Page 1

00809-0100-4140, Rev BA

Rosemount™ 2140 and 2140:SIS Level

Detectors

Vibrating Fork

Reference Manual

March 2022

Page 2

Safety messages

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum product performance,

ensure you thoroughly understand the contents before installing, using, or maintaining this product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

• United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

• Asia Pacific- 65 777 8211

North American Response Center

Equipment service needs.

• 1-800-654-7768 (24 hours a day — includes Canada)

• Outside of these areas, contact your local Emerson representative.

WARNING

Failure to follow safe installation and servicing guidelines could result in death or serious injury.

Ensure the level detector is installed by qualified personnel and in accordance with applicable code of practice.

Use the level detector only as specified in this manual. Failure to do so may impair the protection provided by the level detector.

The weight of a level detector with a heavy flange and extended fork length may exceed 37 lb. (18 kg). A risk assessment is

required before carrying, lifting, and installing the level detector.

For installations in hazardous locations, the level detector must be installed according to the Rosemount 2140 and 2140:SIS Level

Detectors Product Certifications document.

WARNING

Explosions could result in death or serious injury.

Verify that the operating atmosphere of the level detector is consistent with the appropriate hazardous locations certifications.

Before connecting a handheld communicator in an explosive atmosphere, ensure that the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

In explosion-proof/flameproof and non-incendive installations, do not remove the housing covers when power is applied to the

level detector.

Both housing covers must be fully engaged to meet flameproof/explosion-proof requirements.

WARNING

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can cause electrical shock.

Ensure the power to the level detector is off, and the lines to any other external power source are disconnected or not powered

while wiring the level detector.

Ensure the wiring is suitable for the electrical current and the insulation is suitable for the voltage, temperature, and environment.

2

Page 3

WARNING

Process leaks could result in death or serious injury.

Ensure the level detector is handled carefully. If the process seal is damaged, gas might escape from the vessel (tank) or pipe.

WARNING

Any substitution of non-recognized parts may jeopardize safety. Repair (e.g. substitution of components) may also

jeopardize safety and is not allowed under any circumstances.

Unauthorized changes to the product are strictly prohibited as they may unintentionally and unpredictably alter performance and

jeopardize safety. Unauthorized changes that interfere with the integrity of the welds or flanges, such as making additional

perforations, compromise product integrity and safety. Equipment ratings and certifications are no longer valid on any products

that have been damaged or modified without the prior written permission of Emerson. Any continued use of product that has

been damaged or modified without the written authorization is at the customer’s sole risk and expense.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end users’ equipment. This could

be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your system. Restrict physical access

by unauthorized personnel to protect end users’ assets. This is true for all systems used within the facility.

CAUTION

The products described in this document are NOT designed for nuclear-qualified applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware or products may cause inaccurate

readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson Sales Representative.

CAUTION

Hot surfaces

The flange and process seal may be hot at high process temperatures. Allow to cool before servicing.

3

Page 4

4

Page 5

Reference Manual Contents

00809-0100-4140 March 2022

Contents

Chapter 1 Introduction.............................................................................................................. 7

1.1 Using this manual........................................................................................................................ 7

1.2 NAMUR NE 53 revision.................................................................................................................8

1.3 Product certifications...................................................................................................................8

1.4 Product recycling/disposal...........................................................................................................8

Chapter 2 Level detector overview.............................................................................................9

2.1 Measurement principle................................................................................................................9

2.2 Process characteristics.................................................................................................................9

2.3 Vessel characteristics...................................................................................................................9

2.4 Application examples.................................................................................................................10

2.5 Components of the level detector..............................................................................................11

Chapter 3 Mechanical installation............................................................................................ 13

3.1 Safety messages........................................................................................................................ 13

3.2 Installation considerations.........................................................................................................14

3.3 Installation procedures.............................................................................................................. 22

3.4 Adjust display orientation (optional)..........................................................................................28

Chapter 4 Electrical installation................................................................................................29

4.1 Prepare the electrical connections............................................................................................. 29

4.2 Connect wiring and power up.................................................................................................... 32

Chapter 5 Configuration...........................................................................................................37

5.1 Safety messages........................................................................................................................ 37

5.2 Configuration tools....................................................................................................................38

5.3 Local Operator Interface (LOI)....................................................................................................39

5.4 Confirm correct device driver.....................................................................................................40

5.5 Confirm HART® revision capability............................................................................................. 40

Configure device using guided setup......................................................................................... 41

5.6

5.7 Verify the configuration.............................................................................................................41

5.8 Multidrop communication.........................................................................................................43

5.9 HART burst mode...................................................................................................................... 44

5.10 Security................................................................................................................................... 45

Chapter 6 Operation................................................................................................................ 49

6.1 LCD display screen messages.....................................................................................................49

6.2 Set up the LCD display............................................................................................................... 50

6.3 View measurement data............................................................................................................50

6.4 Check device status................................................................................................................... 51

6.5 Partial proof testing................................................................................................................... 53

Rosemount 2140 and 2140:SIS Level Detectors 5

Page 6

Contents Reference Manual

March 2022 00809-0100-4140

Chapter 7 Service and troubleshooting.................................................................................... 57

7.1 Safety messages........................................................................................................................ 57

7.2 Diagnostic messages................................................................................................................. 58

7.3 Troubleshooting the 4-20 mA/HART Output..............................................................................68

7.4 Service and troubleshooting tools..............................................................................................69

7.5 Opening the lid (cover).............................................................................................................. 76

7.6 Service support..........................................................................................................................76

Appendix A Specifications and reference data............................................................................. 79

A.1 General......................................................................................................................................79

A.2 Functional safety....................................................................................................................... 79

A.3 Performance specifications........................................................................................................79

A.4 Electrical specifications..............................................................................................................80

A.5 Environmental specifications.....................................................................................................81

A.6 Physical specifications............................................................................................................... 83

A.7 Dimensional drawings............................................................................................................... 84

Appendix B Configuration parameters........................................................................................ 93

B.1 Manual setup.............................................................................................................................93

B.2 Alert setup...............................................................................................................................104

Appendix C Local Operator Interface (LOI) menu trees.............................................................. 109

C.1 LOI menu trees........................................................................................................................ 109

Appendix D Signal processing................................................................................................... 111

6 Reference Manual

Page 7

Reference Manual Introduction

00809-0100-4140 March 2022

1 Introduction

1.1 Using this manual

The sections in this manual provide detailed information on installing, operating, and

maintaining the Rosemount 2140 and 2140:SIS Level Detectors.

The sections are organized as follows:

Level detector overview provides a description of the Rosemount 2140 and , and their

basic principles.

Mechanical installation contains mechanical installation instructions.

Electrical installation contains electrical installation instructions.

Configuration provides instructions on configuration of the level detector.

Operation contains operation and maintenance techniques.

Service and troubleshooting provides troubleshooting techniques for the most common

operating problems.

Specifications and reference data contains specifications and dimensional drawings.

Configuration parameters provides extended information about the configuration

parameters.

Local Operator Interface (LOI) menu trees contains complete menu maps as a reference

for when using the optional Local Operator Interface.

Signal processing contains a schematic overview of the signal processing.

Rosemount 2140 and 2140:SIS Level Detectors 7

Page 8

Introduction Reference Manual

March 2022 00809-0100-4140

1.2 NAMUR NE 53 revision

The Rosemount 2140 meets the NAMUR recommendation NE 53. Table 1-1 provides the

information necessary to ensure you have the correct device driver for your device.

Table 1-1: Identification and Compatibility According to NAMUR NE 53

Release date Device identification FDI, DD, and DTM identification Release note

NAMUR

hardware

revision

January-2017 1.0.0 1.0.0 5 1 • Initial release

March-2018 1.0.0 1.1.0 5 1 • Removed customer upgrade

(1)

NAMUR

software

revision

HART® universal

(1)

revision

(2)

7 2

7 2

Device revision

(revision level 1 and 2)

feature

• Added Media Learn and

Remote Proof Test to base

model

• Updated the Partial Proof Test

procedure

(1)

(1) NAMUR Revision is located on the device label. Differences in level 3 changes represent minor product changes as

defined per NE53. Compatibility and functionality are preserved and product can be used interchangeably.

(2) HART Revision 5 and 7 can be switched in field.

Related information

Confirm correct device driver

1.3 Product certifications

See the Rosemount 2140 Product Certifications document for detailed information on the

existing approvals and certifications.

1.4 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation or regulations.

8 Reference Manual

Page 9

Reference Manual Level detector overview

00809-0100-4140 March 2022

2 Level detector overview

2.1 Measurement principle

The Rosemount 2140 and 2140:SIS are the world’s first wired HART® level detector using

Emerson's vibrating fork technology.

Using the principle of a tuning fork, a piezo-electric crystal oscillates the forks at their

natural frequency. Changes to the oscillation frequency are continuously monitored by

electronics as it varies depending on the liquid medium in which the forks are immersed.

The denser the liquid, the lower the oscillation frequency.

Whenever a liquid medium in a vessel (tank) or pipe drains down past the forks, it causes a

distinct frequency change. This change is detected by the electronics and a dry condition

is indicated.

Whenever a liquid medium in a vessel (tank) or pipe rises and contacts the forks, again a

distinct frequency change is detected. This time, the electronics will indicate a wet

condition.

The wet and dry conditions can be transmitted digitally as a HART signal or as a discrete

output using the analog output.

Related information

Analog output

Signal processing

2.2 Process characteristics

Emerson's vibrating fork technology is virtually unaffected by turbulence, foam, solids

content, coating products, and liquid properties. The natural frequency (1400 Hz) of the

fork avoids interference from plant vibration that may cause false detection. This allows

for minimum intrusion into the tank or pipe using a short fork.

2.2.1 Liquid-to-sediment detection

The Rosemount 2140 version of the level detector features settings to detect liquid-tosediment interface, and this works on other solids sediment types (e.g. salts). Liquids as

well as wet sediments are detected. All versions of the level detector have a Media Learn

function to fine-tune the switching point even if the media characteristics are unknown.

2.3 Vessel characteristics

The level detector should be mounted using its process connection, and in a horizontal or

vertical orientation so that the liquid medium can flow freely in the gap between the forks.

A vessel (tank) or pipe can be almost any shape or type, but check that the process

conditions are within the operating limits of the level detector.

Rosemount 2140 and 2140:SIS Level Detectors 9

Page 10

Level detector overview Reference Manual

March 2022 00809-0100-4140

Avoid installing near agitators and inlet pipes where the forks are likely to be splashed and

cause a false detection of a wet condition. False detection events can be minimized by a

programmable delay that allows time for the fork to dry.

Never force the level detector into a vessel (tank) or pipe space. Any contact with the

opposite wall, or in-tank objects, could damage the forks and other wetted-process parts.

Extended length versions require supports at regular spaced intervals.

2.4 Application examples

Applications for the Rosemount 2140 version of the level detector include overfill

prevention (Figure 2-1), high and low level alarms, pump protection, and separation

processes (Figure 2-2).

The Rosemount 2140:SIS version is certified to IEC 61508 for safety-critical applications.

Applications also include overfill prevention, high and low level alarms, and pump

protection.

Figure 2-1: Overfill Prevention

Figure 2-2: High and Low level Alarms and Pump Control

10 Reference Manual

Page 11

A

B

C

E

F

J

HH

D

A

K

G

Reference Manual Level detector overview

00809-0100-4140 March 2022

2.5 Components of the level detector

Figure 2-3 shows the components of a Rosemount 2140.

Figure 2-3: Rosemount 2140 Features

A. Terminal compartment

B. Electronics housing

C.

LOI display (optional)

D. ‘Fast drip’ forks

E. Threaded process connection (BSPT (R) or BSPP (G))

F. Tri Clamp process connection

G. Flanged process connection

H. Two cable/conduit entries (½-14 ANPT or M20 x 1.5)

I. External ground screw

J. Thermal tube (on high temperature version only)

2.5.1 Short fork technology

Using short-fork technology, the device can be used in almost all liquid applications.

Extensive research has maximized the operational effectiveness of the fork design, making

it suitable for most liquid mediums including coating liquids, aerated liquids, and slurries.

Rosemount 2140 and 2140:SIS Level Detectors 11

Page 12

Level detector overview Reference Manual

March 2022 00809-0100-4140

2.5.2 Fork design

The “fast drip” design allows the liquid to be quickly drawn away from the fork tip, making

the Rosemount 2140 quicker and more responsive in high density or viscous liquid

applications.

Figure 2-4: “Fast drip” forks

12 Reference Manual

Page 13

Reference Manual Mechanical installation

00809-0100-4140 March 2022

3 Mechanical installation

3.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the

safety of the personnel performing the operations. Information that potentially raises

safety issues is indicated by a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

WARNING

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Ensure the level detector is installed by qualified personnel and in accordance with

applicable code of practice.

Use the level detector only as specified in this manual. Failure to do so may impair the

protection provided by the level detector.

The weight of a level detector with a heavy flange and extended fork length may exceed

37 lb. (18 kg). A risk assessment is required before carrying, lifting, and installing the level

detector.

For installations in hazardous locations, the level detector must be installed according to

the Rosemount 2140 and 2140:SIS Level Detectors Product Certifications document.

Repair, e.g. substitution of components, etc. may jeopardize safety and is under no

circumstances allowed.

WARNING

Explosions could result in death or serious injury.

Verify that the operating atmosphere of the level detector is consistent with the

appropriate hazardous locations certifications.

Before connecting a handheld communicator in an explosive atmosphere, ensure that the

instruments in the loop are installed in accordance with intrinsically safe or non-incendive

field wiring practices.

In explosion-proof/flameproof and non-incendive installations, do not remove the housing

covers when power is applied to the level detector.

Both housing covers must be fully engaged to meet flameproof/explosion-proof

requirements.

Rosemount 2140 and 2140:SIS Level Detectors 13

Page 14

Mechanical installation Reference Manual

March 2022 00809-0100-4140

WARNING

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can

cause electrical shock.

Ensure the power to the level detector is off, and the lines to any other external power

source are disconnected or not powered while wiring the level detector.

Ensure the wiring is suitable for the electrical current and the insulation is suitable for the

voltage, temperature, and environment.

WARNING

Process leaks could result in death or serious injury.

Ensure the level detector is handled carefully. If the process seal is damaged, gas might

escape from the vessel (tank) or pipe.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or unintentional and

needs to be protected against.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access by unauthorized personnel to protect end

users’ assets. This is true for all systems used within the facility.

CAUTION

Hot surfaces

The flange and process seal may be hot at high process temperatures. Allow to cool before

servicing.

3.2 Installation considerations

Before installing the level detector, review the safety, environmental, application, and preinstallation sections.

3.2.1 Environmental considerations

The Rosemount 2140 is weatherproof and protected against the ingress of dust, but must

be protected from flooding. Avoid installing the level detector near heat sources.

14 Reference Manual

Page 15

OKOK

Reference Manual Mechanical installation

00809-0100-4140 March 2022

Figure 3-1: Environmental Considerations

3.2.2 Application considerations

The level detectors can be mounted in an open or closed tank, or a pipe. There is a wide

range of threaded, flanged, and hygienic process connection options.

For most liquids, including coating, aerated liquids and slurries, the function is virtually

unaffected by flow, turbulence, bubbles, foam, vibration, solid particles, build-up, or

properties of the liquid medium.

Avoid process medium build-up on the forks

Avoid situations where a drying and coating process medium may create an excessive

build-up or implement preventative maintenance programs to ensure the build-up is not

enough to impair performance (see Figure 3-2).

Rosemount 2140 and 2140:SIS Level Detectors 15

Page 16

OK

Mechanical installation Reference Manual

March 2022 00809-0100-4140

Always ensure:

• There is sufficient distance between build-up on the tank wall and the fork.

• There is no risk of ‘bridging’ the level switch forks.

Examples of products that can create ‘bridging’ of forks and impair performance are

dense paper slurries and bitumen.

Figure 3-2: Avoid Product Build-up

Operating temperature and pressure ranges

Ensure the process is operating within the instrument operating temperature and pressure

ranges.

Liquid density requirements

Minimum liquid density is 0.4 SG (400 kg/m3).

Liquid viscosity range

Up to 10000 cP (centiPoise) when operating in the Normal mode.

Up to 1000 cP (centiPoise) when operating in Enhanced mode.

Foams

In almost all cases, the Rosemount 2140 is insensitive to foams (i.e. does not see the

foam).

However in rare occasions, some very dense foams may be seen as liquid; known examples

of this are found in ice-cream and orange juice manufacturing.

16 Reference Manual

Page 17

SP

HYSP

0.5

(13)

0.1

(2.5)

0.5

(13)

Reference Manual Mechanical installation

00809-0100-4140 March 2022

Switching point

The switching point varies with different liquid densities. The switching point (SP) and

hysteresis (HY) for water are shown in Figure 3-3.

Figure 3-3: Switching Point in Inches (Millimeters)

Note

When mounted vertically, a low density medium has a switching point closer to the

process connection. A high density medium has a switching point closer to fork tip.

3.2.3 Pre-installation considerations

Measurement accuracy is dependent upon the proper installation of the device. Keep in

mind the need for easy access, personnel safety, practical field calibration, and a suitable

environment for the device.

Device identification

To identify a version of the level detector, see the label on the housing.

How to handle a level detector

Handle the level detector with great care.

The weight of the level detector with a heavy flange and extended fork length may exceed

37 lb. (18 kg). A risk assessment is required to be done before carrying, lifting, and

installing the level detector.

Use both hands to carry the extended length and high temperature versions, and do not

hold a level detector by the forks (see Figure 3-4).

Rosemount 2140 and 2140:SIS Level Detectors 17

Page 18

Mechanical installation Reference Manual

March 2022 00809-0100-4140

Figure 3-4: Handling

Make no alterations to the level detector

Never make any alterations to the mechanical or electrical features of the level detector

(see Figure 3-5).

Figure 3-5: Make No Alterations

Allow adequate space outside tank or pipe

Mount a level detector so that it is removable and allow both covers to be removed.

Ensure there is also enough room for fitting cable glands and cables.

Clearances:

• A clearance of 0.75 in. (19 mm) is required for the standard covers to be removed.

• If an LCD display is installed, provide 3 in. (76.2 mm) of clearance for the extended

cover to be removed.

Note

The electronics housing can be rotated for optimal viewing position of an LCD display (if

fitted) and to assist with the cabling.

18 Reference Manual

Page 19

D

A

B

Reference Manual Mechanical installation

00809-0100-4140 March 2022

Covers installation

Ensure a proper seal by installing the electronics housing covers so that metal contacts

metal. Always use Emerson's O-rings.

Mounting orientation

Mount the Rosemount 2140 at any angle that allows the level of the process medium to

rise, fall, or flow through the fork gap.

Related information

Correct fork alignment

Pipe installation requirements

• The inside pipe diameter (D) must be 1.4 in. (35 mm) or larger.

• Ensure the fork tines intrude at least 0.9 in. (22 mm) into the pipe.

• Keep at least 0.3 in. (7 mm) of clearance between the fork tines and the pipe wall.

Figure 3-6: Pipe Installation

A. Minimum intrusion 0.9 in. (22 mm)

B. Minimum clearance 0.3 in. (7 mm)

Rosemount 2140 and 2140:SIS Level Detectors 19

Page 20

B

B

A

Mechanical installation Reference Manual

March 2022 00809-0100-4140

Other recommendations

• Avoid:

— Installing near to liquid entering the tank at the filling-point.

— Heavy splashing on the forks.

Increasing the sensor output delay reduces accidental detection caused by splashing.

• Always ensure:

— The overall system is tested during commissioning.

— The installation does not create tank crevices around the forks where a liquid

medium may collect. This event can happen with high-viscosity and high-density

liquids.

— The forks do not come into contact with the vessel (tank) or pipe wall, internal

fittings, or any other obstructions.

• Extra consideration is needed if the plant vibration is close to the 1400 Hz operating

frequency of the fork.

Required supports for extended fork

Supporting the extended fork avoids long fork length vibration.

Figure 3-7: Vertical Installation

20 Reference Manual

B. 3.28 ft. (1.0 m)

A. Maximum 3.28 ft. (1.0 m)

Page 21

A

B B

Reference Manual Mechanical installation

00809-0100-4140 March 2022

Figure 3-8: Horizontal Installation

A. Maximum 3.28 ft. (1.0 m)

3.28 ft. (1.0 m)

B.

Rosemount 2140 and 2140:SIS Level Detectors 21

Page 22

B

A

C

D

E

F

Mechanical installation Reference Manual

March 2022 00809-0100-4140

3.3 Installation procedures

3.3.1 Process connection seals

Figure 3-9: Process Connection Seals

A. PTFE tape

B. NPT or BSPT (R) thread

C. Gasket

D. BSPP (G) thread

22 Reference Manual

E. Tri Clamp

F. The Tri Clamp seal is supplied in an accessory kit

Page 23

OKOK

OK

C

A

B

OK

A

B

OK

A

B

Reference Manual Mechanical installation

00809-0100-4140 March 2022

3.3.2 Correct fork alignment

Fork alignment in a vessel (tank) installation

The fork is correctly aligned by positioning the groove or notch as indicated (Figure 3-10).

Figure 3-10: Correct Fork Alignment for Vessel (Tank) Installation

A. Tri Clamp process connections have a circular notch

B. Threaded process connections have a groove

C.

Flanged process connections have a circular notch

Fork alignment in a pipe installation

The fork is correctly aligned by positioning the groove or notch as indicated (Figure 3-11).

Figure 3-11: Correct Fork Alignment for Pipe Installation

A. Tri Clamp process connections have a circular notch

B. Threaded process connections have a groove

Rosemount 2140 and 2140:SIS Level Detectors 23

Page 24

A

A

Mechanical installation Reference Manual

March 2022 00809-0100-4140

3.3.3 Mounting the threaded version

Threaded vessel (tank) or pipework connection

Procedure

1. Seal and protect the threads. Use anti-seize paste or PTFE tape according to site

procedures.

A gasket may be used as a sealant for BSPP (G) threaded connections.

2. Screw the level detector into the process connection.

Note

Tighten using the hexagon nut only.

Figure 3-12: Vertical Installation

A. Gasket for BSPP (G) threaded connection

Figure 3-13: Horizontal Installation

A. Gasket for BSPP (G) threaded connection

24 Reference Manual

Page 25

A

Reference Manual Mechanical installation

00809-0100-4140 March 2022

Threaded flange connection

Procedure

1. Place the customer-supplied flange and gasket on the vessel (tank) nozzle.

A. Gasket (customer supplied)

2. Tighten the bolts and nuts with sufficient torque for the flange and gasket.

3. Seal and protect the threads. Use anti-seize paste or PTFE tape according to site

procedures.

A gasket may be used as a sealant for BSPP (G) threaded connections.

Rosemount 2140 and 2140:SIS Level Detectors 25

Page 26

A

A

Mechanical installation Reference Manual

March 2022 00809-0100-4140

4. Screw the level detector into the flange thread.

Note

Tighten using the hexagon nut only.

A. Gasket for BSPP (G) threaded connection

3.3.4 Mounting the flanged version

Procedure

1. Lower the level detector into the nozzle.

A. Gasket (customer supplied)

26 Reference Manual

Page 27

A

Reference Manual Mechanical installation

00809-0100-4140 March 2022

2. Tighten the bolts and nuts with sufficient torque for the flange and gasket.

3.3.5 Mounting the Tri Clamp version

Procedure

1. Lower the level detector into the flange face.

A. Seal (supplied with Tri Clamp)

Rosemount 2140 and 2140:SIS Level Detectors 27

Page 28

H3/32 in.

Torque 30 in-lb (3 Nm)

Mechanical installation Reference Manual

March 2022 00809-0100-4140

2. Fit the Tri Clamp.

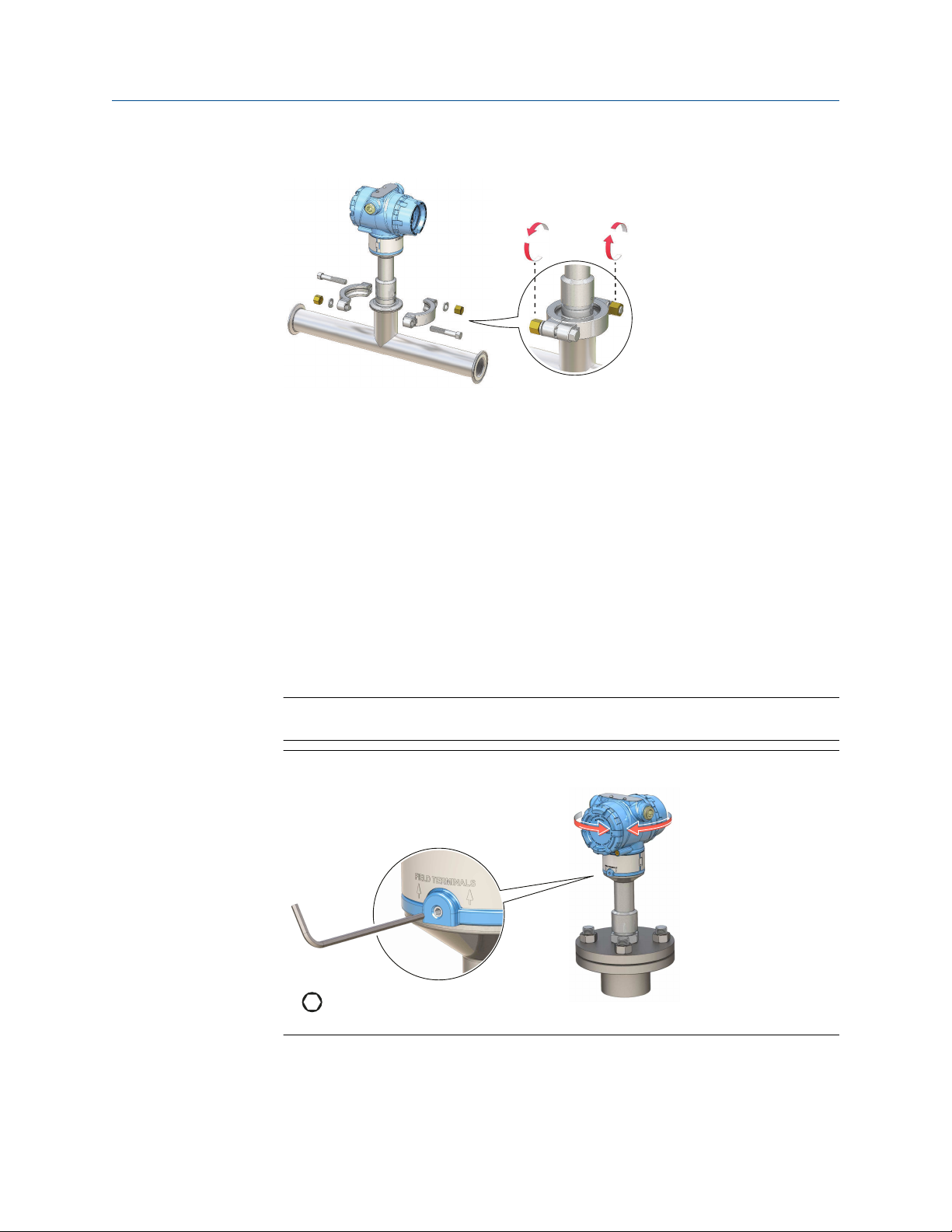

3.4 Adjust display orientation (optional)

To improve field access to wiring or to better view the optional LCD display:

Procedure

1. Loosen the set screw until the level detector housing can rotate smoothly.

Do not unscrew all the way. Rotating the housing, without this screw in place, can

damage the internal wiring.

2.

First, rotate the housing clockwise to the desired location.

If the desired location cannot be achieved due to thread limit, rotate the housing

counterclockwise.

3. Re-tighten the set screw.

Note

Do not attempt to rotate the display beyond the thread limits.

Figure 3-14: Housing Rotation

28 Reference Manual

Page 29

Reference Manual Electrical installation

00809-0100-4140 March 2022

4 Electrical installation

4.1 Prepare the electrical connections

4.1.1 Cable selection

Use 24–14 AWG wiring. Twisted-pairs and shielded wiring is recommended for

environments with high EMI (electromagnetic interference). Two wires can be safely

connected to each terminal screw.

4.1.2 Cable glands/conduits

For intrinsically safe, explosion-proof/flameproof, and dust-proof installations, only use

certified cable glands or conduit entry devices. Ordinary location installations can use

suitably rated cable glands or conduit entry devices to maintain the Ingress Protection (IP)

rating.

Unused conduit entries must always be sealed with a suitably rated blanking/stopping

plug.

Note

Do not run signal wiring in conduit or open trays with power wiring or near heavy electrical

equipment.

4.1.3 Power supply

Each level detector operates on 10.5 – 42.4 Vdc (10.5 – 30 Vdc in Intrinsically Safe

installations) at the level detector terminals.

4.1.4 Power consumption

Maximum of 1 W, and current maximum is 23 mA.

4.1.5 Hazardous areas

When the device is installed in hazardous areas (classified locations), local regulations and

the conditions-of-use specified in applicable certificates must be observed. Review the

Rosemount 2140 Product Certifications document for information.

4.1.6 Load limitations

For HART® communications, a minimum load resistance of 250 Ω is required.

The maximum loop resistance is determined by the voltage level of the external power

supply (see Figure 4-1).

Rosemount 2140 and 2140:SIS Level Detectors 29

Page 30

1400

1200

1000

800

600

400

200

0

100 20 30 40 50

250

587

848

1392

16.3 24 42.4

10.5

A

B

-

+

-

+

Fn

1

2

3

4

5

6

7

8

9

0

-

.

A

C

D

E

FB

Electrical installation Reference Manual

March 2022 00809-0100-4140

Figure 4-1: Load Limitations

Maximum loop resistance = 43.5 × (external power supply voltage - 10.5)

A. Loop resistance in Ohms (Ω)

B.

External power supply voltage (Vdc)

4.1.7 Wiring diagram

Figure 4-2: 4-20 mA/HART® Communication

A. Handheld communicator

B. Approved IS barrier (for Intrinsically Safe installations only)

HART modem

C.

D. Load resistance (≥250 Ω)

E. Current meter

F. Power supply

30 Reference Manual

Page 31

A

B

A

B

B

C C

D

Reference Manual Electrical installation

00809-0100-4140 March 2022

4.1.8 Grounding

Make sure grounding is done according to national and local electrical codes. Failure to do

so may impair the protection provided by the equipment.

Grounding the housing

The most effective grounding method is direct connection to earth ground with minimal

impedance. There are two grounding screw connections provided (see Figure 4-3).

Figure 4-3: Ground Screws

A. External ground screw

Internal ground screw

B.

Signal cable shield grounding

Make sure the instrument cable shield is:

• Trimmed close and insulated from touching the housing.

• Continuously connected throughout the segment.

• Connected to a good earth ground at the power supply end.

Figure 4-4: Signal Cable Shield Grounding at Power Supply End

A. Trim shield and insulate

B. Minimize distance

Trim shield

C.

D. Connect shield back to the power supply ground

Transient protection terminal block grounding

The level detector can withstand electrical transients of the energy level usually

encountered in static discharges or induced switching transients. However, high-energy

transients, such as those induced in wiring from nearby lightning strikes, can damage the

level detector.

Rosemount 2140 and 2140:SIS Level Detectors 31

Page 32

M2.5

Electrical installation Reference Manual

March 2022 00809-0100-4140

A transient protection terminal block can be ordered as an installed option (code T1). The

lightning bolt symbol in identifies the transient protection terminal block.

Note

The transient protection terminal block does not provide transient protection unless the

housing is properly grounded.

4.2 Connect wiring and power up

Procedure

1. Verify the power supply is disconnected.

2. Remove the field terminals cover.

In an explosion-proof/flameproof installation, do not remove the level detector

covers when power is applied to the unit. Covers are also not to be removed in

extreme environmental conditions.

a)

Turn the jam screw clockwise until it is completely threaded into the housing.

b) Turn the cover counter-clockwise until it is removed from the housing.

Keep the cover O-ring safe. Replace the O-ring if it is worn or damaged.

32 Reference Manual

Page 33

M20

½-14 NPT

M20 x 1.5

Reference Manual Electrical installation

00809-0100-4140 March 2022

3. Remove the plastic plugs.

4. Pull the cable through the cable gland/conduit.

Identification of thread size and type:

5. Connect the cable wires.

Torque 7 in-lb (0.8 Nm)

6. Ensure proper grounding.

Rosemount 2140 and 2140:SIS Level Detectors 33

Page 34

Electrical installation Reference Manual

March 2022 00809-0100-4140

7. Tighten the cable gland.

Apply PTFE tape or other sealant to the threads.

Note

Make sure to arrange the wiring with a drip loop.

8. Plug and seal the unused conduit connection to avoid moisture and dust

accumulation inside the housing.

Apply PTFE tape or other sealant to the threads.

34 Reference Manual

Page 35

M2.5

M2.5

Reference Manual Electrical installation

00809-0100-4140 March 2022

9. Attach and tighten the cover.

a) Verify the cover jam screw is completely threaded into the housing.

b) Attach and tighten the cover.

Make sure the cover is fully engaged. There should be no gap between the

cover and the housing.

10. Required for explosion-proof/flameproof installations only:

a) Turn the cover jam screw counterclockwise until it contacts the cover.

b) Turn the jam screw an extra ½ turn counterclockwise to secure the cover.

c) Verify that the cover cannot be removed.

11.

Connect the power supply.

Rosemount 2140 and 2140:SIS Level Detectors 35

Page 36

Electrical installation Reference Manual

March 2022 00809-0100-4140

36 Reference Manual

Page 37

Reference Manual Configuration

00809-0100-4140 March 2022

5 Configuration

5.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the

safety of the personnel performing the operations. Information that potentially raises

safety issues is indicated by a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

WARNING

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Ensure the level detector is installed by qualified personnel and in accordance with

applicable code of practice.

Use the level detector only as specified in this manual. Failure to do so may impair the

protection provided by the level detector.

The weight of a level detector with a heavy flange and extended fork length may exceed

37 lb. (18 kg). A risk assessment is required before carrying, lifting, and installing the level

detector.

For installations in hazardous locations, the level detector must be installed according to

the Rosemount 2140 and 2140:SIS Level Detectors Product Certifications document.

Repair, e.g. substitution of components, etc. may jeopardize safety and is under no

circumstances allowed.

WARNING

Explosions could result in death or serious injury.

Verify that the operating atmosphere of the level detector is consistent with the

appropriate hazardous locations certifications.

Before connecting a handheld communicator in an explosive atmosphere, ensure that the

instruments in the loop are installed in accordance with intrinsically safe or non-incendive

field wiring practices.

In explosion-proof/flameproof and non-incendive installations, do not remove the housing

covers when power is applied to the level detector.

Both housing covers must be fully engaged to meet flameproof/explosion-proof

requirements.

Rosemount 2140 and 2140:SIS Level Detectors 37

Page 38

Configuration Reference Manual

March 2022 00809-0100-4140

WARNING

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can

cause electrical shock.

Ensure the power to the level detector is off, and the lines to any other external power

source are disconnected or not powered while wiring the level detector.

Ensure the wiring is suitable for the electrical current and the insulation is suitable for the

voltage, temperature, and environment.

WARNING

Process leaks could result in death or serious injury.

Ensure the level detector is handled carefully. If the process seal is damaged, gas might

escape from the vessel (tank) or pipe.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or unintentional and

needs to be protected against.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access by unauthorized personnel to protect end

users’ assets. This is true for all systems used within the facility.

CAUTION

Hot surfaces

The flange and process seal may be hot at high process temperatures. Allow to cool before

servicing.

5.2 Configuration tools

• Field Device Integration (FDI) based systems

• Device Descriptor (DD) based systems

• Device Type Manager (DTM™ ) based systems

• Local Operator Interface (LOI)

38 Reference Manual

Page 39

A

B

Reference Manual Configuration

00809-0100-4140 March 2022

5.3 Local Operator Interface (LOI)

The LOI requires option code M4 to be selected when ordering a level detector.

It uses a character display (Figure 5-1) to indicate the live output state, diagnostic

messages, and menus. There are two rows of characters, with 8 on the upper row and 6 on

the lower row.

Figure 5-1: Local Operator Interface (LOI) Display

Related information

Local Operator Interface (LOI) menu trees

5.3.1 LOI configuration buttons

To activate the LOI, push any of the configuration buttons. Left and right configuration

buttons are located on the LCD display (accessible after removing a housing cover) and

duplicated underneath the moveable top-tag.

Figure 5-2: LOI Configuration Buttons

A. Internal configuration buttons, left and right

B. External configuration buttons, left and right

5.3.2 LOI button operation

Table 5-1 shows examples of the basic configuration button functionality. Some features

in the LOI menu use multiple screens to complete their configuration. Any data entered is

saved on a screen-by-screen basis, and the LOI indicates this by flashing “SAVED” on the

LCD display each time.

Rosemount 2140 and 2140:SIS Level Detectors 39

Page 40

Configuration Reference Manual

March 2022 00809-0100-4140

Table 5-1: LOI Button Operation

LOI screen Button Function

Left NO

Right YES

Left SCROLL DOWN

Right ENTER

5.4 Confirm correct device driver

Procedure

1. Verify that the correct FDI/DD/DTM Package is loaded on your systems to ensure

proper communication.

2.

Download the latest FDI/DD/DTM Package at Emerson.com/DeviceInstallKits or

FieldCommGroup.org.

Related information

NAMUR NE 53 revision

5.5 Confirm HART® revision capability

If using HART-based control or asset management systems, confirm the HART capability

of those systems prior to installation of the device. Not all systems are capable of

communicating with HART Revision 7 protocol. This device can be configured for either

HART Revision 5 or 7.

5.5.1 Switch HART revision

Procedure

1. Select

2. Under Communication Settings, select Change HART Revision and follow the on-

5.5.2 Switch HART revision with a generic menu

If the HART configuration tool is not capable of communicating with a HART Revision 7

device, it will load a generic menu with limited capability.

Configure → Manual Setup → HART.

screen instructions.

Procedure

Locate the “Message” field.

• To switch to HART Revision 5, enter HART5 and 27 spaces in the message field.

40 Reference Manual

Page 41

Reference Manual Configuration

00809-0100-4140 March 2022

• To switch to HART Revision 7, enter HART7 and 27 spaces in the message field.

5.5.3 Switch HART revision using the LOI

To switch the HART revision mode using the LOI (Local Operator Interface):

Procedure

1. Press any LOI configuration button to activate the menu.

Scroll down (

2.

3. Scroll down ( ) and then select HART REV ( ) .

4. To change HART revision, select

HART REV 7 ( ).

5. Exit the menu system by either waiting one minute for the

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

) and then select EXTENDED MENU ( ) .

HART REV 5 (

), or scroll down ( ) and then select

EXIT MENU? prompt, or

5.6 Configure device using guided setup

The options available in the Guided Setup wizard include all items required for basic

operation.

Procedure

Select

1.

2. Select Basic Setup and follow the on-screen instructions.

Configure → Guided Setup.

5.6.1 Configure using the LOI

The Guided Setup wizard is not available on the LOI (Local Operator Interface). See the

appendix Configuration parameters for the LOI instructions to configure basic parameters,

and then return here to verify configuration.

5.7 Verify the configuration

It is recommended that configuration parameters are verified prior to using the level

detector live in a process.

5.7.1 Verify configuration using a handheld communicator

Table 5-2 lists the configuration parameters to be reviewed before using the level detector

live in a process. From the HOME screen of the handheld communicator, enter the fast key

sequences as listed.

Rosemount 2140 and 2140:SIS Level Detectors 41

Page 42

Configuration Reference Manual

March 2022 00809-0100-4140

Table 5-2: Verifying Configuration (Fast Key Sequences)

Parameter Fast key sequence

HART 7 HART 5

Tag 1, 8, 1, 2 1, 8, 1, 1

Model 1, 8, 1, 3 1, 8, 1, 3

Primary Variable 3, 2, 1, 1 3, 2, 1, 1

Sensor Operating Mode 2, 2, 1, 1, 1 2, 2, 1, 1, 1

Sensor Output Delay 2, 2, 1, 1, 2 2, 2, 1, 1, 2

Media Density 2, 2, 1, 1, 3 2, 2, 1, 1, 3

Sensor Fault Delay 2, 2, 1, 3, 2 2, 2, 1, 3, 2

(4)

(4)

(2)

(2)

(1)

(3)(4)

(3)(4)

(3)

(3)

2, 2, 2, 1, 1 2, 2, 2, 1, 1

2, 2, 2, 1, 3 2, 2, 2, 1, 3

2, 2, 2, 1, 4 2, 2, 2, 1, 4

2, 2, 2, 2, 2 2, 2, 2, 2, 2

2, 2, 2, 2, 3 2, 2, 2, 2, 3

2, 2, 2, 5, 3 2, 2, 2, 5, 3

2, 2, 2, 5, 6 2, 2, 2, 5, 6

2, 2, 2, 5, 4 2, 2, 2, 5, 4

2, 2, 2, 5, 5 2, 2, 2, 5, 5

Current Output Type

Custom Off Current

Custom On Current

PV URV (Upper Range Value)

PV LRV (Lower Range Value)

High Alarm Level

Low Alarm Level

High Saturation Level

Low Saturation Level

Alarm Switch Position/Direction 2, 2, 2, 5, 2 2, 2, 2, 5, 2

(1) Only applicable when the Primary Variable is mapped to the Output State variable.

(2) Only applicable when Current Output Type is set to “Custom”.

(3) Only applicable when the Primary Variable is mapped to the Sensor Frequency or Scaled Variable

variables.

(4) Alarm level and saturation level depend on the Alarm Level switch setting and the ordered Alarm

Level option code.

5.7.2 Verify configuration using the LOI

Table 5-3 lists the configuration parameters to be reviewed on the LOI (Local Operator

Interface) before using the level detector live in a process.

Procedure

1. Press any LOI configuration button to activate the menu.

2.

Select VIEW CONFIG (

3. Scroll down ( ) to review the parameters.

4. Exit the menu system by either waiting one minute for the

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

).

EXIT MENU? prompt, or

42 Reference Manual

Page 43

Reference Manual Configuration

00809-0100-4140 March 2022

Table 5-3: Verifying Configuration (LOI)

Parameter Information

TAG Free-form text for giving the device an identity

MODEL e.g. “2140”

T Range Operating temperature range

IS PV Primary Variable mapping

S UNIT Secondary Variable units

T UNIT Electronics temperature units

OP MODE Operating mode

DENSITY Media density

O DLY Sensor output delay

F DLY Fault output delay

(1)

(1)

(1)

Analog Output operating mode

Custom mA output for ‘off’ output state

Custom mA output for ‘on’ output state

AOMODE

OFF MA

ON MA

S-START Device test/proof test at start

(2)

URV

LRV

(2)

Upper range value for analog output

Lower range value for analog output

DAMPING Scaled Variable damping

HIALRM

LOALRM

HI SAT

LO SAT

(3)

(3)

(2)(3)

(2)(3)

High alarm level

Low alarm level

High saturation level

Low saturation level

ALARM Alarm switch position/direction

SECURE Security switch position

(1) Only visible when the Primary Variable (“PV”) is mapped to the Output State variable.

(2) Only visible when the Primary Variable (“PV”) is mapped to the Sensor Frequency or

Scaled Variable variables.

(3) Alarm level and saturation level depend on the Alarm Level switch setting and the

ordered Alarm Level option code.

5.8 Multidrop communication

Multidropping refers to the connection of several devices to a single communications

transmission line. Communication between the host device and another device takes

place digitally with the analog output of the level detector deactivated. Figure 5-3 shows a

typical multidrop network.

Rosemount 2140 and 2140:SIS Level Detectors 43

Page 44

A

B

Configuration Reference Manual

March 2022 00809-0100-4140

Figure 5-3: Typical Multidrop Network

A. HART modem

B. Power supply

Multidrop installation requires consideration of the update rate necessary from each

device, the combination of different device types, and the length of the transmission line.

Communication with devices can be accomplished with HART modems and a host

implementing the HART protocol. Each device is identified by a unique address and

responds to the commands defined in the HART protocol.

Note

A multidrop device in HART Revision 7 mode has a fixed analog output of 4 mA for all but

one device. Only one device is allowed to have an active analog signal.

The level detector is set to address zero (0) at the factory, which allows operation in the

standard point-to-point manner with a 4–20 mA output signal.

5.8.1 Establish multidrop communication

To activate multidrop communication, the address must be changed to a number from 1

to 15 for HART Revision 5, or 1 to 63 for HART Revision 7. This change deactivates the 4–

20 mA analog output, sending it to 4mA.

It also disables the failure mode alarm signal, which is controlled by the upscale/downscale

switch position. Failure signals in multidropped devices are communicated through HART

messages.

Procedure

1. Select

2. Under Communication Settings, select Change Polling Address and follow the on-

Configure → Manual Setup → HART.

screen instructions.

5.9 HART burst mode

Burst mode is compatible with the analog output signal. Due to the way that HART

44 Reference Manual

protocol features simultaneous digital and analog data transmission, the analog value can

drive other equipment in the loop while the control system is receiving the digital

information.

Page 45

Reference Manual Configuration

00809-0100-4140 March 2022

Burst mode applies only to the transmission of dynamic variables (PV, SV, TV, and QV), and

does not affect the way other data is accessed. However, when activated, burst mode can

slow down communication of non-dynamic variable data to the host by 50%.

Access to information, other than dynamic variables, is obtained through the normal polland-response method of HART communication. The configuration tool or control system

may request any of the information that is normally available while the device is in burst

mode. Between each message sent by the device, a short pause allows a host

(configuration tool or control system) to initiate a request.

5.9.1 Configure burst mode

Prerequisites

Check if the host system supports burst mode and what options are required. The burst

from the level detector will be at a continuous rate of once every 0.5 seconds.

Procedure

1. Select

2. Under Burst Mode Configuration, in the Burst mode list, select Enabled.

3. In the Burst command list, select the desired burst option (e.g. PV, SV, TV, and

4. Optional: Select Configure Additional Messages to configure Burst Message 2 and

Configure → Manual Setup → HART.

QV).

Burst Message 3.

5.10 Security

There are four security methods:

• Security switch

• HART lock

• Configuration button lock

• Local Operator Interface (LOI) password

5.10.1 Alarm and security switches

Alarm level switch

Under alarm conditions, the output current is forced to a high or low level beyond the

normal 4 mA to 20 mA operating range.

The Alarm Level hardware switch is set to a 'H' or 'L' position to determine if it is the high or

low alarm current. Figure 5-4 shows the Alarm Level switch inside the housing.

Security switch

The security switch is set to the Locked position to prevent configuration changes using

the optional Local Operator Interface (LOI) or HART® interfaces.

Figure 5-4 shows the security switch inside the housing.

Rosemount 2140 and 2140:SIS Level Detectors 45

Page 46

Without LOI display

With LOI display

A

B

Configuration Reference Manual

March 2022 00809-0100-4140

Figure 5-4: Alarm Level and Security Switches

A. Alarm level switch

Security switch

B.

5.10.2 Set the position of the security switch

When the security switch is set to the locked position ( ) , all configuration requests made

using HART, LOI, or local configuration buttons are rejected.

Procedure

1. Set process loop to manual and remove power.

2. Remove the housing cover.

Use a small screwdriver to slide the security switch to the preferred position.

3.

4. Replace the housing cover.

Note

The cover must be fully engaged with the cover jam screw to comply with

explosion-proof requirements.

View the security switch status

The position of the security switch can be checked without removing the housing cover.

Procedure

Select Service Tools → Maintenance → Security.

The Write protect box shows the status of the security switch.

View the security switch status using the LOI

46 Reference Manual

The position of the security switch can be checked without removing the housing cover.

Procedure

Press any LOI configuration button to activate the menu.

The display shows LOCK WRITE if the security switch is enabled.

Page 47

Reference Manual Configuration

00809-0100-4140 March 2022

5.10.3 Set the HART lock

The HART Lock function prevents HART commands from making changes to the

configuration.

Prerequisites

The device must be using HART Revision 7.

Procedure

1. Select

2. Under HART Lock (Software), select Lock/Unlock and follow the on-screen

Related information

Switch HART revision

Configure → Manual Setup → Security.

instructions.

5.10.4 Set the configuration button lock

The configuration button lock disables all local button functionality.

Procedure

Select

1.

2. In the Configuration Buttons list, select Disabled to lock the external local buttons

Configure → Manual Setup → Security.

or Enabled to unlock.

5.10.5 Local Operator Interface (LOI) lock

A Local Operator Interface (LOI) password can used to prevent the review and modification

of the level detector configuration using the LOI. The password is a 4-digit code that is to

be set by the user.

Note

This password protection does not prevent access to the level detector configuration

using HART communications.

Set the LOI password

Procedure

1. Select

2. Select Configure Password (LOI Password Protection in handheld communicator)

Configure → Manual Setup → Security.

and follow the on-screen instructions.

Set the LOI password using the LOI

Procedure

1. Press any LOI configuration button to activate the menu.

2. Scroll down (

Rosemount 2140 and 2140:SIS Level Detectors 47

) and then select EXTENDED MENU ( )

Page 48

Configuration Reference Manual

March 2022 00809-0100-4140

3. Scroll down ( ) and then select PASSWORD ( ) .

4. Enable the LOI password protection.

5.

Enter a 4-digit number as the password.

6. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

48 Reference Manual

Page 49

Reference Manual Operation

00809-0100-4140 March 2022

6 Operation

6.1 LCD display screen messages

The optional Local Operator Interface (LOI) includes a LCD display that shows output

variables and abbreviated diagnostic messages.

Figure 6-1: LOI and LCD Display (Option Code M4)

Variable screens

The level detector can display the following variables:

Table 6-1: LCD Display Variables

Parameter Presentation on

display

Output State

Sensor State STATE Live fork state: ‘dry’ (0.0) or ‘wet’ (1.0).

Sensor Frequency Hz Live vibration frequency of the fork.

Percent of Range

Primary Variable

Scaled Variable

Electronics

Temperature

Supply Voltage V The live voltage at the terminals.

Analog Output MA The live analog output current.

(1) Default parameter displayed.

(2) Not available for Rosemount 2140:SIS.

(1)

(2)

OUTPUT Live output state: ‘off’ (0.0) or ‘on’ (1.0).

%RANGE A live variable value expressed in percent within

SCALED A live variable calculated from a scaling table (as

DEG F / DEG C The live temperature at the electronics.

Description

a range defined by a Lower Range Value (LRV)

and an Upper Range Value (URV).

defined by pairs of input/scaled values).

Rosemount 2140 and 2140:SIS Level Detectors 49

Page 50

Operation Reference Manual

March 2022 00809-0100-4140

6.2 Set up the LCD display

It is possible to specify the variables to be presented on the optional LCD display.

Procedure

1. Select

2. Select the desired variables to be displayed on the LCD display.

Configure → Manual Setup → Display.

6.2.1 Set up the LCD display using the LOI

It is possible to specify the variables to be presented on the optional LCD display.

Procedure

1. Press any LOI configuration button to activate the menu.

Scroll down (

2.

3. OUTPUT is the first variable in this menu.

Select

a)

b) Select

4. For all other variables of interest:

a) Scroll down (

b) Select

The last item, STARTUP, enables or disables the startup screens when the

level detector is started. By default, this is not enabled. Startup screens

include a display test and the VIEW CONFIG content.

) and then select DISPLAY ( )

OUTPUT (

No or Yes to answer the prompt asking if it is to be displayed or not.

No or Yes to answer the prompt asking if it is to be displayed or not.

).

) and then select ( ) .

5. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

6.3 View measurement data

Current measurement data of the primary variables are presented on the Overview screen.

To view all current measurement values:

Procedure

Service Tools → Variables.

Select

1.

2. Select Variable Summary, Mapped Variables, or Device Variables.

6.3.1 Interpret measurement status

A “Good” or “Bad” status next to a value is an indication of the reliability or integrity of the

data being received, not an indication of whether or not the value is within the configured

upper or lower ranges. A value that triggers an alert, such as a high or low temperature

indication, will change the overall status of the device, but the measurement might still be

indicated as “Good” if the reliability of the data is good.

50 Reference Manual

Page 51

Reference Manual Operation

00809-0100-4140 March 2022

6.3.2 View measurement data using the LOI

The optional LOI and LCD is configurable to show a different variable every few seconds.

Related information

Set up the LCD display using the LOI

6.4 Check device status

The overall device status is presented under the Overview screen. The device reports

diagnostic alerts when there is a device malfunction.

Procedure

1. Go to the

2. If status is anything other than Good, select the button in the device status image to

open a window with Active Alerts.

Active Alerts can also be obtained via Service Tools → Alerts.

Related information

Diagnostic messages

Overview screen to view the overall device status.

Rosemount 2140 and 2140:SIS Level Detectors 51

Page 52

Operation Reference Manual

March 2022 00809-0100-4140

6.4.1 Device status images

Table 6-2: Presentation of Device Status Images as per NAMUR NE 107 – AMS Device Manager

Device status image Category Description Action

Good No active alert. N/A

Failure At least one Failure alert is

active.

Function Check At least one Function Check alert

is active (and no Failure alerts).

Out of

Specification

Maintenance

Required

At least one Out of Specification

alert is active (and no Failure or

Function Check alerts).

At least one Maintenance

Required alert is active (and no

Failure, Function Check, or Out

of Specification alerts).

Click the Troubleshoot button

to open a window with active

alerts together with

recommended actions.

Click the Investigate button to

open a window with active alerts

together with recommended

actions.

52 Reference Manual

Page 53

Reference Manual Operation

00809-0100-4140 March 2022

6.5 Partial proof testing

Partial proof testing simulates sensor changes from dry-to-wet and wet-to-dry when a

level detector is already installed, but does not require the actual process to change.

Comprehensive proof testing requires the forks to be immersible in a liquid and observing

the output changes.

The level detector has partial proof testing support as standard, and it can be triggered

locally using the Local Operator Interface (if fitted) or remotely using a HART command

e.g. from a DD-based host system.

Initially, the device diagnostics are checked by the level detector before simulating sensor

states. Any detected faults will end the proof test immediately, requiring further

investigation.

Proof testing then exercises the analog output to produce the electrical currents

representing:

• The ‘off’ and ‘on’ states (if configured for a switched output).

• Lower and upper range values (if configured for a 4–20 mA output).

• High and low alarms.

When the Primary Variable is mapped to the Scaled Variable

variables, the analogue output is also exercised from the low saturation level to the high

saturation level.

For Safety Instrumented System (SIS) applications, the Rosemount 2140:SIS must be

tested at regular intervals. This is to detect any failures not automatically detected by the

device self-test at start-up and the continuous fork sensor diagnostics when operating in

Enhanced mode.

Related information

Rosemount 2140:SIS Safety Manual

6.5.1 Start the remote partial proof test

Procedure

1. Select

2. Select Partial Proof-Test and follow the on-screen instructions.

Service Tools → Maintenance → Test.

(1)

or Sensor Frequency device

(1) Available on Rosemount 2140 version of the level detector only.

Rosemount 2140 and 2140:SIS Level Detectors 53

Page 54

Operation Reference Manual

March 2022 00809-0100-4140

6.5.2 Start the local partial proof test

By default, the partial proof testing sequence is not started at every power-up. It can be

started by an operator using the Local Operator Interface (LOI).

Procedure

In the menu system, select TEST → PROOF TEST or, when no LOI is not fitted, by using the

single external push-button fitted to the top of the level detector (underneath the

movable nameplate).

6.5.3 Configure the proof test function

Procedure

1. Select

2. Set the Duration as desired.

3. In the Start-up Proof-Test list, select Enabled or Disabled.

Configure → Manual Setup → Operation → Proof Test.

Configure proof test function using the LOI

Procedure

1. Press any LOI configuration button to activate the menu.

2. Scroll down (

3. Scroll down ( ) and then select PROOF TEST ( ).

4. Choose the proof-test parameter to change:

Select DURATION for setting how long the partial proof-test lasts.

a)

b) Select START-UP for setting if partial proof-testing at start-up is enabled or

disabled

5. Exit the menu system by either waiting one minute for the EXIT MENU? prompt, or

scrolling down menus to find and select BACK TO MENU and EXIT MENU.

) and then select EXTENDED MENU ( ).

Duration of the proof test routine

The Proof-Test Duration parameter determines the duration of the whole partial prooftesting sequence.

Four steps performed are:

• Low Alarm Current step

— The analog output current is overridden to the Low Alarm level (as configured).

• Off Current step

— The analog output current is overridden to the level of the ‘off’ switched output

state (as configured).

• On Current step

— The analog output current is overridden to the level of the ‘on’ switched output

state (as configured).

54 Reference Manual

Page 55

Reference Manual Operation

00809-0100-4140 March 2022

• High Alarm Current step

— The analog output current is overridden to the High Alarm level (as configured).

Note

Setting a value of “0 s” (zero seconds) results in the analog output not being exercised

during the proof-test. Only a diagnostic check of the device is performed in this case.

Rosemount 2140 and 2140:SIS Level Detectors 55

Page 56

Operation Reference Manual

March 2022 00809-0100-4140

56 Reference Manual

Page 57

Reference Manual Service and troubleshooting

00809-0100-4140 March 2022

7 Service and troubleshooting

7.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the

safety of the personnel performing the operations. Information that potentially raises

safety issues is indicated by a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

WARNING

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Ensure the level detector is installed by qualified personnel and in accordance with

applicable code of practice.

Use the level detector only as specified in this manual. Failure to do so may impair the

protection provided by the level detector.

The weight of a level detector with a heavy flange and extended fork length may exceed

37 lb. (18 kg). A risk assessment is required before carrying, lifting, and installing the level

detector.

For installations in hazardous locations, the level detector must be installed according to

the Rosemount 2140 and 2140:SIS Level Detectors Product Certifications document.

Repair, e.g. substitution of components, etc. may jeopardize safety and is under no

circumstances allowed.

WARNING

Explosions could result in death or serious injury.

Verify that the operating atmosphere of the level detector is consistent with the

appropriate hazardous locations certifications.

Before connecting a handheld communicator in an explosive atmosphere, ensure that the

instruments in the loop are installed in accordance with intrinsically safe or non-incendive

field wiring practices.

In explosion-proof/flameproof and non-incendive installations, do not remove the housing

covers when power is applied to the level detector.

Both housing covers must be fully engaged to meet flameproof/explosion-proof

requirements.

Rosemount 2140 and 2140:SIS Level Detectors 57

Page 58

Service and troubleshooting Reference Manual

March 2022 00809-0100-4140

WARNING

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can

cause electrical shock.

Ensure the power to the level detector is off, and the lines to any other external power

source are disconnected or not powered while wiring the level detector.

Ensure the wiring is suitable for the electrical current and the insulation is suitable for the

voltage, temperature, and environment.

WARNING

Process leaks could result in death or serious injury.

Ensure the level detector is handled carefully. If the process seal is damaged, gas might

escape from the vessel (tank) or pipe.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or unintentional and

needs to be protected against.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access by unauthorized personnel to protect end

users’ assets. This is true for all systems used within the facility.

CAUTION

Hot surfaces

The flange and process seal may be hot at high process temperatures. Allow to cool before

servicing.

7.2 Diagnostic messages

The diagnostic messages in this section are organized according to the four NAMUR

NE 107 alert categories. NE 107 is used when operating in HART 7 mode.

For HART5 devices, the descriptions and recommended actions are the same, but the

alerts are mapped to the three Plantweb™ alerts categories.

58 Reference Manual

Page 59

Reference Manual Service and troubleshooting

00809-0100-4140 March 2022

7.2.1 Failure

Electronics board failure

Category

LOI screen

Cause

A failure has been detected in the electronics circuit board.

Recommended actions

1. Reset the device.

2.

Related information

Reset the device

Failure – Fix Now

FAIL

BOARD