Page 1

Reference Manual

00809-0100-4029, Rev AB

July 2008

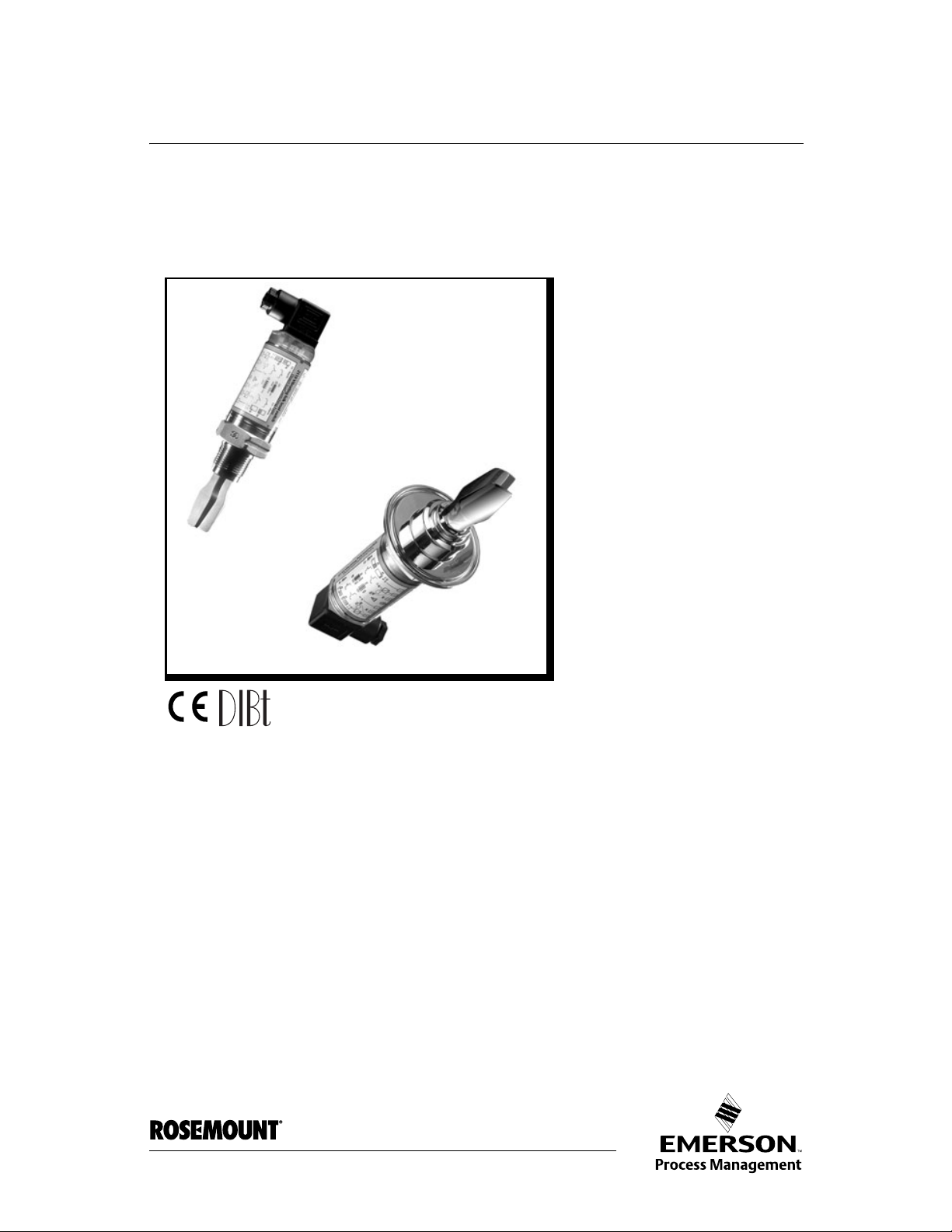

Rosemount 2110

Compact Vibrating Fork Liquid Level Switch

www.rosemount.com

Page 2

Page 3

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

2110 Compact Vibrating Fork

Liquid Level Switch

IMPORTANT NOTICE

Read this manual before working with the product. For personal and system safety, and

for optimum product performance, make sure you thoroughly understand the contents

before installing, using, or maintaining this product.

The United States has two toll-free assistance numbers and one International number.

Customer Central

1-800-999-9307 (7:00 a.m. to 7:00 P.M. CST)

International

1-(952) 906-8888

National Response Center

1-800-654-7768 (24 hours a day)

Equipment service needs

CAUTION

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require nuclearqualified hardware or products may cause inaccurate readings.

For information on Emerson Process Management nuclear-qualified products, contact

your local Emerson Process Management Sales Representative.

CAUTION

Rosemount pursues a policy of continuous development and product improvement. The

specification in this document may therefore be changed without notice. To the best of our

knowledge, the information contained in this document is accurate and Rosemount

cannot be held responsible for any errors, omissions or other misinformation contained

herein. No part of this document may be photocopied or reproduced without the prior

written consent of Rosemount.

www.rosemount.com

Page 4

Rosemount 2110

Reference Manual

00809-0100-4029, Rev AB

July 2008

Page 5

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

Table of Contents

SECTION 1

Introduction

Switch Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Short Fork Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Rosemount 2110 Application and Mounting Examples. . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Overfill Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Pump Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

High and Low Level Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Leak Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Pump Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Hygienic Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Handling the 2110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Rosemount Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Installation Considerations and Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Switchpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Service Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

SECTION 2

Installation

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Correct Fork Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Pipe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Vessel Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Cover Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

LED Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

SECTION 3

Troubleshooting

Magnetic Test Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

www.rosemount.com

Page 6

Reference Manual

00809-0100-4029, Rev AB

Rosemount 2110

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

July 2008

APPENDIX A

Reference Data

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Performance Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Functional Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Dimensional Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

APPENDIX B

Product Certifications

L.V. Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Electro Magnetic Compatibility (EMC) Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Overfill Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Approved Manufacturing Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

TOC-2

Page 7

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

SECTION 1INTRODUCTION

Switch Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Rosemount 2110 Application and Mounting Examples . . . . . . . . . . . . . page 1-2

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-4

Handling the 2110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-4

Installation Considerations and Recommendations . . . . . . . . . . . . . . . . page 1-7

Rosemount Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-6

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-9

Procedures and instructions in this manual may require special precautions to ensure the

safety of the personnel performing the operations. Information that raises potential safety

issues is indicated by a caution symbol ( ). The external hot surface symbol ( ) is used

when a surface is hot and care must be taken to award possible burns. If there is a risk of an

electrical shock the ( ) symbol is used. Refer to the safety messages listed at the

beginning of each section before performing an operation preceded by this symbol.

Failure to follow these installation guidelines could result in death or serious

injury.

• Protection afforded by compliance to EN61010-1 (2001) may be impaired if the

equipment is not used as specified.

• The Rosemount 2110 is a liquid level switch. It must be installed, connected,

commissioned, operated and maintained by suitably qualified personnel only,

observing any national and local requirements that may apply.

• Ensure the wiring is suitable for the electrical current and the insulation is suitable for

the voltage, temperature and environment.

External Surface may be hot.

• Care must be taken to avoid possible burns.

Process leaks could result in death or serious injury.

• Do not remove the level switch while in operation. Removing while in operation may

cause process fluid leaks.

Electrical shock could cause death or serious injury.

• If the level switch is installed in a high voltage environment and a fault condition or

installation error occurs, high voltage may be present on switch leads and terminals.

• Use extreme caution when making contact with the leads and terminals.

www.rosemount.com

Page 8

Reference Manual

00809-0100-4029, Rev AB

Rosemount 2110

Any substitution of non-recognized parts may jeopardize safety, repair, e.g. Substitution

of components, etc., may also jeopardize safety and is under no circumstances allowed.

July 2008

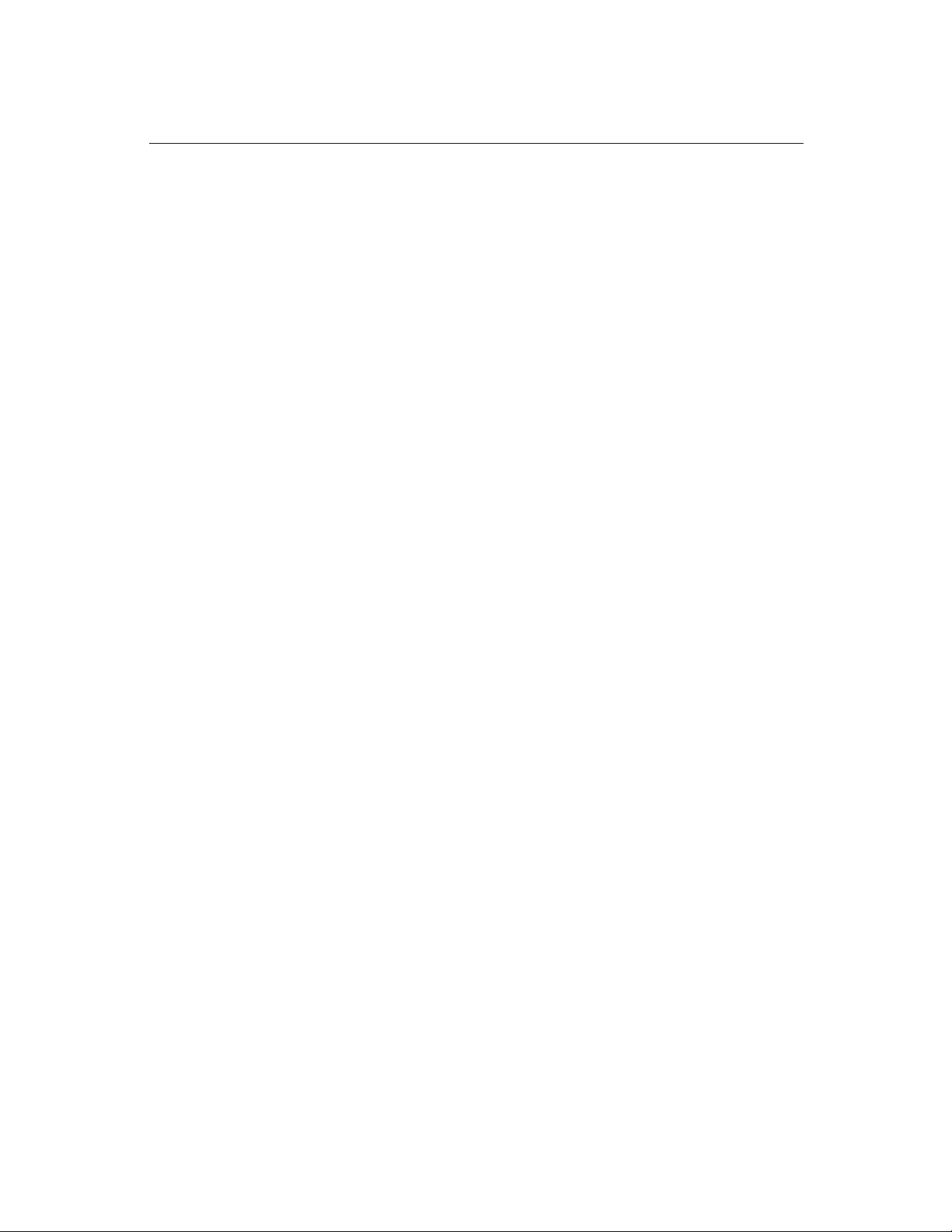

Switch Overview

The Rosemount 2110 is a liquid point level switch based on the vibrating short fork

technology. It is a compact switch with a rugged stainless steel body and forks for use in a

wide range of liquid applications. Economical

tanks or hygienic mounting for food industry use. Direct load switching suits all supplies or

PNP output for direct interface to PLCs. For use in safe area only.

3

/4-in. or 1-in. threaded mounting in pipes or

2110clear_rev.tif

Short Fork Technology

The natural frequency (~1300Hz) of the fork is chosen to avoid interference from plant

vibration which may cause false switching. This also gives short fork length for minimal

intrusion into vessel and pipe. Using Short Fork Technology, the Rosemount 2110 is

designed for use in virtually all liquid applications. Extensive research has maximized the

operational effectiveness of the fork design making it suitable for almost all liquids, including

coating liquids (avoid bridging of forks), aerated liquids, and slurries.

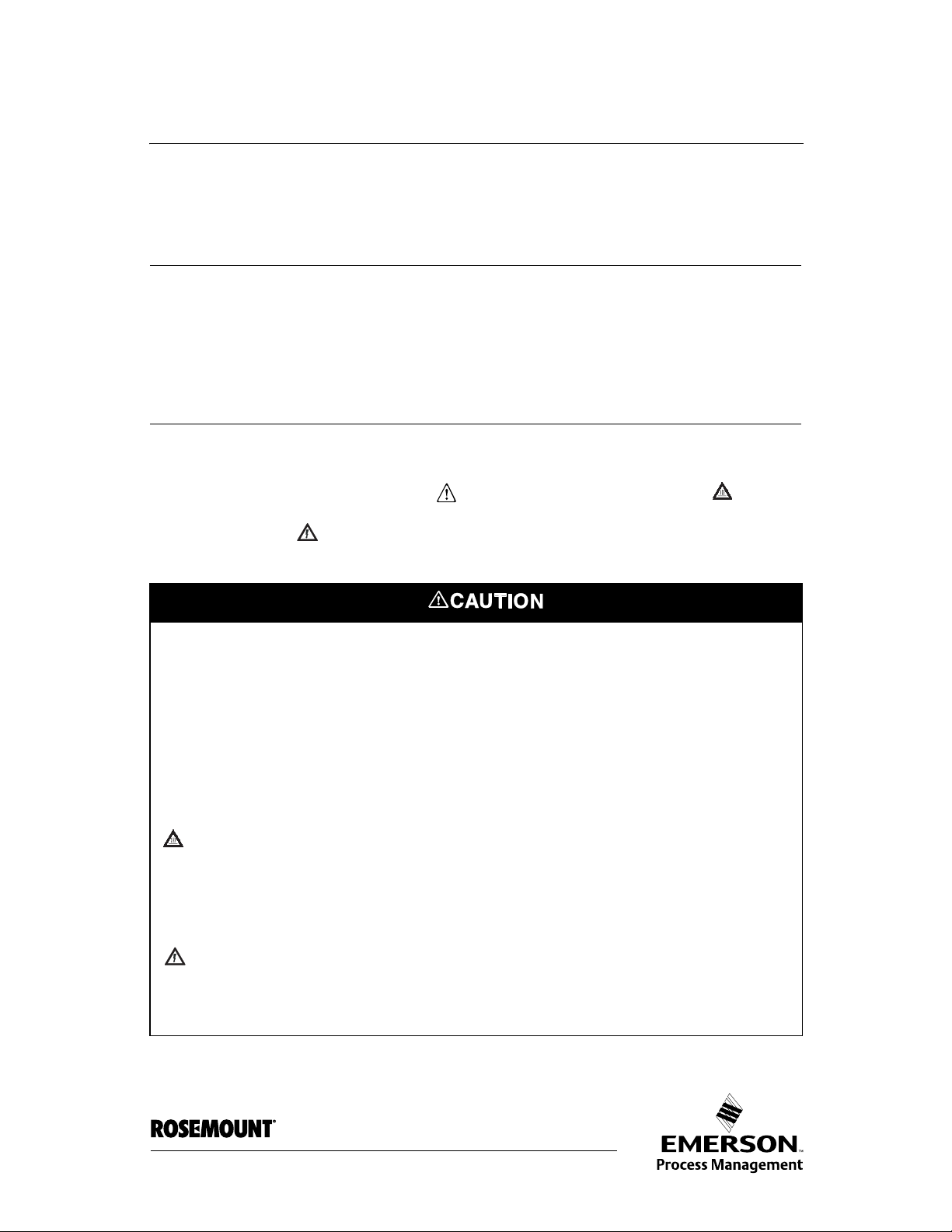

Rosemount 2110 Application and Mounting Examples

For most liquids including coating and aerated liquids and slurries, the function is virtually

unaffected by flow, turbulence, bubbles, foam, vibration, solid particles, build-up or

properties of the liquid.

For use in safe area and process temperatures up to 302°F (150°C).

Mount in any position in the tank or pipe. Mounting is by

fitting.

1-2

3

/4-in. or 1-in. threaded or hygienic

Page 9

Reference Manual

00809-0100-4029, Rev AB

July 2008

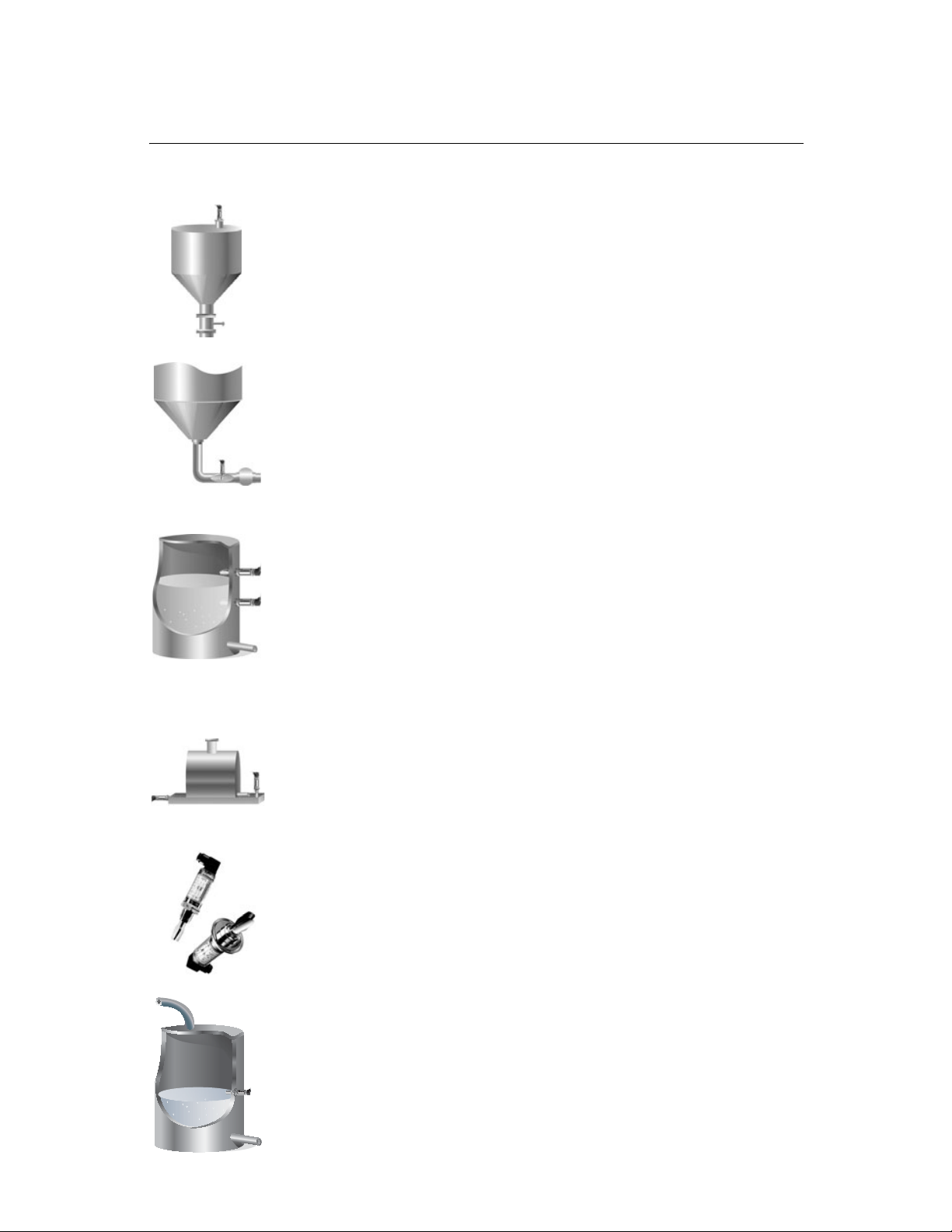

Overfill Protection

Spillage caused by overfilling can be hazardous to people and the

environment, resulting in lost product, and clean up costs. The 2110 is a

limit level switch used to signal overfill at any time.

Pump Protection

Short forks mean minimum intrusion wetside and allow simple low cost

installation at any angle into your pipes or vessels. With the fork projecting

only 2-in. (50 mm) (dependant on connection type), the 2110 can be

installed in even small diameter pipes. By selecting the option of direct load

switching electronics, the 2110 is ideal for reliable pump control and can be

used to protect against pumps running dry.

Rosemount 2110

High and Low Level Alarm

Maximum and minimum level detection in tanks containing many different

types of liquids are an ideal application for the 2110. The robust 2110

operates continuously at temperatures up to 302°F (150°C) and operating

pressure up to 1450 psig (100 barg) making it perfect for use as a high or

low level alarm. It is common practice to fit an independent high level alarm

switch to provide extra back up to the level switch in case of failure.

Leak Detection

Flanges, gaskets, seals, corrosive liquids – they all have the potential to

leak at the most inconvenient times. Many users site tanks and vessels

above trays or in containments to prevent any liquids from escaping. A

level switch can quickly and accurately detect any leakage and thereby

eliminating cost.

Pump Control

Many processes have batching and header tanks, and there is usually the

need to control a pump to maintain levels between set points. These tanks

are often manufactured from thin wall materials and cannot support the

weight of heavy instrumentation.

Hygienic Applications

With the option of highly polished forks providing a surface finish (Ra)

better than 0.8 µm, the 2110 meets the principle design criteria of the most

stringent hygienic requirements used in food and beverage, and

pharmaceutical applications. Manufactured in stainless steel the 2110 is

robust enough to easily withstand steam cleaning (CIP) routines at

temperatures up to 302°F (150°C).

1-3

Page 10

Reference Manual

00809-0100-4029, Rev AB

Rosemount 2110

Application Considerations

• Ensure liquid is inside the temperature and pressure ranges (see specifications).

• Check that the liquid is inside recommended viscosity range 0.2 to 10,000 cP.

• Examples of products with too high of viscosity is chocolate syrup, ketchup, peanut

butter and bitumen. The switch will still detect these products but the drain time can be

very long.

• Check that the liquid density is above 37.5 lb/ft

• Examples of products with too low of density is acetone, pentane and hexane.

• Check for risk of build-up on the forks.

• Avoid situations where drying and coating products may create excessive build-up.

• Ensure no risk of bridging the forks.

• Examples of products that can create bridging of forks are dense paper slurries and

bitumen.

• Check if solid content in liquid

• Problems may occur if product coats and dries causing caking

• As a guideline maximum solid particle diameter in the liquid is 0.2-in. (5 mm)

• Extra consideration is needed when dealing with particles bigger than 0.2-in. (5 mm),

consult factory

3

(600 kg/m3).

July 2008

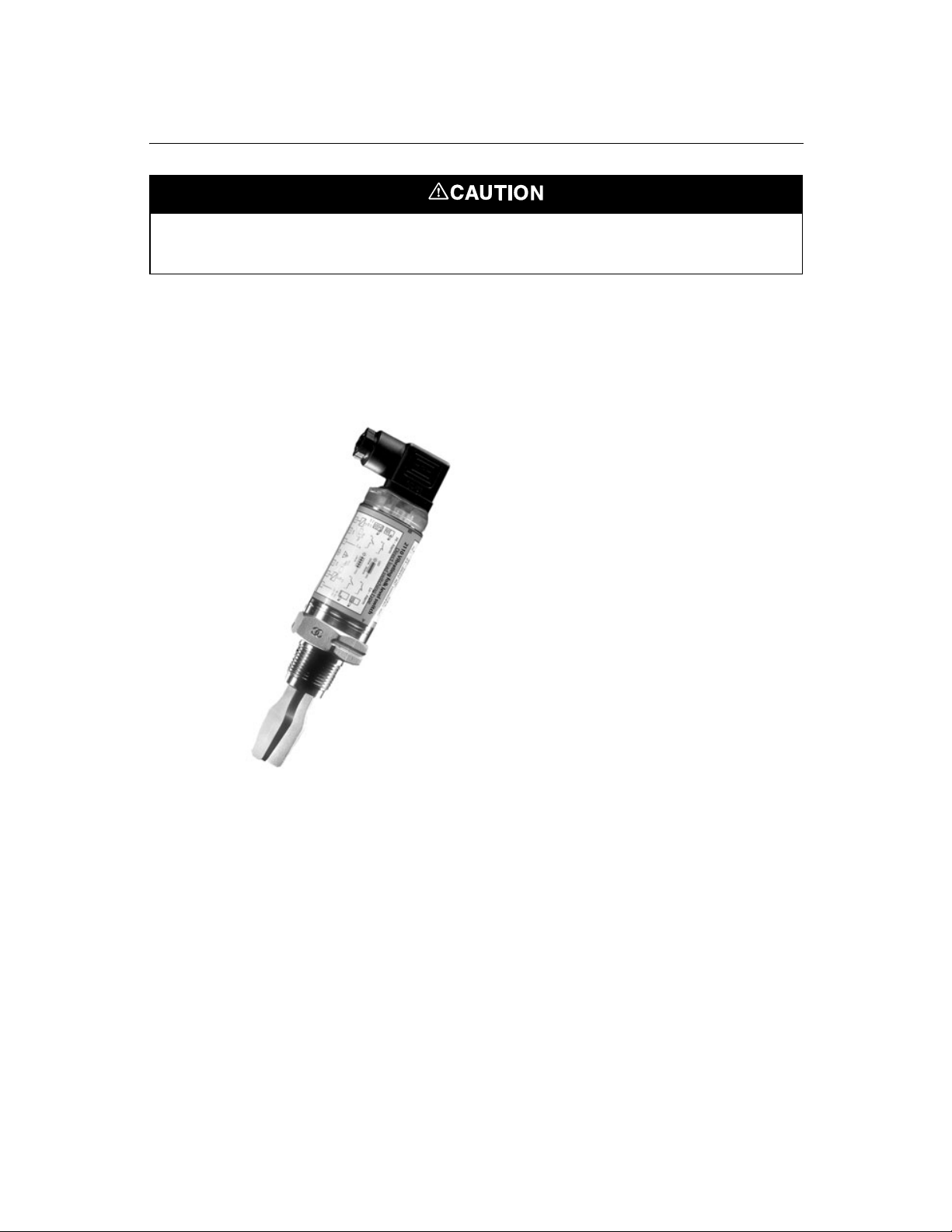

Handling the 2110

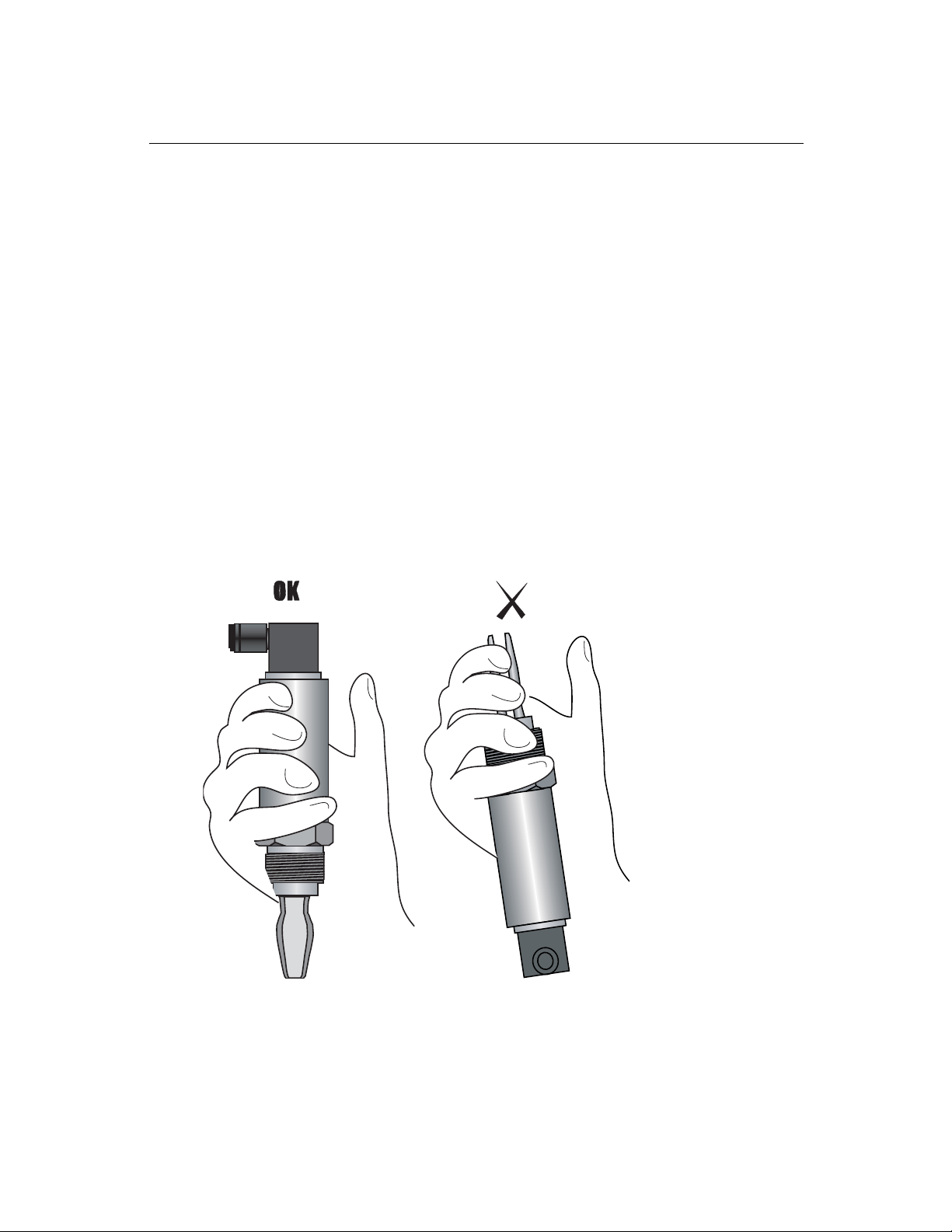

Figure 1-1. Do not hold the 2110 by forks.

2110/2110_19aa, 2110_19aa.eps

1-4

Page 11

Reference Manual

00809-0100-4029, Rev AB

July 2008

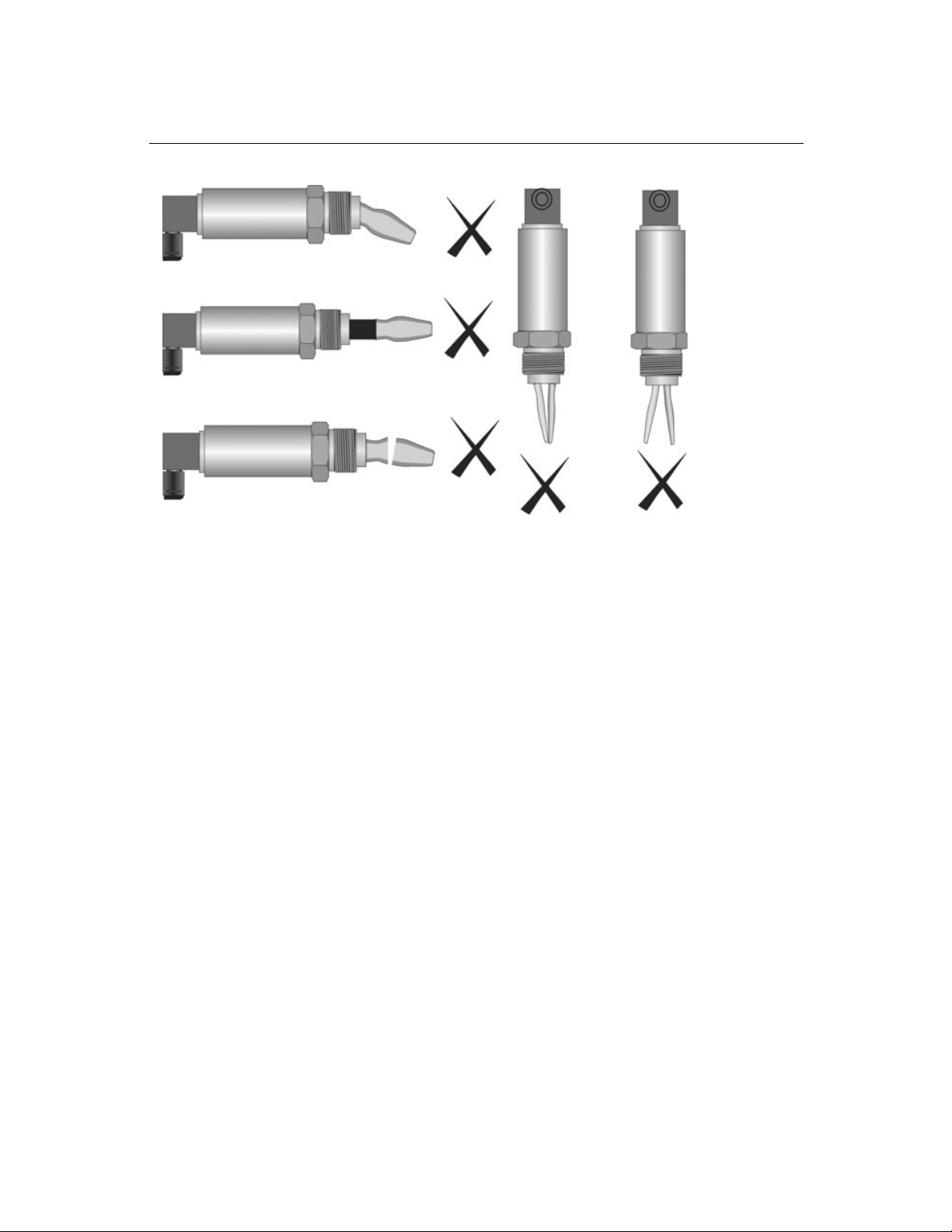

Figure 1-2. Do not alter the 2110 in any way.

Rosemount 2110

2110/2110_27aa.eps

1-5

Page 12

Reference Manual

00809-0100-4029, Rev AB

Rosemount 2110

Rosemount Identification

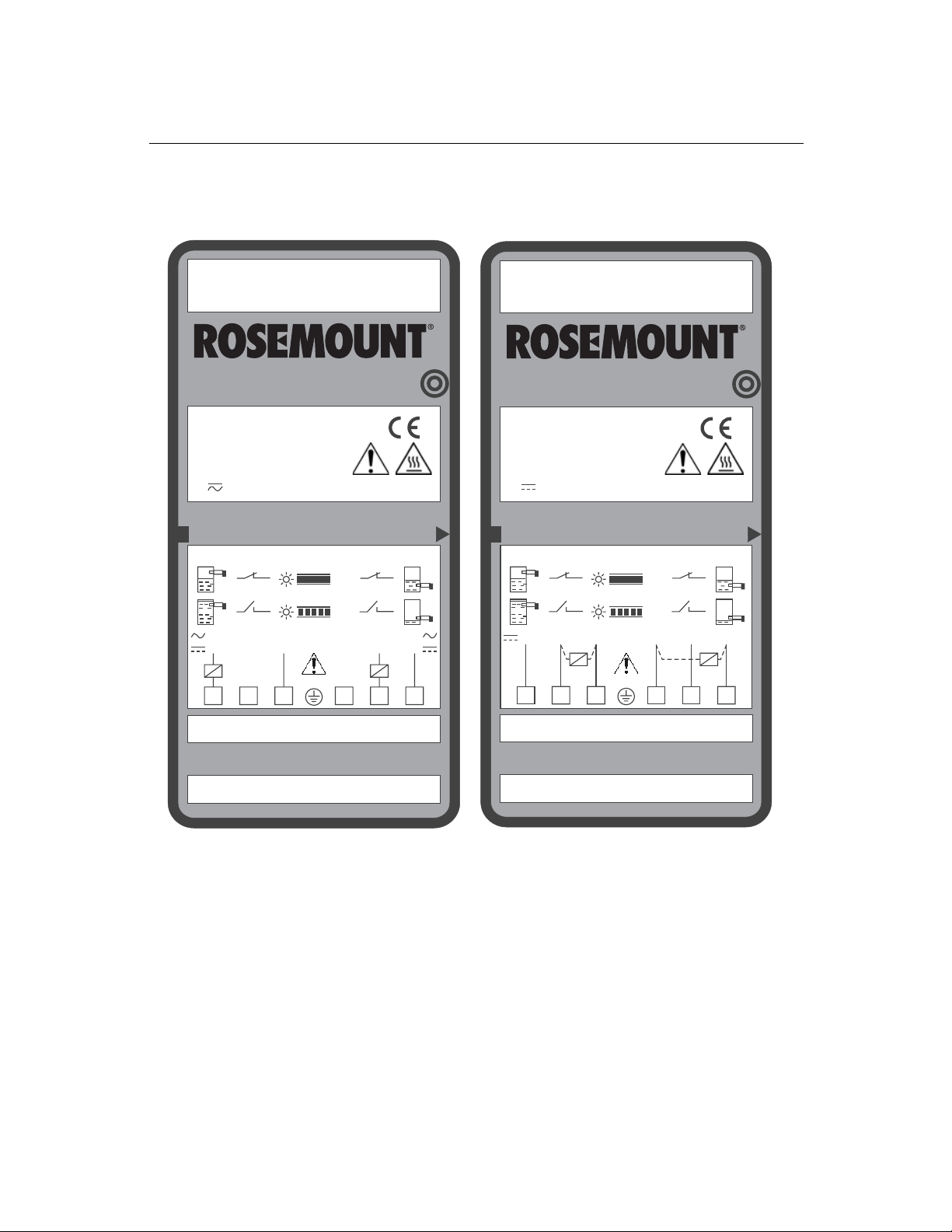

Figure 1-3. Load Switching Models: ac/dc Figure 1-4. PNP solid state output Models:

dc low voltage

July 2008

MAGNETIC

TEST

POINT

IP66/67

I: 20...500mA

-40...80°C amb

T : -40...150°C op

: 21...264V AC (50/60Hz) /DC

2110 Vibrating Fork Level Switch

Direct load switching type

Hi - Alarm Lo - Alarm

N

0V

211002RNA

Model Fitting

LED

31 2 1

20mA...500mA

L1

+V

NC NC

<3mA

(on)

(1Hz)

2131

2-in.

Tri-C la mp

N

0V

L1

+V

23

www.rosemount.com

1312

MAGNETIC

TEST

POINT

IP66/67

I: <500mA

-40...80°C amb

T : -40...150°C op

: 18...60V DC

2110 Vibrating Fork Level Switch

Low Voltage PNP type

Hi - Alarm Lo - Alarm

+V 0V

Model Fitting

LED

32 2 3

PLC

Sig

211010ANA

<500mA

(on)

(1Hz)

Sig

2332

3

BSPT

23

/4-in.

www.rosemount.com

0V+VPLC

112 3

2110/2110_57aa, 2110_58aa.eps

1-6

Page 13

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

Installation Considerations and Recommendations

Before you install the Rosemount 2110 Level Switch, consider specific installation

recommendations and mounting requirements.

• Install in any orientation in tank containing liquid.

• Always install in the normally “on” state

• For high level recommendation is Dry = on (see “Function” on page 2-6).

• For low level recommendation is Wet = on (see “Function” on page 2-6).

• Always ensure the system is tested by using the local magnetic test point during

commissioning (see “Magnetic Test Point” on page 3-1).

• Ensure sufficient room for mounting and electrical connection (see “Dimensional

Drawing” on page A-5).

• Ensure that the forks do not come into contact with the tank wall or any internal fittings

or obstructions.

• Ensure the forks does not come into contact with the tank wall of any internal fitting.

• Avoid installing the 2110 where it will be exposed to liquid entering the tank at the fill

point.

• Avoid heavy splashing on fork

• Avoid product buildup

• Ensure no risk of bridging the forks.

• Ensure there is sufficient distance between build-up on the tank wall and the fork.

• Ensure installation does not create tank crevices around the forks where liquid may

connect (important in high viscosity and high density liquids).

• Extra consideration is needed if the plant vibration is close to the 1300 Hz operating

frequency of the 2110.

• Ensure sufficient clearance for the fork so highly viscous liquids quickly flow off the

forks.

• Extra consideration is needed if the plant vibration is close to the 1300 Hz operating

frequency of the 2110.

Figure 1-5. Example of OK and not OK build-up on tank wall.

2110/2110_25aa, 2110_26aa.eps

1-7

Page 14

Rosemount 2110

Switchpoint

In the top diagram a lower

density media will give

switchpoint closer to the

connection. A higher density

media will give switchpoint

closer to fork tip.

0.5-in. (13 mm)

0.5-in. (13 mm)

0.5-in. (13 mm)

Reference Manual

00809-0100-4029, Rev AB

July 2008

±0.039-in. (±1 mm)

Switchpoint (H20) (SP)

Switching hysteresis (HY)

±0.039-in. (±1 mm)

2120/fig12.eps

1-8

Page 15

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

Service Support

To expedite the return process outside of the United States, contact the nearest Rosemount

representative.

Within the United States, call the Rosemount National Response Center using the

1-800-654-RSMT (7768) toll-free number. This center, available 24 hours a day, will assist

you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a Return Material

Authorization (RMA) number. The center will also ask for the process material to which the

product was last exposed.

Rosemount National Response Center representatives will explain the additional

information and procedures necessary to return goods exposed to hazardous substance

can avoid injury if they are informed of and understand the hazard. If the product being

returned was exposed to a hazardous substance as defined by OSHA, a copy of the

required Material Safety Data Sheet (MSDS) for each hazardous substance identified must

be included with the returned goods.

Warranty

Emerson Process Management will replace a faulty or failed 2110 with a new unit provided

that the fault or failure is reported either directly or via an accredited representative, within 1

year from the date of supply, and the product has been installed and used in accordance

with Emerson Process Management instruction manual 00809-0100-4029. Emerson

Process Management reserves the right to examine such product and to refuse replacement

at its discretion if the above conditions are not met.

1-9

Page 16

Rosemount 2110

Reference Manual

00809-0100-4029, Rev AB

July 2008

1-10

Page 17

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

SECTION 2INSTALLATION

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Correct Fork Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

Safety Messages

Procedures and instructions in this manual may require special precautions to ensure the

safety of the personnel performing the operations. Information that raises potential safety

issues is indicated by a caution symbol ( ). The external hot surface symbol ( )is used

when a surface is hot and care must be taken to award possible burns. If there is a risk of an

electrical shock the ( )symbol is used. Refer to the safety messages listed at the

beginning of each section before performing an operation preceded by this symbol.

Mechanical Installation

Figure 2-1. Sealing Figure 2-2. Tighten the Switch

NPT, BSPT (R)

PTFE (Teflon)

BSPP (G1)

Gasket

Seal (supplied in

02100-1020-0001)

Tri-Clamp

2110/2110_28aa, 2110_29aa.eps

www.rosemount.com

Page 18

Rosemount 2110

Correct Fork Alignment

Ensure correct fork alignment.

Pipe Installation

Reference Manual

00809-0100-4029, Rev AB

July 2008

Alignment groove

2110/14aa.eps

Vessel Installation

2110/24aa,

2110_16aa.eps

2-2

2110/2110_34aa.tif

Page 19

Reference Manual

00809-0100-4029, Rev AB

July 2008

Cover Orientation

Rosemount 2110

2110/2110_36aa.eps

2-3

Page 20

Reference Manual

00809-0100-4029, Rev AB

Rosemount 2110

Electrical Installation

Mode Selection

Mode Selection by customer wiring.

Code 0 1

Load Switching: ac/dc

Direct load switching: ac/dc

DRY = ON: High level alarm PE (Ground) PE (Ground)

PNP Output: dc

NP for PLC/SPS connection: dc

July 2008

1

3

2A(T)

L1

+V

R

21-264V ac 50/60Hz

N

21-264V dc

0V

2A

(T)

0V

WET = ON: Low level alarm PE (Ground) PE (Ground)

1

2

2A

(T)

L1

+V

R

21-264V ac 50/60Hz

N

21-264V dc

0V

R

0V

1

2

3

R

PLC

Input

+V (18-60V dc)

1

2

3

2A

(T)

PLC

Input

(18-60V dc)

+V

2-4

R = External Load

(must be wired)

= External Load

Maximum inrush current: 5A (Over current protected)

I Maximum continuous: 500 mA

I Minimum continuous: 20mA Supply current: 3mA nominal

Voltage drop: 6.5V @ 24V dc /

Voltage drop: <3V

5.0V @ 240 V ac

I Load off: <3mA I Load off: <0.5mA

Page 21

Reference Manual

00809-0100-4029, Rev AB

July 2008

LED Indication

LED Flash Rate Switch Status

1 every 2 seconds Uncalibrated

Rosemount 2110

Continuous Output state is on

1 every second Output state is off

1 every 4 seconds Load fault; load current too high; load short circuit

2 times / second Indication of successful calibration

3 times / second Internal fault (micro, ROM, or RAM)

Off Problem (e.g. supply)

2-5

Page 22

Rosemount 2110

V

V

V

Function

Reference Manual

00809-0100-4029, Rev AB

July 2008

High Level DRY = ON Low Level Wet = ON

PLC (positive output)

+V

P

L

Sig

C

0V

PNP dc

Load switching ac/dc

U

<3V

I

L

2

I/P

1

-

3

+

PLC

U

<3V

2

U

<12V

1

3

V0

+

<100uA

I

L

2

I/P

1

-

3

+

PLC

<100uA

I

L

3

V0

+

<3mA

1

2

+

2

3

<3V

<3V

U

3

I/P

U

2

V0V

+

<12V

I

L

PLC

U

<100uA

I

L

3

I/P

PLC

<100uA

I

2

V0

+

<3mA

1

-

L

1

1

-

1

2

+

3

LED

13

0V

N

LED on continuously

V

+

L1

= Load On

13

0V

N

LED flashes every

second

+

V

L1

0V

N

LED on

continuously

= Load Off

12

0V

V

+

L1

N

LED flashes every

second

+

L1

12

V

2-6

Page 23

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

Wiring

The 2110 is IP66 and IP67 when correctly assembled with the supplied connector and

suitable cable.

NOTE

Use only connector supplied.

1. Insert cable into plug housing and connect to terminals.

5.9 (1.5)

Maximum 0.31 (8)

Minimum 0.24 (6)

2. Ensure both seals are in place to maintain the weatherproof rating.

Screw

Seal

Fixing Screw

Plug

Seal

3. Fit plug to body.

2110/2110_15aa.eps

2110/ 2110_15ab.eps

2110/ 2110_28ac.eps

2-7

Page 24

Rosemount 2110

4. Tighten the screw.

5. Plug fitted.

Plug Fitted

Reference Manual

00809-0100-4029, Rev AB

July 2008

2110/ 2110_28ab.eps

2110/2110_17aa.eps

RELAY CONNECTION WARNING (FOR DIRECT LOAD SWITCHING)

The Rosemount 2110 requires a minimum current of 3mA, which continues to flow when the

2110 is ‘off’. If selecting a relay to wire in series with the 2110, the user must ensure that the

drop-out voltage of the relay is greater than the voltage which will be generated across the

relay coil when 3mA flows through it.

NOTE (FOR DIRECT LOAD SWITCHING)

DPST = ‘Double Pole, Single Throw’ (on/off) switch - must be fitted for safe disconnection of

the power supply. Fit the switch as near to the 2110 as possible. Keep the switch free of

obstructions. Label the switch to indicate that it is the supply disconnection device for the

2110.

2-8

Page 25

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

SECTION 3TROUBLESHOOTING

Magnetic Test Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Magnetic Test Point

A magnetic test point is marked on the side of the housing allowing a functional test of the

2110. By touching a magnet on the target the 2110 output will change state for as long as the

magnet is present.

No Magnet

Normal Condition

Magnet

Test Condition

Inspection

Visually examine the 2120 for damage. If it is damaged, do not use. Check connector and

seals are correctly fitted, also that the connector fixing screw and gland are tight.

Ensure the LED flash rate is 1 Hz or continually on. If anything else is demonstrated see

“LED Indication” on page 2-5.

2110/2110_47aa.eps

www.rosemount.com

Page 26

Reference Manual

00809-0100-4029, Rev AB

Rosemount 2110

Maintenance

NOTE

If using a brush to clean, ensure it is of a soft type.

Troubleshooting

If there is a malfunction, see Table 3-1 for information on possible causes.

July 2008

2110_07aa, 2110_20aa, 2110_12aa

Table 3-1. Troubleshooting chart.

Fault Symptom/Indication Action/Solution

Does not switch

Incorrect switching

Faulty switching

• No LED; no power • Check the power supply; (check

load on direct load switching

electronics model)

• LED 3 flashes per second • Internal failure; contact supplier

• LED 1 flash every 2 seconds • Uncalibrated; return to supplier

• LED 1 flash every 4 seconds • Load fault; load current too high,

load short circuit; check

installation

• Fork damaged • Replace

• Thick encrustation on forks • Clean the fork with care

• 5 second delay on changing mode/delay • Wait 5 seconds

• Dry = On, Wet = On set correctly • Check wiring in the connector.

See “Mode Selection” on

page 2-4

• Excessive electrical noise • Suppress the cause of the

interference

Spare Parts

See “Accessories” on page A-7.

3-2

Page 27

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

APPENDIX AREFERENCE DATA

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-1

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-2

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-2

Dimensional Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-5

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-6

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-7

Physical Specifications

Product

Rosemount 2110 Compact Liquid Level Switch

Measuring principle

Vibrating Fork

Applications

Most liquids including coating liquids, aerated liquids, and slurries

Mechanical

Process material

316L Stainless Steel (1.4404)

For Tri-Clamp connection hand polished to better than 0.8 Pm. Gasket material for 1 in. BSPP (G1) is

Non-asbestos BS7531 Grade X carbon fiber with rubber binder.

Housing materials

Body: 304 SST with polyester label

LED window: Flame retardant Polyamide (Pa12) UL94 V2

Plug: Polyamide glass reinforced

Plug seals: Nitrile butadiene rubber 122-in. (50 mm)

Connections

See “Process Connection Size / Type” on page A-6.

Mounting

3

/4-in. BSPT (R) or NPT

•

• 1-in. BSPT (R) or BSPP (G) thread, or

• Hygienic 2-in. (51 mm) Tri-clamp fitting

Dimensional Drawings

See “Dimensional Drawing” on page A-5

Ingress of Protection Rating

IP66/67 to EN60529

www.rosemount.com

Page 28

Rosemount 2110

Performance Specifications

Hysteresis (water)

±0.039-in. (± 1mm) nom.

Switching point (water)

0.5-in. (13mm) from tip (vertical) / from edge (horizontal) of fork

(this will vary with different liquid densities)

Functional Specifications

Maximum Operating Pressure

Final rating depends on tank connection

Threaded Connection

See Figure A-1.

Hygienic Connection

435 psig (30 barg)

Figure A-1. Process Pressure

Reference Manual

00809-0100-4029, Rev AB

July 2008

1450 (100)

1160 (80)

0 (0)

-3.62 (-0.25)

-40

(-40)

Process Pressure psig (barg)

Process Temperature °F (°C)

Temperature

See Figure A-2.

Figure A-2. Temperature

176 (80)

122 (50)

0 (0)

-40 (-40)

-40

(-40)

Ambient Temperature °F (°C)

Process Temperature °F (°C)

32

(0)

32

(0)

140

(60)

122

(50)

302

(150)

2120/2120_18ab.eps

302

(150)

2120/2120_18ac.eps

A-2

Page 29

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

Liquid Density

Minimum 37.5 lb/ft

Liquid Viscosity Range

0.2 to 10,000 cP (centiPoise)

Solids Content and Coating

Maximum recommended diameter of solid particles in the liquid is 0.2-in. (5 mm).

For coating product, avoid bridging of forks.

Switching delay

1 sec dry to wet/wet to dry

CIP (Clean In Place) Cleaning

Withstands steam cleaning routines up to 302°F (150°C)

3

(600 kg/m3)

Electrical

Switching mode

User selectable (Dry =on or Wet =on) by selecting plug wiring

Cable connection

Via 4-way plug provided - DIN43650. Max. conductor size - 15AWG. Orientation 4-position

(90/180/270/360 deg).

Conductor size

Maximum 0.06 inch

Cable gland

PG9 provided - cable diameter 0.24 to 0.31-in. (6 to 8 mm)

2

(1.5 mm2)

Protection

Reverse polarity insensitive. Missing load / short circuit protection

Grounding

The 2110 should always be grounded either through the terminals or using the external ground

connection provided.

A-3

Page 30

00809-0100-4029, Rev AB

Rosemount 2110

Direct load switching (Code 0)

Operating Voltage 21 to 264V ac (50-60Hz)/dc

Maximum switched load 500mA

Maximum peak load 5A for 40 ms max.

Minimum switched load 20mA continuous

Voltage drop 6.5V @ 24V dc / 5.0V @ 240V ac

Current draw (load off) <3.0mA continuous

Load

PNP Switching (Code 1)

Operating Voltage 18-60V dc

Maximum switched load 500mA

Maximum peak load 5A for 40 ms max.

Voltage drop <3V

Supply Current 3mA nominal

Output current (load off) <0.5mA

Reference Manual

July 2008

0V/N

+V/N

PE

+V

PLC

0V

PE

A-4

Page 31

Reference Manual

00809-0100-4029, Rev AB

July 2008

Dimensional Drawing

Rosemount 2110

2-in. Tri-Clamp

Thread 1-in.

0.51 (13)

Switchpoint

0.51 (13)

Switchpoint

or

3

/4-in.

A

41 A/F

B

D

Notch to indicate fork

orientation

External

Earth

Point/Connector

C

Cable Gland

Supplied

Table A-1. Dimensions are in inches (millimeters)

Connections A B C D

3

/4-in. BSPT (R) 2.72 (69) 1.97 (50) 7.40 (188) N/A

3

/4-in. NPT 2.72 (69) 1.97 (50) 7.40 (188) N/A

1-in. BSPT (R) 2.72 (69) 1.97 (50) 7.40 (188) N/A

1-in. BSPP (G) 3.07 (78) 2.36 (60) 7.91 (201) N/A

2-in. (51 mm) Tri-Clamp 2.72 (69) 1.97 (50) 7.40 (188) 2.52 (64)

1-in. Semi-extended 4.57 (116) 3.86 (98) 9.41 (239) N/A

1.50

(38)

2110-06aa.eps

A-5

Page 32

Reference Manual

00809-0100-4029, Rev AB

Rosemount 2110

Ordering Information

Model Product Description

2110 Compact Vibrating Fork Liquid Level Switch

Code Electronic Type

0 Direct load switching with plug connection (2 wire) 21 to 264 V ac 50/60 Hz, 21 to 264 V dc

1 PNP/PLC low voltage switching with plug connection 18 to 60 V dc

Code Process Connection Size / Type

0A

1A 1-in. BSPT (R) thread

0D

2R 2-in. (51mm) Tri-clamp

1B 1-in. BSPP (G) thread

1L 1-in. BSPP (G) Semi-extended 4.6-in. (116 mm)

Code Product Certificates

NA No Hazardous Locations Certifications (safe area use only)

U1 DIBt/WHG Overfill protection

Code Options

Q4 Certificate of functional test

ST Tag plate SST engraved plate (maximum 16 digits)

WT Tag plate laminated paper (maximum 40 digits)

Typical Model: 2110 0 2R NA

3

/4-in. BSPT (R) thread

3

/4-in. NPT thread

Overfill

Calibration Data Certificate

Tag Plates

July 2008

A-6

Page 33

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

Accessories

Part Number Spares and Accessories

02100-1000-0001 Seal for 1-in. BSPP (G1A).

02100-1010-0001 Hygienic adaptor boss 1-in. BSPP. Material: 316 SS fitting. Viton ‘O’ ring

Material: Non-asbestos BS7531 grade X carbon fiber with rubber binder

1.54

(39)

1.30

(34)

0.12 (3)

1.20

(30.5)

0.18

(4.5)

1-in.

BSPP

2.36

(60)

02100-1020-0001 2-in. (51 mm) Tri-clamp kit including vessel fitting, clamp ring, seal.

Material: 316 St. steel, NBR Nitrile

02100-1030-0001 Telescopic test magnet

1.54

(39)

A-7

Page 34

Rosemount 2110

Reference Manual

00809-0100-4029, Rev AB

July 2008

A-8

Page 35

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 2110

APPENDIX BPRODUCT CERTIFICATIONS

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B-1

L.V. Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B-1

Overfill Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B-1

L.V. Directive

EN61010-1 Pollution degree 2, Category II (264V max),

Pollution degree 2, Category III (150V max)

Electro Magnetic Compatibility (EMC) Directive

EN61326

Overfill Protection

Option available for DIBt/WHG

Approved Manufacturing Locations

Slough, UK

www.rosemount.com

Page 36

Rosemount 2110

ᴹᴹ

List of

Part Name

Rosemount 210

䫵

Lead

(Pb)

㇑㇑᧗᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

Parts with China RoHS Concentration above MCVs

/ Hazardous Substances

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(Cr +6)

Polybrominated

biphenyls

Reference Manual

00809-0100-4029, Rev AB

July 2008

Rosemount 210

Polybrominated

diphenyl ethers

(PBB)

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

༣փ㓴Ԧ

Housing

Assembly

Րᝏಘ㓴Ԧ

Sensor

Assembly

ᵜ㺘Ṭ㌫ᦞ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the

limit requirement ofGB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

26572

homogeneous materials used for this part is above the limit requirement of GB/T 26572.

SJ/T11364

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O OX OOO

O OO OO

O OX OOO

O

Ⲵ㿴ᇊ㘼ࡦ

GB/T 26572

X: Indicate that said hazardous substance contained in at least one of the

ᡰ㿴ᇊⲴ䲀䟿㾱≲

GB/T

B-2

Page 37

Page 38

Page 39

Page 40

Reference Manual

00809-0100-4029, Rev AB

July 2008

Cover Photos: 2110/ 2110 clear_rev, 2110 hyg_rev.

Rosemount and the Rosemount logotype are registered trademarks of Rosemount Inc.

PlantWeb is a registered trademark of one of the Emerson Process Management group of

companies.

HART is a registered trademark of the HART Communication Foundation

Teflon, VITON, and Kalrez are registered trademarks of E.I. du Pont de Nemours & Co.

F

OUNDATION is a trademark of the Fieldbus Foundation.

Hastelloy and Hastelloy C-22 are registered trademarks of Haynes International.

All other marks are the property of their respective owners.

Emerson Process Management

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN USA 55317

T (US) (800) 999-9307

T (Intnl) (952) 906-8888

F (952) 949-7001

Emerson Process Management

Heath Place

Bognor Regis

West Sussex PO22 9SH

England

Tel 44 (1243) 863 121

Fax 44 (1243) 867 5541

Emerson Process Management

Asia Pacific Private Limited

1 Pandan Crescent

Singapore 128461

T (65) 6777 8211

F (65) 6777 0947 / (65) 6777 0743

Enquiries@AP.EmersonProcess.com

www.rosemount.com

Loading...

Loading...