Page 1

Product Data Sheet

00813-0100-4001, Rev TA

Rosemount™ 3051 Pressure Transmitter

February 2017

With the Rosemount 3051 Pressure Transmitter, you’ll gain more control over your plant. You’ll be able to

reduce product variation and complexity as well as your total cost of ownership by leveraging one device

across a number of pressure, level and flow applications. You’ll have access to information you can use to

diagnose, correct and even prevent issues. And with unparalleled reliability and experience, the Rosemount

3051 is the industry standard that will help you perform at higher levels of efficiency and safety so you can

remain globally competitive.

Page 2

Rosemount 3051

Setting the standard for pressure measurement

Proven best-in-class performance, reliability and safety

Over seven million installed

Reference accuracy 0.04 percent of span

Installed total performance of 0.14 percent of span

10-year stability of 0.2 percent of URL

SIL2/3 certified (IEC 61508)

Maximize installation and application flexibility with the coplanar platform

Improve reliability and performance with integrated DP

Flowmeters, DP Level solutions and integral manifolds

Easy installation with all solutions fully assembled, leak-tested

and calibrated

Meet your application needs with an unsurpassed offering

February 2017

Advanced functionality

Power advisory diagnostics

Detect on-scale failures caused by electrical loop issues before they impact your process

operation

This capability is safety certified for your most critical applications

Local operator interface (LOI)

Straightforward menus and built-in configuration buttons allow you commission the device in

less than a minute

Configure in hazardous-area locations without removing the transmitter cover using external

buttons

Contents

Rosemount 3051C Coplanar™ Pressure Transmitter . . 4

Rosemount 3051T In-Line Pressure Transmitter . . . . .11

Rosemount 3051L Level Transmitter . . . . . . . . . . . . . . 37

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rosemount 3051CF Flowmeter selection guide . . . . .17

Rosemount 3051CFA Annubar Flowmeter . . . . . . . . .18

Rosemount 3051CFC Compact Flowmeter . . . . . . . . .26

Rosemount 3051CFP Integral Orifice Flowmeter . . . .31

2

Product Certifications

Pipe I.D. range codes

. . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Emerson.com/Rosemount

Page 3

February 2017

Rosemount 3051

Industry leading capabilities extended to IEC 62591

®

(WirelessHART

Cost effectively implement wireless on the industry's most proven platform

Optimize safety with the industry's only intrinsically safe power module

Eliminate wiring design and construction complexities to lower costs by 40–60 percent

Quickly deploy new pressure, level and flow measurements in 70 percent less time

)

Innovative, integrated DP Flowmeters

Fully assembled, configured, and leak tested for out-of-the-box installation

Reduce straight pipe requirements, lower permanent pressure loss and achieve accurate

measurement in small line sizes

Up to 1.65 percent volumetric flow accuracy at 8:1 turndown

Proven, reliable, and innovative DP Level Technologies

Connect to virtually any process with a comprehensive offering of process connections, fill

fluids, direct mount or capillary connections and materials

Quantify and optimize total system performance with QZ option

Operate at higher temperature and in vacuum applications

Optimize level measurement with cost efficient Rosemount Tuned-System

™

Assemblies

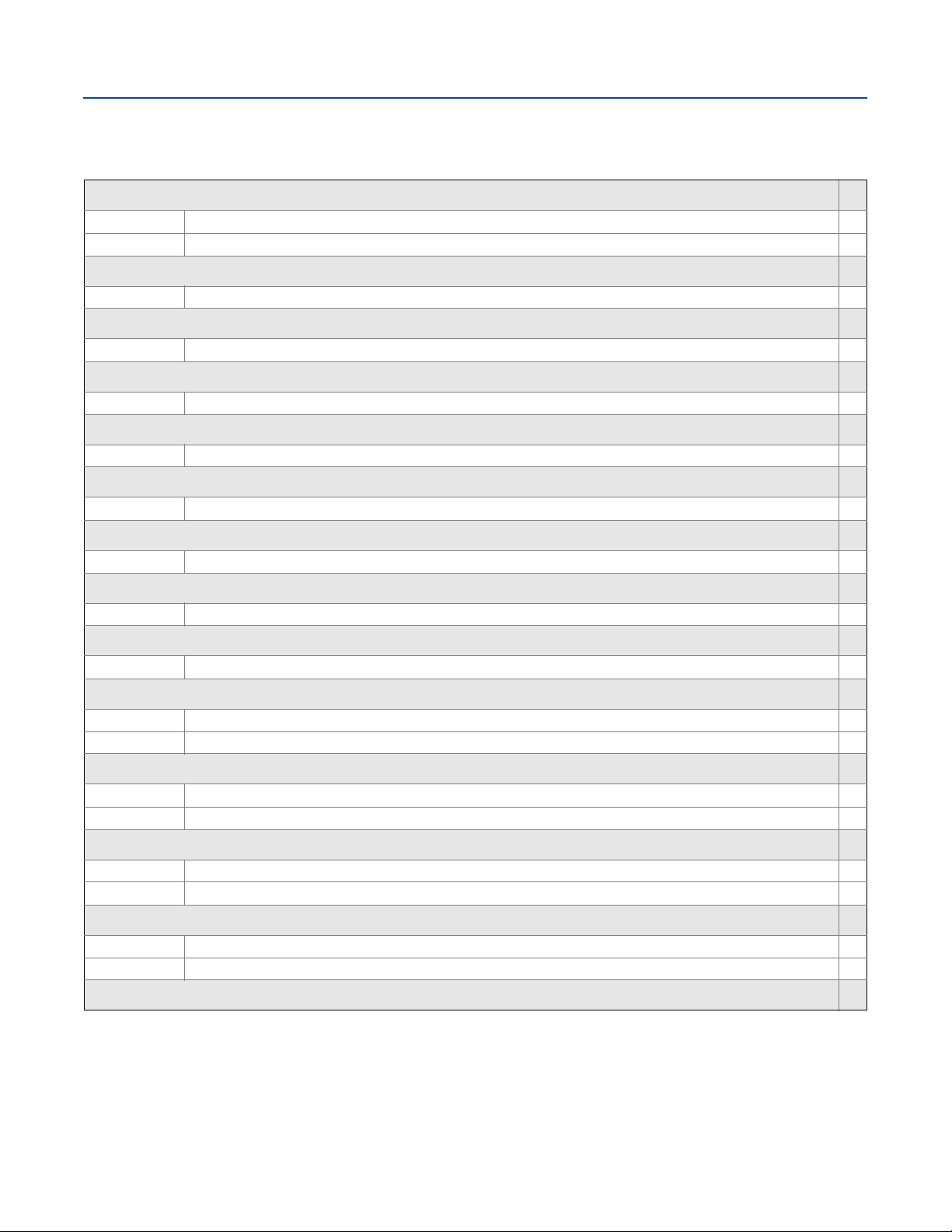

Instrument manifolds – quality, convenient, and easy

Designed and engineered for optimal performance with Rosemount transmitters

Save installation time and money with factory assembly

Offers a variety of styles, materials and configurations

Emerson.com/Rosemount

3

Page 4

Rosemount 3051

February 2017

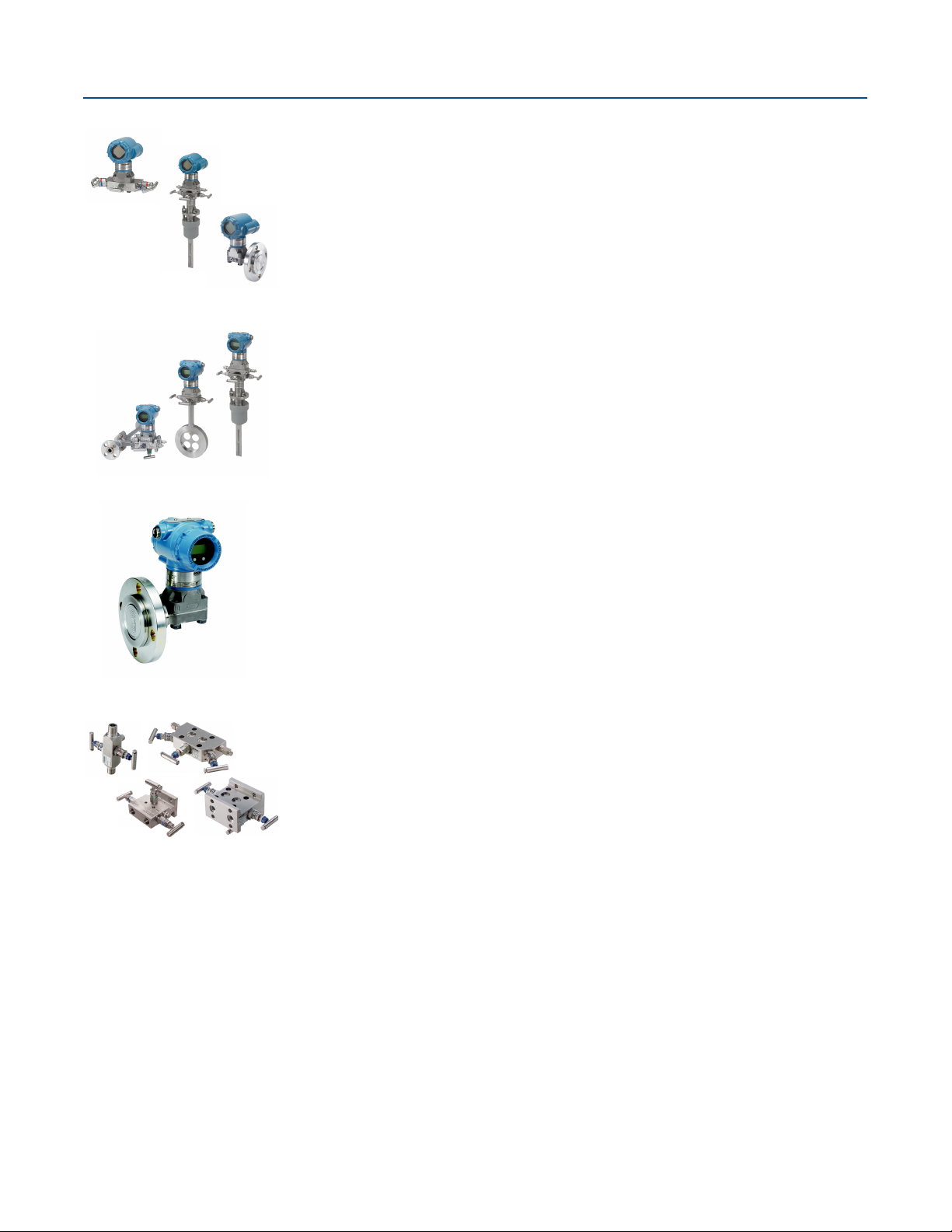

Rosemount 3051C Coplanar™ Pressure Transmitter

Rosemount 3051C Coplanar Pressure Transmitters are the industry standard for differential,

gage, and absolute pressure measurement. The coplanar platform enables seamless integration

with manifolds, flow and level solutions. Capabilities include:

Power advisory can proactively detect degraded electrical loop integrity issues

(option code DA0)

LOI with straightforward menus and built-in configuration buttons (option code M4)

Safety Certification (option code QT)

Additional information:

Specifications: page 44

Certifications: page 55

Dimensional drawings: page 65

See Specifications and options for more details on each configuration. Specification and selection of product materials, options, or

components must be made by the purchaser of the equipment. See page 53 for more information on Material Selection.

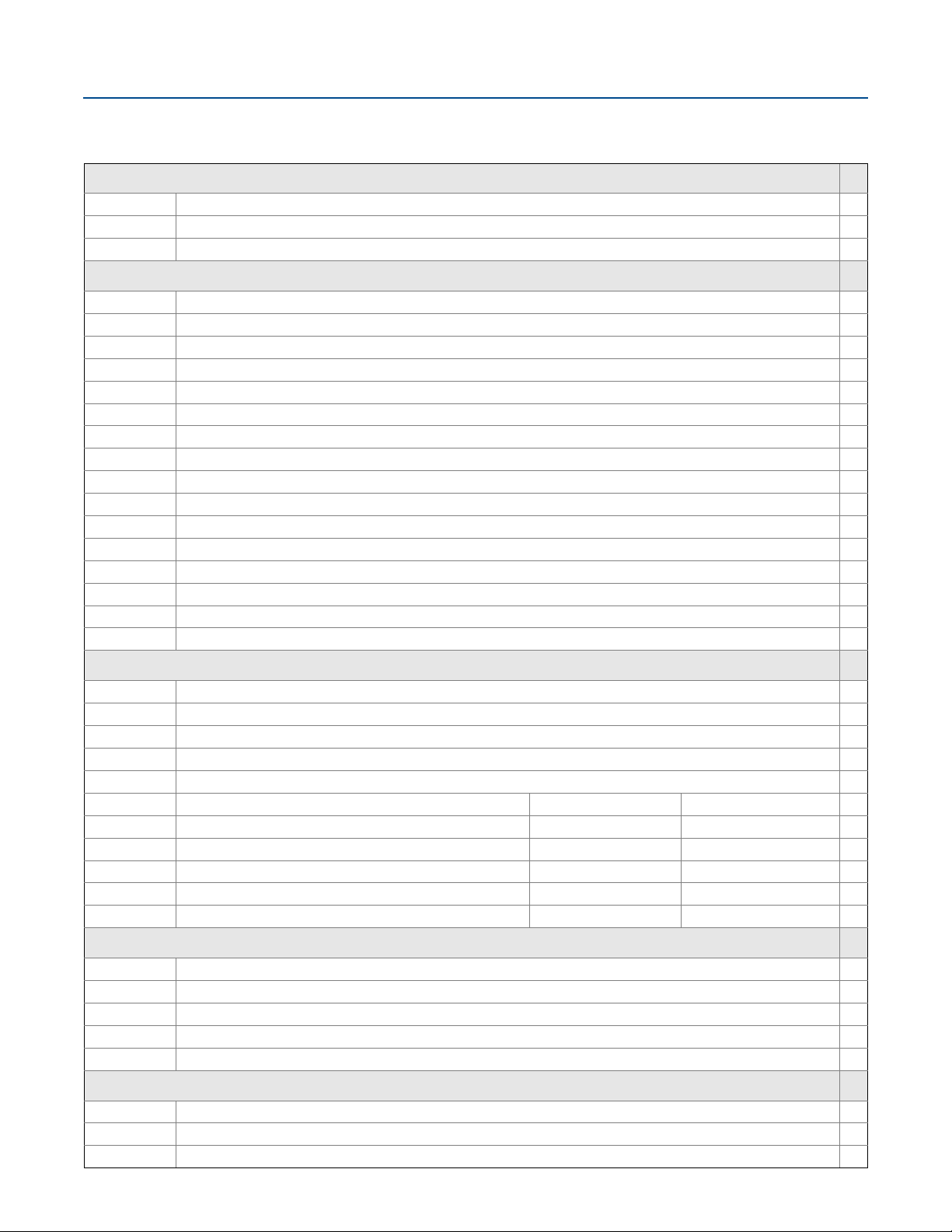

Table 1. Rosemount 3051C Coplanar Pressure Transmitters Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

(1)

Model

3051C Coplanar pressure transmitter

Transmitter type

Measurement type

D Differential ★

G Gage ★

(2)

A

Absolute

Pressure range

Differential (3051CD) Gage (3051CG) Absolute (3051CA)

1

2

3

4

5

(3)

0

–25 to 25 inH2O

(–62,16 to 62,16 mbar)

–250 to 250 inH2O

(–621,60 to 621,60 mbar)

–1000 to 1000 inH2O

(–2,48 to 2,48 bar)

–300 to 300 psi

(–20,68 to 20,68 bar)

–2000 to 2000 psi

(–137,89 to 137,89 bar)

–3 to 3 inH2O

(-7,46 to 7,46 mbar)

–25 to 25 inH2O

(–62,16 to 62,16 mbar)

–250 to 250 inH2O

(–621,60 to 621,60 mbar)

–393 to 1000 inH2O

(–0,97 to 2,48 bar)

–14.2 to 300 psi

(–0,97 to 20,68 bar)

–14.2 to 2000 psi

(–0,97 to 137,89 bar)

N/A N/A

0 to 30 psia

(0 to 2,06 bar)

0 to 150 psia

(0 to 10,34 bar)

0 to 800 psia

(0 to 55,15 bar)

0 to 4000 psia

(0 to 275,79 bar)

N/A ★

Transmitter output

(4)

A

F FOUNDATION™ Fieldbus Protocol ★

(5)

W

(6)

X

(7)

M

4–20 mA with Digital Signal Based on HART® Protocol ★

PROFIBUS® PA Protocol ★

Wireless (requires wireless options and engineered polymer housing) ★

Low-Power, 1–5 Vdc with Digital Signal Based on HART Protocol

★

★

★

★

4

Emerson.com/Rosemount

Page 5

February 2017

Rosemount 3051

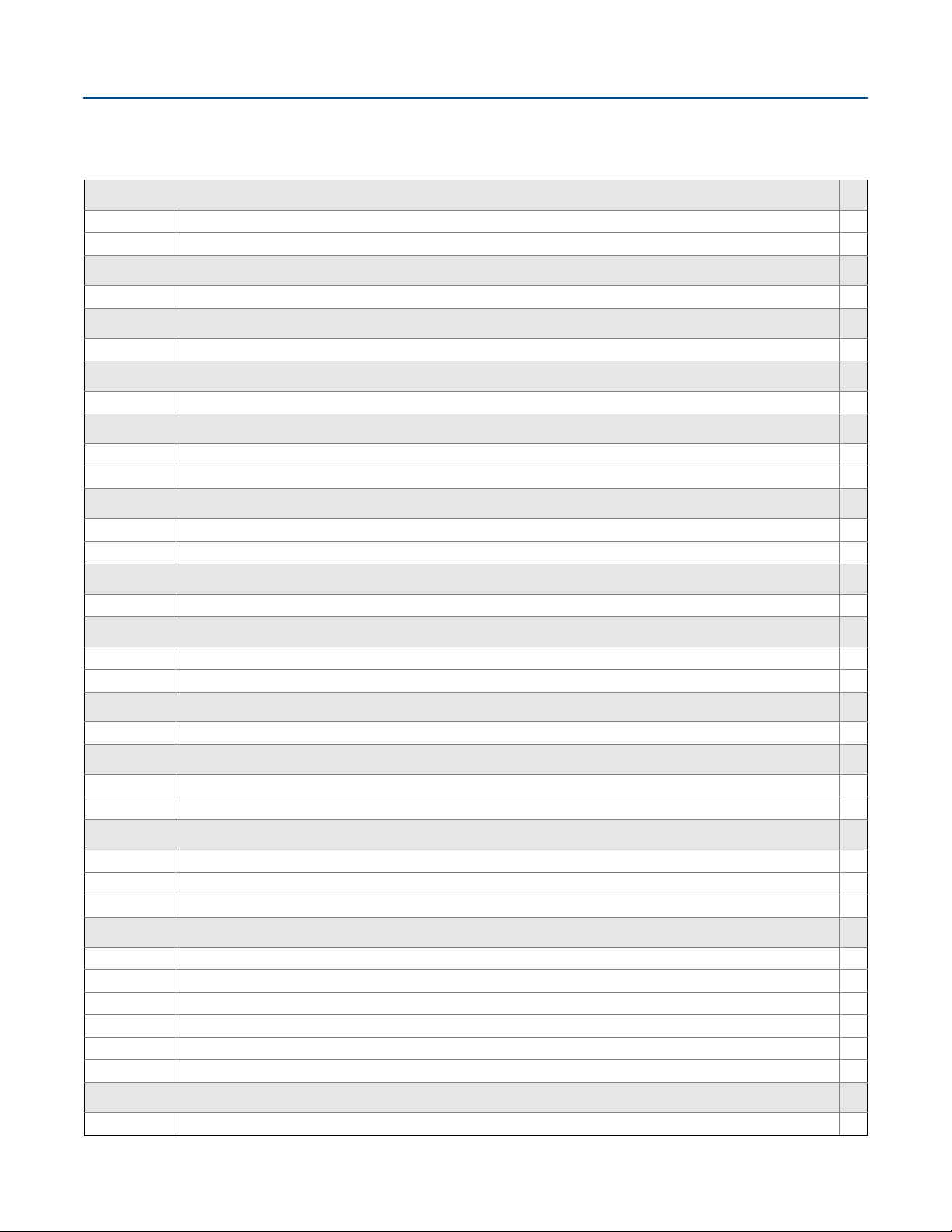

Table 1. Rosemount 3051C Coplanar Pressure Transmitters Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Materials of construction

Process flange type Flange material Drain/vent

2 Coplanar SST SST ★

(8)

3

Coplanar Cast C-276 Alloy C-276 ★

4 Coplanar Alloy 400 Alloy 400/K-500 ★

5 Coplanar Plated CS SST ★

(8)

7

(8)

8

Coplanar SST Alloy C-276 ★

Coplanar Plated CS Alloy C-276 ★

0 Alternate process connection ★

Isolating diaphragm

(8)

2

(8)

3

(9)

4

(9)

5

(9)

6

(9)

7

316L SST ★

Alloy C-276 ★

Alloy 400

Tantalum (available on Rosemount 3051CD and CG, ranges 2–5 only; not available on Rosemount 3051CA)

Gold-plated alloy 400 (use in combination with O-ring option code B)

Gold-plated 316 SST

O-ring

A Glass-filled PTFE ★

B Graphite-filled PTFE ★

Sensor fill fluid

1 Silicone ★

(9)

2

Inert (differential and gage only) ★

Housing material Conduit entry size

A Aluminum

B Aluminum M20 ⫻ 1.5 ★

J SST

K SST M20 ⫻ 1.5 ★

(10)

P

(11)

D

(11)

M

Engineered polymer No conduit entries ★

Aluminum G1/2

SST G1/2

1

/2–14 NPT ★

1

/2–14 NPT ★

Wireless options (requires wireless output code X and Engineered Polymer Housing Code P)

Wireless transmit rate, operating frequency, and protocol

WA3 User Configurable Transmit Rate, 2.4GHz WirelessHART ★

Antenna and SmartPower

WP5 Internal antenna, compatible with Green Power Module (I.S. Power Module sold separately) ★

™

Emerson.com/Rosemount

5

Page 6

Rosemount 3051

February 2017

Table 1. Rosemount 3051C Coplanar Pressure Transmitters Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Options (include with selected model number)

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

PlantWeb™ control functionality

A01 FOUNDATION Fieldbus control function block suite ★

PlantWeb diagnostic functionality

(13)

DA0

(12)

D01

Alternate flange

Power Advisory HART Diagnostic ★

FOUNDATION Fieldbus Diagnostics Suite ★

(14)

H2 Traditional flange, 316 SST, SST drain/vent ★

(8)

H3

Traditional flange, alloy C, alloy C-276 drain/vent ★

H4 Traditional flange, cast alloy 400, alloy 400/K-500 drain/vent ★

(8)

H7

Traditional flange, 316 SST, alloy C-276 drain/vent ★

HJ DIN-compliant traditional flange,SST,7/16-in. adapter/manifold bolting ★

FA Level flange, SST, 2-in., ANSI class 150, vertical mount 316 SST drain/vent ★

FB Level flange, SST, 2-in., ANSI Class 300, vertical mount 316 SST drain/vent ★

FC Level flange, SST, 3-in., ANSI Class 150, vertical mount 316 SST drain/vent ★

FD Level flange, SST, 3-in., ANSI Class 300, vertical mount 316 SST drain/vent ★

FP DIN level flange, SST, DN 50, PN 40, vertical mount 316 SST drain/vent ★

FQ DIN level flange, SST, DN 80, PN 40, vertical mount 316 SST drain/vent ★

(15)

HK

DIN compliant traditional flange, SST, 10 mm adapter/manifold bolting 316 SST

HL DIN compliant traditional flange, SST, 12 mm adapter/manifold bolting 316 SST

Manifold assembly

(16)

S5 Assemble to Rosemount 305 Integral Manifold ★

S6 Assemble to Rosemount 304 Manifold or Connection System ★

Integral mount primary element

S3 Assemble to Rosemount 405 Compact Orifice Plate ★

(17)

S4

Seal assemblies

(18)

S1

(19)

S2

Mounting bracket

B4 Coplanar flange bracket, all SST, 2-in. pipe and panel ★

B1 Traditional flange bracket, CS, 2-in. pipe ★

B2 Traditional flange bracket, CS, panel ★

B3 Traditional flange flat bracket, CS, 2-in. pipe ★

B7 Traditional flange bracket, B1 with SST bolts ★

B8 Traditional flange bracket, B2 with SST bolts ★

B9 Traditional flange bracket, B3 with SST bolts ★

Assemble to Rosemount Annubar™ or Rosemount 1195 Integral Orifice ★

(16)

Assemble to one Rosemount 1199 seal ★

Assemble to two Rosemount 1199 seals ★

(20)

(12)

(15)(16)

6

Emerson.com/Rosemount

Page 7

February 2017

Rosemount 3051

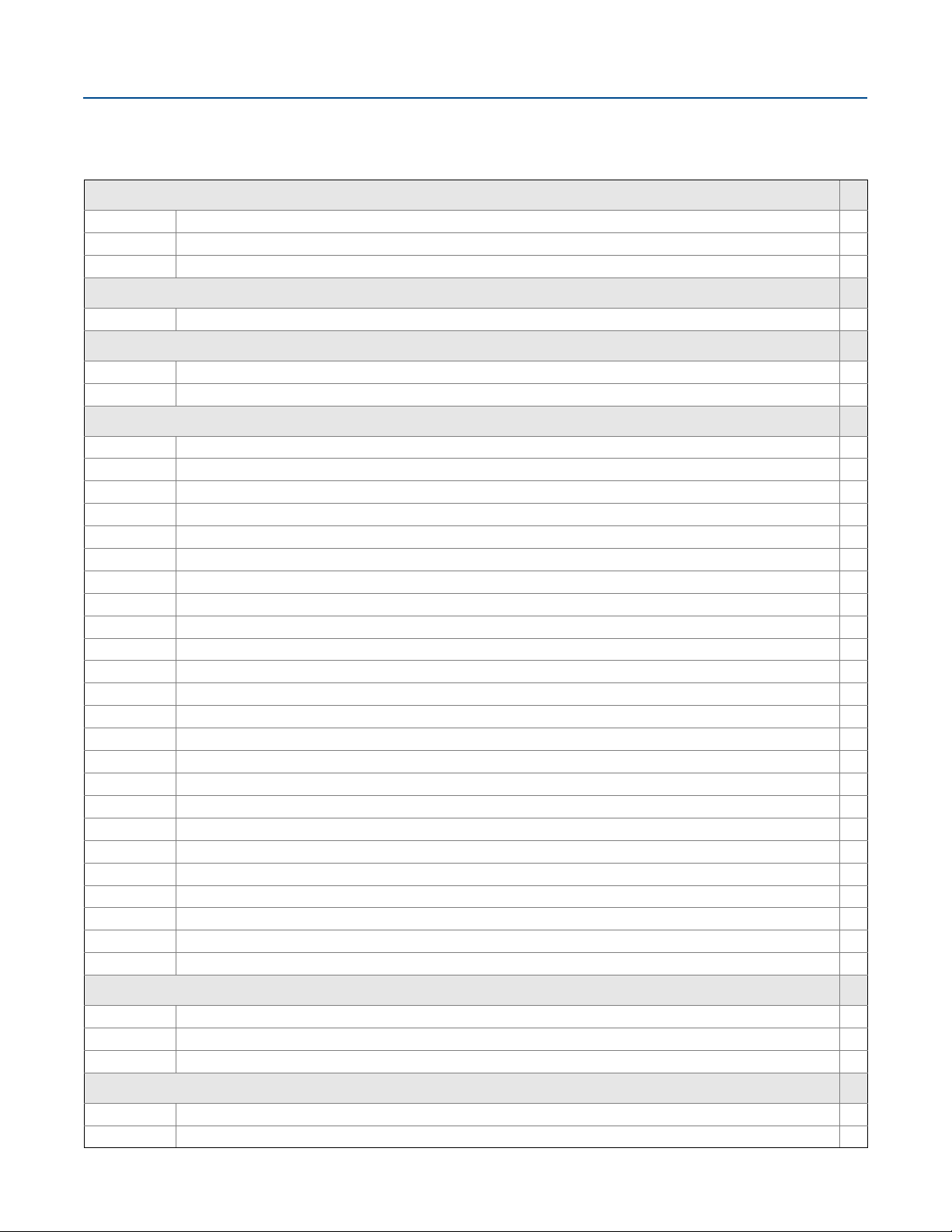

Table 1. Rosemount 3051C Coplanar Pressure Transmitters Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

BA Traditional flange bracket, B1, all SST ★

BC Traditional flange bracket, B3, all SST ★

Product certifications

E8 ATEX Flameproof and Dust Certification ★

(21)

I1

IA ATEX FISCO Intrinsic Safety; for FOUNDATION Fieldbus or PROFIBUS PA protocol only ★

N1 ATEX Type n Certification and Dust ★

K8 ATEX Flameproof, Intrinsic Safety, Type n, Dust (combination of E8, I1 and N1) ★

(22)

E4

E5 FM Explosion-proof, Dust Ignition-Proof ★

(23)

I5

IE FM FISCO Intrinsically Safe; for FOUNDATION Fieldbus or PROFIBUS PA protocol only ★

K5 FM Explosion-proof, Dust Ignition-Proof, Intrinsically Safe, and Division 2 ★

C6 CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 ★

(10)

I6

K6 CSA and ATEX Explosion-proof, Intrinsically Safe, and Division 2 (combination of C6, E8, and I1) ★

E7 IECEx Flameproof, Dust Ignition-proof ★

I7 IECEx Intrinsic Safety ★

N7 IECEx Type n Certification ★

K7 IECEx Flame-proof, Dust Ignition-proof, Intrinsic Safety, and Type n (combination of I7, N7, and E7) ★

E2 INMETRO Flameproof ★

I2 INMETRO Intrinsic Safety ★

IB INMETRO FISCO intrinsically safe; for FOUNDATION Fieldbus or PROFIBUS PA protocols only ★

K2 INMETRO Flameproof, Intrinsic Safety ★

E3 China Flameproof ★

I3 China Intrinsic Safety ★

N3 China Type n ★

EM Technical Regulations Customs Union (EAC) Flameproof ★

IM Technical Regulations Customs Union (EAC) Intrinsic Safety ★

KM Technical Regulations Customs Union (EAC) Flameproof and Intrinsic Safety ★

KB FM and CSA Explosion-proof, Dust Ignition Proof, Intrinsically Safe, and Division 2 (combination of K5 and C6) ★

KD FM, CSA, and ATEX Explosion-proof, Intrinsically Safe (combination of K5, C6, I1, and E8) ★

Drinking water approval

DW NSF drinking water approval ★

Shipboard approvals

SBS American Bureau of Shipping ★

(25)

SBV

SDN Det Norske Veritas ★

(25)

SLL

Custody transfer

C5

ATEX Intrinsic Safety and Dust ★

TIIS Flame-proof ★

FM Intrinsically Safe, Nonincendive ★

CSA Intrinsic Safety ★

(24)

(9)

Bureau Veritas (BV) ★

Lloyds Register (LR) ★

(13)

Measurement Canada Accuracy Approval (limited availability depending on transmitter type and range;

contact an Emerson representative)

★

Emerson.com/Rosemount

7

Page 8

Rosemount 3051

February 2017

Table 1. Rosemount 3051C Coplanar Pressure Transmitters Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Bolting material

L4 Austenitic 316 SST bolts ★

L5 ASTM A 193, grade B7M bolts ★

L6 Alloy K-500 bolts ★

Display and interface options

(26)

M4

LCD display with LOI ★

M5 LCD display ★

Calibration certificate

Q4 Calibration Certificate ★

(27)

QG

Calibration Certificate and GOST Verification Certificate ★

QP Calibration certification and tamper evident seal ★

Material traceability certification

Q8 Material Traceability Certification per EN 10204 3.1 ★

Quality certification for safety

QS Prior-use certificate of FMEDA data ★

QT Safety certified to IEC 61508 with certificate of FMEDA ★

(13)

Configuration buttons

(13)

D4

(28)

DZ

Transient protection

Analog zero and span ★

Digital zero trim ★

(9)(29)

T1 Transient protection terminal block ★

Software configuration

(28)

Custom Software Configuration

C1

(For wired, see the Rosemount 3051 Configuration Data Sheet

For wireless, see the Rosemount 3051 Wireless Configuration Data Sheet.

.

)

Low power output

C2 0.8–3.2 Vdc output with Digital Signal Based on HART Protocol (available with output code M only) ★

Gage pressure calibration

C3 Gage calibration (Rosemount 3051ca4 only) ★

Alarm levels

C4 Analog output levels compliant with NAMUR recommendation NE 43, alarm high ★

CN Analog output levels compliant with NAMUR recommendation NE 43, alarm low ★

CR

CS

CT Rosemount standard low alarm ★

(13)

Custom alarm and saturation signal levels, high alarm

(requires C1 and Rosemount 3051 Configuration Data Sheet

Custom alarm and saturation signal levels, low alarm

(requires C1 and Rosemount 3051 Configuration Data Sheet

)

)

★

★

★

Pressure testing

P1 Hydrostatic testing with certificate

8

Emerson.com/Rosemount

Page 9

February 2017

Rosemount 3051

Table 1. Rosemount 3051C Coplanar Pressure Transmitters Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Cleaning process area

P2 Cleaning for special service

P3 Cleaning for <1 PPM chlorine/fluorine

Flange adapters

DF

(30)

1

/2–14 NPT flange adapter(s) ★

Vent/drain valves

D7 Coplanar flange without drain/vent ports

Conduit plug

(9)(31)

DO 316 SST conduit plug ★

RC1/4 RC1/2 process connection

(32)

D9 RC 1/4 flange with RC 1/2 flange adapter - SST

Max static line pressure

P9 4500 psig (310,26 bar) static pressure limit (Rosemount 3051CD Ranges 2–5 only) ★

Ground screw

V5 External ground screw assembly ★

(9)(33)

Surface finish

Q16 Surface finish certification for sanitary remote seals ★

Toolkit total system performance reports

QZ Remote seal system performance calculation report ★

Conduit electrical connector

(9)

GE M12, 4-pin, male connector (eurofast®) ★

GM A size Mini, 4-pin, male connector (minifast®) ★

NACE certificate

(34)

Q15 Certificate of Compliance to NACE MR0175/ISO 15156 for wetted materials ★

Q25 Certificate of Compliance to NACE MR0103 for wetted materials ★

Cold temperature

BR5 –58 °F (–50 °C) cold temperature ★

BR6 –76 °F (–60 °C) cold temperature ★

HART Revision configuration (requires HART protocol output code A)

(4)

HR5 Configured for HART Revision 5 ★

HR7 Configured for HART Revision 7 ★

Typical model number: 3051CD 2 A 2 2 A 1 A B4

1. Select configuration buttons (option code D4 or DZ) or LOI (option code M4) if local configuration buttons are required.

2. If ordered with Wireless output code X, only range 1–4, 316L SST diaphragm material (code 2), silicone fill fluid (code 1) and wireless housing (code P) are available.

3. Rosemount 3051CD0 is only available with output code A and X. For output code A, only process flange code 0 (Alternate flange H2, H7, HJ or HK), isolating

diaphragm code 2, O ring code A and bolting option L4 are available. For output code X, only process flange code 0 (Alternate flange H2), isolating diaphragm code

2, O ring code A and bolting option L4 are available.

Emerson.com/Rosemount

9

Page 10

Rosemount 3051

4. O pti on HR 5 co nfig ure s the HAR T out put to HA RT Re vis ion 5 . Op tion HR7 conf igu res t he H ART outp ut to HAR T Rev isio n 7. The devi ce can be field configured to H ART

Revision 5 or 7 if desired. HART Revision 5 is the default HART output.

5. For local addressing and configuration, M4 (LOI) is required.

6. Available approvals are FM Intrinsically Safe, (option code I5), CSA Intrinsically Safe (option code I6) , ATE X Intrinsic Safety (option code I1), IECEx Intrinsic Safety

(option code I7) and EAC Intrinsic Safety (option code IM).

7. Only available with C6, E2, E5, I5, K5, KB and E8 product certifications. Not available with GE, GM, SBS, DA0, M4, D4, DZ, QT, HR5, HR7, CR, CS, CT.

8. Materials of Construction comply with recommendations per NACE MR0175/ISO 15156 for sour oil field production environments. Environmental limits apply to

certain materials. Consult latest standard for details. Selected materials also conform to NACE MR0103 for sour refining environments.

9. Not available with wireless output (code X).

10. Only available with wireless output (code X).

11. Not available with Product certifications options E8, K8, E5, K5, C6, K6, E7, K7, E2, K2, E3, KB, KD.

12. Only valid with F

13. Only available with HART 4–20 mA output (code A).

14. Requires 0 code in materials of construction for alternate process connection.

15. Not valid with option code P9 for 4500 psi Static Pressure.

16. “Assemble-to” items are specified separately and require a completed model number.

17. Process flange limited to coplanar (option codes 2, 3, 5, 7, 8) or traditional (option codes H2, H3, H7).

18. Not valid with option code D9 for RC

19. Not valid for option codes DF and D9 for adapters.

20. Panel mounting bolts are not supplied.

21. Dust approval not applicable to output code X. See “IEC 62591 (WirelessHART Protocol)” on page 61 for wireless approvals.

22. Only available with output codes A - 4–20mA HART, F - F

23. Nonincendive certification not provided with Wireless output option code (X).

24. Not available with Alloy C-276 isolator (code 3), tantalum isolator (code 5), all cast C-276 flanges, all plated CS flanges, all DIN flanges, all Level flanges, assemble-to

manifolds (codes S5 and S6), assemble-to seals (codes S1 and S2), assemble-to primary elements (codes S3 and S4), s urface finish certification (code Q16), and

remote seal system report (code QZ).

25. Only available with product certifications E7, E8, I1, I7, IA, K7, K8, KD, N1, N7

26. Not available with F

27. Contact an Emerson representative for availability.

28. Only available with HART 4–20 mA Output (output code A) and Wireless Output (output code X)

29. The T1 option is not needed with FISCO Product Certifications; transient protection is included in the FISCO product certification codes IA, IB, and IE.

30. Not valid with Alternate Process Connection options S3, S4, S5, and S6.

31. Transmitter is shipped with a 316 SST conduit plug (uninstalled) in place of standard carbon steel conduit plug.

32. Not available with alternate process connection; DIN flanges and level flanges.

33. The V5 option is not needed with the T1 option; external ground screw assembly is included with the T1 option.

34. NACE compliant wetted materials are identified by Footnote 8.

OUNDATION Fieldbus output code F.

1

/2 adapters.

OUNDATION Fieldbus, and W - PROFIBUS PA. Also only available with G

OUNDATION Fieldbus (output code F), wireless (output code X), or low power (output code M).

1

/2 housing thread types.

February 2017

10

Emerson.com/Rosemount

Page 11

February 2017

Rosemount 3051

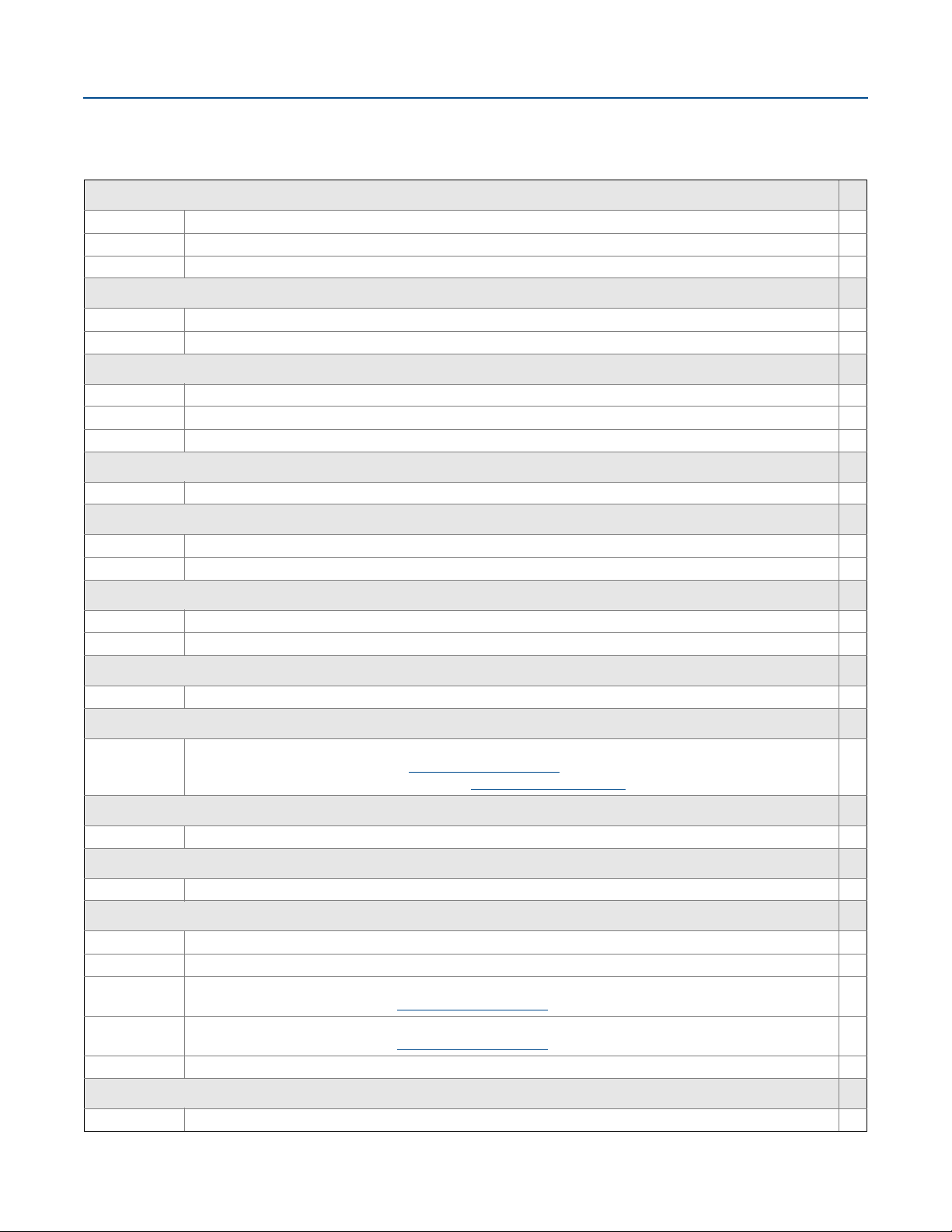

Rosemount 3051T In-Line Pressure Transmitter

Rosemount 3051T In-Line Pressure Transmitters are the industry standard for gage and

absolute pressure measurement. The in-line, compact design allows the transmitter to

be connected directly to a process for quick, easy and cost effective installation.

Capabilities include:

Power Advisory can proactively detect degraded electrical loop integrity issues

(option code DA0)

LOI with straightforward menus and built-in configuration buttons (option code M4)

Safety Certification (option code QT)

Additional information:

Specifications: page 44

Certifications: page 55

Dimensional drawings: page 65

See “Specifications” on page 44 and options for more details on each configuration. Specification and selection of product materials,

options, or components must be made by the purchaser of the equipment. See page 53 for more information on material selection.

Table 2. Rosemount 3051T In-Line Pressure Transmitter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

(1)

Model

Transmitter type

3051T In-line pressure transmitter

Pressure type

G Gage ★

(2)

A

Absolute ★

Pressure range

Gage (3051TG)

1 –14.7 to 30 psi (–1,01 to 2,06 bar) 0 to 30 psia (0 to 2,06 bar) ★

2 –14.7 to 150 psi (–1,01 to 10,34 bar) 0 to 150 psia (0 to 10,34 bar) ★

3 –14.7 to 800 psi (–1,01 to 55,15 bar) 0 to 800 psia (0 to 55,15 bar) ★

4 –14.7 to 4000 psi (–1,01 to 275,79 bar) 0 to 4000 psia (0 to 275,79 bar) ★

5 –14.7 to 10000 psi (–1,01 to 689,47 bar) 0 to 10000 psia (0 to 689,47 bar) ★

(4)

6

–14.7 to 20000 psi (–1,01 to 1378,95 bar) 0 to 20000 psia (0 to 1378,95 bar)

(3)

Absolute (3051TA)

Transmitter output

(5)

A

F FOUNDATION Fieldbus Protocol ★

(6)

W

(7)

X

(8)

M

4–20 mA with Digital Signal Based on HART Protocol ★

PROFIBUS PA Protocol ★

Wireless (requires wireless options and engineered polymer housing) ★

Low-power 1–5 Vdc with Digital Signal Based on HART Protocol

Process connection style

2B

2C

(9)

1

/2–14 NPT female (range 1–5 only) ★

G1/2 A DIN 16288 male (range 1–4 only) ★

Emerson.com/Rosemount

11

Page 12

Rosemount 3051

February 2017

Table 2. Rosemount 3051T In-Line Pressure Transmitter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

(10)

2F

(11)

61

Isolating diaphragm

Coned and threaded, compatible with autoclave Type F-250-C (range 5–6 only)

Non-threaded Instrument flange (range 1–4 only)

(12)

Process connection wetted parts material

2 316L SST 316L SST ★

3 Alloy C-276 Alloy C-276 ★

Sensor fill fluid

1 Silicone ★

(11)

2

Inert ★

Housing material Conduit entry size

A Aluminum

B Aluminum M20 ⫻ 1.5 ★

J SST

K SST M20 ⫻ 1.5 ★

(13)

P

(14)

D

(14)

M

Engineered polymer No conduit entries ★

Aluminum G½

SST G½

1

/2–14 NPT ★

1

/2–14 NPT ★

Wireless options (requires wireless output code X and engineered polymer housing code P)

Wireless transmit rate, operating frequency, and protocol

WA3 User Configurable Transmit Rate, 2.4GHz WirelessHART ★

Antenna and SmartPower

WP5 Internal antenna, compatible with Green Power Module (I.S. Power Module sold separately) ★

Options (include with selected model number)

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

PlantWeb control functionality

A01 FOUNDATION Fieldbus control function block suite ★

PlantWeb diagnostic functionality

(24)

DA0

(15)

D01

Integral assembly

Power Advisory HART diagnostic ★

FOUNDATION Fieldbus diagnostics suite ★

(16)

(15)

S5 Assemble to Rosemount 306 Integral Manifold ★

12

Emerson.com/Rosemount

Page 13

February 2017

Rosemount 3051

Table 2. Rosemount 3051T In-Line Pressure Transmitter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Diaphragm seal assemblies

(16)

S1 Assemble to one Rosemount 1199 seal ★

Mounting bracket

(17)

B4 Bracket for 2-in. pipe or panel mounting, all SST ★

Product certifications

E8 ATEX Flameproof and Dust Certification ★

(18)

I1

ATEX Intrinsic Safety and Dust ★

IA ATEX Intrinsic Safety for FISCO; for F

OUNDATION Fieldbus or PROFIBUS PA protocols only ★

N1 ATEX Type n Certification and Dust ★

K8 ATEX Flame-proof, Intrinsic Safety, Type n, Dust (combination of E8, I1 and N1) ★

(19)

E4

TIIS Flameproof ★

E5 FM Explosion-proof, Dust Ignition-proof ★

(20)

I5

FM Intrinsically Safe, Nonincendive ★

IE FM FISCO Intrinsically Safe; for FOUNDATION Fieldbus or PROFIBUS PA protocols only ★

K5 FM Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 ★

C6 CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 ★

(13)

I6

CSA Intrinsic Safety ★

K6 CSA and ATEX Explosion-proof, Intrinsically Safe, and Division 2 (combination of C6, E8, and I1) ★

E7 IECEx Flameproof, Dust Ignition-proof ★

I7 IECEx Intrinsic Safety ★

N7 IECEx Type n Certification ★

K7 IECEx Flameproof, Dust Ignition-proof, Intrinsic Safety, and Type n (combination of I7, N7, and E7) ★

E2 INMETRO Flameproof ★

I2 INMETRO Intrinsic Safety ★

IB INMETRO FISCO intrinsically safe; for FOUNDATION Fieldbus or PROFIBUS PA protocols only ★

K2 INMETRO Flameproof, Intrinsic Safety ★

E3 China Flameproof ★

I3 China Intrinsic Safety ★

N3 China Type n ★

EM Technical Regulations Customs Union (EAC) Flameproof ★

IM Technical Regulations Customs Union (EAC) Intrinsic Safety ★

KM Technical Regulations Customs Union (EAC) Flameproof and Intrinsic Safety ★

KB FM and CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 (combination of K5 and C6) ★

KD FM, CSA, and ATEX Explosion-proof, Intrinsically Safe (combination of K5, C6, I1, and E8) ★

Drinking water approval

(21)

DW NSF drinking water approval ★

Emerson.com/Rosemount

13

Page 14

Rosemount 3051

February 2017

Table 2. Rosemount 3051T In-Line Pressure Transmitter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Shipboard approvals

(11)

SBS American Bureau of Shipping ★

(22)

SBV

Bureau Veritas (BV) ★

SDN Det Norske Veritas ★

(22)

SLL

Lloyds Register (LR) ★

Custody transfer

C5

Measurement Canada Accuracy Approval

(limited availability depending on transmitter type and range. Contact an Emerson representative.)

★

Calibration certification

Q4 Calibration Certificate ★

(23)

QG

Calibration Certificate and GOST Verification Certificate ★

QP Calibration Certification and tamper evident seal ★

Material traceability certification

Q8 Material Traceability Certification per EN 10204 3.1 ★

Quality certification for safety

(24)

QS Prior-use certificate of FMEDA Data ★

QT Safety certified to IEC 61508 with certificate of FMEDA ★

Configuration buttons

(24)

D4

DZ

(25)

Analog zero and span ★

Digital zero trim ★

Display and interface options

(26)

M4

LCD display with LOI ★

M5 LCD display ★

Wireless SST sensor module

(13)

WSM Wireless SST sensor module ★

Conduit plug

(11)(27)

DO 316 SST conduit plug ★

Transient terminal block

(11)(28)

T1 Transient protection terminal block ★

Software configuration

(25)

Custom Software Configuration

C1

(For wired, see the Rosemount 3051 Configuration Data Sheet

For wireless, see the Rosemount 3051 Wireless Configuration Data Sheet.

.

)

Low power output

C2 0.8–3.2 Vdc output with digital signal based on HART Protocol (available with output code M only)

14

Emerson.com/Rosemount

★

Page 15

February 2017

Rosemount 3051

Table 2. Rosemount 3051T In-Line Pressure Transmitter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Alarm levels

(24)

C4 Analog output levels compliant with NAMUR recommendation NE 43, alarm high ★

CN Analog output levels compliant with NAMUR recommendation NE 43, low alarm ★

CR

CS

Custom alarm and saturation signal levels, high alarm

(requires C1 and Rosemount 3051 Configuration Data Sheet)

Custom alarm and saturation signal levels, low alarm

(requires C1 and Rosemount 3051 Configuration Data Sheet

★

)

★

CT Rosemount standard low alarm ★

Pressure testing

P1 Hydrostatic testing with certificate

Cleaning process area

(29)

P2 Cleaning for special service

P3 Cleaning for <1 PPM chlorine/fluorine

Ground screw

(11)(30)

V5 External ground screw assembly ★

Surface finish

Q16 Surface finish certification for sanitary remote seals ★

Toolkit total system performance reports

QZ Remote seal system performance calculation report ★

Conduit electrical connector

(11)

GE M12, 4-pin, male connector (eurofast) ★

GM A size mini, 4-pin, male connector (minifast) ★

NACE certificate

(31)

Q15 Certificate of Compliance to NACE MR0175/ISO15156 for wetted materials ★

Q25 Certificate of Compliance to NACE MR0103 for wetted materials ★

Cold temperature

BR5 –50 °F (–58 °C) cold temperature ★

BR6 –76 °F (–60 °C) cold temperature ★

HART Revision configuration (requires HART Protocol output code A)

(5)

HR5 Configured for HART Revision 5 ★

HR7 Configured for HART Revision 7 ★

Typical model number: 3051T G 5 F 2A 2 1 A B4

1. Select configuration buttons (option code D4 or DZ) or LOI (option code M4) if local configuration buttons are required.

2. Wireless output (code X) only available in absolute measurement type (code A) in range 1–5 with

(code P). Wireless output and range 6 is only available with coned and threaded process connection (code 2F) and polymer housing.

1

/2–14 NPT process connection (code 2B), and polymer housing

Emerson.com/Rosemount

15

Page 16

Rosemount 3051

3. Rosemount 3051TG lower range limit varies with atmospheric pressure.

4. Not available with PROFIBUS PA or Low Power 1–5 Vdc transmitter output (option code W or M), inert sensor fill fluid (option code 2), NSW drinking water approval

(option code DW), or assemble to manifolds (option code S5).

5. O pti on HR 5 co nfig ure s the HAR T out put to H ART Re vis ion 5. O ptio n HR 7 con figu res the HART out put t o HA RT Re visi on 7 . Th e dev ice can be field configured to HART

Revision 5 or 7 if desired. HART Revision 5 is the default HART output.

6. For local addressing and configuration, M4 (LOI) is required.

7. Requires wireless options and engineered polymer housing. Available approvals are FM Intrinsically Safe, (option code I5), CSA Intrinsically Safe (option code I6),

ATEX Intrinsic Safety (option code I1), IECEx Intrinsic Safety (option code I7), and EAC Intrinsic Safety (option code IM).

8. Only available with C6, E2, E5, I5, K5, KB and E8 product certifications. Not available with GE, GM, SBS, DA0, M4, D4, DZ, QT, HR5, HR7, CR, CS, CT.

9. Wireless output (code X) only available in G

fluid (code 1) and housing (code P).

10. Not available with wireless output for range 5.

11. Not available with wireless (output code X).

12. Materials of construction comply with recommendations per NACE MR0175/ISO 15156 for sour oil field production environments. Environmental limits apply to

certain materials. Consult latest standard for details. Selected materials also conform to NACE MR0103 for sour refining environments.

13. Only available with wireless (output code X).

14. Not available with Product certifications options E8, K8, E5, K5, C6, K6, E7, K7, E2, K2, E3, KB, KD.

15. Only valid with F

16. “Assemble-to” items are specified separately and require a completed model number.

17. Panel mounting bolts are not supplied.

18. Dust approval not applicable to output code X. See “IEC 62591 (WirelessHART Protocol)” on page 61 for wireless approvals.

19. Only available with output codes A - 4–20mA HART, F - F

20. Nonincendive certification not provided with wireless output option code (X).

21. Not available with Alloy C-276 isolator (option code 3), assemble-to manifolds (option code S5), assemble-to seals (option code S1), surface finish certification

(option code Q16), and remote seal system report (option code QZ).

22. Only available with product certifications E7, E8, I1, I7, IA, K7, K8, KD, N1, N7.

23. Contact an Emerson representative for availability.

24. Only available with HART 4–20 mA output code A.

25. Only available with HART 4–20 mA output code A and wireless output code X.

26. Not available with F

27. Transmitter is shipped with 316 SST conduit plug (uninstalled) in place of standard carbon steel conduit plug.

28. The T1 option is not needed with FISCO Product Certifications; transient protection is included in the FISCO product certification codes IA, IB, and IE.

29. Not valid with alternate process connection S5.

30. The V5 option is not needed with T1 option; external ground screw assembly is included with the T1 option.

31. NACE compliant wetted materials are identified by Footnote 11.

OUNDATION Fieldbus output code F.

OUNDATION Fieldbus (output code F) and wireless output code X) or low power (output code M).

1

/2 A DIN 16288 male process connection (code 2C) with range 1–4, 316 SST isolating diaphragm (code 2), silicone fill

OUNDATION Fieldbus, and W - PROFIBUS PA. Also only available with G

1

/2 housing thread types.

February 2017

16

Emerson.com/Rosemount

Page 17

February 2017

Rosemount 3051

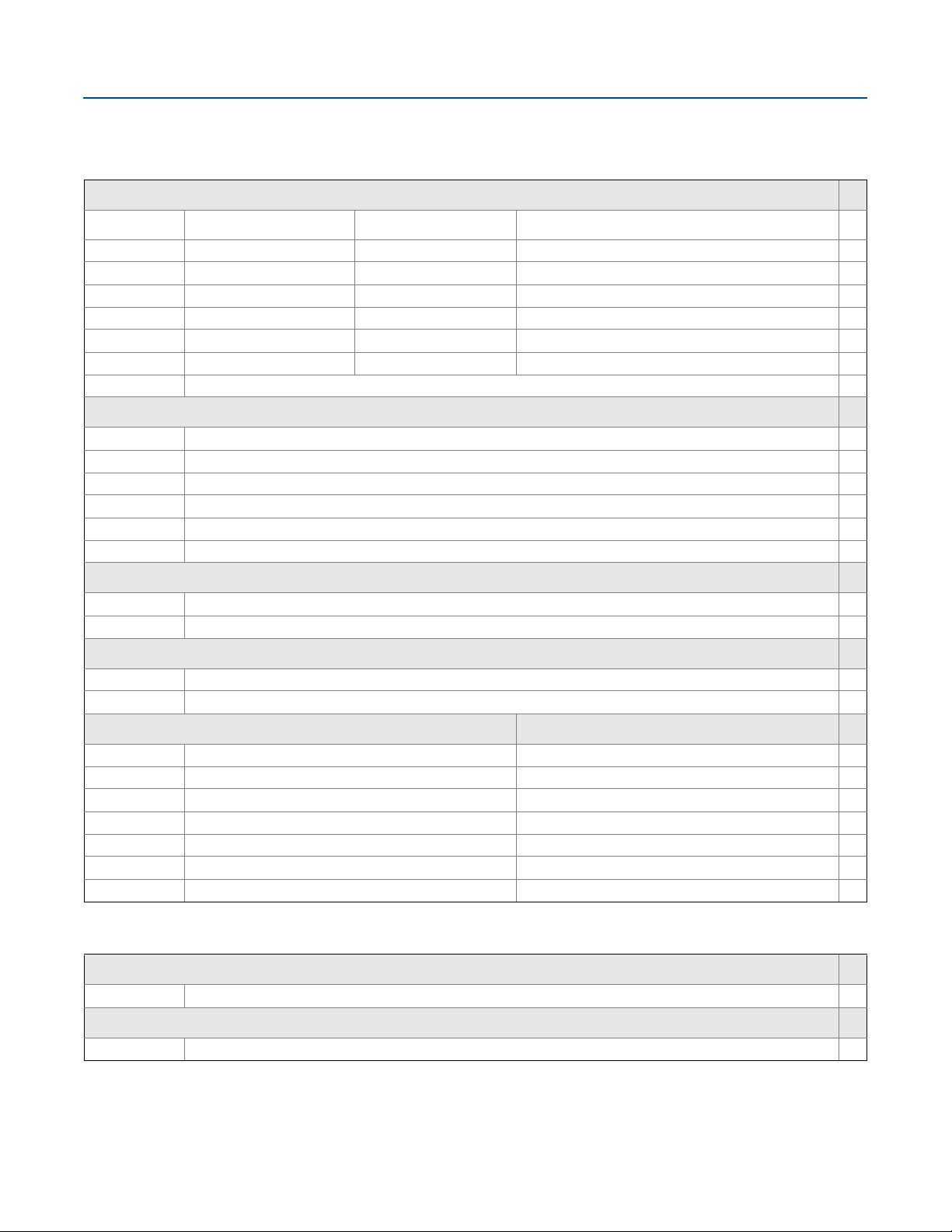

Rosemount 3051CF Flowmeter selection guide

Rosemount 3051CF Flowmeters combine the proven Rosemount 3051 Pressure Transmitter and the latest primary element

technologies. All flowmeters are fully assembled, calibrated, configured, and leak tested for out-of-the-box installation and are

available with wired or wireless capabilities to meet all of your application needs.

Rosemount 3051CFA Annubar Flowmeter

Rosemount Annubar technology minimizes permanent pressure loss

while delivering best in class accuracy.

Lowest material costs for large line sizes

Flo-tap enables installation without process shutdown

Realize up to 96 percent less permanent pressure loss compared to

traditional orifice plate installations

Rosemount 3051CFC Compact Conditioning Flowmeter

Rosemount Compact Conditioning technologies provide

unprecedented performance with minimal straight-run requirements.

Solutions include conditioning orifice plate or Rosemount Annubar

primary elements.

Conditioning Orifice requires only 2 pipe diameters upstream and

downstream

Eliminate swirl and regular profiles resulting in more stable and

accurate flow measurement

Savings up to 55 percent when compared to a traditional orifice plate

installation can be realized

Emerson.com/Rosemount

Rosemount 3051CFP Integral Orifice Flowmeter

Rosemount Integral Orifice Flowmeters deliver highly accurate

small-bore flow measurement capability with minimal installation and

maintenance requirements.

Best performance for small line sizes

(15 to 40 mm)

Precision honed pipe section and tight machining tolerances deliver

higher installed performance

Reduces uncertainty by up to five percent compared to traditional

orifice plate installation

1

/2- to 11/2-in.

17

Page 18

Rosemount 3051

February 2017

Rosemount 3051CFA Annubar Flowmeter

The Rosemount 3051CFA Annubar Flowmeter utilizes the T-shaped sensor design that

delivers best in class accuracy and performance while meeting the needs of diverse

process applications, whether it is high accuracy for precision control or high strength

for severe flow applications. Main capabilities include:

Up to 1.8 percent of flow rate accuracy

Available in 2 to 96-in. (50 to 2400 mm) line

Fully assembled and leak tested for out-of-the-box installation

Power Advisory can proactively detect degraded electrical loop integrity issues

(option code DA0)

LOI with straightforward menus and built-in configuration buttons (option code

M4)

Additional information:

Specifications: page 44

Certifications: page 55

Dimensional Drawings: page 65

See “Specifications” on page 44 and options for more details on each configuration. Specification and selection of product materials,

options, or components must be made by the purchaser of the equipment. See page 53 for more information on Material Selection.

Table 3. Rosemount 3051CFA Annubar Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

(1)

Model

3051CFA Rosemount Annubar Flowmeter

Product description

Measurement type

D Differential Pressure ★

Fluid type

L Liquid ★

G Gas ★

S Steam ★

Line size

020 2-in. (50 mm) ★

025 21/2-in. (63.5 mm) ★

030 3-in. (80 mm) ★

035 31/2-in. (89 mm) ★

040 4-in. (100 mm) ★

050 5-in. (125 mm) ★

060 6-in. (150 mm) ★

070 7-in. (175 mm) ★

080 8-in. (200 mm) ★

100 10-in. (250 mm) ★

120 12-in. (300 mm) ★

140 14-in. (350 mm)

160 16-in. (400 mm)

180 18-in. (450 mm)

200 20-in. (500 mm)

18

Emerson.com/Rosemount

Page 19

February 2017

Table 3. Rosemount 3051CFA Annubar Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

240 24-in. (600 mm)

300 30-in. (750 mm)

360 36-in. (900 mm)

420 42-in. (1066 mm)

480 48-in. (1210 mm)

600 60-in. (1520 mm)

720 72-in. (1820 mm)

780 78-in (1950 mm)

840 84-in. (2100 mm)

900 90-in. (2250 mm)

960 96-in (2400 mm)

Rosemount 3051

Pipe I.D. range

C Range C from the Pipe I.D. range codes table ★

D Range D from the Pipe I.D. range codes table ★

A Range A from the Pipe I.D. range codes table

B Range B from the Pipe I.D. range codes table

E Range E from the Pipe I.D. range codes table

Z Non-standard Pipe I.D. range codes or line sizes greater than 12 inches

Pipe material/mounting assembly material

C Carbon steel (A105) ★

S 316 stainless steel ★

0 No mounting (customer supplied) ★

G Chrome-moly grade F-11

N Chrome-moly grade F-22

J Chrome-moly grade F-91

Piping orientation

H Horizontal piping ★

D Vertical piping with downwards flow ★

U Vertical piping with upwards flow ★

Annubar type

P Pak-Lok ★

F Flanged with opposite side support ★

L Flange-Lok

G Gear-drive Flo-Tap

M Manual Flo-Tap

Sensor material

S 316 stainless steel ★

H Alloy C-276

Emerson.com/Rosemount

19

Page 20

Rosemount 3051

February 2017

Table 3. Rosemount 3051CFA Annubar Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Sensor size

1 Sensor size 1 — line sizes 2- to 8-in. (50 to 200 mm) ★

2 Sensor size 2 — line sizes 6- to 96-in. (150 to 2400 mm) ★

3 Sensor size 3 — line sizes greater than 12-in. (300 mm) ★

Mounting type

T1 Compression or threaded connection ★

A1 Class 150 RF ANSI ★

A3 Class 300 RF ANSI ★

A6 Class 600RF ANSI ★

D1 DN PN16 flange ★

D3 DN PN40 flange ★

D6 DN PN100 flange ★

(2)

A9

(2)

AF

(2)

AT

R1 Class 150 RTJ flange

R3 Class 300 RTJ flange

R6 Class 600RTJ flange

(2)

R9

(2)

RF

(2)

RT

Class 900 RF ANSI

Class 1500 RF ANSI

Class 2500 RF ANSI

Class 900 RTJ flange

Class 1500 RTJ flange

Class 2500 RTJ flange

Opposite side support or packing gland

0 No opposite side support or packing gland (required for Pak-Lok and Flange-Lok models) ★

Opposite side support – required for flanged models

C NPT threaded opposite support assembly – extended tip ★

D Welded opposite support assembly – extended tip ★

Packing gland – required for Flo-Tap models

Packing Gland Material Rod material Packing material

(3)

J

(3)

K

(3)

L

(3)

N

Stainless steel packing gland/cage nipple Carbon steel PTFE

Stainless steel packing gland/cage nipple Stainless steel PTFE

Stainless steel packing gland/cage nipple Carbon steel Graphite

Stainless steel packing gland/cage nipple Stainless steel Graphite

R Alloy C-276 packing gland/cage nipple Stainless steel Graphite

Isolation valve for Flo-Tap models

0 Not applicable or customer supplied ★

1 Gate valve, carbon steel

2 Gate valve, stainless steel

5 Ball valve, carbon steel

6 Ball valve, stainless steel

Temperature measurement

T Integral RTD – not available with Flanged model greater than Class 600 ★

0 No Temperature Sensor ★

R Remote Thermowell and RTD

20

Emerson.com/Rosemount

Page 21

February 2017

Rosemount 3051

Table 3. Rosemount 3051CFA Annubar Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Transmitter connection platform

3 Direct-mount, Integral 3-valve Manifold– not available with Flanged model greater than Class 600 ★

5 Direct -mount, 5-valve Manifold – not available with Flanged model greater than Class 600 ★

7 Remote-mount NPT Connections (1/2-in. NPT) ★

6 Direct-mount, high temperature 5-valve Manifold – not available with Flanged model greater than Class 600

8 Remote-mount SW Connections (1/2-in.)

Differential pressure range

1 0 to 25 in H2O (0 to 62,16 mbar) ★

2 0 to 250 in H2O (0 to 621,60 mbar) ★

3 0 to 1000 in H2O (0 to 2,48 bar) ★

Transmitter output

(4)

A

F FOUNDATION Fieldbus Protocol ★

(5)

W

(6)

X

(7)

M

4–20 mA with digital signal based on HART Protocol ★

PROFIBUS PA Protocol ★

Wireless (requires wireless options and engineered polymer housing) ★

Low-power 1–5 Vdc with digital signal based on HART Protocol

Transmitter housing material Conduit entry size

A Aluminum

B Aluminum M20 ⫻ 1.5 ★

J SST

K SST M20 ⫻ 1.5 ★

(8)

P

(9)

D

(9)

M

Engineered polymer No conduit entries ★

Aluminum G1/2

SST G1/2

1

/2–14 NPT ★

1

/2–14 NPT ★

Transmitter performance class

1 1.8 percetn flow rate accuracy, 8:1 flow turndown, 5-yr. stability ★

Wireless options (requires wireless output code X and Engineered Polymer Housing Code P)

Wireless transmit rate, operating frequency, and protocol

WA3 User configurable transmit rate, 2.4GHz WirelessHART ★

Antenna and SmartPower

WP5 Internal antenna, compatible with Green Power Module (I.S. Power Module sold separately) ★

Options (include with selected model number)

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

Pressure testing

P1 Hydrostatic testing with certificate

PX Extended hydrostatic testing

(10)

Emerson.com/Rosemount

21

Page 22

Rosemount 3051

Table 3. Rosemount 3051CFA Annubar Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

February 2017

Special cleaning

P2 Cleaning for special services

PA Cleaning per ASTM G93 Level D (section 11.4)

Material testing

V1 Dye penetrant exam

Material examination

V2 Radiographic Examination

Flow calibration

W1 Flow calibration (Average K)

Special inspection

QC1 Visual and dimensional inspection with certificate ★

QC7 Inspection & performance certificate ★

Surface finish

RL Surface finish for low pipe Reynolds number in gas and steam ★

RH Surface finish for high pipe Reynolds number in liquid ★

Material traceability certification

Q8 Material Traceability Certification per EN 10474:2004 3.1 ★

Code conformance

J2 ANSI/ASME B31.1

J3 ANSI/ASME B31.3

Materials conformance

J5 NACE MR-0175 / ISO 15156

(12)

(13)

(11)

Country certification

J6 European Pressure Directive (PED) ★

J1 Canadian Registration

Installed in flanged pipe spool section

H3 Class 150 flanged connection with Rosemount standard length and schedule

H4 Class 300 flanged connection with Rosemount standard length and schedule

H5 Class 600 flanged connection with Rosemount standard length and schedule

Instrument connections for remote mount options

G2 Needle valves, stainless steel ★

G6 OS&Y gate valve, stainless steel ★

G1 Needle valves, carbon steel

G3 Needle valves, alloy C-276

G5 OS&Y gate valve, carbon steel

G7 OS&Y gate valve, alloy C-276

Special shipment

Y1 Mounting hardware shipped separately ★

22

Emerson.com/Rosemount

Page 23

February 2017

Rosemount 3051

Table 3. Rosemount 3051CFA Annubar Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Special dimensions

VM Variable mounting

VT Variable tip

VS Variable length spool section

PlantWeb control functionality

(14)

A01 FOUNDATION Fieldbus control function block suite ★

PlantWeb diagnostic functionality

(15)

DA0

D01

(14)

Power Advisory HART diagnostic ★

FOUNDATION Fieldbus diagnostics suite ★

Product certifications

E8 ATE X Flam epro of, Dust ★

(16)

I1

IA ATEX FISCO Intrinsic Safety; for FOUNDATION Fieldbus or PROFIBUS PA protocols only ★

N1 ATEX Type n and Dust ★

K8 ATEX Flameproof, Intrinsic Safety, Type n, Dust (combination of E8, I1 and N1) ★

E5 FM Explosion-proof, Dust Ignition-proof ★

(17)

I5

IE FM FISCO Intrinsically Safe; for FOUNDATION Fieldbus or PROFIBUS PA protocols only ★

K5 FM Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 (combination of E5 and I5) ★

C6 CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 ★

(8)

I6

K6 CSA and ATEX Explosion-proof, Intrinsically Safe, and Division 2 (combination of C6, E8, and I1) ★

E7 IECEx Flameproof, Dust Ignition-proof ★

I7 IECEx Intrinsic Safety ★

N7 IECEx Type n ★

K7 IECEx Flameproof, Dust Ignition-proof, Intrinsic Safety, and Type n (combination of I7, N7 and E7) ★

E2 INMETRO Flameproof ★

I2 INMETRO Intrinsic Safety ★

IB INMETRO FISCO intrinsically safe; for FOUNDATION Fieldbus or PROFIBUS PA protocols only ★

K2 INMETRO Flameproof, Intrinsic Safety ★

E3 China Flameproof ★

I3 China Intrinsic Safety ★

KB FM and CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 (combination of K5 and C6) ★

KD CSA, FM, and ATEX Explosion-proof, Intrinsically Safe (combination of K5, C6, I1, and E8) ★

ATEX Intrinsic Safety and Dust ★

FM Intrinsically Safe, Nonincendive ★

CSA Intrinsically Safe ★

Sensor fill fluid and O-ring options

(18)

L1

Inert sensor fill fluid (silicone fill fluid is standard) ★

L2 Graphite-filled (PTFE) O-ring ★

(18)

LA

Shipboard approvals

Inert sensor fill fluid and graphite-filled (PTFE) O-ring ★

(18)

SBS American Bureau of Shipping ★

(19)

SLL

Lloyds Register (LR)

Emerson.com/Rosemount

23

Page 24

Rosemount 3051

February 2017

Table 3. Rosemount 3051CFA Annubar Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Display and interface options

(20)

M4

LCD display with LOI ★

M5 LCD display ★

Transmitter calibration certification

Q4 Calibration certificate for transmitter ★

Quality certification for safety

(15)

QS Prior-use certificate of FMEDA data ★

QT Safety certified to IEC 61508 with certificate of FMEDA ★

Transient protection

(18)(21)

T1 Transient terminal block ★

Manifold for remote mount option

F2 3-valve manifold, stainless steel ★

F6 5-valve manifold, stainless steel ★

F1 3-valve manifold, carbon steel

F3 3-valve manifold, alloy C-276

F5 5-valve manifold, carbon steel

F7 5-valve manifold, alloy C-276

Lower power output

C2 0.8–3.2 Vdc output with digital signal based on HART Protocol (available with output code M only)

Alarm levels

(15)

C4 NAMUR alarm and saturation levels, high alarm ★

CN NAMUR alarm and saturation levels, low alarm ★

CR Custom alarm and saturation signal levels, high alarm ★

CS Custom alarm and saturation signal levels, low alarm ★

CT Rosemount standard low alarm ★

Configuration buttons

(15)

D4

(22)

DZ

Ground screw

Analog zero and span ★

Digital zero trim ★

(18)(23)

V5 External ground screw assembly ★

HART Revision configuration (requires HART Protocol output code A)

(4)

HR5 Configured for HART Revision 5 ★

HR7 Configured for HART Revision 7 ★

Typical model number: 3051CFA D L 060 D C H P S 2 T1 0 0 0 3 2 A A 1

1. Select configuration buttons (option code D4 or DZ) or LOI (option code M4) if local configuration buttons are required.

2. Available in remote mount applications only.

3. The cage nipple is constructed of Rosemount 304 SST.

4. O pti on HR 5 co nfig ure s the HAR T out put to HA RT Re vis ion 5. Op tio n HR7 con figu res the H ART outp ut t o HA RT Rev isi on 7 . The dev ice can be field configured to HART

Revision 5 or 7 if desired. HART Revision 5 is the default HART output.

24

Emerson.com/Rosemount

Page 25

February 2017

5. For local addressing and configuration, M4 (LOI) is required.

6. Requires wireless options and engineered polymer housing. Available approvals are FM Intrinsically Safe, (option code I5), CSA Intrinsically Safe (option code I6),

ATEX Intrinsic Safety (option code I1), and IECEx Intrinsic Safety (option code I7).

7. Only available with C6, E2, E5, I5, K5, KB and E8 approval. Not available with GE, GM, SBS, DA0, M4, D4, DZ, QT, HR5, HR7, CR, CS, CT.

8. Only available with wireless (output code X).

9. Not available with Product certifications options E8, K8, E5, K5, C6, K6, E7, K7, E2, K2, E3, KB, KD.

10. Applies to assembled flowmeter only, mounting not tested.

11. Instrument connections for remote mount options and isolation valves for Flo-tap models are not included in the Material Traceability Certification.

12. Not available with transmitter connection platform 6.

13. Materials of Construction comply with metallurgical requirements within NACE MR0175/ISO for sour oil field production environments. Environmental limits apply

to certain materials. Consult latest standard for details. Selected materials also conform to NACE MR0103 for sour refining environments.

14. Only valid with F

15. Only available with 4–20 mA HART (output code A).

16. Dust approval not applicable to output code X. See “IEC 62591 (WirelessHART Protocol)” on page 61 for wireless approvals

17. Nonincendive certification not provided with wireless output code (X).

18. Not available with wireless output code X.

19. Only available with Product certifications E7, E8, I1, I7, IA, K7, K8, KD, N1, N7

20. Not available with F

21. The T1 option is not needed with FISCO Product Certifications, transient protection is included with the FISCO Product Certification codes IA, IB, and IE.

22. Only available with 4–20 mA HART (output code A) and Wireless (output code X).

23. The V5 option is not needed with the T1 option; external ground screw assembly is included with the T1 option.

OUNDATION Fieldbus output code F.

OUNDATION Fieldbus (output code F) or Wireless (output code X) or low power (output code M).

Rosemount 3051

Emerson.com/Rosemount

25

Page 26

Rosemount 3051

February 2017

Rosemount 3051CFC Compact Flowmeter

Rosemount 3051CFC Compact Flowmeters provide a quick, reliable installation

between existing raised face flanges. Depending on your application needs, you can

reduce energy loss with the Compact Annubar or minimize straight run requirements

with the Conditioning Orifice.

Up to 1.8 percent of flow rate accuracy

Available in

Fully assembled and leak tested for out-of-the-box installation

Power Advisory can proactively detect degraded electrical loop integrity issues.

(option code DA0)

LOI with straightforward menus and built-in configuration buttons

(option code M4)

Additional information:

Specifications: page 44

Certifications: page 55

Dimensional drawings: page 65

See “Specifications” on page 44 and options for more details on each configuration. Specification and selection of product materials,

options, or components must be made by the purchaser of the equipment. See page 53 for more information on Material Selection.

1

/2 to 12-in. (15 to 300 mm) line sizes

Table 4. Rosemount 3051CFC Compact Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

(1)

Model

Product description

3051CFC Compact Flowmeter

Measurement type

D Differential Pressure ★

Primary element technology

A Annubar averaging pitot tube ★

C Conditioning orifice plate ★

P Orifice plate ★

Material type

S 316 SST ★

Line size

(2)

005

(2)

010

(2)

015

020 2-in. (50 mm) ★

030 3-in. (80 mm) ★

040 4-in. (100 mm) ★

060 6-in. (150 mm) ★

080 8-in. (200 mm) ★

(3)

100

(3)

120

1

/2-in. (15 mm) ★

1-in. (25 mm) ★

11/2-in. (40 mm) ★

10-in. (250 mm) ★

12-in. (300 mm) ★

Primary element type

N000 Rosemount Annubar sensor size 1 ★

N040 0.40 beta ratio ★

N050 0.50 beta ratio

(4)

N065

26

0.65 beta ratio ★

Emerson.com/Rosemount

Page 27

February 2017

Rosemount 3051

Table 4. Rosemount 3051CFC Compact Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Temperature measurement

0 No temperature sensor ★

R Remote thermowell and RTD

Transmitter connection platform

3 Direct-mount ★

7 Remote-mount, NPT connections ★

Differential pressure range

1 0 to 25 inH2O (0 to 62,16 mbar) ★

2 0 to 250 inH2O (0 to 621,60 mbar) ★

3 0 to 1000 inH2O (0 to 2,48 bar) ★

Transmitter output

(5)

A

4–20 mA with digital signal based on HART Protocol ★

F FOUNDATION Fieldbus Protocol ★

(6)

W

X

M

(7)

(8)

PROFIBUS PA Protocol ★

Wireless (requires wireless options and engineered polymer housing) ★

Low-power 1-5 Vdc with Digital Signal Based on HART Protocol

Transmitter housing material Conduit entry size

A Aluminum

B Aluminum M20 ⫻ 1.5 ★

J SST

K SST M20 ⫻ 1.5 ★

(9)

P

(10)

D

(10)

M

Engineered polymer No conduit entries ★

Aluminum G1/2

SST G1/2

1

/2–14 NPT ★

1

/2–14 NPT ★

Transmitter performa nce class

1 Up to ±1.65% flow rate accuracy, 8:1 flow turndown, 5-year stability ★

Wireless options (requires wireless output code X and Engineered Polymer Housing code P)

Wireless transmit rate, operating frequency, and protocol

WA3 User configurable transmit rate, 2.4GHz WirelessHART ★

Antenna and SmartPower

WP5 Internal antenna, compatible with Green Power Module (I.S. Power Module sold separately) ★

Options (include with selected model number)

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

Installation accessories

AB ANSI alignment ring (Class 150) (only required for 10-in. (250 mm) and 12-in. (300mm) line sizes) ★

AC ANSI alignment ring (Class 300) (only required for 10-in. (250 mm) and 12-in. (300mm) line sizes) ★

AD ANSI alignment ring (Class 600) (only required for 10-in. (250 mm) and 12-in. (300mm) line sizes) ★

DG DIN alignment ring (PN16) ★

DH DIN alignment ring (PN40) ★

DJ DIN alignment ring (PN100) ★

Emerson.com/Rosemount

27

Page 28

Rosemount 3051

February 2017

Table 4. Rosemount 3051CFC Compact Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

JB JIS alignment ring (10K)

JR JIS alignment ring (20K)

JS JIS alignment ring (40K)

Remote adapters

FE Flange adapters 316 SST (1/2-in NPT) ★

High temperature application

HT Graphite valve packing (T

Flow calibration

(11)

WC Flow calibration, 3 pt, conditioning orifice option C (all pipe schedules)

(12)

WD

Flow calibration, 10 pt, conditioning option C (all schedules), Annubar option A (schedule 40)

= 850 °F)

max

Pressure testing

P1 Hydrostatic testing with certificate

Special cleaning

(13)

P2

Cleaning for special services

PA Cleaning per ASTM G93 level D (section 11.4)

Special inspection

QC1 Visual & dimensional inspection with certificate ★

QC7 Inspection and performance certificate ★

Transmitter calibration certification

Q4 Calibration certificate for transmitter ★

Quality certification for safety

(14)

QS Prior-use certificate of FMEDA data ★

QT Safety certified to IEC 61508 with certificate of FMEDA ★

Material traceability certification

Q8 Material Traceability Certification per EN 10204:2004 3.1 ★

Code conformance

J2 ANSI/ASME B31.1

J3 ANSI/ASME B31.3

J4 ANSI/ASME B31.8

Materials conformance

(15)

J5 NACE MR-0175/ISO 15156

Country certification

J1 Canadian Registration

Product certifications

E8 ATEX Flameproof, Dus t ★

(16)

I1

IA ATEX FISCO Intrinsic Safety; for FOUNDATION Fieldbus or PROFIBUS PA protocols only ★

N1 ATEX Type n and Dust ★

K8 ATEX Flameproof, Intrinsic Safety, Type n, Dust (combination of E8, I1 and N1) ★

E5 FM Explosion-proof, Dust Ignition-proof ★

(17)

I5

ATEX Intrinsic Safety and Dust ★

FM Intrinsically Safe, Nonincendive ★

28

Emerson.com/Rosemount

Page 29

February 2017

Rosemount 3051

Table 4. Rosemount 3051CFC Compact Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

IE FM FISCO Intrinsically Safe; for FOUNDATION Fieldbus or PROFIBUS PA protocols only ★

K5 FM Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 (combination of E5 and I5) ★

C6 CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 ★

(9)

I6

CSA Intrinsically Safe ★

K6 CSA and ATEX Explosion-proof, Intrinsically Safe, and Division 2 (combination of C6, E8, and I1) ★

E7 IECEx Flameproof, Dust Ignition-proof ★

I7 IECEx Intrinsic Safety ★

N7 IECEx Type n ★

K7 IECEx Flameproof, Dust Ignition-proof, Intrinsic Safety, and Type n (combination of I7, N7 and E7) ★

E2 INMETRO Flameproof ★

I2 INMETRO Intrinsic Safety ★

IB INMETRO FISCO intrinsically safe; for FOUNDATION Fieldbus or PROFIBUS PA protocols only ★

K2 INMETRO Flameproof, Intrinsic Safety ★

E3 China Flameproof ★

I3 China Intrinsic Safety ★

KB FM and CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, and Division 2 (combination of K5 and C6) ★

KD CSA, FM, and ATEX Explosion-proof, Intrinsically Safe (combination of K5, C6, I1, and E8) ★

Sensor fill fluid and O-ring options

(18)

L1

Inert sensor fill fluid ★

L2 Graphite-filled (PTFE) O-ring ★

(18)

LA

Shipboard approvals

Inert sensor fill fluid and graphite-filled (PTFE) O-ring ★

(18)

SBS American Bureau of Shipping ★

(19)

SLL

Lloyds Register (LR)

Display and interface options

(20)

M4

LCD display with LOI ★

M5 LCD display ★

Transient protection

(18)(21)

T1 Transient terminal block ★

Manifold for remote mount option

F2 3-valve manifold, stainless steel ★

F6 5-Valve Manifold, Stainless Steel ★

PlantWeb control functionality

(22)

A01 FOUNDATION Fieldbus Control Function Block Suite ★

PlantWeb diagnostic functionality

(14)

DA0

D01

(22)

Power Advisory HART Diagnostic ★

FOUNDATION Fieldbus Diagnostic Suite ★

Low power output

C2 0.8-3.2 Vdc Output with Digital Signal Based on HART Protocol (available with output code M only)

Alarm levels

C4 NAMUR alarm and saturation levels, high alarm ★

CN NAMUR alarm and saturation levels, low alarm ★

(14)

Emerson.com/Rosemount

29

Page 30

Rosemount 3051

February 2017

Table 4. Rosemount 3051CFC Compact Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

CR Custom alarm and saturation signal levels, high alarm ★

CS Custom alarm and saturation signal levels, low alarm ★

CT Rosemount standard low alarm ★

Ground screw

(18)(23)

V5 External ground screw assembly ★

Configuration buttons

(14)

D4

(24)

DZ

HART Revision Configuration (requires HART Protocol output code A)

Analog zero and span ★

Digital zero trim ★

(5)

HR5 Configured for HART Revision 5 ★

HR7 Configured for HART Revision 7 ★

Typical model number: 3051CFC D C S 060 N 065 0 3 2 A A 1 WC E5 M5

1. Select configuration buttons (option code D4 or DZ) or LOI (option code M4) if local configuration buttons are required.

2. Available with Primary Element Technology P only.

3. 10-in. (250 mm) and 12-in. (300 mm) line sizes not available with Primary Element Technology A.

4. For 2-in. (50 mm) line sizes the Primary Element Type is 0.6 for Primary Element Technology Code C.

5. O pti on HR 5 co nfig ure s the HAR T out put to HA RT Re vis ion 5 . Op tion HR7 conf igu res t he H ART o utp ut to HAR T Rev isio n 7. The devi ce can be field configured to HART

Revision 5 or 7 if desired. HART Revision 5 is the default HART output.

6. For local addressing and configuration, M4 (LOI) is required.

7. Requires wireless options and engineered polymer housing. Available approvals are FM Intrinsically Safe, (option code I5), CSA Intrinsically Safe (option code I6),

ATEX Intrinsic Safety (option code I1), and IECEx Intrinsic Safety (option code I7).

8. Only available with C6, E2, E5, I5, K5, KB and E8 approval. Not available with GE, GM, SBS, DA0, M4, D4, DZ, QT, HR5, HR7, CR, CS, and CT.

9. Only available with Wireless output code X.

10. Not available with product certifications options E8, K8, E5, K5, C6, K6, E7, K7, E2, K2, E3, KB, KD.

11. Available with Primary Element Technology C only.

12. For Annubar option A, consult factory for pipe schedules other than schedule 40.

13. Available with Primary Element Technology C or P only.

14. Only available with HART 4–20 mA output code A.

15. Materials of construction comply with metallurgical requirements within NACE MR0175/ISO for sour oil field production environments. Environmental limits apply

to certain materials. Consult latest standard for details. Selected materials also conform to NACE MR0103 for sour refining environments.

16. Dust approval not applicable to output code X. See “IEC 62591 (WirelessHART Protocol)” on page 61 for wireless approvals

17. Nonincendive certification not provided with wireless option code (X).

18. Not available with Wireless output code X.

19. Only available with product certifications E7, E8, I1, I7, IA, K7, K8, KD, N1, N7

20. Not available with output code F - F

21. The T1 option is not needed with FISCO Product Certifications, transient protection is included with the FISCO Product Certification code IA, IB, and IE.

22. Only valid with F

23. The V5 option is not needed with the T1 option; external ground screw assembly is included with the T1 option.

24. Only available with 4–20 mA HART output code A and wireless output code X.

OUNDATION Fieldbus (output code F).

OUNDATION Fieldbus or Wireless output code X or low power (output code M).

30

Emerson.com/Rosemount

Page 31

February 2017

Rosemount 3051

Rosemount 3051CFP Integral Orifice Flowmeter

Rosemount 3051CFP Integral Orifice Flowmeters enable highly accurate flow

measurement in small line sizes. Integral Orifice utilize precision honed pipe section

for increased accuracy and self-centering plate design to prevent alignment error s that

magnify measurement inaccuracies in small line sizes.

Up to 1.75 percent of flow rate accuracy

Available in

Fully assembled and leak tested for out-of-the-box installation

Power advisory can proactively detect degraded electrical loop integrity issues.

(option code DA0)

LOI with straightforward menus and built-in configuration buttons

(option code M4)

Additional information:

Specifications: page 44

Certifications: page 55

Dimensional drawings: page 65

See “Specifications” on page 44 and options for more details on each configuration. Specification and selection of product materials,

options, or components must be made by the purchaser of the equipment. See page 53 for more information on Material Selection.

Table 5. Rosemount 3051CFP Integral Orifice Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

(1)

Model

Product description

3051CFP Integral Orifice Flowmeter

Measurement type

D Differential Pressure ★

Body material

S 316 SST ★

Line size

005

010 1-in. (25 mm) ★

015 11/2-in. (40 mm) ★

1

/2-in. (15 mm) ★

Process connection

T1 NPT female body (not available with remote thermowell and RTD) ★

(2)

S1

Socket weld body (not available with remote thermowell and RTD) ★

P1 Pipe ends: NPT threaded ★

P2 Pipe ends: beveled ★

D1 Pipe ends: Flanged, DIN PN16, slip-on ★

D2 Pipe ends: Flanged, DIN PN40, slip-on ★

D3 Pipe ends: Flanged, DIN PN100, slip-on ★

W1 Pipe ends: Flanged, RF, ANSI Class 150, weld-neck ★

W3 Pipe ends: Flanged, RF, ANSI Class 300, weld-neck ★

W6 Pipe ends: Flanged, RF, ANSI Class 600, weld-neck ★

A1 Pipe ends: Flanged, RF, ANSI Class 150, slip-on

A3 Pipe ends: Flanged, RF, ANSI Class 300, slip-on

A6 Pipe ends: Flanged, RF, ANSI Class 600, slip-on

R1 Pipe ends: Flanged, RTJ, ANSI Class 150, slip-on

R3 Pipe ends: Flanged, RTJ, ANSI Class 300, slip-on

R6 Pipe ends: Flanged, RTJ, ANSI Class 600, slip-on

Emerson.com/Rosemount

1

/2 to 11/2-in. (15 - 40 mm) line sizes

31

Page 32

Rosemount 3051

Table 5. Rosemount 3051CFP Integral Orifice Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

February 2017

Orifice plate material

S 316 SST ★

H Alloy C-276

M Alloy 400

Bore size option

0066 0.066-in. (1.68 mm) for 1/2-in. pipe ★

0109 0.109-in. (2.77 mm) for 1/2-in. pipe ★

0160 0.160-in. (4.06 mm) for 1/2-in. pipe ★

0196 0.196-in. (4.98 mm) for 1/2-in. pipe ★

0260 0.260-in. (6.60 mm) for 1/2-in. pipe ★

0340 0.340-in. (8.64 mm) for 1/2-in. pipe ★

0150 0.150-in. (3.81 mm) for 1-in. pipe ★

0250 0.250-in. (6.35 mm) for 1-in. pipe ★

0345 0.345-in. (8.76 mm) for 1-in. Pipe ★

0500 0.500-in. (12.70 mm) for 1-in. pipe ★

0630 0.630-in. (16.00 mm) for 1-in. pipe ★

0800 0.800-in. (20.32 mm) for 1-in. pipe ★

0295 0.295-in. (7.49 mm) for 11/2-in. pipe ★

0376 0.376-in. (9.55 mm) for 11/2-in. pipe ★

0512 0.512-in. (13.00 mm) for 11/2-in. pipe ★

0748 0.748-in. (19.00 mm) for 11/2-in. pipe ★

1022 1.022-in. (25.96 mm) for 11/2-in. pipe ★

1184 1.184-in. (30.07 mm) for 11/2-in. pipe ★

0010 0.010-in. (0.25 mm) for 1/2-in. pipe

0014 0.014-in. (0.36 mm) for 1/2-in. pipe

0020 0.020-in. (0.51 mm) for 1/2-in. pipe

0034 0.034-in. (0.86 mm) for 1/2-in. pipe

Transmitter connection platform

D3 Direct-mount, 3-valve manifold, SST ★

D5 Direct-mount, 5-valve manifold, SST ★

R3 Remote-mount, 3-valve manifold, SST ★

R5 Remote-mount, 5-valve manifold, SST ★

D4 Direct-mount, 3-valve manifold, alloy C-276

D6 Direct-mount, 5-valve manifold, alloy C-276

D7 Direct-mount, high temperature, 5-valve manifold, SST

R4 Remote-mount, 3-valve manifold, alloy C-276

R6 Remote-mount, 5-valve manifold, alloy C-276

Differential pressure ranges

1 0 to 25 inH2O (0 to 62,16 mbar) ★

2 0 to 250 inH2O (0 to 621,60 mbar) ★

3 0 to 1000 in H2O (0 to 2,48 bar) ★

Transmitter output

(3)

A

F FOUNDATION Fieldbus Protocol ★

(4)

W

4–20 mA with digital signal based on HART Protocol ★

PROFIBUS PA Protocol ★

32

Emerson.com/Rosemount

Page 33

February 2017

Rosemount 3051

Table 5. Rosemount 3051CFP Integral Orifice Flowmeter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

(5)

X

(6)

M

Wireless ★

Low-power 1–5 Vdc with digital signal based on HART Protocol

Transmitter housing material Conduit entry size

A Aluminum

B Aluminum M20 ⫻ 1.5 ★

J SST

K SST M20 ⫻ 1.5 ★

(7)

P

(8)

D

(8)

M

Engineered polymer No conduit entries ★

Aluminum G1/2

SST G1/2

1

/2–14 NPT ★

1

/2–14 NPT ★

Transmitter performa nce class

1 up to ±1.8% flow rate accuracy, 8:1 flow turndown, 5-year stability ★

Wireless options (requires Wireless output code X and Engineered Polymer Housing Code P)

Wireless transmit rate, operating frequency, and protocol