Page 1

Quick Start Guide

00825-0100-4951, Rev BC

March 2021

Rosemount™ 1067 Temperature Sensor

Page 2

Quick Start Guide March 2021

Contents

About this guide...........................................................................................................................3

Wiring diagrams...........................................................................................................................5

Dimensional drawings..................................................................................................................7

Specifications...............................................................................................................................9

Product certifications................................................................................................................. 13

Declaration of Conformity..........................................................................................................20

China RoHS................................................................................................................................ 22

2 Emerson.com/Rosemount

Page 3

March 2021 Quick Start Guide

1 About this guide

This guide provides basic guidelines for Rosemount 1067 Sensor models. It

does not provide instructions for configuration, diagnostics, maintenance,

service, troubleshooting, explosion-proof, flameproof, or intrinsically safe

(I.S.) installations.

If the Rosemount 1067 Sensor was ordered assembled to a temperature

transmitter, see the appropriate transmitter Quick Start Guide for

information on configuration and hazardous locations certifications.

NOTICE

Complications can arise when sensors and the transmitters to which they are

assembled are certified to compatible, but have unique approvals. Be aware

of the following situation:

• If an I.S. approved Rosemount 1067 Sensor is ordered with a housing, a

transmitter enclosed in that housing may have a different I.S. approval

rating. Refer to the transmitter IS certificate if applicable.

• If a sensor and transmitter have different certifications, or if either has

more certifications than the other, installation must comply with the

most restrictive requirements of either component. This is especially

(but not exclusively) relevant when combination approvals are ordered

on either the sensor or transmitter. Review certifications on both the

sensor and transmitter for installation requirements and ensure

installation of the sensor/transmitter assembly complies with a single

certification that is shared by both of these components and that meets

the requirements of the application.

Quick Start Guide 3

Page 4

Quick Start Guide March 2021

WARNING

Explosions could result in death or serious injury.

Installation of this sensor in an explosive environment must be in accordance

with the appropriate local, national, and international standards, codes, and

practices.

Conduit/cable entries

• Unless marked, the conduit/cable entries in the transmitter housing use

a 1/2–14 NPT thread form. Entries marked “M20” are M20 1.5 thread

form. On devices with multiple conduit entries, all conduit entries will

have the same thread form.

• When installing in a hazardous location, use only appropriately listed or

Ex certified flameproof/dust plugs, adapters, or glands in cable/conduit

entries.

• Only use plugs, adapters, glands, or conduit with a compatible thread

form when closing these entries.

Physical Access

• Unauthorized personnel may potentially cause significant damage to

and/or misconfiguration of end users’ equipment. This could be

intentional or unintentional and needs to be protected against.

• Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

CAUTION

Refer to Product Certification section of this Quick Start Guide

documentation.

4 Emerson.com/Rosemount

Page 5

White

White

Red

Red

Red

Red

Black

Blue

Blue

Green

Red

Red

Wht

Wht

4

3

1

6

1

3

4

6

Red

Red

Wht

3

2

1

Red

Red

Wht

6

5

4

123

456

March 2021 Quick Start Guide

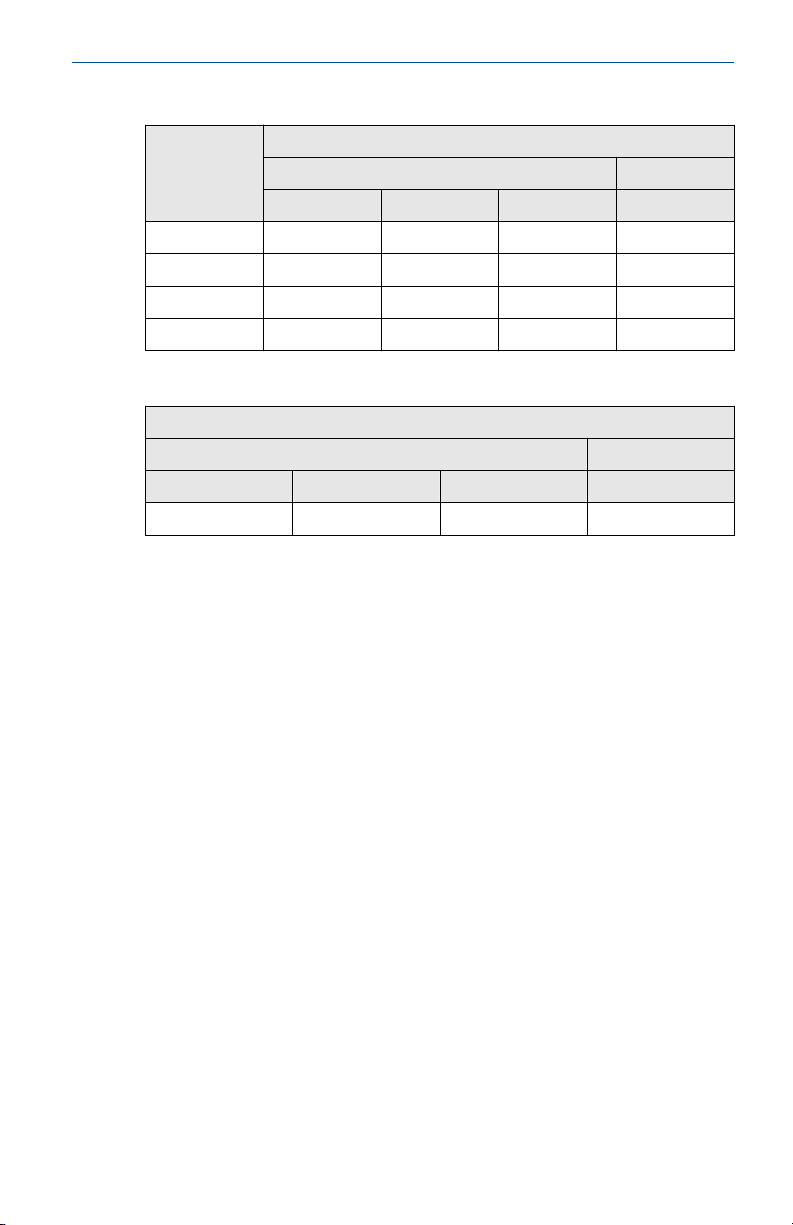

2 Wiring diagrams

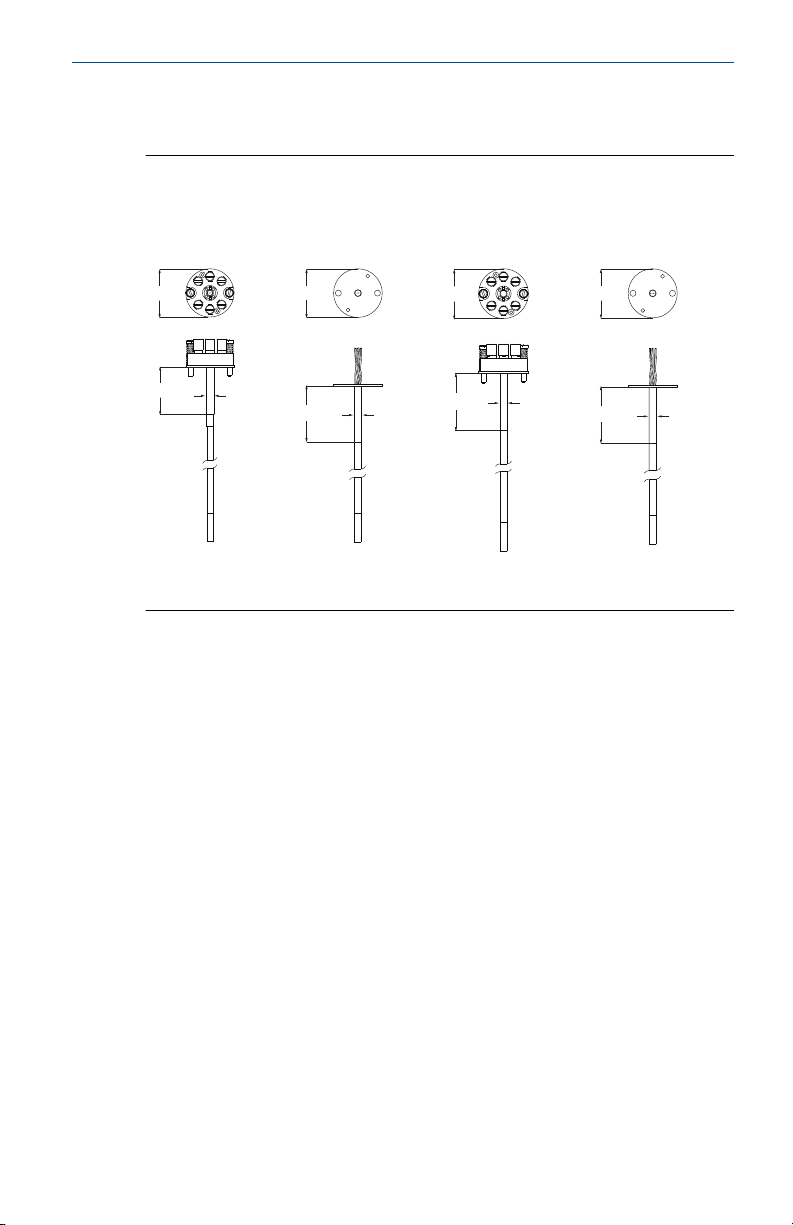

Figure 2-1: Rosemount 1067 RTD Lead Wire Configuration

Flying leads termination code 0 Terminal block termination code 2

Single element Dual element Single element Dual element

Figure 2-2: Rosemount 1067 Thermocouple Lead Wire Configuration

Flying leads termination code 0 Terminal block termination code 2

Single element Dual element Single element Dual element

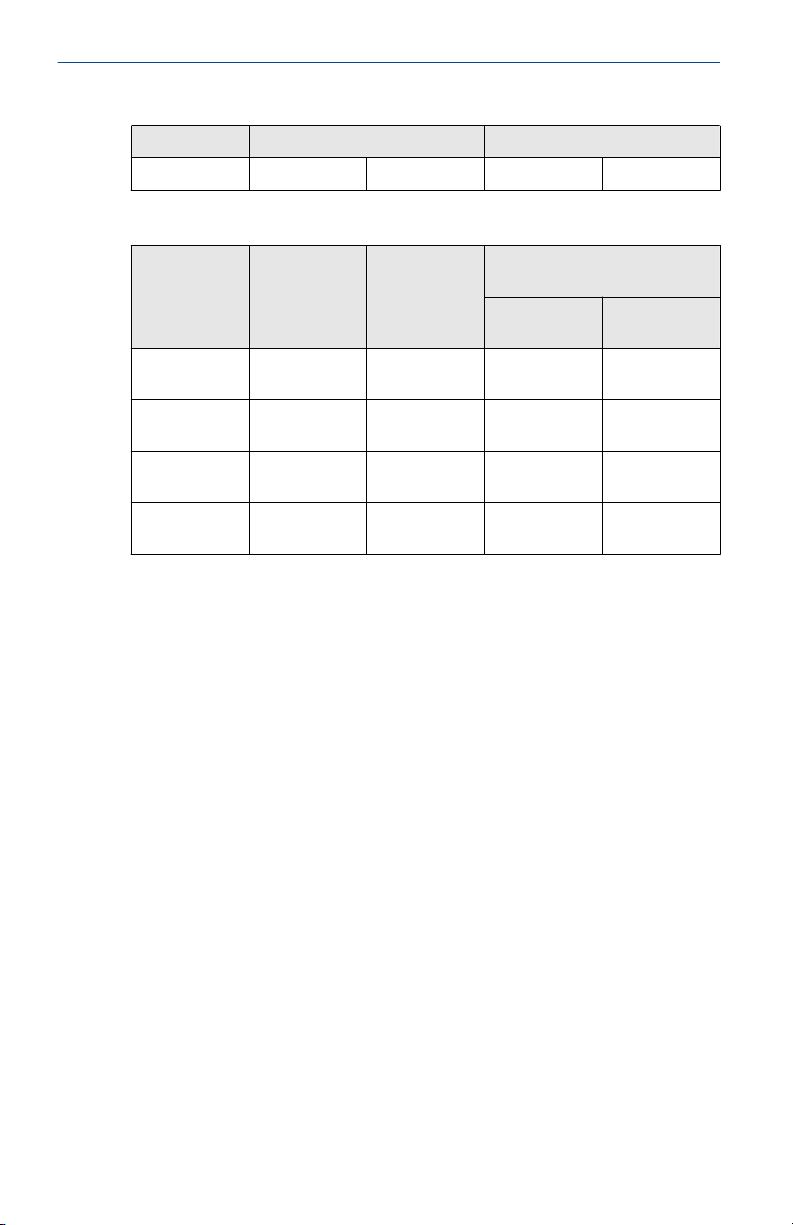

Table 2-1: Rosemount 1067 Thermocouple Wire Color

IEC wire color ISA wire color

Type Positive (+) Negative (-) Positive (+) Negative (-)

E Violet White Violet Red

J Black White White Red

K Green White Yellow Red

N Rose White Orange Red

Quick Start Guide 5

R Orange White Black Red

S Orange White Black Red

Page 6

Quick Start Guide March 2021

Table 2-1: Rosemount 1067 Thermocouple Wire Color (continued)

IEC wire color ISA wire color

T Brown White Blue Red

Table 2-2: Lead Wire Specifications

Rosemount

1067

RTD Single

Element

RTD Dual

Element

Thermocouple

Single Element

Thermocouple

Dual Element

Sensor

diameter -

mm

3/6 4 140 N/A

3/6 6 140 140

3/6 2 140 N/A

3/6 4 140 140

Number of

leads

Approximate lead wire length

(flying leads)

Element 1 -mmElement 2 -

mm

6 Emerson.com/Rosemount

Page 7

41

33

5.95 + 0.00 - 0.06

41

33

5.95 + 0.00 - 0.06

28

5.95 + 0.00 - 0.06

41

5.95 + 0.00 - 0.06

41

28

March 2021 Quick Start Guide

3 Dimensional drawings

Figure 3-1: Rosemount 1067 RTD and Thermocouple

3 mm 6 mm

Terminal block Flying leads Terminal block Flying leads

Dimensions are in millimeters.

Quick Start Guide 7

Page 8

Rosemount 644 Rosemount 248 Rosemount 644

Rosemount 3144

Rosemount 248

40 mm

25 mm

L L

A

B

C

Quick Start Guide March 2021

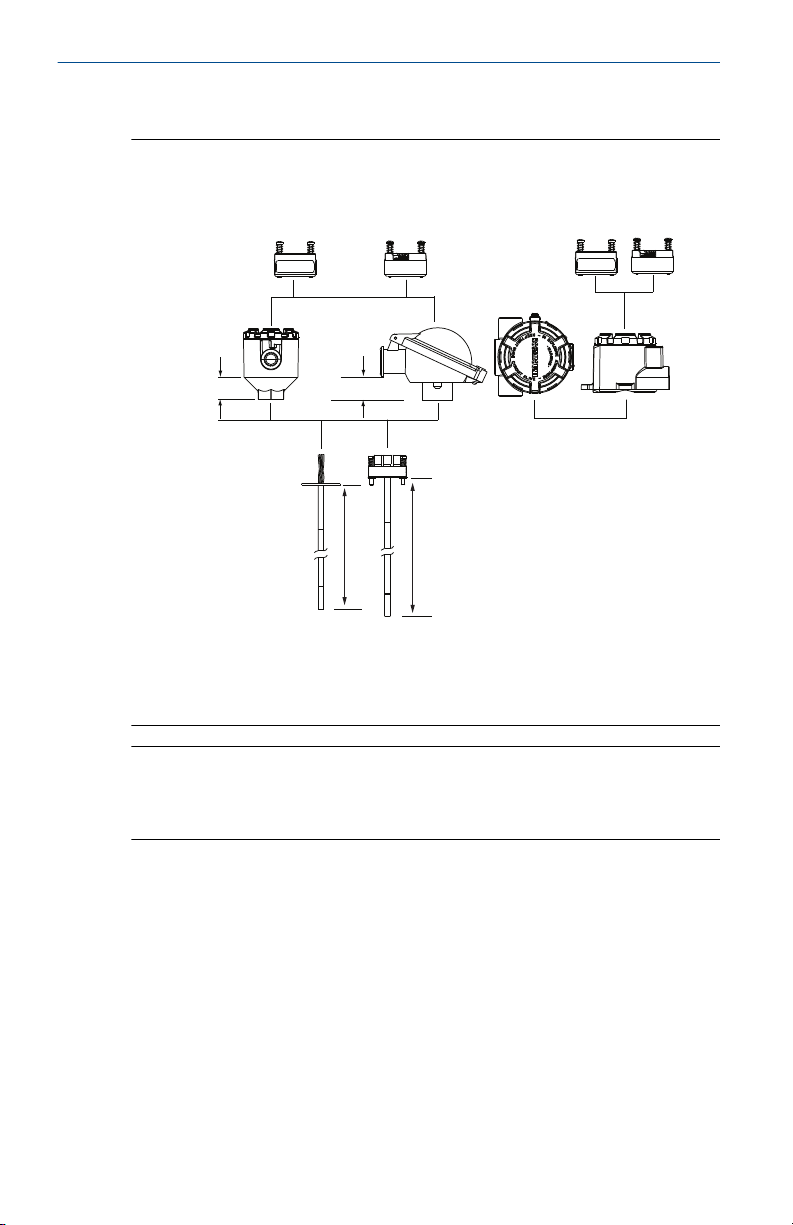

3.1 Sensor assembly

Figure 3-2: Sensor Assembly

Integral mount Remote mount

A. Head or field mount transmitters

B. Connection heads

C. Sensor with flying leads, terminal block

Note

Sensor assemblies can be provided without an enclosure or with an

enclosure such as the connection heads shown above or assembled to a

Rosemount transmitter.

8 Emerson.com/Rosemount

Page 9

March 2021 Quick Start Guide

4 Specifications

4.1 Material selection

Emerson provides a variety of Rosemount product with various product

options and configurations including materials of construction that can be

expected to perform well in a wide range of applications. The Rosemount

product information presented is intended as a guide for the purchaser to

make an appropriate selection for the application. It is the purchaser’s sole

responsibility to make a careful analysis of all process parameters (such as all

chemical components, temperature, pressure, flow rate, abrasives,

contaminants, etc.), when specifying product, materials, options and

components for the particular application. Emerson is not in a position to

evaluate or guarantee the compatibility of the process fluid or other process

parameters with the product, options, configuration or materials of

construction selected.

4.2 Rosemount 1067 Platinum RTD

100 Ω RTD at 0 °C, α = 0.00385 Ω/Ω × °C

Temperature range

–196 to 300 °C (–320.8 to 572 °F)

Insulation resistance

1,000 MΩ minimum insulation resistance when measured at 500 Vdc and at

room temperature.

Sheath material

316 SST/321 SST with mineral-insulated cable construction

Lead wire

PTFE insulated, 24 AWG, silver-plated copper wire. See Figure 2-1 for wire

configuration.

Ingress Protection (IP) ratings

Table 4-1: IP Ratings

Option code IP rating

B, D, H, F, G, L, M, Q, U, V, W, Y 66/68

C 65

Self heating

0.15 K/mW when measured per method defined in DIN EN 60751:1996

Quick Start Guide 9

Page 10

Quick Start Guide March 2021

Thermal response time

Thermal response times for the 1067 sensor only. Tested in accordance to

IEC 751 guidelines.

Table 4-2: Water Flowing at 0.4 m/s

Sensor Pt 100 TC grounded TC ungrounded Deviation

t(0.5) [s] t(0.5) [s] t(0.5) [s]

6-mm dia. 7.7 1.8 2.8 ± 10%

3-mm dia. 2.5 1.1 1.2 ± 10%

Table 4-3: Air Flowing at 3.0 m/s

Sensor Pt 100 TC grounded TC ungrounded Deviation

t(0.5) [s] t(0.5) [s] t(0.5) [s]

6-mm dia. 35 38 42 ± 10%

3-mm dia. 18 14 14 ± 10%

More response time information is available online for other sensor and

thermowell configurations

4.3 Rosemount 1067 Thermocouple

Temperature range

See Table 4-4 and Table 4-5.

Insulation resistance

1,000 MΩ minimum insulation resistance when measured at 500 Vdc and at

room temperature.

Sheath material

Rosemount thermocouples are made of a mineral insulated cable design wit

h a variety of sheath materials available to suit both the temperature and the

environment. For temperature up to 800 °C (1472 °F) in air, the sheath is

made from 321 SST. For temperatures above 800 °C (1472 °F) in air, the

sheath is made from Alloy 600. For strongly oxidizing or reducing

atmospheres, consult your local Emerson representative for information.

Lead wires

Thermocouple, internal – 19 AWG solid wire (max) and 21 AWG solid wire

(min.). External extension leads, Type E, J, K, N, R, S, and T. PTFE insulated.

20 AWG (max.) and 24 AWG (min.) Color coded per IEC or ISA standards.

Figure 2-2 shows the wire configuration.

10 Emerson.com/Rosemount

Page 11

March 2021 Quick Start Guide

Ingress Protection (IP) ratings

For information see Table 4-1.

Table 4-4: Characteristics of 1067 IEC Thermocouples (IEC Standards are

Typically Used in European Applications)

Type Wire alloys Sheath

E Chromel/

Constantan

J Iron/

Constantan

K Chromel/

Alumel

N Nicrosil/

Nisil

R Platinum-1

3%

Rhodium/

Platinum

S Platinum-1

0%

Rhodium/

Platinum

T Copper/

Constantan

(1) Whichever is greater.

material

321 SST -40 to 800 °C

321 SST -40 to 750 °C

Alloy 600 -40 to 1000 °C

Alloy 600 -40 to 1000 °C

Alloy 600 0 to 1000 °C

Alloy 600 0 to 1000 °C

321 SST -40 to 350 °C

Temperature

range

(-40 to 1472 °F)

(-40 to 1382 °F)

(-40 to 1832 °F)

(-40 to 1832 °F)

(32 to 1832 °F)

(32 to 1832 °F)

(-40 to 662 °F)

Interchangeability error IEC

60584-2

±1.5 °C (±2.7 °F) or

±0.4%

±1.5 °C (±2.7 °F) or

±0.4%

±1.5 °C (±2.7 °F) or

±0.4%

±1.5 °C (±2.7 °F) or

±0.4%

±1.0 °C (±1.8 °F) or

±(1+0.3% x

[t-1100]) °C

±1.0 °C (±1.8 °F) or

±(1+0.3% x

[t-1100]) °C

±0.5 °C (±1.0 °F) or

±0.4%

(1)

Table 4-5: Characteristics of 1067 ASTM Thermocouples (ASTM

Standards are Typically Used in North American Applications)

Accuracy

Class 1

Class 1

Class 1

Class 1

Class 1

Class 1

Class 1

Type Wire alloys Sheath

E Chromel/

Constantan

J Iron/

Constantan

K Chromel/

Alumel

N Nicrosil/

Nisil

Quick Start Guide 11

material

321 SST 0 to 900 °C

321 SST 0 to 750 °C

Alloy 600 0 to 1000 °C

Alloy 600 0 to 1000 °C

Temperature

range (°C)

(32 to 1652 °F)

(32 to 1382 °F)

(32 to 1832 °F)

(32 to 1832 °F)

Interchangeability error ASTM

(1)

E230

±1.0 °C (±1.8 °F) or

±0.4%

±1.1 °C (±2.0 °F) or

±0.4%

±1.1 °C (±2.0 °F) or

±0.4%

±1.1 °C (±2.0 °F) or

±0.4%

Accuracy

Special

limits

Special

limits

Special

limits

Special

limits

Page 12

Quick Start Guide March 2021

Table 4-5: Characteristics of 1067 ASTM Thermocouples (ASTM

Standards are Typically Used in North American Applications)

(continued)

Type Wire alloys Sheath

R Platinum-1

3%

Rhodium/

Platinum

S Platinum-1

0%

Rhodium/

Platinum

T Copper/

Constantan

(1) Whichever is greater.

material

Alloy 600 0 to 1000 °C

Alloy 600 0 to 1000 °C

321 SST 0 to 350 °C

4.4 Functional specifications

Power

Environmental

Temperature

range (°C)

(32 to 1832 °F)

(32 to 1832 °F)

(32 to 662 °F)

Interchangeability error ASTM

E230

±0.6 °C (±1.0 °F) or

±0.1%

±0.6 °C (±1.0 °F) or

±0.1%

±0.5 °C (±1.0 °F) or

±0.4%

Overvoltage category I

Pollution degree 4

Accuracy

(1)

Special

limits

Special

limits

Special

limits

12 Emerson.com/Rosemount

Page 13

March 2021 Quick Start Guide

5 Product certifications

Rev 2.4

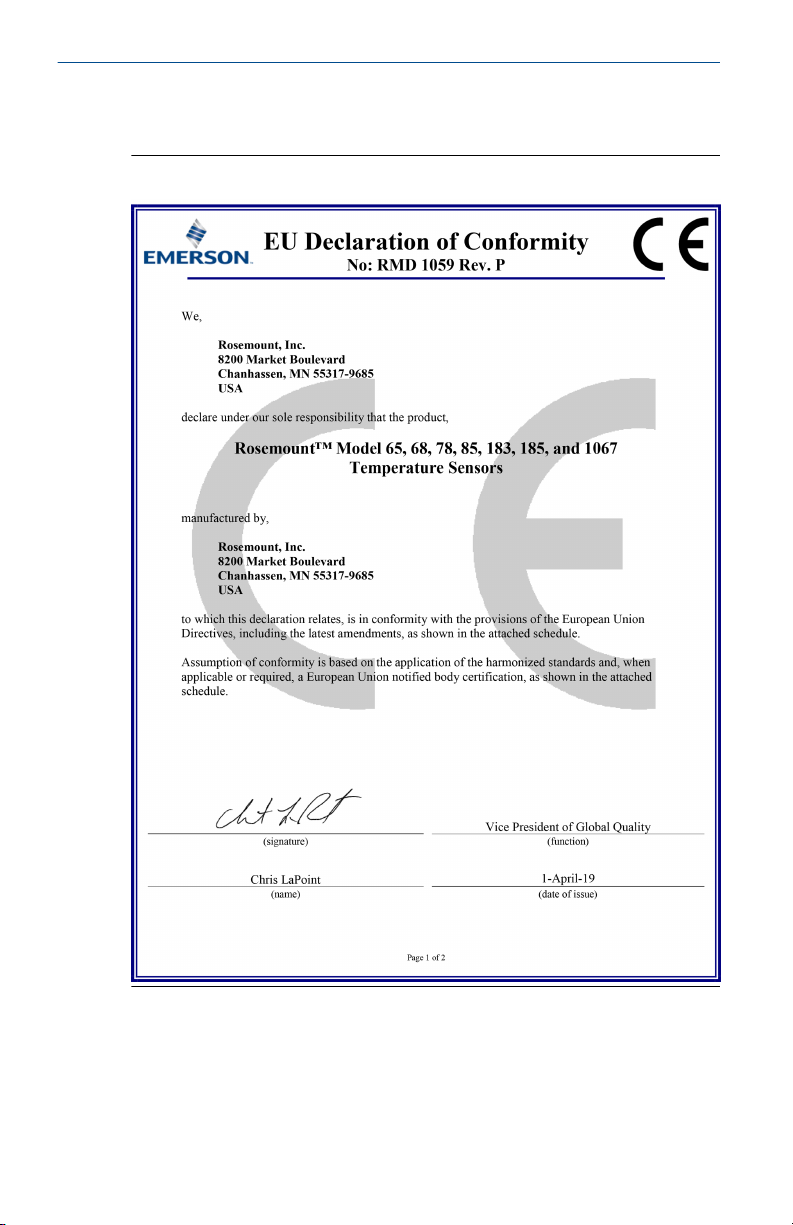

5.1 European Directive Information

A copy of the EU Declaration of Conformity can be found at the end of the

Quick Start Guide. The most recent revision of the EU Declaration of

Conformity can be found at Emerson.com/Rosemount.

5.2 Ordinary Location Certification

As standard, the transmitter has been examined and tested to determine

that the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

5.3 North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in the respective codes.

5.3.1 USA

E5 US Explosion proof, Dust-Ignition proof

Certificate

Standards

Markings

FM17US0170X

FM Class 3600: 2011; FM Class 3611: 2004; FM Class 3615:

2006; FM Class 3810: 2005; ANSI/NEMA® - 250: 1991

XP CL I, Div 1, GP B, C, D; DIP CL II/III, Div 1, GP E, F, G; T5(–50

°C≤ Ta ≤ 85 °C); when installed per Rosemount drawing

00068-0013; Type 4X

5.3.2 Canada

E6 Canada Explosion proof and Dust-Ignition proof

Certificate

Standards

Markings

Quick Start Guide 13

70044744

CAN/CSA C22.2 No. 0:2010, CAN/CSA No. 25-1966 (R2000),

CAN/CSA C22.2 No. 30-M1986 (R2012), CAN/CSA C22.2 No.

94-M1991 (R2011), CAN/CSA C22.2 No. 61010-1:2012

XP CL I, DIV 1, GP B, C, D; DIP CL II, DIV 1, GP E, F, G; CL III; T6

(–50 °C ≤ Ta ≤ +80 °C), T5 (–50 °C ≤ Ta ≤ +95 °C); Seal not

Page 14

Quick Start Guide March 2021

required; installed per Rosemount drawing 00068-0033; Type

4X and IP 66/67; Vmax 35 VDC, 750 mWmax

5.4 Europe

5.4.1 E1 ATEX Flameproof

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

3. Guard the LCD display cover against impact energies greater than 4

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

6. Care shall be taken by the end user to ensure that the external

7. Non-Standard Paint options may cause risk from electrostatic

FM12ATEX0065X

EN 60079-0: 2012+A11:2013, EN 60079-1: 2014, EN

60529:1991 +A1:2000+A2:2013

II 2 G Ex db IIC T6…T1 Gb; T6…T1: Ta = –50 °C to + 40 °C;

T5…T1: Ta= –50 °C to +60 °C

See Process temperature limits for process temperatures.

a source of ignition in Group III environments

joules.

to temperature probes with Enclosure option “N”.

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

5.4.2 ND ATEX Dust

Certificate:

Standards:

Markings:

14 Emerson.com/Rosemount

FM12ATEX0065X

EN 60079-0: 2012+A11:2013, EN 60079-31:2014, EN

60529:1991 +A1:2000+A2:2013

II 2 D Ex tb IIIC T130 °C Db Ta= –40 °C to +70 °C; IP66

See Process temperature limits for process temperatures.

Page 15

March 2021 Quick Start Guide

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than 4

joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex db or Ex tb enclosure is required to be

connected to temperature probes with Enclosure option "N".

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from electrostatic

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

5.4.3 I1 ATEX Intrinsic Safety

5.5

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

The equipment must be installed in an enclosure which affords it a degree of

ingress protection of at least IP20.

International

Baseefa16ATEX0101X

EN 60079-0:2012+A11:2013, EN 60079-11:2012

II 1 G Ex ia IIC T5/T6 Ga (SEE CERTIFICATE FOR SCHEDULE)

Thermocouples; Pi = 500 mW T6 –60 °C ≤ Ta ≤ +70 °C

RTDs; Pi = 192 mW T6 –60 °C ≤ Ta ≤ +70 °C

RTDs; Pi = 290 mW T6 –60 °C ≤ Ta ≤ +60 °C

T5 –60 °C ≤ Ta ≤ +70 °C

5.5.1 E7 IECEx Flameproof

Certificate:

Standards:

Quick Start Guide 15

IECEx FMG 12.0022X

IEC 60079-0:2011, IEC 60079-1:2014

Page 16

Quick Start Guide March 2021

Markings:

Ex db IIC T6…T1 Gb; T6…T1: Ta= –50 °C to +40 °C; T5…T1: Ta=

–50 °C to +60 °C

See Process temperature limits for process temperatures.

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than 4

joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

to temperature probes with Enclosure option "N".

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from electrostatic

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

5.5.2 NK IECEx Dust-Ignitionproof

Certificate:

Standards:

Markings:

IECEx FMG 12.0022X

IEC 60079-0:2011, IEC 60079-1:2013

Ex tb IIIC T130 °C Db Ta= –40 °C to +70 °C; IP66

See Process temperature limits for process temperatures.

Special Conditions for Safe Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments

3. Guard the LCD display cover against impact energies greater than 4

joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex db or Ex tb enclosure is required to be

connected to temperature probes with Enclosure option "N".

16 Emerson.com/Rosemount

Page 17

March 2021 Quick Start Guide

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

7. Non-Standard Paint options may cause risk from electrostatic

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

5.5.3 I7 IECEx Intrinsic Safety

Certificate:

Standards:

Markings:

IECEx BAS 16.0077X

IEC 60079-0: 2011, IEC 60079-11:2011

Ex ia IIC T5/T6 Ga (SEE CERTIFICATE FOR SCHEDULE)

Thermocouples; Pi = 500 mW T6 –60 °C ≤ Ta ≤ +70 °C

RTDs; Pi = 192 mW T6 –60 °C ≤ Ta ≤ +70 °C

RTDs; Pi = 290 mW T6 –60 °C ≤ Ta ≤ +60 °C

T5 –60 °C ≤ Ta ≤ +70 °C

Special Conditions for Safe Use (X):

The equipment must be installed in an enclosure which affords it a degree of

ingress protection of at least IP20

5.5.4 E2 Brazil Flameproof and Dust-Ignitionproof

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. See product description for ambient temperature limits and process

UL-BR 13.0535X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-1:2016,

ABNT NBR IEC 60079-31:2014

Ex db IIC T6…T1 Gb; T6…T1: Ta= –50 °C to +40 °C; T5…T1: Ta=

–50 °C to +60 °C; Ex tb IIIC T130 °C Db IP66; (–40 °C ≤ Ta ≤ +70

°C)

temperature limits.

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than 4

joules.

Quick Start Guide 17

Page 18

Quick Start Guide March 2021

4. Consult the manufacturer if dimensional information on the

flameproof joints is necessary.

5. A suitable certified Ex “d” or Ex “tb” enclosure is required to be

connected to temperature sensors with Enclosure option "N".

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

7. For all equipment, non-standard paint options may cause risk from

electrostatic discharge. Avoid installations that cause electrostatic

build-up on painted surfaces, and only clean the painted surfaces

with a damp cloth. If paint is ordered through a special option code,

contact the manufacturer for more information.

5.6 Process temperature limits

Table 5-1: Sensor Only (No Transmitter Installed)

Process temperature (˚C)

Gas Dust

T6 T5 T4 T3 T2 T1 T130 ˚C

Any extension

length

85 100 135 200 300 450 130

Table 5-2: Transmitter

Process temperature (˚C)

Gas Dust

T6 T5 T4 T3 T2 T1 T130 ˚C

No extension 55 70 100 170 280 440 100

3-in. extension 55 70 110 190 300 450 110

6-in. extension 60 70 120 200 300 450 110

9-in. extension 65 75 130 200 300 450 120

Adhering to the process temperature limitations of Table 5-3 will ensure that

the service temperature limitations of the LCD display cover are not

exceeded. Process temperatures may exceed the limits defined in Table 5-3

if the temperature of the LCD display cover is verified to not exceed the

service temperatures in Table 5-4 and the process temperatures do not

exceed the values specified in Table 5-2.

18 Emerson.com/Rosemount

Page 19

March 2021 Quick Start Guide

Table 5-3: Transmitter with LCD Display Cover

Process temperature (˚C)

Gas Dust

T6 T5 T4…T1 T130 ˚C

No extension 55 70 95 95

3-in. extension 55 70 100 100

6-in. extension 60 70 100 100

9-in. extension 65 75 110 110

Table 5-4: Transmitter with LCD Display Cover

Service temperature (˚C)

Gas Dust

T6 T5 T4…T1 T130 ˚C

65 75 95 95

Quick Start Guide 19

Page 20

Quick Start Guide March 2021

6 Declaration of Conformity

Figure 6-1: Rosemount 1067 Declaration of Conformity

20 Emerson.com/Rosemount

Page 21

March 2021 Quick Start Guide

Quick Start Guide 21

Page 22

Quick Start Guide March 2021

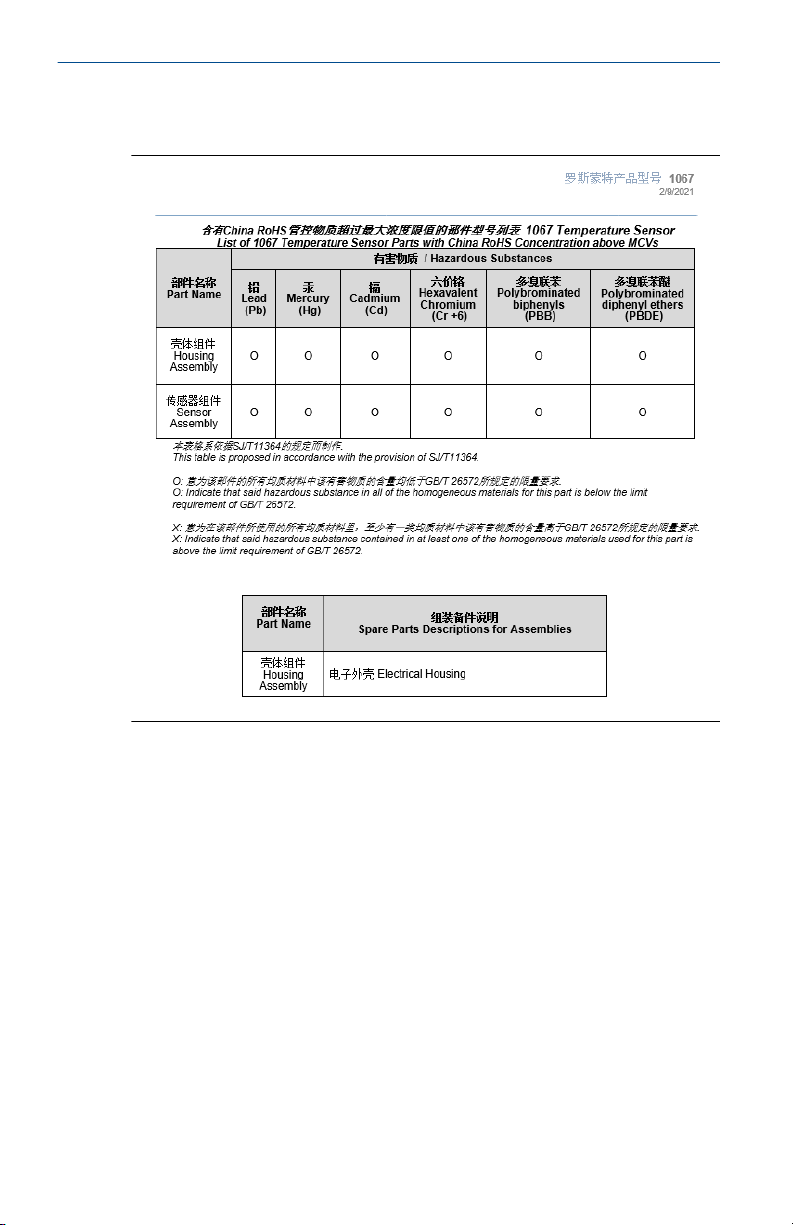

7 China RoHS

22 Emerson.com/Rosemount

Page 23

March 2021 Quick Start Guide

Quick Start Guide 23

Page 24

*00825-0100-4951*

00825-0100-4951, Rev. BC

Quick Start Guide

March 2021

For more information:

©

2021 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo

is a trademark and service mark of

Emerson Electric Co. Rosemount is a mark

of one of the Emerson family of

companies. All other marks are the

property of their respective owners.

www.emerson.com

Loading...

Loading...