Page 1

Quick Start Guide

00825-0100-4828, Rev DC

July 2014

Rosemount 1595 Conditioning Orifice

Plate

Page 2

Quick Start Guide

July 2014

NOTICE

This installation guide provides basic guidelines for Rosemount 1595 Conditioning Orifice

Plate. It does not provide instructions for configuration, diagnostics, maintenance, service,

troubleshooting, Explosion-proof, Flame-Proof, or intrinsically safe (I.S.) installations. Refer to

the 1595 reference manual (document number 00809-0100-4828) for more instruction.

This manual is also available electronically on www.rosemount.com.

WARNING

Process leaks may cause harm or result in death.

To avoid process leaks, only use gaskets designed to seal with the corresponding flange and

o-rings to seal process connections.

Contents

Primary element location . . . . . . . . . . . . . 3

Primary element orientation . . . . . . . . . . 4

2

Primary element installation . . . . . . . . . . .6

Product Certifications . . . . . . . . . . . . . . . 10

Page 3

July 2014

Quick Start Guide

Step 1: Primary element location

Install the 1595 in the correct location within the piping branch to prevent

inaccurate measurement caused by flow disturbances.

1

(1)

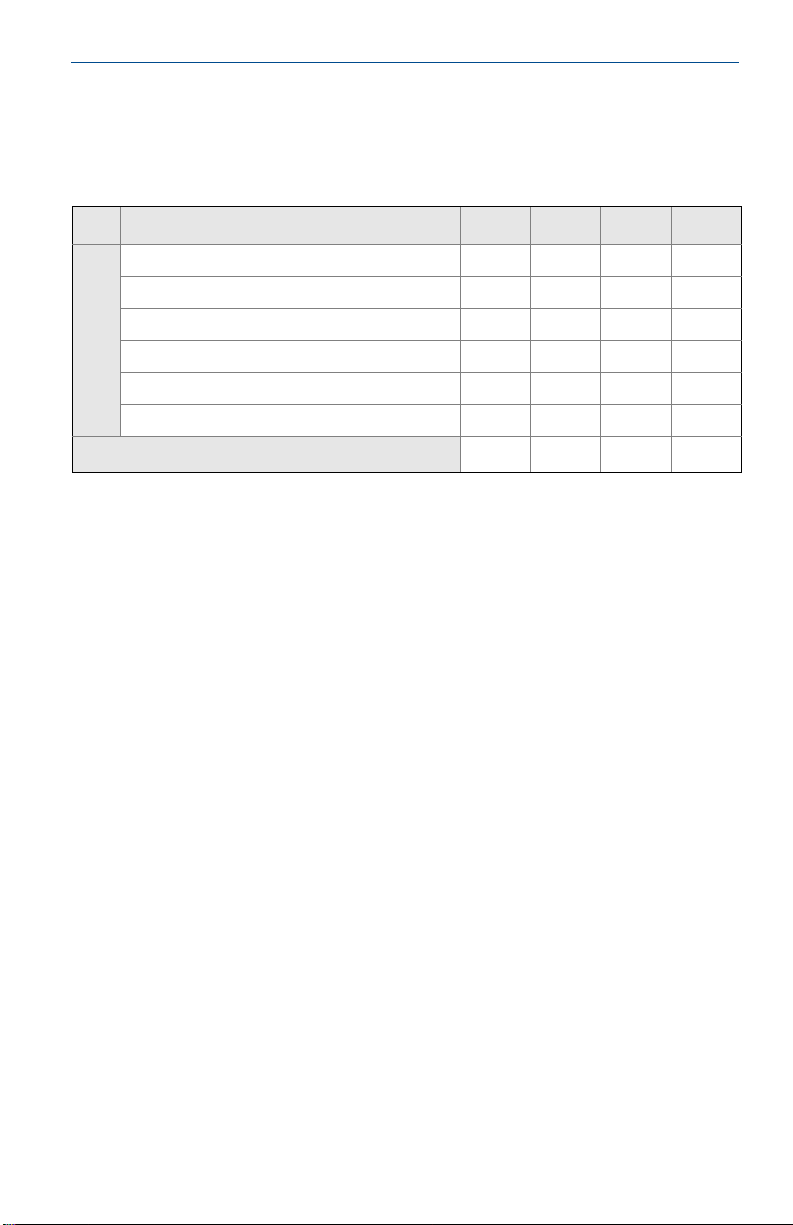

Table 1. 1595 Straight Pipe Requirements

Beta 0.20 0.40 0.50 0.65

Single 90° bend or tee

Two or more 90° bends in the same plane

Two or more 90° bends in different plane

Up to 10° of swirl

side of primary

Upstream (inlet)

Reducer (1 line size)

Butterfly valve (75% to 100% open)

Downstream (outlet) side of primary

1. Consult an Emerson Process Management representative if disturbance is not listed.

2. Not applicable in line sizes greater than 24-in. (600 mm).

(2) 2

(2)

(2)

Pressure tap orientation

Orient the 1595 Conditioning Orifice Plate so the pressure taps are centered

between any two (of four) orifice bore holes. In addition, the pressure taps should

be located at 90° to the plane of the last elbow.

2222

2 2 2 2

2222

2 2 2 2

2222

2 2 5 5

2222

Centering requirements

The 1595 should be installed so that it is centered in the pipe as recommended by

ISO-5167.

3

Page 4

Quick Start Guide

30°

Recommended

Zone 120°

30°

F

l

o

w

F

l

o

w

Step 2: Primary element orientation

The following drawings show paddle style conditioning orifice plate, but

orientation pertains to both paddle and universal plate styles.

Horizontal pipe installation

Figure 1. Gas in Horizontal Pipes

FLOW

Figure 2. Liquid or Steam in Horizontal Pipes

July 2014

4

Page 5

July 2014

Flow

FLOW

Flow

Vertical pipe installation

Figure 3. Gas in Vertical Pipes

FLOW

Figure 4. Liquid or Steam in Vertical Pipes

Quick Start Guide

5

Page 6

Quick Start Guide

July 2014

Step 3: Primary element installation

Use the following steps to install the 1595 Conditioning Orifice Plate (paddle or

universal plate style).

1. Determine location and orientation (see page 4).

2. Install the orifice plate.

a. Depressurize the line using site-specific requirements.

b. Loosen all studs and nuts.

c. Remove the studs in one-half of the flange union.

d. Spread flange union by turning jackscrews clockwise.

e. For line sizes > 24-in (600 mm), refer to Figure 7 and instructions using

alignment tool.

f. Install the new plate or remove the existing plate for replacement or

inspection.

g. Install the new gaskets when installing the plate. It is recommended that

new gaskets be installed each time the orifice flange union is separated.

h. Center the plate in the pipe I.D.

i. Release the flange union by turning the jackscrews counter-clockwise.

j. Replace the studs.

k. Tighten studs in a star pattern.

Note

Standa rd 1/16-in. thick fiber gaskets are recommended for use with the 1595. Using other gaskets

could potentially affect the measurement.

6

Page 7

July 2014

A

I

G

F

E

C

B

A

H

D

D

F

l

o

w

Quick Start Guide

Figure 5. Rosemount 1595P Installation

A. Nuts F. Pipe Section

B. Plug G. Stud

C. Jackscrew H. Gasket

D. Jackscrew Nut I. Transmitter

E. Rosemount 1595

1. The installation drawings applies when using the Rosemount 2051C, Rosemount 3051C, Rosemount 3051S and

Rosemount 3051SMV. See the following documents for quick installation instruction of the transmitters.

Rosemount 2051C: document number 00825-0100-4101

Rosemount 3051C: document number 00825-0100-4001

Rosemount 3051S: document number 00825-0100-4801

Rosemount 3051SMV: document number 00825-0100-4803

1

(1)

7

Page 8

Quick Start Guide

A

G

F

E

A

C

B

D

H

Figure 6. Rosemount 1595U with Plate Holder (PH) Installation

A. Nuts E. Pipe Section

B. Jackscrew F. Stu d

C. Universal Plate Screw G. Transmitter

D. Rosemount 1595

1

(1)

H. Jackscrew Nut

July 2014

1. The installation drawings applies when using the Rosemount 2051C, Rosemount 3051C, Rosemount 3051S and

Rosemount 3051SMV. See the following documents for quick installation instruction of the transmitters.

Rosemount 2051C: document number 00825-0100-4101

Rosemount 3051C: document number 00825-0100-4001

Rosemount 3051S: document number 00825-0100-4801

Rosemount 3051SMV: document number 00825-0100-4803

Note

For 1595U Universal Conditioning Orifice Plate style, refer to manufacturer’s orifice fitting

installation manual for installation details.

For sizes > 24-in. (600 mm) and use with alignment tool

1. When an alignment tool is provided, install the alignment tool on the flange

studs shown in Figure 7.

2. For horizontal installation, use the horizontal lift hole (stamped HLH on

paddle) to lift the conditioning orifice plate from a horizontal position and

guide into location between the flanges.

3. For vertical installation, first use the horizontal lift hole (HLH) to lift the

conditioning orifice plate from a horizontal position to vertical, then use the

vertical lift hole (stamped VLH on paddle) to lift the conditioning orifice plate

vertically and guide into location between the flanges.

8

Page 9

July 2014

A

C

B

A

F

B

C

H

D

G

I

E

DETAIL “A”

D

E

H

DETAIL “A”

Figure 7. Rosemount 1595P (sizes > 24-in (600 mm)) Installation

A. Nuts F. Pipe Section

B. Jackscrew G. Stud

C. Jackscrew Nut H. Gasket

D. Rosemount 1595

E. Alignment Tools

1

(1)

I. Transmitter

Quick Start Guide

1. The installation drawings applies when using the Rosemount 2051C, Rosemount 3051C, Rosemount 3051S and

Rosemount 3051SMV. See the following documents for quick installation instruction of the transmitters.

Rosemount 2051C: document number 00825-0100-4101

Rosemount 3051C: document number 00825-0100-4001

Rosemount 3051S: document number 00825-0100-4801

Rosemount 3051SMV: document number 00825-0100-4803

Note

To ensure the best possible flow measurement accuracy, Rosemount provides an Official DP

Calculation Sheet with every 1595 Conditioning Orifice Plate. The Official DP Calculation sheet

uses the calibration factor which is unique to that device and is also stamped on the orifice plate.

The Official DP Calculation Sheet displays the expected full scale flow value and the calculated full

scale DP value and is corrected for the unique calibration factor which is also displayed on the

sheet. This full scale DP value should be used to range a DP transmitter for the referenced

application. Or, the calibration factor should be used as a correction factor when configuring a flow

computer for the Rosemount Conditioning Orifice Plate.

9

Page 10

Quick Start Guide

Product Certifications

Approved Manufacturing Locations

Rosemount Inc. — Chanhassen, Minnesota USA

European Directive Information

The EC declaration of conformity for all applicable European directives for this product can

be found on the Rosemount website at www.rosemount.com. A hard copy may be obtained

by contacting our local sales office.

European Pressure Equipment Directive (PED) (97/23/EC)

Rosemount 1595 Conditioning Orifice Plate

— Sound Engineering Practice (SEP)

Pressure Transmitter

— See appropriate Pressure Transmitter QIG

Hazardous Locations Certifications

For information regarding the electronics product certification, see the appropriate

transmitter QIG:

Rosemount 3051SF Series Flowmeter Electronics with HART Protocol (document

number 00825-0100-4801)

Rosemount 3095MF Mass Flowmeter Electronics (document number

00825-0100-4716)

July 2014

10

Page 11

July 2014

File ID: DSI C E Marking Page 1 of 3 DSI 1000I-DoC

EC Declaration of Conformity

No: DSI 1000 Rev. I

We,

Emerson Process Management

Heath Place - Bognor Regis

West Sussex PO22 9SH

England

declare under our sole responsibility that the products,

Primary Element Models 405 / 1195 / 1595 & Annubar®

Models 485 / 585

manufactured by,

Rosemount / Dieterich Standard, Inc.

5601 North 71

st

Street

Boulder, CO 80301

USA

to which this declaration relates, is in conformity with the provisions of the European

Community Directives as shown in the attached schedule.

Assumption of conformity is based on the application of the harmonized standards and, when

applicable or required, a European Community notified body certification, as shown in the

attached schedule.

As permitted by 97/23/EC, Annex 7, the authorized signatory for the legally binding declaration of

conformity for Rosemount/Dieterich Standard, Inc. is Vice President of Quality, Timothy J. Layer.

20-Oct-2011

Timothy J. Layer

Vice President, Quality

(signature)

(date of issue)

Quick Start Guide

11

Page 12

Quick Start Guide

File ID: DSI C E Marking Page 2 of 3 DSI 1000I-DoC

Schedule

EC Declaration of Conformity DSI 1000 Rev. I

PED Directive (97/23/EC)

Models: 405 / 485 / 585/ 1195 / 1595

QS Certificate of Assessment – CE-0041-H-RMT-001-10-USA

IV* Flo Tap - 485/3051SFA/3095MFA: Sensor Size 3 600# 60" to 72" Line (Category IV Flo Tap will require a B1

Certificate for design examination and H1 Certificate for special surveillance)

All other models:

Sound Engineering Practice

Summary of Classifications

Model/Range

PED Category

Group 1

Fluid

Group 2

Fluid

585M - 2500# All Lines

N/A

SEP

585S - 1500# & 2500# All Lines

III

SEP

MSL46 - 2500# All Lines

N/A

SEP

MSR: 1500# & 2500# All Lines

III

SEP

1195, 3051SFP, 3095MFP: 150# 1-1/2

I

SEP

1195, 3051SFP, 3095MFP: 300# & 600# 1-1/2

II

I

1195, 3051SFP, 3095MFP: 1-1/2” Threaded & Welded

II

I

DNF - 150# 1-1/4”, 1-1/2” & 2

I

SEP

DNF - 300# 1-1/4”, 1-1/2” & 2

II

I

DNF, DNT, & DNW: 600# 1-1/4”, 1-1/2” & 2”

II

I

Flanged 485/3051SFA/3095MFA: 1500# & 2500# All Lines

II

SEP

FloTap 485/3051SFA/3095MFA: Sensor Size 2 150# 6to 24 Line

I

SEP

FloTap 485/3051SFA/3095MFA: Sensor Size 2 300# 6to 24 Line

II

I

FloTap 485/3051SFA/3095MFA: Sensor Size 2 600# 6to 16 Line

II

I

FloTap 485/3051SFA/3095MFA: Sensor Size 2 600# 18to 24 Line

III

II

FloTap 485/3051SFA/3095MFA: Sensor Size 3 150# 12to 44 Line

II

I

FloTap 485/3051SFA/3095MFA: Sensor Size 3 150# 46to 72 Line

III

II

FloTap 485/3051SFA/3095MFA: Sensor Size 3 300# 12” to 72 Line

III

II

FloTap 485/3051SFA/3095MFA: Sensor Size 3 600# 12to 48 Line

III

II

FloTap 485/3051SFA/3095MFA: Sensor Size 3 600# 60 to 72 Line

IV*

III

July 2014

12

Page 13

File ID: DSI C E Marking Page 3 of 3 DSI 1000I-DoC

Schedule

EC Declaration of Conformity DSI 1000 Rev. I

Pressure Equipment Directive (93/27/EC) Notified Body:

Bureau Veritas UK Limited

[Notified Body Number: 0041]

Parklands, Wilmslow Road, Didsbury

Manchester M20 2RE

United Kingdom

July 2014

Quick Start Guide

13

Page 14

00825-0100-4828,RevDC

Quick Start Guide

00825-0100-4828, Rev DC

July 2014

Emerson Process Management

Rosemou nt Inc.

8200 Market Boulevard

Chanhassen, MN USA 55317

T (US) (800) 999-9307

T (Intnl) (952) 906-8888

F (952) 906-8889

Emerson Process Management

Asia Pacific Priva te Limited

1 Pandan Crescent

Singapore 128461

T (65) 6777 8211

F (65) 6777 0947/65 6777 0743

Emerson Process Management

GmbH & Co. OHG

Argelsrieder Feld 3

82234 Wessling Germany

T 49 (8153) 9390, F49 (8153) 939172

Beijing Rosemount Far East

Instrument Co., Limited

No. 6 North Street, Hepingli,

Dong Cheng Distric t

Beijing 100013, China

T (86) (10) 6428 2233

F (86) (10) 6422 8586

00825-0100-4828, Rev DC, 07/14

Emerson Process Management

Latin America

1300 Concord Terrace, Suite 400

Sunrise Florida 33323 USA

Tel + 1 954 846 5030

www.rosemount.com

© 2014 Rosemount Inc. All rights reserved. All marks property of owner.

The Emerson logo is a trade mark and service mark of Emerson Electric Co

Rosemount and the Rosemount logotype are registered trademarks of Rosemount

Inc.

Loading...

Loading...