Page 1

Quick Installation Guide

Step 1: Mount the Transmitter

Step 2: Consider Housing Rotation

Step 3: Connect the Wiring and Power Up

Step 4: Set Switches

Step 5: Configuration

Step 6: Trim the Transmitter

Product Certifications

Start

End

Product Discontinued

00825-0100-4593, Rev BA

July 2009

Rosemount 1151

Rosemount 1151 Pressure Transmitter

with 4-20 mA HART Protocol

www.rosemount.com

¢00825-0100-4360N¤

Page 2

Quick Installation Guide

WARNING

IMPORTANT NOTICE

00825-0100-4593, Rev BA

Rosemount 1151

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordan ce with t he ap propriat e

local, national, and international standards, code s, and practices. Pl ease review the approval s section

of the 1151 reference manual for any restrictions associated with a safe installation.

• Before connecting a HART-based communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or non-incendive field

wiring practices.

• In an Explosion-Proof/Flame-Proof installation, do not remove the transmitter covers when power

is applied to the unit.

Process leaks may cause harm or result in death.

• To avoid process leaks, only use the o-ring designed to seal with the corresponding flange

adapter.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and the terminals. High voltage that may be present on leads can

cause electrical shock.

This installation guide provides basic guidelines for Rosemount 1151 transmitters. It does not provide

instructions for configuration, diagnostics, maintenance, service, troubleshooting, Explosion-Proof,

Flame-Proof, or intrinsically safe (I.S.) installat i ons. Refer to the Rosemount 1151 reference manual

(document number 00809-0100-4360) for more instruction. This manual is also available electr onically

on www.emersonprocess.com/rosemount.

July 2009

2

Page 3

Quick Installation Guide

STEP 1: MOUNT THE TRANSMITTER

Flow

Flow

Flow

00825-0100-4593, Rev BA

July 2009

A. Applications

Liquid Flow Applications

1. Place taps to the side of the line.

2. Mount beside or be low the taps.

Gas Flow Applications

1. Place taps in the top or side of the line.

2. Mount beside or above the taps.

Steam Flow Applications

1. Place taps to the side of the line.

2. Mount beside or be low the taps.

3. Fill impulse line s with water.

Rosemount 1151

3

Page 4

Quick Installation Guide

STEP 1 CONTINUED...

00825-0100-4593, Rev BA

Rosemount 1151

July 2009

B. Optional Mounting Brackets

When installing the transmitter to one of the optional mounting brackets, torque the bracket

bolts to 125 in.-lbs. (0,9 N-m).

Pipe Mount

(1) Panel bolts are customer supplied.

Panel Mount

Flat Mount

(1)

4

Page 5

Quick Installation Guide

STEP 1 CONTINUED...

WARNING

Rosemount 3051S / 3051 / 2051 / 3001 / 3095

Rosemount 1151

Flange Adapter

O-ring

Flange Adapter

O-ring

PTFE Based

Elastomer

PTFE

Elastomer

00825-0100-4593, Rev BA

July 2009

Rosemount 1151

C. O-rings with Flange Adapters

Failure to install proper flange adapter O-rings may cause process leaks, which can result in death or

serious injury. The two flange adapters are distinguished by unique O-ring grooves. Only use the O-ring

that is designed for its specific flange adapter, as shown below.

Whenever the flanges or adapters are removed, visually inspect the o-rings. Replace them if

there are any signs of damage, such as nicks or cuts. If you replace the o-rings, re-torque

the flange bolts and alignment screws after installation to compensate for seating of the

PTFE o-ring.

5

Page 6

Quick Installation Guide

STEP 2: CONSIDER HOUSING ROTATION

Housing Lock Nut

00825-0100-4593, Rev BA

Rosemount 1151

To improve field access or to better view the optional LCD display:

1. Loosen the housing lock nut.

2. Rotate the housing clockwise to the desired position – up to 90° from its original position.

Over rotating will damage the transmitter.

3. If the desired position is attained, tighten the housing lock nut.

4. If the desired position cannot be reached because the housing will not rotate further,

rotate the housing counterclockwise until in the desired position (up to 90° from its

original position).

5. Tighten the housing lock nut to 420-in/lb. Use a sealing compound

(Loctite 222 – Small Screw Threadlocker) on the threads to ensure a watertight seal on

the housing.

NOTE

If the desired position cannot be attained within the 90° limit, the transmitter will need to be

disassembled. See the Rosemount 1151 reference manual (document number

00809-0100-4360) for further instruction.

July 2009

6

Page 7

Quick Installation Guide

STEP 3: CONNECT THE WIRING AND POWER UP

RL 250 ⍀

Optional

Indicator

Current

Meter

Power

Supply

00825-0100-4593, Rev BA

July 2009

Use the following steps to wire the transmitter:

1. Remove the housing cover on the side marked TERMINALS on the nameplate.

2. Connect the po sitive lead to the “+” terminal and the negative lead to the “–” terminal.

Figure 1. Field Wiring Diagram

Installation of the transient protection ter minal block does n ot provide transien t protection unl ess the 1151

case is properly grounded.

3. Ensure proper grounding. It is important that the instrument cable shield:

• be trimmed close and insulated from touching the transmitter housing

• be connected to the next shield if cable is routed through a junction box

• be connected to a good earth ground at the power supply end

NOTE

Do not connect the powered signal wiring to the test terminals. Power could damage the test

diode in the test connection. Twisted pair cable should be used for best results. In high

EMI/RFI environments, use either transient terminal block or shielded signal wiring. Use 12

to 24 AWG wire and do not exceed 5,000 feet (1500 meters).

Rosemount 1151

4. Plug and seal unused conduit connections.

5. If applicable, install wiring with a drip loop. Arrange the drip loop so the bottom is lower

than the conduit connections and the transmitter housing.

6. Replace the housin g cover.

7

Page 8

Quick Installation Guide

STEP 3 CONTINUED...

R

max

R

L

R

min

V

min

V

S

V

max

Operating

Region

00825-0100-4593, Rev BA

Rosemount 1151

July 2009

Power Supply

The dc power supply should provide power with less than two percent ripple. The total

resistance load is the sum of the resistance of the signal leads and the load resistance of the

controller, indicator , and related pieces. Note that the resistance of intrinsic safety barriers, if

used, must be included.

Figure 2. Load Limitation

Code V

S

minVmaxRminRmaxRL

(1)

12 45 0 1650 RL = 43.5 (VS – 12)

(1) A minimum of 250 is required for communication.

at Supply Voltage (VS)

8

Page 9

Quick Installation Guide

STEP 4: CONFIGURE THE TRANSMITTER

HI

Failure Mode Switch

Write-Protection Switch

Zero Adjustment

Buttons

00825-0100-4593, Rev BA

July 2009

Failure Mode Alarm Switch

1. Remove the housing cover.

2. Locate the failure mode switch (see Figure 3).

3. Move the switch to the desired alarm setting. To set the failure mode to high alarm,

position the switch toward “HI.” To set the failure mode to low alarm, position the switch

to “LO.”

4. Replace the housin g cover.

Write-Protect Switch

In the “ON” position, the write-protect switch prevents changes to the configuration data.

1. Remove the housing cover.

2. Move the write-protect switch to the “OFF.”

3. Verify transmitter configuration (see “Verify Transmitter Configuration”).

4. Move the write-protect switch to the “ON.”

5. Replace the housing cover.

Figure 3. Switch Locations

Rosemount 1151

9

Page 10

Quick Installation Guide

STEP 5: CALIBRATE THE T RANSMITTER

00825-0100-4593, Rev BA

Rosemount 1151

July 2009

Verify Transmitter Configuration

NOTE:

A check (✓) indicates the basic configuration parameters. At minimum, these parameters

should be verified as part of the configuration and startup procedure.

Table 1. HART Communicator Fast Key Sequence

Function Fast Key Sequences

Analog Output 3

Analog Output Alarm 1, 4, 3, 3

Burst Mode Control 1, 4, 3, 4, 3

Burst Operation 1, 4, 3, 4, 4

Calibration 1, 2, 3

Characterize 1, 4, 1, 1, 2, 2

✓ Damping 1, 3, 6

Date 1, 3, 4, 1

Descriptor 1, 3, 4, 2

Digital-to-Analog Trim (4–20 mA Output) 1, 2, 3, 2, 1

Field Device Information 1, 4, 4, 1

Full Trim 1, 2, 3, 3

Keypad Input 1, 2, 3, 1, 1

Loop Test 1, 2, 2

Lower Range Value 4, 1

Lower Sensor Trim 1, 2, 3, 3, 2

Message 1, 3, 4, 3

Meter Type 1, 3, 4, 5

Number of Requested Preambles 1, 4, 3, 4, 2

Percent Range 1, 1, 2

Poll Address 1, 4, 3, 4, 1

Pressure 2

✓ Range Values 1, 3, 3

Rerange 1, 2, 3, 1

Scaled D/A Trim (4–20 mA Output) 1, 2, 3, 2, 2

Self-Test (Transmitter) 1, 2, 1, 1

Sensor Information 1, 4, 4, 2

Sensor Trim Points 1, 2, 3, 3, 4

Status 1, 2, 1, 2

✓ Tag 1, 3, 1

✓ Transfer Function (Setting Output Type) 1, 3, 5

Transmitter Security (Write Protect) 1, 3, 4, 4

Trim Analog Output 1, 2, 3, 2

✓ Units (Process Variable) 1, 3, 2

Upper Range Value 5, 2

Upper Sensor Trim 1, 2, 3, 3, 3

Zero Trim 1, 2, 3, 3, 1

10

Page 11

Quick Installation Guide

STEP 5 CONTINUED...

Retaining Ring

Right

Configuration

Button

Left

Configuration

Button

Digital Bar Graph

00825-0100-4593, Rev BA

July 2009

Rosemount 1151

Configure LCD Display

Figure 4. Sample 1151 LCD Display

NOTE

The LCD display time-out is approximately 16 seconds. If keys are not pressed within this

period, the indicator reverts to reading the signal.

Position the Decimal Point and Select the Meter Function

1. Unscrew the retaining ring shown in Figure 4 and remove the LCD display cover.

2. Press t he left and right configuration buttons simultaneously and release immediately.

3. To move the decimal point to the desired location, press the left configuration button.

Note that the decimal point wraps around.

4. To scroll through the mode options, press the right configuration button until the desired

mode is displayed (see Table 2).

5. Press both configuration buttons simultaneously for two seconds.

6. Replace the LCD Display cover.

Table 2. LCD Display Modes

Options Relationship between Input Signal and Digital Display

L in Linear

L in F Linear with five-second filter

Srt Square root

SrtF Square root with five-second filter

Square root function: relates to the digital display. The bar graph output

remains linear with the current signal.

Square root response: digital display will be proportional to the square root of

the input current where 4 mA=0 and 20 mA=1.0, scaled per the calibration

procedure. The transition point from linear to square root is at 25% of full scale

flow.

Filter response: operates upon “present input” and “input received in the

previous five second interval” in the following manner:

Display = (0.75 x previous input) + (0.25 x present input)

This relationship is maintained provided that the previous reading minus the

present reading is less than 25% of full scale.

NOTE

The meter displays “----” for approximately 7.5 seconds while the information is being

stored.

11

Page 12

Quick Installation Guide

STEP 5 CONTINUED...

00825-0100-4593, Rev BA

Rosemount 1151

Set the Display Equivalent to a 4 mA Signal

1. Unscrew the retaining ring shown in Figure 4 and remove the LCD display cover.

2. Press t he left button for two seconds.

3. To decrement the display numbers, press the left configuration button and to increment

the numbers, press the right configuration button. Set the numbers between –999 and

1000.

4. To store the information, press both configuration buttons simultaneously for two

seconds.

5. Replace the LCD display cover.

Set the Display Equivalent to a 20 mA Signal

1. Unscrew the retaining ring shown in Figure 4 and remove the LCD display cover.

2. Press t he right button for two seconds.

3. To decrement the display numbers, press the left configuration button on the display and

to increment the numbers, press the right configuration button. Set the numbers between

–999 and 9999. The sum of the 4 mA point and the span must not exceed 9999.

4. To store the information, press both configuration buttons simultaneously for two

seconds. The LCD display is now configured.

5. Replace the LCD Display cover.

July 2009

12

Page 13

Quick Installation Guide

STEP 6: TRIM THE TRANSMITTER

00825-0100-4593, Rev BA

July 2009

Rosemount 1151

NOTE

Transmitters are shipped fully calibrated per request or by the factory default of full scale

(span = upper range limit).

Full Trim

A full trim is a two-point sensor calibration where two end-point pressures are applied, and

the transmitter process variable output is adjusted to agree with the pressure input.

Using the HART Communicator

HART Fast Keys Steps

1, 2, 3, 3 1. Equalize or vent the transmitter and connect HART

communicator.

2. At the menu, input the HART Fast Key sequence.

3. Follow the commands to perform a full trim.

Zero Trim

A zero trim is a single-point adjustment used for compensating mounting position effects.

When performing a zero trim, ensure that the equalizing valve is open and all wet legs are

filled to the correct level. If zero offset is less than 3% of true zero, follow the “Using the

HART Communicator” instructions below. If zero offset is greater than 3% of true zero, follow

the “Using the Transmitter Zero Adjustment Buttons” instructions.

Using the HART Communicator

HART Fast Keys Steps

1, 2, 3, 3, 1 1. Equalize or vent the transmitter and connect HART

communicator.

2. At the menu, input the HART Fast Key sequence.

3. Follow the commands to perform a zero trim.

13

Page 14

Quick Installation Guide

STEP 6 CONTINUED...

00825-0100-4593, Rev BA

Rosemount 1151

Using the Transmitter Zero Adjustment Buttons

Perform the following steps to perform a rerange using the zero adjustment buttons (see

Figure 3).

1. Apply a pressure equivalent to the lower calibrated value on the high side of the

transmitter.

2. Remove the circu it side cover to expose the span and zero buttons. Hold both the span

and zero buttons down simultaneously for at least five seconds to activate the controls.

3. Press t he zero button for five seconds to set the 4 mA point. Verify that the output is 4

mA.

4. Apply a pressure equivalent to the higher calibrated value to the high side of the

transmitter.

5. Press the span button for five seconds to set the 20 mA point. Verify that the output is 20

mA.

July 2009

4-20 mA Output Trim

A 4-20 mA output trim adjusts the transmitter milliampere output to match plant standards.

This procedure is used to trim the transmitter using a current meter.

Using the HART Communicator

HART Fast Keys Steps

1, 2, 3, 2, 2 1. Equalize or vent the transmitter and connect HART

communicator.

2. At the menu, input the HART Fast Key sequence.

3. Follow the commands to perform a full trim.

14

Page 15

Quick Installation Guide

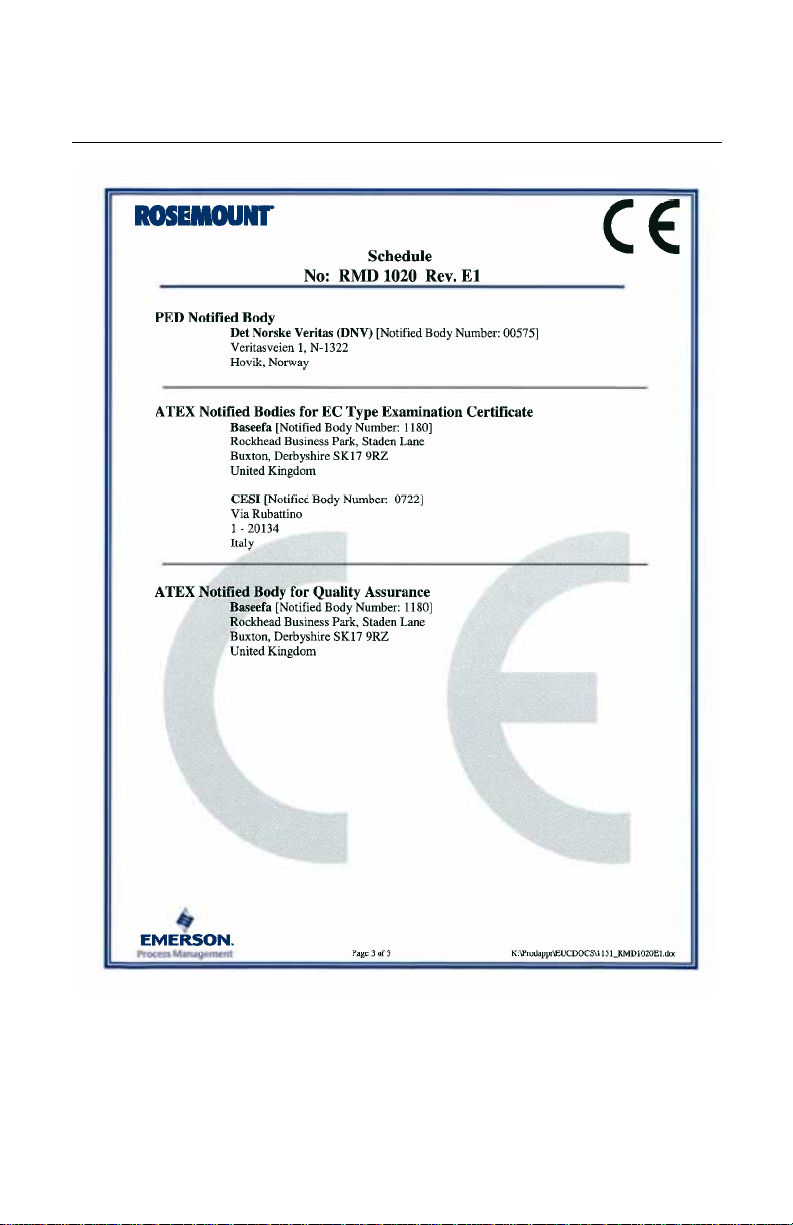

PRODUCT CERTIFICATIONS

00825-0100-4593, Rev BA

July 2009

Rosemount 1151

Approved Manufacturing Locations

Rosemount Inc. — Chanhassen, Minnesota, USA

Fisher-Rosemount GmbH & Co. — Wessling, Germany

Emerson Process Management Asia Pacific

Private Limited — Singapore

Beijing Rosemount Far East Instrument Co., Limited – Beijing, China

European Directive Information

The EC declaration of conformity can be found on page 19. The most recent revision can be

found on www.emersonprocess.com/rosemount.

ATEX Directive (94/9/EC)

Emerson Process Management complies with the ATEX Directive.

European Pressure Equipment Directive (PED) (97/23/EC)

1151GP9, 0; 1151HP4, 5, 6, 7, 8 Pressure Transmitters

— QS Certificate of Assessment - EC No. PED-H-20

Module H Conformity Assessment

All other 1151 Pressure Transmitters

— Sound Engineering Practice

Transmitter Attachments:

Diaphragm Seal - Process Flange - Manifold

— Sound Engineering Practice

Electro Magnetic Compatibility (EMC) (2004/108/EC)

All models

EN 61326-1: 2006, EN61326-2-3: 2006

Hazardous Locations Certif ic ati ons

North American Certifications

Factory Mutual (FM) Approvals

FM Explosion Proof tag is standard. Appropriate tag will be substituted if optional

certification is selected.

Explosion Proof: Class I, Division 1, Groups B, C, and D, T5 (T

Proof: Class II, Division 1, Groups E, F, and G; Class III, Division 1, T5 (T

Indoor and outdoor use. Enclosure Type 4X. Factory Sealed.

I5 Intrinsically safe for Class I, II, and III Division 1, Groups A, B, C, D, E, F, and G, T4

hazardous locations in accordance with entity requirements and Control drawing

01151-0214. Non- incendive for Class I, Division 2, Groups A, B, C and D, T4

hazardous locations. Enclosure Type 4X.

For entity parameters see control drawing 01151-0214.

= 85 °C). Dust-Ignition

a

= 85 °C).

a

15

Page 16

Quick Installation Guide

00825-0100-4593, Rev BA

Rosemount 1151

Canadian Certifications

Canadian Standards Association (CSA) Approvals

E6 Explosion Proof for Class I, Division 1, Groups C and D; Class II, Division 1, Groups E,

F, and G; Class III, Division 1 Hazardous Locations. Suitable for Cla s s I , Di v is i on 2,

Groups A, B, C, and D; CSA enclosure type 4X. Factory Se aled.

I6 Intrinsically safe for Class I, Division 1, Groups A, B, C, and D hazardous locations

when connected per Drawing 01151-2575. For entity parameters see control drawing

01151-2575. Temperature Code T2D.

Measurement Canada Approvals

C5 Accuracy Approval to the Electricity and Gas Inspection Act for the purchase and sale

of natural gas.

European Certifications

E8 ATEX Flameproof

Certification Number CESI03ATEX037

ATEX Marking II 1/2 G

EEx d IIC T6 (–40 °C T

EEx d IIC T4 (–40 °C T

1180

V = 60 Vdc maximum

I1 ATEX Intrinsic Safety and Combustible Dust Certification

Certification Number BAS99ATEX1294X

ATEX Marking II 1 GD

Ex ia IIC T5 (–60 °C T

Ex ia IIC T4 (–60 °C T

Dust Rating: T90 °C (T

IP66

1180

Entity Parameters

Ui = 30V

I

= 125 mA

i

Pi = 1.0 W (T4) or 0.67 W (T5)

C

= 0.034 F

i

Li = 20 H

Special Conditions for safe use (x):

The apparatus is not capable of withstanding the 500V insulation test required by

EN60079-1. This must be taken into account when installing the apparatus.

40 °C)

amb

80 °C)

amb

40 °C)

amb

80 °C)

amb

= –20 °C to 40 °C)

amb

July 2009

16

Page 17

Quick Installation Guide

00825-0100-4593, Rev BA

July 2009

N1 ATEX Type N and Dust Certification

Certificate Number: BAS99ATEX3293X

ATEX Marking: II 3 GD

Ex nL IIC T5 (-40 °C T

EX nL IIC T4 (-40 °C T

Dust Rating: T90 °C (T

40 °C)

amb

80 °C)

amb

= -20 °C to 40 °C)

amb

Ui = 45 Vdc maximum

IP66

Special Conditions for safe use (x):

The apparatus is not capable of withstanding the 500V insulation test required by

EN60079-1. This must be taken into account when installing the apparatus.

Australian Certifications

Standards Association of Australia (SAA) Certification

E7 Flameproof

Certificate Number Aus Ex 494X

Ex d IIB + H

DIP T6

T6

2

IP65

Special Conditions for safe use (x):

For transmitters having NPT, PG or G cable entry threads, an appropriate flameproof

thread adaptor shall be used to facilitate application of certified flameproof cable glands

or conduit system.

I7 Intrinsic Safety

Certificate Number: Aus Ex 122X

Ex ia I/IIB T4 (T

= 60 °C) / T5 IP66

a

Special Conditions for Safe Use (x):

1. It is a condition of safe use that the following parameters shall be taken into account

during installation.

2. It is a condition of safe use that the transmitter must be supplied from a resistive

current limiting barrier.

3. It is a condition of safe use that when the optional transie nt protection is used its

metallic housing shall be bonded to the system earth.

4. It is a condition of safe use that only the stainless steel case version can be labeled

as suitable for Group I.

Table 3. Entity Parameters

Ui = 30V

I

= 125 mA

i

Pi = 1.0 W (T4) or 0.67W (T5)

C

= 14.8 nF

i

Li = 20 H

Rosemount 1151

17

Page 18

Quick Installation Guide

00825-0100-4593, Rev BA

Rosemount 1151

N7 Type N

Certificate Number: Aus Ex 122X

Ex n IIC T5 (T

Special Conditions for safe use (x):

1. It is a condition of safe use that a nominal voltage of 30 V for Ex n application shall

not be exceeded.

2. It is a condition of safe use that when the optional transie nt protection is used its

metallic housing shall be bonded to the system earth.

Combination Certifications

Stainless steel certification tag is provided when optional approval is specified. Once a

device labeled with multiple approval types is installed, it should not be reinstalled using any

other approval types. Permanently mark the approval label to distinguish it from unused

approval types.

C6 Combination of I6 and E6, CSA Explosion Proof and Intrinsic Safety Approval. Factory Sealed.

K5 Combination of FM Explosion Proof, Intrinsic Safety, and Non-incendive Approvals.

K6 Combination of E6, I6, I1, and E8.

= 80 °C) / T6 IP66

a

July 2009

18

Page 19

Quick Installation Guide

00825-0100-4593, Rev BA

July 2009

DoC

Rosemount 1151

19

Page 20

Rosemount 1151

Quick Installation Guide

00825-0100-4593, Rev BA

July 2009

20

Page 21

Quick Installation Guide

00825-0100-4593, Rev BA

July 2009

Rosemount 1151

21

Page 22

Rosemount 1151

Quick Installation Guide

00825-0100-4593, Rev BA

July 2009

22

Loading...

Loading...