Page 1

Rosemount™ 2110 Level Switch

Vibrating Fork

Product Data Sheet

March 2018

00813-0100-4029, Rev FA

Virtually unaffected by turbulence, foam,

vibration, coating, or changing liquid properties

Built in diagnostics continuously monitors

instrument health and Heartbeat LED provides

visual indication

Magnetic test point makes testing of the

Rosemount 2110 and system easy

Minimal installation and maintenance, and no

calibration required, keeps costs down

DIBt / WHG overfill protection certification keeps

peace of mind

Compact size makes the Rosemount 2110

suitable for use in small vessels and tanks or for

in-pipe mounting

Hygienically certified to 3-A

complies with FDA and ASME-BPE

®

and EHEDG, and

Page 2

Rosemount 2110 Level Switch

Compact and lightweight

Tri Clamp process

connection

Threaded process

connection

Overview of the Rosemount 2110 Level Switch

Measurement principle

The Rosemount 2110 is designed using the principle of a tuning fork.

A piezo-electric crystal oscillates the forks at their natural frequency.

Changes to this frequency are continuously monitored. The frequency

of the vibrating fork sensor changes depending on the medium in

which it is immersed. The denser the liquid, the lower the frequency.

When used as a low level alarm, the liquid in the tank or pipe drains

down past the fork, causing a change of natural frequency that is

detected by the electronics and switches the output state.

When the Rosemount 2110 is used as a high level alarm, the liquid

rises in the tank or pipe, making contact with the fork which then

causes the output state to switch.

Key features and benefits

Stainless steel housing and plug/socket connection for fast- fit,

high-volume users

March 2018

Contents

Compact and lightweight design for side or top mounting

The industry standard DIN 43650 plug/socket is used for a fast

connection. The polarity insensitivity and short circuit protection

make electrical hook-up safe and easy

The Rosemount 2110 is designed for operation in temperatures

from –40 to 302 °F (–40 to 150 °C)

Rapid wet-to-dry time for highly responsive switching

‘Fast Drip’ fork design gives quicker response time, especially with

viscous liquids

The ‘heartbeat’ LED gives an instant visual indication that the unit is

operational

Fork shape is optimized for polishing to meet hygienic

requirements. Mechanical-polishing and electro-polishing options

No moving parts or crevices for virtually no maintenance

Magnetic test point makes functional test easy

Overview of the Rosemount 2110 Level Switch . .page 2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . page 4 Product Certifications . . . . . . . . . . . . . . . . . . . . . page 8

Spare Parts and Accessories . . . . . . . . . . . . . . . . . . .page 5 Dimensional Drawings . . . . . . . . . . . . . . . . . . . . page 9

2

Emerson.com/Rosemount

Page 3

March 2018

Overfill protection

High and low level alarm

Leak detection

Pump protection

Fit and forget

Once installed, the Rosemount 2110 is ready to go.

It needs no calibration and requires minimum installation

Functional testing of the instrument and system is easy with a magnetic

test point

You can install, and forget it

Superior performance

Functionality is virtually unaffected by turbulence, foam, vibration, coating,

or liquid properties

The ‘Fast Drip’ design allows the liquid to be quickly drawn away from the

fork tip, making the Rosemount 2110 quicker and more responsive in high

density or viscous liquid applications

Applications

Overfill protection

Rosemount 2110 Level Switch

High and low level alarms

Leak detection

Run dry or pump protection

Pump control or limit detection

Hygienic applications

Emerson.com/Rosemount

3

Page 4

Rosemount 2110 Level Switch

March 2018

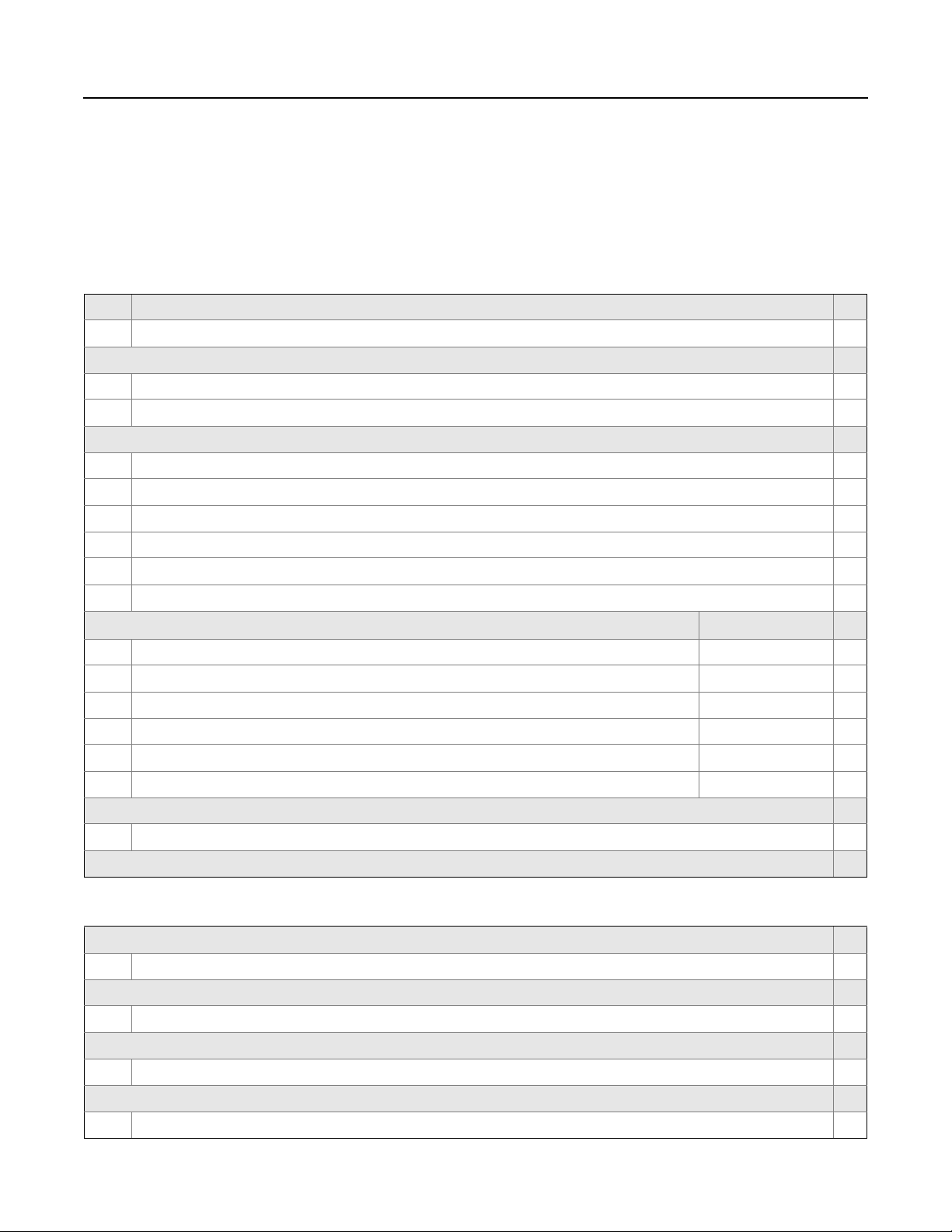

Ordering Information

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See page 6 for more information on Material Selection.

Table 1. Rosemount 2110 Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. Any non-starred offerings are

subject to additional delivery lead time.

Model Product description

2110 Compact Vibrating Fork Liquid Level Switch

Electronic type

0 Direct load switching with plug connection (2 wire) 21 to 264 Vac 50/60Hz, 21 to 264 Vdc

1 PNP/PLC low voltage switching with plug connection 18 to 60 Vdc

Process connection size / type

0A

1A 1-in. BSPT (R) thread

0D

2R 2-in. (51 mm) Tri Clamp

1B 1-in. BSPP (G) thread

1L 1-in. BSPP (G) semi-extended 4.6 in. (116 mm)

3

/4-in. BSPT (R) thread

3

/4-in. NPT thread

★

★

★

★

★

★

★

★

Surface finish Available Connections

1

2

3

4

7

8

NA No hazardous locations certifications (safe area use only)

Q4 Certificate of functional test

Q16 Surface finish certification

QA Certificate of compliance to 3-A

QE Certificate of compliance to EHEDG

Standard surface finish

(1)

Hand polished (Ra < 0.4 μm)

Ra < 0.76 μm, hygienically approved

Electro-polished to 0.76 μm, hygienically approved

Mechanically-polished to Ra < 0.1 μm, hygienically approved

Electro-polished to Ra < 0.38 μm, hygienically approved

Product certificates

Typical Model Number: 2110 0 2R 1 NA

Options (include with the selected model number)

Calibration data certificate

Wetted surface finish certification

3-A certification

EHEDG certification

(2)

(3)

(3)

(3)

All ★

Tri Clamp only

Tri Clamp only

Tri Clamp only

Tri Clamp only

Tri Clamp only

★

★

★

★

★

4

Emerson.com/Rosemount

Page 5

March 2018

Rosemount 2110 Level Switch

Table 1. Rosemount 2110 Ordering Information

The starred options (★) represent the most common options and should be selected for best delivery. Any non-starred offerings are

subject to additional delivery lead time.

ASME BPE certification

QB Declaration of conformity to ASME BPE

FDA certification

QH Declaration of conformity to FDA

Tag plate

ST Tag plate SST engraved plate (maximum 16 digits), wire-on

WT Tag plate laminated paper (maximum 40 digits)

Overfill

U1 WHG/DIBt overfill protection

Example of options included with the model number: 2110 0 2R 1 NA Q4 ST U1

1. Hand-polished for hygienic connections to better than 0.4 μm Ra such that there are no pits, folds, crevices or cracks discernible to the naked eye (i.e. no features

larger than 75 micrometers based on resolving 1/60 degree at a distance of 250 mm).

2. Includes the Technical Regulation Customs Union (EAC) ordinary location mark.

3. Available only for a Rosemount 2110 with a Tri Clamp fitting and Surface Finish code 3, 4, 7, or 8.

(3)

(3)

★

★

★

★

★

Spare Parts and Accessories

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See page 6 for more information on Material Selection.

.

Table 2. Spare Parts and Accessories

The starred options (★) represent the most common options and should be selected for best delivery. Any non-starred offerings are

subject to additional delivery lead time.

Part number Description

02100-1000-0001 Seal for 1-in. BSPP (G1A). Material: Non-asbestos BS7531 grade X carbon fiber with rubber binder

02100-1010-0001 Adaptor boss 1-in. BSPP to 11/2-in. (38mm) Tri Clamp. Material: 316 SST fitting. FPM/FKM O-ring

02100-1020-0001

02100-1030-0001 Telescopic test magnet

1. This is not approved to be used with a 3-A or EHEDG approved products and is not assessed for use with FDA or ASME-BPE compliant products.

(1)

2-in. (51 mm) Tri Clamp kit (vessel fitting, clamp ring, and seal). Material: 316 SST, NBR Nitrile

★

★

★

★

Emerson.com/Rosemount

5

Page 6

Rosemount 2110 Level Switch

1450 (100)

1160 (80)

-3.62 (-0.25)

-40

(-40)

122

(50)

302

(150)

Process Temperature °F (°C)

Process Pressure psig (barg)

32 (0)

32

(0)

Specifications

March 2018

General

Product

Rosemount 2110 Compact Level Switch

Measuring principle

Vibrating fork

Applications

Most liquids including coating liquids, aerated liquids, and

slurries

Mechanical

Mounting connections

3

/4-in. BSPT (R) or NPT,

1-in. BSPT (R) or BSPP (G) thread, or

Hygienic 2-in. (51 mm) Tri Clamp fitting

Materials selection

Emerson provides a variety of Rosemount product with various

product options and configurations including materials of

construction that can be expected to perform well in a wide

range of applications. The Rosemount product information

presented is intended as a guide for the purchaser to make an

appropriate selection for the application. It is the purchaser’s

sole responsibility to make a careful analysis of all process

parameters (such as all chemical components, temperature,

pressure, flow rate, abrasives, contaminants, etc.), when

specifying product, materials, options and components for the

particular application. Emerson is not in a position to evaluate or

guarantee the compatibility of the process fluid or other process

parameters with the product, options, configuration or

materials of construction selected.

This declaration is applicable to the 2-in. (51 mm) Tri Clamp

connection option when ordered with Surface Finish option

codes 3, 4, 7 and 8.

Housing / enclosure materials

Body: 304 SST with polyester label

LED window: Flame retardant Polyamide (Pa12) UL94 V2

Plug: Polyamide glass reinforced

Plug seals: Nitrile butadiene rubber

Ingress protection rating

IP66/67 to EN60529

Performance

Hysteresis (water)

±0.039-in. (± 1 mm) nominal

Switching point (water)

0.5 in. (13 mm) from fork tip if mounted vertically

0.5 in. (13 mm) from the fork edge if mounted horizontally

The switch point varies with different liquid densities.

Functional

Maximum operating pressure

The final rating depends on the process connection.

Threaded connection: see Figure 1

Hygienic connection: 435 psig (30 barg)

Figure 1. Process Pressure

Process connection materials

316L stainless steel (1.4404)

Gasket material for 1 in. BSPP (G1) is Non-asbestos BS7531

Grade X carbon fiber with rubber binder.

Transmissible Spongiform Encephalopathy (TSE)

declaration

Emerson™ certifies no process wetted components used in this

product contain substances of animal origin. Materials used in

the production or processing of wetted components for this

product meet the requirements stated in EMA/410/01 Rev. 3

and ISO 22442-1:2015. Wetted components in this product are

considered free of TSE.

6

Emerson.com/Rosemount

Page 7

March 2018

176 (80)

140

(60)

-40 (-40)

-40

(-40)

302

(150)

Process Temperature °F (°C)

Ambient Temperature °F (°C)

32 (0)

32

(0)

122 (50)

Load

0V/N

+V/L

PE

+V

PLC

0V

PE

Rosemount 2110 Level Switch

Minimum and maximum operating temperatures

See Figure 2 for the maximum and minimum operating

temperatures.

Figure 2. Temperature

Liquid density requirement

Minimum 37.5 lb/ft3 (600 kg/m3)

Cable connection

Via 4-way plug provided (DIN43650)

Maximum conductor size is 15AWG

4-position orientation (90° / 180° / 270° / 360°)

Terminal connection (wire diameter)

Maximum 0.06 in.2 (1.5 mm2)

Cable gland

PG9 provided. Cable diameter 0.24 to 0.31 in. (6 to 8 mm)

Grounding

Always ground the Rosemount 2110 either through the

terminals or using the external ground connection provided.

Electronics options

Figure 3. Direct Load Switching (Electronics Code 0)

Liquid Viscosity Range

0.2 to 10000 cP (centiPoise)

Solids content and coating

Maximum recommended diameter of solid particles in the liquid

is 0.2 in. (5 mm). For coating product, avoid ‘bridging’ of forks.

Switching delay

1 second delay for dry-to-wet or wet-to-dry switching

CIP (Clean In Place) cleaning

Withstands steam cleaning routines up to 302 °F (150 °C)

Electrical

Switching mode

User selectable (Dry=on or Wet=on) by selecting plug wiring

Protection

Polarity insensitive – Direct Load electronics only,

over-current protection, short-circuit protection, load-missing

protection, and surge protection (to IEC61326)

Magnetic test point

A magnetic test point is located on the side of the housing,

allowing a functional test of the Rosemount 2110 and a system

connected to it. By holding a magnet to the target, the output

changes state for as long as the magnet is held there.

Emerson.com/Rosemount

Direct load switching (electronics code 0)

Operating voltage 21 to 264 Vac (50 to 60 Hz)/dc

Maximum switched load 500 mA

Maximum peak load 5 A for 40 ms maximum

Minimum switched load 20 mA continuous

Voltage drop 6.5 V @ 24 Vdc / 5 V @ 240 Vac

Current draw (load off) < 3.0 mA continuous

Figure 4. PNP Switching (Electronics Code 1)

PNP switching (electronics code 1)

Operating voltage 18 to 60 Vdc

Maximum switched load 500 mA

Maximum peak load 5 A for 40 ms maximum

Voltage drop < 3 V

Supply current 3 mA nominal

Output current (load off) < 0.5 mA

7

Page 8

Rosemount 2110 Level Switch

Product Certifications

European Union directive information

A copy of the EU Declaration of Conformity can be found at the

end of the Rosemount 2110 Quick Start Guide

The most recent revision of the EU Declaration of Conformity

can be found at Emerson.com/Rosemount

Overfill protection

If required, select Product Certificates code U1 for DIBt/WHG

overfill protection. The approval number is Z-65.11-236.

Hygienic certifications and

compliances

(surface finish codes 3, 4, 7, and 8)

3-A Authorization (3496)

.

.

March 2018

EHEDG Certificate: (102016)

ASME-BPE and FDA compliant.

Canadian Registration Number (CRN)

The CRN is 0F04227.2C for model numbers with a NPT threaded

process connection selected.

Technical Regulation Customs Union

(EAC), ordinary locations mark

TRCU 004/2011

Certificate: TR RU C-GB.AB72.B.01974

EN61010-1 Pollution degree 2, Category II (264V maximum),

Pollution degree 2, Category III (150 V maximum)

TRCU 020/2011

Certificate: TCRU C-GB.AB72.B.00916

EN61326

8

Emerson.com/Rosemount

Page 9

March 2018

9.41

(238)

A

Ø1.5 (Ø38)

1.73

(44)

2.36

(60)

4.57

(116)

1.97

(50)

3.86

(98)

BSPT/NPT

thread

BSPP thread

(semi extended)

BSPP thread

0.5 (13) switching point

when mounted vertically

0.5 (13) switching point

when mounted horizontally

Ø1.5 (Ø38)

A

0.5 (13) switching point

when mounted vertically

7.91

(201)

1.73

(44)

0.5 (13) switching point

when mounted horizontally

3.07

(78)

Ø1.5 (Ø38)

A

0.5 (13) switching point

when mounted vertically

1.73

(44)

0.5 (13) switching point

when mounted horizontally

7.4

(188)

2.72

(69)

1.97

(50)

Dimensional Drawings

Figure 5. Threaded Process Connections

Rosemount 2110 Level Switch

A. 1.61 (41) A/F hexagon with fork orientation groove

Dimensions are in inches (mm).

Emerson.com/Rosemount

9

Page 10

Rosemount 2110 Level Switch

Ø1.5 (Ø38)

1.73

(44)

2.52

(64)

0.5 (13) switching point

when mounted vertically

0.5 (13) switching point

when mounted horizontally

A, B

7.40

(188)

Ø1.65

(Ø42)

2.72

(69)

Figure 6. Tri Clamp Process Connection

March 2018

A. 2-in. (51 cm) Tri Clamp, hygienically certified (surface finish codes 3, 4, 7, and 8)

B. 2-in. (51 cm) Tri Clamp, not hygienically certified (surface finish codes 1 and 2)

C. 1.61 (41) A/F hexagon with fork orientation groove

Dimensions are in inches (mm).

10

Emerson.com/Rosemount

Page 11

March 2018

Rosemount 2110 Level Switch

Emerson.com/Rosemount

11

Page 12

Rosemount 2110 Level Switch

00813-0100-4029, Rev FA

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL, 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Product Data Sheet

March 2018

Europe Regional Office

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale are available upon request.

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Rosemount is a mark of one of the Emerson family of companies.

All other marks are the property of their respective owners.

© 2018 Emerson. All rights reserved.

Loading...

Loading...