Page 1

00825-0100-4148, Rev GA

Rosemount™ 148 Temperature

Transmitter

Quick Start Guide

September 2016

Page 2

Quick Start Guide

September 2016

NOTICE

This guide provides basic guidelines for the Rosemount 148. It does not provide instructions for detailed

configuration, diagnostics, maintenance, service, troubleshooting, or installations. Refer to the Rosemount

148 Reference Manual

EmersonPro cess.com/Rosemount

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the appropriate local,

national, and international standards, codes, and practices. Review the Hazardous Locations Certifications for

any restrictions associated with a safe installation.

Process leaks may cause harm or result in death.

Install and tighten thermowells or sensors before applying pressure.

Do not remove the thermowell while in operation.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can cause electrical

shock.

Conduit/cable entries

Unless marked, the conduit/cable entries in the transmitter housing use a

marked “M20” are M20 ⫻ 1.5 thread form. On devices with multiple conduit entries, all entries have the

same thread form. Only use plugs, adapters, glands, or conduit with a compatible thread form when

closing entries.

When installing in a Hazardous Location, use only appropriately listed or Ex certified plugs, adapters or

glands in cable/conduit entries.

for more instruction. The manual and this guide are also available electronically on

.

1

/2–14 NPT thread form. Entries

Contents

Software installation . . . . . . . . . . . . . . . . . 3

Configure . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mount the transmitter . . . . . . . . . . . . . . . 4

2

Connect the wiring . . . . . . . . . . . . . . . . . . . 6

Product Certifications . . . . . . . . . . . . . . . . . 9

Page 3

September 2016

Quick Start Guide

1.0 Software installation

1. Install the Rosemount 148 PC Programmer software.

a. Place the Rosemount 148 PC Programmer CD_ROM into the drive.

b. Run setup.exe from Windows NT, 2000, or XP.

2. When first using the Rosemount 148 PC software, configure the appropriate

COM ports by selecting Port Settings from the Communicate menu.

3. Install MACTek Modem drivers completely before beginning bench

configuration on the Rosemount 148 system.

Note

The software defaults to the first available COM port.

2.0 Configure

The Rosemount 148 must be configured for certain basic variables to operate. In

many cases, all of these variables are pre-configured at the factory. Configuration

may be required if the transmitter is not configured or if the configuration

variables need revision. This can be done in two ways: by ordering

factory-configuration by Emerson

Rosemount 148 PC Programming interface in a bench configuration setting.

The Rosemount 148 PC Programming Kit includes configuration software and a

communication modem. The Rosemount 148 device will need an external power

supply of 12–42.4 Vdc for configuration.

1. Hook up the transmitter and a load resistor (250–1100 ohms) wired in series

with the power supply.

2. Attach the Modem in parallel with the load resistor and connect it to the PC.

See "Table 1: Rosemount 148 Programming Kit spare part numbers" for spares kit

and re-order numbers. For more information, refer to the Rosemount 148

Reference Manual

.

™

Process Management, or by using the

Table 1. Rosemount 148 Programming Kit spare part numbers

Product description Part number

Programming Software (CD) 00148-1601-0002

Rosemount 148 Programmer Kit - USB 00148-1601-0003

Rosemount 148 Programmer Kit - Serial 00148-1601-0004

2.1 Verify transmitter configuration

If the transmitter has a sensor connected (either a test sensor or actual

installation hardware), the configuration can be checked using the Information

tab on the Rosemount 148 PC Programmer interface. Select Refresh to update

the status and confirm that the transmitter has been configured correctly. If there

are any problems, refer to the Rosemount 148 Reference Manual

troubleshooting suggestions.

for

3

Page 4

Quick Start Guide

September 2016

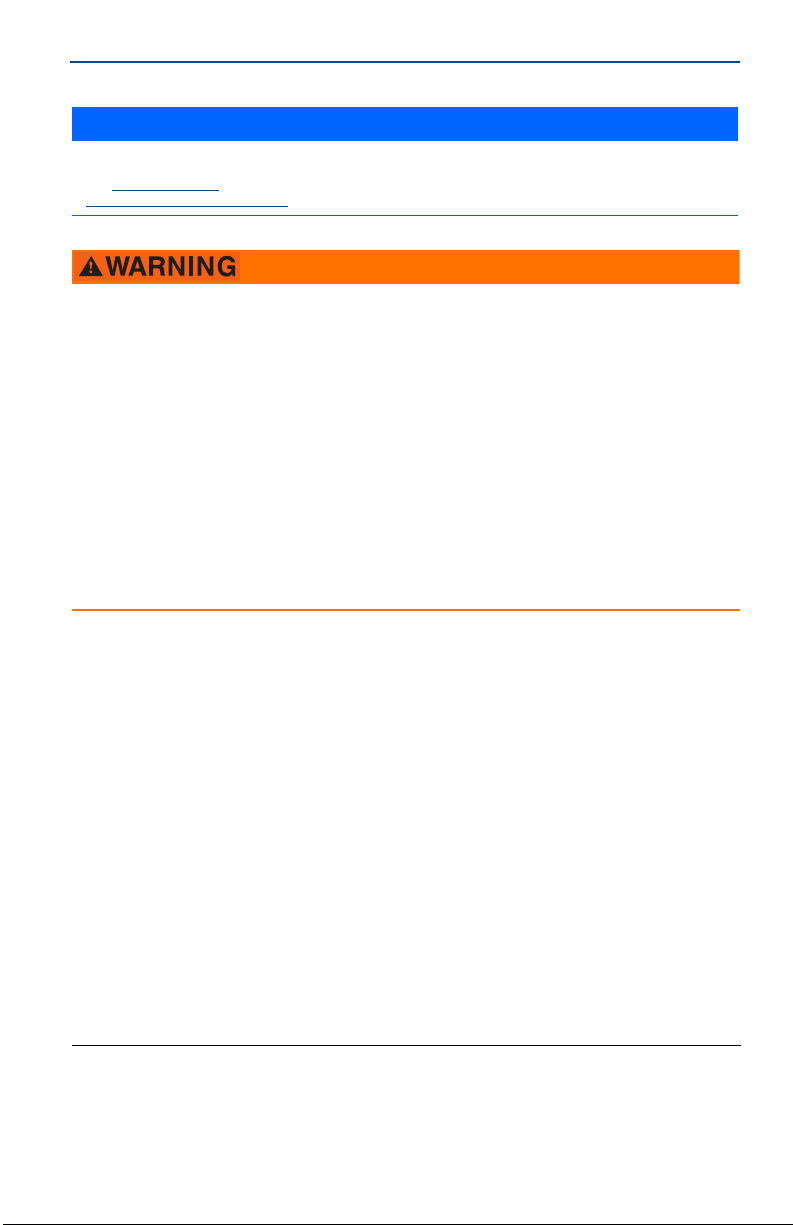

3.0 Mount the transmitter

To prevent moisture from draining into the transmitter housing, mount the

transmitter at a high point in the conduit run.

3.1 Typical European and Asia Pacific installation

Head mount transmitter with DIN plate style sensor

1. Attach the thermowell to the pipe or process container wall. Install and

tighten the thermowell before applying process pressure.

2. Assemble the transmitter to the sensor.

a. Push the transmitter mounting screws through the sensor mounting plate.

b. Insert the snap rings (optional) into the transmitter mounting screw

groove.

3. Wire the sensor to the transmitter.

4. Insert the transmitter-sensor assembly into the connection head.

a. Thread the transmitter mounting screw into the connection head

mounting holes.

b. Assemble the extension to the connection head.

c. Insert the assembly into the thermowell.

5. Slip the shielded cable through the cable gland.

6. Attach a cable gland into the shielded cable.

7. Insert the shielded cable leads into the connection head through the cable

entry.

8. Connect and tighten the cable gland.

9. Connect the shielded power cable leads to the transmitter power terminals.

Avoid contact with sensor leads and sensor connections. (See Connect the

wiring for instructions on grounding the shield wire.)

10. Install and tighten the connection head cover. Enclosure covers must be fully

engaged to meet explosion-proof requirements.

AB C

D

EF

A. Rosemount 148 Transmitter D. Transmitter mounting screws

B. Connection head E. Integral mount sensor with flying leads

C. Thermowell F. Ex tensi on

4

Page 5

September 2016

AB

D

C

E

Quick Start Guide

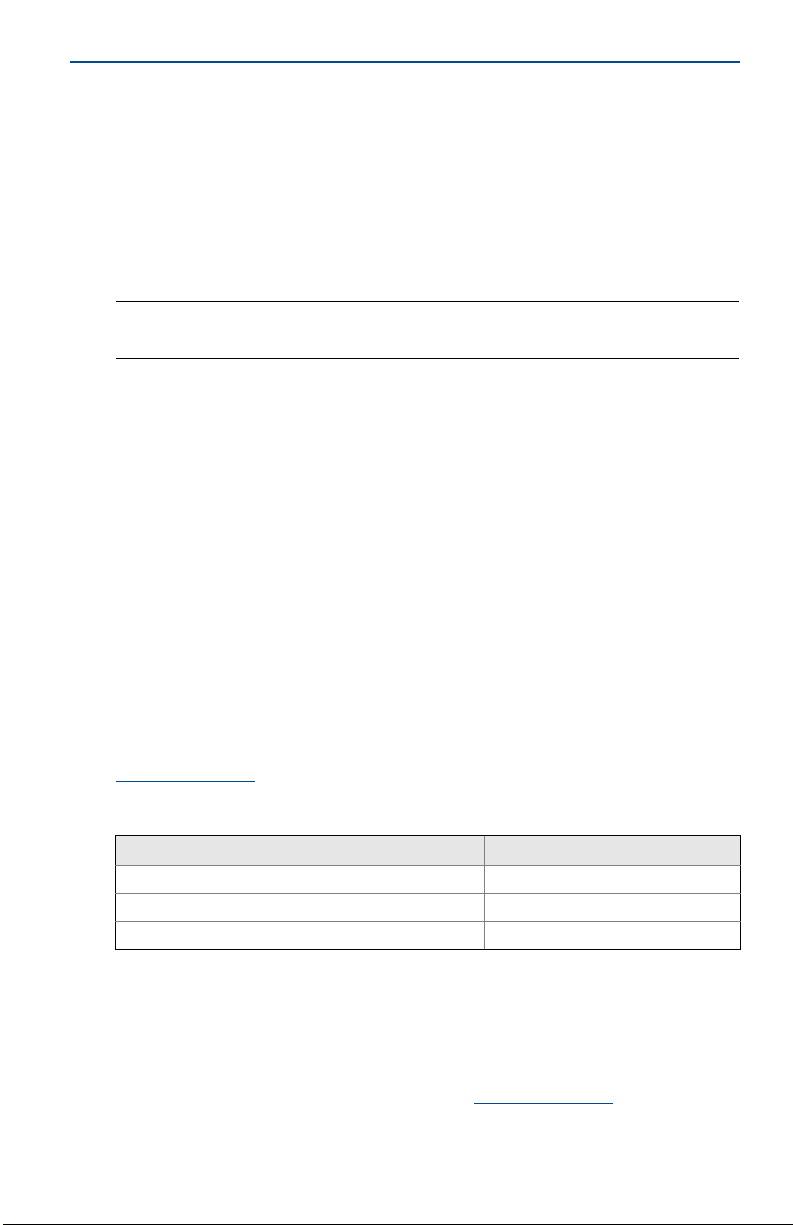

3.2 Typical north and south american installation

Head mount transmitter with threaded sensor

1. Attach the thermowell to the pipe or process container wall. Install and tighten

thermowells before applying process pressure.

2. Attach necessary extension nipples and adapters to the thermowell.

3. Seal the nipple and adapter threads with silicone tape.

4. Screw the sensor into the thermowell. Install drain seals if required for severe

environments or to satisfy code requirements.

5. Pull the sensor wiring leads through the universal head and transmitter.

6. Mount the transmitter in the universal head by threading the transmitter

mounting screws into the universal head mounting holes.

7. Mount the transmitter-sensor assembly into the thermowell. Seal adapter

threads with silicone tape.

8. Install conduit for field wiring to the conduit entry of the universal head. Seal

conduit threads with silicone tape.

9. Pull the field wiring leads through the conduit into the universal head.

10. Attach the sensor and power leads to the transmitter while avoiding contact

with other terminals.

11. Install and tighten the universal head cover.

Note

Enclosure covers must be fully engaged to meet explosion-proof requirements.

A. Threaded thermowell D. Universal head

B. Threaded style sensor E. Conduit entry

C. Standard extension

5

Page 6

Quick Start Guide

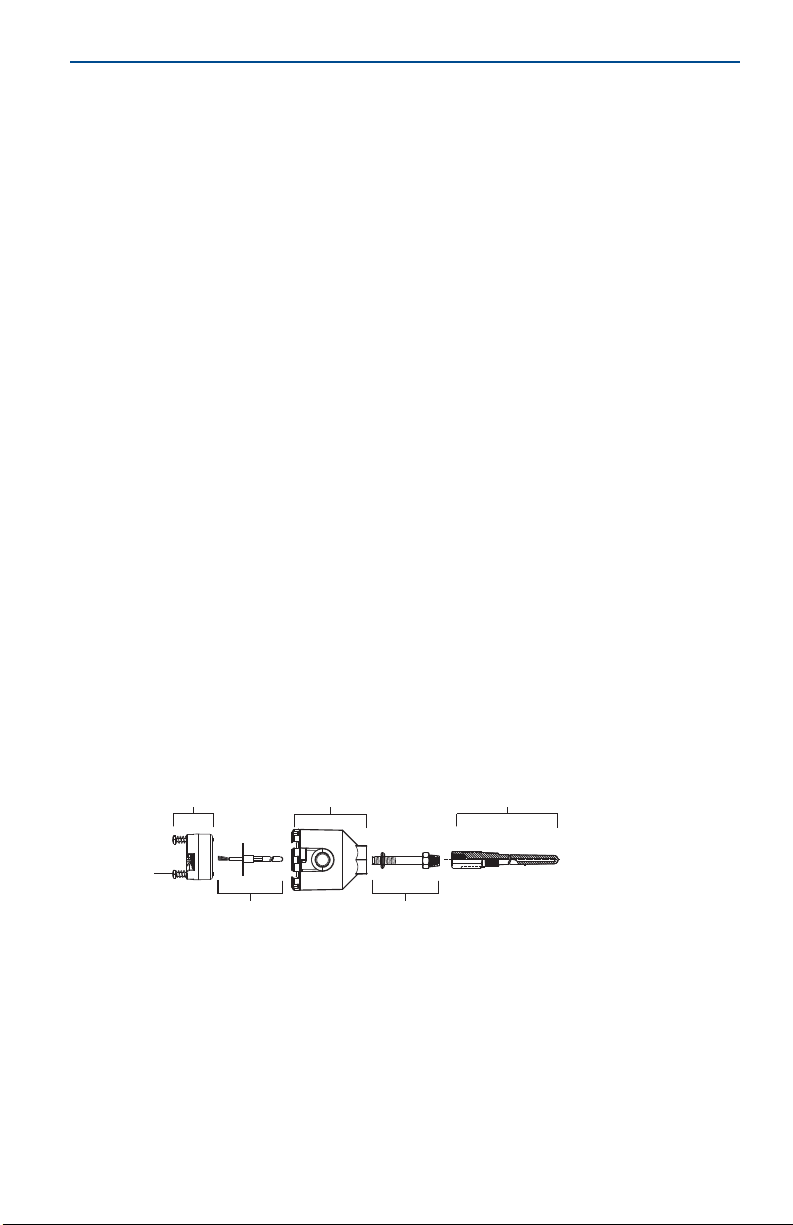

3.3 Mounting to a DIN rail

September 2016

To attach the Rosemount 148H to a

A

DIN rail, assemble the appropriate

rail mounting kit (part number

00248-1601-0001) to the

B

transmitter as shown.

C

A. Mounting hardware

B. Transmitter

C. Rail clip

4.0 Connect the wiring

Wiring diagrams are located on the top label of the transmitter.

An external power supply is required to operate the transmitter.

The power required across the transmitter power terminals is 12 to 42.4 Vdc

(the power terminals are rated to 42.4 Vdc). To prevent damaging the

transmitter, do not allow terminal voltage to drop below 12.0 Vdc when

changing the configuration parameters.

4.1 Power the transmitter

1. Connect the positive power lead to the “+” terminal.

2. Connect the negative power lead to the “–” terminal.

3. Tighten the terminal screws.

4. Apply power (12–42 Vdc).

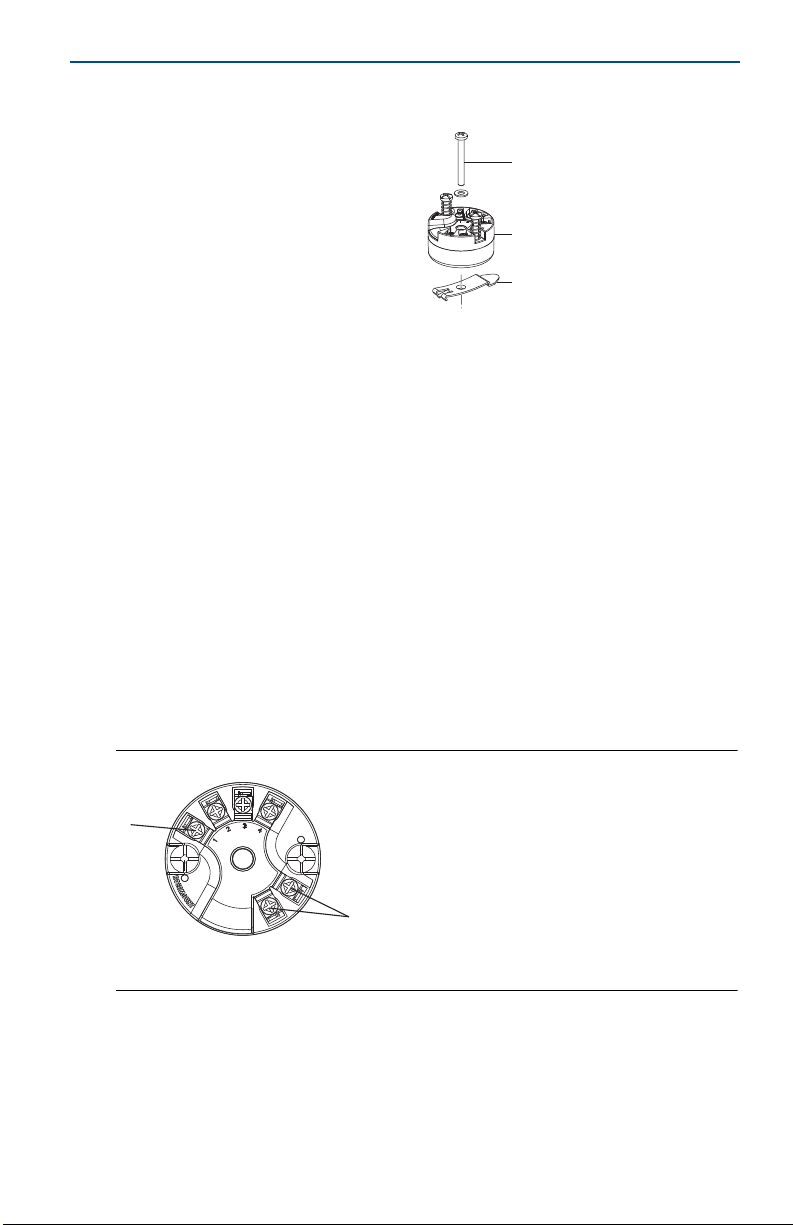

Figure 1. Power, Communication, and Sensor Terminals

A

+

–

B

A. Sensor terminals

B. Power/communication terminals

6

Page 7

September 2016

A

B

D

C

Quick Start Guide

4.2 Ground the transmitter

Ungrounded thermocouple, and RTD/Ohm inputs

Each process installation has different requirements for grounding. Use the

grounding options recommended by the facility for the specific sensor type or

begin with grounding Option 1 (the most common).

Option 1 (for grounded housing):

1. Connect sensor wiring shield to the transmitter housing.

2. Ensure the sensor shield is electrically isolated from surrounding fixtures that

may be grounded.

3. Ground signal wiring shield at the power supply end.

A. Sensor wires

B. Transmitters

C. 4–20 mA loop

D. Shield ground point

Option 2 (for ungrounded housing):

1. Connect signal wiring shield to the sensor wiring shield.

2. Ensure the two shields are tied together and electrically isolated from the

transmitter housing.

3. Ground shield at the power supply end only.

4. Ensure the sensor shield is electrically isolated from the surrounding grounded

fixtures.

B

A

A. Sensor wires

B. Transmitters

C. 4–20 mA loop

D. Shield ground point

C

D

Option 3 (for grounded or ungrounded housing):

1. Ground sensor wiring shield at the sensor, if possible.

2. Insure that the sensor wiring and signal wiring shields are electrically isolated

from the transmitter housing.

3. Do not connect the signal wiring shield to the sensor wiring shield.

7

Page 8

Quick Start Guide

A

B

D

C

4. Ground signal wiring shield at the power supply end.

September 2016

A. Sensor wires

B. Transmitters

C. 4–20 mA loop

D. Shield ground point

Grounded thermocouple inputs

Option 4

1. Ground sensor wiring shield at the sensor.

2. Ensure that the sensor wiring and signal wiring shields are electrically isolated

from the transmitter housing.

3. Do not connect the signal wiring shield to the sensor wiring shield.

4. Ground signal wiring shield at the power supply end.

A

A. Sensor wires

B. Transmitters

B

C

D

C. 4–20 mA loop

D. Shield ground point

8

Page 9

September 2016

Quick Start Guide

5.0 Product Certifications

Rev 1.5

5.1 Approved Manufacturing Locations

Emerson Process Management - Chanhassen, Minnesota, USA

Rosemount Temperature GmbH - Germany

Emerson Process Management Asia Pacific - Singapore

5.2 European Directive Information

A copy of the EC Declaration of Conformity can be found at the end of the Quick Start Guide.

The most recent revision of the EC Declaration of Conformity can be found at

EmersonProcess.com/Rosemount

5.3 Ordinary Location Certification from FM Approvals

As standard, the transmitter has been examined and tested to determine that the design

meets the basic electrical, mechanical, and fire protection requirements by FM Approvals, a

nationally recognized test laboratory (NRTL) as accredited by the Federal Occupational

Safety and Health Administration (OSHA).

North America

E5 FM Explosionproof, Dust-Ignitionproof, and Nonincendive

Certificate: 3032198

Standards: FM Class 3600:2011, FM Class 3611:2004, FM Class 3615:2006,

Markings: XP CL I, DIV 1, GP B, C, D; DIP CL II/III, DIV 1, GP E, F, G; NI CL I, DIV 2, GP A, B,

I5 FM Intrinsic Safety and Nonincendive

Certificate: 3032198

Standards Used: FM Class 3600:2011, FM Class 3610:2010, FM Class 3611:2004, FM

Markings: IS CL I/II/III, DIV 1, GP A, B, C, D, E, F, G; NI CL1, DIV 2, GP A, B, C, D; T6(–50 °C

Special Conditions for Safe Use (X):

1. When no enclosure option is selected, the Rosemount 148 Transmitter shall be installed

in an enclosure meeting the requirements of ANSI/ISA S82.01 and S82.03 or other

applicable ordinary location standards.

2. No enclosure or Buz Head option cannot be selected to maintain a Type 4X rating.

3. Enclosure option must be selected to maintain a Type 4 Rating.

I6 CSA Intrinsic Safety and Division 2

Certificate:1091070

Standards: CAN/CSA C22.2 No. 0-M90, CSA Std. C22.2 No. 25-1966, CAN/CSA C22.2

Markings: IS CL I, DIV 1 GP A, B, C, D when installed per Rosemount drawing

FM Class 3810:2005, IEC 60529: 2004, NEMA

C, D; T5(–50 °C ≤ T

00148-1065; Type 4X; IP66/68

Class 3810:2005, IEC 60529: 2004, NEMA - 250: 1991

≤ T

≤ +40 °C), T5(–50 °C ≤ Ta ≤ +75 °C) when installed per Rosemount

a

drawing 00148-1055; Type 4X; IP66/68

No. 94-M91, CAN/CSA C22.2 No. 157-92, CSA C22.2 No. 213-M1987, C22.2

No 60529-05

00248-1056; Suitable for CL I DIV 2 GP A, B, C, D when installed per

Rosemount drawing 00248-1055; T6(–50 °C ≤ T

+60 °C); Type 4X, IP66/68 for enclosure options “A”, “G”, “H”, “U”; Seal not

required (See drawing 00248-1066).

.

®

- 250: 1991

≤ +85 °C); when installed per Rosemount drawing

a

≤ +40 °C), T5(–50 °C ≤ Ta ≤

a

9

Page 10

Quick Start Guide

September 2016

K6 CSA Explosionproof, Intrinsic Safety, and Division 2

Certificate: 1091070

Standards: CAN/CSA C22.2 No. 0-M90, CSA Std. C22.2 No. 25-1966, CSA Std. C22.2 No.

30-M1986, CAN/CSA C22.2 No. 94-M91, CSA Std. C22.2 No.142-M1987,

CAN/CSA C22.2 No. 157-92, CSA C22.2 No. 213-M1987, C22.2 No

60529-05

Markings: XP CL I/II/III, DIV 1, GP B, C, D, E, F, G when installed per Rosemount drawing

00248-1066; IS CL I, DIV 1 GP A, B, C, D when installed per Rosemount

drawing 00248-1056; Suitable for CL I DIV 2 GP A, B, C, D when installed per

Rosemount drawing 00248-1055; T6(–50 °C ≤ T

+60 °C); Type 4X, IP66/68 for enclosure options “A”, “G”, “H”, “U”; Seal not

≤ +40 °C), T5(–50 °C ≤ Ta ≤

a

required (See drawing 00248-1066).

Europe

E1 ATEX Flameproof

Certificate: FM12ATEX0065X

Standards: EN 60079-0: 2012, EN 60079-1: 2007, EN 60529:1991 +A1:2000

Markings: II 2 G Ex d IIC T6…T1 Gb, T6(-50 °C ≤ Ta ≤ +40 °C), T5…T1(-50 °C ≤ T

See Tab le 2 at the end of the Product Certifications section for process temperatures

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become a source of

ignition in Group III environments.

3. Guard the LCD cover against impact energies greater than 4 joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected to temperature

probes with Enclosure option “N”.

6. Care shall be taken by the end user to ensure that the external surface temperature on

the equipment and the neck of DIN Style Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from electrostatic discharge. Avoid

installations that cause electrostatic build-up on painted surfaces, and only clean the

painted surfaces with a damp cloth. If paint is ordered through a special option code,

contact the manufacturer for more information.

I1 ATE X Int rinsi c Sa fety

Certificate: Baseefa08ATEX0030X

Standards: EN 60079-0: 2012, EN 60079-11: 2012

Markings: II 1 G Ex ia IIC T5/T6 Ga, T5(-60 °C ≤ T

See Tab le 3 at the end of the Product Certifications section for entity parameters

Special Condition for Safe Use (X):

1. The apparatus must be installed in an enclosure which affords it a degree of protection

of at least IP20. Non-metallic enclosures must have a surface resistance of less than

1 GΩ; light alloy or zirconium enclosures must be protected from impact and friction

when installed.

N1 ATEX Type n - with enclosure

Certificate: BAS00ATEX3145

Standards: EN 60079-0:2012, EN 60079-15:2010

Markings: II 3 G Ex nA IIC T5 Gc (-40 °C ≤ T

+60 °C)

≤ +80 °C), T6(-60 °C ≤ Ta ≤ +60 °C)

a

≤ +70 °C);

a

≤

a

10

Page 11

September 2016

Quick Start Guide

NC ATEX Type n - without enclosure

Certificate: Baseefa13ATEX0092X

Standards: EN 60079-0:2012, EN 60079-15:2010

Markings: II 3 G Ex nA IIC T5/T6 Gc, T5(–60 °C ≤ T

≤ +80 °C), T6(–60 °C ≤ Ta ≤

a

+60 °C)

Special Condition for Safe Use (X):

1. The Rosemount 148 Transmitter must be installed in a suitably certified enclosure such

that it is afforded a degree of protection of at least IP54 in accordance with IEC 60529

and EN 60079-15.

ND ATEX Du st

Certificate: FM12ATEX0065X

Standards: EN 60079-0: 2012, EN 60079-31: 2009, EN 60529:1991 +A1:2000

Markings: II 2 D Ex tb IIIC T130 °C Db, (–40 °C ≤ T

SeeTab le 2 at the end of the Product Certifications section for process temperatures.

≤ +70 °C); IP66

a

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become a source of

ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than 4 joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected to temperature

probes with Enclosure option “N”.

6. Care shall be taken by the end user to ensure that the external surface temperature on

the equipment and the neck of DIN Style Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from electrostatic discharge. Avoid

installations that cause electrostatic build-up on painted surfaces, and only clean the

painted surfaces with a damp cloth. If paint is ordered through a special option code,

contact the manufacturer for more information.

International

E7 IECEx Flameproof and Dust

Certificate: IECEx FMG 12.0022X

Standards: IEC 60079-0:2011, IEC 60079-1:2007-04, IEC 60079-31:2008

Markings: Ex d IIC T6…T1 Gb, T6(–50 °C ≤ T

tb IIIC T130 °C Db, (–40 °C ≤ T

See Tab le 2 at the end of the Product Certifications section for process temperatures.

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become a source of

ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than 4 joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected to temperature

probes with Enclosure option “N”.

6. Care shall be taken by the end user to ensure that the external surface temperature on

the equipment and the neck of DIN Style Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from electrostatic discharge. Avoid

installations that cause electrostatic build-up on painted surfaces, and only clean the

painted surfaces with a damp cloth. If paint is ordered through a special option code,

contact the manufacturer for more information.

≤ +40 °C), T5…T1(–50 °C ≤ Ta ≤ +60 °C); Ex

a

≤ +70 °C); IP66

a

11

Page 12

Quick Start Guide

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 08.0011X

Standards: IEC 60079-0:2011, IEC 60079-11:2011

Markings: Ex ia IIC T5/T6 Ga, T5(-60 °C ≤ T

See Tab le 3 at the end of the Product Certifications section for entity parameters.

≤ +80 °C), T6(-60 °C ≤ Ta ≤ +60 °C);

a

September 2016

Special Conditions for Safe Use (X):

1. The apparatus must be installed in an enclosure which affords it a degree of protection

of at least IP20. Non-metallic enclosures must have a surface resistance of less than

1 GΩ; light alloy or zirconium enclosures must be protected from impact and friction

when installed.

N7 IECEx Type n - with enclosure

Certificate: IECEx BAS 07.0055

Standards Used: IEC 60079-0:2011, IEC 60079-15:2010

Markings: Ex nA IIC T5 Gc; T5(-40 °C ≤ T

NG IECEx Type n - without enclosure

Certificate: IECEx BAS 13.0052X

Standards Used: IEC 60079-0:2011, IEC 60079-15:2010

Markings: Ex nA IIC T5/T6 Gc; T5(-60 °C ≤ T

≤ +70 °C).

a

≤ +80 °C), T6(-60 °C Ta ≤ +60 °C).

a

Special Conditions for Safe Use (X):

1. The Rosemount 148 Temperature Transmitter must be installed in a suitably certified

enclosure such that it is afforded a degree of protection of at least IP54 in accordance

with IEC 60529 and IEC 60079-15.

5.4 Combinations

K5 Combination of E5 and I5.

12

Page 13

September 2016

5.5 Tables

Table 2. Process Temperature

Quick Start Guide

Tem pe ra tu re

class

T6 –50 °C to +40 °C 55 55 60 65

T5 –50 °C to +60 °C 70 70 70 75

T4 –50 °C to +60 °C 100 110 120 130

T3 –50 °C to +60 °C 170 190 200 200

T2 –50 °C to +60 °C 280 300 300 300

T1 –50 °C to +60 °C 440 450 450 450

Ambient

temperature

Process temperature w/o LCD display cover (°C)

No ext. 3-in. 6-in. 9-in.

Table 3. Entity Parameter

Parameters HART loop terminals + and – Sensor terminals 1 to 4

Volta ge U

Current I

i

Power P

i

Capacitance C

Inductance L

i

i

i

30 V 45 V

130 mA 26 mA

1 W 290 mW

3.6 nF 2.1 nF

0 mH 0 μH

13

Page 14

Quick Start Guide

Figure 2. Rosemount 148 Declaration of Conformity

September 2016

14

Page 15

September 2016

Quick Start Guide

15

Page 16

Quick Start Guide

September 2016

16

Page 17

September 2016

ᴹ

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

Rosemount 148

List of Rosemount 148 Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘䍘Hazardous Substances

䫵

Lead

(Pb)

⊎

Mercury

(Hg)

䭹

Cadmium

(Cd)

ޝԧ䬜䬜

Hexavalent

Chromium

(Cr +6)

ཊⓤ㚄㚄㤟

Polybrominated

biphenyls

(PBB)

ཊⓤ㚄㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

X O O O O

O

༣փ㓴Ԧ

Housing

Assembly

O O O X O

O

Րᝏಘ㓴Ԧ

Sensor

Assembly

X O O O O

O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

Quick Start Guide

17

Page 18

Global Headquarters

Emerson Process Management

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@EmersonProcess.com

North America Regional Office

Emerson Process Management

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Process Management

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@EmersonProcess.com

Europe Regional Office

Emerson Process Management Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@EmersonProcess.com

Asia Pacific Regional Office

Emerson Process Management Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.EmersonProcess.com

Middle East and Africa Regional Office

Emerson Process Management

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emi rates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

*00825-0100-4148*

Quick Start Guide

00825-0100-4148, Rev GA

Linkedin.com/company/Emerson-Process-Management

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/us er/RosemountMeasur ement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found at

www.Emerson.com/en-us/pages/Terms-of-Use.aspx

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Rosemount and Rosemount logotype are trademarks of Emerson

Process Management.

NEMA is a registered trademark and service mark of the National

Electrical Manufacturers Association.

All other marks are the propert y of their respective owners.

© 2016 Emerson Process Management. All rights reserved.

September 2016

Loading...

Loading...