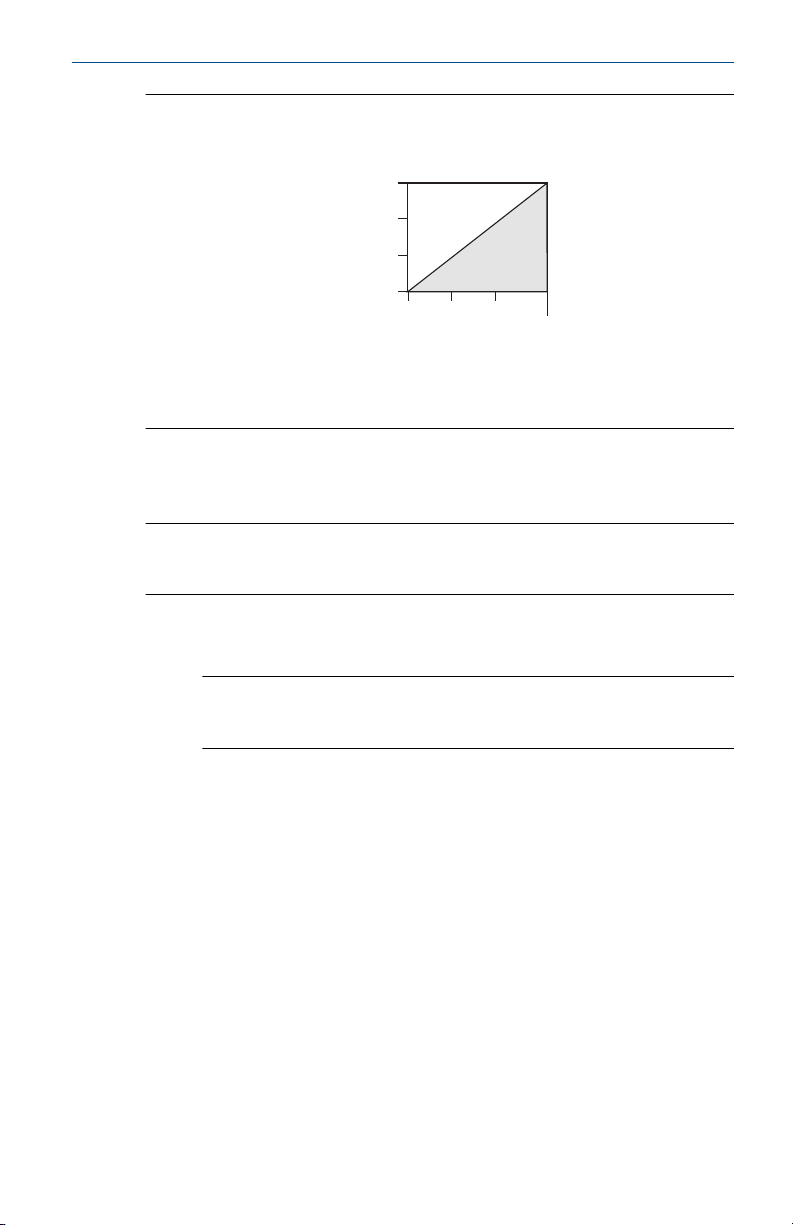

Power supply

The dc power supply should provide power with less than two percent ripple.

The total resistance load is the sum of the resistance of the signal leads and

the load resistance of the controller, indicator, intrinsic safety barriers, and

related components.

®

14 Rosemount 3051SMV

1322

1000

500

0

12.0 20 30

42.4

Voltage (Vdc)

Load (Ohms)

Operating

region

October 2021 Quick Start Guide

Figure 5-2: Load Limitation

Maximum loop resistance = 43.5 x (power supply voltage – 12.0)

HART communication requires a minimum loop resistance of 250Ω

5.3 Install optional process temperature input (Pt 100 RTD sensor)

Note

To meet ATEX/IECEx Flameproof certification, only ATEX/IECEx Flameproof

cables (temperature input code C30, C32, C33, or C34) may be used.

Procedure

1. Mount the Pt 100 RTD sensor in the appropriate location.

Note

Use shielded four-wire cable for the process temperature

connection.

2. Connect the RTD cable to the Rosemount 3051SMV by inserting the

cable wires through the unused housing conduit and connect to the

four screws on the transmitter terminal block. An appropriate cable

gland should be used to seal the conduit opening around the cable.

3. Connect the RTD cable shield wire to the ground lug in the housing.

Quick Start Guide 15

A

C

B

Red

Red

White

White

Quick Start Guide October 2021

Figure 5-3: RTD Wiring Connection

A. Ground lug

B. RTD cable assembly wires

C. Pt 100 RTD sensor

16 Rosemount 3051SMV

October 2021 Quick Start Guide

6 Engineering Assistant installation

Engineering Assistant 6.1 or later

The Rosemount 3051SMV Engineering Assistant 6.1 or later is PC-based

software that performs configuration, maintenance, diagnostic functions,

and serves as the primary communication interface to the transmitter with

the fully compensated mass and energy flow feature board.

The Rosemount 3051SMV Engineering Assistant software is required to

complete the flow configuration.

NOTICE

To ensure correct operation, download the most current version of the

Engineering Assistant software at Emerson.com/Rosemount-Engineering-

Assistant.

6.1 System requirements

The following are the minimum system requirements to install the

Rosemount 3051SMV Engineering Assistant software:

• Pentium®-grade processor: 500 MHz or faster

• Operating system: Windows™ XP Professional (32-bit), or Windows 7

(32-bit or 64-bit)

• 256 MB RAM

• 100 MB free hard disk space

• RS232 serial port or USB port (for use with HART® modem)

• CD-ROM

6.2

Install Rosemount 3051SMV Engineering Assistant 6.1 or later

Procedure

1. Uninstall any existing versions of Engineering Assistant 6.

2. Insert the new Engineering Assistant disk into the CD-ROM.

3. Windows should detect the presence of a CD and start the

installation program. Follow the on-screen prompts to finish the

installation. If Windows does not detect the CD, use Windows

Explorer or My Computer to view the contents of the CD-ROM, and

then double click the SETUP.EXE program.

Quick Start Guide 17

A

RL ≥ 250Ω

B

A

RL ≥ 250Ω

B

Quick Start Guide October 2021

4. A series of screens (Installation Wizard) will appear and assist in the

installation process. Follow the on-screen prompts. It is

recommended to use the default installation settings.

Note

Engineering Assistant versions 6.1 or later require the use of

Microsoft®.NET Framework version 4.0 or later. If .NET version 4.0 is

not currently installed, the software will be automatically installed

during the Engineering Assistant installation. Microsoft .NET version

4.0 requires an additional 200 MB of disk space.

6.3 Connect to a personal computer

Procedure

1. Remove the cover from the field terminals side of the housing.

2. Power the device as outlined in Connect wiring and power up.

3. Connect the HART modem cable to the PC.

4. On the side of the transmitter marked “Field Terminals,” connect the

modem mini-grabbers to the two terminals marked “PWR/COMM.”

5. Launch the Engineering Assistant software. For more information on

launching software, see Launch Engineering Assistant 6.1 or later.

6. Once the configuration is complete, replace cover and tighten until

metal contacts metal to meet explosion-proof requirements.

Figure 6-1 shows how to connect a computer to a Rosemount

3051SMV.

Figure 6-1: Connecting a PC to the Transmitter

Without optional process temperature

connection

With optional process temperature

connection

A. Power supply

B. Modem

18 Rosemount 3051SMV

October 2021 Quick Start Guide

7 Flow configuration

Rosemount 3051SMV Engineering Assistant 6.1 or later

The Rosemount 3051SMV Engineering Assistant is designed to guide the

user through the setup of the flow configuration for a Rosemount 3051SMV.

The flow configuration screens allow the user to specify the fluid, operating

conditions, and information about the primary element, including inside

pipe diameter. This information will be used by the Rosemount 3051SMV

Engineering Assistant software to create flow configuration parameters that

will be sent to the transmitter or saved for future use.

Online and offline modes

The Engineering Assistant software can be used in two modes: Online and

Offline. In Online mode, the user can receive the configuration from the

transmitter, edit the configuration, send the changed configuration to the

transmitter, or save the configuration to a file. In offline mode, the user can

create a new flow configuration and save the configuration to a file or open

and modify an existing file.

The following pages provide instructions on creating a new flow

configuration in offline mode. For more information on other functionality,

see the Rosemount 3051SMV Reference Manual.

Quick Start Guide 19

A

B C D E

G

H

F

Quick Start Guide October 2021

7.1 Basic navigation overview

Figure 7-1: Engineering Assistant Basic Navigation Overview

Screen component Description of use

A The navigation tabs contain the flow configuration

B The Reset button will return each field within all of the

information. In Offline mode, each tab will not become

active until the required fields on the previous tab are

completed. In Online mode, these tabs will be

functional at all times.

flow configuration tabs (Fluid Selection, Fluid

Properties, and Primary Element Selection) to the

values initially displayed at the start of the

configuration.

• In Online mode, the values will return to the initial

values received from the device before the start of

the configuration.

• If editing a previously saved flow configuration, the

values will return to those that were last saved. If

starting a new flow configuration, all entered

values will be erased.

C The Back button is used to step backward through the

flow configuration tabs.

20 Rosemount 3051SMV

October 2021 Quick Start Guide

Screen component Description of use

D The Next button is used to step forward through the

flow configuration tabs. In Offline mode, the Next

button will not become active until all required fields

on the current page are completed.

E The Help button can be clicked at any time to get a

detailed explanation of the information that is required

on the current configuration tab.

F Any configuration information that needs to be

G These menus navigate to the Configure Flow, Basic

H These buttons navigate to Config/Setup, Device

entered or reviewed will appear in this portion of the

screen.

Setup, Device, Variables, Calibration, and Save/Send

Configuration tabs.

Diagnostics or Process Variables sections.

7.2 Launch Engineering Assistant 6.1 or later

Flow configuration for the Rosemount 3051SMV is achieved by launching

the Engineering Assistant software from the Start menu.

Procedure

1. Select the Start menu → All Programs → Engineering Assistant.

Engineering Assistant will open to the screen shown in Figure 7-2.

2. Select Offline button located in the lower right hand corner of the

screen shown in Figure 7-2.

Figure 7-2: Engineering Assistant Device Connection Screen

Quick Start Guide 21

Quick Start Guide October 2021

7.3 Use Preferences tab

The Preferences tab, shown in Figure 7-3, allows you to select the preferred

engineering units to display.

Procedure

1. Select the preferred engineering units.

2. If Custom Units are selected, configure the Individual Parameters.

3. Check the box if unit preferences should be retained for future

Engineering Assistant sessions.

Figure 7-3: Preferences Tab

7.4 Select fluid for database liquid/gas

The Fluid Selection tab shown in Figure 7-4 allows the user to choose the

process fluid.

22 Rosemount 3051SMV

October 2021 Quick Start Guide

Figure 7-4: Fluid Selection Tab

Note

The following example will show a flow configuration for the database gas

air used with a Rosemount 405C Conditioning Orifice Plate as the primary

element. The procedure to set up any other fluid with any other primary

element will be similar to this example. Natural gases, custom liquids, and

custom gases require additional steps during the configuration. See the

Rosemount 3051SMV Reference Manual for more information.

Procedure

1. Engineering Assistant may open to the Preferences tab. Using the tabs

at the top of the screen, navigate to the Fluid Selection tab.

2. Expand the Gas category (click on the + icon).

3. Expand the Database Gas category.

4. Select Air from the list of database fluids.

5. Enter the Nominal Operating Pressure, select the Enter or Tab key.

6. Enter the Nominal Operating Temperature, select the Enter or Tab key.

Engineering Assistant will automatically fill in suggested operating

ranges, as shown in Figure 7-4. These values may be edited as

needed by the user.

7. Verify the Reference/Atmospheric Conditions are correct for the

application. These values may be edited as needed.

Note

Reference pressure and temperature values are used by Engineering

Assistant to convert the flow rate from mass units to mass units

expressed as standard or normal volumetric units.

Quick Start Guide 23

Quick Start Guide October 2021

8. Select Next to proceed to the Fluid Properties tab.

7.5 Fluid properties

Note

The Fluid Properties tab is an optional step and is not required to complete a

flow configuration.

The Fluid Properties tab for the database gas air is shown in Figure 7-5. This is

used to verify the properties of the chosen fluid are acceptable.

To check density, compressibility, and viscosity of the selected fluid at other

pressure and temperature values, enter a Pressure and Temperature and

select Calculate.

Note

Changing the pressure and temperature values on the Fluid Properties tab

does not affect the fluid configuration.

Figure 7-5: Fluid Properties Tab

7.6 Select primary element

The Primary Element Selection tab shown in Figure 7-6 allows the user to

choose the primary element.

24 Rosemount 3051SMV

October 2021 Quick Start Guide

Figure 7-6: Primary Element Selection Tab

Continuing with the example configuration:

Procedure

1. Expand the Conditioning Orifice Plate category.

2. Select 405C/3051SFC.

3. Enter the measured Meter Tube Diameter (pipe ID) at a reference

temperature. If the meter tube diameter cannot be measured, select

a Nominal Pipe Size and Pipe Schedule to input an estimated value

for the meter tube diameter (English units only).

4. If necessary, edit the Meter Tube Material.

5. Enter the Line Size and select the Beta of the conditioning orifice

plate. The required primary element sizing parameters will be

different depending on what primary element was selected.

6. If necessary, select a primary element Material from the dropdown

menu.

7. Select Next > to advance to the Save/Send Configuration tab.

Note

To be in compliance with appropriate national or international

standards, beta ratios and differential producer diameters should be

within the limits as listed in the applicable standards. The

Engineering Assistant software will alert the user if a primary element

value exceeds these limits, but will allow the user to proceed with the

flow configuration.

Quick Start Guide 25

Quick Start Guide October 2021

7.7 Save/send configuration

The Save/Send Configuration tab shown in Figure 7-7 allows you to verify,

save, and send the configuration information to the transmitter with the

fully compensated mass and energy flow feature board.

Procedure

1. Review the information under the Flow Configuration and Device

Configuration headings.

Note

For more information, see Verifying device configuration.

Figure 7-7: Save/Send Configuration Tab

2. Select the icon above each window to edit the configuration

information in these windows.

Note

The user will be notified if the configuration has been modified since

it was last sent to the transmitter. A warning message will be shown

to the right of the Send Flow Data and/or Send Transmitter Data check

boxes.

3. To send the configuration, select the Send To button.

Note

The Send Flow Data and Send Transmitter Data check boxes can be

used to select what configuration data is sent to the transmitter. If

either check box is unselected, the corresponding data will not be

sent.

26 Rosemount 3051SMV

October 2021 Quick Start Guide

4. The Engineering Assistant Device Connection screen will appear, see

Figure 7-8.

Figure 7-8: Engineering Assistant Device Connection Screen

5. Select the Search button located in the lower right hand corner of

the screen. Engineering Assistant will begin to search for connected

devices.

6. When the search is completed, select the device to communicate

with and select Send Configuration button.

Note

After the configuration is sent to the device, saving the configuration

file is recommended. The user can select the Save button on the

Save/Send screen or select Save from the program menu.

Once the configuration is finished being sent to the device, the user

will be notified by a pop-up dialog box.

7. If finished with the configuration process, close Engineering

Assistant.

Quick Start Guide 27

Quick Start Guide October 2021

8 Verifying device configuration

Use Rosemount 3051SMV Engineering Assistant or any HART-compliant

master to communicate with and verify configuration of the Rosemount

3051SMV.

Table 8-1 shows the Field Communicator fast keys for the fully compensated

mass and energy flow. Table 8-2 shows the Fast Keys for the direct process

variable output.

Note

Device configuration procedures are given for Rosemount 3051SMV

Engineering Assistant 6.1 or later and AMS Device Manager 9.0 or later in the

Rosemount 3051SMV Reference Manual.

A check (✓) indicates the basic configuration parameters. At a minimum,

these parameters should be verified as part of the configuration and startup

procedure.

Table 8-1: Fast Keys for Fully Compensated Mass and Energy Flow

Function Fast Key

Absolute Pressure Reading and Status 1, 4, 2, 1, 5

Absolute Pressure Sensor Limits 1, 4, 1, 5, 8

Absolute Pressure Units 1, 3, 3, 5

Alarm and Saturation Level Configuration 1, 4, 2, 6, 6

Alarm and Saturation Levels 1, 4, 2, 6

Analog Output Trim Options 1, 2, 5, 2

Burst Mode Setup 1, 4, 3, 3, 3

Burst Mode Options 1, 4, 3, 3, 4

Callendar-van Dusen Sensor Matching 1, 2, 5, 5, 4

Configure Fixed Variables 1, 2, 4

✓ Damping 1, 3, 7

Diaphragm Seals Information 1, 4, 4, 5

✓ Differential Pressure Low Flow Cutoff 1, 4, 1, 1, 6

Differential Pressure Reading and Status 1, 4, 2, 1, 4

Differential Pressure Sensor Trim Options 1, 2, 5, 3

✓ Differential Pressure Zero Trim 1, 2, 5, 3, 1

Differential Pressure Units 1, 3, 3, 4

sequence

28 Rosemount 3051SMV

October 2021 Quick Start Guide

Table 8-1: Fast Keys for Fully Compensated Mass and Energy Flow

(continued)

Function Fast Key

Energy Rate Units 1, 3, 3, 2

Energy Reading and Status 1, 4, 2, 1, 2

Equipped Sensors 1, 4, 4, 4

Field Device Information 1, 4, 4, 1

Flow Calculation Type 1, 4, 1, 1, 2

✓ Flow Rate Units 1, 3, 3, 1

Flow Reading and Status 1, 4, 2, 1, 1

Gage Pressure Reading and Status 1, 4, 2, 1, 6

Gage Pressure Sensor Limits 1, 4, 1, 5, 9

Gage Pressure Units 1, 3, 3, 6

LCD Configuration 1, 3, 8

Loop Test 1, 2, 2

Module Temperature Reading and Status 1, 4, 2, 1, 8

Module Temperature Units 1, 3, 3, 8

Poll Address 1, 4, 3, 3, 1

Process Temperature Reading and Status 1, 4, 2, 1, 7

✓ Process Temperature Sensor Mode 1, 4, 1, 6, 8

Process Temperature Sensor Trim Options 1, 2, 5, 5

Process Temperature Unit 1, 3, 3, 7

✓ Ranging the Analog Output 1, 2, 5, 1

Recall Factory Trim Settings 1, 2, 5, 2, 3

Sensor Information 1, 4, 4, 2

Static Pressure Sensor Lower Trim (AP Sensor) 1, 2, 5, 4, 2

Static Pressure Sensor Trim Options 1, 2, 5, 4

Static Pressure Sensor Zero Trim (GP Sensor) 1, 2, 5, 4, 1

Status 1, 2, 1

✓ Tag 1, 3, 1

Test Flow Calculation 1, 2, 3

sequence

Quick Start Guide 29

Quick Start Guide October 2021

Table 8-1: Fast Keys for Fully Compensated Mass and Energy Flow

(continued)

Function Fast Key

Totalizer Configuration 1, 4, 1, 3

Totalizer Reading and Status 1, 4, 2, 1, 3

Totalizer Units 1, 3, 3, 3

Variable Mapping 1, 4, 3, 4

Write Protect 1, 3, 5, 4

sequence

Table 8-2: Fast Keys for Direct Process Variable Output

Function Fast Key

Absolute Pressure Reading and Status 1, 4, 2, 1, 2

Absolute Pressure Sensor Limits 1, 4, 1, 2, 8

Absolute Pressure Units 1, 3, 3, 2

Alarm and Saturation Level Configuration 1, 4, 2, 6, 6

Alarm and Saturation Levels 1, 4, 2, 6

Analog Output Trim Options 1, 2, 4, 2

Burst Mode Setup 1, 4, 3, 3, 3

Burst Mode Options 1, 4, 3, 3, 4

Callendar-van Dusen Sensor Matching 1, 2, 4, 5, 4

✓ Damping 1, 3, 7

Diaphragm Seals Information 1, 4, 4, 4

Differential Pressure Reading and Status 1, 4, 2, 1, 1

Differential Pressure Sensor Trim Options 1, 2, 4, 3

✓ Differential Pressure Zero Trim 1, 2, 4, 3, 1

✓ Differential Pressure Units 1, 3, 3, 1

Equipped Sensors 1, 4, 4, 3

Field Device Information 1, 4, 4, 1

Gage Pressure Reading and Status 1, 4, 2, 1, 3

Gage Pressure Sensor Limits 1, 4, 1, 2, 9

Gage Pressure Units 1, 3, 3, 3

sequence

30 Rosemount 3051SMV

October 2021 Quick Start Guide

Table 8-2: Fast Keys for Direct Process Variable Output (continued)

Function Fast Key

LCD Configuration 1, 3, 8

Loop Test 1, 2, 2

Module Temperature Reading and Status 1, 4, 2, 1, 5

Module Temperature Units 1, 3, 3, 5

Poll Address 1, 4, 3, 3, 1

Process Temperature Reading and Status 1, 4, 2, 1, 4

Process Temperature Sensor Trim Options 1, 2, 4, 5

Process Temperature Unit 1, 3, 3, 4

✓ Ranging the Analog Output 1, 2, 4, 1

Recall Factory Trim Settings 1, 2, 4, 2, 3

Sensor Information 1, 4, 4, 2

Static Pressure Sensor Lower Trim (AP Sensor) 1, 2, 4, 4, 2

Static Pressure Sensor Trim Options 1, 2, 4, 4

Static Pressure Sensor Zero Trim (GP Sensor) 1, 2, 4, 4,1

Status 1, 2, 1

✓ Tag 1, 3, 1

✓ Transfer Function 1, 3, 6

Variable Mapping 1, 4, 3, 4

Write Protect 1, 3, 5, 4

sequence

Quick Start Guide 31

Quick Start Guide October 2021

9 Trimming the transmitter

Transmitters are shipped fully calibrated per request or by the factory

default of full scale.

9.1 Zero trim

A zero trim is a single-point adjustment used for compensating mounting

position and line pressure effects on static and differential pressure sensors.

When performing a zero trim, ensure that the equalizing valve is open and

all wet legs are filled to the correct level.

The transmitter will only allow up to five percent of URL zero error to be

trimmed.

9.1.1 Perform a zero trim using the Field Communicator

Procedure

1. Equalize or vent the transmitter and connect the Field

Communicator (for more information on connecting,see Figure 5-1).

2. If the device is equipped with a static pressure sensor, zero the sensor

by inputting the following Fast Key sequence at the Rosemount

3051SMV menu:

Flow Fast

Keys

1, 2, 5, 4 1, 2, 4, 4 Static pressure sensor trim options

Direct output

Fast Keys

Description

3. Use the zero trim (selection 1) for a transmitter equipped with a gage

static pressure sensor or lower sensor trim (selection 2) for a

transmitted equipped with an absolute static pressure sensor.

Note

When performing a lower sensor trim on an absolute pressure

sensor, it is possible to degrade the performance of the sensor if

inaccurate calibration equipment is used. Use a barometer that is at

least three times as accurate as the absolute sensor of the

transmitter.

4. Zero the differential pressure sensor by inputting the following Fast

Key sequence at the Rosemount 3051SMV menu:

Flow Fast

Keys

1, 2, 5, 3, 1 1, 2, 4, 3, 1 Differential pressure sensor zero trim

32 Rosemount 3051SMV

Direct output

Fast Keys

Description

October 2021 Quick Start Guide

10 Safety instrumented systems installation

For safety certified installations, refer to the appropriate reference manual

for the installation procedure and system requirements:

• For DP only measurements (measurement type D) refer to the

Rosemount 3051S Reference Manual.

• For MultiVariable measurements (measurement type 1–7) refer to the

Rosemount 3051SMV Reference Manual.

Quick Start Guide 33

Quick Start Guide October 2021

11 Product certifications

11.1 Rosemount 3051SMV/3051SFx

Rev 2.10

European directive information

A copy of the EC Declaration of Conformity can be found at the end of the

Quick Start Guide. The most recent revision of the EC Declaration of

Conformity can be found at Emerson.com/Rosemount.

Ordinary location certification

As standard, the transmitter has been examined and tested to determine

that the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

Installing Equipment in North America

The US National Electrical Code (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in the respective codes.

11.1.1 USA E5 US Explosionproof (XP) and Dust-Ignitionproof (DIP)

Certificate

Standards

Markings

FM16US0089X

FM Class 3600 – 2011, FM Class 3615 – 2006, FM Class 3616 –

2011, FM Class 3810 – 2005, ANSI/NEMA 250 – 2003

XP CL I, DIV 1, GP B, C, D; T5; DIP CL II, DIV 1, GP E, F, G; CL III;

T5(–50 °C ≤ Ta ≤ +85 °C); Factory Sealed; Type 4X

I5 US Intrinsically Safe (IS) and Nonincendive (NI)

Certificate

Standards

Markings

34 Rosemount 3051SMV

FM16US0233

FM Class 3600 –2011, FM Class 3610 – 2007, FM Class 3611 –

2004, FM Class 3616 – 2006, FM Class 3810 – 2005, NEMA

250 – 1991

IS CL I, DIV 1, GP A, B, C, D; CL II, DIV 1, GP E, F, G; Class III; Class

1, Zone 0 AEx ia IIC T4; NI CL 1, DIV 2, GP A, B, C, D; T4(–50 °C ≤

Ta ≤ +70 °C) when connected per Rosemount drawing

03151-1206; Type 4X

October 2021 Quick Start Guide

Note

Transmitters marked with NI CL 1, DIV 2 can be installed in Division 2

locations using general Division 2 wiring methods or Nonincendive Field

Wiring (NIFW). See Drawing 03151-1206.

US Intrinsic Safety (IS) and Nonincendive (NI)

Certificate:

Standards:

Markings:

1143113

FM Class 3600:2011, FM Class 3610:2010, FM Class

3611:2004, FM Class 3810:2005, UL50E (1st Ed.)

IS Class I/II/III, Division 1, Groups A, B, C, D, T4/ E, F, and G

T135 °C; Class I, Zone 0 AEx ia IIC T4 Ga;

T4 (-50 °C ≤ Ta ≤ +70 °C) [HART];

T4 (-50 °C ≤ Ta ≤ +60 °C) [Fieldbus];

when connected per Rosemount drawing 03151-1207; Type

4X

IE US FISCO Intrinsically Safe

Certificate

Standards

Markings

US FISCO Intrinsically Safe

Certificate:

Standards:

Markings:

FM16US0233

FM Class 3600 – 2011, FM Class 3610 – 2010, FM Class 3611 –

2004, FM Class 3616 – 2006, FM Class 3810 – 2005, NEMA

250 – 1991

IS CL I, DIV 1, GP A, B, C, D; T4(–50 °C ≤ Ta ≤ +70 °C); when

connected per Rosemount drawing 03151-1006; Type 4X

1143113

FM Class 3600:2011, FM Class 3610:2010, FM Class

3611:2004, FM Class 3810:2005, UL50E (1st Ed.)

IS Class I/II/III, Division 1, Groups A, B, C, D, T4/ E, F, and G

T135 °C; Class I, Zone 0 AEx ia IIC T4 Ga;

T4 (-50 °C ≤ Ta ≤ +70 °C) [HART];

T4 (-50 °C ≤ Ta ≤ +60 °C) [Fieldbus];

when connected per Rosemount drawing 03151-1207; Type

4X

11.1.2 Canada E6 Canada Explosionproof, Dust Ignition-proof, Division 2

Certificate

Quick Start Guide 35

1143113

Quick Start Guide October 2021

Standards

Markings

CAN/CSA C22.2 No. 0-10, CSA Std C22.2 No. 25-1966, CSA

Std C22.2 No. 30-M1986, CSA C22.2 No. 94.2-07 , CSA Std

C22.2 No. 213-M1987, CAN/CSA C22.2 60079-11:14, CAN/

CSA-C22.2 No. 61010-1-12, ANSI/ISA 12.27.01-2003, CSA Std

C22.2 No. 60529:05 (R2010)

Explosionproof Class I, Division 1, Groups B, C, D; DustIgnitionproof Class II, Division 1, Groups E, F, G; Class III;

suitable for Class I, Division 2, Groups A, B, C, D; Type 4X

I6 Canada Intrinsically Safe

Certificate

Standards

Markings

1143113

CAN/CSA C22.2 No. 0-10, CSA Std C22.2 No. 25-1966, CSA

Std C22.2 No. 30-M1986, CSA C22.2 No. 94.2-07 , CSA Std

C22.2 No. 213-M1987, CAN/CSA C22.2 60079-11:14, CAN/

CSA-C22.2 No. 61010-1-12, ANSI/ISA 12.27.01-2003, CSA Std

C22.2 No. 60529:05 (R2010)

Intrinsically Safe Class I, Division 1; Groups A, B, C, D; suitable

for Class 1, Zone 0, IIC, T3C, Ta = 70 °C; when connected per

Rosemount drawing 03151-1207; Type 4X

IF Canada FISCO Intrinsically Safe

Certificate

Standards

Markings

1143113

CAN/CSA C22.2 No. 0-10, CSA Std C22.2 No. 25-1966, CSA

Std C22.2 No. 30-M1986, CSA C22.2 No. 94.2-07 , CSA Std

C22.2 No. 213-M1987, CAN/CSA C22.2 60079-11:14, CAN/

CSA-C22.2 No. 61010-1-12, ANSI/ISA 12.27.01-2003, CSA Std

C22.2 No. 60529:05 (R2010)

FISCO Intrinsically Safe Class I, Division 1; Groups A, B, C, D;

suitable for Class I, Zone 0; T3C, Ta = 70 °C; when installed per

Rosemount drawing 03151-1207; Type 4X

11.1.3 Europe E1 ATEX Flameproof

Certificate

Standards

Markings

36 Rosemount 3051SMV

KEMA 00ATEX2143X

EN 60079-0:2012+A11:2013, EN 60079-1: 2014, EN

60079-26:2015

Ex II 1/2 G Ex db IIC T6…T4 Ga/Gb, T6(–60 °C ≤ Ta ≤ +70 °C),

T5/T4(–60 °C ≤ Ta ≤ +80 °C)

October 2021 Quick Start Guide

Temperature class Process temperature

T6 –60 °C to +70 °C

T5 –60 °C to +80 °C

T4 –60 °C to +120 °C

Special Conditions for Safe Use (X):

1. This device contains a thin wall diaphragm less than 1 mm thickness

that forms a boundary between Category 1 (process connection) and

Category 2 (all other parts of the equipment). The model code and

datasheet are to be consulted for details of the diaphragm material.

Installation, maintenance, and use shall take into account the

environmental conditions to which the diaphragm will be subjected.

The manufacturer's instructions for installation and maintenance

shall be followed in detail to assure safety during its expected

lifetime.

2. Flameproof joints are not intended for repair.

3. Non-standard paint options may cause risk from electrostatic

discharge. Avoid installations that could cause electrostatic build-up

on painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

4. Appropriate cable, glands, and plugs need to be suitable for a

temperature of 5 °C greater than maximum specified temperature

for location where installed.

I1 ATEX Intrinsic Safety

Certificate

Standards

Markings

Parameter HART®FOUNDATION

Voltage Ui30 V 30 V 7.14 V 30 V 30 V

Current Ii300mA300 mA 300 mA 2.31 mA 18.24 mA

Power P

i

Capacitance

C

i

Quick Start Guide 37

Baseefa08ATEX0064X

EN 60079-0:2012, EN 60079-11:2012

Ex II 1 G Ex ia IIC T4 Ga, T4(–60 °C ≤Ta ≤ +70 °C)

™

Fieldbus

1 W 1.3 W 887 mW 17.32 mW 137 mW

14.8 nF 0 0.11 μF 0 0.8 nF

SuperModule

only

™

RTD (for 3051SFx)

HART Fieldbus

Quick Start Guide October 2021

Parameter HART®FOUNDATION

Inductance

L

i

0 0 0 0 1.33 mH

Fieldbus

™

SuperModule

only

™

RTD (for 3051SFx)

HART Fieldbus

Special Conditions for Safe Use (X):

1. If the equipment is fitted with the optional 90 V transient suppressor,

it is incapable of withstanding the 500 V isolation from earth test and

this must be taken into account during installation.

2. The enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it

from impact or abrasion if located in a Zone 0 environment.

IA ATEX FISCO

Certificate

Standards

Markings

Parameter FISCO

Voltage U

Current I

Power P

Capacitance C

Inductance L

i

i

Baseefa08ATEX0064X

EN 60079-0:2012, EN 60079-11:2012

Ex II 1 G Ex ia IIC T4 Ga, T4(–60 °C ≤Ta ≤ +70 °C)

i

i

i

17.5 V

380 mA

5.32 W

0

0

ND ATEX Dust

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. Cable entries must be used which maintain the ingress protection of

2. Unused cable entries must be filled with suitable blanking plugs

38 Rosemount 3051SMV

BAS01ATEX1374X

EN 60079-0:2012+A11:2013, EN 60079-31:2009

Ex II 1 D Ex ta IIIC T105 °C T

V

= 42.4 V

max

95 °C Da, (–20 °C ≤Ta ≤ +85 °C),

500

the enclosure to at least IP66.

which maintain the ingress protection of the enclosure to at least

IP66.

October 2021 Quick Start Guide

3. Cable entries and blanking plugs must be suitable for the ambient

temperature range of the apparatus and capable of withstanding a 7J

impact test.

4. The SuperModule(s) must be securely screwed in place to maintain

the ingress protection of the enclosure(s).

N1 ATEX Type n

Certificate

Standards

Markings

Special Condition for Safe Use (X):

1. If fitted with a 90 V transient suppressor, the equipment is not

capable of withstanding the 500 V electrical strength test as defined

in Clause 6.5.1 of EN 60079-15:2010. This must be taken into

account during installation.

11.1.4 International E7 IECEx Flameproof and Dust

Certificate

Standards

Markings

Temperature class Process temperature

T6 –60 °C to +70 °C

T5 –60 °C to +80 °C

T4 –60 °C to +120 °C

Baseefa08ATEX0065X

EN 60079-0:2012, EN 60079-15:2010

Ex II 3 G Ex nA IIC T4 Gc, (–40 °C ≤Ta ≤ 70 °C), V

max

= 45 V

IECEx KEM 08.0010X (Flameproof)

IEC 60079-0:2011, IEC 60079-1:2014,IEC 60079-26:2014

Ex db IIC T6…T4 Ga/Gb, T6(–60 °C≤ Ta ≤ +70 °C), T5/T4(–60 °C

≤ Ta ≤ +80 °C)

Special Conditions for Safe Use (X):

1. This device contains a thin wall diaphragm less than 1 mm thickness

that forms a boundary between EPL Ga (process connection) and EPL

Gb (all other parts of the equipment). The model code and datasheet

are to be consulted for details of the diaphragm material.

Installation, maintenance and use shall take into account the

environmental conditions to which the diaphragm will be subjected.

The manufacturer's instructions for installation and maintenance

shall be followed in detail to assure safety during its expected

lifetime.

2. Flameproof joints are not intended for repair.

Quick Start Guide 39

Quick Start Guide October 2021

3. Non-standard paint options may cause risk from electrostatic

discharge. Avoid installations that could cause electrostatic build-up

on painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

4. Appropriate cable, glands and plugs need to be suitable for a

temperature of 5 °C greater than maximum specified temperature

for location where installed.

Certificate

Standards

Markings

IECEx BAS 09.0014X (Dust)

IEC 60079-0:2011, IEC 60079-31:2008

Ex ta IIIC T105 °C T

95 °C Da, (–20 °C ≤ Ta ≤ +85 °C), Vmax =

500

42.4 V

Special Conditions for Safe Use (X):

1. Cable entries must be used which maintain the ingress protection of

the enclosure to at least IP66.

2. Unused cable entries must be filled with suitable blanking plugs

which maintain the ingress protection of the enclosure to at least

IP66.

3. Cable entries and blanking plugs must be suitable for the ambient

temperature range of the apparatus and capable of withstanding a 7J

impact test.

4. The Rosemount 3051S SuperModule™ must be securely screwed in

place to maintain the ingress protection of the enclosure.

I7 IECEx Intrinsic Safety

Certificate

Standards

Markings

Parameter HART

Voltage Ui30 V 30 V 7.14 V 30 V 30 V

Current I

Power P

Capacitance

C

i

i

i

IECEx BAS 08.0025X

IEC 60079-0:2011, IEC 60079-11:2011

Ex ia IIC T4 Ga, T4(–60 °C ≤ Ta ≤ +70 °C)

®

FOUNDATION

Fieldbus

300 mA 300 mA 300 mA 2.31 mA 18.24 mA

1 W 1.3 W 887 mW 17.32

14.8 nF 0 0.11 μF 0 0.8 nF

™

SuperModule

only

™

RTD (for 3051SFx)

HART Fieldbus

mW

137 mW

40 Rosemount 3051SMV

October 2021 Quick Start Guide

Parameter HART

Inductance

L

i

0 0 0 0 1.33 mH

®

FOUNDATION

Fieldbus

™

SuperModule

only

™

RTD (for 3051SFx)

HART Fieldbus

Special Conditions for Safe Use (X):

1. If the equipment is fitted with the optional 90 V transient suppressor,

it is incapable of withstanding the 500 V isolation from earth test and

this must be taken into account during installation.

2. The enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it

from impact or abrasion if located in a Zone 0 environment.

I7 IECEx Intrinsic Safety - Group 1 - Mining (I7 with Special A0259)

Certificate

Standards

Markings

Safety parameter HART

Voltage U

Current I

Power P

Capacitance C

Inductance L

i

i

i

IECEx TSA 20.0015X

IEC 60079-0: 2017, IEC 60079-11: 2011

Ex ia I Ma (-60 °C ≤ Ta ≤ +70 °C)

®

30 V Voltage U

300 mA Current I

1 W Power P

14.8 nF Capacitance C

i

i

0 Inductance L

Safety parameter RTD (HART)

o

o

o

30 V

2.31 mA

17.32 mW

33 nF

o

3.33 H

o

Note

This must be sourced from a resistively limited power supply.

Specific Condition of Use (X):

1. If the apparatus is fitted with optional 90 V transient suppressor, it is

not capable of withstanding the 500 Vac insulation test required by

Clause 6.3.13 of IEC60079-11. This must be taken into account when

installing the apparatus.

IG IECEx FISCO

Certificate

Standards

Markings

Quick Start Guide 41

IECEx BAS 08.0025X

IEC 60079-0:2011, IEC 60079-11:2011

Ex ia IIC T4 Ga, T4(–60 °C≤ Ta ≤ +70 °C)

Quick Start Guide October 2021

Parameter FISCO

Voltage U

Current I

Power P

Capacitance C

Inductance L

i

i

i

i

i

17.5 V

380 mA

5.32 W

0

0

N7 IECEx Type n

Certificate

Standards

Markings

Special Condition for Safe Use (X):

11.1.5 Brazil E2 Brazil Flameproof

Certificate

Standards

Markings

Temperature class Ambient temperature Process connection

T6 -60 °C to +70 °C –60 °C to +70 °C

T5 -60 °C to +80 °C –60 °C to +80 °C

T4 -60 °C to +80 °C –60 °C to +120 °C

IECEx BAS 08.0026X

IEC 60079-0:2011, IEC 60079-15:2010

Ex nA IIC T5 Gc,(–40 °C ≤Ta ≤ 70 °C)

1. If fitted with a 90 V transient suppressor, the equipment is not

capable of withstanding the 500 V electrical strength test as defined

in Clause 6.5.1 of IEC 60079-15:2010. This must be taken into

account during installation.

UL-BR 15.0393X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-1:2016,

ABNT NBR IEC 60079-26:2016

Ex db IIC T6...T4 Ga/Gb, T6(–60 °C ≤ Ta ≤ +70 °C), T5/T4 (–60

°C ≤ Ta ≤ +80 °C), IP66

temperature

Special Conditions for Safe Use (X):

1. The device contains a thin wall diaphragm less than 1 mm thick that

forms a boundary between zone 0 (process connection) and zone 1

(all other parts of the equipment). The model code and datasheet are

to be consulted for details of the diaphragm material. Installation,

maintenance, and use shall take into account the environmental

42 Rosemount 3051SMV

October 2021 Quick Start Guide

conditions to which the diaphragm will be subjected. The

manufacturer’s instructions for maintenance shall be followed in

detail to assure safety during its expected lifetime.

2. Flameproof joints are not intended for repair.

3. Non-standard paint options may cause risk from electrostatic

discharge. Avoid installations that could cause electrostatic build-up

on painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

I2 Brazil Intrinsic Safety

Certificate

Standards

UL-BR 15.0357X

ABNT NBR IEC 60079-0:2008 + Addendum 1:2011, ABNT NBR

IEC 60079-11:2009

Markings

Ex ia IIC T4 Ga (–60 °C ≤ Ta ≤ +70 °C)

Special Conditions for Safe Use (X):

1. If the equipment is fitted with the optional 90 V transient suppressor,

it is incapable of withstanding the 500 V isolation from earth test and

this must be taken into account during installation.

2. The enclosure may be made of aluminium alloy and given a

protective polyurethane paint finish; however, care should be taken

to protect it from impact or abrasion if located in a Zone 0

environment, areas requiring EPL Ga.

Parameter

Voltage U

Current I

Power P

Capacitance Ci14.8 nF 0 0 0.8 nF

Inductance L

i

i

i

i

®

HART

Input RTD Input RTD

30 V 30 V 30 V 30 V

300 mA 2.31 mA 300 mA 18.24 mA

1 W 17.32 mW 1.3 W 137 mW

0 0 0 1.33 mH

Fieldbus

11.1.6 China E3 China Flameproof and Dust Ignition-proof

Certificate

Quick Start Guide 43

3051SMV: GYJ18.1550X [Mfg USA, China, Singapore]

3051SFx: GYJ11.1466X [Mfg USA, China, Singapore]

Quick Start Guide October 2021

Standards

3051SMV: GB3836.1-2010, GB3836.2-2010,

GB3836.20-2010

3051SFx: GB3836.1-2010, GB3836.2-2010, GB3836.20-2010,

GB12476.1-2013, GB12476.5-2013

Markings

3051SMV: Ex d IIC T6~T4 Ga/Gb

3051SFx: Ex d IIC T4~T6 Ga/Gb; Ex tD T 105 °C T

95 °C; IP66

500

Special Conditions for Safe Use (X):

一、产品安全使用特殊条件

证书编号后缀“X”表明产品具有安全使用特殊条件:

1. 涉及隔爆接合面的维修须联系产品制造商。

2. 产品使用厚度小于 1 mm 的隔膜作为 0 区(过程连接)和 1 区(产

品其他部分)的隔离,安装和维护时需严格遵守制造商提供的说明

书,以确保安全性。

3. 产品外部涂层可能产生静电危险,使用时须防止产生静电火花,只

能用湿布清理。

二、产品使用注意事项

1. 产品温度组别和使用环境温度之间的关系为:

温度组别 使用环境温度 过程温度

T6 -60 °C to +70 °C –60 °C to +70 °C

T5 -60 °C to +80 °C –60 °C to +80 °C

T4 -60 °C to +80 °C –60 °C to +120 °C

2. 用于爆炸性粉尘环境中,产品使用环境温度为:-20 ℃ ≤ Ta ≤+ 85

℃。

3. 产品外壳设有接地端子,用户在使用时应可靠接地。

4. 安装现场应不存在对产品外壳有腐蚀作用的有害气体。

5. 现场安装时,电缆引入口须选用经国家指定的防爆检验机构检验认

可、具有 Ex dⅡC Gb, Ex tD A20 IP66 防爆等级的电缆引入装置或堵封

件,冗余电缆引入口须用堵封件有效密封。

6. 用于爆炸性气体环境中,现场安装、使用和维护必须严格遵守“严禁

带电开盖!”的警告语。

7. 用于爆炸性粉尘环境中,产品外壳表面需保持清洁,以防粉尘堆

积,但严禁用压缩空气吹扫。

44 Rosemount 3051SMV

October 2021 Quick Start Guide

8. 用户不得自行更换该产品的零部件,应会同产品制造商共同解决运

行中出现的故障,以杜绝损坏现象的发生。

9. 产品的安装、使用和维护应同时遵守产品使用说明书、

GB3836.13-2013“爆炸性环境 第 13 部分:设备的修理、检修、修

复和改造”、GB/T3836.15-2017“爆炸性环境 第 15 部分:电气装置

的设计、选型和安装”、GB/T3836.16-2017“爆炸性环境 第 16 部

分:电气装置的检查与维护”和 GB50257-2014“电气装置安装工程

爆炸和火灾危险环境电力装置施工及验收规范”和 GB15577-2007

“粉尘防爆安全规程”、GB12476.2-2010“可燃性粉尘环境用电气设

备 第 2 部分:选型和安装”的有关规定。

I3 China Intrinsic Safety

Certificate

3051SMV: GYJ18.1551X [Mfg USA, China, Singapore]

3051SFx: GYJ16.1465X [Mfg USA, China, Singapore]

Standards

3051SMV: GB3836.1-2010, GB3836.4-2010,

GB3836.20-2010

3051SFx: GB3836.1/4-2010, GB3836.20-2010,

GB12476.1-2000

Markings

3051SMV: Ex ia IIC T4 Ga

3051SFx: Ex ia IIC T4 Ga,

c 输出代码 防爆标志

A, F Ex iaⅡC T4 Ga,Ex tD A20 IP66

X Ex iaⅡC T4 Ga

T105 ℃ T500 95 ℃

一、 产品安全使用特殊条件

产品防爆合格证号后缀“X”代表产品安全使用有特殊条件:

1. 产品外壳含有轻金属,用于 0 区时需注意防止由于冲击或摩擦产生

的点燃危险。

2. 此设备不能承受 GB3836.4-2010 标准中第 6.3.12 条规定的 500V 交

流有效值试验电压的介电强度试验。

3. c 为 X 时,天线表面电阻大于 1 GΩ,为了避免静电积聚,不允许用

溶剂或者干布擦拭;电源模块表面电阻大于 1 GΩ,如果在危险区域

更换,则需要避免静电积聚;只能使用由原制造厂提供的 P/N

753-9220-XXXX 电池。

二、产品使用注意事项

Quick Start Guide 45

Quick Start Guide October 2021

1. 用于爆炸性气体环境中,产品使用环境温度为:-60 ℃ ≤ Ta ≤+ 70

℃ 用于爆炸性粉尘环境中,产品使用环境温度为:-20 ℃ ≤ Ta ≤+

85 ℃

2. 本安电气参数:

c 输出代码端子 最高输

SuperMo

dule

A +, -, CAN 30 300 1 12 0

A 配

M7、M8

或 M9 显

示

F +, - 30 300 1.3 0 0

FISCO +, - 17.5 300 5.32 0 0

+, -, CAN 30 300 1 30 0

+, - 30 300 1 12 60

入电压

Ui (V)

最大输

入电流 I

(mA)

i

最大输

入功率

Pi (W)

最大内部 等效参数

Ci (nF) Li (μH)

d 代码为 A 时

最高输出

电压 U

(V)

RTD 30 2.31 17.32 0 0

SuperMod

ule

7.14 300 887 110 0

o

最大输出

电流 I

o

(mA)

最大输出

功率 P

o

(mW)

最大内部 等效参数

Ci (nF) Li (μH)

注: 本安电气参数符合 GB3836.19-2010 对 FISCO 现场仪表的参数要

求。

3. 选择 Remote Mount 选项 M7、M8、M9 时,电缆分布电容小于 24

nF,分布电感小于 60 μH。

4. 该产品必须与已通过防爆认证的关联设备配套共同组成本安防爆系

统方可使用于爆炸性气体环境。其系统接线必须同时遵守本产品和

所配关联设备的使用说明书要求,接线端子不得接错。

5. 用于爆炸性粉尘环境中,电缆引入口须选用国家指定的防爆检验机

构按检验认可、具有 Ex tD A20 IP66 防爆等级的电缆引入装置或堵

封件,冗余电缆引入口须用堵封件有效密封。

6. 用户不得自行更换该产品的零部件,应会同产品制造商共同解决运

行中出现的故障,以杜绝损坏现象的发生。

7. 产品的安装、使用和维护应同时遵守产品使用说明书、

GB3836.13-2013“爆炸性环境 第 13 部分:设备的修理、检修、修

46 Rosemount 3051SMV

October 2021 Quick Start Guide

复和改造”、GB/T3836.15-2017“爆炸性环境 第 15 部分:电气装置

的设计、选型和安装”、GB/T3836.16-2017“爆炸性环境 第 16 部

分:电气装置的检查与维护”、GB/T 3836.18-2017“爆炸性环境 第

18 部分:本质安全电气系统”、GB50257-2014“电气装置安装工程

爆炸和火灾危险环境电力装置施工及验收规范” GB12476.2-2010“可

燃性粉尘环境用电气设备 第 2 部分:选型和安装”的有关规定。

11.1.7 Technical Regulation Custom Union (EAC) EM EAC Flameproof and Dust Ignition-proof

Certificate

Markings

IM Technical Regulation Customs Union (EAC) Intrinsic Safety

Certificate

Markings

11.1.8 Japan E4 Japan Flameproof

Certificate

Markings

Temperatu

re class

T6 –60 to +70 °C –60 to +70 °C

T5 –60 to +80 °C –60 to +80 °C

T4 –60 to +80 °C –60 to +120 °C

Special Conditions for Safe Use (X):

1. This device contains a thin wall diaphragm less than 1 mm thickness

EAЭC RU C-US.AA87.B.00587/20

Ga/Gb Ex d IIC T6…T4 X

Ex tb IIIC T105 °C T

Ex ta IIIC T105 °C T

95 °C Db X

500

95 °C Da X

500

RU C-US.AA87.B.00378

0Ex ia IIC T4 Ga X

CML 17JPN1147X

Ex db IIC T6…T4 Ga/Gb

Ambient temperature Process temperature

that forms a boundary between EPL Ga (process connection) and EPL

Gb (all other parts of the equipment). The model code and datasheet

are to be consulted for details of the diaphragm material.

Installation, maintenance, and use shall consider the environmental

conditions to which the diaphragm will be subjected. The

manufacturer’s instructions for installation and maintenance shall be

followed in detail to assure safety during its expected lifetime.

2. Flameproof joints are not intended for repair.

Quick Start Guide 47

Quick Start Guide October 2021

3. Non-standard paint options may cause risk from electrostatic

discharge. Avoid installations that could cause electrostatic build-up

on painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

11.1.9 Republic of Korea EP Republic of Korea Flameproof

Certificate

Markings

19-KA4BO-0913X [Mfg USA], 12-KB4BO-0180X [Mfg USA],

11-KB4BO-0068X [Mfg Singapore]

Ex d IIC T6...T4 Ga/Gb

IP Republic of Korea Intrinsic Safety [HART Only]

Certificate

Markings

10-KB4BO-0021X [Mfg SMMC], 16-KB4BO-0440X [Mfg USA],

19-KA4BO-0911X [Mfg USA]

Ex ia IIC T4

11.1.10 Combinations

K1

K2

K5

K6

K7

KA

KB

KC

KD

KM

KP

Combination of E1, I1, N1, and ND

Combination of E2 and I2

Combination of E5 and I5

Combination of E6 and I6

Combination of E7, I7, and N7

Combination of E1, I1, E6, and I6

Combination of E5, I5, E6, and I6

Combination of E1, I1, E5, and I5

Combination of E1, I1, E5, I5, E6, and I6

Combination of EM and IM

Combination of EP and IP

11.1.11 Additional certifications SBS American Bureau of Shipping (ABS) Type Approval

Certificate

Intended Use

48 Rosemount 3051SMV

17-RJ1679518-PDA

Measure gauge or absolute pressure of liquid, gas or vapor

applications on ABS classed vessels, marine, and offshore

installations. [HART only]

October 2021 Quick Start Guide

SBV Bureau Veritas (BV) Type Approval

Certificate

Requirements

Application

31910 BV

Bureau Veritas Rules for the Classification of Steel Ships

Class Notations: AUT-UMS, AUT-CCS, AUT-PORT and AUTIMS. [HART only]

SDN Det Norske Veritas (DNV) Type Approval

Certificate

Intended

Use

Application

TAA00000K9

Det Norske Veritas’ Rules for Classification of Ships, High

Speed and Light Craft, and Det Norske Veritas’ Offshore

Standards.[HART only]

Location classes

Type 3051S

Temperature D

Humidity B

Vibration A

EMC A

Enclosure D/IP66/IP68

SLL Lloyds Register (LR) Type Approval

Certificate

Application

11/60002

Environmental categories ENV1, ENV2, ENV3, and ENV5.

[HART only]

Quick Start Guide 49

Quick Start Guide October 2021

11.2 Declaration of conformity

50 Rosemount 3051SMV

October 2021 Quick Start Guide

Quick Start Guide 51

Quick Start Guide October 2021

52 Rosemount 3051SMV

October 2021 Quick Start Guide

11.3 China RoHS

Quick Start Guide 53

Quick Start Guide October 2021

54 Rosemount 3051SMV

October 2021 Quick Start Guide

Quick Start Guide 55

*00825-0100-4803*

00825-0100-4803, Rev. GA

Quick Start Guide

October 2021

For more information:

©

2021 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo

is a trademark and service mark of

Emerson Electric Co. Rosemount is a mark

of one of the Emerson family of

companies. All other marks are the

property of their respective owners.

www.emerson.com

Loading...

Loading...