Page 1

Rosemount™ 2090P Pulp and Paper Pressure Transmitter

Product Data Sheet

November 2016

00813-0100-4699, Rev HC

1-in. flush mount compatible with a PMC process connection, or 1

Absolute or gage pressure ranges up to 300 psi

20:1 turndown

4–20 mA Selectable HART

Performance of 0.10% with high accuracy option

®

Protocol

1

/2-in. threaded mounting connection

Page 2

Rosemount 2090P

November 2016

Accurate, stable, and reliable pressure measurements for the pulp and paper industry

1-in. flush mount compatible with PMC

1

process connection, or 1

/2-in. threaded

mounting connection

The Rosemount 2090P has process connections that position the

isolation diaphragm flush with vessel or pipe walls, eliminating

clogging problems associated with highly viscous processes that

tend to crystallize, polymerize, or precipitate, such as those in the

pulp and paper industry.

Absolute or gauge pressure ranges up to 300 psi and 20:1 turndown

Higher turndown allows for lower inventories by allowing you to

measure pressures from 1.5 psi to 300 psi with only three

transmitter ranges.

Communicates via the 4–20 mA Selectable HART Protocol

The Rosemount 2090P utilizes the advantages of HART

Communication, enabling quick and easy reranging, calibration

and troubleshooting.

0.10% reference accuracy performance with P8 high accuracy option

The single-filled sensor system of the Rosemount 2090P leads to

outstanding accuracy due to full sensor compensation.

Contents

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2

Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

EmersonProcess.com/Rosemount

Page 3

November 2016

Rosemount 2090P

Ordering information

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment. See page 7

for more information on material selection.

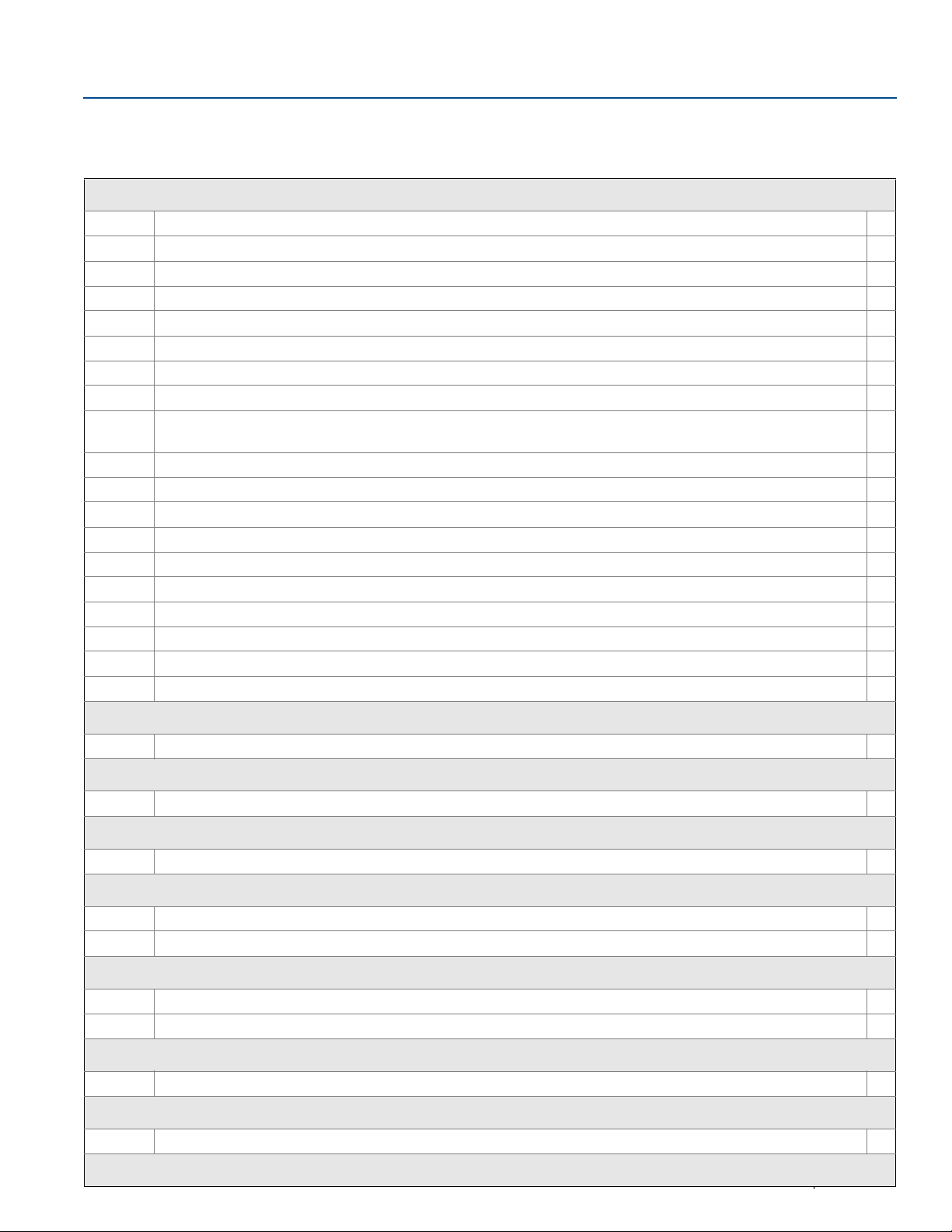

Table 1. Rosemount 2090P Pulp and Paper Pressure Transmitter Ordering Information

★ The Standard offering represents the most common options. The starred options (★) should be selected for best delivery.

The Expanded offering is manufactured after receipt of order and is subject to additional delivery lead time.

Model Product description

2090P Pulp and Paper Pressure Transmitter

Transmitter type

A Absolute ★

G Gage ★

Pressure ranges (range/minimum span)

Rosemount 2090PG Rosemount 2090PA

1 -14.7 to 30 psi/1.5 psi (-1,01 to 2,1 bar/103 mbar) 0 to 30 psia/1.5 psi (0 to 2,1 bar/103 mbar) ★

2 -14.7 to 150 psi/7.5 psi (-1,01 to 10,3 bar/517 mbar) 0 to 150 psia/7.5 psi (0 to 10,3 bar/517 mbar) ★

3 -14.7 to 300 psi/40 psi (-1.01 to 20,7 bar/2,8 bar) 0 to 300 psia/40 psi (0 to 20,7 bar/2,8 bar) ★

Output

S 4–20 mA dc/digital HART Protocol

Material of construction

Process connection Isolating diaphragm Oil fill

22 316L SST 316L SST Silicone ★

Process connection

A 11/2-in. threaded, no weld spud, 11/2-in. PTFE gasket ★

C 11/2-in. threaded, 316L SST weld spud with stress isolation and PTFE gasket ★

D 1-in. flush mount ★

G 1-in. flush mount with weld-on nipple ★

Conduit entry

1

2 M20 ⫻ 1.5 female ★

1

/2–14 NPT ★

Options (include with selected model number)

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

Digital display

M5 LCD display ★

Mounting brackets

B4 SST mounting bracket with SST bolts ★

EmersonProcess.com/Rosemount

3

Page 4

Rosemount 2090P

November 2016

Table 1. Rosemount 2090P Pulp and Paper Pressure Transmitter Ordering Information

★ The Standard offering represents the most common options. The starred options (★) should be selected for best delivery.

The Expanded offering is manufactured after receipt of order and is subject to additional delivery lead time.

Product certifications

E5 USA Explosionproof (XP) and Dust-Ignitionproof (DIP) ★

ED ATE X Flam eproof ★

EM Technical Regulations Customs Union (EAC) Flameproof ★

I5 USA Intrinsic Safety (IS) and Nonincendive (NI) ★

K5 USA Explosionproof (XP), Dust-Ignitionproof (DIP), Intrinsic Safety (IS), and Nonincendive (NI) ★

I1 ATEX Intrinsic Safety ★

N1 ATEX Type n ★

C6 Canada Explosionproof, Intrinsic Safety, Division 2, and Dust-Ignitionproof ★

KB

KM Technical Regulation Customs Union (EAC) Flameproof and Intrinsic Safety ★

KH ATEX Flameproof, Intrinsic Safety, USA Explosionproof, Dust-Ignitionproof, Intrinsic Safety, and Nonincendive ★

ND ATEX Dust ★

NK IECEx Dust ★

K7 IECEx Flameproof, Dust, Intrinsic Safety, Type n ★

K1 ATEX Flameproof, Dust, Intrinsic Safety, Type n ★

K6 Canada Explosion-Proof, Intrinsic Safety, Division 2, Dust-ignitionproof and ATEX Flameproof, Intrinsic Safety ★

I3 China Intrinsic Safety ★

IM Technical Regulation Customs Union (EAC) Intrinsic Safety ★

E3 China Flameproof ★

USA Explosionproof, Dust-Ignitionproof, Intrinsic Safety, Nonincendive and Canada Explosionproof, Intrinsic Safety,

Division 2, and Dust-Ignitionproof

★

Terminal blocks

T1 Tra nsie nt p rot ectio n ★

Special certificate

Q4 Calibration certificate ★

Quality calibration certificate traceability certification

Q8 Material traceability certification per EN 10204 3.1 ★

Alarm limit

C4 NAMUR alarm and saturation levels, high alarm ★

CN NAMUR alarm and saturation levels, low alarm ★

Wetted O-ring material

W2 Buna-N ★

W3 Ethylene-Propylene ★

Special procedures

P2 Cleaning for special service

Calibration accuracy

P8 0.1% accuracy to 10:1 turndown ★

Typical model number: 2090P G 2 S 22 A 1

4

EmersonProcess.com/Rosemount

Page 5

November 2016

Standard configuration

Unless otherwise specified, transmitter is shipped as follows:

Engineering units: psi

4 mA: 0 psi

20 mA: Upper range limit

Alarm output: High

LCD display: 0–100%

Custom configuration

Calibration

Transmitters are factory calibrated to customer's specified range.

If calibration is not specified, transmitters are calibrated at

maximum range. Calibration is at ambient temperature and

pressure.

Tagging

Rosemount 2090P

The transmitter will be tagged, at no charge, in accordance with

customer requirements. All tags are stainless steel. The standard

1

tag is wired to the transmitter. Tag character height is

/8-in.

(0.318 cm). A permanently attached tag is available upon request.

Accessories

Item description

Calibration adapter

Use to connect a calibration device to a transmitter. See Figure 3.

316 SST plug/heat sink

Use during installation to prevent welding damage. See Figure 3.

1-in. flush mount calibration adapter

Use to connect a calibration device to the 1-in. flush mount. See Figure 3.

1-in. flush mount weld spud

See Figure 3.

11/2-in. threaded weld spud kit

Includes PTFE O-ring.

1. Process connection codes A and C only.

2. Process connection codes D and G only.

(1)

(1)

(2)

Part number

02088-0197-0001

02088-0196-0001

02088-0198-0002

02088-0285-0001

02088-0295-0003

EmersonProcess.com/Rosemount

5

Page 6

Rosemount 2090P

185 – (Process Temp – 185)

1.5

85 – (Process Temp – 85)

1.5

Specifications

November 2016

Functional specifications

Service

Liquid, gas, vapor, and high-viscosity applications

Ranges

Range

1. Assumes atmospheric pressure of 14.7 psig.

Output

4–20 mA Selectable HART Protocol

Rangedown

20:1

Load limitations

Maximum loop resistance is determined by the power supply

voltage as described by the following equation:

Maximum loop resistance = 43.5 (Power supply voltage – 10.5)

Load (Ohms)

The Field Communicator requires a minimum loop resistance of 250 Ω for

communication.

1. For hazardous location approvals, power supply must not exceed 36 V.

Power supply

External power supply required. Transmitter operates on

10.5–42.4 V dc with no load. Reverse polarity protection is

standard.

Overpressure limits

Range Overpressure limit

1. Overpressure limit is dependent on the clamp/pressure

6

Minimum

1

(103 mbar)

2

(517 mbar)

3

(2,76 bar)

1387

1000

500

0

10.5 20

1 120 psi (8,3 bar)

2 300 psi (20,7 bar)

3 600 psi (41,4 bar)

adapter or sensor rating (whichever is lower).

span

1.5 psi

7.5 psi

40 psi

Voltage (Vdc)

(10,3 bar)

(20,7 bar)

Operating

Region

30

Upper

(URL)

30 psi

(2,1 bar)

150 psi

300 psi

42.4

Lower

(LRL)

0 psia

(0 bar)

0 psia

(0 bar)

0 psia

(0 bar)

(1)

Lower

(LRL)(gage)

-14.7 psig

(-1,01 bar)

-14.7 psig

(-1,01 bar)

-14.7 psig

(-1,01 bar)

(1)

(1)

Temperature limits

Process

Process connection codes A and C: –40 to 250 °F (–40 to 121 °C)

Process connection codes D and G: –4 to 250 °F (–20 °C to 121 °C)

Ambient

–4 to 185 °F (–20 to 85 °C)

Storage

–50 to 185 °F (–46 to 85 °C)

Process temperatures above 185 °F (85 °C) require derating the

ambient limits by a 1.5:1 ratio.

Max. ambient temperature in °F =

Max. ambient temperature in °C =

Humidity limits

0–100% relative humidity

Volumetric displacement

Less than 0.0005 in3 (0,008 cm3)

Turn-on time

Performance within specifications less than 2.0 seconds after

power is applied to the transmitter

Failure alarm

If self-diagnostics detect a sensor or microprocessor failure, the

analog signal is driven either high or low to alert the user. High or

low failure mode is user-selectable with a jumper on the

transmitter. The values to which the transmitter drives its output

in failure mode depend on whether it is factory-configured to

standard or NAMUR-compliant operation. The values for each are

as follows:

Standard operation

Linear output: 3.9 ≤ I ≤ 20.8

Fail high: I ≥ 21.75 mA

Low: I ≤ 3.75 mA

NAMUR-compliant operation

Linear output: 3.8 ≤ I ≤ 20.5

Fail high: I ≥ 22.5 mA

Low: I ≤ 3.6 mA

Transmitter security

Activating the transmitter security function prevents changes to

the transmitter configuration, including local zero and span

adjustments. Security is activated by an internal jumper.

EmersonProcess.com/Rosemount

Page 7

November 2016

Rosemount 2090P

Performance specifications

Zero-based spans, reference conditions, and 316 SST isolating

diaphragm.

Reference accuracy

±0.20% of calibrated span. Includes combined effects of linearity,

hysteresis, and repeatability.

High accuracy (P8) option:

±0.10% of calibrated span to 10:1 turndown

Ambient temperature effect per 50 °F (28 °C)

±(0.15% URL + 0.15% span) from 1:1 to 20:1

Stability

±0.10% of URL for 1 year, reference stability

Time response

145 ms (at 75 °F [24 °C] reference conditions)

Vibration effect

Less than ±0.1% of upper range limit when subjected to vibration

of peak to peak constant displacement of 4 mm (5–15 Hz) and

constant acceleration of 2 g (15–150 Hz) and 1 g (150–2000 Hz).

Power supply effect

Less than ±0.005% of calibrated span per volt

Electromagnetic compatibility (EMC)

Meets all industrial environment requirements of EN61326 and

(1)

NAMUR NE-21

disturbance

1. NAMUR NE-21 does not apply to Low-Power (Transmitter output option code

N).

2. During surge event device may exceed maximum EMC deviation limit or reset;

however, device will self-recover and return to normal operation within

specified start-up time.

. Maximum deviation < 1% span during EMC

(2)

.

Physical specifications

Material selection

Emerson™ provides a variety of Rosemount product with various

product options and configurations including materials of

construction that can be expected to perform well in a wide range

of applications. The Rosemount product information presented is

intended as a guide for the purchaser to make an appropriate

selection for the application. It is the purchaser’s sole

responsibility to make a careful analysis of all process parameters

(such as all chemical components, temperature, pressure, flow

rate, abrasives, contaminants, etc.), when specifying product,

materials, options and components for the particular application.

Emerson Process Management is not in a position to evaluate or

guarantee the compatibility of the process fluid or other process

parameters with the product, options, configuration or materials

of construction selected.

Electrical connection

1

/2–14 NPT or M20 ⫻ 1.5 conduit entry

Process wetted parts

Isolating diaphragm

316L stainless steel

Process connector

316L stainless steel

Process connection size

1

/2 –11.5 NPT or 1-in. flush mount

1

Process connector gasket (1

TFE

Process connection O-rings (1-in.)

Standard: Viton

Optional: Buna-N or Ethylene propylene

®

Non-wetted parts

1

/2-in.)

Mounting position effect

Zero shift of up to 5.0 inH2O (12.4 mbar), which can be calibrated

out. No span effect.

EmersonProcess.com/Rosemount

Electronics housing

Low-copper aluminum

Enclosures meet NEMA

installed.

Paint

Polyurethane

Cover O-rings

Buna-N

Fill fluid

Silicone oil

Weight

Approximately 2.96 lb (1,34 kg)

®

Type 4X, IP66 and IP68 when properly

7

Page 8

Rosemount 2090P

Product Certifications

Rev 1.6

November 2016

European Directive Information

A copy of the EU Declaration of Conformity can be found at the end

of the Quick Start Guide. The most recent revision of the EU

Declaration of Conformity can be found at

EmersonProcess.com/Rosemount

.

Ordinary Location Certification

As standard, the transmitter has been examined and tested to

determine that the design meets the basic electrical, mechanical,

and fire protection requirements by a nationally recognized test

laboratory (NRTL) as accredited by the Federal Occupational Safety

and Health Administration (OSHA).

North America

E5 USA Explosionproof (XP) and Dust-Ignitionproof (DIP)

Certificate: 1V2A8.AE

Standards: FM Class 3600 – 2011, FM Class 3615 – 2006,

FM class 3616 – 2011, FM Class 3810 – 2005,

ANSI/NEMA 250 – 1991

Markings: XP CL I, DIV 1, GP B, C, D; DIP CL II, DIV 1, GP E, F,

≤ T

G; CL III, DIV 1; T5(–40 °C

Sealed; Type 4X

I5 USA Intrinsic Safety (IS) and Nonincendive (NI)

Certificate: 0V9A7.AX

Standards: FM Class 3600 – 1998, FM Class 3610 – 2010,

FM Class 3611 – 2004, FM Class 3810 – 1989

Markings: IS CL I, DIV 1, GP A, B, C, D; CL II, DIV 1, GP E, F,

G; Class III; DIV 1 when connected per Rosemount

drawing 02088-1018; NI CL 1, DIV 2, GP A, B, C,

≤ T

D; T4(–40 °C

Special Condition for Safe Use (X):

1. The Rosemount 2090 Transmitter with the transient terminal

block (option code T1) will not pass the 500 V r.m.s.dielectric

strength test and this must be taken into account during

installation.

C6 Canada Explosionproof, Intrinsically Safe, and Division 2,

Dust-Ignitionproof

Certificate: 1015441

Standards: CAN/CSA C22.2 No. 0-M91 (R2001),

CSA Std C22.2 No. 25-1966, CSA Std C22.2 No.

30-M1986, CAN/CSA-C22.2 No. 94-M91,

CSA Std C22.2 No. 142-M1987, CAN/CSA-C22.2

No. 157-92, CSA Std C22.2 No. 213-M1987,

ANSI-ISA-12.27.01-2003

Markings: Explosionproof for Class I, Division 1, Groups B, C

and D; Class II, Groups E, F, and G; Class III;

Intrinsically Safe Class I, Division 1 when

connected in accordance with Rosemount

drawing 02088-1024, Temperature Code T3C;

Ex ia; Class I Division 2 Groups A, B, C and D;

8

Type 4X; Factory Sealed

≤ +70 °C); Type 4x

a

≤ +85 °C); Factory

a

Europe

ED ATE X Flam eproof

Certificate: KEMA97ATEX2378X

Standards: EN60079-0:2012 + A11:2013, EN60079-1:2014,

EN60079-26:2015

≤ T

Markings: II 1/2 G Ex db IIC T6… T4, T6(–60 °C

°C), T4/T5(–60 °C ≤ Ta ≤ +80 °C)

Special Conditions for Safe Use (X):

1. This device contains a thin wall diaphragm. Installation,

maintenance and use shall take into account the

environmental conditions to which the diaphragm will be

subjected. The manufacturer’s instructions for installation

and maintenance shall be followed in detail to assure safety

during its expected lifetime.

2. Flameproof joints are not intended for repair

3. Non-standard paint options may cause risk from electrostatic

discharge. Avoid installations that could cause electrostatic

build-up on painted surfaces, and only clean the painted

surfaces with a damp cloth. If paint is ordered through a

special option code, contact the manufacturer for more

information.

I1 ATEX Intrinsic Safety

Certificate: BAS00ATEX1166X

Standards: EN60079-0:2012, EN60079-11:2012

Markings: II 1 G Ex ia IIC T5/T4 Ga, T5(–55 °C

T4(–55 °C ≤ Ta ≤ +70 °C)

Table 2. Input Parameters

Parameter

Voltage U

Current I

Power P

Capacitance C

Special Condition for Safe Use (X):

1. The apparatus is not capable of withstanding the 500 V

insulation test required by EN60079-11. This must be taken

into account when installing the apparatus.

N1 ATEX Type n

Certificate: BAS00ATEX3167X

Standards: EN60079-0:2012, EN60079-15:2010

Markings: II 3 G Ex nA IIC T5 Gc (–40 °C

Special Condition for Safe Use (X):

1. This apparatus is not capable of withstanding the 500 V

insulation test that is required by EN60079-15. This must be

taken into account when installing the apparatus.

i

i

i

i

HART

30 V

200 mA

0.9 W

0.012 μF

≤ T

a

EmersonProcess.com/Rosemount

≤ +70

a

≤ T

≤ +40 °C),

a

≤ +70 °C)

Page 9

November 2016

Rosemount 2090P

ND ATE X Dust

Certificate: BAS01ATEX1427X

Standards: EN60079-0:2012, EN60079-31:2009

Markings: Ex t IIIC T 50 °C T

500

60 °C Da

Special Conditions for Safe Use (X):

1. The user must ensure that the maximum rated voltage and

current (36 volts, 24 milliamps, d.c.) are not exceeded. All

connection to other apparatus or associated apparatus shall

have control over this voltage and current to a category ‘ib’

circuit.

2. Cable entries must be used which maintain the ingress

protection of the enclosure to at least IP66.

3. Unused cable entries must be filled with suitable blanking

plugs which maintain the ingress protection of the enclosure

to at least IP66.

4. Cable entries and blanking plugs must be suitable for the

ambient range of the apparatus and capable of withstanding

a 7 J impact test.

5. The Rosemount 2090 sensor module must be securely

screwed in place to maintain the ingress protection of the

enclosure.

International

K7 Combination

IECEx Flameproof

Certificate: IECEx KEM 06.0021X

Standards: IEC60079-0:2011, IEC60079-1:2014,

IEC60079-26:2014

≤ T

Markings: Ex db IIC T6…T4 Ga/Gb, T6(–60 °C

T4/T5(–60 °C ≤ Ta ≤ +80 °C)

Special Conditions for Safe Use (X):

1. This device contains a thin wall diaphragm. Installation,

maintenance and use shall take into account the

environmental conditions to which the diaphragm will be

subjected. The manufacturer's instructions for installation

and maintenance shall be followed in detail to assure safety

during its expected lifetime.

2. Flameproof joints are not intended for repair.

3. Non-standard paint options may cause risk from electrostatic

discharge. Avoid installations that could cause electrostatic

build-up on painted surfaces, and only clean the painted

surfaces with a damp cloth. If paint is ordered through a

special option code, contact the manufacturer for more

information.

IECEx Dust

Certificate: IECEx BAS12.0073X

Standards: IEC60079-0:2011, IEC60079-31:2008

Markings: Ex t IIIC T 50 °C T

500

60 °C Da

Table 3. Input Para meters

Parameter

HART

≤ +70 °C),

a

Special Conditions for Safe Use (X):

1. Cable entries must be used which maintain the ingress

protection of the enclosure to at least IP66.

2. Unused cable entries must be filled with suitable blanking

plugs which maintain the ingress protection of the enclosure

to at least IP66.

3. Cable entries and blanking plugs must be suitable for the

ambient temperature range of the apparatus and capable of

withstanding a 7 J impact test.

IECEx Intrinsic Safety

Certificate: IECEx BAS 12.0071X

Standards: IEC60079-0:2011, IEC60079-11:2011

≤ T

Markings: Ex ia IIC T5/T4 Ga, T5(–55 °C

≤ T

T4(–55 °C

≤ +70 °C)

a

≤ +40 °C),

a

Table 4. Input Parameters

Parameter

Voltage U

Current I

Power P

Capacitance C

Special Conditions for Safe Use (X):

1. When fitted with a transient suppression terminal block, the

Rosemount 2090 is incapable of passing the 500 V isolation

test. This must be taken into account during installation.

2. The enclosure may be made of aluminum alloy and given a

protective polyurethane paint finish; however, care should

be taken to protect it from impact or abrasion if located in a

Zone 0 environment.

IECEx Type n

Certificate: IECEx BAS 12.0072X

Standards: IEC60079-0:2011, IEC60079-15:2010

Markings: Ex nA IIC T5 Gc (–40 °C

Special Condition for Safe Use (X):

1. When fitted with a transient suppression terminal block, the

Rosemount 2090 is incapable of passing the 500 V isolation

test. This must be taken into account during installation.

NK IECEx Dust

Certificate: IECEx BAS12.0073X

Standards: IEC60079-0:2011, IEC60079-31:2008

Markings: Ex t IIIC T 50 °C T

i

i

i

i

HART

30 V

200 mA

0.9 W

0.012 μF

60 °C Da

500

≤ T

≤ +70 °C)

a

Table 5. Input Parameters

Parameter

Voltage U

Current I

i

i

HART

36 Vdc

24 mA

Voltage U

Current I

i

i

36 Vdc

24 mA

EmersonProcess.com/Rosemount

9

Page 10

Rosemount 2090P

November 2016

Special Conditions for Safe Use (X):

1. Cable entries must be used which mention the ingress

protection of the enclosure to at least IP66.

2. Unused cable entries must be filled with suitable blanking

plugs which maintain the ingress protection of the enclosure

to at least IP66.

3. Cable entries and blanking plugs must be suitable for the

ambient range of the apparatus and capable of withstanding

a 7 J impact test.

China

E3 China Flameproof

Certificate: GYJ15.1506X

Standards: GB3836.1-2010, GB3836.2-2010

≤ T

Markings: Ex d IIC T6/T4 Gb, T6(–20 °C

T4(–20 °C ≤ Ta ≤ +80 °C)

Special Conditions for Safe Use (X):

1. The ambient temperature is as follows:

T

a

–20 °C ≤ Ta ≤ 80 °C T4

–20 °C ≤ Ta ≤ 40 °C T6

2. The earth connection facility in the enclosure should be

connected reliably.

3. During installation in hazardous location, cable glands,

conduits, and blanking plugs, certified by state-appointed

inspection bodies with Ex d IIC type of protection, should be

used.

4. During installation, use and maintenance in explosive gas

atmospheres, observe the warning “Do not open when

energized.”

5. During installation, there should be no mixture harm to

flameproof housing.

6. End user is not permitted to change any components insides,

but to settle the problem in conjunction with manufacturer

to avoid damage to the product.

7. Maintenance should be done in non-hazardous location.

8. During installation, use and maintenance of this product,

observe the following standards: GB3836.13-2013,

GB3836.15-2000, GB3836.16-2006, GB50257-2014.

Temperature class

≤ +40 °C),

a

I3 China Intrinsic Safety

Certificate: GYJ15.1508X

Standards: GB3836.1-2010, GB3836.4-2010,

GB3836.20-2010

Markings: Ex ia IIC T4/T5 Ga

Special Conditions for Safe Use (X):

1. The enclosure may be made of aluminum alloy and given a

protective polyurethane paint finish; however, care should

be taken to protect it from impact or abrasion if located in a

zone 0 environment.

2. This apparatus is not capable of withstanding the

500 V r.m.s. insulation test required by Clause 6.3.12 of

GB3836.4-2010.

3. The ambient temperature is:

T

a

–55 °C ≤ Ta ≤ 40 °C T5

–55 °C ≤ Ta ≤ 70 °C T4

4. Intrinsically safe parameters:

Parameter

Voltage U

Current I

Power P

Capacitance C

Inductance L

5. The product should be used with Ex-certified linear

associated apparatus to establish explosion protection

system that can be used in explosive gas atmospheres.

Wiring and terminals should comply with the instruction

manual of the product and associated apparatus.

6. The cables between this product and associated apparatus

should be shielded cables (the cables must have insulated

shields). The shield has to be grounded reliably in a

non-hazardous area.

7. End users are not permitted to change any internal

components, but to settle the problem in conjunction with

the manufacturer to avoid damage to the product.

8. During installation, use and maintenance of this product,

observe the following standards: GB3836.13-2013,

GB3836.15-2000, GB3836.16-2006, G3836.18-2010,

GB50257-2014.

i

i

i

i

i

Temperature class

HART

30 V

200 mA

0.9 W

0.012 μF

0 mH

10

EmersonProcess.com/Rosemount

Page 11

November 2016

Rosemount 2090P

Technical Regulations Customs Union (EAC)

EM EAC Flameproof

Certificate: RU C-US.GB05.B.01197

≤ T

Markings: Ga/Gb Ex d IIC T4/T6 X, T4(-40 °C

≤ T

T6(-40 °C

≤ +40 °C)

a

≤ +80 °C),

a

Special Condition for Safe Use (X):

See certificate for special conditions.

IM EAC Intrinsically Safe

Certificate: RU C-US.GB05.B.01197

≤ T

Markings: 0Ex ia IIC T4 Ga X (-55 °C

≤ +70 °C)

a

Special Conditions for Safe Use (X):

See certificate for special conditions.

Combinations

K1 Combination of ED, I1, ND, and N1

K5 Combination of E5 and I5

K6 Combination of C6, ED, and I1

K7 Combination of E7, I7, NK, and N7

KB Combination of K5 and C6

KM Combination of EM and IM

KH Combination of ED, I1, and K5

Table 7. Thread Adapter Thread Sizes

Male thread Identification mark

M20 ⫻ 1.5 – 6H M20

1

/2–14 NPT

3

/4–14 NPT

1

/2–14 NPT

3

/4–14 NPT

Female thread Identification mark

M20 ⫻ 1.5 – 6H M20

1

/2–14 NPT

PG 13.5 PG 13.5

Special Conditions for Safe Use (X):

1. When the thread adapter or blanking plug is used with an

enclosure in type of protection increased safety “e” the entry

thread shall be suitably sealed in order to maintain the

ingress protection rating (IP) of the enclosure.

2. The blanking plug shall not be used with an adapter.

3. Blanking Plug and Threaded Adapter shall be either NPT or

Metric thread forms. G

acceptable for existing (legacy) equipment installations.

1

/2–14 NPT

1

/2 and PG 13.5 thread forms are only

Conduit plugs and adapters

IECEx Flameproof and Increased Safety

Certificate: IECEx FMG 13.0032X

Standards: IEC60079-0:2011, IEC60079-1:2007,

IEC60079-7:2006-2007

Markings: Ex de IIC Gb

ATEX Flameproof and Increased Safety

Certificate: FM13ATEX0076X

Standards: EN60079-0:2012, EN60079-1:2007,

EN60079-7:2007

Markings: II 2 G Ex de IIC Gb

Table 6. Conduit Plug Thread Sizes

Thread Identification mark

M20 ⫻ 1.5 M20

1

/2–14 NPT

G1/2A G1/2

1

/2 NPT

EmersonProcess.com/Rosemount

11

Page 12

Rosemount 2090P

C

D

E

B

A

5.13 (130)

4.29 (109) max.

1.03 (26.2)

1.0 (25.4)

1.05 (26.6)

1.32 (33.4)

A

B

C

D

E

5.13 (130)

4.29 (109) max.

0.82 (21)

2.37 (62)

Dimensional drawings

Figure 1. Rosemount 2090P 1-in. Flush Mount

November 2016

A. Weld spud

5

B. 3 ⫻

/16–18 UNC mounting holes for rotational mounting

C. Terminal connections side

D. Optional display cover

E. Transmitter circuitry side

Dimensions are in inches (millimeter).

0.7 (17.8)

F. Ve ss el wall

G. 2 ⫻

H. External zero/span under nameplate

I. Nameplate

J. O-ring (Viton standard)

H

3.85 (98)

I

4.71

(120)

5.73

G

F

1

/4–20 UNC–2BX 0.60 deep mounting bracket holes

J

(146)

Figure 2. Rosemount 2090P 11/2-in. Flush Mount

H

3.85 (98)

4.71

(120)

A. Weld spud

B. M44⫻ 1.25

C. Terminal connections

D. Optional display cover

E. Transmitter circuitry

Dimensions are in inches (millimeter).

12

G

F

F. Ve ssel wa ll

1

G. 2 ⫻

/4–20 UNC–2BX depth 0.60 mounting bracket holes

H. Nameplate

I. Stress isolator groove

4.97 (126)

Typical

I

EmersonProcess.com/Rosemount

Page 13

November 2016

A

Figure 3. 2090P Process Connection Accessories

Calibration adapter

A. 1/4–18 NPT

1. See ordering information.

(1)

for process connection codes A and C

316 SST plug/heat sink

Note

See “Accessories” on page 5 for part numbers.

Rosemount 2090P

Weld spud

for process connection codes D and G

EmersonProcess.com/Rosemount

13

Page 14

Rosemount 2090P

00813-0100-4699, Rev HC

Global Headquarters

Emerson Process Management

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@EmersonProcess.com

North America Regional Office

Emerson Process Management

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Process Management

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@EmersonProcess.com

Product Data Sheet

November 2016

Europe Regional Office

Emerson Process Management Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@EmersonProcess.com

Asia Pacific Regional Office

Emerson Process Management Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.EmersonProcess.com

Middle East and Africa Regional Office

Emerson Process Management

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Process-Management

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found at:

www.Emerson.com/en-us/pages/Terms-of-Use

The Emerson logo is a trademark and service mark of Emerson Electric Co.

Rosemount and Rosemount logotype are trademarks of Emerson Process

Management.

HART is a registered trademark of the FieldComm Group.

NEMA is a registered trademark and service mark of the National

Electrical Manufacturers Association.

Viton is a registered trademark of DuPont.

All other marks are the property of their respective owners.

© 2016 Emerson Process Management. All rights reserved.

Loading...

Loading...