Page 1

Reference Manual

00809-0100-4148, Rev CA

Rosemount® 148 Temperature Transmitter

April 2014

Page 2

Page 3

Reference Manual

NOTICE

00809-0100-4148, Rev CA

Rosemount 148 Temperature

Transmitter

Rosemount 148 Hardware Revision 5

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure to thoroughly understand the contents before

installing, using, or maintaining this product.

The United States has two toll-free assistance numbers and one international number:

Customer Central

1-800-999-9307 (7:00 a.m. to 7:00 p.m. CST)

National Response Center

1-800-654-7768 (24 hours a day)

Equipment service needs

International

1-952-906-8888

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified

hardware or products may cause inaccurate readings.

For information on nuclear-qualified products, contact an Emerson Process Management

Sales Representative.

v

Page 4

Reference Manual

00809-0100-4148, Rev CA

vi

Page 5

Reference Manual

00809-0100-4148, Rev CA

1Contents

2Section 1: Introduction

Table of Contents

April 2014

1.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.2 Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.3 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.4 Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Return of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Product Recycling/Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3Section 2: Installation

2.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.1 Typical European and Asia Pacific installation. . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.2 Typical North and South American installation. . . . . . . . . . . . . . . . . . . . . . .11

2.4 Set the switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.4.1 Failure mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.5.1 Sensor connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.6 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.6.1 Surges/transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.6.2 Ground the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4Section 3: Configuration

3.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.2 Rosemount 148 PC Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Tab le of C ontents

3.2.1 PC Programmer software installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.2.2 PC Programmer hardware setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.2.3 Configuring with the Rosemount 148 PC Programmer. . . . . . . . . . . . . . . .21

3.2.4 Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

i

Page 6

Table of Contents

April 2014

Reference Manual

00809-0100-4148, Rev CA

5Section 4: Operation and Maintenance

4.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.1.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.2 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4.2.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4.2.2 Diagnostic messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

AAppendix A: Specifications

A.1 Transmitter specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

A.1.1 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

A.1.2 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

A.1.3 Performance specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

A.2 Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

A.3 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

BAppendix B: Product Certifications

B.1 Approved manufacturing locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

B.2 European directive information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

B.3 Ordinary location certification from FM approvals . . . . . . . . . . . . . . . . . . . . . . . . .37

B.3.1 North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

B.3.2 Europe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

B.3.3 International . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

B.3.4 Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

B.4 Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

ii

Table of Contents

Page 7

Reference Manual

00809-0100-4148, Rev CA

Section 1 Introduction

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Return of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

1.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol . Please refer to the following safety messages before

performing an operation preceded by this symbol.

Section 1: Introduction

April 2014

1.1.1 Warnings

Failure to follow these installation guidelines could result in death or serious injury:

Make sure only qualified personnel perform the installation

Explosions could result in death or serious injury:

Do not remove the connection head cover in explosive atmospheres when the circuit

is live.

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

All connection head covers must be fully engaged to meet explosion-proof

requirements.

Process leaks could result in death or serious injury:

Do not remove the thermowell while in operation.

Install and tighten thermowells and sensors before applying pressure.

Electrical shock could cause death or serious injury:

Use extreme caution when making contact with the leads and terminals.

Introduction

1

Page 8

Section 1: Introduction

April 2014

1.2 Overview

1.2.1 Manual

This manual is designed to assist in the installation, operation, and maintenance of the

Rosemount 148 Temperature Transmitter.

Section 1: Introduction

Transmitter and Manual Overview

Things to consider

How to return the transmitter

Section 2: Installation

How to mount the transmitter

How to install the transmitter

How to set the switches to ensure proper use

How to wire and power up the transmitter

Reference Manual

00809-0100-4148, Rev CA

Section 3: Configuration

Configuring the transmitter

Section 4: Operation and maintenance

Explanation of hardware maintenance

Appendix A: Specifications

Transmitter and sensor specifications

Dimensional drawings

Ordering information

Appendix B: Product Certifications

Product Certifications/Hazardous Locations Certifications

Installation drawings

1.2.2 Transmitter

Features of the Rosemount 148 include:

Accepts inputs from a wide variety of RTD and thermocouple sensors

Electronics that are completely encapsulated in epoxy and enclosed in a plastic

housing, making the transmitter extremely durable and ensuring long-term reliability.

A compact size and many housing options allow mounting flexibility in the field

Model code option that allows it to be assembled to any sensor, thermowell, and

extension accessory

2

Introduction

Page 9

Reference Manual

00809-0100-4148, Rev CA

Refer to the following literature for sensors and thermowells that can be assembled to the

Rosemount 148. They include additional connection heads that may not be available in the

Rosemount 148 model structure.

Temperature Sensors and Accessories (English) Product Data Sheet (Document

Number 00813-0100-2654)

Temperature Sensors and Accessories (Metric) Product Data Sheet (Document Number

00813-0200-2654)

Rosemount Series 1075 and 1099 High-Temperature Thermocouples Product Data

Sheet (Document Number 00813-0400-2654)

1.3 Considerations

1.3.1 General

Electrical temperature sensors such as RTDs and thermocouples produce low-level signals

proportional to the sensed temperature. The Rosemount 148 converts the low-level sensor

signal to a standard 4–20 mA DC signal that is relatively insensitive to lead length and electrical

noise. This current signal is transmitted to the control room via two wires.

Section 1: Introduction

April 2014

1.3.2 Mechanical

Location

Take into account the need for access to the transmitter when choosing an installation location.

Special mounting

Special hardware is available for mounting a Rosemount 148 head mount transmitter to a DIN

rail.

1.3.3 Electrical

Proper electrical installation is necessary to prevent errors due to sensor lead resistance and

electrical noise. For best results, shielded cable should be used in electrically noisy

environments.

Make wiring connections through the cable entry in the side of the connection head. Be sure to

provide adequate clearance for cover removal.

1.3.4 Environmental

The transmitter electronics module is permanently sealed within the housing, resisting

moisture and corrosive damage. Verify that the operating atmosphere of the transmitter is

consistent with the appropriate hazardous locations certifications.

Introduction

3

Page 10

Section 1: Introduction

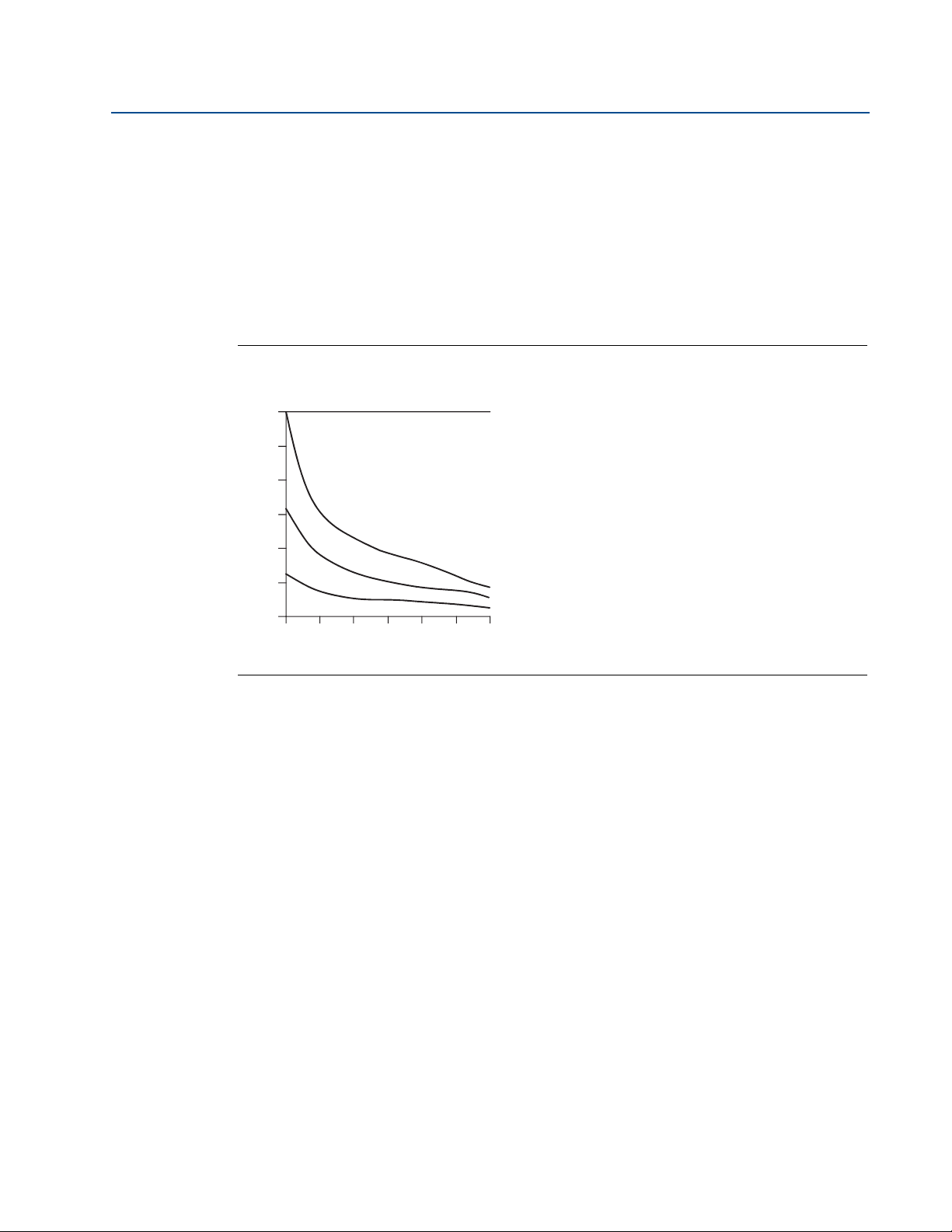

60

50

40

30

20

10

0

75 10 125 150 175 200 225

Temperature Rise Above Ambient (°C)

Extension Length (mm)

8

1

5

°

C

P

r

o

c

e

s

s

T

e

m

p

e

r

a

t

u

r

e

5

4

0

°

C

P

r

o

c

e

s

s

T

e

m

p

e

r

a

t

u

r

e

2

5

0

°

C

P

r

o

c

e

s

s

T

e

m

p

e

r

a

t

u

r

e

April 2014

Temperature effects

The transmitter will operate within specifications for ambient temperatures between -40 °F and

185 °F (-40 °C and 85 °C). Heat from the process is transferred from the thermowell to the

transmitter housing. If the expected process temperature is near or above specification limits,

consider using additional thermowell lagging, and extension nipple, or a remote mounting

configuration to isolate the transmitter from the process.

Figure 1-1 provides an example of the relationship between transmitter housing temperature

rise and extension length.

Figure 1-1. Rosemount 148 transmitter connection head temperature rise vs. Extension

Reference Manual

00809-0100-4148, Rev CA

length.

4

Example

The transmitter specification limit is 85 °C. If the ambient temperature is 55 °C and the process

temperature to be measured is 800 °C, the maximum permissible connection head temperature

rise is the transmitter specification limit minus the ambient temperature (moves 85 °C to 55 °C),

or 30 °C.

In this case, an extension of 100 mm meets this requirement, but 125 mm provides a margin of

8 °C, thereby reducing any temperature effects in the transmitter.

Introduction

Page 11

Reference Manual

00809-0100-4148, Rev CA

1.4 Return of materials

To expedite the return process in North America, call the Emerson Process Management

National Response Center toll-free at 800-654-7768. This center, available 24 hours a day, can

assist with any needed information or materials.

The center will ask for the following information:

Product model

Serial numbers

The last process material to which the product was exposed

The center will provide:

A Return Material Authorization (RMA) number

Instructions and procedures that are necessary to return goods that were exposed to

hazardous substances

Note

If a hazardous substance is identified, a Material Safety Data Sheet (MSDS), required by law to be

available to people exposed to specific hazardous substances, must be included with the

returned materials.

Section 1: Introduction

April 2014

Outside of North America, contact a local Emerson Process Management representative.

1.5 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in

accordance with local and national legislation/regulations.

Introduction

5

Page 12

Section 1: Introduction

April 2014

Reference Manual

00809-0100-4148, Rev CA

6

Introduction

Page 13

Reference Manual

00809-0100-4148, Rev CA

Section 2 Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Set the switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

2.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol . Please refer to the following safety messages before

performing an operation preceded by this symbol.

Section 2: Installation

April 2014

2.1.1 Warnings

Failure to follow these installation guidelines could result in death or serious injury:

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury:

Do not remove the connection head cover in explosive atmospheres when the circuit

is live.

Before connecting a communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

All connection head covers must be fully engaged to meet explosion-proof

requirements.

Process leaks could result in death or serious injury:

Do not remove the thermowell while in operation.

Install and tighten thermowells and sensors before applying pressure.

Electrical shock could cause death or serious injury:

Use extreme caution when making contact with the leads and terminals.

Installation

7

Page 14

Section 2: Installation

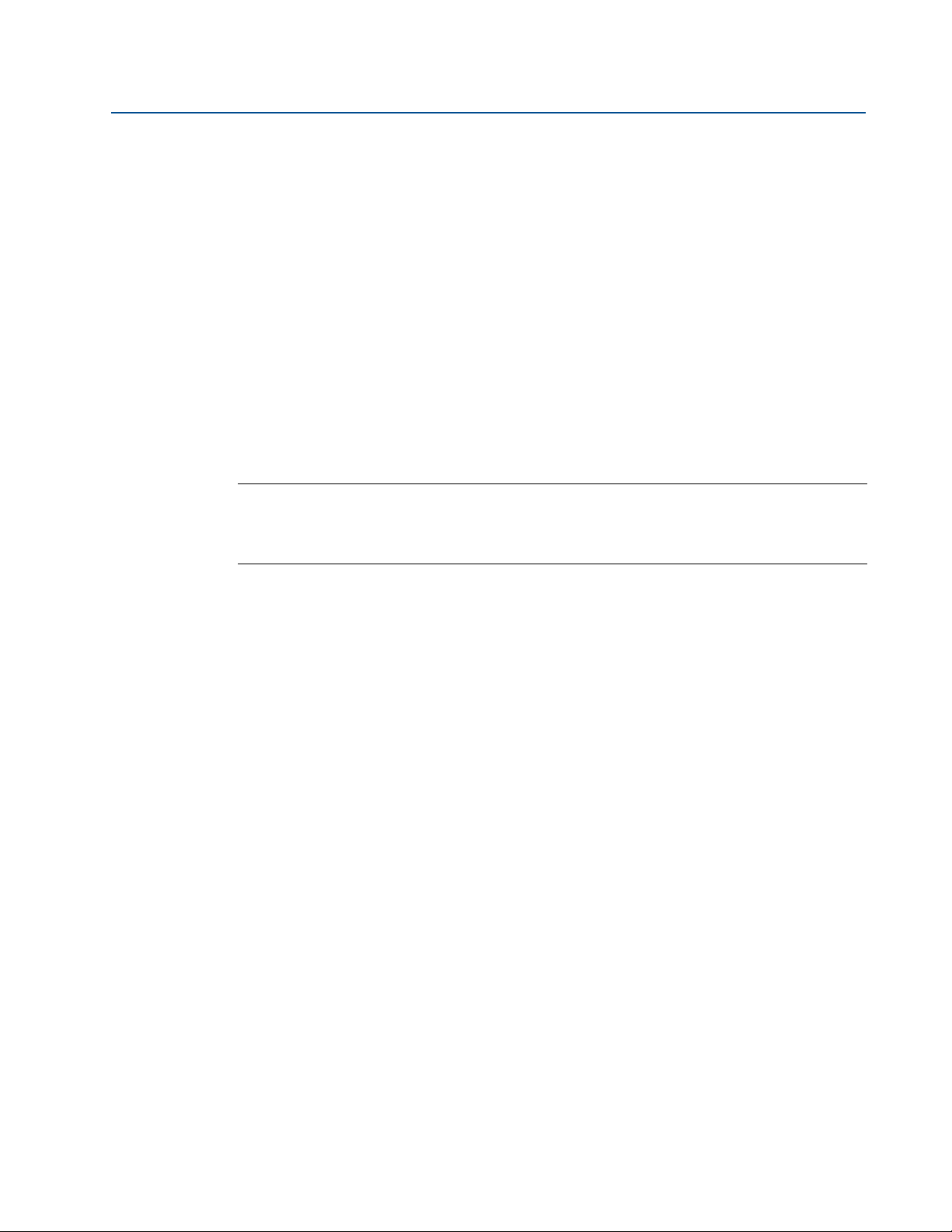

START

HERE

Bench

Configuration?

BASIC SETUP

Set Sensor Type

Set Number of Wires

Set Units

Set Range Values

Set Damping

VERIFY

Simulate Sensor

Input (Optional)

Within

Specifications?

Refer to

Section 4: Operation

and maintenance

FIELD INSTALL

Mount Transmitter

Wire

Tra ns mit te r

Power

Tra ns mit te r

FINISHED

April 2014

Figure 2-1. Installation flowchart

Reference Manual

00809-0100-4148, Rev CA

2.2 Mounting

Mount the transmitter at a high point in the conduit run to prevent moisture from draining into

the transmitter housing.

The Rosemount 148 installs:

In a connection head or universal head mounted directly on a sensor assembly

Apart from a sensor assembly using a universal head

To a DIN rail using an optional mounting clip

8

Installation

Page 15

Reference Manual

Tra ns mit te r

Mounting

Hardware

Rail Clip

00809-0100-4148, Rev CA

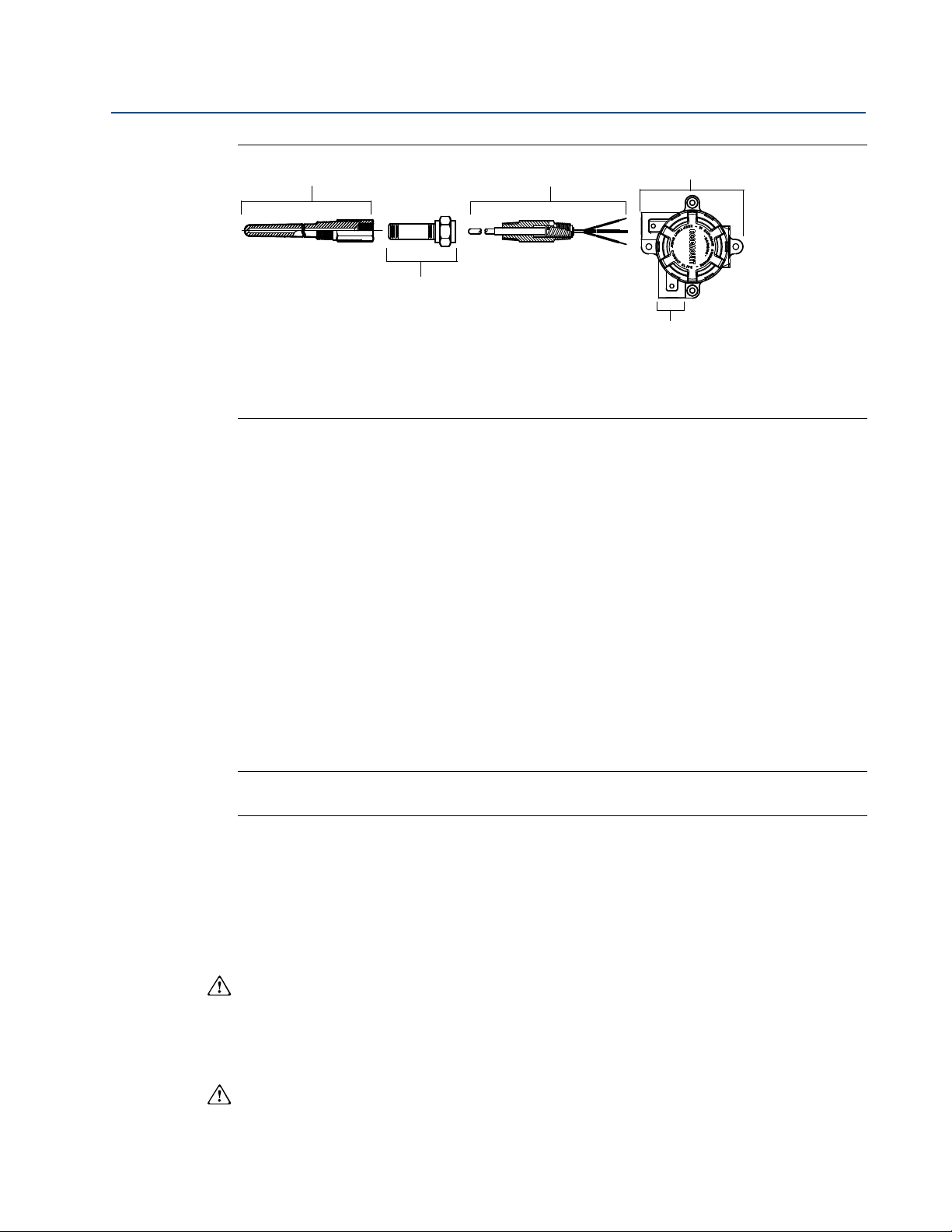

Mounting a Rosemount 148 to a DIN Rail

To attach a head mount transmitter to a DIN rail, assemble the appropriate rail mounting kit

(Part Number 00248-1601-0001) to the transmitter as shown in

Figure 2-2. Assembling rail clip hardware to a Rosemount 148.

2.3 Installation

Section 2: Installation

April 2014

Figure 2-2.

The Rosemount 148 can be ordered assembled to a sensor with the XA option code and

thermowell or as a stand-alone unit. If ordered without the sensor assembly, use the following

guidelines when installing the transmitter with an integral sensor assembly.

2.3.1 Typical European and Asia Pacific installation

Transmitter with DIN plate style sensor

1. Attach the thermowell to the pipe or process container wall. Install and tighten the

thermowell before applying process pressure.

2. Assemble the transmitter to the sensor. Push the transmitter mounting screws through

the sensor mounting plate and insert the snap rings (optional) into the transmitter

mounting screw groove.

3. Wire the sensor to the transmitter (see

4. Insert the transmitter-sensor assembly into the connection head. Thread the

transmitter mounting screw into the connection head mounting holes. Assemble the

extension to the connection head. Insert the assembly into the thermowell.

5. Slip the shielded cable through the cable gland.

6. Attach a cable gland into the shielded cable.

Figure 2-6 on page 13).

Installation

7. Insert the shielded cable leads into the connection head through the cable entry.

Connect and tighten the cable gland.

8. Connect the shielded power cable leads to the transmitter power terminals. Avoid

contact with sensor leads and sensor connections. (See

page 15

9. Install and tighten the connection head cover. Enclosure covers must be fully engaged

to meet explosion-proof requirements.

for instructions on grounding the shield wire.)

“Ground the transmitter” on

9

Page 16

Section 2: Installation

A

D

B

C

E

F

April 2014

Figure 2-3. Typical European and Asia Pacific installation

A . Rosemount 148 Transmitter

B . Connection Head

C . Thermowell

D . Transmitter Mounting Screws

E . Integral Mount Sensor with Flying Leads

F . Extension

2.3.2 Typical North and South American installation

Reference Manual

00809-0100-4148, Rev CA

Transmitter with threaded sensor

1. Attach the thermowell to the pipe or process container wall. Install and tighten

thermowells before applying process pressure.

2. Attach necessary extension nipples and adapters to the thermowell. Seal the nipple and

adapter threads with silicone tape.

3. Turn the sensor into the thermowell until it is secure. Install drain seals if required for

severe environments or to satisfy code requirements.

4. Pull the sensor wiring leads through the universal head and transmitter. Mount the

transmitter in the universal head by threading the transmitter mounting screws into

the universal head mounting holes.

5. Mount the transmitter-sensor assembly into the thermowell. Seal adapter threads with

silicon tape.

6. Install conduit for field wiring to the conduit entry of the universal head. Seal conduit

threads with silicon tape.

7. Pull the field wiring leads through the conduit into the universal head. Attach the sensor

and power leads to the transmitter. Avoid contact with other terminals.

8. Install and tighten the universal head cover. Enclosure covers must be fully engaged to

meet explosion-proof requirements.

10

Installation

Page 17

Reference Manual

A

B

C

D

E

00809-0100-4148, Rev CA

Figure 2-4. Typical North and South American installation

A . Threaded Thermowell

B . Threaded Style Sensor

C . Standard Extension

D . Universal Head

E . Conduit Entry

2.4 Set the switches

Section 2: Installation

April 2014

2.4.1 Failure mode

As part of normal operation, each transmitter continuously monitors its own performance. This

automatic diagnostics routine is a timed series of checks repeated continuously. If diagnostics

detect an input sensor failure or a failure in the transmitter electronics, the transmitter drives its

output to low or high alarm depending on the failure mode configuration. If the sensor (process)

temperature value is out of range, the transmitter outputs default saturation values. Low end

saturation levels are either 3.90 or 3.80 mA and the high end saturation level is 20.5 mA.

Corresponding NAMUR compliant operation levels are 3.80 and 20.5 mA. These values are also

custom configurable by the factory or using the Rosemount 148 PC Programmer interface. See

“

Section 3: Configuration” on page 19 for instructions on how to change the alarm and saturation

levels with the 148 PC Programmer.

Note

Microprocessor failures cause high alarm regardless of alarm direction (high or low) choice.

The values to which the transmitter drives its output in failure mode depend on whether it is

configured to standard, NAMUR-compliant, or custom operations. See (

NAMUR-compliant operation parameters.

2.5 Wiring

All power to the transmitter is supplied over the signal wiring. Use ordinary copper wire of

sufficient size to ensure that the voltage across the transmitter power terminals does not drop

below 12.0 V DC. Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications. Use extreme caution when making contact with

the leads and terminals.

★) for standard and

Installation

If the sensor is installed in a high-voltage environment and a fault condition or installation error

occurs, the sensor leads and transmitter terminals could carry lethal voltages. Use extreme

caution when making contact with the leads and terminals.

11

Page 18

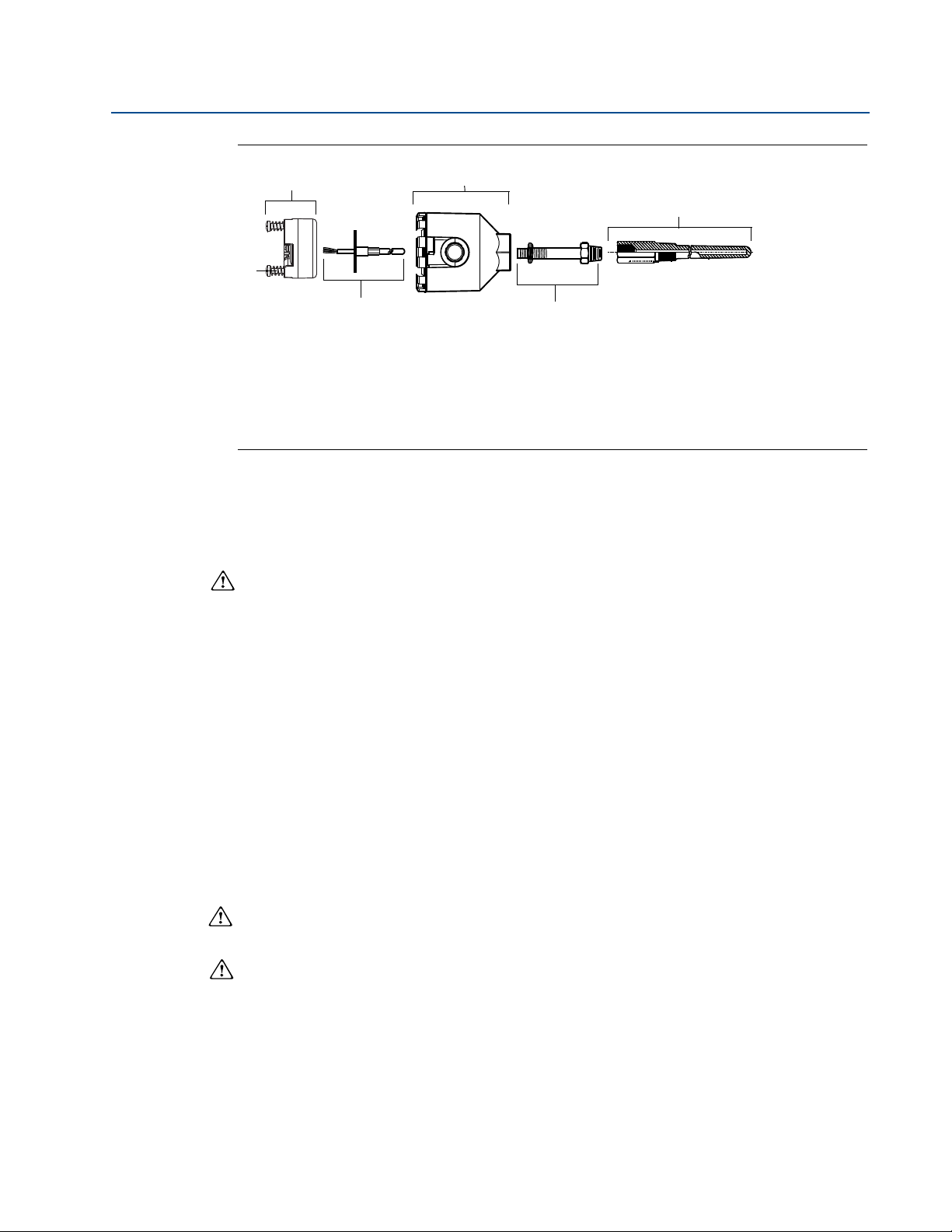

Section 2: Installation

44.0 (1.7)

33 (1.3)

12.9 (0.51)

24.5 (0.97)

Sensor Terminals

Power/Communication

Ter mi na ls

April 2014

Note

Do not apply high voltage (e.g., AC line voltage) to the transmitter terminals, since abnormally

high voltage can damage the unit. Sensor and transmitter power terminals are rated to 42.4 V

DC). Use extreme caution w hen making contact with the leads and terminals.

The transmitters will accept inputs from a variety of RTD and thermocouple types. Refer to

Figure 2-6 on page 13 when making sensor connections.

Use the following steps to wire the transmitter:

1. Remove the terminal block cover, if applicable.

2. Connect the positive power lead to the “+” terminal. Connect the negative power lead

3. Tighten the terminal screws.

4. Reattach and tighten the cover, if applicable. All connection head covers must be fully

to the “-” terminal. See

Figure 2-5 on page 12. Use extreme caution when making contact

with the leads and terminals.

engaged to met explosion-proof requirements.

Reference Manual

00809-0100-4148, Rev CA

5. Apply power (see “Power supply”)

Figure 2-5. Rosemount 148 Wiring

Power, Communication and Sensors Terminals

Note: Signal loop may be grounded at any single point or left ungrounded.

2.5.1 Sensor connections

The Rosemount 148 is compatible with a number of RTD and thermocouple sensor types.

Figure 2-6 shows the correct input connections to the sensor terminals on the transmitter. To

ensure a proper sensor connection, anchor the sensor lead wires into the appropriate

compression terminals and tighten the screws. Use extreme caution when making contact with

the leads and terminals.

12

Installation

Page 19

Reference Manual

1234234 12 34 1234

1

2-wire

RTD and ⍀

3-wire*

RTD

and ⍀

T/C

4-wire RTD

and ⍀

00809-0100-4148, Rev CA

Figure 2-6. Sensor wiring diagrams

Thermocouple

The thermocouple can be connected directly to the transmitter. Use appropriate thermocouple

extension wire if mounting the transmitter remotely from the sensor.

Section 2: Installation

Rosemount 148 Sensor Connections Diagram

* Emerson Process Management provides 4-wire sensors for all single element RTDs. Use these RTDs in 3-wire

configurations by leaving the unneeded leads disconnected and insulated with electrical tape.

April 2014

RTD or ohm inputs

The Rosemount 148 will accept a variety of RTD configurations, including 2-wire, 3-wire, and

4-wire designs. If the transmitter is mounted remotely from a 3-wire or 4-wire RTD, it will

operate within specifications, without recalibration, for lead wire resistances of up to 60 ohms

per lead (equivalent to 6,000 feet of 20 AWG wire). In this case, the leads between the RTD and

transmitter should be shielded. If using only two leads, both RTD leads are in series with the

sensor element, so significant errors can occur if the lead lengths exceed three feet of 20 AWG

wire (approximately 0.05 °C/ft). For longer runs, attach a third of fourth lead as described above.

Sensor lead wire resistance effect - RTD input

When using a 4-wire RTD, the effect of lead resistance is eliminated and has no impact on

accuracy. However, a 3-wire sensor will not fully cancel lead resistance error because it cannot

compensate for imbalances in resistance between the lead wires. Using the same type of wire

on all three lead wires will make a 3-wire RTD installation as accurate as possible. A 2-wire sensor

will produce the largest error because it directly adds the lead wire resistance to the sensor

resistance. For 2- and 3-wire RTDs, an additional lead wire resistance error is induced with

ambient temperature variations. The table and the examples shown below help quantify these

errors.

Table 2-1. Examples of approximate basic error.

Sensor input Approximate basic error

Installation

4-wire RTD None (independent of lead wire resistance)

3-wire RTD

2-wire RTD 1.0 in reading per ohm of lead wire resistance

± 1.0 in reading per ohm of unbalanced lead wire resistance

(Unbalanced lead wire resistance = maximum imbalance

between any two leads.)

13

Page 20

Section 2: Installation

Basic Error

Imbalance of Lead Wires

PtRo

------------------------------------------------------------ ----- -

=

Error due to amb. temp. variation

Cu

T

amb

Imbalance of Lead Wires

Pt

Ro

---------------------------------------------------------------- ---------------------------------------------------------

=

Basic error

0.5

0.00385 / C100

----------------------------------------------------------- ---------------------- -

1.3 C==

Error due to amb. temp. var. of 25 °C

0.0039 / C25 C 0.5

0.00385 / C100

----------------------------------------------------------- --------------------------------------------

0.13·C==

Basic Error

Lead Wire Resistance

PtRo

----------------------------------------------------------

=

Error due to amb. temp. variation

Cu

T

amb

Lead Wire Resistance

Pt

Ro

------------------------------------------------------------- ----------------------------------------------------

=

Basic error

7.5

0.00385 / C100

------------------------------------------------------------ --------------------- -

19.5 C==

Error due to amb. temp. var. of 25 °C

0.0039 / C25 C 7.5

0.00385 / C100

--------------------------------------------------------------- ----------------------------------------

1.9 C==

April 2014

Examples of approximate lead wire resistance effect

calculations

Given:

Total cable length: 150 m

Imbalance of the lead wires at 20 °C: 0.5

Resistance/length (18 AWG Cu): 0.025 /m °C

Temperature coefficient of Cu (Cu): 0.039 / °C

Temperature coefficient of Pt(Pt): 0.00385 / °C

Reference Manual

00809-0100-4148, Rev CA

Change in Ambient Temperature (T

): 25 °C

amb

RTD Resistance at 0 °C (Ro): 100 (for Pt 100 RTD)

Pt100 4-wire RTD: No lead wire resistance effect.

Pt100 3-wire RTD:

Lead wire imbalance seen by the transmitter = 0.5

Pt100 2-wire RTD:

14

Lead wire resistance seen by the transmitter = 150 m × 2 wires × 0.025

/m = 7.5

Installation

Page 21

Reference Manual

4–20 mA loop

Sensor Wires

Shield ground point

Tra ns mit te r

00809-0100-4148, Rev CA

2.6 Power supply

The power supplied to the transmitter should not drop below the transmitter lift-off voltage of

12 V DC.

2.6.1 Surges/transients

The transmitter will withstand electrical transients of the energy level encountered in static

discharges or induced switching transients. However, high-energy transients, such as those

induced in wiring from nearby lightening strikes, welding, heavy electrical equipment, or

switching gears, can damage both the transmitter and the sensor. To protect against

high-energy transients, install the transmitter into a suitable connection head with the

Rosemount 470 Transient Protector. Refer to the Rosemount 470 Transient Protector Product

Data Sheet (Document Number 00813-0100-4191) for further information.

2.6.2 Ground the transmitter

The transmitter will operate with the current signal loop either floating or grounded. However,

the extra noise in floating systems affects many types of readout devices. If the signal appears

noisy or erratic, grounding the current signal loop at a single point may solve the problem. The

best place to ground the loop is at the negative terminal of the power supply. Do not ground the

current signal loop at more than one point.

Section 2: Installation

April 2014

The transmitter is electrically isolated at 500 V AC rms (707 V DC) at 50/60 Hz, so the input

circuit may also be grounded at any single point. When using a grounded thermocouple, the

grounded junction serves as this point.

Note

Do not ground the signal wire at both ends.

Ungrounded thermocouple, and RTD/ohm inputs

Each process installation has different requirements for grounding. Use the grounding options

recommended by the facility for the specific sensor type, or begin with grounding Option 1 (the

most common).

Option 1:

1. Connect sensor wiring shield to the transmitter housing (only if the housing is

grounded).

2. Ensure the sensor shield is electrically isolated from surrounding fixtures that may be

grounded.

3. Ground signal wiring shield at the power supply end.

Figure 2-7. Grounded housing option (most common)

Installation

15

Page 22

Section 2: Installation

Sensor Wires

4–20 mA loop

Shield ground point

Connect shields together, electrically isolated from the transmitter

Tra ns mit te r

4–20 mA loopSensor Wires

Shield ground point

Transmitter

April 2014

Option 2 (for ungrounded housing):

1. Connect signal wiring shield to the sensor wiring shield.

2. Ensure the two shields are tied together and electrically isolated from the transmitter

3. Ground shield at the power supply end only.

4. Ensure that the sensor shield is electrically isolated from the surrounding grounded

Figure 2-8. Ungrounded housing

Reference Manual

00809-0100-4148, Rev CA

housing.

fixtures.

Option 3:

1. Ground sensor wiring shield at the sensor, if possible.

2. Ensure that the sensor wiring and signal wiring shields are electrically isolated from the

transmitter housing.

3. Do not connect the signal wiring shield to the sensor wiring shield.

4. Ground signal wiring shield at the power supply end.

Figure 2-9. Ground sensor wiring

16

Installation

Page 23

Reference Manual

4–20 mA loop

Sensor Wires

Shield ground point

Tra ns mit te r

00809-0100-4148, Rev CA

Grounded thermocouple inputs

Option 4:

1. Ground sensor wiring shield at the sensor.

2. Ensure that the sensor wiring and signal wiring shields are electrically isolated from the

3. Do not connect the signal wiring shield to the sensor wiring shield.

4. Ground signal wiring shield at the power supply end.

Figure 2-10. Grounded thermocouple input option

Section 2: Installation

April 2014

transmitter housing.

Installation

17

Page 24

Section 2: Installation

April 2014

Reference Manual

00809-0100-4148, Rev CA

18

Installation

Page 25

Reference Manual

00809-0100-4148, Rev CA

Section 3 Configuration

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

Rosemount 148 PC Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

3.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

3.1.1 Warnings

Section 3: Configuration

April 2014

Failure to follow these installation guidelines could result in death or serious injury:

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury:

Do not remove the connection head cover in explosive atmospheres when the

circuit is live.

Before connecting a communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

When sending or requesting data that would disrupt the loop or change the output of

the transmitter, set the process application loop to manual.

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

All connection head covers must be fully engaged to meet

explosion-proof requirements.

Process leaks could result in death or serious injury:

Do not remove the thermowell while in operation.

Install and tighten thermowells and sensors before applying pressure

Electrical shock could cause death or serious injury:

Use extreme caution when making contact with the leads and terminals.

Configuration

19

Page 26

Section 3: Configuration

April 2014

3.2 Rosemount 148 PC Programmer

The Rosemount 148 must be configured for certain basis variables to operate. In many cases, all

of these variables are pre-configured at the factory. Configuration may be required if the

transmitter is not configured or if the configuration variables need revision.

Configuration consists of testing the transmitter and verifying transmitter configuration data.

The Rosemount 148 must be configured before installation. This can be done two ways:

ordering factory-configuration by Emerson, or using the Rosemount 148 PC Programmer

interface in a bench configuration setting.

3.2.1 PC Programmer software installation

The Rosemount 148 PC Programmer exchanges information with the transmitter in a bench

configuration setting through a personal computer and interface box. See below for detailed

instructions on installing the programming software.

1. Install the Rosemount 148 PC Programmer software.

– Place the Rosemount 148 PC Programmer CD_ROM into the drive

Reference Manual

00809-0100-4148, Rev CA

– Run setup.exe from Windows NT, 2000, or XP

2. When first using the Rosemount 148 PC software, configure the appropriate COM ports

by choosing Port Settings from the Communicate menu.

3. Install MACTek Modem drivers completely before beginning bench configuration on

the Rosemount 148 system.

Note

The software defaults to the first available COM port.

3.2.2 PC Programmer hardware setup

The Rosemount 148 PC Programming Kit includes configuration software and a communication

modem. The Rosemount 148 device will need an external power supply of 12-42.4 Vdc for

configuration.

1. Hook up the transmitter and a load resistor (250 - 1100 ohms) wired in series with the

power supply.

2. Attach the Modem in parallel with the load resistor and connect it to the PC.

Please see Tab l e 3 - 1 for Spares Kit and re-order numbers.

Table 3-1. Rosemount 148 Programming Kit spare part numbers

20

Product description Part number

Programming Software (CD) 00148-1601-0002

Rosemount 148 Programmer Kit - USB 00148-1601-0003

Rosemount 148 Programmer Kit - Serial 00148-1601-0004

The device can be configured from the main screen, and will also show the current transmitter

status. The following pages detail the settings that can be configured on the Rosemount 148.

Configuration

Page 27

Reference Manual

00809-0100-4148, Rev CA

Section 3: Configuration

3.2.3 Configuring with the Rosemount 148 PC Programmer

In order to operate properly, the Rosemount 148 has basic variables that need to be configured.

Some of the variables are factory configured, however, some of the variables may need to be

initially set up or revised. The first two tabs on the main screen are Basic and Advanced Settings,

which include all of the configuration variables that can be set for the Rosemount 148. Any

changes to the configuration must be sent to the transmitter by clicking the Send to Transmitter

button on the right of the screen. The current configuration of the connected 148 may be

viewed by clicking the Load From Transmitter button.

Transmitter identification

The Tag variable is the easiest way to identify/distinguish between transmitters. It can be used

to label transmitters electronically according to the requirements of the application. The tag

may be up to eight characters in length, and does not impact the measurement of the

transmitter.

Sensor configuration

April 2014

The following sensors indicate the sensor type and the number of wires to be connected:

2-, 3-, or 4-wire Pt 100: = 0.00385 /°C

2-, 3-, or 4-wire Pt 100: = 0.003916 /°C

2-, 3-, or 4-wire Ni 120 nickel RTDs

2-, 3-, or 4-wire Cu 10 RTDs

IEC/NIST/DIN Type B, J, K, N, R, S Thermocouples

2-, 3-, or 4-wire 0 - 2000 ohms

A complete line of temperature sensors, thermowells, and accessory mounting hardware is

available from Emerson Process Management.

Output configuration

The Output Configuration area allows the user to set the desired measurement values for the

transmitter:

Degrees Celsius

Degrees Fahrenheit

Degrees Rankine

Kelvin

Ohms

Configuration

Millivolts

The 4 mA and 20 mA measurement point will need to be set to determine the analog output

based on the temperature reading.

The Lower and Upper Range Limit of the sensor type selected above can also be viewed.

21

Page 28

Section 3: Configuration

PNP–1e

t–

T

----

–

+

P =previous damped value

N =new sensor value

T = damping time constant

U =update rate

April 2014

Damping

The Damping value changes the response time of the transmitter to smooth variations in the

readings caused by rapid changes in input. Determine the appropriate damping setting based

on the necessary response time, signal stability, and other requirements of the loop dynamics of

the system. The default damping value is 5.0 seconds and can be reset to any value between 0

and 32 seconds.

The value chosen for damping affects the response time of the transmitter. When set to zero (or

disabled), the damping function is off and the transmitter output reacts to changes in input as

quickly as the intermittent sensor algorithm allows (refer to “*”) for a description of the

intermittent sensor algorithm. Increasing the damping value increases the transmitter response

time.

With damping enabled, the transmitter outputs values according to the following relationship.

At time t

Damping Value =

Reference Manual

00809-0100-4148, Rev CA

At the time which the damping time constant is set, the transmitter output is at 63% of the

input changes and it continues to approach the input according to the damping equation above.

After one damping time constant following a sensor input step change, the transmitter output

will be 63.2% of that change. The output will continue to approach the input according to the

damping equation above.

For example, as illustrated in *, if the temperature undergoes a step change from 100 ° to 100 °,

and the damping is set to 5.0 seconds, the transmitter calculates and reports a new reading

using the damping equation. At 5.0 seconds, the transmitter outputs 106.3 °, or 63.2% of the

input change, and the output continues to approach the input curve according to the above

equation.

Figure 3-1. Change in input vs. Change in output with Damping set to five seconds

22

Configuration

Page 29

Reference Manual

00809-0100-4148, Rev CA

Alarm and saturation

Alarm Direction, Low Alarm Level, High Alarm Level, Low Saturation, and High Saturation values

can be set here. Rosemount and NAMUR standard values can be found on Ta b le A - 1 * or

user-configured values may be entered. The guidelines are as follows:

Low Alarm value must be between 3.50 and 3.75 mA

High Alarm value must be between 21.0 and 23.0 mA

Low Saturation level must be between the Low Alarm value plus 0.1 mA and 3.9 mA.

The High Saturation level must be between 20.5 mA and the High Alarm value minus

See “Failure mode” for Failure Mode considerations.

50/60 Hz selection

The 50/60 Hz Selection sets the transmitter electronic filter to reject the frequency of the AC

power supply in the plant.

Section 3: Configuration

April 2014

Example: The Low Alarm value has been set to 3.7 mA, so the Low Saturation level (S) must

be 3.8 - 3.9 mA.

0.1 mA. Example: The High Alarm value has been set to 20.8 mA, so the Low Saturation level

(S) must be 20.5 - 20.7 mA.

Write protect

Write Protect safeguards the transmitter configuration data from accidental or unwarranted

changes.

3.2.4 Information

The transmitter information tab can be selected from the main stat up screen, and lists the

transmitter information variables that can be viewed. The Refresh button must be clicked to

update the view of the current state of the transmitter.

Sensor temperature

The sensor temperature readings are displayed in the units set in the Basic Settings.

Analog output (mA)

Displays the transmitter output, read by the host system, in milliamperes.

Transmitter temperature

Shows the reading used by the onboard RTD to compensate the cold junction of

thermocouples.

Configuration

Status indicator buttons

Two buttons that indicate if the device is in Sensor Malfunction or Transmitter Malfunction.

Device identification

This shows revisions for the Software, Hardware and Final Assembly Number.

23

Page 30

Section 3: Configuration

April 2014

Reference Manual

00809-0100-4148, Rev CA

24

Configuration

Page 31

Reference Manual

00809-0100-4148, Rev CA

Section 4: Operation and Maintenance

Section 4 Operation and Maintenance

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

4.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety

of the personnel performing the operations. Information that potentially raises safety issues is

indicated by a warning symbol ( ). Please refer to the following safety messages before

performing an operation preceded by this symbol.

4.1.1 Warnings

April 2014

Failure to follow these installation guidelines could result in death or serious injury:

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury:

Do not remove the connection head cover in explosive atmospheres when the

circuit is live.

Before connecting a Field Communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

When sending or requesting data that would disrupt the loop or change the output of

the transmitter, set the process application loop to manual.

Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

All connection head covers must be fully engaged to meet explosion-proof

requirements.

Process leaks could result in death or serious injury:

Do not remove the thermowell while in operation.

Install and tighten thermowells and sensors before applying pressure

Electrical shock could cause death or serious injury:

Use extreme caution when making contact with the leads and terminals.

Operation and Maintenance

25

Page 32

Section 4: Operation and Maintenance

April 2014

4.2 Hardware

The Rosemount 148 has no moving parts and requires minimal scheduled maintenance.

4.2.1 Maintenance

Sensor checkout

To determine whether the sensor is at fault, replace it with another sensor or connect a test

sensor locally at the transmitter to test remote sensor wiring. Do not remove the thermowell

while in operation. Select any standard, off-the-shelf sensor for use with a Rosemount 148 or

consult the factory for a replacement special sensor and transmitter combination.

4.2.2 Diagnostic messages

If a malfunction is suspected, follow the procedures described in Ta b le 4 - 1 to verify that

transmitter hardware and process connections are in good working order. Under each of the

three major symptoms, specific suggestions are offered for solving the problem.

Reference Manual

00809-0100-4148, Rev CA

Table 4-1. Rosemount 148 troubleshooting chart

Symptom Potential source Corrective action

Check for a sensor open or short circuit.

High Output

Sensor Input Failure

or Connection

Loop Wiring

Check the process variable to see if it is out of

range.

Check for dirty or defective terminals,

interconnecting pins, or receptacles.

Check the output voltage of the power supply at

the transmitter terminals. It should be 12.0 to

42.4 V dc (over entire 3.75 to 23 mA operating

Power Supply

Check for adequate voltage to the transmitter. It

range).

should be 12.0 to 42.4 V dc at the transmitter

terminals (over entire 3.75 to 23 mA operating

range).

Erratic

Output Loop Wiring

Low Output

or No Output Sensor Element

Check for intermittent shorts, open circuits, and

multiple grounds.

Check the process variable to see if it is out of

range.

Check for adequate voltage to the transmitter. It

should be 12.0 to 42.4 V dc (over entire 3.75 to

23 mA operating range).

26

Loop Wiring

Check for shorts and multiple grounds.

Check for proper polarity at the signal terminal.

Check the loop impedance.

Check wire insulation to detect possible shorts

to ground.

Operation and Maintenance

Page 33

Reference Manual

00809-0100-4148, Rev CA

Appendix A: Specifications and reference data

Appendix A Specifications

Transmitter specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

A.1 Transmitter specifications

A.1.1 Functional specifications

Inputs

User-selectable. See “Transmitter accuracy and ambient temperature effects ” for sensor options.

April 2014

Outputs

2-wire 4–20 mA, linear with temperature or input.

Isolation

Input/output isolation tested to 500 V AC rms (707 V DC) at 50/60 Hz.

Power supply

An external power supply is required. The transmitter operates on 12.0 to 42.4 V DC transmitter

terminal voltage.

Humidity limits

0 - 95% relative humidity, non-condensing

NAMUR recommendations

The Rosemount 148 meets the following NAMUR recommendations:

NE 21 - Electromagnetic compatibility (EMC) for Process and Laboratory Apparatus

NE 43 - Standard of the signal level breakdown information of digital transmitters

Specifications

Transient protection

The optional Rosemount 470 prevents damage from transients induced by lightening, welding,

heavy electrical equipment, or switch gears. Refer to the Rosemount 470 Product Data Sheet

(Document Number 00813-0100-4191) for more information.

27

Page 34

Appendix A: Specifications and reference data

April 2014

Temperature limits

Operating limit

–40 to 185 °F (–40 to 85 °C)

Storage limit

–58 to 248 °F (–50 to 120 °C)

Turn-on time

Performance within specifications in less than 5.0 seconds after power is applied to transmitter,

when damping value is set to zero seconds.

Update rate

Less than 0.5 seconds

Custom alarm and saturation levels

Reference Manual

00809-0100-4148, Rev CA

Custom configuration of alarm and saturation levels is available by using the 148 PC

Programmer.

Software detected failure mode

The values at which the transmitter drives its output in failure mode depends on device

configuration. The device can be configured to meet NAMUR-compliant (NAMUR

recommendation NE 43) operation. The values for standard and NAMUR-compliant operation

are as follows:

Table A-1. Operation Parameters

Standard

Linear Output: 3.9 I 20.5 3.8 I 20.5

Fail High: 21 I 23 (default) 21 I 23

Fail Low: I 3.75 I 3.6

(1) Measured in milliamperes.

Certain hardware failures, such as microprocessor failures, will always drive the output to

greater than 23 mA.

A.1.2 Physical specifications

(1)

NAMUR NE43- Compliant

(1)

28

Communication connections

Communication Terminal: Clips permanently fixed to the terminals.

Specifications

Page 35

Reference Manual

00809-0100-4148, Rev CA

Materials of construction

Electronics housing

Noryl

Universal (option codes U and H) heads

Housing: Low-copper aluminum (option code U)

Paint: Polyurethane

Cover O-Ring: Buna-N

Mounting

The Rosemount 148 installs in a connection head or universal head mounted directly on a

sensor assembly or apart from a sensor assembly using a universal head. The Rosemount 148

can also mount to a DIN rail using an optional mounting clip.

Weight

®

glass reinforced

Stainless Steel (option code H)

Appendix A: Specifications and reference data

April 2014

Code Options Weight

148 Head Mount Transmitter 42 g (1.5 oz)

U Universal Head 520 g (18.4 oz)

H Universal Head (SST) 1700 g (60 oz)

Enclosure ratings

The Universal (option codes U and H) Heads are NEMA 4X, IP66, and IP68. The Universal Head

1

with

/2-in. NPT threads is CSA Enclosure Type 4X.

A.1.3 Performance specifications

EMC (ElectroMagnetic Compatibility) NAMUR NE21 Standard

The Rosemount 148 meets the requirements for NAMUR NE21 Rating

Susceptibility Parameter Influence

ESD

Radiated •80 – 1000 MHz at 10 V/m AM None

Burst •1 kV for I.O. None

Surge

Conducted • 150 kHz to 80 MHz at 10 V None

•6 kV contact discharge

•8 kV air discharge

•0.5 kV line–line

•1 kV line–ground

None

None

Specifications

CE mark

The Rosemount 148 meets all requirements listed under IEC 61326: Amendment 1, 2006

29

Page 36

Appendix A: Specifications and reference data

1234234 12 34 1234

1

2-wire

RTD and ⍀

3-wire*

RTD

and ⍀

4-wire

RTD

and ⍀

T/C

April 2014

Power supply effect

Less than ±0.005% of span per volt

Vibration effect

The Rosemount 148 is tested to the following specifications with no effect on performance:

Frequency Vibration

10 to 60 Hz 0.21 mm displacement

60 to 2000 Hz 3 g peak acceleration

Stability

For RTD and thermocouple inputs, the transmitter will have a stability of ±0.15% of reading or

0.15 °C (whichever is greater) for twelve months.

Sensor connections

Rosemount 148 Sensor connections diagram

Reference Manual

00809-0100-4148, Rev CA

* Rosemount Inc. provides 4-wire sensors for all single element RTDs. You can use these

RTDs in 3-wire configurations by leaving the unneeded leads disconnected and insulated

with electrical tape.

Transmitter accuracy and ambient temperature effects

Note

The accuracy and ambient temperature effect is the greater of the fixed and percent of span

values (see example below).

30

Specifications

Page 37

Reference Manual

0.320.09

2

+ 0.31 C=

00809-0100-4148, Rev CA

Appendix A: Specifications and reference data

Table A-2. Rosemount 148 Transmitter Input Options, Accuracy, and Ambient Temperature Effects

April 2014

Temperature Effects per 1.0 °C

(1.8 °F) Change in Ambient

Temperature

Fixed

(2)

% of

Span

Sensor

Transmitter In put Ran ges

(1)

°C °F Fixed

Accuracy

% of

Span

2-, 3-, 4-wire RTDs

(3)

Pt 100

Pt 100

Ni 120

Cu 10

Thermocouples

Type B

Type J

Type K

Type N

Type R

Type S

( = 0.00385)

(4)

( = 0.003916)

(5)

(6)

(7)

(8)(9)

(8)

(8)(10)

(8)

(8)

(8)

–200 to 850 –328 to 1562 0.3 °C (0.54 °F) ±0.15 0.009 °C (0.016 °F) ±0.006

–200 to 645 –328 to 1193 0.3 °C (0.54 °F) ±0.15 0.009 °C (0.016 °F) ±0.006

–70 to 300 –94 to 572 0.2 °C (0.36 °F) ±0.15 0.006 °C (0.011 °F) ±0.006

–50 to 250 –58 to 482 3 °C (5.40 °F) ±0.15 0.09 °C (0.16 °F) ±0.006

100 to 1820 212 to 3308 2.3 °C (4.05 °F) ±0.15 0.084 °C (0.150 °F) ±0.006

–180 to 760 –292 to 1400 0.8 °C (1.35 °F) ±0.15 0.03 °C (0.054 °F) ±0.006

–180 to 1372 –292 to 2502 0.8 °C (1.35 °F) ±0.15 0.03 °C (0.054 °F) ±0.006

–200 to 1300 –328 to 2372 1.2 °C (2.16 °F) ±0.15 0.03 °C (0.054 °F) ±0.006

0 to 1768 32 to 3214 1.8 °C (3.24 °F) ±0.15 0.09 °C (0.16 °F) ±0.006

0 to 1768 32 to 3214 1.5 °C (2.70 °F) ±0.15 0.09 °C (0.16 °F) ±0.006

2-, 3-, 4-wire Ohm Input 0 to 2000 ohms 1.1 ohm ±0.15 0.042 ohm ±0.006

(1) Input ranges are for transmitter only. Actual sensor (RTD or Thermocouple) operating ranges may be more limited.

(2) Change in ambient is with reference to the calibration temperature of the transmitter at 68 °F (20 °C) from factory.

(3) IEC 751, 1995.

(4) JIS 1604, 1981.

(5) Edison Curve No. 7.

(6) Edison Copper Winding No. 15.

(7) Total accuracy for thermocouple measurement: sum of accuracy +0.5 °C.

(8) NIST Monograph 175, IEC 584.

(9) Fixed accuracy for NIST Type B is ±5.4 °F (±3.0 °C) from 212 to 572 °F (100 to 300 °C).

(10)Fixed accuracy for NIST Type K is ±1.3 °F (±0.7 °C) from -292 to -130 °F (-130 to -90 °C).

Specifications

Transmitter accuracy example

When using a Pt 100 (a = 0.00385) sensor input with a 0 to 100 °C span, use the greater of the

two calculated values. In this case the accuracy would be +/-0.3 °C.

Transmitter temperature effects example

Transmitters can be installed in locations where the ambient temperature is between –40 and

85 °C (–40 and 185 °F). In order to maintain excellent accuracy performance, each transmitter is

individually characterized over this ambient temperature range at the factory.

When using a Pt 100 (a = 0.00385) sensor input with a 0–100 °C span at 30 °C ambient

temperature:

Temperature Effects: 0.009 °C x (30 - 20) = 0.09 °C

Total transmitter error

Worst Case Transmitter Error: Accuracy + Temperature Effects = 0.3 °C + 0.09 °C = 0.39 °C

Total Probable Transmitter Error:

31

Page 38

Appendix A: Specifications and reference data

44 (1.7)

33 (1.3)

12.9 (0.51)

24.5

(0.97)

95

(3.74)

96 (3.76)

112 (4.41)

SST “U” Bolt

Mounting,

2-inch Pipe

Approval

Label

75

(2.93)

104

(4.09)

100

(3.93)

78

(3.07)

Approval Label

84 (3.331)

118

April 2014

A.2 Dimensional drawings

Rosemount 148 Transmitter

(enlarged)

Reference Manual

00809-0100-4148, Rev CA

Dimensions are in millimeters (inches).

Enclosures

Universal head

(option codes H and U)

Dimensions are in millimeters (inches).

32

(1) A “U” Bolt is shipped with each universal head unless a sensor is ordered assembled to the enclosure. However, since the head can be

integrally mounted to the sensor it may not need to be used.

(2) Consult factory for ordering availability.

(1)

Connection head

(2)

BUZ and polypropylene

heads

(2)

Specifications

Page 39

Reference Manual

N

U

25 (1.0)

BUZ Connection Head

N

U

40 (1.6)

60 (2.3)

Connection Head

U

N

60 (2.3)*

Universal Head

00809-0100-4148, Rev CA

Appendix A: Specifications and reference data

April 2014

Examples of 148 Assemblies with Sensors and Thermowells

Tubular Thermowell and DIN Plate

Style Sensor

SEE SENSOR DOCUMENTATION FOR MORE ASSEMBLY OPTIONS

Dimensions are in millimeters (inches).

Barstock Thermowell, Nipple-Union

Barstock Thermowell and DIN Plate

Extension, and

Style Sensor

* 80 (3.2) for Class 900 flanges and larger

N = Extension Length, U= Thermowell Immersion Length,

1

/2-in. NPT Spring Loaded

Sensor

Specifications

33

Page 40

Appendix A: Specifications and reference data

April 2014

Reference Manual

00809-0100-4148, Rev CA

A.3 Ordering information

Table A-3. Rosemount 148 PC-Programmable Temperature Transmitter

★ The Standard offering represents the most common options. The starred options (★) should be selected for best delivery.

__The Expanded offering is subject to additional delivery lead time.

Model Product description

148 PC Programmable Temperature Transmitter

Transmitter type

Standard Standard

H DIN B Head Mount ★

Transmitter output

Standard Standard

N Analog Output ★

Product certifications

Standard Standard

I5 FM Intrinsic Safety and Class 1, Division 2 ★

(1)

E5

FM Explosion-Proof ★

(1)

K5

FM Intrinsic Safety, Explosion-Proof, and Class 1, Division 2 ★

I6 CSA Intrinsic Safety and Class 1, Division 2 ★

(1)

K6

CSA Intrinsic Safety, Explosion-Proof, and Class 1, Division 2 ★

I1 ATEX Intrinsic Safety ★

(1)

E1

ATE X Fl ameproof ★

(1)

N1

ATEX Type n ★

NC ATEX Type n Component ★

(1)

ND

E7

N7

NG IECEx Type n Component ★

NA No approvals ★

Enclosure options Material IP Rating

Standard Standard

Expanded

Conduit entry size

Standard Standard

ATEX Dust Ignition-Proof ★

I7 IECEx Intrinsic Safety ★

(1)

IECEx Flameproof and Dust ★

(1)

IECEx Type n ★

A Connection Head Aluminum IP68 ★

U Universal Head (Junction Box) Aluminum IP68 ★

B BUZ Head Aluminum IP65 ★

C BUZ Head Polypropylene IP65 ★

N No Enclosure ★

G Connection Head SST IP68

H Universal Head (Junction Box) SST IP68

S Sanitary Connection Head, DIN B Polished SST IP66

F Sanitary Connection Head, DIN A Polished SST IP66/IP68

1 M20 x 1.5 (CM20) ★

1

2

/2-14 in. NPT ★

0 No Enclosure ★

34

Specifications

Page 41

Reference Manual

00809-0100-4148, Rev CA

Appendix A: Specifications and reference data

April 2014

Table A-3. Rosemount 148 PC-Programmable Temperature Transmitter

★ The Standard offering represents the most common options. The starred options (★) should be selected for best delivery.

__The Expanded offering is subject to additional delivery lead time.

Options (include with selected model number)

Alarm level configuration

Standard Standard

A1 NAMUR alarm and saturation levels, high alarm ★

CN NAMUR alarm and saturation levels, low alarm ★

Calibration certificate

Standard Standard

Q4 Calibration Certificate (3-point Calibration) ★

Line filter

Standard Standard

F6 60 Hz Line Voltage Filter ★

External ground option (available w/enclosures U, H)

Standard Standard

G1 External Ground Lug Assembly ★

Cover chain option (available w/enclosures U, H)

Standard Standard

G3 Cover Chain ★

Cable gland option

Standard Standard

G2 Cable Gland–Explosion Proof–7.5 mm - 11.9 mm ★

G4 Cable Gland–Explosion Proof, Thin Wire - 3.0 mm - 8.0 mm ★

Conduit electrical connector

Standard Standard

GE M12, 4-pin, Male Connector (eurofast®) ★

GM A size Mini, 4-pin, Male Connector (minifast®) ★

Assemble to options

Standard Standard

XA Sensor Specified Separately and Assembled to Transmitter ★

Typical model number: 148 H N I5 U1 A1 XA

(1) Approval Codes E1, N1, N7, ND, E5, K5, K6, and E7 require an enclosure.

Specifications

35

Page 42

Appendix A: Specifications and reference data

April 2014

Reference Manual

00809-0100-4148, Rev CA

36

Specifications

Page 43

Reference Manual

00809-0100-4148, Rev BC

Appendix B: Product Certifications

April 2014

Appendix B Product Certifications

B.1 Approved Manufacturing Locations

Rosemount Inc. - Chanhassen, Minnesota, USA

Rosemount Temperature GmbH - Germany

Emerson Process Management Asia Pacific - Singapore

B.2 European Directive Information

A copy of the EC Declaration of Conformity can be found at the end of the Quick Start Guide. The

most recent revision of the EC Declaration of Conformity can be found at www.rosemount.com.

B.3 Ordinary Location Certification from FM Approvals

As standard, the transmitter has been examined and tested to determine that the design meets

the basic electrical, mechanical, and fire protection requirements by FM Approvals, a nationally

recognized test laboratory (NRTL) as accredited by the Federal Occupational Safety and Health

Administration (OSHA).

B.3.1 North America

E5 FM Explosionproof, Dust-Ignitionproof, and Nonincendive

Certificate: 3032198

Standards Used: FM Class 3600:1998, FM Class 3611:2004, FM Class 3615:1989, FM Class

3810:2005, IEC 60529: 2001, NEMA - 250: 1991

Markings: XP CL I, DIV 1, GP B, C, D; DIP CL II/III, DIV 1, GP E, F, G; NI CL I, DIV 2, GP A, B, C, D;

T5(-50 °C Ta + 85 °C); when installed per Rosemount drawing 00148-1065; Type 4X;

IP66/68.

I5 FM Intrinsic Safety and Nonincendive

Certificate: 3032198

Standards Used: FM Class 3600:1998, FM Class 3610:1999, FM Class 3611:2004, FM Class

3810:2005, IEC 60529: 2001, NEMA - 250: 1991

Markings: IS CL I/II/III, DIV 1, GP A, B, C, D, E, F, G; NI CL1, DIV 2, GP A, B, C, D; T6(-50 °C Ta

+ 40 °C), T5(-50 °C Ta + 75 °C) when installed per Rosemount drawing 00148-1055;

Type 4X; IP66/68.

Special conditions for safe use (X):

1. When no enclosure option is selected, the Model 148 Temperature Transmitter shall be

installed in an enclosure meeting the requirements of ANSI/ISA S82.01 and S82.03 or

other applicable ordinary location standards.

2. No enclosure or Buz Head option cannot be selected to maintain a Type 4X rating.

3. Enclosure option must be selected to maintain a Type 4 Rating.

Product Certifications

37

Page 44

Appendix B: Product Certifications

April 2014

I6 CSA Intrinsic Safety, and Division 2

Certificate: 1091070

Standards Used: CAN/CSA C22.2 No. 0-M90, CSA Std. C22.2 No. 25-1966, CSA Std. C22.2

No. 30-M1986, CAN/CSA C22.2 No. 94-M91, CSA Std. C22.2 No.142-M1987, CAN/CSA

C22.2 No. 157-92, CSA C22.2 No. 213-M1987, C22.2 No 60529-05.

Markings: IS CL I, DIV 1 GP A, B, C, D when installed per Rosemount drawing 00248-1056;

Suitable for CL I DIV 2 GP A, B, C, D when installed per Rosemount drawing 00248-1055;

T6(-50 °C Ta +40 °C), T5(-50 °C Ta +60 °C); Type 4X, IP66/68 for enclosure options “A”,

“G”, “H”, “U”; Seal not required (See drawing 00248-1066).

K6 CSA Explosionproof, Intrinsic Safety, and Division 2

Certificate: 1091070

Standards Used: CAN/CSA C22.2 No. 0-M90, CSA Std. C22.2 No. 25-1966, CSA Std. C22.2

No. 30-M1986, CAN/CSA C22.2 No. 94-M91, CSA Std. C22.2 No.142-M1987, CAN/CSA

C22.2 No. 157-92, CSA C22.2 No. 213-M1987, C22.2 No 60529-05.

Markings: XP CL I/II/III, DIV 1, GP B, C, D, E, F, G when installed per Rosemount drawing

00248-1066; IS CL I, DIV 1 GP A, B, C, D when installed per Rosemount drawing

00248-1056; Suitable for CL I DIV 2 GP A, B, C, D when installed per Rosemount drawing

00248-1055; T6(-50 °C Ta +40 °C), T5(-50 °C Ta +60 °C); Type 4X, IP66/68 for

enclosure options “A”, “G”, “H”, “U”; Seal not required (See drawing 00248-1066).

Reference Manual

00809-0100-4148, Rev BC

B.3.2 Europe

E1 ATE X Fla m eproof

Certificate: FM12ATEX0065X

Standards Used: EN 60079-0: 2012, EN 60079-1: 2007, EN 60529:1991 +A1:2000

Markings: II 2 G Ex d IIC T6…T1 Gb, T6(-50 °C Ta +40 °C), T5…T1(-50 °C Ta +60 °C);

See Ta bl e B - 1 at the end of the Product Certifications section for Process Temperatures

Special conditions for safe use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become a source of ignition

in Group III environments.

3. Guard the LCD cover against impact energies greater than 4 joules.

4. Consult the manufacturer if dimensional information on the flameproof joints is

necessary.

I1 ATE X Intrinsic Safet y

Certificate: Baseefa08ATEX0030X

Standards Used: EN 60079-0: 2012, EN 60079-11: 2012

Markings: II 1 G Ex ia IIC T5/T6 Ga, T5(-60 °C Ta +80 °C), T6(-60 °C Ta +60 °C);

See Ta bl e B - 2 at the end of the Product Certifications section for Entity Parameters.

Special condition for safe use (X):

1. The apparatus must be installed in an enclosure which affords it a degree of protection of

at least IP20. Non-metallic enclosures must have a surface resistance of less than 1 G;

light alloy or zirconium enclosures must be protected from impact and friction when

installed.

38

N1 ATEX Type n - with enclosure

Certificate: BAS00ATEX3145

Standards Used: EN 60079-0:2012, EN 60079-15:2010

Markings: II 3 G Ex nA IIC T5 Gc (-40 °C Ta +70 °C);

Product Certifications

Page 45

Reference Manual

00809-0100-4148, Rev BC

NC ATEX Type n - without enclosure

1. The Model 148 Temperature Transmitter must be installed in a suitably certified

ND ATEX Dust

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become a source of

3. Guard the LCD cover against impact energies greater than 4 joules.

4. Consult the manufacturer if dimensional information on the flameproof joints is

Appendix B: Product Certifications

April 2014

Certificate: Baseefa13ATEX0092X

Standards Used: EN 60079-0:2012, EN 60079-15:2010

Markings: II 3 G Ex nA IIC T5/T6 Gc, T5(-60 °C Ta +80 °C), T6(-60 °C Ta +60 °C);

Special condition for safe use (X):

enclosure such that it is afforded a degree of protection of at least IP54 in accordance

with IEC 60529 and EN 60079-15.

Certificate: FM12ATEX0065X

Standards Used: EN 60079-0: 2012, EN 60079-31: 2009, EN 60529:1991 +A1:2000

Markings: II 2 D Ex tb IIIC T130 °C Db, (-40 °C Ta +70 °C); IP66

See Table B -1 at the end of the Product Certifications section for Process Temperatures

Special conditions for safe use (X):

ignition in Group III environments.

necessary.

B.3.3 International

E7 IECEx Flameproof and Dust

Certificate: IECEx FMG 12.0022X

Standards Used: IEC 60079-0:2011, IEC 60079-1:2007-04, IEC 60079-31:2008

Markings: Ex d IIC T6…T1 Gb, T6(-50 °C Ta +40 °C), T5…T1(-50 °C Ta +60 °C);

Ex tb IIIC T130 °C Db, (-40 °C Ta +70 °C); IP66;

See Ta bl e B - 1 at the end of the Product Certifications section for Process Temperatures

Special conditions for safe use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become a source of

ignition in Group III environments.

3. Guard the LCD cover against impact energies greater than 4 joules.

4. Consult the manufacturer if dimensional information on the flameproof joints is

necessary.

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 08.0011X

Standards Used: IEC 60079-0:2011, IEC 60079-11:2011

Markings: Ex ia IIC T5/T6 Ga, T5(-60 °C Ta +80 °C), T6(-60 °C Ta +60 °C);

See Ta bl e B - 2 at the end of the Product Certifications section for Entity Parameters

Special condition for safe use (X):

1. The apparatus must be installed in an enclosure which affords it a degree of protection

of at least IP20. Non-metallic enclosures must have a surface resistance of less than

1G; light allow or zirconium enclosures must be protected from impact and friction

when installed.

Product Certifications

39

Page 46