Page 1

Model 2081 pH

Smart Microprocessor

Analyzer

Instruction Manual

PN 5102081P

November 2000

FREE

EXTENDED

WARRANTY!

(See offer at back of manual)

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

SS-2081

Feb. 1992

Rosemount Analytical designs, manufactures, and

tests its products to meet many national and international standards. Because these instruments are

sophisticated technical products, you must properly install, use, and maintain them to ensure they

continue to operate within their normal specifications. The following instructions must be adhered to

and integrated into your safety program when

installing, using, and maintaining Rosemount

Analytical products. Failure to follow the proper

instructions may cause any one of the following situations to occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating,

and servicing the product. If this Instruction

Manual is not the correct manual, telephone 1800-654-7768 and the requested manual will be

provided. Save this Instruction Manual for future

reference.

• If you do not understand any of the instructions,

contact your Rosemount representative for clarification.

• Follow all warnings, cautions, and instructions

marked on and supplied with the product.

• Inform and educate your personnel in the proper

installation, operation, and maintenance of the

product.

• Install your equipment as specified in the

Installation Instructions of the appropriate

Instruction Manual and per applicable local and

national codes. Connect all products to the proper electrical sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and

maintain the product.

• When replacement parts are required, ensure

that qualified people use replacement parts

specified by Rosemount. Unauthorized parts and

procedures can affect the product’s performance

and place the safe operation of your process at

risk. Look alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and

protective covers are in place, except when maintenance is being performed by qualified persons,

to prevent electrical shock and personal injury.

Rosemount Analytical Inc.

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 863-1181

1-800-854-8257

www.RAuniloc.com

© Rosemount Analytical Inc. 1999

Page 3

MODEL 2081 pH

MICROPROCESSOR TRANSMITTER

TABLE OF CONTENTS

Section Title Page

1.0 INSTALLATION....................................................................................................... 1

1.1 Unpacking and Inspection...................................................................................... 1

1.2 Mechanical Installation............................................................................................ 1

1.3 Wiring ...................................................................................................................... 1

1.4 Jumper Settings ...................................................................................................... 2

1.5 Hazardous Locations - Explosion Proof Installations .............................................. 3

1.6 Hazardous Locations - Intrinsically Safe Installations............................................. 3

2.0 QUICK START-UP PROCEDURE........................................................................... 11

2.1 General.................................................................................................................... 11

2.2 Set-Up Instrument ................................................................................................... 11

2.3 Temperature Standardization .................................................................................. 12

2.4 Two-Point Calibration .............................................................................................. 13

2.5 Current Output Check ............................................................................................. 14

3.0 DESCRIPTION OF CONTROLS............................................................................. 15

3.1 General.................................................................................................................... 15

3.2 Menu Selection........................................................................................................ 15

3.3 Value Adjustment .................................................................................................... 15

4.0 RANGE CONFIGURATION .................................................................................... 16

5.0 START UP AND CALIBRATION ............................................................................ 17

5.1 General.................................................................................................................... 17

5.2 Temperature Calibration.......................................................................................... 17

5.3 Buffer Calibration .................................................................................................... 17

5.4 pH Standardization ................................................................................................. 18

5.5 pH Glass Slope ....................................................................................................... 18

5.6 Hold Mode for Maintenance.................................................................................... 19

5.7 Sensor Maintenance ............................................................................................... 19

6.0 KEYBOARD SECURITY......................................................................................... 20

7.0 THEORY OF OPERATION ..................................................................................... 21

8.0 DIAGNOSTICS AND TROUBLESHOOTING.......................................................... 22

8.1 Diagnostics ............................................................................................................. 22

8.2 Troubleshooting....................................................................................................... 22

9.0 DESCRIPTION AND SPECIFICATIONS ................................................................ 26

9.1 Features .................................................................................................................. 26

9.2 Functional Specifications ........................................................................................ 27

9.3 Performance Specifications .................................................................................... 27

9.4 Physical Specifications ........................................................................................... 27

9.5 Recommended Sensors.......................................................................................... 28

9.6 Ordering Information ............................................................................................... 28

9.7 Model 2081 pH Replacement Parts and Accessories ............................................ 29

10.0 RETURN OF MATERIALS...................................................................................... 30

i

MODEL 2081 pH TABLE OF CONTENTS

Page 4

TABLE OF CONTENTS CONT’D.

LIST OF FIGURES

Figure No. Title Page

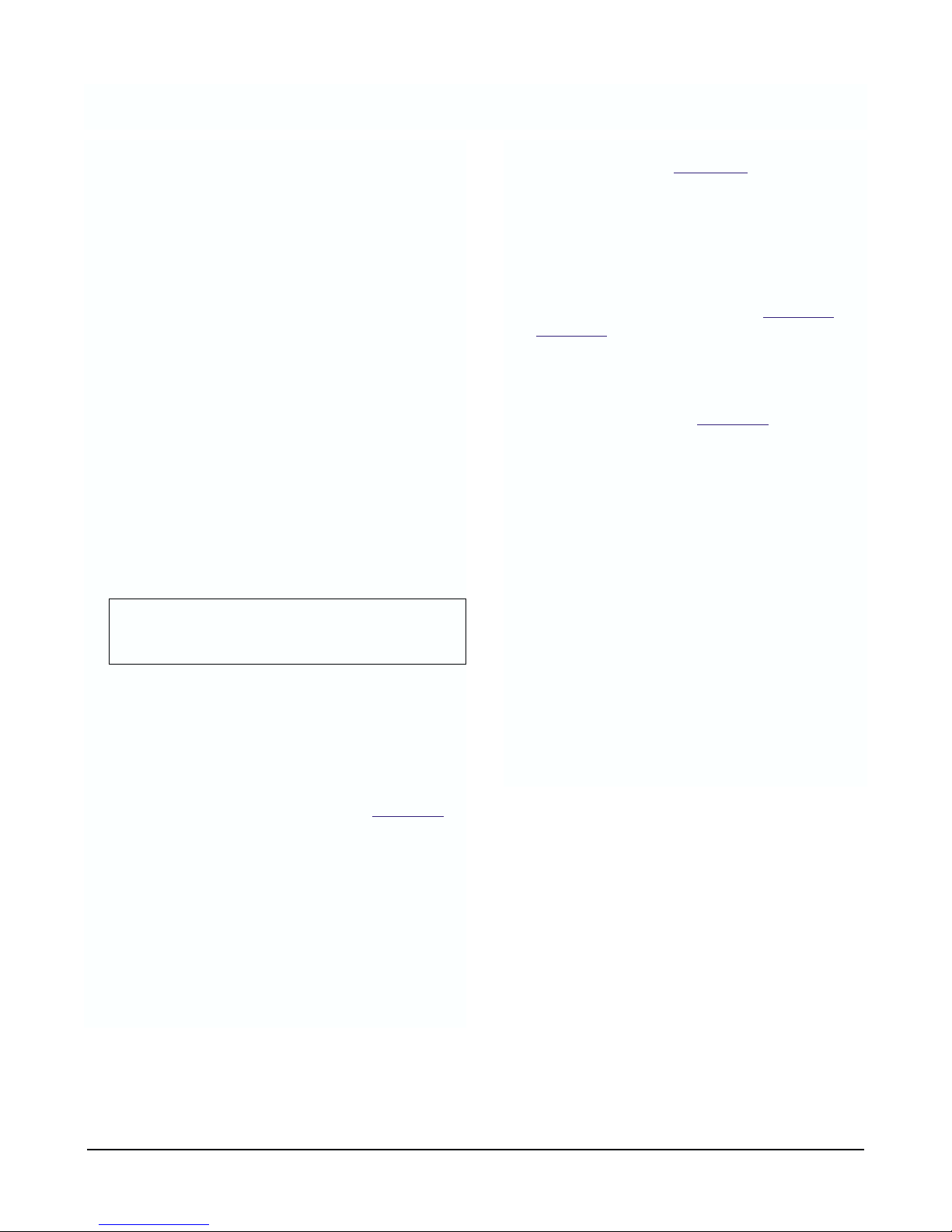

1-1 Model 2081 pH Power and Sensor Wiring.............................................................. 4

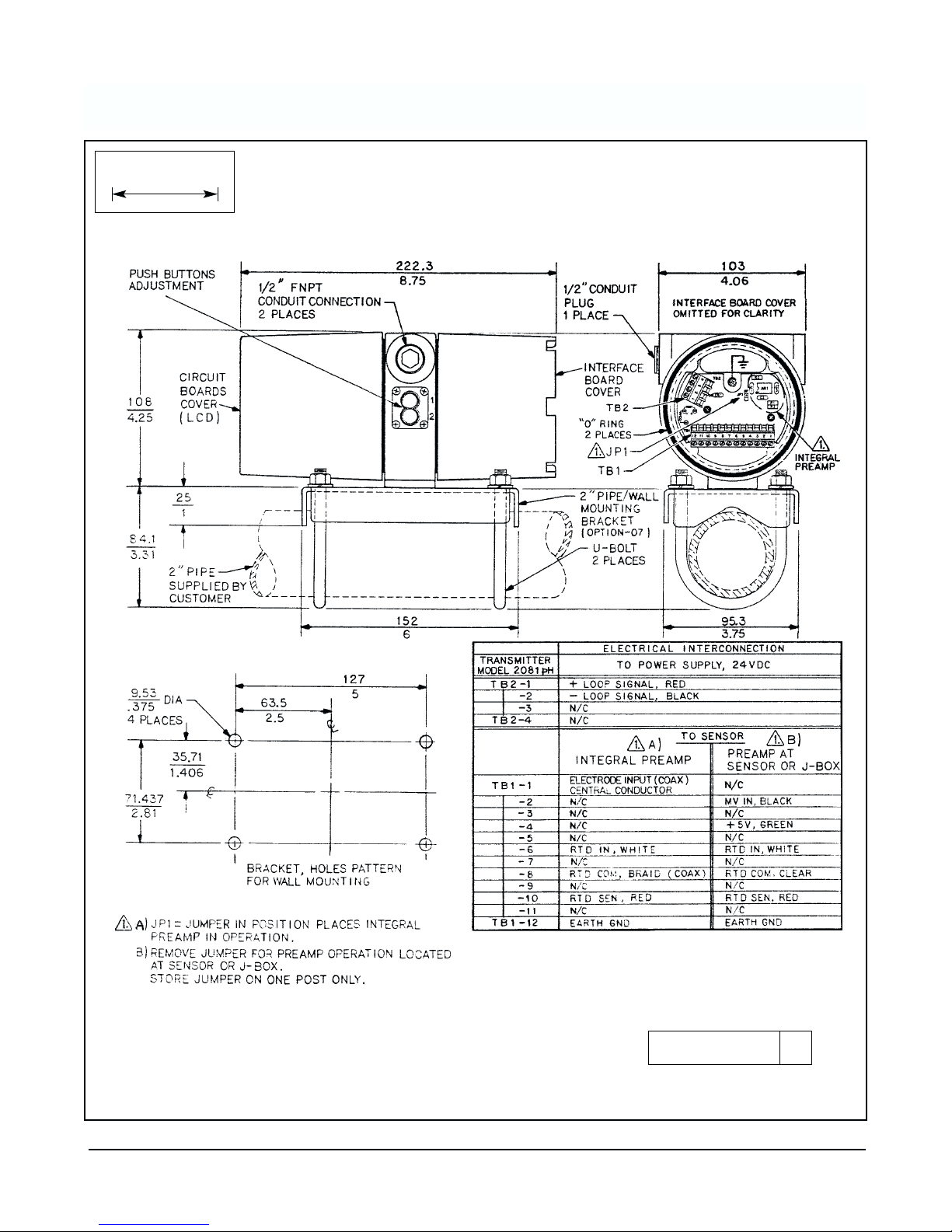

1-2 Sensor Wiring Details for use with 2081 pH............................................................ 5

1-3 Model 2081 pH Jumper Settings ............................................................................ 6

1-4 BASEEFA Label for Instrinsically Safe Installation .................................................. 6

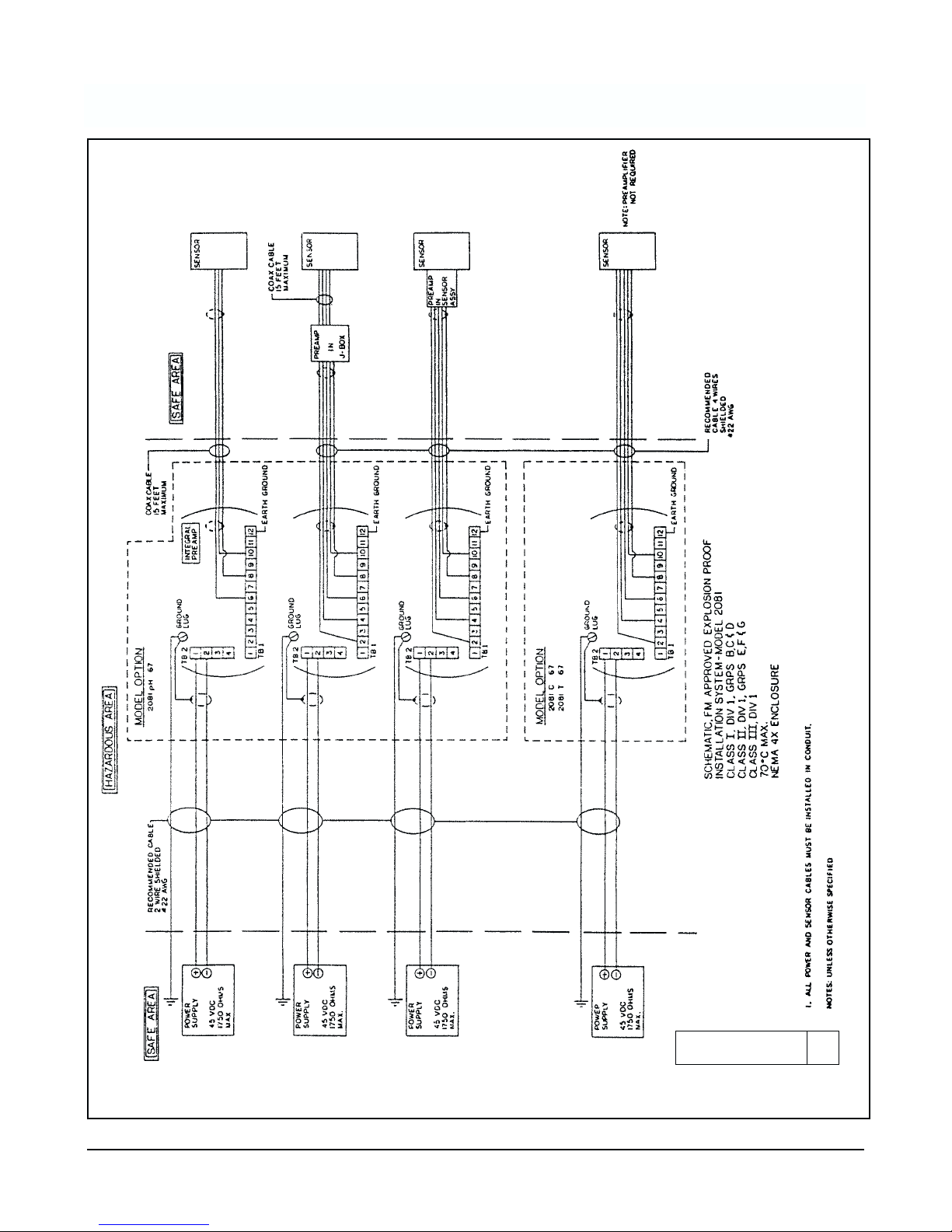

1-5 Explosion Proof System Installation Schematic (FM) .............................................. 7

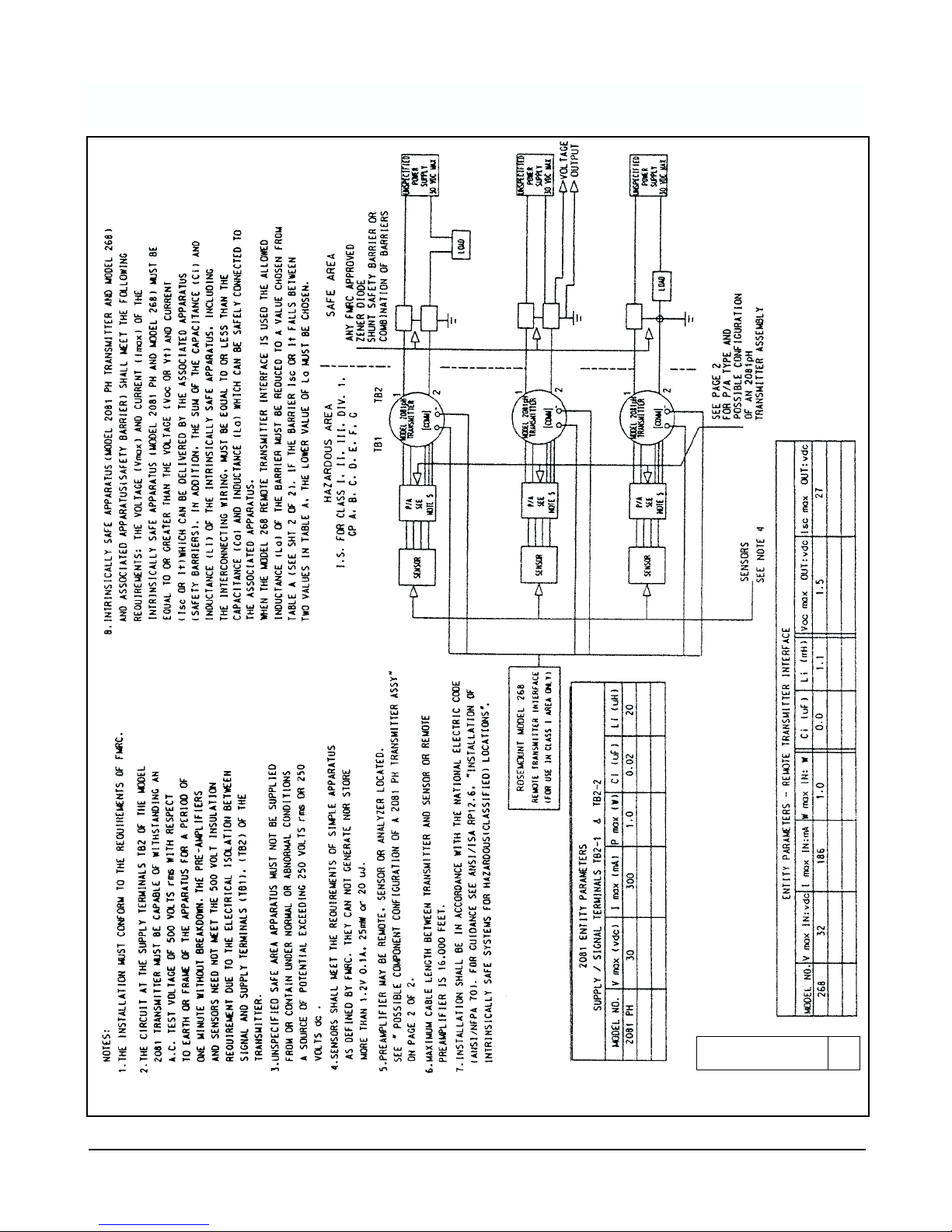

1-6 Intrinsically Safe System Installation Schematic (FM) Page 1 of 2 ......................... 8

1-7 Intrinsically Safe System Installation Schematic (FM) Page 2 of 2 ......................... 9

1-8 Intrinsically Safe System Installation Schematic (CSA)........................................... 10

2-1 Wiring Setup............................................................................................................ 11

2-2 Button Use............................................................................................................... 12

3-1 Menu Description.................................................................................................... 15

6-1 Model 2081 pH Jumper Settings ............................................................................ 20

8-1 Bench Check with preamp...................................................................................... 25

8-2 Bench Check without preamp................................................................................. 25

LIST OF TABLES

Table No. Title Page

8-1 Fault Mnemonics..................................................................................................... 22

8-2 RTD Resistance Values ........................................................................................... 22

8-3 Sensor Input V. pH at Four Temperatures ............................................................... 23

8-4 Voltage Input to Transmitter .................................................................................... 23

8-5

Troubleshooting Guide ............................................................................................ 24

ii

MODEL 2081 pH TABLE OF CONTENTS

Page 5

1.1 UNPACKING AND INSPECTION. Inspect the

transmitter for shipping damage. If damaged, notify

the carrier immediately. Confirm that all items shown

on the packing list are present. Notify Rosemount

Analytical if items are missing. If the transmitter

appears to be in satisfactory condition proceed to

Section 1.2.

NOTE

Save the original packing cartons and

materials as most carriers require proof of

damage due to mishandling.

1.2 MECHANICAL INSTALLATION.

1.2.1 General. The transmitter may be installed in

harsh environments. However, it should be installed in

an area where sources of extreme temperature fluctuation, vibration and shock are at a minimum or absent.

Select an installation site that (1) permits the use of the

standard cable lengths (unless a J-box is used), (2) is

easily accessed by operating and maintenance personnel, and (3) is at least 12 inches (.3 m) from

sources of high voltage.

1.2.2 Mounting. The transmitter may be mounted on

a flat surface using the two threaded mounting holes

located on the bottom of the transmitter or through the

use of an optional 2-inch pipe/wall mounting bracket,

Code 07 (Figur

e 1-1).

NOTE

The meter may be installed in 90-degree increments for easy viewing. Remove the four screws

holding the meter in place and change the

meter to the desired angle. Plug in the display

and tighten the four screws.

1.3 WIRING. The transmitter is equipped with two 1/2-

inch NPT conduit openings, one on each side of the

housing. One is for the power supply/signal wiring and

the other is for the sensor wiring.

To prevent moisture from entering the housing, the use

of weathertight cable glands or conduit is recommended. If conduit is used, it should be positioned to

prevent condensation from draining into the housing.

Conduit connections on the transmitter housing should

be plugged and sealed to avoid moisture accumulation

in the terminal side of the housing.

CAUTION

If the connections are not sealed, the

transmitter should be mounted with the

electrical housing positioned downward

for drainage. Wiring should be installed

with a drip loop, and the bottom of the drip

loop should be lower than the conduit connections or the transmitter housing.

The signal wiring should be twisted pairs for best

results. The twisted pairs should also be shielded and

grounded. The best place to ground the loop is at the

negative terminal of the power supply. Do not ground

the signal loop in more than one point. The transmitter

case shall be grounded.

Signal or sensor wiring should never be run in the

same conduit or open tray as AC power or relay actuated signal cables. Keep signal or sensor wiring at

least 12 in. (.3 m) from heavy electrical equipment.

NOTE

For best EMI/RFI protection the output cable

should be shielded and enclosed in an earth

grounded rigid metal conduit. Connect the

cable’s outer shield to the ground terminal

provided next to TB2, Figur

e 1-1.

The sensor cable should also be shielded.

Connect this outer shield to earth ground as in

the instructions above. If the outer shield is

braided an appropriate metal cable gland fitting may be used to connect the outer braid to

earth groud via the instrument case.

1

SECTION 1.0 INSTALLATION

MODEL 2081 pH SECTION 1.0

INSTALLATION

Page 6

2

NOTE

For RFI/EMI protection, the power

supply/signal wiring and sensor wiring must

be shielded, preferably in metal conduit,

and the shields terminated to earth ground.

1.3.1 Sensor Wiring. The sensor wiring terminals are

located on the side of the housing opposite of the LCD

meter. Remove the housing cover to gain access to the

terminals. Pass the sensor cable through the transmitter’s

conduit opening. Connect the sensor wiring to TB1 terminals 1 through 12 as shown on Figure 1-1.

NOTE

Sensors are supplied with a standard

cable length of 10 feet (3.0 m) or 15 feet

(4.5 m). If the standard cable length is not

sufficient for the planned installation, the

use of a junction box with extension cable

is strongly recommended. Do not exceed

1000 feet (305 m) total cable length from

the sensor to the transmitter.

1.3.2 Integral Preamplifier Jumper. If direct input

from a sensor without a preamplifier is used, refer to

Figure 1-1 and Figure 1-2 for sensor wiring. The sen-

sor cannot be more than 15 (4.5m) feet from the transmitter for this option.

Many pH sensors without preamps come with BNC

connectors, but the Model 2081 pH only takes bare

wire connections. To make the sensor compatible, cut

off the BNC and terminate it according to Figure 1-2.

1.3.3 Power and Signal Wiring. The power and signal

wiring terminal is TB2 terminals 1 through 4 as shown

in Figure 1-1.

1.4 JUMPER SETTINGS.

1.4.1 General This section describes how to set the

jumpers on the CPU board for the following:

CAUTION

The circuit board is electrostatically sensitive. Be sure to observe handling precautions for static-sensitive components.

1. Output value in fault (alarm) mode

2. 50/60 Hz operation

3. Security

1.4.2 Fault Mode Output. The default output of the

transmitter during a fault condition is determined by

the position of the default current output jumper located on [JP3] (refer to Figur

e 1-3). The output can be set

to default either:

- below 4mA - JP3 with jumper

- above 20mA - JP3 without jumper (factory setting).

Place jumper on one post only to prevent misplacing

it. The following are possible faults. See Section 8.0

for

further information.

Fault Mnemonics

“SLP – FAIL” - Electrode slope out of limits

“ELEC – FAIL” - Transmitter electronics failure

“rngE – LOOP” - pH value outside 4-20 mA range

points

“tEnP – Lo” - Temperature too low or RTD shorted

“tEnP – Hi” - Temperature too high or RTD open

1.4.3 Fifty Hz Operation. See Figur

e 1-3. Although

the 2081 uses direct current, a jumper selection may

be made to help reduce electrical noise from the operating environment. North America uses 60 Hz ac

power, while Europe uses 50 Hz ac power.

– 50 Hz - JP1 with jumper

– 60 Hz - JP1 without jumper (factory setting).

Place jumper on one post only to prevent misplacing it.

1.4.4 Security. Also explained in Section 6.0

. See

Figur

e 1-3.

– Disable 2081 push buttons - JP4 without jumper.

Place jumper on one post only to prevent misplacing it.

– Enable 2081 push buttons - JP4 with jumper (fac-

tory setting).

MODEL 2081 pH SECTION 1.0

INSTALLATION

Page 7

3

1.5 HAZARDOUS LOCATIONS-EXPLOSION PROOF

INSTALLATIONS. In order to maintain the explosion

proof rating for installed transmitter, the following conditions must be met.

1. The transmitter enclosure covers must be on hand

tight and the threads must not be damaged.

NOTE

These covers seat on rings which serve to

provide a dust proof enclosure for Class II

and Class III installations.

2. Explosion proof "Y" fittings must be properly

installed and plugged with a sealing compound to

prevent explosive gases from entering the transmitter. CSA has determined that the transmitter

housing is "Factory Sealed". Installation of "Y" fittings and the use of sealing compound is not

required for CSA approved Explosion Proof installations.

NOTE

Do not install sealing compound until all

field wiring is completed.

CAUTION

Sealing compound must be installed prior

to applying power to the transmitter.

3. If one of the conduit connections on the housing is

not used, it must be closed with a threaded metal

plug with at least five threads engaged.

4. The serial tag cover on the external ZERO and

SPAN adjustments must be in place.

6. Explosion proof installation must be in accordance

with Drawing Number 1400160 (see Figure 1-5).

5. For sensors in hazardous area locations, explosion

proof junction boxes can be provided to house the

preamplifier. This does not warrant the pH or ORP

sensor explosion-proof. Maximum safety can be

achieved by installing an intrinsically safe system

where Hazardous Area requirements must be met.

1.6 HAZARD LOCATIONS - INTRINSICALLY SAFE

INSTALLATIONS. See Figure 1-4. To secure and

maintain intrinsically safe installations for the appropriate approval agency, the following conditions must

be met:

1. Code 67 must be specified when ordering F.M.

(Factory Mutual) units. Approved “Entity”

installation must be in accordance with

Drawing Number 1400161 (see Figure 1-6 and

Figure 1-7).

2. Code 69 must be specified when ordering

C.S.A. (Canadian Standards Association) units.

Installation must be in accordance with Drawing

Number 1400162 (see Figure 1-8).

MODEL 2081 pH SECTION 1.0

INSTALLATION

Page 8

4

FIGURE 1-1. Model 2081 pH Power and Sensor Wiring (see also Figure 1-2 for sensor wiring)

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

DWG. NO. REV.

40208101 B

MODEL 2081 pH SECTION 1.0

INSTALLATION

Page 9

5

FIGURE 1-2. Sensor Wiring Details For use with 2081 pH

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

DWG. NO. REV.

40039903 G

MODEL 2081 pH SECTION 1.0

INSTALLATION

Page 10

6

DWG. NO. REV.

233050-00

FIGURE 1-3. Model 2081 pH Jumper Settings

FIGURE 1-4. BASEEFA Label for Intrinsically Safe Installation

DWG. NO. REV.

9240044-00 A

MODEL 2081 pH SECTION 1.0

INSTALLATION

Page 11

7

FIGURE 1-5. Explosion Proof System Installation Schematic (FM)

DWG. NO. REV.

1400160 A

MODEL 2081 pH SECTION 1.0

INSTALLATION

Page 12

8

FIGURE 1-6. Intrinsically Safe System Installation Schematic (FM) Page 1 of 2

DWG. NO. REV.

1400161 A

MODEL 2081 pH SECTION 1.0

INSTALLATION

Page 13

9

FIGURE 1-7. Intrinsically Safe System Installation Schematic (FM) Page 2 of 2)

DWG. NO. REV.

1400161 A

MODEL 2081 pH SECTION 1.0

INSTALLATION

Page 14

10

FIGURE 1-8. Intrinsically Safe System Installation Schematic (CSA)

DWG. NO. REV.

1400162 A

MODEL 2081 pH SECTION 1.0

INSTALLATION

Page 15

11

FIGURE 2-1

Wiring Setup

SECTION 2.0 QUICK START-UP PROCEDURE

2.1 General. The 2081 pH is shipped from the factory

in a configuration that is acceptable in many applications. The instrument is set-up as follows:

• Measures from 0-14 pH

• 0 pH will correlate to a 4 mA current output

• 14 pH will correlate to a 20 mA output

• Temperature readings will be in degrees C

• Automatic temp. compensation will be on

• External preamplifier

If this described set-up is compatible with your application, you can utilize the following Quick Start-up

instructions, below, to expedite the commissioning

and calibration of your instrument. Otherwise, follow

the detailed instructions in Section 3.0

to set the

desired pH range, Section 4.0 to start-up, and

Section 5.0 to calibrate your instrument.

2.2 Set-up instrument.

Connect a power supply, current meter and an appropriate sensor to the 2081 Transmitter, as illustrated in

the figure below.

2.1.1 Connect loop power: -wire

power supply to the 2081 (TB2) adjust supply to approx. +24VDC

2.1.2 Connect current meter:

-wire meter to TEST connections to read

mA output (+ to +)

Model 2081 (short cover removed)

View of Interface PCB

* Install JP1 if internal preamplifier is

used. Remove if sensor or junction

box preamplifier is used.

2.1.3 Connect Sensor to 2081:

- wire sensor to TB1 as

illustrated below

2.1.4 Prep Sensor for calibration: (Refer to Sensor Manual)

Examples: - 381 Sensor must have a liquid junction and glass electrode installed

-399 Sensor requires removal of red boot cover, only

– *Black to TB1-1, instead of TB1-2, if unit has

JP1 in place.

12 11 10 9 8 7 6 5 4 3 2

4 3 2

TB2

TB1

SENSOR

mA

Power

Supply

– Loop

+ Loop

Black (mV-in)

Green (+5)

White (RTD IN)

Clear (RTD COM)

Red (RTD SEN)

TEST

+

+

+

MODEL 2081 pH SECTION 2.0

QUICK START-UP PROCEDURE

Page 16

FIGURE 2-2. Button Use.

12

2.3.3 Access the temperature adjustment feature of

the 2081 by pressing both push buttons at the same

time. Display will scroll through the menu selections.

2.3.4 When “tAdj” appears on the display, release

both buttons. Display will show the current temperature read by the RTD built into the sensor connected

to the transmitter.

1. If this reading matches your standardized

measuring device within your tolerances, go on

to Section 2.4

(Two-Point Calibration).

2. If this reading is not close enough to your standardized temperature measuring instrument,

refer to steps 1 through 4 in Section 5.2

Te mp erature Calibration, to set the temperature reading of the sensor to your standard temperature

measuring instruments value.

Both buttons in:

1. Scrolls through menu if held.

2. Enters new value into memory if only held

momentarily.

Number one in, to scroll through digit values.

Number two in, to select digit position.

2.3 Temperature Calibration. Since pH value is related

to the temperature of the process, the 2081 transmitter

temperature readings should be checked for matching

with your standardized temperature measuring sensor.

To do so:

2.3.1 Place your sensor connected to the 2081 transmitter in a beaker of process material. Place your standardized temperature measuring instrument (thermometer) into the same solution.

2.3.2 Allow a minimum of 10 to 15 minutes for the transmitters sensors to acclimate to the solutions temperature.

NOTE

The 2081 has two pushbuttons on its side for

manual operation. Keypress combinations

allow you to activate software menus to display and enter information. See Figur

e 2-2.

Push Buttons (side view)

OUT

IN

➡

➡

➡

2081 Display

02

0255..CC

5

IN

➡

2081 Display

025

025..CC

C

IN

1

2

1

2

MODEL 2081 pH SECTION 2.0

QUICK START-UP PROCEDURE

Page 17

13

2.4 Two-Point Calibration

Sensor should still be in the first buf

fer solution.

The sensor is placed in a buffer solution and the buffer value

is entered into the 2081. The sensor is placed in a different

buffer solution and that value is entered into the 2081. The

2081 will calculate the new slope from these values.

2.4.1 Compare the 2081 pH reading to the buffer value

that the sensor is in. If the display doesn't read the buffer

value, then enter the buffer value into the 2081, using the

following directions. If display reading is correct, skip to

Section 2.4.3, step 5.

2.4.2 Access the “buF1” feature on the 2081:

1. Press both push buttons in; display will scroll through

menu selections

2. When display reads “buF1”; release the buttons; display reads last buffer value entered. Far right digit will

be flashing, indicating that you may enter data.

2.4.3 Enter the buffer pH value that the sensor is in:

1. Press button #2 to select digit position to modify.

Selected digit will be flashing. Holding the button in

will cause selected position to shift to the left, then

back around again.

2. Release button when the desired digit is flashing.

3. Press button #1 to change digit's value. Holding the

button in will cause the selected digit to increase in

value, then back around again.

4. Release the button when the desired digit value is displayed.

5. Press both buttons in, briefly, to enter the new value into

memory. The 2081 will default to the pH reading. The

2081's pH reading will not change until the “buF2” value

is entered into memory. at the end of Section 2.4.5.

To 2081

pH Sensor

Buffer #1

(i.e., 4 pH)

Push Buttons

(side-view)

2081 Display

buF1

buF1

2081 Display

Scrolling

OUT

IN

➡

➡

➛

>

>

➡

2081 Display

00..00

00

2081 Display

11..00

00

1

0

IN

>

>

2081 Display

44..00

00

2081 Display

33..95

95

4

>

2081 Display

33..95

95

=

Buffer #1

4.00 pH ?

>

>

➡

2081 Display

00

00..00

2081 Display

00..000

0

0

2081 Display

00..000

0

0

0

IN

>

>

1

2

1

2

MODEL 2081 pH SECTION 2.0

QUICK START-UP PROCEDURE

Page 18

14

2.4.3 2-Point Calibration (cont.)

Remove the sensor from buffer #1. Rinse Sensor in water

(Deionized), then place in the 2nd buffer solution. The sensor is placed in the second buffer solution and that buffer

value is entered into the 2081. The 2081 will calculate the

new slope from the two buffer values.

2.4.4 Compare the 2081 pH reading to the buffer value

that the sensor is in. If the display doesn’t read the buffer

value, then enter the buffer value into the 2081, by performing Sections 2.4.2 - 2.4.3

; substituting the buffer #2

value for the buffer # I value.

If display reading is correct, go to Section 2.4.3, step 5..

2.4.5 After the buffer value #2 value is entered into the

2081, it calculates the sensor’s slope. The transmitter and

sensor are now calibrated. Upon installation into the

process, a Standardization should be performed to

improve the reading accuracy (refer to Section 5.4

after

completing the Quick Start-up procedure).

Leave the sensor in buf

fer #2.

2.5 Current Output Check

Check the current output of the transmitter; sensor should

still be in buffer #2 (i.e., 10 pH).

2.5.1 Calculate the proper current output for the buffer

being used, with the adjacent formula.

Example: Sensor is acclimated in 10 pH buffer.

Transmitter is factory configured for 0-14 pH full-scale

range, and 4-20 mA output.

Current output should read 15.43 mA.

2.5.2 Remove the sensor from buffer #2. Rinse Sensor in

water(Deionized), then place in the 1st buffer solution.

Check the current output with the sensor acclimated to

buffer #1.

2.5.3 Calculate the proper current output for the buffer

being used, with the mA output formula.

Example: Sensor is acclimated in 4 pH buffer.

Transmitter is factory configured for 0-14 pH full-scale

range, and 4-20 mA output. Current output should read

8.57 mA.

NOTE

If the pH buffer readings are accurate and the

current output values are within tolerance, then

the unit is calibrated and ready to be placed

into service.

2081 Display

10

10..

05

05

=

Buffer #2

10.00 pH ?

+ Buffer Value #2

+ Buffer Value #1

mV reading

pH Value

2081 calculates the

sensor slope

(ideal is 59.1 mV/pH)

mA Buffer Value

=

(

––––––––––––––––

) X 16 + 4

output Full-scale Range

mA 10.00 pH

=

(

––––––––––––––––

) X 16 + 4

output 14

= 15.43 mA ± .16

mA Buffer Value

=(––––––––––––––––

) X 16 + 4

output Full-scale Range

mA 4.00 pH

=(––––––––––––––––

) X 16 + 4

output 14

= 8.57 mA ± .16

MODEL 2081 pH SECTION 2.0

QUICK START-UP PROCEDURE

pH Sensor

Buffer #2

(i.e., 10 pH)

Water (DI)

Rinse Sensor

➛

Page 19

15

3.1 GENERAL. Nearly all functions of the transmitter

are accessed through the dual push buttons. The

transmitter uses no potentiometers.

3.2 MENU SELECTION. The dual push buttons are

located on the side of the transmitter. Press and hold

both buttons to display the transmitter menu items.

See Figur

e 3-1. The display will show each item for

about one second then scroll to the next item. It will

continue to loop through the items until one is selected. To select an item, release both push buttons when

the desired item is displayed.

NOTE

When no push button is pressed for a period

of 60 seconds, the transmitter defaults to

reading pH. If the push buttons are accidentally released (e.g. buF2) and this would upset

the process, escape by waiting 60 seconds

for the transmitter to default to the pH reading.

3.2.1 Display Submenu. Functionality of the display

submenu (dISP) is the same as the main menu. To enter

the main menu, release both buttons on “dISP” and the

display will read “PH”. To read the pH value in the sub-

menu when “PH” is displayed, press and quickly

release both push buttons. To escape from the submenu, simply depress both buttons and hold to enter

the main menu or wait 60 seconds for a pH reading.

3.2.2 Display Flags and Hold Mode. The transmitter

will activate a flag on the LCD corresponding to the

labeled units when appropriate. When the transmitter

is in hold output mode a flashing flag will appear on

the middle right hand side of the display and “HoId”

will flash periodically. The output will remain at the last

process value. To remove the hold mode, scroll to

“HoId” again and release both buttons.

3.3 VALUE ADJUSTMENT. Selection of a menu item

that has a user-adjustable value will cause a numeric

display with the right-most digit flashing. Depressing

and holding push button #1 will cause the number

flashing to increment upwards, looping back to zero.

Depressing and holding push button #2 will shift the

flashing cursor to the next decade, looping back to the

right most decade. Once the number is correctly

entered, depressing both buttons briefly will enter the

displayed value into memory. The transmitter will

return to reading pH.

SECTION 3.0 DESCRIPTION OF CONTROLS

MAIN DISPLAY

MENU SUBMENU

dISP – – – – – – – – – – – – – – – – – – – – – – –

→

PH pH value

Std Standardize pH inPt mV input

Ho Id Initiate and remove hold output mode curr Output in mA

buF1 Buffer #1 DIo Output in % of full scale

buF2 Buffer #2 DC Temperature, °C

SLP Electrode slope (mV/pH unit) DF Temperature, °F

LoPH 4 mA range point

HiPH 20 mA range point

tAdJ Standardize temperature, °C

• Press and hold both buttons auto scrolls through main menu

and submenu.

• Release buttons to select item.

• Push button #1: Press and hold auto scrolls digits.

• Push button #2: Press and hold auto shifts decades.

• Enter a value: Depress both buttons briefly.

FIGURE 3-1. Menu Description

MODEL 2081 pH SECTION 3.0

DESCRIPTION OF CONTROLS

Page 20

SECTION 4.0 RANGE CONFIGURATION

4.1 RANGE CONFIGURATION. Corresponding pH

values for output zero (4 mA) and full scale (20 mA)

are user selectable. The factory values are 4 mA = 0

pH and 20 mA = 14 pH.

A. Output Zero (4 mA) “LoPH”

1. Depress and hold both push buttons. The display

will begin to auto scroll.

2. Release both keys when “LoPH” is displayed. The

present 4 mA pH value in memory will be displayed with the last digit flashing.

3. Depress and hold push button #1 (scroll) and #2

(shift) as needed to display the desired pH value.

4. Enter the value into memory by depressing both

push buttons briefly. The display will return to displaying the present pH value.

B. Full Scale (20 mA) “HiPH”

1. Depress and hold both push buttons. The display will begin to auto scroll.

2. Release both keys when “HiPH” is displayed. The

present 20 mA pH value in memory will be displayed with the last digit flashing.

3. Depress and hold push button #1 (scroll) and #2

(shift) as needed to display the desired pH value.

4. Enter the value into memory by depressing both

push buttons briefly. The display will return to displaying the present pH value.

NOTE

For a reverse output, enter the higher value

for “LoPH”, and the lower value for “HiPH”.

NOTE

If the factory values are to be used, the

Quick Start-up Procedure may be used.

See Section 2.0

.

MODEL 2081 pH SECTION 4.0

RANGE CONFIGURATION

16

Page 21

17

SECTION 5.0 START-UP AND CALIBRATION

5.1 GENERAL. The sensor must be wired to the

transmitter for calibration. See the appropriate sensor manual for additional instructions relating specifically to the sensor.

5.2 TEMPERATURE CALIBRATION. For the most

accurate temperature compensation, the temperature reading may need adjusting. The following

steps should be performed with the sensor in a grab

sample or process of known temperature. Calibrate

at or near the process temperature for greatest

accuracy.

1. Depress and hold both push buttons simultaneously to enter the transmitter menu. The transmitter will auto scroll through the menu items.

2. When the display shows “tAdJ”, release both buttons. The display will show the present temperature value in degrees Celsius with the last digit

flashing. The tenths digit will alternate between a

value and °C. (The temperature can only be standardized in °F by using the Model 275 for configuration).

3. Compare the displayed reading with a calibrated temperature reading device. If the reading

requires adjustment, proceed to step 4. Otherwise, depress both push buttons briefly to

accept the displayed value.

4. Depress and hold push buttons #1 (scroll) and

#2 (shift) as needed to display the desired temperature value.

5. Enter the correct value into memory by depressing both push buttons briefly. The display will

return to displaying the present pH value.

5.3 BUFFER CALIBRATION. The two buffer calibra-

tion will calculate the slope (efficiency) of the pH

sensor. (Computed limits: 47.3 to 59.9 mV/pH).

1. Obtain two pH buffer solutions with values at

least two pH units apart. Unopened buffers have

a shelf life of about a year, and once opened,

should ideally not be reused because of possible contamination.

2. Depress and hold both push buttons to scroll

through the menu items to “HoId”, then release

both buttons to place the transmitter in hold status (“HoId” will periodically flash). This will maintain the output at the last process value read by

the transmitter and activate the hold flag on the

middle right hand side of the display.

3. Remove the sensor from the process and clean

it if necessary. Shake the sensor down to

remove entrapped air bubbles from the measurement tip.

4. Place the sensing portion of the pH sensor into

a beaker containing the first buffer solution.

5. Allow the pH reading to stabilize, note the sensor temperature from the display submenu, then

note the value at the buffer at that temperature.

Buffer pH values of various temperatures are

located on most buffer bottles. For example, at

5°C (41°F) a typical buffer is 6.95 pH but at 25°C

(77°F) it is 6.86 pH. See “Note on Buf

fers” on the

following page.

6. Depress and hold both push buttons to scroll

through the menu items to “buF1” then release

both push buttons. The display will show the pH

value currently in “buF1” memory.

7. Depress and hold push button #1 (scroll) then

#2 (shift) as needed to display the buffer1 pH

value.

8. Enter the buffer value (at the sensor temperature) into memory by depressing both push buttons briefly. The transmitter will memorize this

value but will not change the calibration until

buffer #2 is entered. The display will return to

reading the present pH value.

9. Remove the sensor from the buffer, rinse and

gently dry it.

10. Place the sensing portion of the pH sensor into

a beaker containing the second buffer solution.

11. Follow the instructions in steps 5 through 8 for

buffer 2 (“buF2”). After entering the “buF2” value

the transmitter will calculate the electrode slope

and standardize the reading.

MODEL 2081 pH SECTION 5.0

START-UP AND CALIBRATION

Page 22

18

12. Return the sensor to the process.

13. Depress and hold both push buttons to scroll

through the menu items to “HoId”, then release

both push buttons to remove the transmitter

from hold status. The hold flag will disappear

and the display will stop flashing “Ho Id”.

NOTE

To observe the calculated slope value, follow

the instructions in Section 5.5

.

NOTE ON BUFFERS

The pH of buffer solutions changes with

temperature. This is very important to know

if you are calibrating in a very hot or cold

environment and you need good accuracy.

Rosemount Analytical recommends use of

the following NIST (National Institute of

Standards and Technology - formerly NBS)

buffers:

5.4 pH STANDARDIZATION.

After a buffer calibration, the system should be standardized on line by taking a grab sample. Standardization will not calculate the electrode slope, but will

improve system accuracy.

1. Take a grab sample which is as close to the

sensor as possible. Note the transmitter pH

reading at this time.

2. Using a calibrated pH instrument, determine

the pH of the process or grab sample. The

reading must be temperature compensated to

25°C (77°F) if the sample is not at 25°C. Note

this value.

3. Calculate the difference by subtracting the pH

value noted in Step 1 from the pH value found

in step 2.

4. Depress and hold both push buttons to scroll

through the menu items to “Std”, then release

both push buttons. The display will show the

present pH value with the last digit flashing.

5. Correct the pH standardize value for time lag by

adding the difference calculated in step 3 to the

amount displayed on the transmitter.

Example: If pH in step 1 is 2.3 and pH in step

2 is 2.8, the difference noted in step 3 would be

+.5 pH. The present transmitter pH value would

be increased by .5 pH.

6. Depress and hold push button #1 (scroll) and

#2 (shift) as needed to display the pH value calculated in step 5.

7. Enter the value into memory by depressing both

push buttons briefly. The transmitter will return

to displaying the present pH value.

5.5 pH GLASS SLOPE.

The slope (efficiency) of the pH glass electrode can

be entered directly if known (slope limits: 47.3 to

59.9 mV/pH). As the electrode ages the slope will

decrease.

1. Depress and hold both push buttons to scroll

through the menu items to “SLP”, then release

both buttons. The display will show the present

slope with the last digit flashing.

2. Depress and hold push button #1 (scroll) and

#2 (shift) as needed to manually enter a slope

value, if desired.

3. Enter the value into memory by depressing both

push buttons briefly. The transmitter will return

to displaying the present pH value.

°C °F pH pH pH

5 41 4.00 6.95 9.39

10 50 4.00 6.92 9.33

15 59 4.00 6.90 9.28

20 68 4.00 6.88 9.22

25 77 4.01 6.86 9.18

30 86 4.01 6.85 9.14

35 95 4.02 6.84 9.10

40 104 4.03 6.84 9.07

45 113 4.04 6.83 9.04

50 122 4.06 6.83 9.01

MODEL 2081 pH SECTION 5.0

START-UP AND CALIBRATION

Page 23

19

MODEL 2081 pH SECTION 5.0

START-UP AND CALIBRATION

5.6 HOLD MODE FOR MAINTENANCE.

Before performing maintenance of the sensor, or

buffer checks, the transmitter should be placed in

the "Hold" mode. This mode of operation maintains

the output current at the last process value. To initiate "hold " mode:

1. Depress and hold both push buttons simultaneously until "Hold" is displayed on the screen.

2. Release both buttons.

a The "Hold" flag will flash, and

b. The display will show "Hold" every two sec-

onds to confirm the hold status.

To place the transmitter back into normal operation,

(remove from "Hold" mode)

1. Depress and hold both push buttons simultaneously until "Hold" is displayed on the screen.

2. Release both buttons.

a. The "Hold" flag will stop flashing.

b. The display will stop showing "Hold" every

two seconds.

c. The transmitter output current will return to

normal operation.

5.7 SENSOR MAINTENANCE.

Always calibrate after cleaning or repair of the pH

sensor.

Always place transmitter into the "Hold " mode of

operation while preforming any maintenance to the

sensor to avoid loss of process control.

Always return transmitter to normal operation after

installing the sensor back into the process.

NOTE

To clean the electrode, rinse with distilled

water or dilute acid/base, then gently dry

with a clean tissue. The electrode should

not be rubbed or abraded because this

increases the electrostatic forces and

thus the response time of the electrode,

and it also rapidly ages the delicate electrode gel layer. If possible, the stirring or

flow velocity past the electrode should

be increased rather than rubbing or

brushing the electrode.

Also, see the appropriate sensor manual

for any additional instructions.

Page 24

20

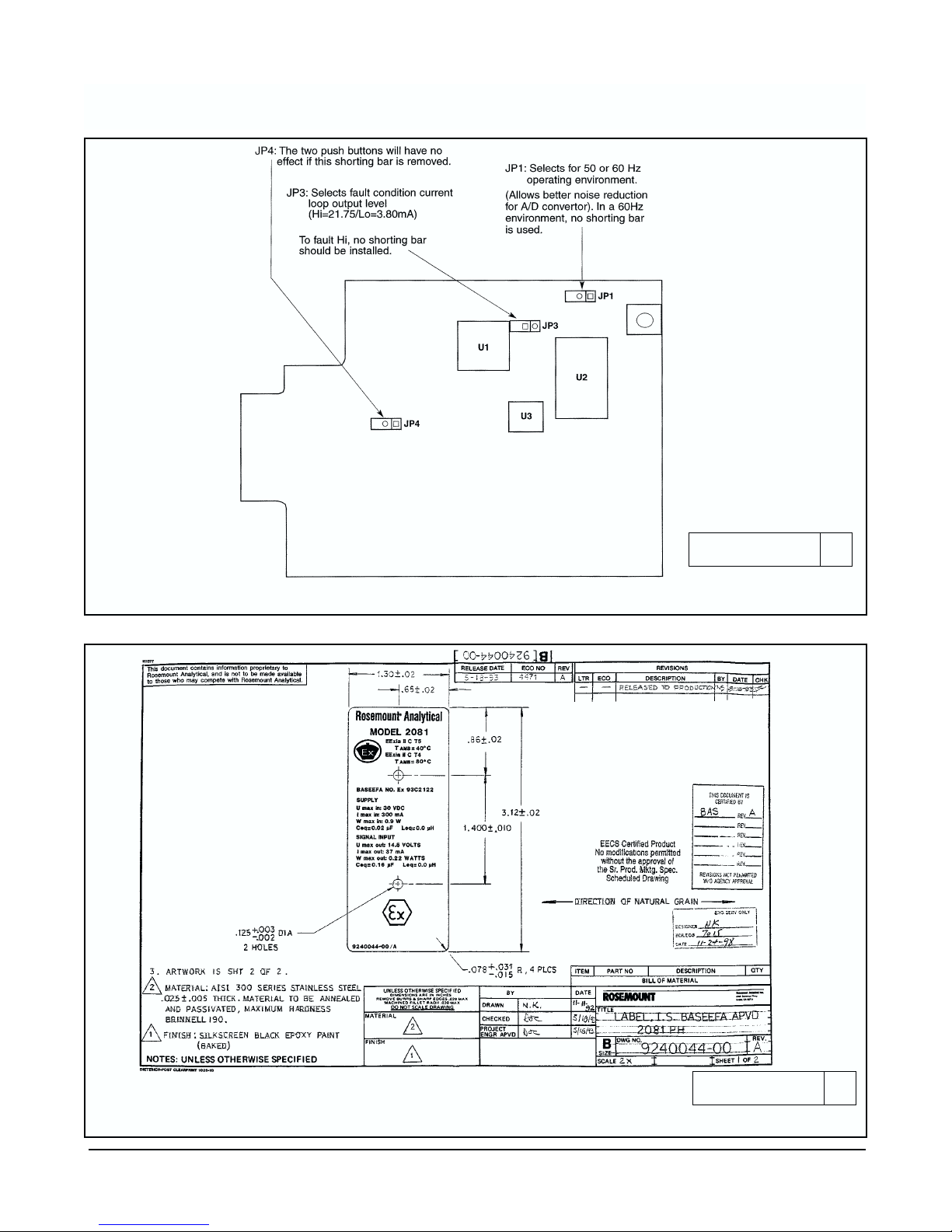

SECTION 6.0 KEYBOARD SECURITY

GENERAL. This feature allows the user to disable the

dual push buttons on the transmitter, preventing accidental or unauthorized changes to the calibration and

configuration via the transmitter. HART communication

is not effected by this change. Perform the following

steps to disable the push buttons:

CAUTION

The circuit board is electrostatically sensitive. Be sure to observe handling precautions for static-sensitive components.

1. Remove the display side cover.

2. On the CPU board (Figur

e 6-1, Model 2081 pH

jumper settings), move JP4 to one post only.

NOTE

For easy access, the electronics assembly

may be removed by pulling the assembly

straight out.

3. Replace the display side cover.

CAUTION

A minimum of seven cover threads must

be engaged in order for the transmitter to

meet explosion-proof requirements.

Replace the jumper to enable push button operation.

FIGURE 6-1. Model 2081 pH Jumper Settings

JP3

JP4

JP1

JP1: Selects for 50 or 60 Hz operating environment.

(Allows better noise reduction for A/D convertor). In a

60Hz environment, no shorting bar is used.

JP4: The two push buttons will have no

effect if this shorting bar is removed.

JP3: Selects fault condition current loop

output level (Hi=21.75/Lo=3.80mA)

To fault Hi, no shorting

bar should be installed.

U2

U3

U1

DWG. NO. REV.

233050-00

MODEL 2081 pH SECTION 6.0

KEYBOARD SECURITY

Page 25

21

SECTION 7.0 THEORY OF OPERATION

GENERAL This section is a general description of how the transmitter operates. This section is for those users

who desire a greater understanding of the transmitter’s operation.

The measurement of the process’ pH is accomplished by the use of two electrodes within the sensor. The glass

electrode is pH sensitive and generates a high impedance millivolt potential directly proportional to the process

pH. The reference electrode is a second half cell that completes the circuit via a liquid junction. The high impedance signal is preamplified at or near the sensor to allow a stable noise-free signal that can be transmitted up to

1000 feet.

The transmitter also measures the process temperature via a platinum 100 ohm RTD imbedded in the sensor.

Advanced circuitry is used to eliminate errors due to changes in cable resistance. The transmitter uses this temperature measurement to compensate for the changes in the sensor’s millivolt output caused by process temperature change.

MODEL 2081 pH SECTION 7.0

THEORY OF OPERATION

Page 26

22

SECTION 8.0 DIAGNOSTICS AND TROUBLESHOOTING

TABLE 8-2. RTD Resistance Values

TABLE 8-1. Diagnostic Messages

Temperature Resistance

0°C 100.00 ohms

10°C 103.90 ohms

20°C 107.79 ohms

30°C 111.67 ohms

40°C 115.54 ohms

50°C 119.40 ohms

60°C 123.24 ohms

70°C 127.07 ohms

80°C 130.89 ohms

90°C 134.70 ohms

100°C 138.50 ohms

Display Description Corrective Action

“SLP – FAIL” Electrode slope out of limits See Table 8-5

“FAIL” Transmitter electronics failure See Table 8-5

“rngE – LOOP” pH value outside 4-20 mA range points Return pH to within range, replace sensor

“SnSr – FAIL” Sensor failure or A-D failure See Table 8-5

“tEnP – Lo” Temperature too low or RTD shorted Check wiring, calibrate temperature, bring sensor within

“tEnP – Hi” Temperature too high or RTD open temperature specifications, replace stack, replace sensor.

Note: If in manual temp. mode, RTD or appropriate resistor

must

be in place. See Table 8-2.

MODEL 2081 pH SECTION 8.0

DIAGNOSTICS AND TROUBLESHOOTING

8.1 DIAGNOSTICS. The transmitter has a diagnostic

feature which continuously monitors for fault conditions that would cause an error in the measured pH

value. A fault condition is reported to the current loop

as jumper selected. If jumper JP3 in in place, the output will be driven below 4 mA. If the jumper is not in

place, the output will be driven above 20 mA. See

Figure 1-3 for jumper location. The display will alter-

nate between the pH value and the appropriate fault

mnemonic (Table 8-1). The fault sequence will contin-

ue until the cause of the fault has been corrected.

8.1.1 Diagnostic Messages. Table 8-1 lists the fault dis-

play, discribes the meaning of each and appropriate

corrective action. All of these faults are detected

online, except for the slope error which can occur during an off-line buffer calibration.

8.1.2 Temperature Compensation. Table 8-2 is a refer-

ence of RTD resistance values at various temperatures.

These are used for test and evaluation of the sensor.

NOTE

Ohmic values are read across the RTD element and are based on the manufacturer’s

stated values (±1%). Allow enough time for the

RTD element to stabilize to the surrounding

temperature.

8.2 TROUBLESHOOTING. The Model 2081 pH transmitter is designed with state-of-the-art surface mount

technology and microprocessor technology, making

troubleshooting simple and direct. Subassembly

replacement, i.e. PCB stack replacement, is all that is

required.

NOTE

Transmitters should not be left in service once

they have been determined to be inoperable.

8.2.1 General. If failure does occur, complete the following steps:

1. Check for a fault flag. If a fault condition exists, refer

to Table 8-1 for the fault mnemonic explanation.

2. Check wiring connections for proper installation.

3. Refer to Troubleshooting Table 8-5. The table is

arranged with the most common problems listed

first.

Page 27

23

8.2.2 Bench Check. Sensor simulation may be used

to check the operation of the Model 2081. If the Model

2081 is using the integral preamplifier, connect the

simulator(s) according to Figur

e 8-1. If the model 2081

has no preamplifier, connect the simulator(s) as shown

in Figure 8-2. Refer to Table 8-2 for the appropriate

RTD resistance.

CAUTION

Do not use over 55 volts to check the loop, or

damage to the transmitter electronics may

result.

1. After completing power and simulator(s) wiring,

apply 24Vdc power to the Model 2081.

2. Simulate 25°C to the transmitter by placing 110

resistance between TB6 and TB8. The Model 2081

should display ~25°C (refer to Section 3.2.1).

Adjust the temperature display if necessary (Refer

to Section 5.2).

3. Simulate 4 pH by applying +177 millivolts dc

(W/integral preamplifier) or +1.52 VOLTS DC (W/O

preamplifier).

NOTE

Using mV inputs for units without preamps will

result in a “SnSr FAIL” fault code.

4. Depress and hold both push buttons to scroll

through the menu items to “buF1” then release

both buttons. The display will show the pH value

currently in “buF1” memory.

5. Depress and hold push button #1 (scroll) then #2

(shift) as needed to display 4.00.

6. ENTER the value into memory by simultaneously

depressing both push buttons briefly.

7. Simulate 10 pH by applying -177 millivolts dc

(

W

/preamplifier) or 1.173 VOLTS DC (W/O pream-

plifier).

8. Follow steps 4-6 for “buF2”, entering 10.0pH.

9. The Model 2081 should display ~ 10.00.

10. If the transmitter performs properly, then the sen-

sor should be checked.

If the integral preamplifier is suspect, bypass it and

follow the instructions for calibration without the preamplifier.

8.2.3 Sensor Troubleshooting. In addition to the fault

mnemonics that relate to a possible sensor problem

(Table 8-1 and Table 8-5), the transmitter can display

the input in millivolts generated from the sensor. See

Table 8-3 for how the millivolt input relates to pH. If the

transmitter values are not within about 20% of those in

Table 8-3, the transmitter has been incorrectly stan-

dardized for pH, the reference may be significantly

poisoned, or some other significant problem exists. To

read the millivolt input, go to “inPt” in the display submenu.

*99% pH electrode efficiency

8.2.4 PCB Stack Replacement. If it becomes necessary to replace the PCB stack (both CPU and Sensor

boards) there is no need to field calibrate electronics

upon replacement, since the millivolt input and output

digital trim is performed at the factory. Simply remove

the old assembly, reconnect the new stack, and perform the sensor calibration.

8.2.5 LCD Display Replacement. If the display board

needs to be replaced you will need both the generic

display assembly P/N 23419-00 and the pH overlay

P/N 9240008-00.

CAUTION

Remove power from transmitter before

removing the electronics cover.

pH Input to Transmitter in MILLIVOLTS

15°C

(59°F)

25°C

(77°F)

50°C

(122°F)

80°C

(176°F)

0 396 410 444 486

1 340 351 381 416

2 283 293 317 347

3 226 234 254 277

4 170 176 190 208

5 113.2 117.1 127.0 138.7

6 56.6 58.6 63.5 69.4

70000

8 –56.6 –58.6 –63.5 –69.4

9 –113.2 –117.1 –127.0 –138.7

10 –170 –176 –190 –208

11 –226 –234 –254 –277

12 –283 –293 –317 –347

13 –340 –351 –381 –416

14 –396 –410 –444 –486

TABLE 8-3. Sensor Input* to Transmitter Verses

pH at Four Temperatures

15°C

(RTD = 105.85 )

25°C

(RTD = 109.74 )

80°C

(RTD = 130.89 )

pH Vdc input Vdc input Vdc input

0 1.75 1.76 1.84

1 1.69 1.71 1.77

2 1.63 1.65 1.70

3 1.58 1.59 1.63

4 1.52 1.53 1.56

5 1.47 1.47 1.49

6 1.41 1.41 1.42

7 1.35 1.35 1.35

8 1.29 1.29 1.28

9 1.24 1.23 1.21

10 1.18 1.17 1.14

11 1.12 1.11 1.07

13 1.01 1.00 0.93

14 0.95 0.94 0.86

TABLE 8-4

VOLTAGE Input to Transmitter (no integral preamplifier)

MODEL 2081 pH SECTION 8.0

DIAGNOSTICS AND TROUBLESHOOTING

Page 28

24

SYMPTOM PROBLEM ACTION

Change in pH slope (value 1. Old or coated glass electrode. 1. Clean or replace glass electrode.

decreasing to 49.0 or less). 2. Bad RTD value. 2.

See Table 8-2 with RTD resistance

and temperature values.

pH value locks up (no change 1. Glass electrode cracked. 1. Replace glass electrode.

of reading in different buffers). (if value stays at 6.5-7.0 pH) 2. Clean glass electrode.

2. Coated glass electrode.

2081 pH value not the same 1. Grab sample incorrect. 1. Re-evaluate sample technique

as grab sample of process. and equipment.

2. Unclear what is correct. 2. Test with buffer solution.

3. 2081 pH out of calibration. 3. Recalibrate per start-up and

calibration section.

Fault code “tEnP-Lo” or 1. Miswire. 1. Check wiring between the sensor

“tEnP-H i”. and the transmitter.

2. Open or shorted RTD. 2. Replace RTD or sensor.

3. Manual temperature mode. 3. Appropriate resistor must be

in place TB1-6 & 8. See Table 8-2.

Fault code “SLP-FAIL”. 1. Coated electrode. 1. Clean or replace electrode.

2. Improper buffer calibration. 2. Recheck buffer accuracies.

Change slope value (SLP) to 59.1

3. Defective electrode. 3. Replace electrode.

4. Plugged liquid junction. 4. Replace liquid junction.

Fault code “rngE-LOOP”. 1. Process value is outside. 1. Return process to normal.

4-20 mA range points. Check grab sample.

Fault code “FAIL”. 1. Input signals are invalid. 1. Toggle Power

2. Calculation is invalid. 2. Change slope value (SLP) to 59.1

3. Defective PCB stack. 3. Perform a complete bench check

to try to clear the error.

No output current. 1. Defective PCB stack. 1. Replace PCB stack.

2. Miswire. 2. Check for short.

Low output current. 1. Circuit loading with excessive 1. Consult output loading limits

resistance on output .

2081 pH specifications (1840 ohms

max load).

“inPt” in display submenu reads 1. Junction poisoning. 1. Replace junction or sensor.

increasingly greater or less than

0 mV at 7.00 pH.

Fault code “LOOP” flashing 1. Model 268 or other host has 1. Model 268 or other host can

intermittently with pH and set the output to a specific value. return transmitter to normal

output value. operation.

Fault code “SnSr - FAIL 1. mV input exceeds ±675mV or 1. Check wiring; toggle power.

RTD resistance is over 600 . 2. Perform a complete bench check.

2. A-D failure 3. Replace PCB stack.

TABLE 8-5. Troubleshooting Guide

MODEL 2081 pH SECTION 8.0

DIAGNOSTICS AND TROUBLESHOOTING

Page 29

25

FIGURE 8-1

Bench Check (With Preamplifier)

FIGURE 8-2

Bench Check (Without Preamplifier)

12 11 10 9 8 7 6 5 4 3 2 1

4 3 2 1

TB2

Pin connection on

10 to check thru

the Preamp

mA

Power

Supply

RTD Decade

Box or Resistor

– Loop

+ Loop

TEST

+

COMM

+

Millivolt Source

+

+

Jmpr

12 11 10 9 8 7 6 5 4 3 2 1

4 3 2 1

TB2

Pin connection

on 11 to bypass

the Preamp

Pin connection

on 2 to check without

Preamp

mA

Power

Supply

RTD Decade

Box or Resistor

– Loop

+ Loop

TEST

+

COMM

+

Voltage Source

+

+

Jmpr

■■

■■

* JP1 installed.

NOTE: Using millivolts for this test will result

in a “SnSr-FAIL” fault code. See Table 8-4 for

valid voltage inputs.

■■

■■

* JP1 is removed.

MODEL 2081 pH SECTION 8.0

DIAGNOSTICS AND TROUBLESHOOTING

Page 30

26

SECTION 9.0 DESCRIPTION AND SPECIFICATIONS

•

FIELD MOUNTED TRANSMITTER ideal for central data processing and control.

• MEMBER OF THE ROSEMOUNT SMART FAMILY

®

• LOCAL, PUSH-BUTTON INTERFACE for convenient calibration and range adjustment.

• HAZARDOUS AREA INSTALLATION certified NEMA 7B explosion-proof.

• NEMA 4X (IP65) WEATHERPROOF, CORROSION-RESISTANT ENCLOSURE.

• CONTINUOUS DIAGNOSTICS drive the output to a jumper-selectable high or low value in

the event of a failure.

9.1 FEATURES.

The Model 2081 pH Smart Transmitter, with the

appropriate sensor, is designed to continuously

measure pH in industrial and municipal processes.

This two-wire transmitter is a member of the

Rosemount SMART FAMILY of instruments, which

are designed to communicate with the hand-held

Model 275 SMART FAMILY Interface and any other

hosts that support the HART communications protocol. The Model 2081 design permits remote configuration, interrogation, testing, and diagnostics.

The Model 2081 pH features an easy-to-use, dual

push-button interface on the transmitter housing for

local calibration and range adjustment. The standard

LCD display menu indicates the pH value as well as

temperature, current output value, range values,

electrode slope, and fault messages. All functions

are microprocessor based, using no switches or

potentiometers.

The isolated 4-20 mA output is continuously

expandable over the measurement range, and may

be displayed in either milliamps or percent of full

scale. A hold output function is available for manual

control during routine sensor maintenance. While in

hold mode the current output signal will remain constant at the last current value.

In the event of a failure, the transmitter diagnostic

routine will drive the output below 4 mA or above 20

mA in addition to displaying a fault code on the transmitter.

With a two-point buffer calibration, the transmitter

automatically calculates the electrode slope and

memorizes the buffer values. On-line standardization is easily accomplished by simply entering the

pH value of a grab sample into the transmitter. The

transmitter uses an RTD signal from the sensor to

automatically compensate the pH reading for process

temperature fluctuations.

The Model 2081 pH transmitter is designed to be

weatherproof and corrosion resistant to meet NEMA

4X (IP65) standards. An optional pipe or wall mounting bracket is available. The transmitter is certified

NEMA 7B explosion-proof by Factory Mutual.

The Rosemount logo, HART and SMART Family are registered trademarks of

Rosemount Inc.

MODEL 2081 pH SECTION 9.0

DESCRIPTION AND SPECIFICATIONS

Page 31

27

MODEL 2081 pH SECTION 9.0

DESCRIPTION AND SPECIFICATIONS

9.3 PERFORMANCE SPECIFICATIONS

(Transmitter only)

Range: 0 to 14 pH

Output Scale: Zero Suppression: Up to 13 pH units

Span: From 1 to 14 pH units

Accuracy: ± 0.02 pH, 0.1°C

Resolution: 0.01 pH, 0.1°C

Repeatability: ± 0.01 pH

Stability: 1%/ year at 25°C

Temperature Effect: 0.02% F.S./°C

Vibration Effect: ± 1.0% of F.S. per SAMA PMC

31.1, Section 5.3, Condition 2.

EMI/RFI:

EN50081-1

EN50082-2

9.4 PHYSICAL SPECIFICATIONS

Electrical Connections: 1/2 in. NPT.

Model 275 SMART FAMILY Interface

connections permanently fixed to terminal block.

The terminal block also has removable

connectors for bare wire sensor connections.

Housing: Epoxy-polyester painted over low-copper

aluminum. BUNA-N O-rings on cover.

Recommended Cable: Transmitter to power supply

two-wire, 18 AWG, shielded, Belden 8760 or

equal (Rosemount Analytical PN 9200001).

Weight/Shipping Weight: 2.18 kg/2.68 kg (4.8 lb/5.9 lb)

9.2 FUNCTIONAL SPECIFICATIONS

Inputs: mV (for pH); resistance (for temperature)

Output: Two-wire 4-20 mA with superimposed HART

digital signal.

Power Supply and Load Requirements: See graph

below. A minimum loop resistance (load) of 250

ohms and minimum power supply voltage of 18

volts DC is required for digital communication.

Local Indication: Four digit LCD

Ambient Temperature: –30 to 70°C (–22 to 158°F)

Failure Mode Alarm: The analog signal will be driven

either below 4 mA or above 20 mA (userselectable) to alert the user.

Transmitter Security: Security activation (by internal

jumper) prevents changes to the transmitter

configuration from the local interface.

Relative Humidity : 0-95%

Automatic Temperature Compensation: Pt100 RTD

–15 to 115°C (5 to 239°F)

Enclosure: NEMA 4X (IP65) , weatherproof and

corrosion-resistant NEMA 7B, explosion proof

Hazardous Area Classification:

Explosion Proof:

FM: Class I, Div. 1, Groups B, C & D

Class II, Div. 1, Groups E, F, & G

Class III, Div. 1

CSA: Class I, Div. 1, Groups C& D

Class I, Div. 2, Groups A, B, C & D

Class II, Div. 2, Groups E, F & G

Class III, Div. 1

Intrinsic Safety:

FM: Class I, II & III, Div. 1

T4 T AMB= 40°C; T3AT AMB= 70°C

CSA: Class I, Div. 1

T 3C T AMB=40°C; T3 T AMB=80°C

CENELEC: EEx ia IIC

T5 Tamb=40°C T4 Tamb=80°C

Non-Incendive:

FM: Class I, Div. 2, Groups A, B, C & D

CSA: Class I, Div. 2, Groups A, B, C & D T5

(Tamb=40°C)

LOAD/POWER SUPPLY REQUIRE-

MENTS

12 VDC 18 VDC 42.4 VDC @ ZERO LOAD

LIFT OFF 42.4 VDC MAXIMUM

POWER SUPPLY VOLTAGE

1848–

1800–

1500–

1000–

500 –

250 –

0

–

Load (ohms)

WITHOUT HART COMMUNICATION

OPERATING

REGION

Page 32

28

MODEL 2081 pH SECTION 9.0

DESCRIPTION AND SPECIFICATIONS

9.5 RECOMMENDED pH SENSORS:

Model 300 Retractable

Model 320B Flow-Through

Model 320HP High Purity Flow-Through

Model 328A Steam Sterilizable

Model 370, 371, & 371VP Eurosenz

Model 381 Insertion/Submersion/Flow-Through

Model 385 Retractable

Model 389 Disposable

Models TUpH 396/396P Disposable, 396R Retractable

Model 397 Quik-Loc

Models TUpH 398 Insertion/Submersion, 398R Retractable

Model 399 Disposable

Model GP1 Disposable

PREAMP LOCA TION: A preamplifier is used to convert the high impedance pH glass electrode signal to

a low impedance signal.The pH signal may then be

reliably transmitted from the sensor to the transmitter

using standard shielded 4-wire instrument cable.The

preamplifier may be located in one of three areas: in

the pH sensor for best performance, in a remote

junction box when process temperatures exceed

80°C (176°F) in submersion applications, or in the

transmitter when the distance between the pH sensor and the transmitter is 15 ft (4.6 m) or less. The

2081 pH transmitter contains a jumper selectable

preamp that allows operation in any of these 3

modes.

9.6 ORDERING INFORMATION

Model 2081 pH Two-Wire Transmitter is housed in a NEMA 4X (IP65) weatherproof, corrosion-resistant enclo-

sure suitable for pipe mounting.Standard features include LCD digital display, automatic temperature compensation, and isolated 4-20 mA output with HART digital communications capability. External DC loop power is required

from a distributed control system or Model 515 isolated power supply. Remote alarms with independently

adjustable setpoints are available with the Model 230A Alarm Module.

Code Options (Order PN’s as separate line items)

07 Order as PN 2002577 2 in. pipe/wall mounting bracket (1lb/.5kg)

11 Order as PN 9240864 Stainless steel Tag (specify marking)

Code Agency Approvals

67 FM approved, Intrinsically Safe (when used with approved sensor and safety barrier), and

explosion-proof

69 CSA approved, Intrinsically Safe (when used with approved sensor and safety barrier), and

explosion-proof

73 CENELEC instrinsically Safe (Safety barrier required)

MODEL

2081 pH TWO-WIRE TRANSMITTER

Former Options

2081 pH 67 EXAMPLE

Page 33

29

PN DESCRIPTION

RECOMMENDED SPARES

23419-00 PCB, 2081 LCD Display (Requires pH overlay P/N 9240008-00) 1

23420-01 PCB, 2081 Interface

23421-04 PCB Electronics Stack with LCD Display (factory calibrated) 1

23519-00 Push Buttons, 2081, Kit 1

33197-00 Enclosure, Middle

23701-00 Enclosure Cover, LCD Display Side

2002577 Pipe Mounting Bracket

2002604 O-ring Kit (Qty. 2), Enclosure 2

3002468 Enclosure Cover, Tall

9200001 Cable, 2 Conductor, 18 AWG, Shielded

9240008-00 Overlay, 2081pH LCD Display 1

9.7 MODEL 2081 PH REPLACEMENT PARTS AND ACCESSORIES

* NOTE: The PCB Stack comes factory calibrated for the highest possible accuracy. No field calibration is required.

MODEL 2081 pH SECTION 9.0

DESCRIPTION AND SPECIFICATIONS

HART COMMUNICATION

MODEL 275 HART COMMUNICATOR: This hand-held

interface provides a common communication link to all

HART SMART, microprocessor-based instruments and

allows access to AMS (Asset Management Solutions).

Digital communication may be used to set up and control

the field device, and read the measured variable over the

communication link. Without modification, these instruments are ready for fully-digital system use.

ON-LINE MENU: When connected, pressing the On key

will display the On-line menu. From the On-line menu, all

setup parameters are accessible.

4/20 mA + Digital

250

ohm

Control System

Computer

Model 2081

SMART

Transmitter

Bridge

HART COMMUNICATOR

Hand Held

Communicator

(“Configurator”)

Page 34

30

SECTION 10.0 RETURN OF MATERIAL

10.1 GENERAL.

To expedite the repair and return of instruments, proper

communication between the customer and the factory

is important. Call 1-949-863-1181 for a Return

Materials Authorization (RMA) number.

10.2 WARRANTY REPAIR.

The following is the procedure for returning instruments still under warranty:

1. Call Rosemount Analytical for authorization.

2. To verify warranty, supply the factory sales order

number or the original purchase order number. In

the case of individual parts or sub-assemblies,

the serial number on the unit must be supplied.

3. Carefully package the materials and enclose your

“Letter of Transmittal” (see Warranty). If possible,

pack the materials in the same manner as they

were received.

4. Send the package prepaid to:

Rosemount Analytical Inc., Uniloc Division

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606

Attn: Factory Repair

RMA No. ____________

Mark the package: Returned for Repair

Model No. ____

10.3 NON-WARRANTY REPAIR.

The following is the procedure for returning for repair

instruments that are no longer under warranty:

1. Call Rosemount Analytical for authorization.

2. Supply the purchase order number, and make

sure to provide the name and telephone number

of the individual to be contacted should additional information be needed.

3. Do Steps 3 and 4 of Section 10.2.

NOTE

Consult the factory for additional information regarding service or repair.

MODEL 2081 pH SECTION 10.0

RETURN OF MATERIAL

Page 35

U.S. Field Service

Field Watch Response Center

1-800-654-7768

International

CANADA

Rosemount Instruments Ltd.

1-800-268-1151

AUSTRALIA

Melbourne

Fisher-Rosemount

AUSTRIA

Vienna

Fisher-Rosemount

BELGIUM

Brussels

Fisher-Rosemount

BRAZIL

Sao Paulo

Fisher-Rosemount

de Brasil

DENMARK

Copenhagen

Fisher-Rosemount

FRANCE

Paris

Fisher-Rosemount

GERMANY

Munich

Fisher-Rosemount

HONG KONG

Hong Kong

Fisher-Rosemount

INDIA

Bombay

Fisher-Rosemount

ITALY

Muggio (Milano)

Fisher-Rosemount

JAPAN

Tokyo

Fisher-Rosemount Japan Co. Ltd.

LATIN AMERICA

Regional Office

Eden Prairie, Minnesota

MALAYSIA

Kuala Lumpur

Rosemount Instruments

MEXICO

Mexico City

Fisher-Rosemount

NETHERLANDS

Schiedam

Veenendaal

Fisher-Rosemount B.V.

NEW ZEALAND

Auckland

Fisher-Rosemount

NORWAY

Porsgrunn

Fisher-Rosemount

PEOPLE'S REPUBLIC OF CHINA

Shanghai

Shanghai Rosemount,

Company LTD

PUERTO RICO

San Juan

Fisher-Rosemount

REPUBLIC OF KOREA

Seoul

Fisher-Rosemount

SINGAPORE

Singapore

Fisher-Rosemount

SPAIN

Madrid

Fisher-Rosemount

SWEDEN

Karlstad

Fisher-Rosemount

SWITZERLAND

Baar-Walterswil

Fisher-Rosemount

UNITED ARAB EMIRATES

Dubai

Fisher-Rosemount

UNITED KINGDOM

Bognor Regis

Fisher-Rosemount

˜

A Worldwide Network of Sales and Service

The Rosemount customer sales and service organization comprises a network of fully equipped support centers strategically located throughout the world. From many of these locations, the Rosemount Group provides support, distribution of

finished products, repair facilities, and training for our customers.

Immediate, Reliable Analytical Support

Now there’s a way to quickly get the right answers for your liquid analytical instrumen-

tation questions: the Analytical Customer Support Center.

Our staff of trained professionals are ready to provide the information you need. If you

are placing an order, verifying delivery, requesting application information, or just want

to contact a Rosemount Analytical representative, a toll-free call to 1-800-854-8257 will

provide you with the right people, the right answers, right now.

The right people, the right answers, right now.

Credit Cards for U.S. Purchases Only.

Rosemount Analytical Inc.

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 863-1181

1-800-854-8257

www.RAuniloc.com

© Rosemount Analytical Inc. 1999

Page 36

FOLD ALONG DOTTED LINES

Page 37

DOUBLE WARRANTY REGISTRATION

Date of Purchase (of instrument) __________________________ Your Name _______________________________________

Company Name _______________________________________ Title ____________________________________________

Address _____________________________________________ Phone Number ___________________________________

City ________________________________________________ E-Mail Address ____________________________________

State/Country ___________________ Zip __________________ Fax Number ______________________________________

Mail Drop __________________________________________________________________________________________________

Model number of instrument (e.g., 3081pH) _______________________________________________________________________

*Serial number (located on nameplate) ________________________________________________________________________

How many liquid analyzers are purchased at this site per year? (check one)

1 to 5 6 to 10 10 to 20 20 or more

What are your principal applications? ____________________________________________________________________________

___________________________________________________________________________________________________________

Through which of the following means do you prefer receiving product updates and application news? (check one)

sales representative

mail

fax (my fax number is ____________________)

E-mail (my e-mail address is ____________________)

phone

CUSTOMER SATISFACTION SURVEY

Please let us know how satisfied you are with your new instrument.

MODEL ______________________________

How easy was it to do the following: Very Easy Somewhat Not Very Not At All

Easy Easy Easy

Unpack 1234

Wire 1234

Mount 1234

Calibrate 1234

Program 1234

Operate 1234

How satisfied were you with the following: Very Somewhat Not Very Not At All

Satisfied Satisfied Satisfied Satisfied

The instrument manual 1234

The instrument’s performance 1234

Please explain any 3’s and 4’s above:

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

Thank you, For Customer Support

Mike Stoessl 24 hours a day/365 days a year,

President, Rosemount Analytical-Uniloc Division Call 1-800-854-8257

Complete this registration, fold it in thirds so the return address shows, and drop it in any mailbox, or visit our website at

www.RAuniloc.com

and register on-line to double your standard warranty from 1 year to 2 years.

*Serial number must be indicated to register for extended warranty.

Warranty applicable only to instrument accompanying this manual.

Page 38

WARRANTY

Goods and part(s) (excluding consumables) manufactured by Seller are warranted to be free from defects in workmanship and material under normal use and service for a period of twelve (12) months from the date of shipment by

Seller. Consumables, pH electrodes, membranes, liquid junctions, electrolyte, O-rings, etc. are warranted to be free from