Page 1

Rosemount™ Integral Orifice

Flow Meter Series

Reference Manual

00809-0100-4686, Rev KA

December 2017

Page 2

Page 3

Reference Manual

00809-0100-4686, Rev KA

Contents

1Section 1: Introduction

2Section 2: Installation

Contents

December 2017

1.1 Using this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Returning the product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 Functional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Receiving and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.1 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.2 Straight run requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.3 Bolting a transmitter to the Rosemount 1195 . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.4 Direct mount orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.5 Remote mount orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.6 Temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3Section 3: Commissioning

3.1 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Direct mount applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.1 Liquid service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.2 Gas service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.3 Steam service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Remote mount applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.1 Liquid service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.2 Gas service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.3 Steam service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4Section 4: Operation and Maintenance

4.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3 RTD Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.1 Replacing an RTD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Contents

AAppendix A: Specifications and Reference Data

iii

Page 4

Contents

December 2017

Reference Manual

00809-0100-4686, Rev KA

A.1 Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

A.2 Ordering Information, Specifications, and Drawings . . . . . . . . . . . . . . . . . . . . . . 27

iv

Contents

Page 5

Reference Manual

00809-0100-4686, Rev KA

Rosemount Integral Orifice Flow Meter

Series

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

Asia Pacific- 65 777 8211

Europe/Middle East/Africa - 49 (8153) 9390

North American Response Center

Title Page

December 2017

Equipment service needs.1-800-654-7768 (24 hours—includes Canada)

Outside of these areas, contact your local Emerson

The products described in this document are NOT designed for nuclear-qualified applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware or

products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson Sales

Representative.

This device is intended for use in temperature monitoring applications and should not be used

in control and safety applications.

™

representative.

Title Page

v

Page 6

Title Page

December 2017

Reference Manual

00809-0100-4686, Rev KA

vi

Title Page

Page 7

Reference Manual

00809-0100-4686, Rev KA

Section 1 Introduction

1.1 Using this manual

The sections in this manual provide information on installing, operating, and maintaining the

Rosemount Integral Orifice Flow Meter Series.

The sections in this manual are organized as follows:

Section 2: Installation contains mechanical and electrical installation instructions.

Section 3: Commissioning contains techniques for properly commissioning the device.

Section 4: Operation and Maintenance contains operation and maintenance techniques.

Appendix A: Specifications and Reference Data supplies procedure on how to get the

specifications, ordering information, and product certification.

Section 1: Introduction

December 2017

1.2 Returning the product

To expedite the return process, call the Rosemount National Response Center toll-free at

800-654-7768. This center, available 24 hours a day, will assist you with any needed information

or materials.

The center will ask for the following information:

Product model

Serial numbers

The last process material to which the product was exposed

The center will provide

A Return Material Authorization (RMA) number

Instructions and procedures that are necessary to return goods that were exposed to

hazardous substances

Note

If a hazardous substance is identified, a Material Safety Data Sheet (MSDS), required by law to be

available to people exposed to specific hazardous substances, must be included with the

returned materials.

Introduction

1

Page 8

Section 1: Introduction

December 2017

1.3 Considerations

1.3.1 Functional

The Rosemount 1195 produces the most accurate and repeatable measurement when it is used

in single-phase flow or steam flow above the saturation temperature. Location of the

Rosemount 1195 in pulsating flow will cause a noisy signal. Vibration can also distort the output

signal and compromise the structural limits of the flow meter.

Mount the Rosemount 1195 in a secure run of pipe as far as possible from pulsation sources

such as check valves, reciprocating compressors or pumps, and control valves.

Install the Rosemount 1195 in the correct location within the piping branch to prevent

measurement inaccuracies caused by flow disturbances.

Process temperature limits for direct mount applications is from –40 to 450 °F (–40 to 232°C).

Process temperature limits for remote mount applications is –112 to 554°F (–80 to 290°C).

Contact DP Flow specialists on availability of special all welded designs for applications with

process temperatures as low as –320 °F (–195 °C) or as high as 850 °F (454 °C).

Reference Manual

00809-0100-4686, Rev KA

Vibration effect for Rosemount 1195, 3051SFP, 3051CFP,

2051CFP

Less than ±0.1percent of URL when tested per the requirements of IEC60068-2-6 (10 to 1000 Hz

test frequency range, 0.075 mm displacement peak amplitude, 10 m/s2 acceleration

amplitude).

2

Introduction

Page 9

Reference Manual

00809-0100-4686, Rev KA

Section 2 Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Receiving and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

2.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety of the

personnel performing the operations. Refer to the following safety messages before performing any

operation in this section.

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury:

Do not remove the transmitter cover in explosive atmospheres when the circuit is live.

Before connecting a Field Communicator in an explosive atmosphere, make sure the instruments in

the loop are installed in accordance with intrinsically safe or non-incendive field wiring practices.

Verify that the operating atmosphere of the transmitter is consistent with the appropriate hazardous

locations certifications.

Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and the terminals.

The product may be hot while in service, potentially causing burns. Handle with care.

Installation

December 2017

2.2 Receiving and inspection

Flow meters are available in different models and with different options, so it is important to inspect and

verify that the appropriate model was delivered before installation.

Upon receipt of the shipment, check the packing list against the material received and the purchase

order. All items are tagged with a model number, serial number, and customer tag number. Report any

damage to the carrier.

Installation

3

Page 10

Installation

December 2017

2.3 Installation

2.3.1 Handling

The product tag is not designed to withstand the weight of the flow meter- do not lift the product by the

tag. Do not use any part of the Rosemount 1195 Flow Meter as a step or hand support. Product is not

designed to withstand the weight of individuals.

Reference Manual

00809-0100-4686, Rev KA

2.3.2 Straight run requirements

Figure 2-1. Reducer

U D

(2d to d over a length of 1.5d to 3d)

Figure 2-2. Single 90° Bend Flow from One Branch

U D

Figure 2-3. Two or More 90° Bends in Same Planes

U

D

(1)

Figure 2-4. Two or More 90° Bends in Different Planes

U D

Figure 2-5. Expander

(0.5d to d over a length of d to 2d)

1, For dimensions, see Table 1 on page 5.

4

U D

Installation

Page 11

Reference Manual

00809-0100-4686, Rev KA

Figure 2-6. Ball/Gate Valve Fully Open

U D

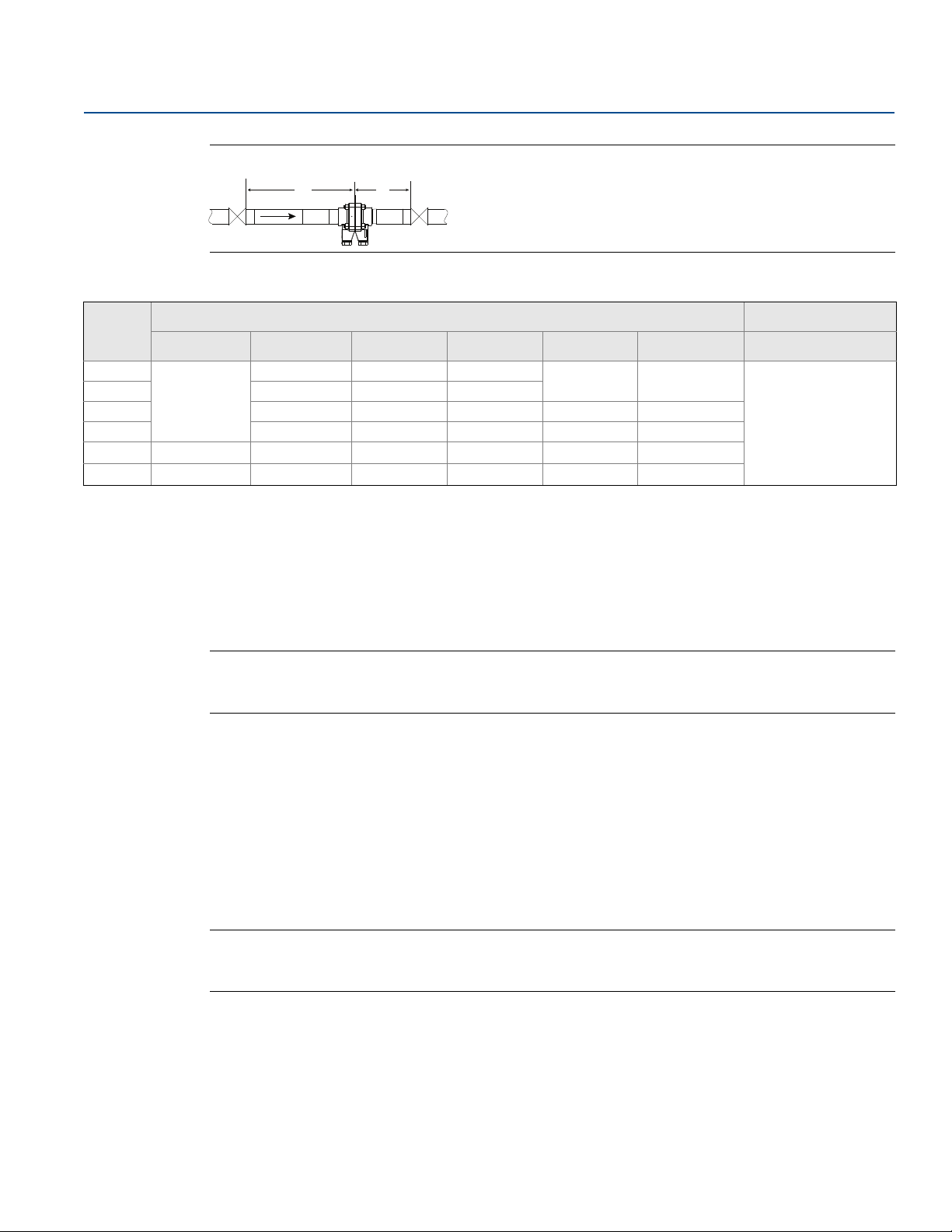

Table 1. Straight Run Requirements (in Pipe Diameters)

Installation

December 2017

(1)

β

Upstream (U) Downstream (D)

Figure 2-1 Figure 2-2 Figure 2-3 Figure 2-4 Figure 2-5 Figure 2-6 Figures 3–8

0.20

0.40 25 27 31

0.50 25 28 33 23 23

0.60 27 31 37 25 25

0.70 23 32 35 42 28 28

0.75 25 35 38 45 30 30

Interpolation of intermediate β values can be used.

1.

2.

All straight lengths are expressed as multiples of the pipe inside diameter (d) and shall be measured from the upstream face of orifice plate.

20

24 25 30

22 22

2.3.3 Bolting a transmitter to the Rosemount 1195

If the Rosemount 1195 is ordered separately from the Rosemount transmitter and will be used in a direct

mount configuration, it will need to be assembled to the transmitter.

Follow the directions below to assemble the Rosemount 1195 to a transmitter with manifold:

Note

Units shipped from the factory direct mounted are pressure tested and characterized with the primary

attached. Factory assembly is recommended for best performance.

Bolt to a 3- or 5-valve manifold

(2)

10

Installation

1. Use studs and nuts supplied with the Rosemount1195 to connect to the transmitter sensor and

manifold.

2. Always use a 3- or 5-valve manifold when direct mounting a transmitter to the Rosemount 1195.

3. Observe the side of the orifice plate marked “Inlet.” This side should align to the High Pressure side of

the DP transmitter.

4. Torque the bolts to 32 lb-ft using a cross pattern.

Note

Protect the transmitter sensing diaphragms and do not remove the O-rings in transmitter sensor

module.

5. Carefully assemble the Rosemount 1195 body to the manifold and pressure transmitter sensor

making sure the “H” and “L” on transmitter and primary match.

6. Preload to 16 lb-ft then final torque at 32 lb-ft using a cross pattern.

5

Page 12

Installation

December 2017

Reference Manual

00809-0100-4686, Rev KA

Figure 2-7. Rosemount 1195 Body

A

B

F

E

A. Manifold

B. Gaskets

C. Studs

D. Nuts

E. Transmitter

F. Rosemount 1195 body

G. Rosemount 1195 orifice plate

(1)

C

D

G

1, Transmitter and housing are shown for clarity purposes - only supplied if ordered.

6

Installation

Page 13

Reference Manual

A

B

C

A

C

B

00809-0100-4686, Rev KA

2.3.4 Direct mount orientation

A direct mounted Rosemount 1195 may be shipped with the transmitter already bolted directly to the

sensor.

Note

Process temperature limits for direct mount applications is from –40 to 450°F (–40 to 232 °C). Refer to

“Remote mount orientation” on page 9 if the process could potentially exceed this temperature range.

Gas in horizontal pipes

Rosemount 1195 should be mounted above the pipe to ensure that condensate does not collect on the

transmitter sensing diaphragms. Orient the unit within the recommended zone as shown in Figure 2-8.

Figure 2-8. Direct Mount Gas in Horizontal Pipes

A

Installation

December 2017

B

C

A. 90° recommended zone

B. Vertical plane

C. Horizontal plane

Liquid or steam in horizontal pipes

Rosemount 1195 should be mounted below the pipe to ensure that gases do not collect on the

transmitter sensing diaphragms. Orient the unit within the recommended zone as shown in Figure 2-9.

Figure 2-9. Direct Mount Liquid or Steam in Horizontal Pipes

C

B

A

A. 90° recommended zone

Installation

B. Vertical plane

C. Horizontal plane

7

Page 14

Installation

A

FLOW

A

A

December 2017

Reference Manual

00809-0100-4686, Rev KA

Liquid in vertical pipes

Note

Rosemount 1195 should not be used in vertical liquid or steam applications if the fluid is flowing down.

Vertical steam should be remote mounted.

Figure 2-10. Direct Mount Liquid in Vertical Pipe

A. 360° recommended zone

Gas in vertical pipes

Note

Due to drain vent orientation, a direct mount Rosemount1195 should not be used in vertical gas

applications if the fluid is flowing up. Consider remote mounting the pressure transmitter to facilitate

condensate draining.

Figure 2-11. Direct Mount Gas in Vertical Pipes

FLOW

A. 360° recommended zone

A

8

Installation

Page 15

Reference Manual

FLOW

A

B

C

D

E

F

00809-0100-4686, Rev KA

2.3.5 Remote mount orientation

Gas in vertical or horizontal pipes

Figure 2-12. Remote Mount Gas in Vertical or Horizontal Pipes

A

B

C

D

Installation

December 2017

E

A. Low valve

B. Vent

C. High valve

D. Equalizer valve

E. Block valves

FLOW

Liquid or steam in vertical or horizontal pipes

Note

Rosemount1195 should not be used in vertical liquid or steam applications if the fluid is flowing down.

Figure 2-13. Remote Mount Liquid or steam in Vertical or Horizontal Pipes

A. Vent

B. High valve

C. Equalizer valve

D. Vent valves

E. Low valve

F. Block val ves

Installation

9

Page 16

Installation

December 2017

Reference Manual

00809-0100-4686, Rev KA

Remote mount adapter installation

Rosemount 1195 is available with 1/2–14-in. NPT connections (option code G2). The 1/2-in. connections

can be rotated to attain connection centers of 2-, 2

1

/8-, or 2 1/4-in. (51, 54, or 57 mm). See Figure 2-14 for

detail. Use a lubricant or sealant when making the process connections.

Ensure all four flange studs are installed and tightened prior to applying pressure to prevent process

leakage.

Figure 2-14. Adapter for Remote Mounting

2.00 (51)

2.13 (54)

2.25 (57)

Note

Do not attempt to loosen or remove the nuts or studs while the Rosemount 1195 is in service.

Perform the following to install flange adapters to the instrument connection of the Rosemount 1195

(see Figure 2-15 on page 11).

1. Place O-ring in the groove on the instrument connection face.

2. Position flange adapters on top of the instrument connection with the machined surface in contact

with the O-ring.

3. Insert studs through the Rosemount 1195 instrument connection and flange adapters.

4. Thread nuts onto studs. Tighten nuts to 32 ft-lbs.

O-rings must be replaced each time the Rosemount 1195 is disassembled for installation or

maintenance.

10

Installation

Page 17

Reference Manual

A

B

C

D

E

F

00809-0100-4686, Rev KA

Figure 2-15. Rosemount 1195 Remote Mount Flange Adapter Installation

A. O-ring groove

B. Nut

C. Flange adapter

D. O-ring

E. Stud

F. Rosemount 1195 instrument connection

Installation

December 2017

2.3.6 Temperature sensors

No cabling is provided on Rosemount 1195 and 3051SFP models ordered with temperature sensors.

Installation

11

Page 18

Installation

December 2017

Reference Manual

00809-0100-4686, Rev KA

12

Installation

Page 19

Reference Manual

00809-0100-4686, Rev KA

Section 3 Commissioning

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Direct mount applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Remote mount applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

3.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the safety of the

personnel performing the operations. Please refer to the following safety messages before performing

any operation in this section.

Explosions could result in death or serious injury:

Do not remove the transmitter cover in explosive atmospheres when the circuit is live.

Before connecting a Field Communicator in an explosive atmosphere, make sure the instruments in

the loop are installed in accordance with intrinsically safe or non-incendive field wiring practices.

Verify that the operating atmosphere of the transmitter is consistent with the appropriate hazardous

locations certifications.

Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Failure to follow these installation guidelines could result in death or serious injury:

Make sure only qualified personnel perform the installation.

If the line is pressurized, serious injury or death could occur by opening valves.

Commissioning

December 2017

Commissioning

13

Page 20

Commissioning

December 2017

3.2 Direct mount applications

3.2.1 Liquid service

1. Pressurize line.

2. Open the equalizer valve.

3. Open the high and low side valves.

4. Bleed drain/vent valves until no gas is apparent in the liquid.

5. Close the vent/drain valves.

6. Close the low side valve.

7. Check the transmitter zero according to the transmitter product manual so that the output on the

test meter reads zero percent of span.

8. Close the equalizer valve.

9. Open the low side valve. The system is now operational.

Reference Manual

00809-0100-4686, Rev KA

Figure 3-1. Direct Mount Liquid Service

C

D

A

B

A. Vent

B. Low valve

C. Equalizer valve

D. High valve

14

Commissioning

Page 21

Reference Manual

A

B

C

D

00809-0100-4686, Rev KA

3.2.2 Gas service

1. Pressurize line.

2. Open the equalizer valve.

3. Open the high and low side valves.

4. Open drain/vent valves to ensure no liquid is present.

5. Close the vent/drain valves.

6. Close the low side valve.

7. Check the transmitter zero according to the transmitter product manual so that the output on the

test meter reads zero percent of span.

8. Close the equalizer valve.

9. Open the low side valve. The system is now operational.

Figure 3-2. Direct Mount Gas Service

Commissioning

December 2017

A. Vent

B. High valve

C. Equalizer

D. Equalizer valve

Commissioning

15

Page 22

Commissioning

A

B

C

D

December 2017

3.2.3 Steam service

1. Remove pressure from line.

2. Open equalizer, high, and low side valves.

3. Fill manifold and transmitter with water via drain vents.

4. Close low side valve.

5. Pressurize line.

6. Gently tap electronics body, manifold head, and Rosemount 1195 body with a small wrench to

dislodge any entrapped air.

7. Zero electronics.

8. Close equalizer valve.

9. Open the low side valve. The system is now operational.

Figure 3-3. Direct Mount Steam Service

Reference Manual

00809-0100-4686, Rev KA

A. Vent

B. Low valve

C. Equalizer valve

D. High valve

16

Commissioning

Page 23

Reference Manual

FLOW

A

B

C

D

E

F

00809-0100-4686, Rev KA

3.3 Remote mount applications

3.3.1 Liquid service

1. Pressurize line.

2. Open equalizer valve on transmitter manifold. Close equalizer valve at Rosemount 1195, if one is

used.

3. Open high and low side transmitter manifold valves and high and low block valves at Rosemount

1195.

4. Bleed drain/vent valves on transmitter manifold until no air is present.

5. Close drain vent valves, then bleed vent valves at the Rosemount 1195 block valves until no air is

present.

6. Close vent valves at Rosemount 1195 block valves.

7. Close equalizer valve at transmitter manifold.

8. Close low and high side block valves at Rosemount 1195.

9. Open vent valves at Rosemount 1195 block valves.

Commissioning

December 2017

10.Check transmitter zero according to transmitter manual.

11.Close vent valves at Rosemount 1195 block valves.

12.Open high and low side block valves at Rosemount 1195.

Figure 3-4. Remote Liquid Service

A. Vent

B. High valve

C. Equalizer valve

D. Vent valves

E. Low valve

F. Block val ves

Commissioning

17

Page 24

Commissioning

December 2017

3.3.2 Gas service

1. Pressurize line.

2. Open equalizer valve on transmitter manifold.

3. Open high and low side transmitter manifold valves.

4. Open drain/vent valves on transmitter manifold to ensure no liquids are present.

5. Close drain/vent valves.

6. Close low side transmitter manifold valve.

7. Check transmitter zero according to transmitter manual.

8. Close equalizer on transmitter manifold.

9. Open low side valve on transmitter manifold. The system is now operational.

Figure 3-5. Remote Gas Service

Reference Manual

00809-0100-4686, Rev KA

B

C

A. Low valve

B. Vent

C. High valve

D. Equalizer valve

E. Block valves

A

D

E

FLOW

18

Commissioning

Page 25

Reference Manual

FLOW

A

B

C

D

E

F

00809-0100-4686, Rev KA

3.3.3 Steam service

1. Remove pressure from line or close block valves at Rosemount 1195.

2. Open equalizer valves, high and low side valves on the transmitter manifold. Close equalize valve at

Rosemount 1195, if one is used.

3. Open vent valves at Rosemount 1195 block valves.

4. Fill transmitter manifold and instrument lines with water via low side vent at Rosemount 1195 block

valves.

5. Open and close vent valves at transmitter to bleed out trapped air.

6. Close the equalizer valve at transmitter manifold.

7. Complete filling the low side sensing line.

8. Gently tap electronics body, transmitter manifold, instrument lines, and Rosemount 1195 with a

small wrench to dislodge any trapped air.

9. Check transmitter zero according to transmitter manual.

10.Close vent valves at Rosemount 1195 block valves.If block valves at Rosemount 1195 had been closed

they should now be opened. System is now operational for steam flow measurement.

Commissioning

December 2017

Figure 3-6. Remote Steam Service

A. Vent

B. High valve

C. Equalizer valve

D. Vent valves

E. Low valve

F. Block val ves

Commissioning

19

Page 26

Commissioning

December 2017

Reference Manual

00809-0100-4686, Rev KA

20

Commissioning

Page 27

Reference Manual

00809-0100-4686, Rev KA

Operation and Maintenance

Section 4 Operation and Maintenance

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

RTD Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

4.1 Safety Messages

Procedures and instructions in this section may require special precautions to ensure the safety of the

personnel performing the operations. Information that raises potential safety issues is indicated by a

warning symbol ( ). Refer to the following safety messages before performing an operation preceded

by this symbol.

December 2017

Explosions can result in death or serious injury:

Do not remove the instrument cover in explosive environments when the circuit is live.

Both transmitter covers must be fully engaged to meet

explosion-proof requirements.

Before connecting a communicator in an explosive atmosphere, make sure the instruments in the

loop are installed in accordance with intrinsically safe or nonincendive field wiring practices.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and the terminals.

Operation and Maintenance

21

Page 28

Operation and Maintenance

December 2017

4.2 Troubleshooting

If a malfunction is suspected despite the absence of diagnostic messages on the communicator display,

follow the procedures described below to verify that the flow meter hardware and process connections

are in good working order. Always approach the most likely and easiest-to-check conditions first.

Table 4-1. Troubleshooting

Symptom Possible cause Corrective action

• Is the flow arrow pointed in the direction of the flow?

Improper installation

System leaks Check for leaks in instrument piping. Repair and seal all leaks.

Contamination/plugging Remove the flow meter and check for contamination.

Questionable accuracy

or erroneous flow signal

Spiking flow signal Two -ph ase flow

Spiking flow signal

(stream service)

Milliamp reading is zero

Electronics not in

communication

Milliamp reading is low

or high

No response to changes

in applied flow

Low reading/high

reading

Closed valve

Connections (remote mount only)

Entrapped air

(liquid and steam applications)

Operating conditions

Improper insulation

(vertical pipes only)

Excessive vibration

• Verify that the cross reservoirs are perfectly level with one another.

• Is there sufficient straight run upstream and downstream of the flow

meter?

Verify that both HI and LO manifold valves are open.

Verify that vent, equalizer, and line valves are properly

positioned per the “start up procedure.”

Verify that the high side of the electronics is connected to the

high side of the flow meter. Check the same for the low side.

Are there uneven water legs caused by air entrapment in the

instrument connections? If so, bleed air.

Are the operating conditions in compliance with those given at

the time the flow meter was purchased?

Check the flow calculation and the fluid parameters for

accuracy.

Double-check pipe inside diameter for proper sizing.

The flow meter is a head measurement device and will not

accurately measure a two-phase flow.

Added insulation may be required to ensure that a phase change

occurs at the cross reservoirs.

Check the impulse piping for vibration.

• Check if power polarity is reversed

• Verify voltage across terminals (should be 10–55 Vdc)

• Check for bad diode in terminal block

• Replace electronics terminal block

• Check power supply voltage at electronics (10.5 Vdc minimum)

• Check load resistance (250 ohms minimum)

• Check if unit is addressed properly

• Replace electronics board

• Check pressure variable reading for saturation

• Check if output is in alarm condition

• Perform 4–20 mA output trim

• Replace electronics board

• Check test equipment

• Check impulse piping for blockage

• Check for disabled span adjustment

• Check electronics security switch

• Verify calibration settings (4 and 20 mA points)

• Contact factory for replacement

• Check impulse piping for blockage

• Check test equipment

• Perform full sensor trim (if software revision is 35 or higher)

• Contact factory for replacement

Reference Manual

00809-0100-4686, Rev KA

22

Operation and Maintenance

Page 29

Reference Manual

00809-0100-4686, Rev KA

Table 4-1. Troubleshooting

Symptom Possible cause Corrective action

• Check impulse piping for blockage

Erratic reading for

pressure variable

• Check damping

• Check for EMF inter ference

• Contact factory for replacement

Check flow direction

Check that the side of the orifice plate marked “Inlet” is facing upstream. If the DP transmitter is remote

mounted from the Rosemount 1195, be sure that the impulse tubing is connected correctly from the

Rosemount 1195 to the DP transmitter (high to high and low to low).

Check orientation

Improper orientation can result in inaccurate measurements.

Check zero

The transmitter may read off in the high or low direction if not zeroed properly at start-up/commissioning. Refer to the appropriate transmitter reference manual for additional information.

Operation and Maintenance

December 2017

Check valves

The correct valve setting for flow measurement are: equalizer valve fully closed, high and low side valves

fully open.

Check configuration/scaling

Is the 20 mA DP URL of the Rosemount 1195 set properly? This may involve sizing the Rosemount 1195

in the Toolkit Software program to confirm.

Confirm the DCS or PLC and transmitter on Rosemount 1195 are scaled consistently.

Is the square root being taken in the DCS or transmitter attached to the Rosemount 1195? The square

root should not be taken in both places.

Check Rosemount 3051SMV configuration

If a Rosemount 3051SMV Transmitter is being used, its enhanced functionality should be taken into

account during configuration and troubleshooting. The square root should not be taken in the DCS if a

Rosemount 3051SMV Transmitter is being used.

See the Rosemount 3051SMV Reference Manual

4.3 RTD Maintenance

To test the 4-wire RTD (refer to Figure 4-1 on page 24):

for additional information.

1. Disconnect power from the electronics.

2. Remove the temperature terminal housing cover.

3. Disconnect the RTD lead wires from the terminal block.

4. Separate the wires so that the un-insulated ends are not touching anything.

Operation and Maintenance

23

Page 30

Operation and Maintenance

W

R

WW

W

R

R

R

4-wire RTD

Terminal housingRosemount 3051SMV

December 2017

5. Check that the resistance measured between the two red wires is the same as the resistance

measured between the two white wires within +/- 0.1 ohms. Take note of the resistance value

measured between the two white wires for use in step 6.

6. Measure the resistance between one red wire and one white wire. Subtract the resistance measured

in step 5 from the resistance measured in this step. Refer to Table 4-2 on page 25 to determine if this

resistance matches the temperature that the RTD is in contact with.

7. Check the resistance between any wire and the RTD head or sheath. An acceptable resistance is 200

K ohms or greater.

8. If any of the above measurements are not within the acceptable range as stated above, contact an

Emerson representative for a replacement RTD.

9. To return the RTD to service, connect the lead wires as shown in Figure 4-1.

10. Replace the Temperature Terminal Housing cover.

11. Re-connect power to the electronics.

Figure 4-1. Temperature Terminal Housing

Reference Manual

00809-0100-4686, Rev KA

4.3.1 Replacing an RTD

If an RTD needs to be replaced, proceed as follows:

1. Disconnect power from the electronics.

2. Remove the temperature terminal housing cover.

3. Disconnect the RTD lead wires from the terminal block.

Note

Take care not to damage the RTD lead wires or insulation.

7

4. Use a

24

/16-in.deep socket and a pair of vise grip pliers to remove the RTD from the thermowell. It is

necessary to feed the wires through the socket to avoid damaging the lead wires. Grip the socket with

the vise grip pliers and turn the socket to remove the RTD.

Operation and Maintenance

Page 31

Reference Manual

00809-0100-4686, Rev KA

Operation and Maintenance

December 2017

Note

A special tool (part number 28-509004-01) may be purchased to perform this task.

5. Install the new RTD using the socket and pliers as in step 4 above.

6. Connect the RTD lead wires to the terminal block (see Figure 4-1).

7. Replace the temperature terminal housing cover.

8. Re-connect power to the electronics.

Table 4-2. Resistance vs. Temperature

IEC 751

Platinum 100, Alpha = 0.00385 RTD

°F Ohms °F Ohms °F Ohms °F Ohms °C Ohms °C Ohms °C Ohms °C Ohms

–330 18.04 60 106.07 450 187.65 840 263.80 –200 18.52 20 107.79 240 190.47 460 267.56

–320 20.44 70 108.23 460 189.67 850 265.68 –190 22.83 30 111.67 250 194.10 470 270.93

–310 22.83 80 110.38 470 191.68 860 267.56 –180 27.10 40 115.54 260 197.71 480 274.29

–300 25.20 90 112.53 480 193.70 870 269.44 –170 31.34 50 119.40 270 201.31 490 277.64

–290 27.57 100 114.68 490 195 .71 880 271.31 –160 35.54 60 123.24 280 204.90 500 280.98

–280 29.93 110 116.83 500 197 .71 890 273.17 –150 39.72 70 127.08 290 208.48 510 284.30

–270 32.27 120 118.97 510 199 .71 900 275.04 –140 43.88 80 130.90 300 212.05 520 287.62

–260 34.61 130 121.11 520 201 .71 910 276.90 –130 48.00 90 134.71 310 215.61 530 290.92

–250 36.94 140 123.24 530 203 .71 920 278.75 –120 52.11 100 138.51 320 219.15 540 294.21

–240 39.26 150 125.37 540 205 .70 930 280.61 –110 56.19 110 142.29 330 222.68 550 297.49

–230 41.57 160 127.50 550 207 .69 940 282.46 –100 60.26 120 146.07 340 226.21 560 300.74

–220 43.88 170 129.62 560 209 .67 950 284.30 –90 64.30 130 149.83 350 229.72 570 304. 01

–210 46.17 180 131.74 570 211 .66 960 286.14 –80 68.33 140 153.58 360 233.21 580 307. 25

–200 48.46 190 133.86 580 213 .63 970 287.98 –70 72.33 150 157.33 370 236.70 590 310. 49

–190 50.74 200 135.97 590 215 .61 980 289.82 –60 76.33 160 161.05 380 240.18 600 313. 71

–180 53.02 210 138.08 600 217 .58 990 291.65 –50 80.31 170 164.77 390 243.64 610 316. 92

–170 55.29 220 140.19 610 219 .55 1000 293.48 –40 84.27 180 168.48 400 247.09 620 320.12

–160 57.55 230 142.29 620 221 .51 1010 295.30 –30 88.22 190 172.17 410 250.53 630 323.30

–150 59.81 240 144.39 630 223 .47 1020 297.12 –20 92.16 200 175.86 420 253.96 640 326.48

–140 62.06 250 146.49 640 225 .42 1030 298.94 –10 96.09 210 179.53 430 257.38 650 329.64

–130 64.30 260 148.58 650 227 .38 1040 300.75 0 100.00 220 183.17 440 260.78 660 332.79

–120 66.54 270 150.67 660 229 .33 1050 302.56 10 103.90 230 186.84 450 26 4.18

–110 68.77 280 152.75 670 231.27 1060 304.37

–100 71.00 290 154.83 680 233.21 1070 306.17

–90 73.22 300 156.91 690 235.15 1080 307.97

–80 75.44 310 158.98 700 237.09 1090 309.77

–70 77.66 320 161.05 710 239.02 1100 311.56

–60 79.86 330 163.12 720 240.95 1110 313.35

–50 82.07 340 165.18 730 242.87 1120 315.14

–40 84.27 350 167.24 740 244.79 1130 316.92

–30 86.47 360 169.30 750 246.71 1140 318.70

–20 88.66 370 171.35 760 248.62 1150 320.47

–10 90.85 380 173.40 770 250.53 1160 322.24

0 93.03 390 175.45 780 252.44 1170 324.01

10 95.21 400 177.49 790 254.34 1180 325.77

20 97.39 410 179.53 800 256.24 1190 327.53

30 99.57 420 181.56 810 258.14 1200 329.29

40 101.74 430 183.59 820 260.0 3 1210 331.04

50 103.90 440 185.62 830 261.9 2 1220 332.79

Note

To convert from °C to °F: (1.8 x [°C]) + 32 = °F

Example: (1.8 x 100) + 32 = 212 °F

To convert from °F to °C: 0.556 ([°F] – 32) = °C

Example: 0.556 (212 – 32) = 100 °C

Operation and Maintenance

25

Page 32

Operation and Maintenance

December 2017

Reference Manual

00809-0100-4686, Rev KA

26

Operation and Maintenance

Page 33

Specifications and Reference Data

December 2017

Reference Manual

00809-0100-4686, Rev KA

Appendix A Specifications and Reference Data

Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Ordering Information, Specifications, and Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 27

A.1 Product Certifications

To view current Rosemount 1195, 2051CFP, 3051CFP, and

3051SFP Product Certifications, follow these steps:

1. Go to Emerson.com/Rosemount/Rosemount-1195-

Integral-Orifice-Primary-Element.

2. Scroll as needed to the green menu bar and click

Documents & Drawings.

3. Click Manuals & Guides.

4. Select the appropriate Quick Start Guide.

A.2 Ordering Information,

Specifications, and

Drawings

To view current Rosemount 1195, 2051CFP, 3051CFP, and

3051SFP Ordering Information, Specifications, and

Drawings, follow these steps:

1. Go to Emerson.com/Rosemount/Rosemount-1195-

Integral-Orifice-Primary-Element.

2. Scroll as needed to the green menu bar and click

Documents & Drawings.

3. For installation drawings, click Drawings &

Schematics and select the appropriate document.

4. For ordering information, specifications, and

dimensional drawings, click Data Sheets & Bulletins

and select the appropriate Product Data Sheet.

27

Specifications and Reference Data

Page 34

Reference Manual

00809-0100-4686, Rev KA

Specifications and Reference Data

December 2017

Specifications and Reference Data

28

Page 35

Page 36

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Reference Manual

00809-0100-4686, Rev KA

December 2017

Europe Regional Office

Emerson Automation Solutions Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found on the Terms and Conditions of

Sale page.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

Paine and Paine logotype are trademarks of Emerson.

All other marks are the propert y of their respective owners.

© 2017 Emerson. All rights reserved.

Loading...

Loading...