Page 1

Product Data Sheet

Z.65.11-518

00813-0100-4160, Rev DA

Rosemount™ 2160 Wireless Level Switch

Vibrating Fork

June 2017

World’s first wireless liquid level switch for

reliable point level detection

Wireless capabilities extend the full benefits of

PlantWeb

Self-organizing network delivers information rich

™

to previously inaccessible locations

data with >99% data reliability

Designed for operation in temperature extremes

of –94 to 500 °F (–70 to 260 °C)

Virtually unaffected by flow, bubbles, turbulence,

foam, vibration, solids content, coating,

properties of the liquid, and product variations

“Fast Drip” fork design gives quicker response

time, especially with viscous liquids

Intrinsically Safe certification option

TÜV tested and approved for overfill protection

according to DiBt/ WHG regulations

Page 2

Rosemount 2160 Wireless Level Switch

2160***E

2160***S

‘Fast drip’ forks

June 2017

Overview of the Rosemount 2160 Wireless Level Switch

Measurement principle

The Rosemount 2160 is designed using the principle of a tuning fork. A

piezo-electric crystal oscillates the forks at their natural frequency. Changes

to this frequency are continuously monitored. The frequency of the vibrating

fork sensor changes depending on the medium in which it is immersed. The

denser the liquid, the lower the frequency.

When used as a

the fork, causing a change of natural frequency that is detected by the

electronics and switches the output state to ‘dry’.

When the Rosemount 2160 is used as a

tank or pipe, making contact with the fork which then causes the output state

to switch to ‘wet’.

low level alarm, the liquid in the tank or pipe drains down past

high level alarm, the liquid rises in the

Key features and benefits

Virtually unaffected by turbulence, foam, vibration, solids content,

coating, or liquid properties

The high temperature version of the Rosemount 2160 is designed for

operation in temperatures from –94 to 500 °F (–70 to 260 °C). It has a

stainless steel thermal tube to move the electronics away from the

process

Electronic self-checking and condition monitoring, and alerts using a

Field Communicator or AMS Device Manager.

Software adjustable switching delay prevents false switching in turbulent

or splashing applications

Wireless and encrypted digital communication of the switch output state

and other variables

Optional integral LCD for indicating the switch output state and

diagnostics

‘Fast Drip’ fork design gives quicker response time, especially with

viscous liquids. Rapid wet-to-dry time for highly responsive switching

Fork shape is optimized for hand polishing to meet hygienic

requirements

No moving parts or crevices for virtually no maintenance

Contents

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . page 4 Product Certifications . . . . . . . . . . . . . . . . . . . . . . . .page 11

Spares and Accessories . . . . . . . . . . . . . . . . . . . . . . . page 7 Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . .page 13

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

2

Emerson.com/Rosemount

Page 3

June 2017

High and low level alarm

AMS Device Manager

In tank gauging systems, a Rosemount 2160 high level

alarm switch can be used as an alternative to a second

radar level gauge (see the Rosemount Tank Gauging

product data sheet 00813-0100-5100 for details)

Point level alarm

Rosemount 2160

Rosemount

5900S

Level

High level alarm: two separate

and configurable relay outputs

For optimal performance, every wireless HART network should have a

minimum of five devices and every device should have a minimum of three

neighbors within effective range of the wireless gateway

Superior diagnostics

Built-in diagnostics continuously check electronic and mechanical

health

Fork conditions detected including internal and external damage,

coated or blocked, and extreme corrosion

Ideal for critical alarm duties

Fit and forget

Once installed, the Rosemount 2160 is ready to go.

It needs no calibration and requires minimum installation

You can install, and forget it

Wireless power module

The Rosemount 2160 is powered by a replaceable wireless Power

Module

The fork sensor requires very little power, and the Power Module life

remains long even with fast update rates

Extended temperature performance

The high temperature version of the Rosemount 2160 enables

™

standardization of Emerson’s

range of process environments, and is ideally suited for harsh

conditions where high reliability is essential

vibrating fork switches across a wide

Rosemount 2160 Wireless Level Switch

Wireless capability

The Rosemount 2160 is the world’s first wireless liquid level switch

Includes all the features of our wired level switches, but without the

complications and cost of wiring

Ideal for level detection in locations previously inaccessible, or too

costly for wired devices

Applications

Overfill protection

High and low level alarms

Pump control or limit detection

Run dry or pump protection

Hygienic applications

High temperature applications

r

a

d

a

R

k

n

a

T

t

n

u

o

m

e

s

o

R

f

f

O

-

M

R

E

T

n

O

i

H

Rx

-

N

I

Tx

A

G

o

L

USB

RS-232

Ext. pwr

0

8

1

2

M

B

F

Emerson.com/Rosemount

3

Page 4

Rosemount 2160 Wireless Level Switch

June 2017

Ordering Information

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See page 9 for more information on Material Selection.

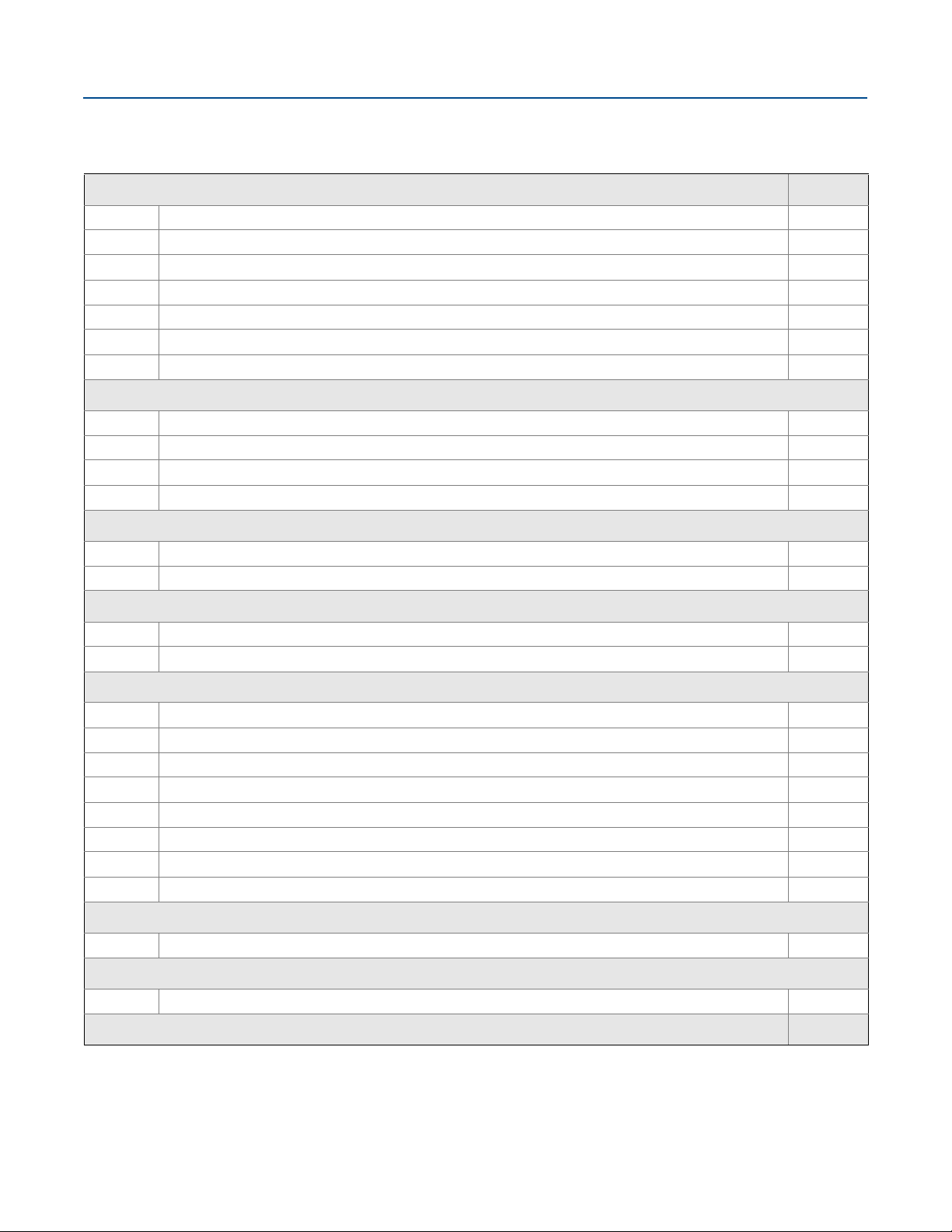

Table 1. Rosemount 2160 Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject to

additional delivery lead time.

Model Product description

2160 Wireless Vibrating Fork Liquid Level Switch

Output

X Wireless

Housing material

D Dual Compartment Housing - Aluminum (Aluminium)

Conduit entry / cable threads

8

1

/2-in. NPT thread

Operating temperature

S Standard: –40 °F (–40 °C)...302 °F (150 °C)

E High: –94 °F (–70 °C)...500 °F (260 °C)

Material of construction: process connection / fork

(1)

S

(2)

H

316/316L Stainless Steel (1.4401/1.4404)

Alloy C (UNS N10002), Alloy C-276 (UNS N10276), solid

Process connection size

9

3

/4 in. / 19 mm

1 1 in. / 25 mm (DN25)

2 2 in. / 50 mm (DN50)

5 11/2 in. / 40 mm (DN40)

3 3 in. / 80 mm (DN80)

4 4 in. / 100 mm (DN100)

7 21/2-in. / 65 mm (DN65)

(3)

X

Customer specific

★

★

★

★

★

★

★

★

★

★

★

★

★

Process connection rating

AA ASME B16.5 Class 150 flange

AB ASME B16.5 Class 300 flange

DB EN1092-1 PN25/40 flange

NN For use with non-flange process connection type

AC ASME B16.5 Class 600 flange

DA EN1092-1 PN10/16 flange

DC EN1092-1 PN63 flange

DD EN1092-1 PN100 flange

(3)

XX

Customer specific

4

★

★

★

★

Emerson.com/Rosemount

Page 5

June 2017

Rosemount 2160 Wireless Level Switch

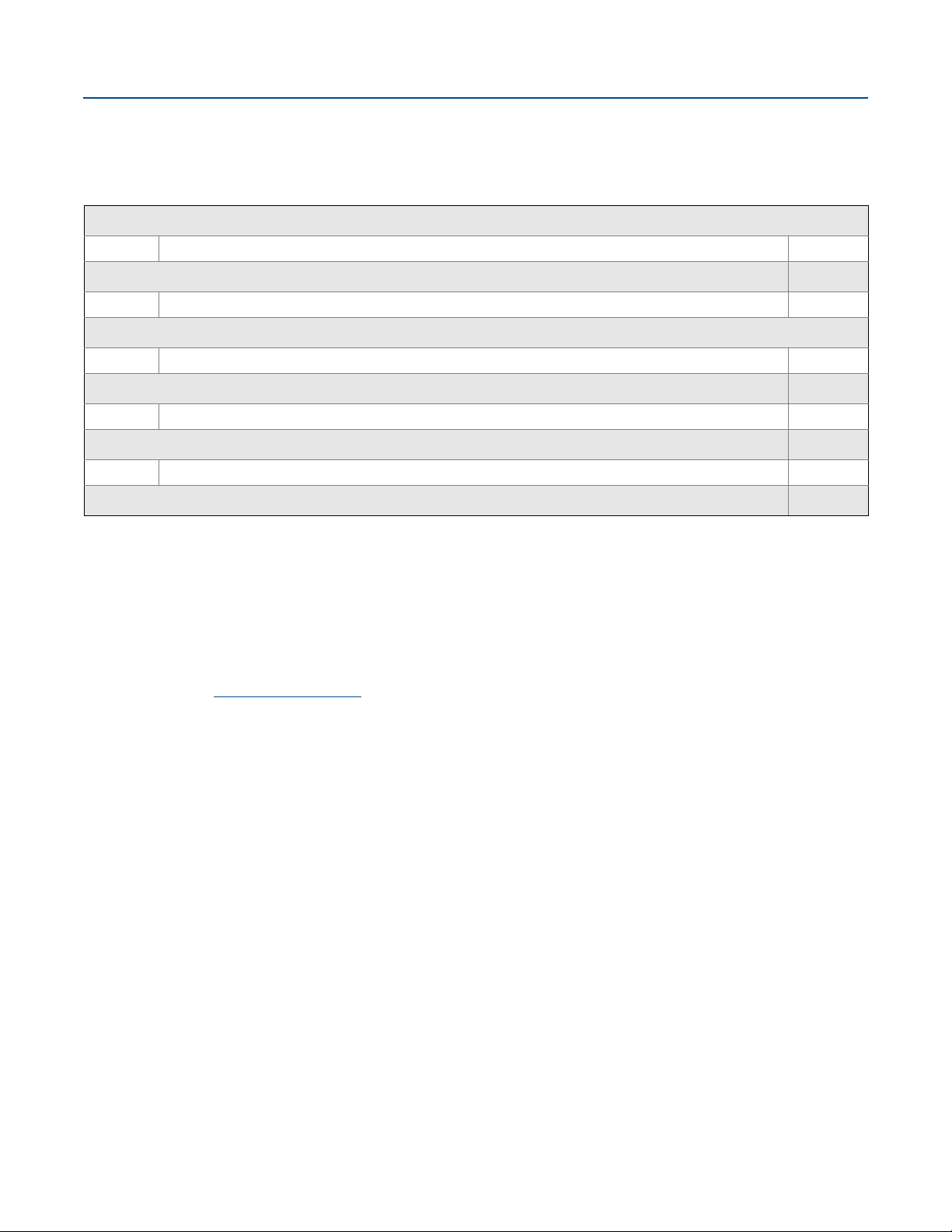

Table 1. Rosemount 2160 Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject to

additional delivery lead time.

Process connection type

R Raised Face (RF) flange

B BSPT (R) thread

G BSPP (G) thread

N NPT thread

P BSPP (G) O-ring

C Tri Clamp

(3)

X

Customer specific

Fork length

A Standard length 1.7-in. (44 mm)

(4)

H

(5)

E

(5)

M

Standard length flange 4.0-in. (102 mm)

Extended, customer specified length in tenths of inches

Extended, customer specified length in millimeters

Specific extended fork length

0000 Factory default length (only if fork length A or H is selected)

(5)

xxxx

Specific customer specified length in tenths of inches or millimeters (xxx.x inches or xxxx mm)

Surface finish

1 Standard surface finish

(6)(7)

2

Hand polished (Ra < 0.4 μm)

★

★

★

★

★

★

★

★

★

★

★

★

★

★

Product certifications

GP Korean Testing Laboratory (KTL), KCC Mark for Ordinary Locations

I2 INMETRO Intrinsic Safety

I3 NEPSI Intrinsic Safety

I5 FM Intrinsic Safety

(8)

I6

CSA Intrinsic Safety

I7 IECEx Intrinsic Safety

IM Technical Regulation Customs Union (EAC) Intrinsic Safety

IP KTL/KOSHA Intrinsic Safety

Wireless update rate, operating frequency and protocol

WA3 User configurable update rate, 2.4 GHz DSSS, IEC 62591 (WirelessHART™)

Omni-directional wireless antenna and SmartPower

(9)

WK1

External antenna, adapter for black power module (I.S. power module sold separately)

Typical model number: 2160 X D 8 S S 1 NN N A0000 1 I5 WA3 WK1

★

★

★

★

★

★

★

★

★

★

Emerson.com/Rosemount

5

Page 6

Rosemount 2160 Wireless Level Switch

June 2017

Table 1. Rosemount 2160 Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject to

additional delivery lead time.

Options (include with the selected model number)

Meter

M5 LCD meter

Factory configuration

(10)

C1 Factory configure Date, Descriptor, Message Fields and Wireless Parameters

★

★

Calibration data certification

Q4 Certificate of functional test

★

Material traceability certification

Q8 Material traceability certification per EN 10204 3.1

Special procedures

(11)

P1 Hydrostatic testing with certificate

★

★

Example of options included with the model number: 2160 X D 8 S S 1 NN N A0000 1 I5 WA3 WK1 M5 Q8

1. Flanges are dual certified 316 and 316L Stainless Steel (1.4401 and 1.4404).

2. Only available for BSPT and NPT threaded process connection types as standard, other upon request.

3. Other process connections available upon request.

4. Not available for hand polished wet side.

5. Example: Code E1181 is 118.1 inches. Code M3000 is 3000 millimeters. See “Extended fork lengths” on page 8 for minimum and maximum extended lengths.

6. Not available with Material of Construction Process / Fork option code H.

7. Hand-polished for hygienic connections to better than 0.4m Ra such that there are no pits, folds, crevices or cracks discernible to the naked eye (i.e. no features

larger than 75 micrometers based on resolving 1/60 degree at a distance of 250 mm).

8. The requirements of CRN are met when a Rosemount 2160 is configured with a CSA approval, 316/316L stainless steel (1.4401/1.4404) wetted parts, and either

NPT threaded or 2-in. to 4-in. ASME B16.5 flanged process connections.

9. Black power module must be shipped separately, order Model 701PBKKF or part number 00753-9220-0001.

10. Submit a completed Configuration Data Sheet (CDS)

11. Option limited to units with extended lengths up to 59.1-in. (1500 mm).

with the order if the C1 option code is selected.

Overfill approval option

The Rosemount 2160 has been TÜV-tested and approved for overfill protection according to the German DIBt/WHG regulations.

If required, add “R2259” to the end of the model code. For example, 2160 X D 8 S S 1 NN N A0000 1 I5 WA3 WK1 R2259.

You can have one or more Options codes added to the end of the model code.

6

Emerson.com/Rosemount

Page 7

June 2017

Rosemount 2160 Wireless Level Switch

Spares and Accessories

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See page 9 for more information on Material Selection.

Table 2. Rosemount 2160 Spares and Accessories

The starred options (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject to

additional delivery lead time.

Part number Description

02100-1000-0001

02100-1040-0001

02100-1010-0001

02100-1020-0001

Seal for 1-in. BSPP (G1A).

Material: Non-asbestos BS7531 grade X carbon fiber with rubber binder

Seal for 3/4-in. BSPP (G3/4A).

Material: Non-asbestos BS7531 grade X carbon fiber with rubber binder

Adapter boss, 1-in. BSPP to 11/2-in. (38 mm) Tri Clamp.

Material: 316 stainless steel fitting. FPM/FKM ‘O’ ring

2-in. (51 mm) Tri Clamp kit (vessel fitting, clamp ring and seal).

Material: 316 stainless steel, NBR Nitrile

★

★

★

★

Emerson.com/Rosemount

7

Page 8

Rosemount 2160 Wireless Level Switch

Specification

June 2017

General

Product

Rosemount 2160 Wireless Level Switch

Measuring technology

Vibrating fork

Applications

Liquids including coating liquids, aerated liquids, and slurries.

Suitable for horizontal and vertical installations.

Physical

Material selection

Emerson provides a variety of Rosemount product with various

product options and configurations including materials of

construction that can be expected to perform well in a wide

range of applications. The Rosemount product information

presented is intended as a guide for the purchaser to make an

appropriate selection for the application. It is the purchaser’s

sole responsibility to make a careful analysis of all process

parameters (such as all chemical components, temperature,

pressure, flow rate, abrasives, contaminants, etc.), when

specifying product, materials, options and components for the

particular application.

Emerson is not in a position to evaluate or guarantee the

compatibility of the process fluid or other process parameters

with the product, options, configuration or materials of

construction selected.

Electronics housing

Enclosure

Housing: Stainless steel or low-copper aluminum

Paint: Polyurethane (aluminum housing only)

Cover O-ring: Nitrile butadiene

Ingress protection

Housing is NEMA 4X and IP66 compliant.

Process wetted connections

Connections

Threaded, Tri Clamp, and flanged process connection options.

See Table 1 on page 4 for a complete list.

Materials

316/316L stainless steel (1.4401/1.4404 dual-certified).

Hand-polished to better than 0.4 m option for Tri Clamp

connections.

Alloy C (UNS N10002) and Alloy C-276 (UNS N10276)

– available for flanged, and selected threaded process

connections (

Gasket material for 3/4-in. and 1-in. BSPP (G) is non-asbestos

BS7531 Grade X carbon fiber with rubber binder. Gaskets are not

supplied with flanged process connections.

Extended fork lengths

The maximum extended length is 118.1 in. (3000 mm) for all

except for hand-polished option where the maximum is

39.4 in. (1000 mm).

Table 3 has a summary of the minimum extended lengths.

See “Dimensional Drawings” on page 13 for other dimensions.

Table 3. Minimum extended lengths

Process connection Minimum extended length

3

/4–in. threaded 3.8 in. (95 mm)

1–in. threaded 3.7 in. (94 mm)

Flanged 3.5 in. (89 mm)

Tri Clamp 4.1 in. (105 mm)

3

/4- and 1-in. BSPT (R), and 3/4- and 1-in. NPT).

Performance

Terminal block and power module pack

PBT

Antenna

PBT/PC integrated omni-directional antenna

Rotation

Rotatable housing allows correct alignment of both the forks

and the omni-directional antenna for optimal signal and best

viewing position of the LCD integral display.

8

Electromagnetic Compatibility (EMC)

All models meet all relevant requirements of EN 61326

Hysteresis (water)

±0.039 in. (±1 mm) nominal

Switching point (water)

0.5 in. (13 mm) from fork tip if mounted vertically.

0.5 in. (13 mm) from the fork edge if mounted horizontally.

The switching point varies with different liquid densities.

Emerson.com/Rosemount

Page 9

June 2017

1450 (100)

1880 (80)

-14.5 (-1.0)

-40

(-40)

122

(50)

302

(150)

Process temperature °F (°C)

Process pressure psig (barg)

32

(0)

2160***S

1450 (100)

885 (61)

-14.5 (-1.0)

-94

(-70)

100

(38)

500

(260)

Process temperature °F (°C)

Process pressure psig (barg)

32

(0)

2160***E

Rosemount 2160 Wireless Level Switch

Liquid density range

3

Minimum liquid density is 31.2 lb/ft

(500 kg/m3).

Liquid viscosity range

0.2 to 10000 cP (centiPoise)

Humidity limits

0 to 100% relative humidity

Solids content and coating

The maximum recommended diameter of solid particles in the

liquid is 0.2 in. (5 mm). Avoid bridging of forks (fork-to-fork).

CIP (Clean In Place) cleaning

The Rosemount 2160 withstands steam cleaning.

Electrical

Wireless power module

Replaceable, intrinsically safe Lithium-Thionyl Chloride power

module with PBT enclosure.

Ten year life at one minute update rate.

Environmental

Maximum operating pressures

Threaded connection: See Figure 1

Hygienic connection: 435 psig (30 bar g)

Flanged connection:

The maximum operating pressure is the lower of the process

pressure (Figure 1) and flange pressure rating (Table 4)

Figure 1. Operating Pressures

Reference conditions are 70 °F (21 °C), and routing data for three

additional network devices. Continuous exposure to ambient

temperature limits -40 °F or 185 °F (-40 °C or 85 °C) may reduce

specified power module life by 20 percent.

Field communicator connections

Clips are permanently fixed to the terminal block.

Functional

Output

IEC 62591 (WirelessHART) 2.4 GHz DSSS

Radio frequency power output from antenna

Maximum of 10 mW (10 dBm) EIRP

Wireless update rate

User-selectable: from one second up to sixty minutes.

The optional integral LCD display updates at each wireless

update.

Local display

A ‘locate device’ function allows easy identification of

instrument during commissioning inspection.

The optional five-digit integral LCD can indicate a sequence of

up to four process variables (dry/wet, electronics temperature,

frequency, and supply voltage) and diagnostic information.

Table 4. Maximum Flange Pressure Rating

Flange standard Stainless steel flanges

(2)

(3)

(3)

(3)

(2)

(2)

(3)

ASME B16.5 Class 150 275 psig

ASME B16.5 Class 300 720 psig

ASME B16.5 Class 600 1440 psig

EN1092-1 PN 10/16 16 bar g

EN1092-1 PN 25/40 40 bar g

EN1092-1 PN 63 63 bar g

EN1092-1 PN 100 100 bar g

1. ASTM stainless steel.

2. At 100 °F (38 °C), the pressure rating decreases with an increasing process

temperature.

3. At 122 °F (50 °C), the pressure rating decreases with an increasing process

temperature.

(1)

Emerson.com/Rosemount

9

Page 10

Rosemount 2160 Wireless Level Switch

176 (80)

122

(50)

-40 (-40)

-40

(-40)

302

(150)

Process temperature °F (°C)

Ambient temperature °F (°C)

122 (50)

32 (0)

32

(0)

2160***S

176 (80)

176

(80)

-40 (-40)

-94

(-70)

500

(260)

Process temperature °F (°C)

Ambient temperature °F (°C)

149 (65)

32 (0)

32

(0)

2160***E

Note

The final maximum operating pressure rating depends on the

process (tank) connection.

Maximum and minimum operating temperatures

See Figure 2 on page 10 for the maximum and minimum

operating temperatures.

Figure 2. Operating Temperatures

June 2017

10

Emerson.com/Rosemount

Page 11

June 2017

Product Certifications

Rosemount 2160 Wireless Level Switch

European Union directive information

The EC declaration of conformity certificate is currently not

available for the Rosemount 2160. Please check the Rosemount

2160 web page

for updates.

Telecommunication compliance

All wireless devices require certification to ensure that they

adhere to regulations regarding the use of the RF spectrum.

Nearly every country requires this type of product certification.

Emerson is working with governmental agencies around the

world to supply fully compliant products and remove the risk of

violating country directives or laws governing wireless device

usage.

FCC and IC

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

This device must be installed to ensure a minimum antenna

separation distance of 8 in. (20 cm) from all persons.

Korean Testing Laboratory (KTL), KCC mark for ordinary locations use

GP EMC certificate: KCC-REM-ERN-RMDSWIT2160XXX

Overfill approval

NAMUR approval

NAMUR NE95 type test report available upon request.

Complies with NAMUR NE21

Canadian Registration Number

CRN 0F04227.2C

The requirements of CRN are met when a Rosemount 2160

CSA-approved vibrating fork level switch model is configured

with 316/316L stainless steel (1.4401/1.4404) process-wetted

parts and either NPT threaded or 2-in. to 4-in. ASME B16.5

flanged process connections.

Hazardous locations certificates

North America and Canada

Factory Mutual (FM) approvals

I5 Project ID: 3036541

FM Intrinsic Safety, Non-incendive, and Dust Ignition-proof

Intrinsically Safe for:

Class I/II/III, Division 1, Groups A, B, C, D, E, F, and G

Zone Marking: Class I, Zone 0, AEx ia llC

Temperature Codes T4 (T

Non-incendive for Class I, Division 2, Groups A, B, C, and D

Dust Ignition-proof for Class II/III, Division I, Groups E, F, G

Ambient temperature limits: –50 to 70 °C

For use with Rosemount SmartPower

P/N 753-9220-0001 only.

Enclosure Type 4X / IP66

= –50 to 70 °C)

amb

®

options

Certificate number: Z-65.11-518

TÜV-tested and approved for overfill protection according to the

German DIBt/WHG regulations. Certified under safety devices

for tanks and piping related to water pollution control.

Drinking water approval

Rosemount Measurement Limited, Slough, UK confirms that the

wetted parts of the Rosemount type 2160 vibrating level

switches are suitable and approved for use in potable water.

The wetted parts of the vibrating level switches executed in:

Stainless steel (option code S) and Alloy C / Alloy C-276 (option

code H) with Flanged (option code R), NPT thread (option code

N), BSPT(R) thread (option code B) or Tri-clamp (option code C)

process connections, are in accordance with the requirements of

DVGW*- Worksheet W270. The materials used are classified as

toxicologically and microbiologically.

Emerson.com/Rosemount

Special condition for safe use

1. Warning – Potential Electrostatic Charging Hazard –

The enclosure is partially constructed from plastic. To

prevent the risk of electrostatic sparking, use only a damp

cloth to clean the plastic surfaces.

Canadian Standards Association (CSA) approval

I6 Certificate Number: 06 CSA 1786345

CSA Intrinsically Safe

Intrinsically Safe for Class I, Division 1, Groups A, B, C and D

Temperature Code T3C

Enclosure Type 4X / IP66

Intrinsically Safe when installed in accordance with

Rosemount drawing 71097/1271.

For use with Rosemount SmartPower options

P/N 753-9220-0001 only.

Single seal

11

Page 12

Rosemount 2160 Wireless Level Switch

International approvals

Technical Regulation Customs Union (EAC) approvals

IM Certificate: RU-C-GB.AB72.B.00916

Intrinsic Safety:

0Ex ia IIC T5...T2 Ga X

Ta (see table in the certificate)

KTL/KOSHA approvals

IP Certificate: 13-KB4BO-0213X

Ex ia IIC T5...T2

Ta (see table in the certificate)

IECEx approval

I7 IECEx Intrinsic Safety

Certificate Number: IECEx BAS 09.0123X

Ex ia IIC T5-T2 (Ta = –40 to 70 °C)

IP66

For use with Rosemount SmartPower options

P/N 753-9220-0001 only.

June 2017

Special conditions for safe use

1. The surface resistivity of the antenna is greater than

one gigaohm. To avoid electrostatic charge build-up, it

must not be rubbed or cleaned with solvents or a dry cloth.

2. Warning – potential electrostatic charging hazard –

The enclosure is partially constructed from plastic. To

prevent the risk of electrostatic sparking, use only a damp

cloth to clean the plastic surfaces.

National Supervision and Inspection Centre

(NEPSI) approval

I3 NEPSI Intrinsic Safety

Certificate: GYJ101138X

Ex ia IIC T5-T2

Special condition for safe use

1. Symbol “X” is used to denote specific conditions of use:

a. Model 648 WTT or Model 3051S WPT type battery

pack provided by the manufacturer should be used.

b. The surface resistivity of the antenna is greater than

one gigaohm. To avoid electrostatic charge build-up,

it must not be rubbed or cleaned with solvents or a

dry cloth.

c. The Rosemount 2160 enclosure is made of aluminum

alloy and given a protective epoxy coating. However,

care should be taken to protect it from impact or

abrasion if located in a Zone 0.

12

Emerson.com/Rosemount

Page 13

June 2017

Aluminum

housing

0.5 (13) switchpoint

(when mounted horizontally)

0.5 (13) switchpoint

(when mounted vertically)

3

/4-in. or 1-in.

thread

6.1 (154) No LCD fitted

1.14 (29) for 1-in. thread

0.9 (23) for

3

/4-in. thread

1.7

(44)

2.7

(69)

Minimum

to allow

removal

of cover

View on

arrow ‘A’

showing

possible

antenna

rotation

90°

6.9

(174)

1.6 (40) A/F

hexagon

0.5 (13) switchpoint

(when mounted horizontally)

0.5 (13) switchpoint

(when mounted vertically)

3

/4-in. or 1-in. thread

1.14 (29) for 1-in. thread

0.9 (23) for

3

/4-in. thread

1.7

(44)

2.7

(69)

14.5

(369)

3.5

(90)

3.5

(90)

7.9 (200)

6.8 (172) LCD fitted

2.4

(60)

3.7 (93)

1.6 (40) A/F

hexagon

6.8 (172) LCD fitted

6.1 (154) No LCD fitted

Minimum

to allow

removal

of cover

2.4

(60)

2160***S

2160***E

Rosemount 2160 Wireless Level Switch

Dimensional Drawings

Figure 3. 3/4- and 1-in. Threaded Process Connections (Standard Length Fork)

A

A

Dimensions are in inches (millimeters).

Refer to the Type 1 drawings on the Rosemount 2160 web page

Emerson.com/Rosemount

for dimensions of the O-ring seal (BSPP) versions.

13

Page 14

Rosemount 2160 Wireless Level Switch

A

A

1.65 (40) A/F

hexagon

3

/4-in. or 1-in. thread

E(M)

1.7

(44)

0.5 (13) switchpoint

(when mounted horizontally)

0.5 (13) switchpoint

(when mounted vertically)

1.14 (29) for 1-in. thread

0.9 (23) for

3

/4-in. thread

90°

14.4

(367)

6.8

(172)

1.6 (40) A/F

hexagon

0.5 (13) switchpoint

(mounted horizontally)

0.5 (13) switchpoint

(when mounted vertically)

3

/4-in. or 1-in. thread

1.14 (29) for 1-in. thread

0.9 (23) for

3

/4-in. thread

1.7

(44)

E(M)

3.5

(90)

3.5

(90)

6.1 (154) No LCD fitted

Minimum

to allow

removal

of cover

6.8 (172) LCD fitted

2.4

(60)

6.8 (172) LCD fitted

6.1 (154) No LCD fitted

Minimum

to allow

removal

of cover

2.4

(60)

Aluminum

housing

View on

arrow ‘A’

showing

possible

antenna

rotation

7.9 (200)

3.7 (93)

2160***S

2160***E

Figure 4. 3/4- and 1-in. Threaded Process Connections (Extended Length Fork)

June 2017

Dimensions are in inches (millimeters). See Type 1 drawings on the Rosemount 2160 web page for dimensions of the O-ring seal (BSPP) versions.

Table 5. Fork Length for 3/4- and 1-in. Threaded Rosemount 2160

1. Maximum extended length of fork with hand-polished option is 39.4 in. (1000 mm).

14

Process

connection

3

/4-in. thread 1.73 in. (44 mm) 3.75 in. (95 mm) 118.1 in. (3000 mm)

Standard length

fork length code A

1-in. thread 1.73 in. (44 mm) 3.74 in. (94 mm) 118.1 in. (3000 mm)

Minimum length

fork length code E (M)

fork length code E (M)

Emerson.com/Rosemount

Maximum length

(1)

Page 15

June 2017

A

A

1.7

(44)

4.0

(102)

0.5 (13) switchpoint

(when mounted horizontally)

1.14 (29) for 1

1

/2-in. or

larger flange;

0.9 (23) for up to 1-in. flange

0.5 (13) switchpoint

(when mounted vertically)

90°

13.8

(351)

1.7

(44)

4.0

(102)

0.5 (13) switchpoint

(when mounted horizontally)

1.14 (29) for 1

1

/2-in. or

larger flange;

0.9 (23) for up to 1-in. flange

0.5 (13) switchpoint

(when mounted vertically)

2160***S

2160***E

7.0

(177)

3.5

(90)

3.5

(90)

6.1 (154) No LCD fitted

Minimum

to allow

removal

of cover

6.8 (172) LCD fitted

2.4

(60)

6.8 (172) LCD fitted

6.1 (154) No LCD fitted

Minimum

to allow

removal

of cover

2.4

(60)

Aluminum

housing

View on

arrow ‘A’

showing

possible

antenna

rotation

7.9 (200)

3.7 (93)

Figure 5. Flanged Process Connections (Standard Length Fork)

Rosemount 2160 Wireless Level Switch

Dimensions are in inches (millimeters).

Emerson.com/Rosemount

15

Page 16

Rosemount 2160 Wireless Level Switch

A

A

1.7

(44)

E(M)

0.5 (13) switchpoint

(when mounted horizontally)

1.14 (29) for 1

1

/2-in. or

larger flange;

0.9 (23) for up to 1-in. flange

0.5 (13) switchpoint

(when mounted vertically)

7.0

(177)

13.8

(351)

1.7

(44)

0.5 (13) switchpoint

(when mounted horizontally)

1.14 (29) for 1

1

/2-in. or

Larger Flange;

0.9 (23) for up to 1-in. Flange

0.5 (13) switchpoint

(when mounted vertically)

E(M)

3.5

(90)

3.5

(90)

6.1 (154) No LCD fitted

Minimum

to allow

removal

of cover

6.8 (172) LCD fitted

2.4

(60)

6.8 (172) LCD fitted

6.1 (154) No LCD fitted

Minimum

to allow

removal

of cover

2.4

(60)

90°

Aluminum

housing

7.9 (200)

3.7 (93)

View on

arrow ‘A’

showing

possible

antenna

rotation

2160***S

2160***E

Figure 6. Flanged Process Connections (Extended Length Fork)

June 2017

Dimensions are in inches (millimeters).

Table 6. Fork Length for Flanged Rosemount 2160

Process

connection

3

/4-in., 1-in. or larger flange 4.0 in. (102 mm) 3.7 in. (94 mm) 118.1 in. (3000 mm)

16

Standard length

fork length code H

Minimum length

Fork length code E(M)

Maximum length

fork length code E(M)

Emerson.com/Rosemount

Page 17

June 2017

A

A

1.14

(29)

1.7

(44)

2.5

(64)

1

/2-in. (38) or

2-in. (51) Tri Clamp

1.6 (40) A/F

hexagon

1.14

(29)

1.7

(44)

1.6 (40) A/F

hexagon

0.5 (13) switchpoint

(when mounted horizontally)

0.5 (13) switchpoint

(when mounted vertically)

0.5 (13) switchpoint

(when mounted vertically)

0.5 (13) switchpoint

(when mounted horizontally)

2.5

(64)

7.1

(179)

14.9

(379)

1

/2-in. (38) or

2-in. (51) Tri Clamp

3.5

(90)

3.5

(90)

6.1 (154) No LCD fitted

Minimum

to allow

removal

of cover

6.8 (172) LCD fitted

2.4

(60)

6.8 (172) LCD fitted

6.1 (154) No LCD fitted

Minimum

to allow

removal

of cover

2.4

(60)

90°

Aluminum

housing

View on

arrow ‘A’

showing

possible

antenna

rotation

7.9 (200)

3.7 (93)

2160***S

2160***E

Figure 7. Tri Clamp Process Connections (Standard Length Fork)

Rosemount 2160 Wireless Level Switch

Dimensions are in inches (millimeters).

Emerson.com/Rosemount

17

Page 18

Rosemount 2160 Wireless Level Switch

A

A

1.14

(29)

1.7

(44)

1

/2-in. (38) or

2-in. (51) Tri Clamp

E(M)

0.5 (13) switchpoint

(when mounted vertically)

0.5 (13) switchpoint

(when mounted horizontally)

14.9

(379)

7.1

(179)

E(M)

0.5 (13) switchpoint

(when mounted vertically)

1.7

(44)

1.14

(29)

0.5 (13) switchpoint

(mounted horizontally)

3.5

(90)

3.5

(90)

90°

Aluminum

housing

View on

arrow ‘A’

showing

possible

antenna

rotation

7.9 (200)

3.7 (93)

6.1 (154) No LCD Fitted

Minimum

To Allow

Removal

Of Cover

6.8 (172) LCD Fitted

2.4

(60)

6.8 (172) LCD Fitted

6.1 (154) No LCD Fitted

Minimum

To Allow

Removal

Of Cover

2.4

(60)

2160***S

2160***E

Figure 8. Tri Clamp Process Connections (Extended Length Fork)

June 2017

Dimensions are in inches (millimeters).

Table 7. Fork Length for Tri Clamp Rosemount 2160

Process

connection

Standard Length

Fork Length Code H

Tri Clamp 1.73 in. (44 mm) 4.13 in. (105 mm) 118.1 in. (3000 mm)

1. Maximum extended length of fork with hand-polished option is 39.4 in. (1000 mm).

18

Minimum Length

Fork Length Code E(M)

Maximum Length

Fork Length Code E(M)

(1)

Emerson.com/Rosemount

Page 19

June 2017

Rosemount 2160 Wireless Level Switch

Emerson.com/Rosemount

19

Page 20

Rosemount 2160 Wireless Level Switch

00813-0100-4160, Rev DA

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Product Data Sheet

June 2017

Europe Regional Office

Emerson Automation Solutions Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found on the

www.Emerson.com/en-us//Terms-of-Use

The Emerson logo is a trademark and service mark of Emerson Electric Co.

PlantWeb, Rosemount and Rosemount logotype are trademarks of

Emerson.

WirelessHART and HART are registered trade marks of FieldComm Group.

All other marks are the property of their respective owners.

© 2017 Emerson. All rights reserved.

Loading...

Loading...