Page 1

00825-0100-4130, Rev CC

Rosemount™ 2130 Level Switch

Vibrating Fork

Quick Start Guide

July 2017

Page 2

Quick Start Guide

July 2017

NOTICE

This installation guide provides basic guidelines for the Rosemount 2130. It does not provide instructions for

detailed configuration, diagnostics, maintenance, service, troubleshooting, or installations. Refer to the

Rosemount 2130 Reference Manual

Emerson.com/Rosemount

Failure to follow these installation guidelines could result in death or serious injury.

The Rosemount 2130 Vibrating Fork Level Switch (“level switch”) must be installed, connected,

commissioned, operated, and maintained by suitably qualified personnel only, observing any national

and local requirements that may apply.

Ensure the wiring is suitable for the electrical current and the insulation is suitable for the voltage,

temperature, and environment.

Use the equipment only as specified. Failure to do so may impair the protection provided by the

equipment.

Any substitution of non-recognized parts may jeopardize safety and is under no circumstances allowed.

The weight of the level switch with a heavy flange and extended fork length may exceed 37 lb (18 kg).

A risk assessment is required to be done before carrying, lifting and installing the level switch.

Explosions could result in death or serious injury.

Installation of the level switch in a hazardous environment must be in accordance with the appropriate

local, national, and international standards, codes, and practices. Please review the Product Certifications

section for any restrictions associated with a safe installation

Verify that the operating atmosphere of the level switch is consistent with the appropriate hazardous

locations certifications.

External surface may be hot.

Care must be taken to avoid possible burns.

Process leaks could result in death or serious injury.

Install and tighten process connectors before applying pressure.

Do not attempt to loosen or remove process connectors while the level switch is in service.

Electrical shock could cause death or serious injury.

If the level switch is installed in a high voltage environment and a fault condition or installation error

occurs, high voltage may be present on leads and terminals.

Use extreme caution when making contact with the leads and terminals.

Make sure that power to the level switch is off while making connections.

for more instruction. Manuals are available electronically on

2

Page 3

July 2017

A

C

E

D

B

F

H

G

Quick Start Guide

1.0 Introduction

1.1 Overview of the Rosemount 2130

The Rosemount 2130 Level Switch (“level switch”) uses vibrating short fork

technology, and is suitable for virtually all liquid applications.

The level switch is designed using the principle of a tuning fork. A piezo-electric

crystal oscillates the forks at their natural frequency (~1400 Hz). Changes to this

frequency are continuously monitored. The frequency of the vibrating fork sensor

changes depending on the medium in which it is immersed. The denser the

liquid, the lower the frequency.

When used as a low level alarm, the liquid in the tank or pipe drains down past the

fork, causing a change of natural frequency that is detected by the electronics

and switches the output state to a dry condition. When the level switch is used as

a high level alarm, the liquid rises in the tank or pipe, making contact with the fork

which then causes the output state to switch to a wet condition.

The level switch continuously performs instrument health diagnostics to

self-check the condition of the fork and sensor. These diagnostics can detect

damage to the forks including corrosion, internal or external damage to the forks,

and breakages to the internal wiring. Any of these conditions will trigger the

'heartbeat' LED to pulse intermittently, followed by safe handling of the electrical

load. The level switch has a ‘heartbeat’ LED that indicates its operating state. The

LED flashes when the switch output is ‘off’ and is constantly lit when 'on'.

Figure 1. Rosemount 2130 Features

A. Direct Load, PLC/PNP, DPCO Relay, E. Threaded, flanged, or hygienic

Fault + Alarm Relays (2 x SPCO), process connections

NAMUR, or 8/16 mA electronics F. Thermal Tube in 316/316L SST

®

B. NEMA

C. Short fork length with extensions H. Two cable/conduit entries

D. Wetted material in 316/316L SST,

Type 4X (IP66/67) housings in (2130***E only)

aluminum or 316 SST G. Magnetic test point

up to 118 in. (3 m). Fast drip design

solid Alloy C and Alloy C-276, or

ECTFE/PFA coated 316/316L SST

3

Page 4

Quick Start Guide

OKOK

2.0 Before installation

2.1 General considerations

The weight of the Rosemount 2130 Level Switch (“level switch”) with a heavy

flange and extended fork length may exceed 37 lb. (18 kg). A risk assessment

is required to be done before carrying, lifting, and installing the level switch.

Handle the level switch with great care (Figure 2).

Figure 2. Handling the Rosemount 2130

OK OK

The level switch is available as intrinsically safe or explosion-proof/flameproof

versions for hazardous area installations (see page 19 for approvals). There are

ordinary location versions of the level switch for unclassified, safe areas.

This level switch is designed for open or closed tanks, and pipe installation. It is

weatherproof and protected against the ingress of dust, but must be

protected from flooding (Figure 3).

The 2130***E operates in extreme process temperatures of –94 to 500 °F

(–70 to 260 °C), and the 2130***M operates in mid-range process

temperatures of –40 to 356 °F (–40 to 180 °C).

July 2017

Figure 3. Environmental Considerations

4

Page 5

July 2017

Ensure there is adequate space outside the tank or pipe. A clearance of 1.2 in.

Quick Start Guide

(30 mm) is required for the housing cover to be removed.

Always ensure a proper seal by installing the electronics housing cover so that

metal contacts metal. Use Rosemount O-rings.

Always ground the housing in accordance with national and local electrical

codes. The most effective grounding method is a direct connection to earth

(ground) with minimal impedance. Use the fork earth for housings with NPT

conduit entries.

2.2 Installation recommendations

Avoid installing near liquid entering the tank at the fill point.

Avoid heavy splashing on forks. Increasing time delay reduces accidental

switching.

Avoid installing near heat sources.

Ensure the forks do not come into contact with the tank/pipe wall or fittings.

Allow a distance between product build-up on the tank wall and the fork

(Figure 4).

Figure 4. Avoid Product Build-up

OK

5

Page 6

Quick Start Guide

Threaded

installation

Flanged

installation

3.0 Physical installation

1. Install the level switch according to standard installation practices, making

sure to correctly align the fork using the alignment notch or groove (Figure 5).

2. Use supports for extended fork lengths greater than 3.2 ft. (1 m). Refer to the

Rosemount 2130 Reference Manual

3. Close the housing cover and tighten to safety specification. Always ensure a

proper seal so that metal touches metal, but do not over tighten.

4. Insulate the level switch with ROCKWOOL

Reference Manual

for guidance.

Figure 5. Example Installations

for guidance.

®

. Refer to the Rosemount 2130

July 2017

A

B

C

D

D

E

A. PTFE for NPT and BSPT (R) thread D. Fork alignment notch

B. Gasket for BSPP (G) thread E. Fork alignment notch

C. Fork alignment groove

6

Page 7

July 2017

Direct Load

Switching

WARNING

Isolate Supply

Before Removing

OPERATION MODE

Dry On Mode

Dry

Wet

Wet On Mode

Dry

Wet

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

123

LINE

LOAD

PE

(Ground)

Neutral

Live

0V

Fuse 2A(T)

R

I

L

R = External load (must be fitted)

U = 20 - 264 V ~ (ac) (50/60Hz)

I

OFF

< 4

mA

I

L

=

20 - 500

mA

U = 20 - 60 V (dc))

I

OFF

< 4 mA

IL =

20 - 500 mA

DPST

+V

= 5 A, 40 ms (inrush)

I

PK

= 5 A, 40 ms (inrush)

I

PK

= Load On

= Load Off

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Fuse

2A(T)

N L

0V

+V

I

L

<4mA

DPST

Quick Start Guide

4.0 Electrical installation

Before use, check that suitable cable glands and blanking plugs are fitted

and fully tightened.

Isolate supply before connecting the switch or removing the electronics.

The functional earth terminal must be connected to an external

earthing system.

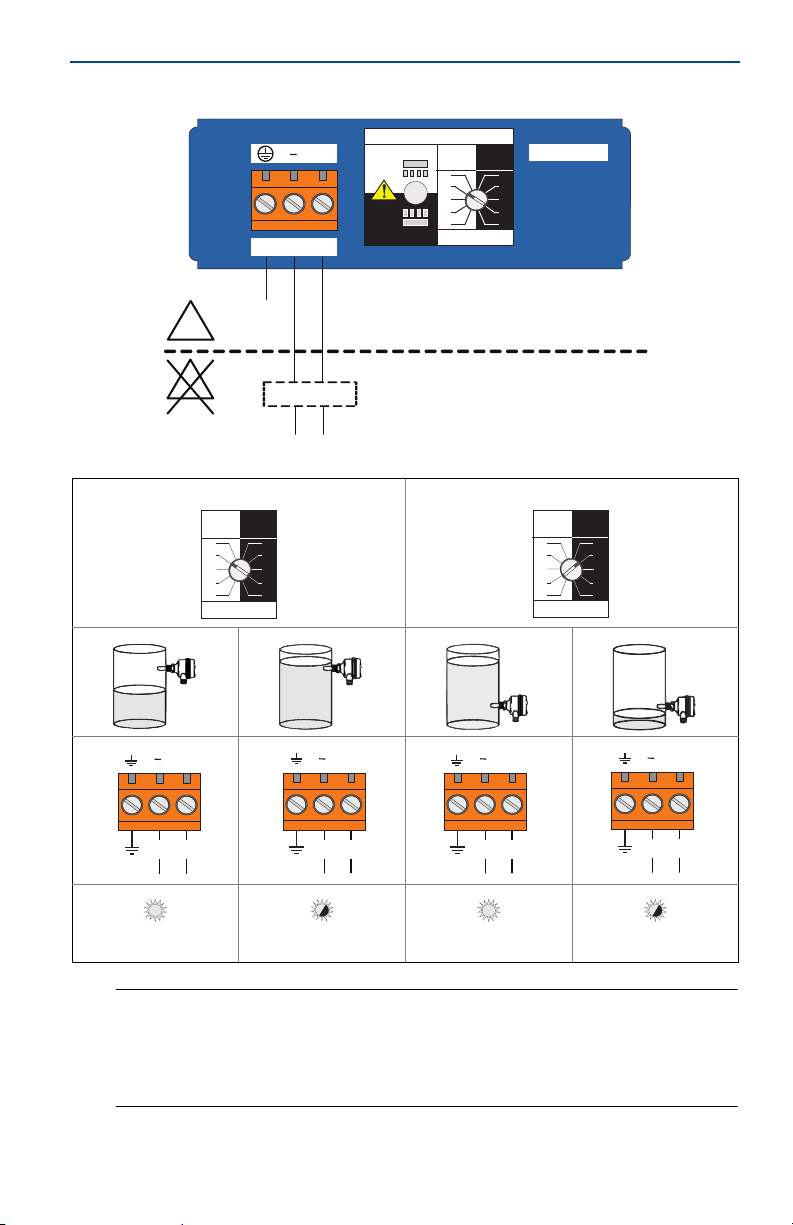

4.1 Direct load switching cassette (two-wire, red label)

LED on continuously

DPST

U

12V

I

L

N L

0V

High level Dry = ON Low level Wet = ON

Dry On Wet On

0.3 0.3

1

1

3

3

10

10

30

30

Seconds Delay

Fuse

2A(T)

+V

DPST

LED flashes each

<4mA

I

L

N L

0V

second

Fuse

2A(T)

+V

U

12V

I

L

Fuse

2A(T)

DPST

N L

+V

0V

LED on continuously

LED flashes each

second

7

Page 8

Quick Start Guide

OPERATION MODE

Dry On Mode

Dry

Wet

Wet On Mode

Dry

Wet

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

12

3

OUT

+

-

4

PLC/PNP

Isolate Supply

Before Removing

PE

(Ground)

0VO/P

U = 20 - 60 V (dc)

I < 4 mA + I

L

I

L (MAX

)

= 0 - 500 mA

U

OUT(ON)

= U -

2.5 V

I

L (OFF)

< 100A

+V

Fuse 2A(T)

= 5 A, 40 ms (inrush)

I

PK

OUT

-

+

PLC

+

I/P

U

<3V

I

L

OUT

-

+

PLC

+

I/P

I

L

<100 A

OUT

-

+

+

U

<3V

I

L

Fuse

1A(T)

R

OUT

-

+

+

U

<3V

I

L

Fuse

1A(T)

R

OUT

-

+

+

I

L

Fuse

1A(T)

R

< 100 A

4.2 PNP/PLC cassette (three-wire, yellow label)

High level Dry = ON Low level Wet = ON

Dry On Wet On

0.3 0.3

1

1

3

3

10

10

30

30

Seconds Delay

Dry On Wet On

0.3 0.3

1

3

10

30

Seconds Delay

July 2017

1

3

10

30

PLC (positive input)PNP dc

LED on continuously

8

OUT

-

+

<100 A

I

L

I/P

+

PLC

OUT

-

+

R

Fuse

1A(T)

LED flashes each

< 100 A

+

second

I

L

OUT

-

+

U

<3V

I

L

I/P

+

PLC

LED on continuously

LED flashes each

second

Page 9

July 2017

NC

C

NO

NC NO

789

NOCNC

RELAY

123

LN

45

6

NOCNC

OPERATION MODE

Dry On

Dry

Wet

Wet O n

Dry

Wet

Dry On

Wet On

Seconds D el ay

30

10

3

1

0.3 0.3

30

10

3

1

Isolate Supply B efore Removing Warning

C

Resistive Load

cos φ = 1 ;

L/R = 0 ms

ac

dc

Inductive Load

Fuse 0.5 (T)PE

(Ground)

DPST

N

0V +V

Live U = 20...264 V ~ (ac)

(50/60 Hz)

U = 20...60 V (dc)

I < 6 mA

I < 6 mA

I

MAX

= 5 A

U

MAX

= 250 V

P

MAX

= 1250 VA

U

MAX

= 30 V

P

MAX

= 240 W

cos φ = 0.4 ;

L/R = 7 ms

ac

dc

I

MAX

= 3.5 A

U

MAX

= 250 V

P

MAX

= 875 VA

U

MAX

= 30 V

P

MAX

= 170W

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Dry On Wet On

Seconds Delay

0.3 0.3

30

10

3

30

10

1

3

1

NC NOC

NC NOC

NC NOC

4.3 DPCO Relay cassette (dark green label)

High level Dry = ON Low level Wet = ON

Quick Start Guide

LED on continuously

NC NOC

NC NOC

LED flashes each

second

NC NOC

NC NOC

LED on continuously

NC NOC

LED flashes each

second

9

Page 10

Quick Start Guide

NC

C

NO

NC NO

789

NOCNC

123

LN

45

6

NOCNC

Alarm Fault

OPERATION MODE

Dry On

Dry

Wet

Wet O n

Dry

Wet

Dry On

Wet On

Seconds D el ay

30

10

3

1

0.3 0.3

30

10

3

1

Isolate Supply

Before Removing

WARNING

C

Resistive Load

cos φ = 1 ;

L/R = 0 ms

ac:

dc:

Inductive Load

Fuse 0.5 (T)PE

(Ground)

DPST

N

0V +V

Live

U = 20...264 V ~ (ac)

(50/60 Hz)

U = 20...60 V (dc)

I < 6 mA

I < 6 mA

I

MAX

= 5 A

U

MAX

= 250 V

P

MAX

= 1250 VA

U

MAX

= 30 V

P

MAX

= 240 W

cos φ = 0.4 ;

L/R = 7 ms

ac:

dc:

I

MAX

= 3.5 A

U

MAX

= 250 V

P

MAX

= 875 VA

U

MAX

= 30 V

P

MAX

= 170 W

FAULT RELAY

(No alarm)

(No fault)

NC NOC

(Alarm)

(No fault)

(No alarm)

(No fault)

(Alarm)

(No fault)

July 2017

4.4 Fault and Alarm Relays (2 x SPCO) cassette (light green label)

High level Dry = ON Low level Wet = ON

Dry On Wet On

0.3 0.3

1

3

10

30

Seconds Delay

1

3

10

30

Dry On Wet On

0.3 0.3

1

3

10

30

Seconds Delay

1

3

10

30

NC NOC

LED on continuously

10

NC NOC

LED flashes each

second

NC NOC

NC NOC

NC NOC

LED on continuously

NC NOC

NC NOC

LED flashes each

second

Page 11

July 2017

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Dry On Wet On

Seconds Delay

0.3 0.3

30

10

3

30

10

1

3

1

+

-

>2.2 mA

+

-

< 1.0 mA

+

-

< 1.0 mA

4.5 NAMUR cassette (light blue label)

OPERATION MODE

Dry On Mode

Dry

Wet

Dry

Wet

Wet On Mo d e

= 0.8 ... 1.0 mA

< 1.0 mA

A certified intrinsically safe

isolating am plifier to IEC 60947-5-6

Ex

Ex

+-

8V

dc

12

ION= 2.2 ... 2.5 mA

I

OFF

I

FAULT

-

+

High level Dry = ON Low level Wet = ON

Dry On Wet On

0.3 0.3

1

3

10

30

Seconds Delay

EN 50227 / NAMUR

1

3

10

30

Quick Start Guide

-

+

>2.2 mA

LED on continuously LED flashes each

second

LED on continuously

Note

This cassette is suitable for intrinsically safe applications and requires an isolating barrier.

See “Product Certifications” on page 18 for intrinsically safe approvals.

This electronics cassette is also suitable for non-hazardous (safe) area applications. It can

only be interchanged with the 8/16 mA cassette.

Do not exceed 8 Vdc.

LED flashes each

second

11

Page 12

Quick Start Guide

OPERATION MODE

Dry On Mode

Dry

Wet

Wet On Mode

Dry

Wet

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

8/16 mA

12

3

+

Drives 4-20 mA Analog Input

I

ON

=

I

OFF

=

+

-

+

A certified intrinsically safe barrier

must be used to meet IS requirements

Ex

Ex

15 ... 17 mA

7.5 ... 8.5 mA

-

PE

(Ground)

U

=

24 Vdc Nominal

I

FAULT

< 3.7 mA

+

> 15 mA

+

+

+

< 8.5 mA

4.6 8/16 mA cassette (dark blue label)

High level Dry = ON Low level Wet = ON

Dry On Wet On

0.3 0.3

1

1

3

3

10

10

30

30

Seconds Delay

Dry On Wet On

0.3 0.3

1

3

10

30

Seconds Delay

July 2017

1

3

10

30

< 8.5 mA

LED flashes each

second

LED on continuously

12

Note

This cassette is suitable for intrinsically safe applications and requires an isolating barrier.

See “Product Certifications” on page 18 for intrinsically safe approvals.

This cassette is also suitable for non-hazardous (safe) area applications. It can only be

interchanged with a NAMUR cassette.

> 15 mA

LED on continuously

LED flashes each

second

Page 13

July 2017

OUT

-

+

+

I

L

Fuse

1A(T)

R

< 100 A

(=Fault)

(=Fault)

(=Fault)

NC NOC

NC NOC

(=Fault)

+

-

< 1.0 mA

(=Fault)

+

< 3.7 mA

(=Fault)

NC NOC

(=No alarm)

(=Fault)

Alarm Relay

Fault Relay

Quick Start Guide

4.7 Fault condition detected (self-check mode only)

When a fault condition is detected in the self-check operating mode, the

‘heartbeat’ LED flashes once every half a second and every third flash is missed.

The output from the level switch will then be as follows:

Direct Load PLC PNP dc

OUT

<100 A

I/P

-

I

L

PLC

+

<4mA

I

L

Fuse

2A(T)

DPST

N L

0V

+V

+

DPCO Relay NAMUR 8/16 mA

Fault and Alarm (2 x SPCO) Relays

NC NOC

Note

See “LED indication” on page 15 for causes of other LED flashing rates.

= Load Off

=Load On

13

Page 14

Quick Start Guide

OPERATION MODE

Dry On Mode

Dry

Wet

Wet On Mode

Dry

Wet

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

12

3

OUT

+

-

4

PLC/PNP

Isolate Supply

Before Removing

Dry On W et On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Dry On W et On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Dry On Wet On

Seconds Dela y

0.3 0.3

3

30

10

1

3

30

10

1

Dry On W et On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

Dry On Wet On

Seconds Delay

0.3 0.3

3

30

10

1

3

30

10

1

5.0 Configuration

5.1 Set the mode switch and switching time delay

1. Select “Dry on” or “Wet on” mode.

2. Select 0.3, 1, 3, 10, or 30 seconds for the delay before switching output state.

Note

There is a five second delay when changing mode or time delay.

The small cut-out in the rotating switch indicates time delay and mode.

Recommended installation for a high level alarm is “Dry on” and for a low level alarm it is

“Wet on”. Do not install in the normally ‘off’ state.

Figure 6. Top-down View of Example Cassette Inside Housing

A. LED B. Mode Switch and Time Delay

5.2 Set the Operating Mode

July 2017

14

Selecting the self-check operating mode

When the self-check mode is operating, the ‘heartbeat’ LED color is yellow.

Selecting the normal operating mode

When the normal mode is operating, the ‘heartbeat’ LED color is red.

Page 15

July 2017

6.0 Verification

6.1 LED indication

Table 1. LED Indication

LED colors Operating modes

Red Normal

Yellow Self-check

1. See “Set the Operating Mode” on page 14.

Table 2. LED Flash Rate

LED flash rate Switch status

Continuous Output state is on

(1)

When the LED is red and flashing, it indicates the Rosemount 2130

may be uncalibrated, successfully calibrated, has an electrical load

problem, or has an internal PCB fault.

See Table 2 for further information.

When the LED is yellow and flashing, it indicates the same as Normal

mode and that there could be external damage to forks, corroded

forks, or internal sensor damage.

See Table 2 for further information.

Quick Start Guide

Description of mode

1

/2 second and every

1 every

third flash missing

1 every second Output state is off

1 every 2 seconds Uncalibrated

1 every 4 seconds Load fault; load current too high; load short circuit

2 times every second Indication of successful calibration

3 times every second Internal PCB fault (microprocessor, ROM, or RAM)

Off Problem (e.g. supply)

1. See “Fault condition detected (self-check mode only)” on page 13.

2. Refer to the “Replacement and Calibration of Electronic Cassettes” section in the Rosemount 2130 Reference

Manual or Manual Supplement.

External damage to forks; corroded forks;

internal wire damage; internal sensor damage

(Self-Check mode only)

(2)

(1)

15

Page 16

Quick Start Guide

6.2 Magnetic Test Point

The magnetic test-point is on the side of the housing, allowing a functional test of

the Rosemount 2130. By touching a magnet on the target, the output will change

state for as long as the magnet is held there.

Figure 7. Magnetic Test Point

July 2017

TP

TP

S

TP

N

7.0 Troubleshooting

Table 3. Troubleshooting Chart

Fault Symptom/Indication Action/Solution

Check the power supply; (check load on direct load

switching electronics model)

Clean the fork with care

This is normal – wait 5 seconds

Set the correct mode on the electronics cassette

Fit the factory supplied cassette

and then calibrate

Does not

switch

Incorrect

switching

Faulty

switching

No LED; no power

LED flashing See “LED indication” on page 15

Fork is damaged Replace the Rosemount 2130

Thick encrustation

on the forks

5 second delay when changing

mode/delay

Dry = On, Wet = On

set correctly

Turbulence Set a longer switching time delay

Excessive electrical noise Suppress the cause of the interference

Cassette has been fitted from another

Rosemount 2130

S

N

(1)

1. Refer to the “Replacement and Calibration of Electronic Cassettes” section in the Rosemount 2130 Reference

Manual or Manual Supplement.

16

Page 17

July 2017

Quick Start Guide

8.0 Maintenance and inspection

Only use a damp cloth for cleaning.

Visually examine the level switch for damage. If it is damaged, do not use.

Ensure the housing cover, cable glands, and blanking plugs are fitted securely.

Ensure the LED flash rate is 1 Hz or continually on.

(See “LED indication” on page 15).

9.0 Spare parts

See the Rosemount 2130 Product Data Sheet for spares and accessories.

17

Page 18

Quick Start Guide

10.0 Product Certifications

10.1 European Union directive information

The EU declaration of conformity for all applicable European Union directives for

this product can be found on page 33 and at Emerson.com/Rosemount.

EN61010-1 Pollution degree 2, Category II (264V max),

Pollution degree 2, Category III (150V max).

10.2 Overfill approval

Certificate number: Z-65.11-519

TÜV-tested and approved for overfill protection according to the German

DIBt/WHG regulations. Certified under safety devices for tanks and piping related

to water pollution control.

10.3 Marine approvals

ABS American Bureau of Shipping

GL Germanischer Lloyd (excludes Alarm and Fault Relays cassette)

SRS Russian Maritime Registered Shipping (RMRS)

10.4 Drinking water approval

Rosemount Measurement Ltd. (United Kingdom) confirms that the wetted parts

of the Rosemount 2130 vibrating fork level switch are suitable and approved for

drinking water usage. The wetted parts of the vibrating fork level switches

executed in stainless steel (option code S) and Alloy C/Alloy C-276 (option code

H) with flanged, NPT thread, BSPT(R) thread, or Tri-clamp process connections,

are in accordance with the requirements of DVGW*- Worksheet W270.The

materials used are classified as toxicologically and microbiologically safe.

July 2017

10.5 NAMUR approval

NAMUR NE95 type test is available upon request. Complies with NAMUR NE21.

10.6 Ordinary location certifications

FM ordinary location certification

G5 Project ID: 3021776

The switch has been examined and tested to determine that the design meets basic

electrical, mechanical, and fire protection requirements by FM, a nationally recognized

testing laboratory (NRTL) as accredited by the Federal Occupational Safety and Health

Administration (OSHA).

CSA ordinary location certification

G6 Certificate Number 06 CSA 1805769

The switch has been examined and tested to determine that the design meets basic

electrical, mechanical, and fire protection requirements by CSA, a nationally recognized

testing laboratory as accredited by the Standards Council of Canada (SCC). Single Seal

18

Page 19

July 2017

Quick Start Guide

10.7 Canadian Registration Number

Certificate Number CRN 0F04227.2C

The requirements of CRN are met when a Rosemount 2130 CSA approved

vibrating fork level switch (with Product Certifications code G6, E6, or I6) is

configured with stainless steel wetted parts and either NPT threaded or

ASME B16.5 2-in. to 8-in. flanged process connections.

10.8 Safety Integrity Level (SIL) certification

The Rosemount 2130 has been independently certified to IEC 61508 as required

by IEC 61511. Certification was conducted by Exida.

The Rosemount 2130 is SIL2-certified.

10.9 Hazardous locations certificates

Note

A certified isolating amplifier to IEC 60947-5-6 is required for intrinsic safety if the NAMUR

electronics is used in a hazardous area installation.

A certified intrinsically safe barrier is required for intrinsic safety if the 8/16 mA electronics is

used in a hazardous area installation.

All CSA-approved units are certified per ANSI/ISA 12.27.01-2003.

Control Drawings are in the Rosemount 2130 Reference Manual.

North American and Canadian approvals

Factory Mutual (FM) explosion-proof approval

(See “Instructions for hazardous area installations (E5 and E6)” on page 23)

E5 Project ID: 3012658

Explosion-proof for Class I, Div. 1, Groups A, B, C, and D

Temperature Class: T6 (See Section 10.b on page 24)

Enclosure: Type 4X

Factory Mutual (FM) intrinsically safe approval

(See “Instructions for hazardous area installations (I5 and I6)” on page 25)

I5 Project ID: 3011456

Intrinsically Safe for Class I, Div. 1, Groups A, B, C, and D

Class I, Zone 0, AEx ia IIC

Temperature Code: T5 (see Control Drawings)

Control Drawing: 71097/1154 (with NAMUR electronics)

Ui=15 V, Ii=32 mA, Pi=0.1 W, Ci=211 nF, Li=0.06 mH

Control Drawing: 71097/1314 (with 8/16 mA electronics)

Ui=30 V, Ii=93 mA, Pi=0.65 W, Ci=12 nF, Li=0.035 mH

Canadian Standards Association (CSA) explosion-proof approval

(See “Instructions for hazardous area installations (E5 and E6)” on page 23)

E6 Project ID: 1786345

Explosion-proof for Class I, Div. 1, Groups A, B, C, and D

Temperature Class: T6 (See Section 10.b on page 24)

Enclosure: Type 4X

Single Seal

19

Page 20

Quick Start Guide

Canadian Standards Association (CSA) intrinsically safe approval

(See “Instructions for hazardous area installations (I5 and I6)” on page 25)

I6 Certificate Number: 06 CSA 1786345

Intrinsically Safe for Class I, Div. 1, Groups A, B, C, and D

Class I, Zone 0, Ex ia IIC

Non-incendive for Class I, Div. 2, Groups A, B, C, and D

Temperature Code: T5 (see Control Drawings)

Control Drawing: 71097/1179 (with NAMUR electronics)

Ui=15 V, Ii=32 mA, Pi=0.1 W, Ci=211 nF, Li=0.06 mH

Control Drawing: 71097/1315 (with 8/16 mA electronics)

Ui=30 V, Ii=93 mA, Pi=0.65 W, Ci=12 nF, Li=0.035 mH

Single Seal

Note

A certified isolating amplifier to IEC 60947-5-6 is required for intrinsic safety if the NAMUR

electronics is used in a hazardous area installation.

A certified intrinsically safe barrier is required for intrinsic safety if the 8/16 mA electronics is

used in a hazardous area installation.

European approvals

ATEX Approvals

E1 Certificate: Sira 05ATEX1129X

Flameproof and dust proof:

ATEX Marking II 1/2 GD

Ex db IIC T6...T2 Ga/Gb

Ex tb IIIC T85 °C...T265 °C Db

(See “Instructions specific to hazardous area installations (E1 / E7)” on page 27)

I1 Certificate: Sira 05ATEX2130X

Intrinsic Safety for gas and dust atmospheres:

ATEX Marking II 1 GD

Ex ia IIC T5...T2 Ga

Ex ia IIIC T85 °C...T265 °C Da

(See “Instructions specific to hazardous area installations (I1 / I7)” on page 30)

July 2017

International approvals

INMETRO approvals

E2 Certificate Number: TÜV 12.1285 X

Flameproof and dust proof:

Ex d IIC T6 to T2 Ga/Gb, Ex tb IIIC T85 °C to T265 °C Db

I2 Certificate Number: TÜV 12.1391 X

Intrinsically Safe for gas and dust atmospheres:

Ex ia IIC T* Ga, Ex ia IIIC T* Da (* See table in the certificate)

Ta* (* See table in the certificate)

Security parameters:

NAMUR: Ui = 15 V / Ii = 32 mA / Pi = 0,1 W / Ci = 12 nF / Li = 0,06 mH

8/16 mA: Ui = 30 V / Ii = 93 mA / Pi = 0,65 W / Ci = 12 nF / Li = 0,035 mH

Safe use special condition:

Non-metallic parts of the equipment casing can generate electrostatic charges under

extreme conditions. The equipment should only be cleaned with a damp cloth.

20

Page 21

July 2017

Quick Start Guide

Note

A certified isolating amplifier to IEC 60947-5-6 is required for intrinsic safety if the NAMUR

electronics is used in a hazardous area installation.

A certified intrinsically safe barrier is required for intrinsic safety if the 8/16 mA electronics is

used in a hazardous area installation.

National Supervision and Inspection Centre for Explosion Protection and Safety

Instrumentation (NEPSI) approvals

E3 Certificate: GYJ101373

Flameproof and dust proof:

Ex d IIC T6~T2

DIP A21 T

(See the certificate or Rosemount 2130 Reference Manual

hazardous area installations)

I3 Certificate: GYJ101372X

Intrinsic Safety (NAMUR electronics):

Ex ia IIC T5~T2

Ui=15 V, Ii=32 mA, Pi=0.1 W, Ci=12 nF, Li=0.06 mH

(See the certificate or Rosemount 2130 Reference Manual

hazardous area installations)

International Electrotechnical Commission (IEC) approvals

E7 Certificate: IECEx SIR 06.0051X

Flameproof and dust proof:

Ex db IIC T6...T2 Ga/Gb

Ex tb IIIC T85 °C...T265 °C Db

(See “Instructions specific to hazardous area installations (E1 / E7)” on page 27)

I7 Certificate: IECEx SIR 06.0070X

Intrinsically Safe for gas and dust atmospheres:

Ex ia IIC T5...T2 Ga

Ex ia IIIC T85 °C...T265 °C Da

(See “Instructions specific to hazardous area installations (I1 / I7)” on page 30)

(T85 °C ~ 265 °C) IP6X

A

for instructions specific to

for instructions specific to

Note

A certified isolating amplifier to IEC 60947-5-6 is required for intrinsic safety if the NAMUR

electronics is used in a hazardous area installation.

A certified intrinsically safe barrier is required for intrinsic safety if the 8/16 mA electronics is

used in a hazardous area installation.

21

Page 22

Quick Start Guide

Technical Regulation Customs Union (EAC),

flameproof approval

EM Certificate: RU C-GB.AB72.B.01385

(M20 conduit entry/cable thread only)

Markings for 2130***M:

1Exd IIC T6 X (-40 °C Ta +75 °C);

1Exd IIC T5 X (-40 °C Ta +70 °C);

1Exd IIC T4 X (-40 °C Ta +65 °C);

1Exd IIC T3 X (-40 °C Ta +50 °C)

Markings for 2130***E:

1Exd IIC T6 X (-40 °C Ta +75 °C);

1Exd IIC T5 X (-40 °C Ta +74 °C);

1Exd IIC T4 X (-40 °C Ta +73 °C);

1Exd IIC T3 X (-40 °C Ta +69 °C);

1Exd IIC T2 X (-40 °C Ta +65 °C)

See certificate for special conditions for safe use (X)

Technical Regulation Customs Union (EAC),

intrinsically safe approval

IM Certificate: RU C-GB.AB72.B.01385

(NAMUR and 8/16 mA electronics only)

Markings for 2130***M:

0Exia IIC T5 X (-50 °C Ta +80 °C);

0Exia IIC T4 X (-50 °C Ta +69 °C);

0Exia IIC T3 X (-50 °C Ta +50 °C)

Markings for 2130***E:

0Exia IIC T5 X (-50 °C Ta +80 °C);

0Exia IIC T4 X (-50 °C Ta +77 °C);

0Exia IIC T3 X (-50 °C Ta +71 °C);

0Exia IIC T2 X (-50 °C Ta +65 °C)

See certificate for special conditions for safe use (X)

July 2017

22

Page 23

July 2017

Quick Start Guide

10.10 Instructions for hazardous area installations (E5 and E6)

Model numbers covered:

2130**9E***********E5***,2130**9E***********E6***

2130**9M***********E5***,2130**9M***********E6***

(“*” indicates options in construction, function and materials).

The following instructions apply to equipment covered by CSA and FM

explosion-proof approvals:

1. The equipment may be used with flammable gases and vapors with apparatus

Class 1, Div 1, Groups A, B, C, and D.

2. CSA and FM explosion-proof approved versions of the 2130***E are certified

for use in ambient temperatures of –58 °F to 167 °F (–50 °C to 75 °C), and with

a maximum process temperature of 500 °F (260 °C).

CSA and FM explosion-proof approved versions of the 2130***M are certified

for use in ambient temperatures of –40 °F to 167 °F (–40 °C to 75 °C), and with

a maximum process temperature of 356 °F (180 °C)

3. Installation of this equipment shall be carried out by suitably trained

personnel, in accordance with the applicable code of practice.

4. Inspection and maintenance of this equipment shall be carried out by suitably

trained personnel, in accordance with the applicable code of practice.

5. The user should not repair this equipment.

6. The certification of this equipment relies upon the following materials used in

its construction:

Body: Aluminum Alloy (ASTM B85 360.0) or 316 Stainless Steel

Cover: Aluminum Alloy (ASTM B85 360.0) or 316 Stainless Steel

Probe:

316 Stainless Steel, or Alloy C276 (UNS N10276) and Alloy C (UNS N10002)

Probe Filling: Perlite

Cover Seal: Silicone

If the equipment is likely to come into contact with aggressive substances, it is

the responsibility of the user to take suitable precautions that prevent it from

being adversely affected, thus ensuring that the type of protection is not

compromised.

Aggressive Substances – e.g. acidic liquids or gases that may attack metals or

solvents that may affect polymeric materials.

Suitable Precautions – e.g. regular checks as part of routine inspections or

establishing from the material’s data sheet that it is resistant to specific

chemicals.

The metallic alloy used for the enclosure material may be at the accessible

surface of this equipment; in the event of rare accidents, ignition sources due

to impact and friction sparks could occur. This shall be considered when the

Rosemount 2130 is installed in locations that specifically require Class 1, Div 1

equipment.

23

Page 24

Quick Start Guide

7. It is the responsibility of the user to ensure:

a. The voltage and current limits for this equipment are not exceeded.

b. That the joint requirements between the probe (switch) and the vessel tank

are compatible with the process media.

c. That the joint tightness is correct for the joint material used.

d. That only suitably certified cable entry devices will be utilized when

connecting this equipment.

e. That any unused cable entries are sealed with suitably certified stopping

plugs.

8. The probe fork is subjected to small vibration stresses as part of its normal

function. As this provides a partition wall, it is recommended that the fork

should be inspected every two years for signs of defects.

9. Technical data:

a. Coding: Class 1, Div 1, Groups A, B, C, and D

b. Temperature:

2130**9E***********E5***, 2130**9E***********E6***:

July 2017

Temperature

classes

T6, T5, T4, T3, T2, T1 75 °C 80 °C

T5, T4, T3, T2, T1 74 °C 95 °C

T4, T3, T2, T1 73 °C 125 °C

T3, T2, T1 69 °C 185 °C

T2, T1 65 °C 260 °C

Maximum ambient air

temperature (Ta)

Maximum process

temperature (Tp)

Minimum ambient air temperature (Ta) = –50 °C

Minimum process temperature (Tp) = –70 °C

2130**9M***********E5***, 2130**9M***********E6***:

Temperature

classes

T6, T5, T4, T3, T2, T1 75 °C 75 °C

T5, T4, T3, T2, T1 70 °C 90 °C

T4, T3, T2, T1 65 °C 125 °C

T3, T2, T1 50 °C 180 °C

Maximum ambient air

temperature (Ta)

Maximum process

temperature (Tp)

Minimum ambient air temperature (Ta) = –40 °C

Minimum process temperature (Tp) = –40 °C

c. Pressure: Must not exceed the rating of the coupling/flange fitted.

d. For electrical details and pressure ratings, see the Rosemount 2130 Product

Data Sheet or Reference Manual.

e. Year of manufacture: printed on product label.

24

Page 25

July 2017

Quick Start Guide

10. Cable selection:

a. It is the responsibility of the user to ensure that suitably temperature rated

cable is used. The table below is a guide to selection:

T class Cable temperature rating

T6 Above 185 °F (85 °C)

T5 Above 212 °F (100 °C)

T4 Above 275 °F (135 °C)

T3 Above 320 °F (160 °C)

10.11 Instructions for hazardous area installations (I5 and I6)

Model numbers covered:

2130N**************I5***

2130N**************I6***

2130M**************I5***

2130M**************I6***

(“*” indicates options in construction, function and materials).

The following instructions apply to equipment covered by CSA and FM

intrinsically safe and non-incendive approvals:

1. The Intrinsically Safe approved Rosemount 2130 may be used in hazardous

locations with flammable gases and vapors Class 1 Division 1 Groups A, B, C,

and D, and Class 1 Zone 0 Group IIC when installed in accordance with control

drawings 71097/1154, 71097/1314, 71097/1179, or 71097/1315. Control

drawings are in the Rosemount 2130 Reference Manual

2. The Non-incendive approved Rosemount 2130 may be used in hazardous

locations with flammable gases and vapors Class 1 Division 2 Groups A, B, C,

and D when installed in accordance with Control Drawing 71097/1179 or

71097/1315. Control drawings are in the Rosemount 2130 Reference Manual.

3. The apparatus electronics is only certified for use in ambient temperatures in

the range of –50 to 80 °C. It should not be used outside this range. However,

the switch may be located in the process medium which may be at a higher

temperature than the electronics but must not be higher than the

Temperature Class for the respective process gas/medium.

4. It is a condition of the approval that the electronics temperature is in the

range of –58 to 176 °F (–50 to 80 °C). It must not be used outside this range.

It will be necessary to limit the external ambient temperature if the process

temperature is high.

5. Suitably trained personnel shall carry out installation in accordance with the

applicable code of practice.

6. The user should not repair this equipment.

7. If the equipment is likely to come into contact with aggressive substances, it is

the responsibility of the user to take suitable precautions that prevent it from

being adversely affected, thus ensuring that the type of protection is not

compromised.

.

25

Page 26

Quick Start Guide

Aggressive Substances – e.g. acidic liquids or gases that may attack metals or

solvents that may affect polymeric materials.

Suitable Precautions – e.g. regular checks as part of routine inspections or

establishing from the material’s data sheet that it is resistant to specific

chemicals.

8. If the enclosure is made of an alloy or plastic material, the following

precautions must be observed:

a. The metallic alloy used for the enclosure material may be at the accessible

surface of this equipment; in the event of rare accidents, ignition sources

due to impact and friction sparks could occur.

b. Under certain extreme circumstances, the non-metallic parts incorporated

in the enclosure of the Rosemount 2130 may generate an ignition-capable

level of electrostatic charge. Therefore, when they are used for applications

that specifically require group II equipment, the Rosemount 2130 shall not

be installed in a location where the external conditions are conducive to the

build-up of electrostatic charge on such surfaces. Additionally, the

Rosemount 2130 shall only be cleaned with a damp cloth.

9. Technical Data:

a. I.S. approval: Class 1 Division 1 Groups A, B, C, and D, Class 1 Zone 0 AEx ia

IIC

Non-incendive Approval: Class 1 Division 2 Groups A, B, C, and D

b. Input parameters:

Rosemount 2130 with NAMUR electronics:

Vmax=15 V, Imax=32 mA, Pi=0.1 W, Ci=211 nF, Li=0.06 mH

Rosemount 2130 with 8/16 mA electronics:

Vmax=30 V, Imax=93 mA, Pi=0.65 W, Ci=12 nF, Li=0.035 mH

c. Materials: see the Rosemount 2130 Product Data Sheet

d. Year of manufacture: printed on product label.

July 2017

.

26

Page 27

July 2017

Quick Start Guide

10.12 Instructions specific to hazardous area installations (E1 / E7)

Model numbers covered:

2130*A2E***********E1****,2130*S2E***********E1****,

2130*A2E***********E7****,2130*S2E***********E7****,

2130*A2M***********E1****,2130*S2M***********E1****,

2130*A2M***********E7****,2130*S2M***********E7****

(“*” indicates options in construction, function and materials).

The following instructions apply to the equipment covered by certificates

Sira 05ATEX1129X and IECEx SIR 06.0051X:

1. The equipment may be used with flammable gases and vapors with apparatus

groups IIA, IIB, and IIC, and with temperature classes T1, T2, T3, T4, T5, and T6

[IECEx: in Zones 1 and 2. The probe may be installed into a Zone 0 vessel].

The temperature class of the installation will be determined from the higher of

the process or ambient temperature.

2. The equipment may be used with explosive dusts with apparatus groups IIIC,

IIIB, and IIIA. The maximum surface temperature of the installation will be

determined from the higher of the process or ambient temperature.

3. The equipment is suitable for installation across the boundary between an

area that specifically requires Equipment Protection Level Ga (Zone 0) and an

area that specifically requires Equipment Protection Level Gb or Db (Zone 1 or

21). The probe forks (and extension tube) only to be installed in Zone 0.

4. The equipment has not been assessed as a safety related device

[ATEX: as referred to by Directive 94/9/EC (2014/34/EU) Annex II, clause 1.5].

5. Installation of this equipment shall be carried out by suitably trained

personnel, in accordance with the applicable code of practice.

6. Inspection and maintenance of this equipment shall be carried out by suitably

trained personnel, in accordance with the applicable code of practice.

7. The user should not repair this equipment. Repair or modification of

flamepaths is not permitted.

8. The certification of this equipment relies upon the following materials used in

its construction:

Body & Lid: Aluminum alloy (ASTM B85 360.0) or stainless steel 316L type

Housing and Cover: Aluminum Alloy (ASTM B85 A360.0) or Stainless Steel

316C12.

Probe: Stainless steel 316 type, or alloy C (UNS N10002) and alloy C-276 (UNS

N10276)

Partition Wall: Stainless steel 316L or 316/316L, or Alloy C275 (UNS N10276)

and Alloy C (UNS N10002 or N30002).

Probe Filling: Perlite

Seals: Silicone

9. If the equipment is likely to come into contact with aggressive substances, it

is the responsibility of the user to take suitable precautions that prevent it

from being adversely affected, thus ensuring that the type of protection is not

compromised.

27

Page 28

Quick Start Guide

Aggressive substances: e.g. acidic liquids or gases that may attack metals, or

solvents that may affect polymeric materials

Suitable precautions: e.g. regular checks as part of routine inspections or

establishing from the material’s data sheet that it is resistant to specific

chemicals

10. It is the responsibility of the user to ensure:

a. The voltage and current limits for this equipment are not exceeded.

b. That the joint requirements between the probe (switch) and the vessel tank

are compatible with the process media.

c. That the joint tightness is correct for the joint material used.

d. That only suitably certified cable entry devices will be utilized when

connecting this equipment.

e. That any unused cable entries are sealed with suitably certified stopping

plugs.

11. The probe fork is subjected to small vibration stresses as part of its normal

function. As this provides a partition wall, it is recommended that the fork

should be inspected every 2 years for signs of defects.

12. Technical data:

a. Coding:

ATEX:

Certificate: Sira 05ATEX1129X

Flameproof and dust proof:

ATEX Marking II 1/2 GD

Ex db IIC T6...T2 Ga/Gb

Ex tb IIIC T85 °C...T265 °C Db

July 2017

28

IECEx:

Ex d IIC T6...T2 Ga/Gb

Ex tb IIIC T85 °C...T265 °C Db

b. Temperature:

2130*A2E***********E1****, 2130*S2E***********E1****,

2130*A2E***********E7**** and 2130*S2E***********E7****:

Temperature

Classes

T6, T5, T4, T3, T2, T1 T85 °C 75 °C 80 °C

T5, T4, T3, T2, T1 T100 °C 74 °C 95 °C

T4, T3, T2, T1 T120 °C 73 °C 115 °C

T3, T2, T1 T190 °C 69 °C 185 °C

T2, T1 T265 °C 65 °C 260 °C

Maximum Surface

Temperature (T)

Maximum Ambient

Air Temperature (Ta)

Maximum Process

Temperature (Tp)

Minimum ambient air temperature (Ta) = –40 °C

Minimum process temperature (Tp) = –70 °C

Page 29

July 2017

Quick Start Guide

2130*A2M***********E1****, 2130*S2M***********E1****,

2130*A2M***********E7**** and 2130*S2M***********E7****:

Temperature

Classes

T6, T5, T4, T3, T2, T1 T85 °C 75 °C 75 °C

T5, T4, T3, T2, T1 T100 °C 70 °C 90 °C

T4, T3, T2, T1 T135 °C 65 °C 125 °C

T3, T2, T1 T190 °C 50 °C 180 °C

Maximum Surface

Temperature (T)

Maximum Ambient

Air Temperature (Ta)

Maximum Process

Temperature (Tp)

Minimum ambient air temperature (Ta) = –40 °C

Minimum process temperature (Tp) = –40 °C

c. Pressure: Must not exceed the rating of the coupling/flange fitted.

d. For electrical details and pressure ratings, see the Rosemount 2130 Product

Data Sheet or the Reference Manual.

e. Year of manufacture: printed on product label.

13. Cable selection

a. It is the responsibility of the user to ensure that suitably temperature rated

cable is used. The table below is a guide to selection:

Note

The cable entry temperature may exceed 70°C.

T Class Cable Temperature Rating

T6 Above 85 °C

T5 Above 100 °C

T4 Above 135 °C

T3 Above 190 °C

14. Special conditions of use

a. The user is to ensure the probe assembly is installed in such a way to

prevent any damage due to impact or ignition source due to friction.

b. Under certain extreme circumstances, a non-standard paint on the

enclosure of the Rosemount 2130 may generate an ignition-capable level of

electrostatic charge. Therefore the Rosemount 2130 shall not be installed in

a location where the external conditions are conducive to the build-up of

electrostatic charge on such surfaces. Additionally, the Rosemount 2130

shall only be cleaned with a damp cloth.

c. The user is to ensure the ambient air temperature (Ta) and the process

temperature (Tp) are within the range detailed above for the T class of the

specific flammable gases or vapors present.

d. The user is to ensure the ambient air temperature (Ta) and the process

temperature (Tp) are within the range detailed above for the maximum

surface temperature of the specific flammable dusts present.

15. Manufacturer

Rosemount Measurement Limited

158 Edinburgh Avenue, Slough, Berkshire, SL1 4UE, United Kingdom.

29

Page 30

Quick Start Guide

July 2017

10.13 Instructions specific to hazardous area installations (I1 / I7)

Model numbers covered:

2130M**E***********I1****,2130M**M***********I1****,

2130M**E***********I7****,2130M**M***********I7****,

2130N**E***********I1****,2130N**M***********I1****,

2130N**E***********I7****,2130N**M***********I7****

(“*” indicates options in construction, function, and materials).

The following instructions apply to the equipment covered by certificates

Sira 05ATEX2130X and IECEx SIR 06.0070X:

1. The Intrinsically Safe (I.S.) approved version of the 2130 may be used in a

hazardous area with explosive gases and vapors with apparatus groups IIC, IIB,

and IIA, and with temperature classes T1, T2, T3, T4, and T5 [IECEx: in Zone 0,

1, and 2].

The temperature class of the installation will be determined from the higher of

the process or ambient temperature.

2. The equipment may be used in a hazardous area with explosive dusts with

apparatus groups IIIC, IIIB, and IIIA [IECEx: in Zones 20, 21, and 22].

3. It is a special condition of the certification that the temperature of the

electronics housing is in the range of –50 to 80 °C.

It must not be used outside this range. It will be necessary to limit the external

ambient temperature if the process temperature is high.

See also “Technical Data” below.

4. Suitably trained personnel shall carry out installation in accordance with the

applicable code of practice.

5. The user should not repair this equipment.

6. If the equipment is likely to come into contact with aggressive substances, it

is the responsibility of the user to take suitable precautions that prevent it

from being adversely affected, thus ensuring that the type of protection is not

compromised.

Aggressive Substances: e.g. acidic liquids or gases that may attack metals or

solvents that may affect polymeric materials.

Suitable Precautions: e.g. regular checks as part of routine inspections or

establishing from the material’s data sheet that it is resistant to specific

chemicals.

7. The Rosemount 2130 meets the requirements of clause 6.3.12 (Isolation of

circuits from earth or frame) in EN 60079-11 (IEC 60079-11).

30

Page 31

July 2017

8. Technical Data:

a. Coding:

b. Temperature:

Temperature

Classes

T5, T4, T3, T2, T1 T85 °C 80 °C 80 °C

T4, T3, T2, T1 T120 °C 77 °C 115 °C

T3, T2, T1 T190 °C 71 °C 185 °C

T2, T1 T265 °C 65 °C 260 °C

Quick Start Guide

ATEX:

Certificate: Sira 05ATEX2130X

Intrinsic Safety for gas and dust atmospheres:

ATEX Marking II 1 GD

Ex ia IIC T5...T2 Ga

Ex ia IIIC T85 °C...T265 °C Da

IECEx:

Ex ia IIC T5...T2 Ga, Ex ia IIIC T85 °C...T265 °C Da

2130N**E***********I1**** and 2130N**E***********I7****:

Gas (Ga) and Dust (Da)

Maximum Surface

Temperature (T)

Maximum Ambient

Air Temperature (Ta)

Maximum Process

Temperature (Tp)

Minimum ambient air temperature (Ta) = –50 °C

Minimum process temperature (Tp) = –70 °C

2130N**M***********I1**** and 2130N**M***********I7****:

Gas (Ga) and Dust (Da)

Temperature

Classes

T5, T4, T3, T2, T1 T85 °C 80 °C 80 °C

T4, T3, T2, T1 T120 °C 69 °C 115 °C

T3, T2, T1 T185 °C 50 °C 180 °C

Maximum Surface

Temperature (T)

Maximum Ambient

Air Temperature (Ta)

Maximum Process

Temperature (Tp)

Minimum ambient air temperature (Ta) = –50 °C

Minimum process temperature (Tp) = –40 °C

2130M**E***********I1**** and 2130M**E***********I7****:

Gas (Ga) Dust (Da)

Temperature

Classes

T5, T4, T3, T2, T1 80 °C 80 °C T85 °C 70 °C 80 °C

T4, T3, T2, T1 77 °C 115 °C T120 °C 70 °C 115 °C

T3, T2, T1 71 °C 185 °C T190 °C 70 °C 185 °C

T2, T1 65 °C 260 °C T265 °C 65 °C 260 °C

Maximum

Ambient Air

Temperature

(Ta)

Maximum

Process

Temperature

(Tp)

Maximum

Surface

Temperature

(T)

Maximum

Ambient Air

Temperature

(Ta)

Maximum

Process

Temperature

(Tp)

31

Page 32

Quick Start Guide

Minimum ambient air temperature (Ta) = –50 °C

Minimum process temperature (Tp) = –70 °C

2130M**M***********I1**** and 2130M**M***********I7****:

Gas (Ga) Dust (Da)

Temperature

Classes

T5, T4, T3, T2, T1 80 °C 80 °C T85 °C 70 °C 80 °C

T4, T3, T2, T1 69 °C 115 °C T120 °C 69 °C 115 °C

T3, T2, T1 50 °C 180 °C T185 °C 50 °C 180 °C

Maximum

Ambient Air

Temperature

(Ta)

Maximum

Process

Temperature

(Tp)

Maximum

Surface

Temperature

(T)

Maximum

Ambient Air

Temperature

(Ta)

Maximum

Process

Temperature

(Tp)

Minimum ambient air temperature (Ta) = –50 °C

Minimum process temperature (Tp) = –40 °C

c. Input parameters:

Rosemount 2130 with NAMUR electronics:

Vmax=15 V, Imax=32 mA, Pi=0.1 W, Ci=12 nF, Li=0.06 mH

Rosemount 2130 with 8/16 mA electronics:

Vmax=30 V, Imax=93 mA, Pi=0.65 W, Ci=12 nF, Li=0.035 mH

d. Materials: see the Rosemount 2130 Product Data Sheet

.

e. Year of manufacture: printed on product label.

9. Special conditions of use:

a. If the enclosure is made of an alloy or plastic material, the following

precautions must be observed:

(i) The metallic alloy used for the enclosure material may be at the

accessible surface of this equipment; in the event of rare accidents, ignition

sources due to impact and friction sparks could occur. This shall be

considered when the Rosemount 2130 is being installed in locations that

specifically require Equipment Protection Level Ga or Da [ATEX: group II,

category 1G or 1D equipment] [IECEx: in Zone 0 or 20 locations].

(ii) Under certain extreme circumstances, the non-metallic parts

incorporated in the enclosure of the Rosemount 2130 may generate an

ignition-capable level of electrostatic charge. Therefore, when they are

used for applications that specifically require Equipment Protection Level

Ga or Da [ATEX: group II, category 1G or 1D equipment] [IECEx: in Zone 0

or 20 locations], the Rosemount 2130 shall not be installed in a location

where the external conditions are conducive to the build-up of electrostatic

charge on such surfaces. Additionally, the Rosemount 2130 shall only be

cleaned with a damp cloth.

b. Ensure the ambient air temperature (Ta) and the process temperature (Tp)

are within the range detailed above for the T class of the specific explosive

gases or vapors present.

c. Ensure the ambient air temperature (Ta) and the process temperature (Tp)

are within the range detailed above for the maximum surface temperature

of the specific explosive dusts present.

July 2017

32

Page 33

July 2017

Quick Start Guide

Figure 8. EU Declaration of Conformity for Rosemount 2130 (Page 1)

33

Page 34

Quick Start Guide

Figure 9. EU Declaration of Conformity for Rosemount 2130 (Page 2)

July 2017

34

Page 35

July 2017

Quick Start Guide

Figure 10. EU Declaration of Conformity for Rosemount 2130 (Page 3)

35

Page 36

Quick Start Guide

Figure 11. EU Declaration of Conformity for Rosemount 2130 (Page 4)

July 2017

36

Page 37

July 2017

ᴹ

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

Rosemount 2130

List of

Rosemount 2130

Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

ᴹᇣ⢙䍘䍘

䫵

⊎

䭹

ޝԧ䬜䬜

ཊⓤ㚄㚄㤟

ཊⓤ㚄㚄㤟䟊

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

Quick Start Guide

/ Hazardous Substances

Part Name

⭥ᆀ㓴Ԧ

Electronics

Assembly

༣փ㓴Ԧ

Housing

Assembly

Րᝏಘ㓴Ԧ

Sensor

Assembly

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(Cr +6)

Polybrominated

biphenyls

(PBB)

Polybrominated

diphenyl ethers

(PBDE)

XO O O O O

OO O X O O

XO O O O O

37

Page 38

Quick Start Guide

July 2017

38

Page 39

July 2017

Quick Start Guide

39

Page 40

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

*00825-0100-4130*

Quick Start Guide

00825-0100-4130, Rev CC

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found at

www.Emerson.com/en-us/Terms-of-Use

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Rosemount and Rosemount logotype are trademarks of Emerson.

ROCKWOOL is a registered trademark of ROCKWOOL International

A/S and/or its affiliates.

NEMA is the registered trademark and service mark of the National

Electrical Manufacturers Association.

All other marks are the property of their respective owners.

© 2017 Emerson. All rights reserved.

July 2017

Loading...

Loading...