Page 1

Quick Start Guide

00825-0100-4007, Rev DD

January 2017

Rosemount™ 3051 Pressure Transmitter

and Rosemount 3051CF Series Flowmeters

with 4–20 mA HART® Revision 5 and 7 Protocol

Note

Before installing the transmitter, confirm the correct device driver is loaded on the host systems.

See page 3 for system readiness.

Page 2

Quick Start Guide

January 2017

NOTICE

This guide provides basic guidelines for Rosemount 3051 Transmitters. It does not provide instructions for

configuration, diagnostics, maintenance, service, troubleshooting, Explosion-proof, Flameproof, or intrinsically

safe (I.S.) installations. Refer to the Rosemount 3051 HART Revision 5 and 7 Reference Manual

instruction. This manual is also available electronically on Emerson.com/Rosemount

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the appropriate local,

national, and international standards, codes, and prac tices. Review the approvals section of the Rosemount

3051 Reference Manual

Before connecting a HART-based communicator in an explosive atmosphere, make sure the instruments in

the loop are installed in accordance with intrinsically safe or non-incendive field wiring practices.

In an Explosion-proof/Flameproof installation, do not remove the transmitter covers when power is applied

to the unit.

Process leaks may cause harm or result in death.

To avoid process leaks, only use the O-ring designed to seal with the corresponding flange adapter.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and the terminals. High voltage that may be present on leads can cause

electrical shock.

Conduit/cable entries

Unless marked, the conduit/cable entries in the transmitter housing use a

Entries marked “M20” are M20 ⫻ 1.5 thread form. On devices with multiple conduit entries, all entries will

have the same thread form.

Only use plugs, adapters, glands, or conduit with a compatible thread form when closing these entries.

for any restrictions associated with a safe installation.

1

/2–14 NPT thread form.

for mor e

.

Contents

System readiness . . . . . . . . . . . . . . . . . . . . . . . . . 3

Transmitter installation . . . . . . . . . . . . . . . . . . . 4

Mount the transmitter . . . . . . . . . . . . . . . . . . . . 4

Consider housing rotation . . . . . . . . . . . . . . . . . 8

Set the switches . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2

Connect the wiring and power up . . . . . . . . . . 9

Verify configuration . . . . . . . . . . . . . . . . . . . . . 11

Trim the transmitter . . . . . . . . . . . . . . . . . . . . . 14

Safety instrumented systems installation . . . 15

Product certifications . . . . . . . . . . . . . . . . . . . . 16

Page 3

January 2017

1.0 System readiness

1.1 Confirm HART Revision capability

If using HART based control or asset management systems, confirm the

HART capability of those systems prior to transmitter installation. Not all

systems are capable of communicating with HART Revision 7 protocol. This

transmitter can be configured for either HART Revision 5 or 7.

For instructions on how to change the HART revision of your transmitter, see

page 13.

Quick Start Guide

1.2 Confirm correct device driver

Device

revisi on

™

) is loaded on your systems to

Review

instructions

Manual document

(3)

number

00809-0100-4007

functionality

Changes to

software

See Footnote 4 for

list of changes.

Review

(4)

Verify the latest device driver (DD/DTM

ensure proper communications.

Download the latest device driver at Emerson.com or Hartcomm.org.

Rosemount 3051 device revisions and drivers

Table 1 provides the information necessary to ensure you have the correct

device driver and documentation for your device.

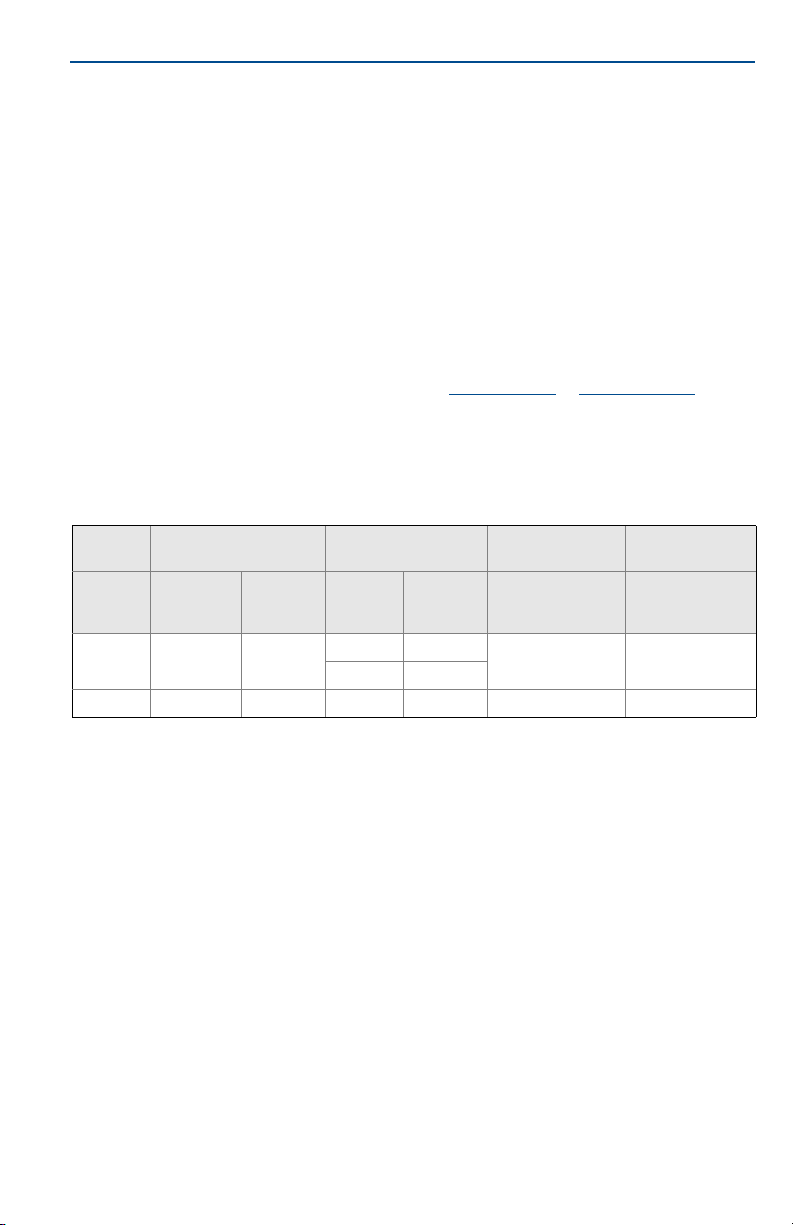

Table 1. Rosemount 3051 Device Revisions and Files

Identify device Find device driver

Software

release

date

Dec-11 1.0.0 01

Jan-98 N/A 178 5 3 00809-0100-4001 N/A

1. NAMUR sof tware revision is located on the hardwa re tag of the device. In ac cordan ce with NE53, revisio ns of the

least significant level X (of 1.0.X) do not change functionality or operation of the device and will not be reflected

in this device revision histor y.

2. HART software revision can be read using a HART capable configuration tool.

3. Device driver file names use device and DD revision, e.g. 10_01. HART protocol is designed to enable legacy

device driver revisions to continue to communicate with new HART devices. To access new functionality, the new

device driver must be downloaded. It is recommended to download new device driver files to ensure full

functionality.

4. HART Revision 5 and 7 Selectable, Power Diagnostics, Safety Certified, Local Operator Interface (LOI), Process

Alerts, Scaled Variable, Configurable Alarms, Expanded Engineering Units.

NAMUR

software

revision

(1)

HART

software

revision

(2)

HART

universal

revision

7 10

5 9

3

Page 4

Quick Start Guide

Flow

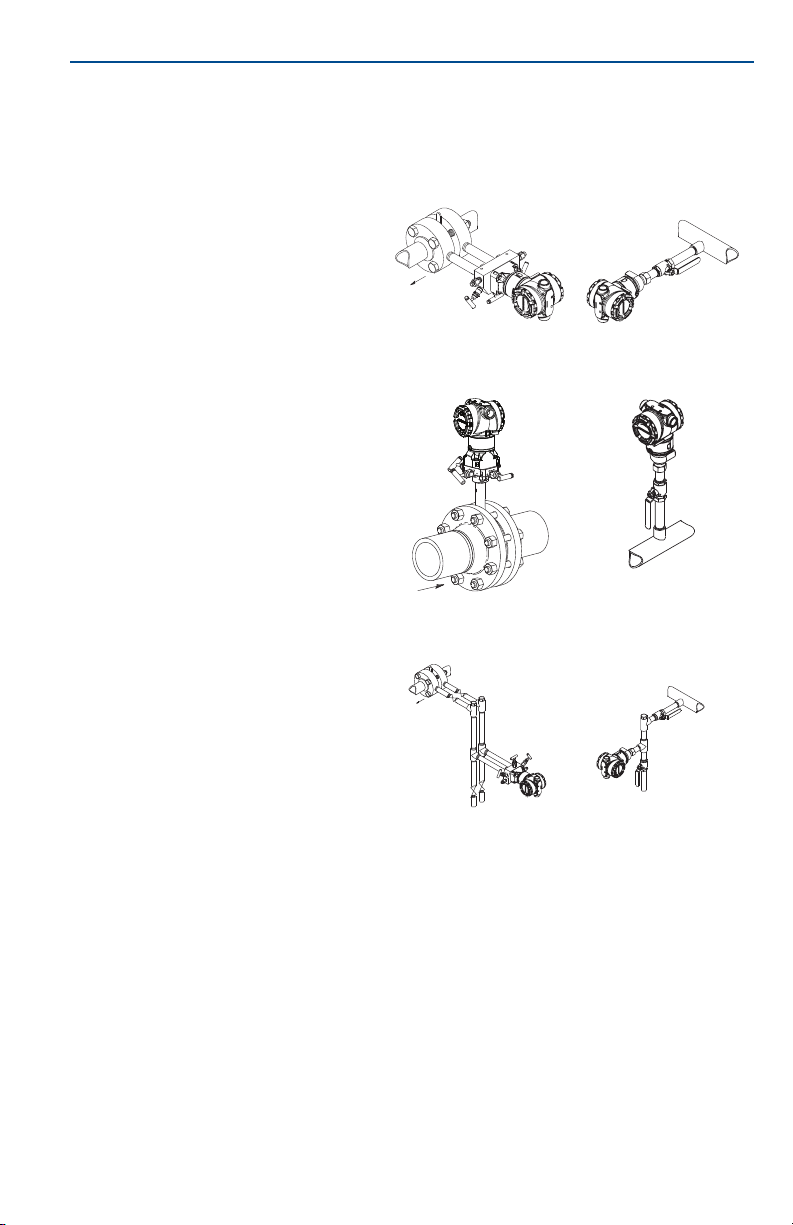

2.0 Transmitter installation

2.1 Mount the transmitter

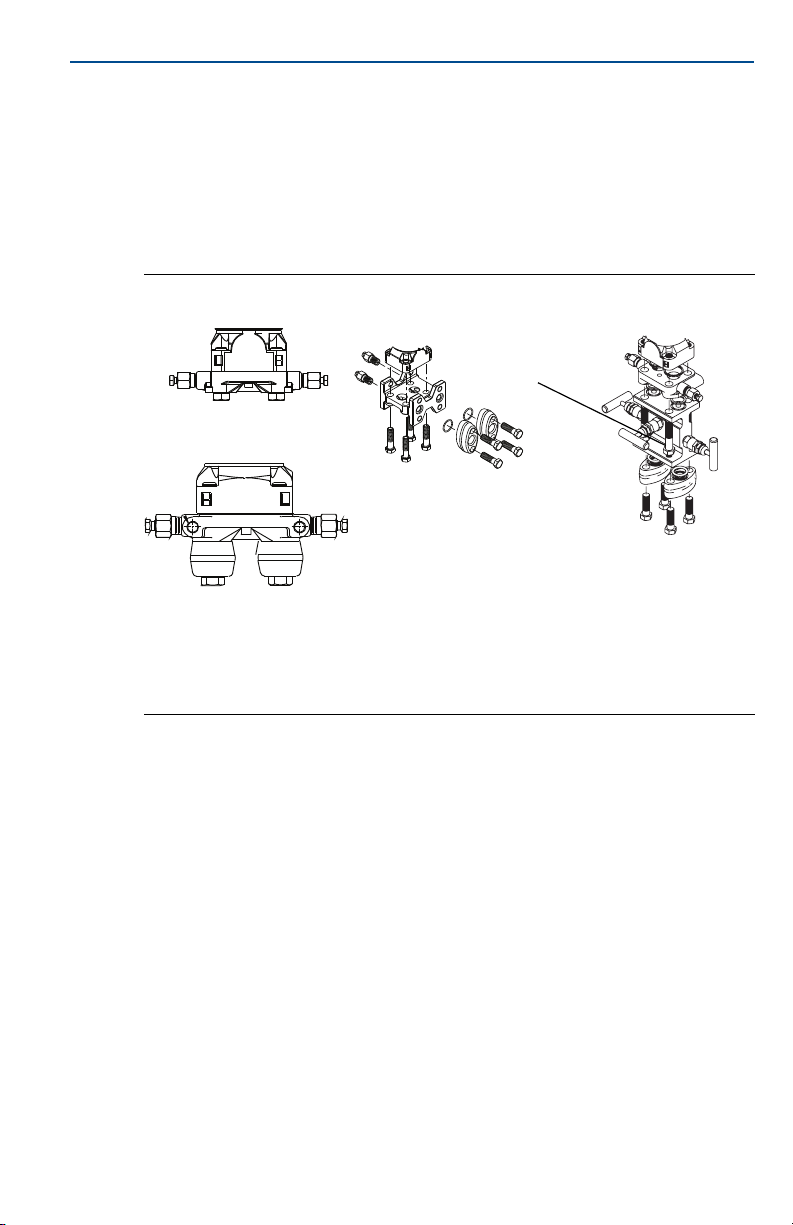

Liquid applications

1. Place taps to the side of the

line.

2. Mount beside or below the

taps.

3. Mount the transmitter so

that the drain/vent valves

are oriented upward.

Gas applications

1. Place taps in the top or side

of the line.

2. Mount beside or above the

taps.

Flow

January 2017

Coplanar In-line

Steam applications

1. Place taps to the side of the

line.

2. Mount beside or below the

taps.

3. Fill impulse lines with

water.

4

Flow

Page 5

January 2017

Quick Start Guide

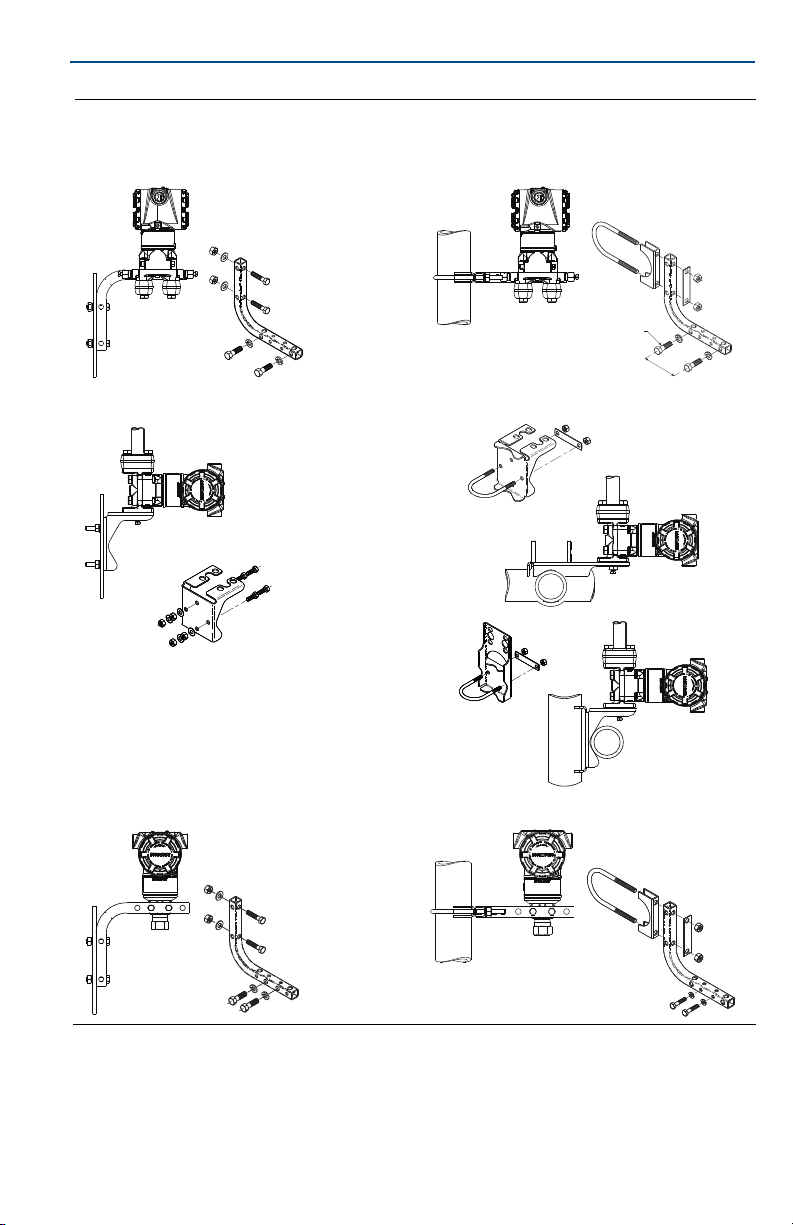

Figure 1. Panel and Pipe Mounting

Panel mount

(1)

Pipe mount

Coplanar flange

Traditional flange

1.5/16 ⫻ 11/2 panel bolts are customer supplied.

Rosemount 3051T

5

Page 6

Quick Start Guide

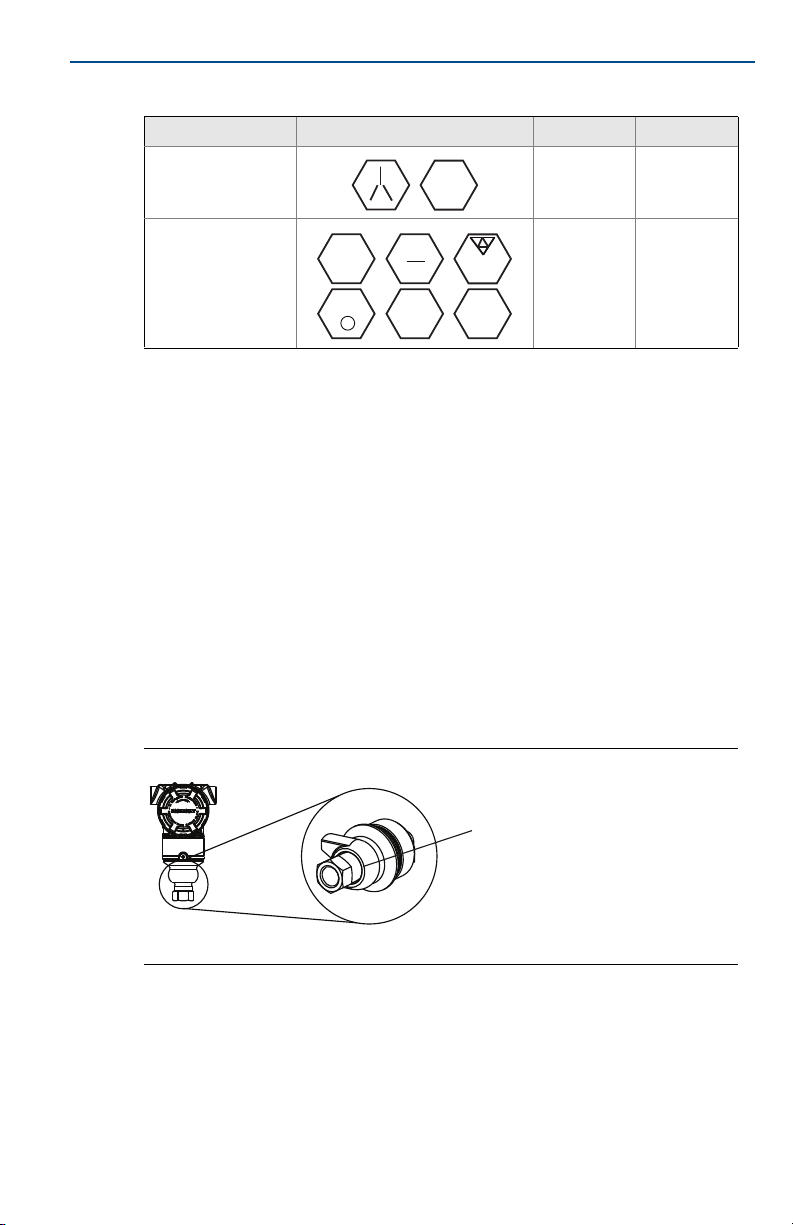

Bolting considerations

If the transmitter installation requires assembly of the process flanges,

manifolds, or flange adapters, follow the assembly guidelines to ensure a tight

seal for optimal performance characteristics of the transmitters. Use only bolts

supplied with the transmitter or sold by Emerson

page 6 illustrates common transmitter assemblies with the bolt length required

for proper transmitter assembly.

January 2017

™

as spare parts. Figure 2 on

Figure 2. Common Transmitter Assemblies

A

4 × 1.75-in. (44 mm)

B

4 × 2.88-in. (73 mm)

A. Transmitter with coplanar flange

B. Transmitter with coplanar flange and optional flange adapters

C. Transmitter with traditional flange and optional flange adapters

D. Transmitter with coplanar flange and optional manifold and flange adapters

C

4 × 1.75-in.

(44 mm)

4 × 2.25-in. (57 mm)

4 × 1.50-in.

(38 mm)

D

4 × 1.75-in. (44 mm)

Bolts are typically carbon steel or stainless steel. Confirm the material by

viewing the markings on the head of the bolt and referencing Table 2 on page 7.

If bolt material is not shown in Table 2, contact a local Emerson representative

for more information.

Use the following bolt installation procedure:

1. Carbon steel bolts do not require lubrication and the stainless steel bolts are

coated with a lubricant to ease installation. However, no additional lubricant

should be applied when installing either type of bolt.

2. Finger-tighten the bolts.

3. Torque the bolts to the initial torque value using a crossing pattern.

See Table 2 for initial torque value.

4. Torque the bolts to the final torque value using the same crossing pattern.

See Table 2 for final torque value.

5. Verify the flange bolts are protruding through the isolator plate before

applying pressure.

6

Page 7

January 2017

A

Table 2. Torque Values for the Flange and Flange Adapter Bolts

Quick Start Guide

Bolt material Head markings Initial torque Final torque

Carbon Steel (CS) 300 in-lb 650 in-lb

316

Stainle ss Steel (SST) 150 in-lb 300 in-lb

316

R

B8M

STM

316

B7M

316

316

SW

Environmental seal for housing

Thread sealing (PTFE) tape or paste on male threads of conduit is required to

provide a water/dust tight conduit seal and meets requirements of NEMA

Type 4X, IP66, and IP68. Consult factory if other ingress protection ratings are

required.

For M20 threads, install conduit plugs to full thread engagement or until

mechanical resistance is met.

®

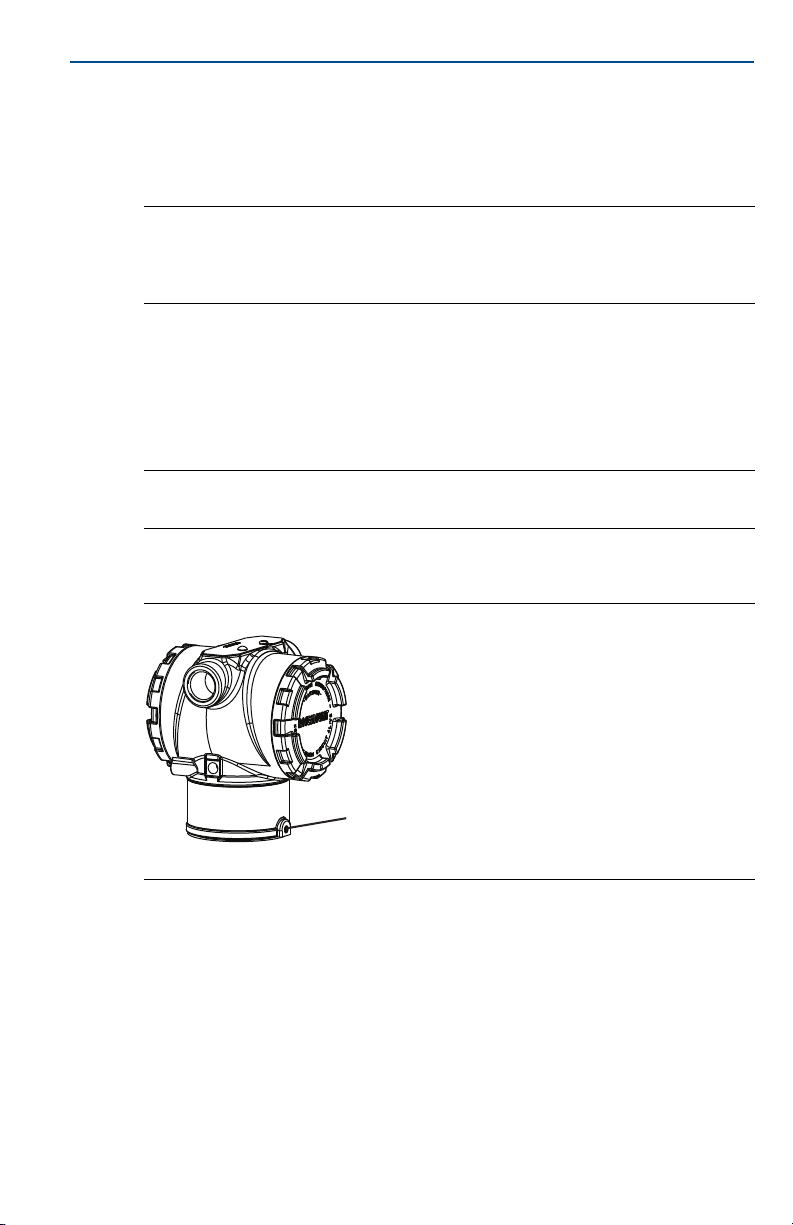

In-line gage transmitter orientation

The low side pressure port (atmospheric reference) on the in-line gage

transmitter is located in the neck of the transmitter, behind the housing. The

vent path is 360° around the transmitter between the housing and sensor.

(See Figure 3.)

Keep the vent path free of any obstruction, including but not limited to paint,

dust, and lubrication by mounting the transmitter so that the process can

drain away.

Figure 3. In-line Gage Low Side Pressure Port

A. Low side pressure port (atmospheric reference)

Installing high pressure coned and threaded connection

The transmitter comes with an autoclave connection designed for high

pressure applications. Follow the steps below to properly connect the

transmitter to your process:

1. Apply a process-compatible lubricant to the gland nut threads.

2. Slip the gland nut onto the tube, then thread the collar onto the tube end

(the collar is reverse threaded).

7

Page 8

Quick Start Guide

A

3. Apply a small amount of process-compatible lubricant applied to the tube

cone to help prevent galling and facilitate sealing. Insert the tubing into the

connection and tighten finger tight.

4. Tighten the gland nut to a torque of 25 ft-lb.

Note

A weep hole has been designed into the transmitter for safety and leak detection. If fluid

begins to leak from the weep hole, isolate the process pressure, disconnect the

transmitter, and reseal until the leak is resolved.

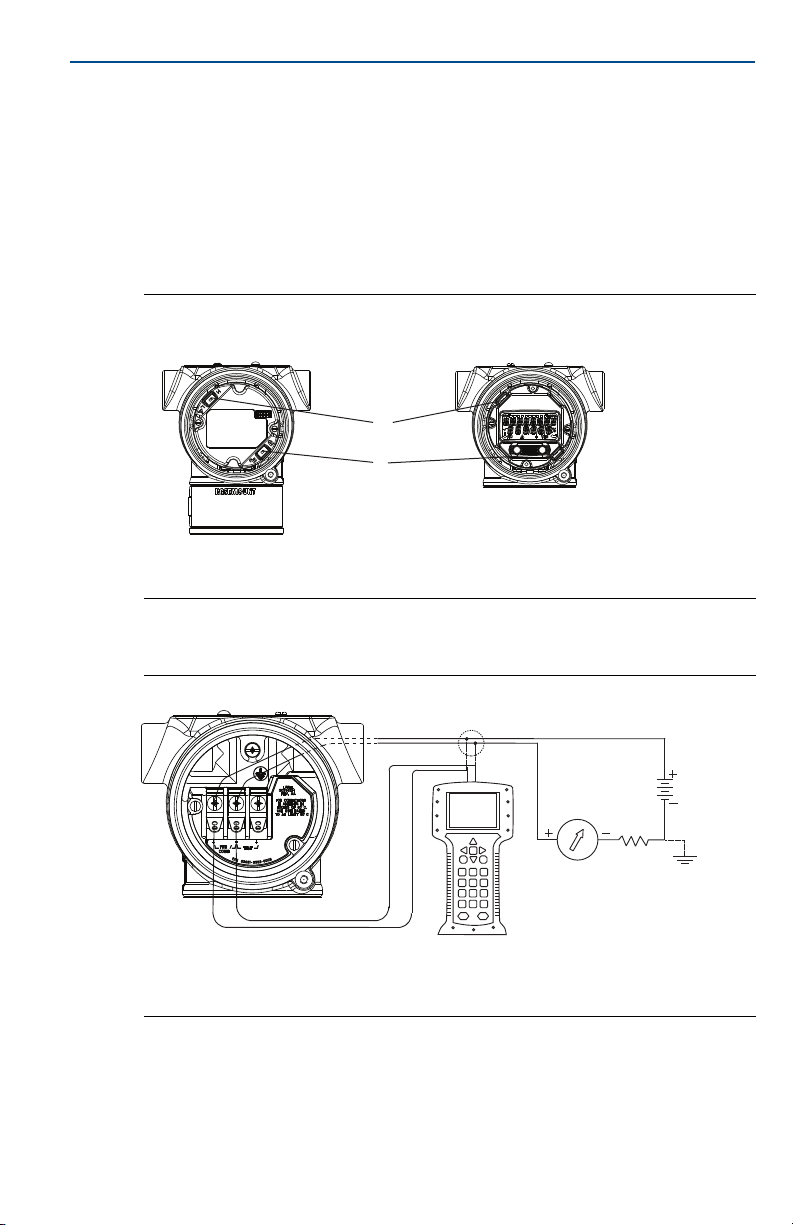

2.2 Consider housing rotation

To improve field access to wiring or to better view the optional LCD display:

1. Loosen the housing rotation set screw using a

2. Turn the housing left or right maximum up to 180° from its original

position.

Note

Over rotating can damage the transmitter.

3. Re-tighten the housing rotation set screw to no more than 7 in-lb when

desired location is reached.

Figure 4. Transmitter Housing Set Screw

(1)

5

/64-in. hex wrench.

January 2017

A. Housing rotation set screw (5/64-in.)

2.3 Set the switches

Set alarm and security switch configuration before installation as shown in

Figure 5.

The alarm switch sets the analog output alarm to high or low.

- Default alarm is high.

The security switch allows (unlocked symbol) or prevents (locked symbol)

any configuration of the transmitter.

- Default security is off (unlocked symbol).

1. Rosemount 3051C original position aligns with “H” side; Rosemount 3051T original position is the opposite side of

bracket holes.

8

Page 9

January 2017

Use the following procedure to change the switch configuration:

1. If the transmitter is installed, secure the loop, and remove power.

2. Remove the housing cover opposite the field terminal side. Do not remove

3. Slide the security and alarm switches into the preferred position using a small

4. Reattach the transmitter cover. The cover must be fully engaged to comply

Figure 5. Transmitter Electronics Board

A. Alarm

B. Security

Quick Start Guide

the instrument cover in explosive atmospheres when the circuit is live.

screwdriver.

with explosion-proof requirements.

Without LCD display With LOI or LCD display

A

B

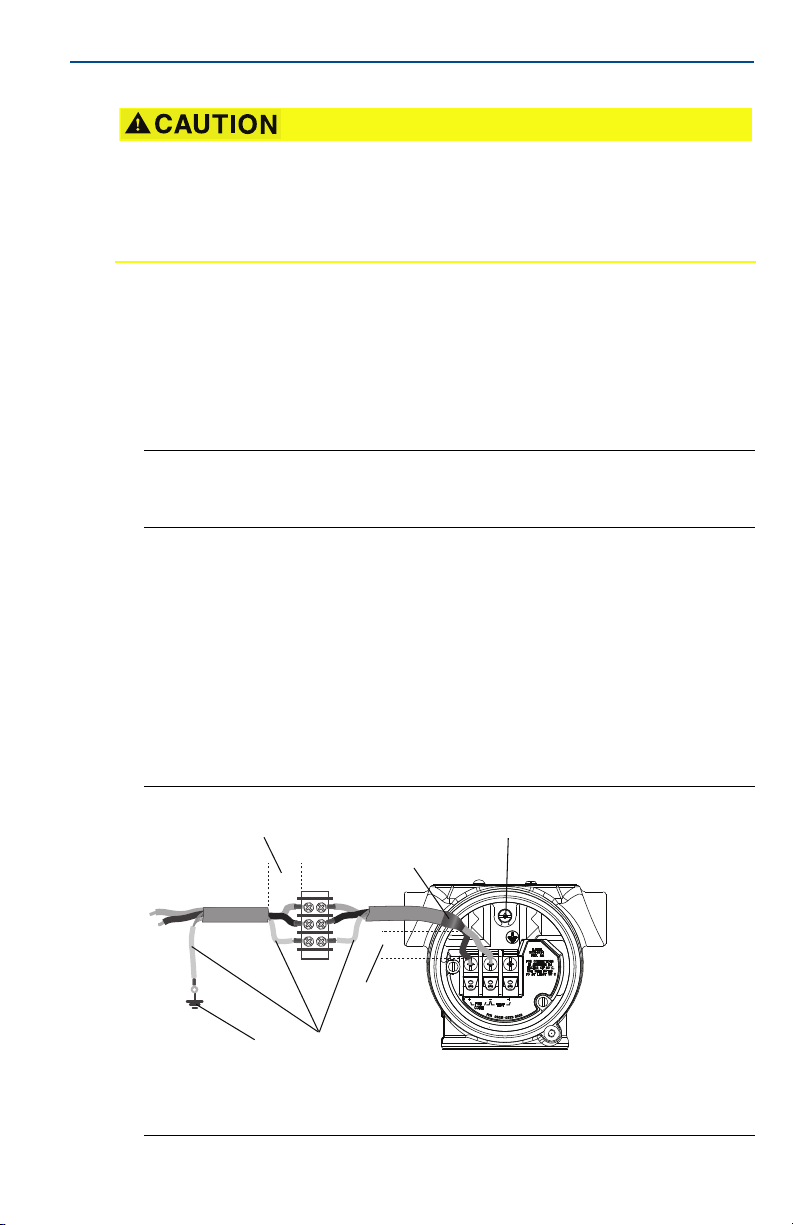

2.4 Connect the wiring and power up

Figure 6. Transmitter Wiring Diagrams (4–20 mA)

A. 24 Vdc supply

B. R

≥ 250

L

C. Current meter (optional)

Shielded twisted pair cable should be used for best results. Use 24 AWG or larger

wire that does not exceed 5,000 feet (1500 meters) in length. If applicable,

install wiring with a drip loop. Arrange the drip loop so the bottom is lower than

the conduit connections and the transmitter housing.

A

B

C

9

Page 10

Quick Start Guide

DP

A

B

C

A

D

E

Installation of the transient protection terminal block does not provide transient protection unless

the Rosemount 3051 case is properly grounded.

Do not run signal wiring in conduit or open trays with power wiring, or near heavy electrical

equipment.

Do not connect the powered signal wiring to the test terminals. Power could damage the test diode

in the terminal block.

Use the following steps to wire the transmitter:

1. Remove the housing cover on the FIELD TERMINALS side.

2. Connect the positive lead to the “+” terminal (PWR/COMM) and the negative

lead to the “–” terminal.

3. Tighten the terminal screws to ensure full contact with the terminal block

screw and washer. When using a direct wiring method, wrap wire clockwise

to ensure it is in place when tightening the terminal block screw.

Note

The use of a pin or ferrule wire terminal is not recommended as the connection may be

more susceptible to loosening over time or under vibration.

4. Ground housing to fulfill local grounding regulations.

5. Ensure proper grounding. It is important that the instrument cable shield be:

a. Trimmed close and insulated from touching the transmitter housing

b. Connected to the next shield if cable is routed through a junction box

c. Connected to a good earth ground at the power supply end

6. If transient protection is needed, refer to section “Grounding for transient

terminal block” on page 11 for grounding instructions.

7. Plug and seal unused conduit connections.

8. Replace the housing cover.

January 2017

10

Figure 7. Wiring

A. Minimize distance

B. Trim shield and insulate

C. Protective grounding terminal

D. Insulate shield

E. Connect shield back to the power supply ground

Page 11

January 2017

Grounding for transient terminal block

Ground termination is provided on the outside of the electronics housing and

inside the terminal compartment. These grounds are used when the transient

protection terminal blocks are installed. It is recommended that 18 AWG or

larger wire is used to connect housing ground to earth ground (internal or

external).

If the transmitter is currently not wired for power up and communication, follow

Connect the wiring and power up , step 1 through 8. When the transmitter is

properly wired, refer to Figure 7 for internal and external transient grounding

locations.

2.5 Verify configuration

Verify the configuration using any HART capable configuration tool or LOI option code M4. Configuration instructions for a Field Communicator and LOI

are included in this step. See Rosemount 3051 Reference Manual

configuration instructions using AMS™ Device Manager.

Verifying configuration with a Field Communicator

A Rosemount 3051 DD must be installed on the Field Communicator to verify

configuration. Fast Key sequences for the latest DD are shown in Table 3 on

page 11. For Fast Key sequences using legacy DD's, contact your local Emerson

Process Management representative.

Quick Start Guide

for

Note

Emerson recommends installing the latest DD to access the complete functionality. Visit

Emerson.com/Field-Communicator for information on updating the DD Library.

1. Verify device configuration using the fast key sequences in Table 3.

a. A check () indicates the basic configuration parameters. At minimum,

these parameters should be verified as part of configuration and startup.

Table 3. Device Revision 9 and 10 (HART 7), DD Revision 1 Fast Key Sequence

Function

Alarm and Saturation Levels 2, 2, 2, 5, 7 2, 2, 2, 5, 7

Damping 2, 2, 1, 1, 5 2, 2, 1, 1, 5

Range Values 2, 2, 2 2, 2, 2

Tag 2, 2, 7, 1, 1 2, 2, 7, 1, 1

Transfer Function 2, 2, 1, 1, 6 2, 2, 1, 1, 6

Units 2, 2, 1, 1, 4 2, 2, 1, 1, 4

Burst Mode 2, 2, 5, 3 2, 2, 5, 3

Custom Display Configuration 2, 2, 4 2, 2, 4

Date 2, 2, 7, 1, 4 2, 2, 7, 1, 3

Fast Key se quen ce

HART 7 HART 5

11

Page 12

Quick Start Guide

B

A

Table 3. Device Revision 9 and 10 (HART 7), DD Revision 1 Fast Key Sequence

January 2017

Function

Descriptor 2, 2, 7, 1, 5 2, 2, 7, 1, 4

Digital to Analog Trim (4–20 mA Output) 3, 4, 2 3, 4, 2

Disable Configuration Buttons 2, 2, 6, 3 2, 2, 6, 3

Rerange with Keypad 2, 2, 2, 1 2, 2, 2, 1

Loop Test 3, 5, 1 3, 5, 1

Lower Sensor Trim 3, 4, 1, 2 3, 4, 1, 2

Message 2, 2, 7, 1, 6 2, 2, 7, 1, 5

Scaled D/A Trim (4–20 mA Output) 3, 4, 2 3, 4, 2

Sensor Temperature/Trend (3051S) 3, 3, 3 3, 3, 3

Upper Sensor Trim 3, 4, 1, 1 3, 4, 1, 1

Digital Zero Trim 3, 4, 1, 3 3, 4, 1, 3

Password 2, 2, 6, 5 2, 2, 6, 4

Scaled Variable 3, 2, 2 3, 2, 2

HART Revisio n 5 to HART Revision 7 switch 2, 2, 5, 2, 3 2, 2, 5, 2, 3

(1)

Long Tag

Find Device

Simulate Digital Signal

1. Only available in HART Revision 7 mode.

(1)

(1)

Fast Key sequence

HART 7 HART 5

2, 2, 7, 1, 2 N/A

3, 4, 5 N/A

3, 4, 5 N/A

Verifying configuration with LOI

The optional LOI can be used for commissioning the device. The LOI is a

two-button design with internal and external buttons. The internal buttons are

located on the display of the transmitter, while the external buttons are located

underneath the top metal tag. To activate the LOI, push any button. LOI button

functionality is shown on the bottom corners of the display. See Table 4 and

Figure 9 for button operation and menu information.

Figure 8. Internal and External LOI Buttons

A. Internal buttons

B. External buttons

12

Page 13

January 2017

Note

See Figure 10 on page 15 to confirm external button functionality.

Table 4. LOI Button Operation

Figure 9. LOI Menu

Quick Start Guide

Button

Left No SCROLL

Right Yes ENTER

Assign PV

HART Revision

Switch HART revision mode

If the HART configuration tool is not capable of communicating with HART

Revision 7, the Rosemount 3051 will load a generic menu with limited

capability. The following procedures will switch the HART revision mode from

the generic menu:

1. Manual Setup > Device Information > Identification > Message

a. To change to HART Revision 5, Enter: HART5 in the Message field.

b. To change to HART Revision 7, Enter: HART7 in the Message field.

Note

See Table 3 on page 11 to change HART Revision when the correct device driver

is loaded.

13

Page 14

Quick Start Guide

2.6 Trim the transmitter

Devices are calibrated by the factory. Once installed, it is recommended to

perform a zero trim on gage and differential pressure transmitters to eliminate

error due to mounting position or static pressure effects. A zero trim can be

performed using either a Field Communicator or configuration buttons.

For instructions using AMS Device Manager, see the Rosemount 3051 HART

Revision 5 and 7 Reference Manual

Note

When performing a zero trim, ensure that the equalization valve is open and all wet legs

are filled to the correct level.

It is not recommended to zero an absolute transmitter, Rosemount 3051CA or 3051TA models.

1. Choose your trim procedure.

a. Analog zero trim – Sets the analog output to 4 mA.

Also referred to as a “rerange,” it sets the lower range value (LRV) equal

to the measured pressure.

The display and digital HART output remains unchanged.

b. Digital zero trim – Recalibrates the sensor zero.

The LRV is unaffected. The pressure value will be zero (on display and

HART output). 4 mA point may not be at zero.

This requires that the factory calibrated zero pressure is within a range

of 3% of the URL [0 + 3% ⫻ URL].

January 2017

.

14

Example

URV = 250 inH2O

Applied Zero Pressure = + 0.03 ⫻ 250 inH2O = + 7.5 inH2O (compared to

factory settings) values outside this range will be rejected by the transmitter.

Trimming with a Field Communicator

1. Connect the Field Communicator, see “Connect the wiring and power up” on

page 9 for instructions.

2. Follow the HART menu to perform the desired zero trim.

Table 5. Zero Trim Fast Keys

Analog zero (set 4 mA) Digital zero

Fast Key Se quenc e 3, 4, 2 3, 4, 1, 3

Trimming with configuration buttons

A zero trim is to be performed using one of the three possible sets of external

configuration buttons located under the top tag.

To access the configuration buttons, loosen the screw and slide the tag on the

top of the transmitter. Confirm the functionality using Figure 10.

Page 15

January 2017

A

BC

D

Figure 10. External Configuration Buttons

Quick Start Guide

A. LOI

B. Analog zero and span

C. Digital zero

D. Configuration buttons

Use the following procedures to perform a zero trim:

Perform trim with LOI (option M4)

1. Set the transmitter pressure.

2. See Figure 9 on page 13 for the operating menu.

a. Perform an analog zero trim by selecting Rerange.

b. Perform a digital zero trim by selecting Zero Trim.

Perform trim with analog zero and span (option D4)

1. Set the transmitter pressure.

2. Press and hold the Zero button for two seconds to perform an analog zero

trim.

Perform trim with digital zero (option DZ)

1. Set the transmitter pressure.

2. Press and hold the Zero button for two seconds to perform a digital zero

trim.

3.0 Safety instrumented systems installation

For safety certified installations, refer to Rosemount 3051 HART Revision 5 and 7

Reference Manual for installation procedure and system requirements.

15

Page 16

Quick Start Guide

4.0 Product certifications

Rev 1.6

4.1 European Directive Information

A copy of the EU Declaration of Conformity can be found at the end of the Quick

Start Guide. The most recent revision of the EU Declaration of Conformity can

be found at Emerson.com/Rosemount

4.2 Ordinary Location Certification

As standard, the transmitter has been examined and tested to determine that

the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited by

the Federal Occupational Safety and Health Administration (OSHA).

North America

E5 USA Explosionproof (XP) and Dust-Ignitionproof (DIP)

Certificate: 0T2H0.AE

Standards: FM Class 3600 – 2011, FM Class 3615 – 2006, FM Class 3810 – 2005,

Markings: XP CL I, DIV 1, GP B, C, D; DIP CL II, DIV 1, GP E, F, G; CL III;

I5 USA Intrinsic Safety (IS) and Nonincendive (NI)

Certificate: FM16US0120X

Standards: FM Class 3600 – 2011, FM Class 3610 – 2010, FM Class 3611 – 2004,

Markings: IS CL I, DIV 1, GP A, B, C, D; CL II, DIV 1, GP E, F, G; Class III; DIV 1 when

Special Conditions for Safe Use (X):

1. The Rosemount 3051 Transmitter housing contains aluminum and is considered a

potential risk of ignition by impact or friction. Care must be taken into account during

installation and use to prevent impact and friction.

2. The Rosemount 3051 Transmitter with the transient terminal block (option code T1)

will not pass the 500 Vrms dielectric strength test and this must be taken into account

during installation.

IE USA FISCO

Certificate: FM16US0120X

Standards: FM Class 3600 – 2011, FM Class 3610 – 2010, FM Class 3611 – 2004,

Markings: IS CL I, DIV 1, GP A, B, C, D when connected per Rosemount drawing

Special Conditions for Safe Use (X):

1. The Rosemount 3051 Transmitter housing contains aluminum and is considered a

potential risk of ignition by impact or friction. Care must be taken into account during

installation and use to prevent impact and friction.

ANSI/NEMA 250 – 2003

T5(–50 °C ≤ T

FM Class 3810 – 2005, ANSI/NEMA 250 - 2008

connected per Rosemount drawing 03031-1019; NI CL 1, DIV 2, GP A, B,

C, D; T4(–50 °C ≤ T

T4(–50 °C ≤ T

FM Class 3810 – 2005

03031-1019 (–50 °C ≤ T

≤ +85 °C); Factory Sealed; Type 4X

a

≤ +60 °C) [Fieldbus/PROFIBUS®]; Type 4x

a

.

≤ +70 °C) [HART], T5(–50 °C ≤ Ta ≤ +40 °C) [HART];

a

≤ +60 °C); Type 4x

a

January 2017

16

Page 17

January 2017

2. The Rosemount 3051 Transmitter with the transient terminal block (option code T1)

C6 Canada Explosionproof, Dust-Ignitionproof, Intrinsic Safety and Nonincendive

E6 Canada Explosionproof, Dust-Ignitionproof and Division 2

Europe

E8 ATEX Flameproof and Dust

Quick Start Guide

will not pass the 500 Vrms dielectric strength test and this must be taken into account

during installation.

Certificate: 1053834

Standards: ANSI/ISA 12.27.01-2003, CSA Std. C22.2 No. 30-M1986,

CSA Std. C22.2 No.142-M1987, CSA Std. C22.2. No.157-92,

CSA Std. C22.2 No. 213-M1987

Markings: Explosionproof for Class I, Division 1, Groups B, C and D; Suitable for Class

I, Zone 1, Group IIB+H2, T5; Dust-Ignitionproof Class II, Division 1, Groups

E, F, G; Class III Division 1; Intrinsically Safe Class I, Division 1 Groups A, B,

C, D when connected in accordance with Rosemount drawing

03031-1024, Temperature Code T3C; Suitable for Class I, Zone 0; Class I

Division 2 Groups A, B, C and D, T5; Suitable for Class I Zone 2, Group IIC;

Type 4X; Factory Sealed; Single Seal (See drawing 03031-1053)

Certificate: 1053834

Standards: ANSI/ISA 12.27.01-2003, CSA Std. C22.2 No. 30-M1986,

CSA Std. C22.2 No.142-M1987, CSA Std. C22.2 No. 213-M1987

Markings: Explosionproof Class I, Division 1, Groups B, C and D; Suitable for Class I,

Zone 1, Group IIB+H2, T5; Dust-Ignitionproof for Class II and Class III,

Division 1, Groups E, F and G; Class I, Division 2, Groups A, B, C and D;

Suitable for Class I Zone 2, Group IIC; Type 4X; Factory Sealed; Single Seal

(See drawing 03031-1053)

Certificate: KEMA00ATEX2013X; Baseefa11ATEX0275X

Standards: EN60079-0:2012 + A11:2013, EN60079-1:2014, EN60079-26:2015,

EN60079-31:2009

Markings: II

1

/2 G Ex db IIC T6...T4 Ga/Gb, T6(–60 °C ≤ Ta ≤ +70 °C),

T4/T5(–60 °C ≤ T

II 1 D Ex ta IIIC T95 °C T

≤ +80 °C);

a

105 °C Da (–20 °C ≤ Ta ≤ +85 °C)

500

Table 6. Process Temperature

Temperature class Process temperature

T6 –60 to +70 °C

T5 –60 to +80 °C

T5 –60 to +120 °C

Special Conditions for Safe Use (X):

1. This device contains a thin wall diaphragm. Installation, maintenance and use shall

take into account the environmental conditions to which the diaphragm will be

subjected. The manufacturer's instructions for installation and maintenance shall be

followed in detail to assure safety during its expected lifetime.

2. Flameproof joints are not intended for repair.

3. Non-standard paint options may cause risk from electrostatic discharge. Avoid

installations that could cause electrostatic build-up on painted surfaces, and only clean

the painted surfaces with a damp cloth. If paint is ordered through a special option

code, contact the manufacturer for more information.

17

Page 18

Quick Start Guide

4. Some variants of the equipment have reduced markings on the nameplate. Refer to

the Certificate for full equipment marking.

I1 ATE X Int rin sic Safety a nd D ust

Certificate: BAS97ATEX1089X; Baseefa11ATEX0275X

Standards: EN60079-0:2012, EN60079-11:2012, EN60079-31:2009

Markings: HART: II 1 G Ex ia IIC T5/T4 Ga, T5(–60 °C ≤ T

Table 7. Input Parameters

Parameter HART Fieldbus/PROFIBUS

Volt age U

Current I

Power P

Capacitance C

Inductance L

Special Conditions for Safe Use (X):

1. The apparatus is not capable of withstanding the 500 V insulation test required by

clause 6.3.12 of EN60079-11:2012. This must be taken into account when installing

the apparatus.

2. The enclosure may be made of aluminum alloy and given a protective polyurethane

paint finish; however care should be taken to protect it from impact or abrasion if

located in Zone 0.

3. Some variants of the equipment have reduced markings on the nameplate. Refer to

the Certificate for full equipment marking.

IA ATEX FIS CO

Certificate: BAS97ATEX1089X

Standards: EN60079-0:2012, EN60079-11:2009

Markings: II 1 G Ex ia IIC T4 Ga (–60 °C ≤ T

Table 8. Input Parameters

T4(–60 °C ≤ T

≤ +70 °C)

a

Fieldbus/PROFIBUS: II 1 G Ex ia IIC Ga T4(–60 °C ≤ T

DUST: II 1 D Ex ta IIIC T95 °C T

i

i

i

i

i

30 V 30 V

200 mA 300 mA

0.9 W 1.3 W

0.012 μF 0 μF

0 mH 0 mH

500

a

January 2017

≤ +40 °C),

a

≤ +60 °C)

a

105 °C Da (–20 °C ≤ Ta ≤ +85 °C)

≤ +60 °C)

18

Parameter FISCO

Volt age U

i

Current I

i

Power P

i

Capacitance C

Inductance L

i

i

17.5 V

380 mA

5.32 W

<5 nF

<10 μH

Special Conditions for Safe Use (X):

1. The apparatus is not capable of withstanding the 500 V insulation test required by

clause 6.3.12 of EN60079-11:2012. This must be taken into account when installing

the apparatus.

2. The enclosure may be made of aluminum alloy and given a protective polyurethane

paint finish; however care should be taken to protect it from impact or abrasion if

located in Zone 0.

Page 19

January 2017

N1 ATE X Typ e n a nd D ust

Special Conditions for Safe Use (X):

1. This apparatus is not capable of withstanding the 500 V insulation test that is required

2. Some variants of the equipment have reduced markings on the nameplate. Refer to

International

E7 IECEx Flameproof and Dust

Table 9. Process Temperature

Quick Start Guide

Certificate: BAS00ATEX3105X; Baseefa11ATEX0275X

Standards: EN60079-0:2012, EN60079-15:2010, EN60079-31:2009

Markings: II 3 G Ex nA IIC T5 Gc (–40 °C ≤ T

II 1 D Ex ta IIIC T95 °C T

500

≤ +70 °C);

a

105 °C Da (–20 °C ≤ Ta ≤ +85 °C)

by EN60079-15. This must be taken into account when installing the apparatus.

the Certificate for full equipment marking.

Certificate: IECEx KEM 09.0034X; IECEx BAS 10.0034X

Standards: IEC60079-0:2011, IEC60079-1:2014-06, IEC60079-26:2014-10,

IEC60079-31:2008

Markings: Ex db IIC T6...T4 Ga/Gb, T6(–60 °C ≤ T

T4/T5(–60 °C ≤ T

Ex ta IIIC T95 °C T

Temperature class Process temperature

T6

T5

T4

≤ +80 °C);

a

105 °C Da (–20 °C ≤ Ta ≤ +85 °C)

500

–60 to +70 °C

–60 to +80 °C

–60 to +80 °C

≤ +70 °C),

a

Special Conditions for Safe Use (X):

1. This device contains a thin wall diaphragm. Installation, maintenance and use shall

take into account the environmental conditions to which the diaphragm will be

subjected. The manufacturer's instructions for installation and maintenance shall be

followed in detail to assure safety during its expected lifetime.

2. Flameproof joints are not intended for repair.

3. Non-standard paint options may cause risk from electrostatic discharge. Avoid

installations that could cause electrostatic build-up on painted surfaces, and only clean

the painted surfaces with a damp cloth. If paint is ordered through a special option

code, contact the manufacturer for more information.

4. Some variants of the equipment have reduced markings on the nameplate. Refer to

the Certificate for full equipment marking.

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 09.0076X

Standards: IEC60079-0:2011, IEC60079-11:2011

Markings: HART: Ex ia IIC T5/T4 Ga, T5(–60 °C ≤ T

Fieldbus/PROFIBUS: Ex ia IIC T4(–60 °C ≤ T

≤ +40 °C), T4(–60 °C ≤ Ta ≤ +70 °C)

a

≤ +60 °C)

a

19

Page 20

Quick Start Guide

Table 10. Input Parameters

Parameter HART Fieldbus/PROFIBUS

Volt age U

Current I

Power P

Capacitance C

Inductance L

Special Conditions for Safe Use (X):

1. If the apparatus is fitted with optional 90 V transient suppressor, it is not capable of

withstanding the 500 V insulation test required by IEC60079-11. This must be taken

into account when installing the apparatus.

2. The enclosure may be made of aluminum alloy and given a protective polyurethane

paint finish; however, care should be taken to protect it from impact or abrasion if

located in Zone 0.

IECEx Mining (Special A0259)

Certificate: IECEx TSA 14.0001X

Standards: IEC60079-0:2011, IEC60079-11:2011

Markings: Ex ia I Ma (–60 °C ≤ T

Table 11. Input Parameters

Parameter HART Fieldbus/PROFIBUS FISCO

Volt age U

Current I

Power P

Capacitance C

Inductance L

Special Conditions for Safe Use (X):

1. If the apparatus is fitted with optional 90 V transient suppressor, it is not capable of

withstanding the 500 V insulation test required by IEC60079-11. This must be taken

into account when installing the apparatus.

2. It is a condition of safe use that the above input parameters shall be taken into account

during installation.

3. It is a condition of manufacture that only the apparatus fitted with housing, covers and

sensor module housing made out of stainless steel are used in Group I applications.

N7 IECEx Type n

Certificate: IECEx BAS 09.0077X

Standards: IEC60079-0:2011, IEC60079-15:2010

Markings: Ex nA IIC T5 Gc (–40 °C ≤ T

Special Condition for Safe Use (X):

1. The apparatus is not capable of withstanding the 500 V insulation test required by

IEC60079-15. This must be taken into account when installing the apparatus.

January 2017

i

i

i

i

i

i

i

i

i

i

30 V 30 V

200 mA 300 mA

0.9 W 1.3 W

0.012 μF 0 μF

0 mH 0 mH

≤ +70 °C)

a

30 V 30 V 17.5 V

200 mA 300 mA 380 mA

0.9 W 1.3 W 5.32 W

0.012 μF 0 μF <5 nF

0 mH 0 mH <10 μH

≤ +70 °C)

a

20

Page 21

January 2017

Brazil

E2 INMETRO Flameproof

Special Conditions for Safe Use (X):

1. This device contains a thin wall diaphragm. Installation, maintenance and use shall

2. In case of repair, contact the manufacturer for information on the dimensions of the

3. The capacitance of the wrap around label, being 1.6 nF, exceeds the limit in Table 9 of

I2 INMETRO Intrinsic Safety

Table 12. Input Parameters

Quick Start Guide

Certificate: UL-BR 13.0643X

Standards: ABNT NBR IEC60079-0:2008 + Errata 1:2011,

ABNT NBR IEC60079-1:2009 + Errata 1:2011,

ABNT NBR IEC60079-26:2008 + Errata 1:2008

Markings: Ex d IIC T6/T5 Ga/Gb, T6(–50 °C ≤ T

≤ +65 °C), T5(–50 °C ≤ Ta ≤ +80 °C)

a

take into account the environmental conditions to which the diaphragm will be

subjected. The manufacturer's instructions for installation and maintenance shall be

followed in detail to assure safety during its expected lifetime.

flameproof joints.

ABNT NBR IEC 60079-0. The user shall determine suitability for the specific

application.

Certificate: UL-BR 13.0584X

Standards: ABNT NBR IEC60079-0:2008 + Errata 1:2011, ABNT NBR

IEC60079-11:2009

Markings: HART: Ex ia IIC T5/T4 Ga, T5(–60 °C ≤ T

Fieldbus/PROFIBUS: Ex ia IIC T4 Ga (–60 °C ≤ T

≤ +40 °C), T4(–60 °C ≤ Ta ≤ +70 °C)

a

≤ +60 °C)

a

Parameter HART Fieldbus/PROFIBUS

Voltag e U

i

Current I

i

Power P

i

Capacitance C

Inductance L

i

i

30 V 30 V

200 mA 300 mA

0.9 W 1.3 W

0.012 μF 0 μF

0 mH 0 mH

Special Conditions for Safe Use (X):

1. If the equipment is fitted with an optional 90 V transient suppressor, it is not capable of

withstanding the 500 V insulation test required by ABNT NBR IRC 60079-11. This must

be taken into account when installing the equipment.

2. The enclosure may be made of aluminum alloy and given a protective polyurethane

paint finish; however, care should be taken to protect it from impact or abrasion if

located in Zone 0.

IB INMETRO FISCO

Certificate: UL-BR 13.0584X

Standards: ABNT NBR IEC60079-0:2008 + Errata 1:2011,

ABNT NBR IEC60079-11:2009

Markings: Ex ia IIC T4 Ga (–60 °C ≤ T

≤ +60 °C)

a

21

Page 22

Quick Start Guide

Table 13. Input Parameters

Parameter FISCO

Volt age U

Current I

Power P

Capacitance C

Inductance L

Special Conditions for Safe Use (X):

1. If the equipment is fitted with an optional 90 V transient suppressor, it is not capable of

withstanding the 500 V insulation test required by ABNT NBR IEC 60079-11. This must

be taken into account when installing the equipment.

2. The enclosure may be made of aluminum alloy and given a protective polyurethane

paint finish; however, care should be taken to protect it from impact or abrasion if

located in Zone 0.

China

E3 China Flameproof

Certificate: GYJ14.1041X; GYJ15.1368X [Flowmeters]

Standards: GB12476-2000; GB3836.1-2010, GB3836.2-2010, GB3836.20-2010

Markings: Ex d IIC T6/T5 Ga/Gb, T6(–50 °C ≤ T

Special Conditions for Safe Use (X):

1. The relation between ambient temperature arrange and temperature class is as

follow s:

January 2017

i

i

i

i

i

17.5 V

380 mA

5.32 W

<5 nF

<10 μH

≤ +65 °C), T5(–50 °C ≤ Ta ≤ +80 °C)

a

22

T

a

–50 °C~+80 °C T5

–50 °C~+65 °C T6

Tem per atu re c las s

When used in a combustible d ust environment, t he maximum ambient temperature is

80 °C.

2. The earth connection facility in the enclosure should be connected reliably.

3. Cable entry certified by notified body with type of protection Ex d IIC in accordance

with GB3836.1-2000 and GB3836.2-2000, should be applied when installed in a

hazardous location. When used in combustible dust environment, cable entry in

accordance with IP66 or higher level should be applied.

4. Obey the warning “Keep tight when the circuit is alive.”

5. End users are not permitted to change any internal components.

6. During installation, use and maintenance of this product, observe the following

standards: GB3836.13-1997, GB3836.15-2000, GB3836.16-2006, GB50257-1996,

GB12476.2-2006, GB15577-2007.

I3 China Intrinsic Safety

Certificate: GYJ13.1362X; GYJ15.1367X [Flowmeters]

Standards: GB3836.1-2010, GB3836.4-2010, GB3836.20-2010, GB12476.1-2000

Markings: Ex ia IIC Ga T4/T5

Page 23

January 2017

Special Conditions for Safe Use (X):

1. Symbol “X” is used to denote specific conditions of use:

2. The relation between T code and ambient temperature range is:

3. Intrinsically Safe parameters:

Quick Start Guide

a. If the apparatus is fitted with an optional 90 V transient suppressor, it is not

capable of withstanding the 500 V insulation test for 1 minute. This must be

taken into account when installing the apparatus.

b. The enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however, care should be taken to protect it from

impact or abrasion if located in Zone 0.

Model T code Temperature range

HART T5 –60 °C ≤ Ta ≤ +40 °C

HART T4 –60 °C ≤ Ta ≤ +70 °C

Fieldbus/PROFIBUS/FISCO T4 –60 °C ≤ Ta ≤ +60 °C

Parameter HART Fieldbus/PROFIBUS FISCO

Volt age U

i

Current I

i

Power P

i

Capacitance C

Inductance L

i

i

30 V 30V 17.5 V

200 mA 300 mA 380 mA

0.9 W 1.3 W 5.32 W

0.012 μF 0 μF <5 nF

0 mH 0mH <10 μH

Note

FISCO parameters apply to both Group IIC and IIB.

[For Flowmeters] When Rosemount 644 Temperature Transmitter is used, the

transmitter should be used with Ex-certified associated apparatus to establish explosion

protection system that can be used in explosive gas atmospheres. Wiring and terminals

should comply with the instruction manual of both Rosemount 644 and associated

apparatus. The cables between Rosemount 644 and associated apparatus should be

shielded cables (the cables must have insulated shield). The shielded cable has to be

grounded reliably in a non-hazardous area.

4. Transmitters comply with the requirements for FISCO field devices specified in

IEC60079-27:2008. For the connection of an intrinsically safe circuit in accordance

with FISCO Model, FISCO parameters are listed in the table above.

5. The product should be used with Ex-certified associated apparatus to establish

explosion protection system that can be used in explosive gas atmospheres. Wiring

and terminals should comply with the instruction manual of the product and

associated apparatus.

6. The cables between this product and associated apparatus should be shielded

cables (the cables must have insulated shield). The shielded cable has to be

grounded reliably in a non-hazardous area.

23

Page 24

Quick Start Guide

7. End users are not permitted to change any intern components but to settle the

problem in conjunction with the manufacturer to avoid damage to the product.

8. During installation, use and maintenance of this product, observe the following

standards: GB3836.13-1997, GB3836.15-2000, GB3836.16-2006, GB50257-1996,

GB12476.2-2006, GB15577-2007.

N3 China Type n

Certificate: GYJ15.1105X

Standards: GB3836.1-2010, GB3836.8-2003

Markings: Ex nA nL IIC T5 Gc (–40 °C ≤ T

Special Condition for Safe Use (X):

1. Symbol “X” is used to denote specific conditions of use: The apparatus is not capable of

withstanding the 500 V test to earth for one minute. The must be taken into

consideration during installation.

Japan

E4 Japan Flameproof

Certificate: TC20577, TC20578, TC20583, TC20584 [HART]; TC20579, TC20580,

Markings: Ex d IIC T5

Technical Regulations Customs Union (EAC)

EM EAC Flameproof

Certificate: RU C-US.GB05.B.01197

Markings: Ga/Gb Ex d IIC T5/T6 X, T5(–60 °C ≤ T

Special Condition for Safe Use (X):

1. See certificate for special conditions.

IM EAC Intrinsically Safe

Certificate: RU C-US.GB05.B.01197

Markings: HART: 0Ex ia IIC T4/T5 Ga X, T4(–60 °C ≤ T

Special Condition for Safe Use (X):

1. See certificate for special conditions.

≤ +70 °C)

a

TC20581, TC20582 [Fieldbus]

≤ +80 °C), T6(–60 °C ≤ Ta ≤ +65 °C)

a

≤ +70 °C),

T5(–60 °C ≤ T

≤ +40 °C)

a

a

Fieldbus/PROFIBUS: 0Ex ia IIC T4 Ga X (–60 °C ≤ T

≤ +60 °C)

a

January 2017

24

Combinations

K2 Combination of E2 and I2

K5 Combination of E5 and I5

K6 Combination of C6, E8, and I1

K7 Combination of E7, I7, and N7

K8 Combination of E8, I1, and N1

KB Combination of E5, I5, and C6

KD Combination of E8, I1, E5, I5, and C6

KM Combination of EM and IM

Conduit plugs and adapters

IECEx Flameproof and Increased Safety

Certificate: IECEx FMG 13.0032X

Standards: IEC60079-0:2011, IEC60079-1:2007, IEC60079-7:2006-2007

Markings: Ex de IIC Gb

Page 25

January 2017

ATEX Flameproof and Increased Safety

Certificate: FM13ATEX0076X

Standards: EN60079-0:2012, EN60079-1:2007, IEC60079-7:2007

Markings: II 2 G Ex de IIC Gb

Table 14. Conduit Plug Thread Sizes

Table 15. Thread Adapter Thread Sizes

Special Conditions for Safe Use (X):

1. When the thread adapter is used with an enclosure in type of protection increased

2. The blanking plug shall not be used with an adapter.

3. Blanking Plug and Threaded Adapter shall be either NPT or Metric thread forms. G

Quick Start Guide

Thread Identification mark

M20 ⫻ 1.5 M20

1

/2–14 NPT

Male thread Identification mark

M20 ⫻ 1.5–6H M20

1

/2–14 NPT

3

/4–14 NPT

Female t hread Identification mark

M20 ⫻ 1.5–6H M20

1

/2–14 NPT

G1/2 G1/2

1

/2 NPT

1

/2–14 NPT

3

/4–14 NPT

1

/2–14 NPT

safety “e” the entry thread shall be suitably sealed in order to maintain the ingress

protection rating (IP) of the enclosure.

thread forms are only acceptable for existing (legacy) equipment installations.

1

/2

Additional Certifications

SBS American Bureau of Shipping (ABS) Type Approval

Certificate: 09-HS446883A-5-PDA

Intended Use: Marine and Offshore Applications — Measurement of either gauge

or absolute pressure for liquid, gas, and vapor.

SBV Bureau Veritas (BV) Type Approval

Certificate: 23155

Requirements: Bureau Veritas Rules for the Classification of Steel Ships

Application: Class notations: AUT-UMS, AUT-CCS, AUT-PORT and AUT-IMS;

Pressure transmitter type 3051 cannot be installed on diesel

engines

SDN Det Norske Veritas (DNV) Type Approval

Certificate: TAA000004F

Intended Use: DNV GL Rules for Classification — Ships and offshore units

25

Page 26

Quick Start Guide

SLL Lloyds Register (LR) Type Approval

C5 Custody Transfer - Measurement Canada Accuracy Approval

January 2017

Application:

Location classes

Tem pe ra tu r e D

Humidity B

Vibration A

EMC B

Enclosure D

Certificate: 11/60002

Application: Environmental categories ENV1, ENV2, ENV3, and ENV5

Certificate: AG-0226; AG-0454; AG-0477

26

Page 27

January 2017

Figure 11. Rosemount 3051 Declaration of Conformity

Quick Start Guide

27

Page 28

Quick Start Guide

January 2017

28

Page 29

January 2017

Quick Start Guide

29

Page 30

Quick Start Guide

January 2017

30

Page 31

January 2017

ᴹ

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

Rosemount 3051

List of Rosemount 3051 Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘䍘

/ Hazardous Substances

䫵

Lead

(Pb)

⊎

Mercury

(Hg)

䭹

Cadmium

(Cd)

ޝԧ䬜䬜

Hexavalent

Chromium

(Cr +6)

ཊⓤ㚄㚄㤟

Polybrominated

biphenyls

(PBB)

ཊⓤ㚄㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

XO O O O O

༣փ㓴Ԧ

Housing

Assembly

XO O X O O

Րᝏಘ㓴Ԧ

Sensor

Assembly

XO O X O O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

Quick Start Guide

31

Page 32

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Europe Regional Office

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emi rates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

*00825-0100-4007*

Quick Start Guide

00825-0100-4007, Rev DD

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/us er/RosemountMeasur ement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found on the Te rm s

and Conditions of Sale page.

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

AMS, Rosemount, and Rosemount logotype are trademarks of

Emerson.

DTM is a trademark of the FDT Group.

HART is a registered trademark of the FieldComm Group.

NEMA is a registered trademark and service mark of the National

Electrical Manufacturers Association.

PROFIBUS is a registered trademark of PROFINET International (PI).

All other marks are the property of their respective owners.

© 2017 Emerson. All rights reserved.

January 2017

Loading...

Loading...