Page 1

Model 1054B CL

Free Residual Chlorine Microprocessor Analyzer

Instruction Manual

PN 51-1054BCL/rev.B

April 2003

Page 2

WARNING

ELECTRICAL SHOCK HAZARD

Making cable connections to and servicing this

instrument require access to shock hazard level

voltages which can cause death or serious injury .

Be sure to disconnect all hazardous voltage

before opening the enclosure.

Relay contacts made to separate power sources

must be disconnected before servicing.

Electrical installation must be in accordance

with the National Electrical Code (ANSI/NFPA-

70) and/or any other applicable national or local

codes.

Unused cable conduit entries must be securely

sealed by non-flammable closures to provide

enclosure integrity in compliance with personal

safety and environmental protection requirements.

The unused conduit openings need to be sealed

with NEMA 4X or IP65 conduit plugs to maintain

the ingress protection rating (IP65).

For safety and proper performance this instrument must be connected to a properly grounded three-wire power source.

Proper relay use and configuration is the

responsibility of the user.

No external connection to the instrument of

more than 69VDC or 43V peak allowed with the

exception of power and relay terminals. Any violation will impair the safety protection provided

Do not operate this instrument without front

cover secured. Refer installation, operation and

servicing to qualified personnel..

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PRO-

CEEDING!

Rosemount Analytical designs, manufactures, and tests its

products to meet many national and international standards. Because these instruments are sophisticated technical products, you must properly install, use, and maintain

them to ensure they continue to operate within their normal

specifications. The following instructions must be adhered

to and integrated into your safety program when installing,

using, and maintaining Rosemount Analytical products.

Failure to follow the proper instructions may cause any one

of the following situations to occur: Loss of life; personal

injury; property damage; damage to this instrument; and

warranty invalidation.

• Read all instructions prior to installing, operating, and

servicing the product. If this Instruction Manual is not the

correct manual, telephone 1-949-757-8500 and the

requested manual will be provided. Save this Instruction

Manual for future reference.

• If you do not understand any of the instructions, contact

your Rosemount representative for clarification.

• Follow all warnings, cautions, and instructions marked

on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

• Install your equipment as specified in the Installation

Instructions of the appropriate Instruction Manual and

per applicable local and national codes. Connect all

products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel

to install, operate, update, program, and maintain the

product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by

Rosemount. Unauthorized parts and procedures can

affect the product’s performance and place the safe

operation of your process at risk. Look alike substitutions may result in fire, electrical hazards, or improper

operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is

being performed by qualified persons, to prevent electrical shock and personal injury.

W

ARNING

This product is not intended for use in the light industrial,

residential or commercial environment, per the instrument’s certification to EN50081-2.

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.RAuniloc.com

© Rosemount Analytical Inc. 2001

Page 3

Page 4

Page 5

MODEL 1054B CL TABLE OF CONTENTS

MODEL 1054B CL

MICROPROCESSOR ANALYZER

TABLE OF CONTENTS

Section Title Page

1.0 DESCRIPTION AND SPECIFICATIONS................................................................. 1

1.1 Features and Applications....................................................................................... 1

1.2 Physical Specifications - General............................................................................ 2

1.3 Analyzer Specifications @ 25°C.............................................................................. 2

1.4 Recommended Sensors.......................................................................................... 2

1.5 Ordering Information................................................................................................ 3

2.0 INSTALLATION........................................................................................................ 4

2.1 General.................................................................................................................... 4

2.2 Unpacking and Inspection ....................................................................................... 4

2.3 Installation................................................................................................................ 4

2.4 Electrical Connections - General............................................................................. 10

2.5 Sensor Wiring.......................................................................................................... 12

3.0 DESCRIPTION OF CONTROLS............................................................................. 14

3.1 Display and Keyboard Functions............................................................................. 14

3.2 View.........................................................................................................................16

3.3 Edit........................................................................................................................... 16

3.4 Configure Display .................................................................................................... 16

4.0 CONFIGURATION................................................................................................... 18

4.1 General ................................................................................................................... 18

4.2 Memory.................................................................................................................... 18

4.3 Start-up.................................................................................................................... 18

4.4 Set Function............................................................................................................. 18

4.5 Alarm 1 and 2 .......................................................................................................... 22

4.6 Interval Timer........................................................................................................... 23

4.7 Temperature Configuration ...................................................................................... 24

4.8 Current Output......................................................................................................... 24

4.9 Defaults.................................................................................................................... 25

4.10 Input Filter................................................................................................................26

4.11 Alarm Setpoint......................................................................................................... 26

4.12 Output Scale Expansion.......................................................................................... 27

4.13 Simulate Current Output ......................................................................................... 28

4.14 pH Correction........................................................................................................... 29

5.0 START UP AND CALIBRATION.............................................................................. 30

5.1 General.................................................................................................................... 30

5.2 Start-up.................................................................................................................... 30

5.3 Calibration................................................................................................................ 30

6.0 KEYBOARD SECURITY.......................................................................................... 34

7.0 THEORY OF OPERATION...................................................................................... 35

8.0 DIAGNOSTICS AND TROUBLESHOOTING .......................................................... 36

8.1 Diagnostics .............................................................................................................. 36

8.2 Troubleshooting ....................................................................................................... 36

8.3 CPU and Power Board Replacement ...................................................................... 39

8.4 Maintenance ............................................................................................................ 39

9.0 RETURN OF MATERIALS....................................................................................... 42

i

Page 6

LIST OF FIGURES

Figure No. Title Page

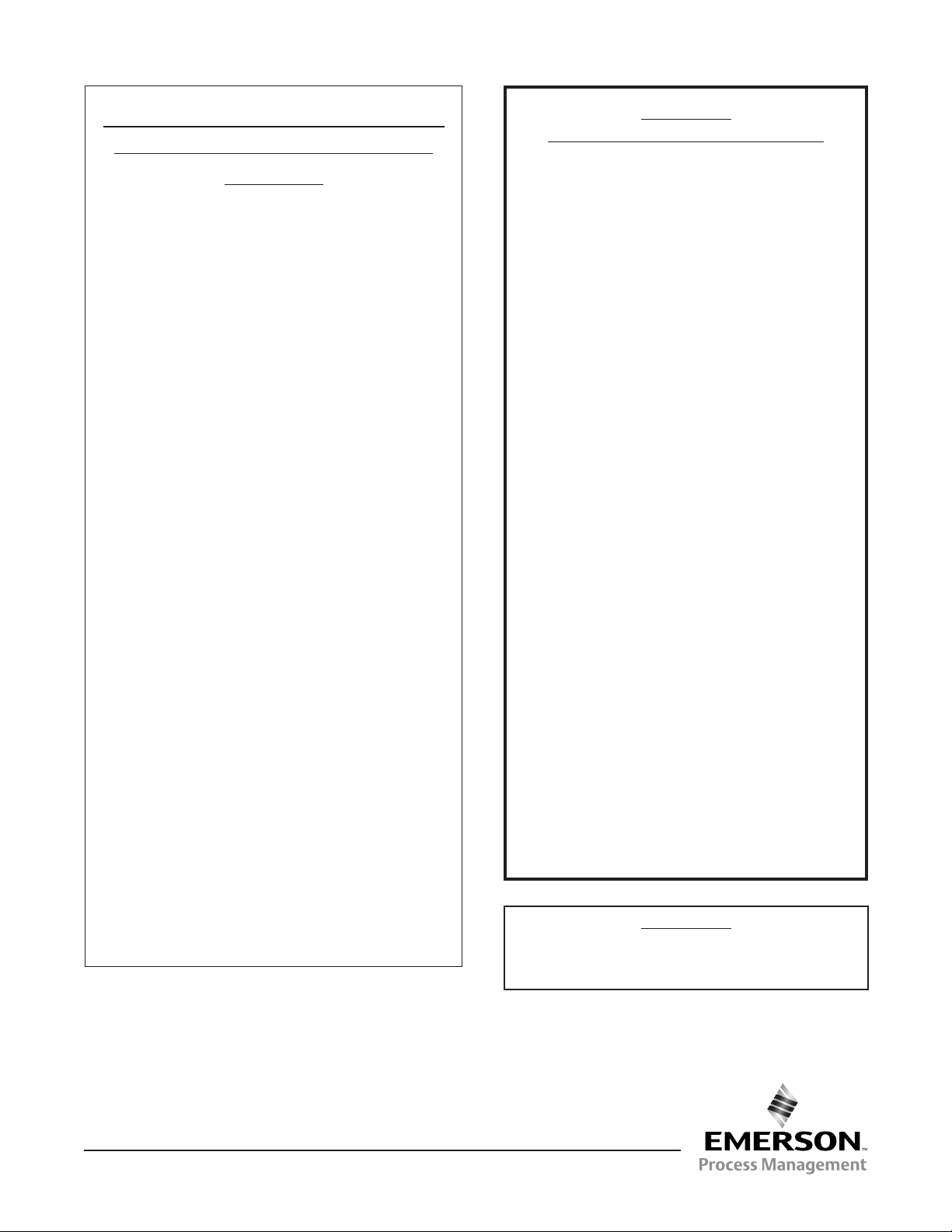

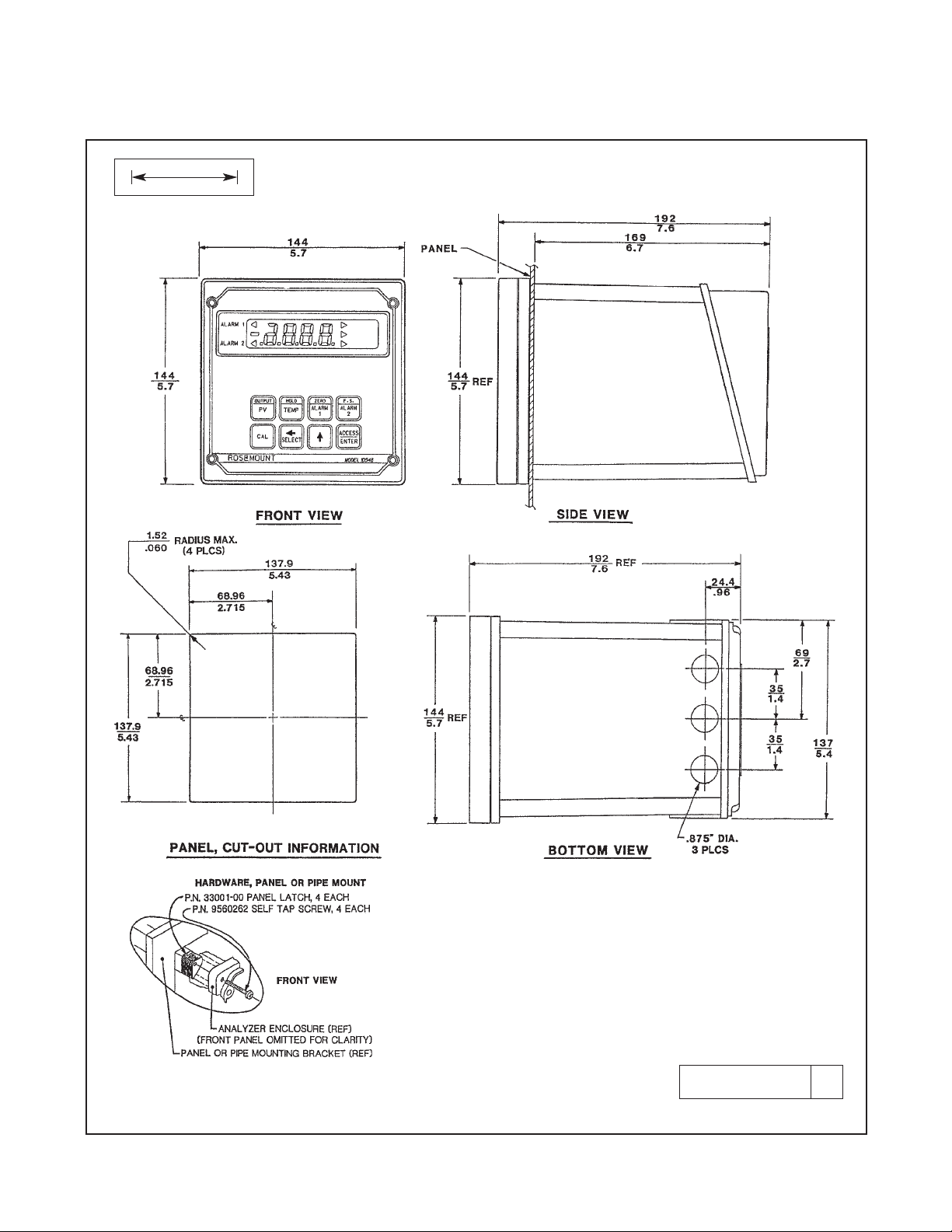

2-1 Panel Mounting Cutout Information......................................................................... 5

2-2 Panel Mounting Tab Installation .............................................................................. 6

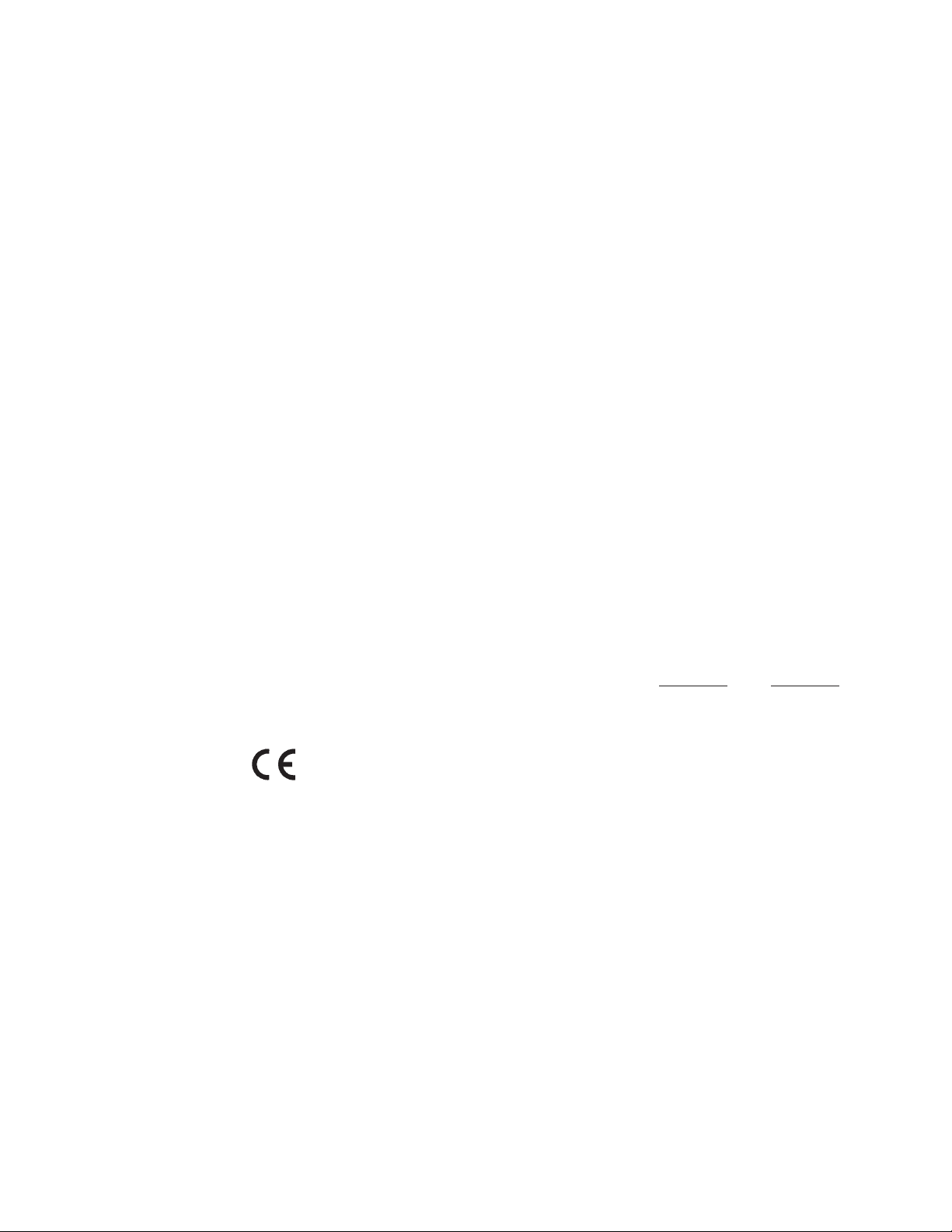

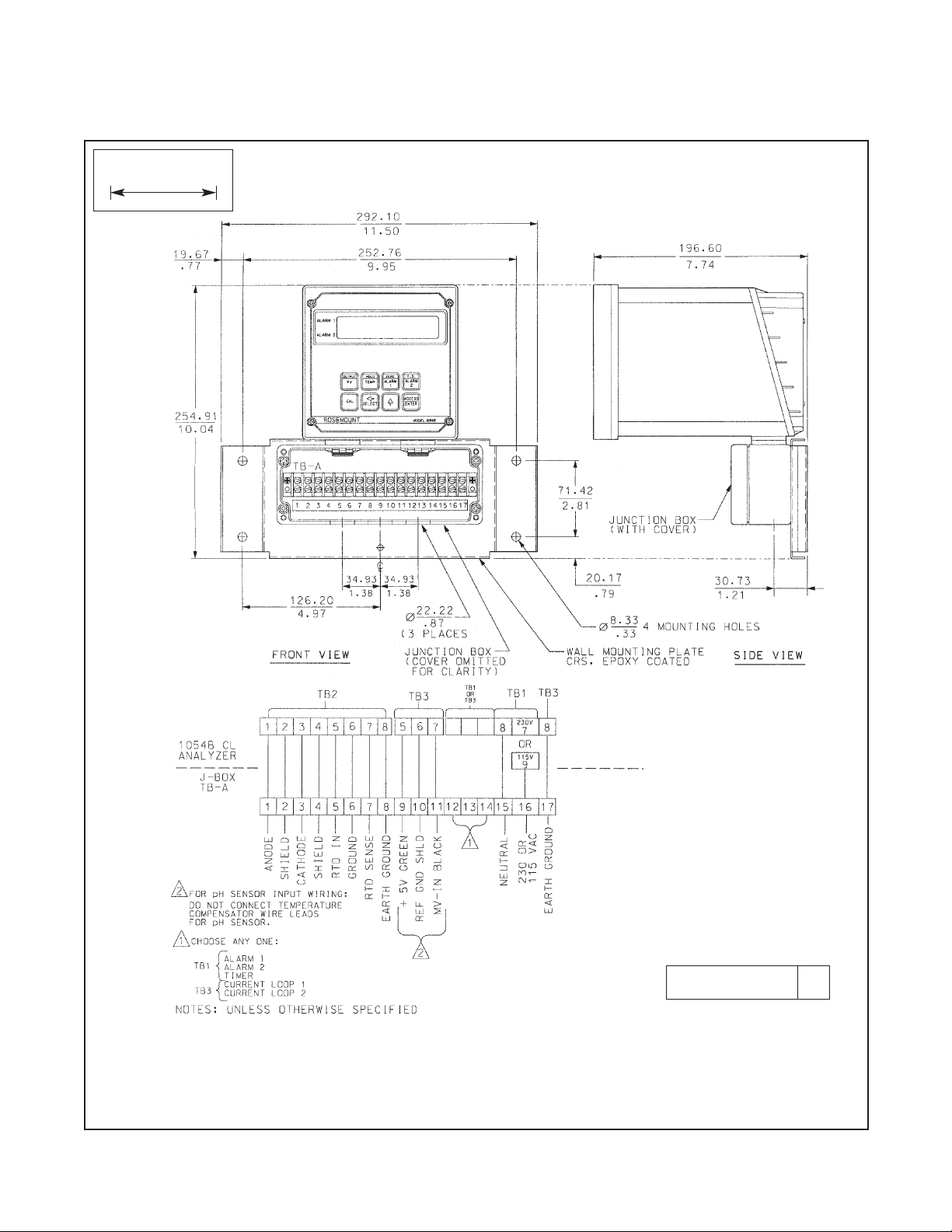

2-3 Wall Mounting Junction Box Assembly.................................................................... 6

2-4 Wall Mounting Junction Box Wiring Diagram........................................................... 7

2-5 Pipe Mounting Installation........................................................................................ 8

2-6 Wall Mount Enclosure (option -20)........................................................................... 9

2-7 Electrical Wiring....................................................................................................... 10

2-8 Wiring Sensor with Standard Cable to 1054B CL Analyzer..................................... 12

2-9 Wiring Sensor with Optimum EMI/RFI Cable to 1054B CL Analyzer....................... 12

2-10 Wiring Sensor Model 389-01-10-54 to Model 1054B CL Analyzer.......................... 13

2-11 Wiring Sensor Model 396P-01-10-54 to Model 1054B CL Analyzer........................ 13

2-12 Wiring Sensor Model 399-07 or 399-08 to Model 1054B CL Analyzer.................... 13

3-1 Front Panel .............................................................................................................. 14

3-2 Key Labels............................................................................................................... 16

3-3 Accessing Editing Function...................................................................................... 16

3-4 Accessing Configuration Menus.............................................................................. 16

4-1 Set Function Menu................................................................................................... 20

4-2 Alarm 1 and Alarm 2 Set Up.................................................................................... 22

4-3 Timer Diagram for One Cycle .................................................................................. 23

4-4 Interval Timer Setup................................................................................................. 23

4-5 Temperature Configuration Setup............................................................................ 24

4-6 Current Output Setup............................................................................................... 24

4-7 Default Setup........................................................................................................... 25

4-8 Alarm Setpoint ......................................................................................................... 26

4-9 Output Scale Expansion.......................................................................................... 27

4-10 Simulate Output Current .......................................................................................... 28

8-1 Three-wire 100 ohm Platinum RTD.......................................................................... 37

8-2 Temperature Simulation into 1054B CL Analyzer.................................................... 37

8-3 Electronic Bench Check Setup................................................................................ 38

LIST OF TABLES

Table No. Title Page

1-1 Replacement Parts .................................................................................................. 3

1-2 Accessories.............................................................................................................. 3

3-1 Description of Keys and Functions.......................................................................... 15

3-2 Information Mnemonics............................................................................................ 16

4-1 Configuration Worksheet.......................................................................................... 19

4-2 Set Mode Function Mnemonics ............................................................................... 21

4-3 Relay States............................................................................................................. 25

8-1 Fault Message Codes.............................................................................................. 36

8-2 RTD Resistance Values........................................................................................... 37

8-3 Troubleshooting Guide............................................................................................. 40

ii

MODEL 1054B CL TABLE OF CONTENTS

Page 7

1

Model 1054B CL SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.1 FEATURES AND APPLICATIONS

The Model 1054B Microprocessor Analyzers with the

appropriate sensor are designed to continuously measure and control pH, ORP, conductivity, percent concentration, ratio, resistivity, dissolved oxygen, free residual

chlorine, or dissolved ozone in industrial and municipal

processes.

The Model 1054B Analyzer is housed in a NEMA 4X

(IP65) weatherproof, corrosion-resistant, flame retardant

enclosure suitable for panel, pipe, or wall mounting. All

functions are accessed through the front panel membrane keypad which features tactile feedback. Settings

may be protected against accidental or unauthorized

changes by a user selectable security code.

Measurement data may be read at any time on either an

LED or LCD display. The display shows the concentration of free residual chlorine, the pH (optional), temperature, alarm status, and hold and fault conditions.

The 1054B transmits isolated current outputs for chlorine and pH that are continuously expandable over the

measurement range. Current outputs can be configured

for either direct or reverse action and can be displayed

in milliamps or percent of full scale. Output dampening

of 0-255 seconds is user selectable. The output and

relay settings for hold and fault mode operation are also

user selectable. The hold output function allows the user

to manually control the process while the sensor is offline for maintenance. Continuous self diagnostics alert

the operator to faults caused by analyzer electronics,

RTD failure, and open wiring.

Two alarm relays are standard, and the relays can be programmed for high or low activation. For Model 1054B CL

Analyzers equipped with dual output (chlorine and pH),

either alarm can monitor either output. Alarm 2 can be

programmed as a fault alarm. Both alarms feature independent setpoints, adjustable deadband or hysteresis,

and time delay action. A dedicated relay with programmable timer function is also provided.

1.1 Features and Applications

1.2 Physical Specifications - General

1.3 Analyzer Specifications @ 25°C

1.4 Recommended Sensors

1.5 Ordering Information

The Model 1054B CL Analyzer is intended for use with

a membrane covered amperometric sensor.* Because

the permeability of the membrane is a function of temperature, a correction is necessary when the sensor is

used at a temperature different from the one at which it

was calibrated. The analyzer automatically applies the

temperature correction factor. The temperature of the

process is measured by an RTD in the sensor and is

displayed in either °C or °F.

An aqueous solution of free chlorine is a mixture of

hypochlorous acid and hypochlorite ion. The relative

amount of each species depends on temperature and

pH. Generally, increasing the pH and temperature

reduces the amount of hypochlorous acid in the mixture.

Because the response of the sensor to hypochlorous

acid is greater than its response to hypochlorite, accurate determination of chlorine requires knowledge of the

pH and temperature of the sample. If the pH is relatively

constant, a fixed pH correction factor can be entered

into the analyzer software. If the pH is greater than 7

and fluctuates by more than 0.1 unit, continuous measurement of pH and automatic pH correction is necessary. For analyzers having automatic pH correction,

two-point buffer calibration is standard.

An input filter allows the user to configure the analyzer

for rapid response or low noise.

The 1054B CL Analyzer is intended for use in applications where species that react with free chlorine, such

as ammonia, certain organic amines, and bromide are

absent.

Page 8

2

Model 1054B CL SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.3 ANALYZER SPECIFICATIONS @ 25°C.

Measurement Range: 0-20 ppm (mg/L) chlorine,

0-14 pH

Resolution: 0.001 ppm free residual chlorine (as CI2)

and 0.01 pH units (3-1/2 digit display)

Automatic pH Correction: 5.0 to 9.5 pH

Output Stability: ± 0.25% of span over 30 days,

non-cumulative

Temperature Compensation: Automatic or manual

0-50°C. Can be disabled if desired.

Input Filter: 1-255 samples

Alarms: Dual, field selectable High/Low, High/High,

or Low/Low

Alarm 2 configurable as a fault alarm

Time delay: 0 to 254 seconds

Dual setpoints, continuously adjustable

Hysteresis is adjustable up to 25% of setpoint

for low side/high alarm and high side/low alarm

Interval Timer: Controls dedicated relay

Interval: 10 min. to 2999 days

On Counts: 1 to 60

On Duration: 1 to 299.9 seconds

Off Duration: 1 to 299.9 seconds

Wait Duration: 1 to 299.9 seconds

Relay Contacts: Epoxy Sealed Form A contacts,

SPST, Normally Open.

Resistive

Inductive

28 VDC 5.0 Amps 3.0 Amps

115 VAC 5.0 Amps 3.0 Amps

230 VAC 5.0 Amps 1.5 Amps

1.4 RECOMMENDED SENSORS

Chlorine: Model 499A CL Free Residual Chlorine

pH: Model 389-01-10-54

Model 396P-01-10-54

Model 399-07 or 399-08

1.2 PHYSICAL SPECIFICATIONS - GENERAL

Panel Mount Enclosure: Black, ABS, NEMA 4X, IP65,

CSA Enclosure 4

144 X 144 X 192 mm

(5.7 X 5.7 X 7.6 in.)

Wall Mount Enclosure: NEMA 4X, Heavy duty

fiberglass, reinforced thermoplastic.

356.4 X 450.1 X 180.2 mm* (14 X 17.7 X 7.1 in.*)

Front Panel: Membrane keypad with tactile feed-

back and user selectable security code

Digital Display: LCD, black on grey

Optional red LED

Character height: 18 mm (0.7 in.)

Electrical Classification:

FM Class I, Div. 2, Group A thru D

28 Vdc relays - 5.0 amps resistive only

150 mA - Groups A & B; 400 mA - Group C;

540 mA - Group D; Ci = 0; Li = 0

CSA Class I, Div. 2, Group A thru D

28 Vdc, 110 Vac & 230 Vac relays

5.0 Amps resistive only

Wall Mount Enclosure: General Purpose

Power: 100 - 127 VAC, 50/60 Hz ±6%, 4.0 W

200 - 253 VAC, 50/60 Hz ±6%, 4.0 W

Current Output: Isolated, 0-20 mA or 4-20 mA into

600 ohms maximum load at 115/230 Vac

or

550 ohms maximum load at 100/200 Vac; direct

or reverse acting; dampening: 0-255 seconds

Output 1: total free chlorine (ppm)

Output 2 (optional): pH

EMI/RFI: EN 61326

LVD: EN 61010-1

Model option -20 Wall Mount Enclosure does not

meet CE requirements

Ambient Temperature: -10 to 65°C (14 to 149°F)

Ambient Humidity: LED: 0-95% RH

LCD: 0-85% RH

Weight/Shipping Weight: 1.0 kg/1.5 kg (3.0 lb/4.0 lb)

*Includes latches and mounting feet

Page 9

3

Model 1054B CL SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

Model 1054B Free Residual Chlorine Microprocessor Analyzer: Housed in a NEMA 4X corrosion resistant,

weatherproof housing suitable for panel, pipe, or wall mounting. Standard features include digital display, isolated

current outputs, dual programmable alarms, programmable timer with independent relays, and manual or automatic

temperature correction for membrane permeability. Optional pH correction is available for processes in which the

pH exceeds 7 and varies by more than ±0.1.

MODEL

1054B MICROPROCESSOR ANALYZER (3.5 lb./1.5 kg)

1.5 ORDERING INFORMATION

PN DESCRIPTION

33469-00 Enclosure Body

33470-00 Enclosure, Rear Cover

32938-00 Gasket, Front Cover

32937-00 Gasket, Rear Cover

22966-00 PCB, LCD Digital Display

23245-01 PCB, LED Digital Display

23695-22 Keyboard Overlay, LCD Version, CL

23695-23 Keyboard Overlay, LED Version, CL

23666-03 PCB, CPU, Free Residual Chlorine

23332-00 PCB, CPU, pH

23739-00 PCB, Power Supply

23740-02 PCB, Motherboard

9100157 Fuse, 0.1A, 250V, 3AB, Slo Blo

9100160 Fuse, 0.25A, 125V Axial Lead PICO II

9100189 Fuse, 0.75A, 125V Axial Lead PICO II

TABLE 1-1. Replacement Parts TABLE 1-2. Accessories

CODE Measurement

CL Free Residual Chlorine

CODE Display (Required Selection)

01 LCD Display

02 LED Display

CODE pH Correction

10 Automatic pH Correction with 2nd Output (Requires pH Sensor with preamplifier)

CODE Options

20 Wall Mount Enclosure (not CE approved)

PN DESCRIPTION

2001492 Tag, Stainless Steel, Specify Marking

23025-01 Panel Mounting Kit

23053-00 Pipe Mounting Kit for 2-inch pipe,

complete; includes mounting bracket,

U-bolts, and all necessary fasteners

23054-01 Wall Mounting Kit, complete; includes wall

mounting bracket, junction box, conduit

nipples to connect analyzer to junction

box, and all necessary seals and fasteners

23268-01 Heater, 115 VAC, 50/60 Hz, 1054B

(Code 20 only)

23268-02 Heater, 230 VAC, 50/60 Hz, 1054B

(Code 20 only)

1054B CL 01 10 EXAMPLE

Page 10

4

MODEL 1054B CL SECTION 2.0

INSTALLATION

SECTION 2.0

INSTALLATION AND WIRING

2.1 GENERAL. The analyzer is suitable for outdoor

use. However, the analyzer should be located in an

area where temperature extremes and vibrations are

minimized or absent. Installation must be performed

by a trained technician.

2.2 UNPACKING AND INSPECTION. Inspect the

analyzer for shipping damage. If damage is found,

notify the carrier immediately. Confirm that all items

shown on the packing list are present. Notify

Rosemount Analytical if items are missing.

2.3 INSTALLATION. Select a location at least one

foot from any high voltage conduit, with easy access

for operating personnel, and not in direct sunlight.

Prepare the analyzer for installation by following the

procedure for the appropriate mounting configuration:

2.3.1 Panel Mounting (Standard). The Model 1054B

fits into a DIN standard 137.9 mm X 137.9 mm (5.43

in. X 5.43 in.) panel cutout. Refer to Figures 2-1 and

2-2.

1. Remove the four screws holding the front panel

assembly of the enclosure and carefully pull the

front panel and connected printed circuit boards

straight out.

2. Align the latches as shown in Figure 2-2 and

insert the analyzer enclosure through the front of

the panel cutout. Tighten the screws for a firm fit.

Do not overtighten.

3. Replace the front panel assembly. The circuit

boards must align with the slots on the inside of

the enclosure. Tighten the four front panel

screws.

2.3.2 Wall Mounting Plate with Junction Box

(PN 23054-01). Refer to Figures 2-3 and 2-4.

1. Remove the four screws holding the front panel

assembly of the enclosure and carefully pull the

front panel and connected printed circuit boards

straight out.

2. Attach the mounting bracket to the junction box

with the hardware provided. See Figure 2-3.

Wiring can be brought to the terminal strip prior to

mounting the analyzer to the junction box.

3. Place the metal stiffener on the inside of the analyzer and install the two 1/2 in. conduit fittings

using two weather seals. Place the NEMA 4X

conduit plug in the center hole.

4. Attach the analyzer to the junction box using the

1/2 in. conduit fittings.

5. Complete the wiring connections between the

analyzer and the junction box. Refer to Figure 2-4.

Panel Mounting Section 2.3.1

Wall Mounting Section 2.3.2

Pipe Mounting Section 2.3.3

Wall Mount Enclosure Section 2.3.4

2.1 General

2.2 Unpacking and Inspection

2.3 Installation

2.4 Electrical Connections - General

2.5 Sensor Wiring

Page 11

5

MODEL 1054B CL SECTION 2.0

INSTALLATION

DWG. NO. REV.

41054B01 A

FIGURE 2-1. Panel Mounting Cutout Information

MILLIMETER

INCH

Page 12

6

Model 1054B CL SECTION 2.0

INSTALLATION

FIGURE 2-3. Wall Mounting Junction Box

Assembly

DWG. NO. REV.

41054A27 A

FIGURE 2-2. Panel Mounting Tab Installation

DWG. NO. REV.

41054A26 A

Install the mounting latches as shown (latches are

shown oversize for clarity). If the latches are not

installed exactly as shown, they will not work correctly. The screws provided are self-tapping. Tap

the screw the full depth of the mounting latch (refer

to side view) leaving a gap greater than the thickness of the cutout panel.

Page 13

7

Model 1054B CL SECTION 2.0

INSTALLATION

FIGURE 2-4. Wall Mounting Junction Box Wiring Diagram

Run the sensor wiring into the left hand opening (from front view) of the junction box. Run all other wiring out

of the right hand opening. The wiring diagram is for the most common sensors. See Figures 2-8 through 2-12

for complete wiring information.

DWG. NO. REV.

41054B39 A

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

Page 14

8

2.3.3 Pipe Mounting (PN 23053-00). The 2 in. pipe mounting kit includes a metal plate with a cutout for the analyz-

er. Refer to Section 2.3.1 for mounting the analyzer into the plate. Mounting details are shown in Figure 2-5 (below).

MODEL 1054B CL SECTION 2.0

INSTALLATION

FIGURE 2-5. Pipe Mounting Installation

DWG. NO. REV.

41054B02 C

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

Page 15

9

2.3.4 Wall Mount Enclosure (option -20). See Figure 2-6 (below) for installation details.

MODEL 1054B CL SECTION 2.0

INSTALLATION

FIGURE 2-6. Wall Mount Enclosure (Option -20)

DWG. NO. REV.

41054B43 A

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

Page 16

Model 1054B CL SECTION 2.0

INSTALLATION

10

2.4 ELECTRICAL CONNECTIONS-GENERAL

All electrical connections are made to terminal blocks on the rear panel (interface board) of the analyzer. To reach

the rear panel, remove the four screws securing the back cover of the enclosure. Gently pull away the cover, which

is connected to the rear panel by a continuity wire. If the wire is disconnected for any reason, reconnect it to the

nearest mounting screw before replacing the cover.

Figure 2-7 (below) shows the interface panel and wiring connections.

FIGURE 2-7. Electrical Wiring

Wire the pH sensor to terminal block TB3 (see Figures 2-10, 2-11, and 2-12).

Wire the chlorine sensor to TB2 (see Figures 2-8 and 2-9).

DWG. NO. REV.

41054B38 A

Page 17

11

Model 1054B CL SECTION 2.0

INSTALLATION

The three openings in the bottom rear of the analyzer

housing accommodate 1/2 in. conduit fittings. Looking

at the analyzer from the rear, the right opening is for

sensor wiring, the center opening is for signal output,

and the left opening is for power, timer, and alarm

wiring. Always run sensor wiring in a separate conduit

from power wiring.

2.4.1 Power Connections. The model 1054BCL analyzer uses either 115 Vac or 230 Vac power. See

Figure 2-7 for connections. AC power wiring should be

14 gauge or greater.

2.4.2 Output Signal Wiring. Terminals 1 and 2 on TB3

are for the chlorine output signal and terminals 3 and 4

are for the pH signal. Maximum output load is 600

ohms. For best EMI/RFI protection shield the output

cable and enclose it in an earth grounded metal conduit. If the output wiring is connected directly to the

analyzer, connect the cable shield to terminal 8 on TB3.

If the output wiring runs through a junction box, connect

the cable shield to earth ground on terminal board TBA.

2.4.3 Alarm Wiring. Connect the alarm and timer circuits to terminals 1 through 6 on TB1. See Figure 2-7

for details.

CAUTION

The sensitivity and stability of the analyzer

will be impaired if the input wiring is not

grounded. DO NOT apply power to the

analyzer until all electrical connections are

verified and secure. The following precautions are a guide using UL 508 as a safeguard for personnel and property.

NOTE

The user must provide a means to disconnect the main power supply in the form of

circuit breaker or switch. The circuit breaker or the switch must be located in close

proximity to the instrument and identified

as the disconnecting device for the instrument.

1. AC connections and grounding must be in compliance with UL 508 and/or local electrical codes.

2. The metal stiffener is required to provide support

and proper electrical continuity between conduit

fittings.

3. This type 4/4X enclosure requires a conduit hub

or equivalent that provides watertight connect,

REF UL 508-26.10.

4. Watertight fittings/hubs that comply with the

requirements of UL 514B must be used.

5. Conduit hubs must be connected to the conduit

before the hub is connected to the enclosure,

REF UL 508-26.10.

6. If the metal support plate is not used, plastic fittings must be used to prevent structural damage

to the enclosure. Also, appropriate grounding lug

and AWG conductor must be used with the plastic fittings.

Page 18

12

Model 1054B CL SECTION 2.0

INSTALLATION

2.5 SENSOR WIRING

2.5.1 Chlorine Sensor.The analyzer is recommended for use with only the 499ACL chlorine sensor. Wire the sen-

sor to terminal block TB2. See Figure 2-8 for sensors having standard cable. See Figure 2-9 for sensors having

optimum EMI/RFI cable.

Sensor cable should also be shielded. If the sensor is wired directly to the analyzer, connect the outer shield of the

sensor cable to earth ground using terminal 8 on TB2. If the sensor is wired through a wall mounting junction box,

connect the outer shield to the earth ground terminal of TBA. If the outer shield of the cable is metal braid, use a

metal cable gland fitting to connect the braid to earth ground by way of the instrument case.

FIGURE 2-8. Wiring Sensor with Standard Cable to 1054B CL Analyzer

FIGURE 2-9. Wiring Sensor with Optimum EMI/RFI Cable to 1054B CL Analyzer

Page 19

13

Model 1054B CL SECTION 2.0

INSTALLATION

2.5.2 pH Sensor. Wire the pH sensor to terminal block

TB3. The table lists recommended pH sensors and the

figure number of the wiring diagram. The pH sensor

must have a preamplifier compatible with the Model

1054B.

Insulate unused leads and connect them to the cable

to prevent shorted connections.

pH Sensor Wiring Diagram

389-01-10-54 Figure 2-10

396P-01-10-54 Figure 2-11

399-07 or 399-08 Figure 2-12

FIGURE 2-10. Wiring Sensor Model 389-01-10-54 to Model 1054B CL Analyzer

FIGURE 2-11. Wiring Sensor Model 396P-01-10-54 to Model 1054B CL Analyzer

FIGURE 2-12. Wiring Sensor Model 399-07 or 399-08 to Model 1054B CL Analyzer

Page 20

14

2. Set alarm points, generate specific output currents

for testing, set zero and full-scale outputs, and calibrate concentration, pH and temperature.

3. Select temperature in °C or °F, configure alarms

(setting an alarm and configuring an alarm are different operations [see Section 4.0]), set timer

functions, establish a password, and set the current output range.

Each key in the top row of the keypad has dual functions. Pressing the key once displays the value identified by the lower (white on blue) label. Pressing the key

twice in rapid succession displays the value or activates the function identified by the upper (blue on

white) label. Two keys in the bottom row also have dual

functions. The use of these keys is explained in later

sections. Table 3-1 summarizes the values and functions associated with each key.

MODEL 1054B CL SECTION 3.0

DESCRIPTION OF CONTROLS

SECTION 3.0

DESCRIPTION OF CONTROLS

3.1 DISPLAY AND KEYBOARD FUNCTIONS. Figure 3-1

shows the front panel of the 1054B CL Microprocessor

Analyzer. The front panel consists of a single line display with information flags and an eight key membrane

keypad. Readings and instrument settings and the

mnemonics that guide the user through configuring the

instrument appear in the main display. The flags at the

sides of the display show whether an alarm relay is activated or deactivated, indicate hold and fault conditions,

and show the units of the value being displayed. As

explained in Figure 3-1 a steady flag and a flashing flag

have different meanings.

The operations of the 1054B Microprocessor Analyzer

are controlled by the eight keys shown in Figure 3-1.

The keys are used to:

1. Display values other than the primary value (PV).

Free residual chlorine concentration is the primary

value.

FIGURE 3-1. Front Panel

DWG. NO. REV.

41054B37 A

3.1 Display and Keyboard Functions

3.2 View

3.3 Edit

3.4 Configure Display

Page 21

15

Model 1054B CL SECTION 2.0

INSTALLATION

Displays the present output in mA or percent of full

scale.

Pressing SELECT with the output showing causes

the analyzer to simulate an output current

Displays the value corresponding to the low current (4 or 0 mA) output.

Pressing SELECT with the value showing allows

the value to be changed.

Displays the value corresponding to the full scale

(20 mA) output .

Pressing SELECT with the value showing allows

the value to be changed.

1. Selects a sub-menu when a mnemonic is displayed.

2. Shifts to next digit when a number is displayed.

1. Moves to the next item in the menu when a

mnemonic is displayed.

2. Pressing once increases the flashing digit by one.

3. Holding the key down autoscrolls the display.

1. Pressing key twice in rapid succession allows

access to the set function menu.

2. Enters displayed value into memory.

3. Enters displayed mnemonic into memory.

Displays Alarm 1 setpoint.

Pressing SELECT with the setpoint

showing allows the setpoint to be

changed.

Displays the concentration of free residual chlorine.

Pressing SELECT with the concentration

showing allows one point standardization

of the analyzer.

Places the analyzer in hold or removes the analyzer from hold. When the analyzer is in hold, the display shows the present chlorine concentration, but

the output remains at the value it was when hold

was initiated.

Displays the process temperature (°C or °F).

Pressing SELECT with temperature

showing allows the temperature to be

scalibrated.

Displays Alarm 2 setpoint.

Pressing SELECT with the setpoint

showing allows the setpoint to be

changed.

Display pH.

Pressing SELECT with pH showing allows the pH reading to be changed.

Pressing SCROLL (éé) with pH showing allows the automatic pH correction feature to be set

and permits the pH sensor to be calibrated.

HOLD

TEMP

OUTPUT

PV

ZERO

ALARM 1

F.S.

ALARM 2

CAL

ç

SELECT

é

ACCESS

ENTER

SECOND FUNCTION (PRESS TWICE QUICKLY)MAIN FUNCTION (PRESS ONCE)

TABLE 3-1. Description of Keys and Functions.

Page 22

16

MODEL 1054B CL SECTION 3.0

DESCRIPTION OF CONTROLS

3.2 VIEW. To view a measurement or a setting without

changing its value, press the appropriate key in the top

row. Press once to display the value of the lower label.

Press twice in rapid succession to display the value of

the upper label (see Figure 3-2).

In some cases, an information mnemonic appears

momentarily before the value is displayed. Table 3-2

explains the meaning of the information mnemonics.

TABLE 3-2. Information Mnemonics

Mnemonic Description Mnemonic Description

AdJ Adjust value LOC Access locked – enter security code

bAd Incorrect entry Pc1 Displays FRC output in percent

bF1 Buffer 1 Pc2 Displays pH output in percent

bF2 Buffer 2 PH pH display (measured process pH)

dc1 Displays FRC output value in mA FrC Free residual chlorine display

dc2 Displays pH output value in mA SEt Set mode

do1 Display output (FRC) Si1 Simulates FRC output (mA)

do2 Display output (pH) Si2 Simulates pH output (mA)

FPH Fixed pH display (manual pH input) SP1 Simulates FRC output (%)

HLd Analyzer in hold mode SP2 Simulates pH output (%)

HI1 Displays 20 mA setpoint (FRC) SLP Displays pH electrode slope

HI2 Displays 20 mA setpoint (pH) SP1 Displays Alarm 1 setpoint

itr Interval timer activated SP2 Displays Alarm 2 setpoint

LO1 Displays 0 or 4 mA setpoint (FRC) Std Standardize

LO2 Displays 0 or 4 mA setpoint (pH)

3.3 EDIT. If desired, the values accessed by the keys in

the upper row of the keypad can be edited. Use the

SELECT, SCROLL (é), SHIFT (ç), and ENTER keys

to change a displayed value. With the value to be

changed showing in the display, press SELECT. An

information mnemonic appears momentarily, then the

number reappears with the right hand digit flashing to

indicate that the number can be changed (see Figure 3-

3). Pressing the é key increases the value of the blinking digit by one unit. To move to the next digit, use the

ç key. To place the new value in memory, press

ENTER. Refer to Table 3-2 for an explanation of the

information mnemonics.

Table 3-1 summarizes the functions of the edit keys.

1. Press key.

2. AdJ shows briefly.

3. Numbers show with digit flashing.

1. Press key twice.

2. Lo shows briefly.

3. Zero point is displayed.

SELECT

ZERO

ALARM

1

FIGURE 3-3. Accessing Editing Function.

ç

FIGURE 3-2. Key Labels.

Single press of the key displays the present

free residual chlorine reading. Read only.

OUTPUT

PV

Quick double press of the key displays the

present output in mA or percent of full

scale. Read only.

Page 23

17

3.4 CONFIGURE DISPLAY. The display and analyzer

functions are configured using the set function program.

To enter the program, quickly double press the

ACCESS/ENTER key (see Figure 3-4).

Figure 4-1 on page 20 shows the main menu, the submenus, and the shorthand labels or mnemonics

assigned to each item in the menus. Table 4-2 on page

24 explains the meaning of each mnemonic. The set

function is used to configure alarms, set the interval

timer, change the units in which temperature is displayed, configure the output signal, tell the analyzer

what to do during fault or hold conditions, filter the input

signal, and set a security code.

To move through the main menu press and hold the

SCROLL (é) key. When the desired item is displayed,

release the key. Most items in the main menu have a

sub-menu associated with them. To enter a sub-menu,

press SELECT and use the SCROLL (é) key to move

through the sub-menu. To choose an item in a submenu, press SELECT. If the item selected can be edited, the screen will change to a flashing display. If digits

are showing, use the SCROLL (é) key to change number and the SHIFT (ç) key to move to the next digit.

Press ENTER to place the value in memory. If a word

or a mnemonic is flashing, indicating it can be changed

to a different mnemonic, use the SCROLL (é) key to

display the desired setting and press ENTER to place

the selection in memory.

To leave a menu or sub-menu without entering the edited value, press PV. The display will change to the concentration of free residual chlorine in the sample.

MODEL 1054B CL SECTION 3.0

DESCRIPTION OF CONTROLS

1. Press twice in rapid succession.

2. SEt appears momentarily to confirm

entry into set function menu.

3.First menu item is displayed.

Analyzer now ready to configure.

4. Use the SCROLL key to move through

the menus.

ACCESS

ENTER

SEt

in

é

FIGURE 3-4. Accessing Configuration Menus

Page 24

18

4.1 GENERAL. This section explains how to configure

the Model 1054 B CL Analyzer to a specific application.

NOTE

The analyzer is configured at the factory for

the best general use. Table 4-1 lists the factory settings. Use the worksheet (Table 4-1)

to record your configuration. The configuration can be done in any order. However, to

reduce the chance of accidentally omitting

important settings, it is best to configure the

analyzer in the order presented in the manual and on the worksheet.

4.2 MEMORY. The Model 1054B CL Analyzer can be

configured before or after installation. Configuration

settings are written into non-volatile memory and

remain in memory when power is removed.

4.3 ST ART-UP. If the sensor is not connected, the analyzer may start up flashing a fault mnemonic. The

mnemonic will be suppressed when the analyzer is in

the set function mode; however, the fault flag will continue to flash.

NOTE

To shorten sensor warmup time, wire the

sensor to the analyzer as soon as possible.

4.4 SET FUNCTION. Enter the set function by pressing the ACCESS/ENTER key twice in rapid succession. The mnemonic SEt appears momentarily, confirming that the analyzer is in the set mode. The display

then changes to the first item in the main menu, in.

NOTE

If LOC is displayed instead of SEt, the keypad is locked, and the security code must

be keyed in to gain access to the set function menus. Refer to Section 6.0.

The first three items in the menu, in, SEn, and

-O- are not used for configuring the analyzer. Instead,

selecting in displays the current being generated in the

sensor, selecting SEn allows the approximate sensitivity (current per ppm) of the sensor to be entered, and

selecting -O- sets the present current equal to zero

concentration.

Figure 4-1 is a map of the set function program. The

program contains a main menu, shown on the left hand

side of the figure, and several sub-menus connected to

items in the main menu. The menu items are identified

by mnemonics. Refer to Table 4-2 for an explanation of

each mnemonic. Selecting an item in the main menu

gives access to the associated sub-menu. For example, choosing AL1 in the main menu moves the user

into a sub-menu containing FrC, PH, and OFF. Selecting

FrC or PH in this sub-menu gives access to a deeper

sub-menu containing H-L, HYS, don, and doF. Selecting

H-L from this menu gives a mnemonic display that can

be edited (HI or LO). Selecting any other item gives a

numeric display for editing.

Model 1054B CL SECTION 4.0

CONFIGURATION

SECTION 4.0

CONFIGURATION

4.1 General

4.2 Memory

4.3 Start-Up

4.4 Set Function

4.5 Alarm 1 and 2

4.6 Interval Timer

4.7 Temperature Configuration

4.8 Current Output

4.9 Defaults

4.10 Input Filter

4.11 Alarm Setpoint

4.12 Output Scale Expansion

4.13 Simulate Current Output

4.14 pH Correction

Page 25

19

Model 1054B CL SECTION 4.0

CONFIGURATION

FACTORY SET USER SET

A. Alarm 1 Setup (

AALL11

)

1. Alarm Configuration (FrC/PH/OFF) FrC _________

2. High or Low (H-L) (Hi/Lo) Lo _________

3. Hysteresis (HYS) 0-25% 0.00 _________

4. Delay Time On (don) 0-255 sec 000 sec _________

5. Delay Time Off (doF) 0-255 sec 000 sec _________

B. Alarm 2 Setup (

AALL22

)

1. Alarm Configuration (FrC/PH/OFF/FLt) FrC _________

2. High or Low (H-L) (H

i

/Lo) Hi _________

3. Hysteresis (HYS) 0-25% 0.00% _________

4. Delay Time On (don) 0-255 sec 000 sec _________

5. Delay Time Off (doF) 0-255 sec 000 sec _________

C. Interval Timer (

iinn

t)

1. Active Status (tOn) (OFF/on) OFF _________

2. Interval Time (

i

nt) minimum 10 minutes 1 Day _________

3. Count (cnt) 1 to 60 5 _________

4. On Time (ont) 0 to 299 sec 1 sec _________

5. Off Time (OFt) 0 to 299 sec 1 sec _________

6. Duration (dur) 0 to 299 sec 2 sec _________

D. Temperature Setup (t-CC)

1. Display Temperature (d-t) (

oC/o

F)

o

C _________

2. Automatic TC (Atc) (on/oFF) on _________

Manual Temp. Value 0°C to 50°C _________

E. Current Output Setup (

OOt11//OOt22

)

1. mA Output (CUr) (020/420) 42O _________

2. Display Current Output (d-O) (Pct/doc) doc _________

3. Dampen Current Output (dPn) 0 to 255 sec 000 sec _________

F. Default Setup (

ddFF

t)

1. Relay 1 Default (rL1) (non/oFF/on) non _________

2. Relay 2 Default (rL2) (non/oFF/on) non _________

3. FrC Output Default (Cu1) (non/cur) non _________

4. PH Output Default (Cu2) (non/cur) non _________

G. Keyboard Security Setup (

CCOOdd

)

1. Keyboard Security Required 001-999 – _________

2. Keyboard Security Not Required 000 000 _________

H. Alarm Setpoints

1. Alarm 1 (SP1) 0-20 ppm or 0-14 pH 0 ppm _________

2. Alarm 2 (SP2) 0-20 ppm or 0-14 pH 20 ppm _________

I. Current Outputs

1. Zero (0 or 4 mA) (LO1/LO2) 0-20 ppm or 0-14 pH 0 ppm or 0 pH _________

2. F.S. (Full Scale) (20 mA) (HI1/ HI2) 0-20 ppm or 0-14 pH 20 ppm or 14 pH _________

TABLE 4-1. Configuration Worksheet

To move around in the main menu or in a sub-menu,

press the SCROLL (é) key. To choose an item in the

menu, press the SELECT key. If pressing SELECT

produces a flashing display, the mnemonic or number shown can be changed. Press the SCROLL (é)

and SHIFT (ç) keys to change a number; press the

SCROLL (é) key to change a mnemonic. To place

the value in memory, press ENTER. After an edited

value has been stored, the display returns to the item

in the sub-menu that allowed access to the value. For

example, selecting HYS from the sub-menu attached

to AL1, allows access to a number whose value can

be changed. After the number has been edited and

stored in memory, the display returns to HYS.

Page 26

20

Model 1054B CL SECTION 4.0

CONFIGURATION

FIGURE 4-1. Set Function Menu

FrC

PH

*

OFF

SEt

rL1

rL2

Cu1

Cu2*

SHO

FrC

PH

*

FLt

OFF

d-t

Atc

in

SEn

-0-

AL1

AL2

Int

t-C

Ftr

Ot1

Ot2

dFt

UEr

dtS

COd

dPn

CUr

d-O

oFF

on

doc

Pct

on

oFF

non

non

cur

on

oFF

420

020

oo

F

oo

C

tOn

int

cnt

ont

OFt

dur

tiL

SEC

uin

hr

dAY

* Not available unless the optional

pH board has been installed

H-L

HYS

don

doF

Hi

Lo

Page 27

21

Model 1054B CL SECTION 4.0

CONFIGURATION

AL1 Alarm 1 setup

AL2 Alarm 2 setup

APH Automatic pH adjustment

Atc Automatic temperature compensation

o

C Temperature °C

COd Security code

cnt Timer count

CUr Configure current output

Cu1 Configure fault output 1 (FRC)

Cu2 Configure fault output 2 (pH)

cur Default current setpoint

dAY Days

dFt Fault configuration

d-O Display output

d-t Display temperature

doc Display output in mA

doF Relay delay off time

don Relay delay on time

dPn Dampen outputs

dtS LCD/LED display test

dur Timer duration

°o

F Temperature °F

FLt Use alarm as fault alarm

Hi Relay action – high

H-L Alarm logic

hr Hours

HYS Hysteresis

in Sensor input current

int Interval period

Int Timer setup

Lo Relay action – low

non No action on fault

not pH CPU PCB not installed

OFF Alarm not used

oFF Function off

ont Timer on time

On Use alarm as process alarm

on Function on

OFt Timer off time

Ot1 Configure output 1 (FRC)

Ot2 Configure output 2 (pH)

Pct Display output in percent

rL1 Relay 1 fault setup

rL2 Relay 2 fault setup

SEC Seconds

SHO Show fault history

t-C Temperature configuration

ti L Timer – time remaining

tOn Timer status

UEr Software version

uin Minutes

420 4mA to 20mA output

020 0mA to 20mA output

-0- Zero sensor

TABLE 4-2.

Set Function Mnemonics

Page 28

22

4.5 ALARM 1 AND 2. The alarms can be configured to

perform on - off process control. Selecting AL1 or AL2

allows alarm 1 or alarm 2, respectively, to be configured.

A. Alarm for Free Residual Chlorine. Select FrC if the

alarm is to monitor the concentration of free residual

chlorine. See steps E through H for further alarm configuration.

B. Alarm for pH. Select PH if the alarm is to monitor

pH. See steps E through H for further alarm configuration.

C. Fault (Alarm 2 Only). Selecting FLt makes Alarm 2

a fault alarm. Relay 2 energizes when the analyzer

senses a fault condition.

D. Off. Select OFF if the alarm is not to be used or to

temporarily disable the alarm. Alarm setpoints will display oFF if this item is selected.

E. Alarm Logic. Select H-L to set high or low alarm

logic. Hi activates the alarm when the reading is

greater than the setpoint value. Lo activates the alarm

when the reading is less than the setpoint value.

F. Relay Hysteresis. Select HYS to set the hysteresis or

dead band. Hysteresis is the difference between the

alarm setpoint and the reading past the setpoint at

which the relay deactivates. Hysteresis may be set

between 0 and 25% of the setpoint. Use hysteresis

when a specific chlorine concentration should be

reached before the alarm deactivates.

Model 1054B CL SECTION 4.0

CONFIGURATION

G. Delay On Time. Select don to set the delay on time.

Delay on time is the time between an alarm setpoint

being reached and the relay activating. The delay may

be set between 0 and 255 seconds. An alarm state

restarts the time from zero.

H. Delay Off Time. Select doF to set the delay off time.

Delay off time is the time between an alarm setpoint

being cleared and a relay deactivating. The delay may

be set between 0 and 255 seconds. An alarm state

restarts the time from zero.

4.5.1 Alarm Setup (

AALL11/AALL22

). Refer to Figure 4-2.

1. Enter the set function menu by double pressing

the ACCESS/ENTER key.

2. SCROLL (é) until AL1 or AL2 appears in the display.

3. Press SELECT to move into the sub-menu. FrC, PH,

OFF, or FLt (Alarm 2 only) will be displayed.

4. SCROLL (é) until the desired item appears, then

press SELECT.

5. If OFF was selected, the display will show oFf.

Press the ENTER key to return to AL1 or AL2

(whichever alarm was being configured). Skip to

Step 1 1.

If FrC or PH was selected, the display will show

FrC or PH momentarily, then change to H-L. Go to

Step 6.

If FLt was selected, the display will show FLt.

Press the ENTER key to return to AL2. Go to Step 11.

6. With H-L showing in the display, press SELECT.

Hi or Lo will appear as a flashing display.

7. SCROLL (é) to the desired setting and press

ENTER to store the setting in memory. The display will return to H-L. To make changes to the

relay activation logic, proceed to Step 8, otherwise go to Step 11.

8. SCROLL (é ) to display HYS, don, or doF then

SELECT the desired item. A flashing numeric display will appear, indicating that a number is

required.

9. Use the SCROLL (é) and SHIFT (ç ) keys to

change the display to the desired value.

10. Press ENTER to store the value in memory. The

analyzer will acknowledge, and the display will return

to the mnemonic that permitted access to the value.

Repeat Step 8 if further changes are desired.

11. Repeat Steps 3 through 10 to configure the other

alarm.

12. To return to the top menu of the set function

menu, press the ACCESS/ENTER key.

FrC

PH

OFF

FrC

PH

FLt

OFF

in

AL1

AL2

H-L

HYS

don

doF

Hi

Lo

SEt

Figure 4-2. Alarm 1 and Alarm 2 Setup.

Page 29

23

4.6 INTERVAL TIMER. Select Int to set the interval

timer relay logic. The timer can be used to activate

and control a sensor cleaner. Refer to Figure 4-3 for an

explanation of the terms used.

A. Interval Timer Enable/Disable. Select t

On

to

enable the interval cycle (on) or disable the interval

cycle (OFF).

B. Interval Period. Select int to set the amount of

time between control cycles (see Figure 4-3). int

opens a sub-menu that asks for time in SEC for seconds, uin for minutes, hr for hours, and dAY for days.

The recommended minimum interval is 10 minutes.

C. Relay Activations Per Cycle. Select cnt to enter

the number of times the relay activates per cycle. The

range is 1 to 60.

D. Relay Activation Duration. Select ont to enter the

amount of time the relay remains on each time it activates. The range is 0.1 to 299.9 seconds.

E. Relay Deactivation Duration. Select OFt to set the

amount of time the relay remains deactivated between

each on-period during the cycle. Deactivation time is

valid only when cnt is 2 or greater. The range is 0.1 to

299.9 seconds.

F. Sensor Recovery Time. Select dur to set the

length of time between the end of the last on-period

and the end of the control cycle. The recovery time

gives the sensor time to restabilize before the analyzer returns to on-line operation. Recovery time may be

set between 0 and 299 seconds.

G. Interval Time Remaining. Select tiL to display the

time remaining before the next cycle starts. If tiL is

selected during the control cycle, display will show --.

NOTE

The Model 1054B CL is placed on HOLD

during the control cycle (from first on-period

through the sensor recovery time). The analyzer simulates a fault condition and briefly

shows itr every eight seconds. The display

continues to show the measured value.

Model 1054B CL SECTION 4.0

CONFIGURATION

4.6.1 Interval Timer Set Up (Int). Refer to Figure 4-4.

1. Enter the set function menu by double pressing

the ACCESS/ENTER key.

2. SCROLL (é) until Int appears in the display.

3. Press SELECT to move to the next menu level. The

display will show tOn. Press the SELECT key again.

4. SCROLL (é ) to display on or OFF and press

ENTER to store the desired setting in memory. If

the interval timer was selected, go to Step 5, otherwise go to Step 10.

5. Press the SCROLL (é) key once to display int,

then press the SELECT key. The display will

change to SEC. SCROLL (é) until the desired

unit, minutes (uin) hours (hr), or days (dAY)

appears in the display. Press SELECT. The display will change to a numeric value with the right

hand digit flashing.

6. Use the SCROLL (é) and the SHIFT (ç) keys

to change the displayed number to the desired

value. ENTER the number into memory.

7. Repeat steps 5 and 6 if needed. For example, if the

desired interval is 6.5 hours, enter 30 uin and 6 hr.

8. Press the ENTER key again to return to the main

timer menu. SCROLL (é) to the next desired

item and press SELECT.

9. Selecting any of the remaining menu items (cnt,

ont, OFt, and dur) causes the display to show a

numeric value. Use the SCROLL (é) and SHIFT

(ç) keys to change the displayed number to the

desired value and ENTER the new value into

memory. Continue until all the settings have been

made.

10. Press the ENTER key to return to the main menu.

RELAY

ON

RELAY

OFF

TIME

int

ont

OFt

ont

dur

cnt = 2

SEt

OFF

on

tOn

int

cnt

ont

OFt

dur

tiL

SEC

uin

hr

dAY

in

Int

Figure 4-3. Timer Diagram for One Cycle

Figure 4-4. Interval Timer Setup

Page 30

24

4.7 TEMPERATURE CONFIGURATION. Select t-C

for temperature reading and compensation choices.

A. Temperature Display. Select d-t to display tem-

perature in °C or °F.

B. Automatic Temperature Compensation. Select

Atc to enable or disable automatic temperature compensation. The 1054B CL Analyzer uses a membranecovered amperometric sensor. Because the permeability of the membrane increases about 3%/°C, temperature compensation is critical if the measurement and

calibration temperatures are different. When on is

selected, the analyzer uses the temperature input from

the sensor for temperature compensation. When oFF is

selected, the analyzer uses the value entered by the

user. Turning off the automatic temperature compensation, i.e., placing the analyzer in manual temperature

compensation, is useful only if the temperature sensor

is faulty and the calibration and measurement temperatures differ by at most 1 or 2 °C. Selecting oFF disables temperature specific fault messages (refer to

Section 8.1).

4.7.1 Temperature Setup (t

--CC

). Refer to Figure 4-5.

1. Enter the set function menu by double pressing the

ACCESS/ENTER key .

2. SCROLL (é) until t-C appears in the display.

3. Press SELECT to move to the next menu level.

d-t will show the display.

4. SCROLL (é ) to display desired item, then

SELECT it.

5. If d-t is selected, the display will flash oC or oF.

SCROLL (é) until the desired unit appears in the

display. Press ENTER to store the selection into

memory . The display will return to d-t.

6. If At c is selected, the display will flash on or oFF.

SCROLL (é) and ENTER the desired temperature

compensation into memory. Choosing on causes the

display to return to At c. Choosing oFF causes a

flashing number to be displayed. Use the

SCROLL (é) and SHIFT (ç) keys to change the

display to the desired temperature and press

ENTER. The display returns to Atc.

7. Press the ENTER key to return to the main menu.

4.8 CURRENT OUTPUT. Select Ot1 to configure the

current output for free residual chlorine. Select Ot2 to

configure the output for pH. Note that Ot2 is available

only if the pH board has been installed. See Figure 4-6.

A. Output Dampening. Select dPn to dampen the analyz-

er output. Dampening reduces the apparent noise but

increases the response time of the output. The dampening

feature averages the signal for a set period of time

(between 0 and 255 seconds) and changes the output by

an amount equal to 63% of change between the present

and previous sampling period.

B. mA Output Range. Select CUr to set the output sig-

nal to 0-20 mA (020) or to 4-20 mA (420).

C. Display Output. Select d-O to display the output in

mA (doc) or in percent of full scale (Pct).

4.8.1 Output Setup (

OOt11/OOt22

). Refer to Figure 4-6.

1.

Enter the set function menu by double pressing the

ACCESS/

ENTER

key .

2. SCROLL (é) until Ot1 appears in the display.

3. Press SELECT to move to the next menu level.

dPn will displayed.

4. SCROLL (é) then SELECT desired item.

5.

If dPn is selected, a numeric display will flash to indicate that a value is required. Use the

SCROLL (é)

and SHIFT (ç) keys to change the display to the

desired value. Press ENTER to place the value in

memory.

Model 1054B CL SECTION 4.0

CONFIGURATION

in

t-C

SEt

in

Ot1

Ot2

SEt

d-t

AtC

on

oFF

o

F

o

C

doc

Pc

t

420

020

dPn

CUr

d-O

Figure 4-5. Temperature Configuration Setup

Figure 4-6. Current Output Setup

Page 31

25

Model 1054B CL SECTION 4.0

CONFIGURATION

SEt

in

dFt

6. If CUr or d-O is selected, SCROLL (é ) to the

desired mnemonic and press ENTER to store it in

memory.

7. Press ENTER to return to the main menu and

SCROLL (é ) until Ot2 shows in the display.

Repeat steps 5 and 6 to configure the pH output.

Ot2 is available only if the pH correction board

has been installed in the analyzer.

8. Press the ENTER key to return to the main

menu.

4.9 DEFAULTS. Select dFt to configure default set-

tings during faults or hold status. See Table 8-1 for a

listing of the fault conditions that can be diagnosed by

the analyzer.

A. Relay 1 and 2. rL1 is relay 1 and rL2 is relay 2.

The relays can be set to activate (on), deactivate

(oFF), or hold present status (non). Table 4-3 describes

how to configure the relays for various fault or hold

conditions. For example, for relay 1 to activate when

the analyzer is in hold, both alarm 1 and relay 1 must

be on.

B. Current Output. Cu1 sets the value to which the

current at output 1 goes and Cu2 sets the value to

which the current at output 2 goes when the analyzer

is in hold or senses a fault. To hold the output current

at the last process value, choose non. To send the output current to a specified value, chose cur; cur is

probably the better choice.

C. Fault History. Selecting SHO causes all the faults

detected during the most recent event to be displayed

one at a time. Several faults occurring at the same

time are considered to be one fault event. To view the

previous fault event, press the SCROLL (é) key. To

clear the SHO history, press ENTER.

4.9.1 Default Setup (

ddFF

t). Refer to Figure 4-7.

1. Enter the set function menu by double pressing

the ACCESS/ENTER key.

2. SCROLL (é) until dFt appears in the display.

3. Press SELECT to move to the next menu level.

rL1 will show in the display.

4. To set default relay 1, SELECT rL1.

5. SCROLL (é ) to on, oFF, or non, and press

SELECT to enter the desired mnemonic.

6. Repeat Steps 4 and 5 for relay 2.

7. To set the default current for output 1, SCROLL

(é) to Cu1 and SELECT it.

8. SELECT non or cur. Choosing cur causes the

display to change to a flashing number. Use the

SCROLL (é) and SHIFT (ç) keys to change

the display to the desired value. Press ENTER to

place the value in memory.

9. To set the default current for output 2, repeat

steps 7 and 8.

10. Press the ENTER key to return to the main

menu.

ANALYZER CONDITION

NORMAL HOLD FAULT

AL1/AL2 setting AL1/AL2 setting AL1/AL2 setting

On OFF FLt On OFF FLt On OFF FLt

(Alarm 2 (Alarm 2 (Alarm 2

only) only) only)

on PV dtmns – – + – – + – +

oFF PV dtmns – – – – – – – +

non PV dtmns – – PV dtmns – – PV dtmns – +

Default

setting

rL1/rL2

PV dtmns : Process value determines the alarm state.

+ : means the relay activates

– : means the relay does not activate

TABLE 4-3. Relay States for Various Analyzer Conditions and Alarm/Default Configurations

on

oFF

non

FIGURE 4-7. Default Setup

non

cur

rL1

rL2

Cu1

Cu2

SHO

Page 32

26

4.10 INPUT FILTER. The input filter (Ftr) compen-

sates for noise by averaging a given number samples

of the input signal. Increasing the sample number

reduces noise but increases the response time (see

Section 7.1 for more information).

4.10.1 Filter Response Setting.

1. Enter the set function menu by double pressing the

ACCESS/ENTER key.

2. SCROLL (é) until Ftr appears in the display.

3. Press SELECT. A numeric display appears with

the right hand digit flashing.

4. Use the SCROLL (é) and SHIFT (ç) keys to

change the display to the desired number of samples.

5. Press ENTER to place the number in memory.

4.11 ALARM SETPOINT. Configure the analyzer as

described in sections 4.5 through 4.10 before

programming the alarm setpoints. Refer to

Figure 4-8.

1. Press the PV key to ensure the analyzer is not in

the set function menu.

2. Press the ZERO/ALARM 1 or F.S./ALARM 2 key.

SP1 for alarm 1 or SP2 for alarm 2 will show briefly,

followed by the present alarm setpoint.

NOTE

If the alarm was set to OFF or, in the

case of alarm 2, to FAULT during configuration, the analyzer will display oFF

or FLt respectively when the ALARM

key is pressed.

3. To change the alarm setpoint, press SELECT.

AdJ will show briefly followed by a numeric display with right hand digit flashing.

4. Use the SCROLL (é) and SHIFT (ç) keys to

change the display to the desired setpoint.

5. Press ENTER to place the new value in memory.

The display will show SP1 (or SP2) briefly followed

by the new setpoint.

6. To program the second alarm setpoint repeat

Steps 2 through 5.

NOTE

Relays are normally open (N.O.), but they can

be changed to normally closed (N.C.). Locate

the relay to be changed. K1 is relay 1, K2 is

relay 2, and K3 is relay 3. For the relay selected,

cut the conductor at the bowtie on the reverse

side of the power supply board. For relay 1, solder a jumper between the center terminal and

W4. For relay 2, solder a jumper between the

center terminal and W6. For relay 3, solder a

jumper between the center terminal and W8.

ACCESS

ENTER

ZERO

ALARM

1

F.S.

ALARM

2

é

ç

SELECT

ç

SELECT

Press

Once

Press

Once

Displays

Briefly

Displays

Briefly

Numeric

Display

Change to

desired

value

Press

Once

Numeric

Display

of

Setpoint

FIGURE 4-8. Alarm Setpoint

Model 1054B CL SECTION 4.0

CONFIGURATION

AdJ

SP1/SP2

SP1/SP2

Displays

Briefly

Page 33

27

B. Full Scale Setpoint. The full scale setpoint is the

reading that produces a 20 mA output. Hi1 identifies

the full scale for output 1, and Hi2 identifies the full

scale setpoint for output 2. For an analyzer equipped

with automatic pH compensation, output 1 is chlorine

and output 2 is pH.

1. Press the PV key to ensure that the analyzer is

not in the set function menu.

2. Quickly double press the F.S./ALARM2 key. HI1

or HI2 will show briefly in the display, followed by

the present full scale setpoint for the output

selected. To switch outputs, press the

F.S./ALARM2 key twice again and the display will

toggle to the other output.

3. To change the setpoint, press the SELECT key.

The display will acknowledge briefly with AdJ followed by a numeric display with the right hand

digit flashing.

4. Use the SCROLL (é) and SHIFT (ç ) keys to

display the desired setpoint.

5. Press ENTER to place the new value in memory.

The display will show HI1 or HI2 briefly followed

by the new zero setpoint.

6. If the analyzer has two setpoints, repeat steps

2 through 5 to program the full scale setpoint for

the second output.

NOTE

For reverse output, enter the higher

concentration or pH for zero and the

lower concentration or pH for full scale.

4.12 OUTPUT SCALE EXPANSION. Configure the

analyzer as described in Sections 4.5 through 4.10

before programming the zero and full scale setpoints.

Refer to Figure 4-9.

A. Zero Setpoint. The zero setpoint is the reading that

produces a 0 or 4mA output (depending on how the

output was configured). LO1 identifies the zero setpoint

for output 1, and LO2 identifies the zero setpoint for

output 2. For analyzers equipped with automatic pH

compensation, output 1 is chlorine and output 2 is pH.

1. Press the PV key to ensure the analyzer is not in

the set function menu.

2. Quickly double press the ZERO/ALARM1 key.

LO1 or LO2 will show briefly in the display, followed

by the present zero setpoint for the output selected. To switch outputs, press the ZERO/ALARM1

key twice again and the display will toggle to the

other output.

3. To change the setpoint, press the SELECT key.

The display will acknowledge briefly with AdJ followed by a numeric display with the right hand

digit flashing.

4. Use the SCROLL (é) and SHIFT (ç) keys to

change the display to the desired value.

5. Press ENTER to place the new value in memory.

The display will show LO1 or LO2 briefly followed by

the new zero setpoint.

6. If the analyzer has two outputs, repeat steps 2

through 5 to program the zero setpoint for the

second output.

ACCESS

ENTER

ZERO

ALARM

1

F.S.

ALARM

2

é

ç

SELECT

ç

SELECT

Press

Twice

Press

Once

Displays

Briefly

Displays

Briefly

Numeric

Display

Change to

desired

value

Press

Once

Numeric

Display

of

Output

FIGURE 4-9. Output Scale Expansion

AdJ

LO1/LO2

HI1/H

I2

Model 1054B CL SECTION 4.0

CONFIGURATION

LO1/LO2

HI1/H

I2

Displays

Briefly

Page 34

28

4.13 SIMULATE CURRENT OUTPUT. The analyzer

can provide a simulated output to check the operation

of pumps, valves, and recorders. The output can be in

current (dO1) or in percent of full scale (Pc1). The output configuration programmed in Section 4.9 determines which mnemonic appears. If the analyzer has

dual outputs, i.e., the pH correction board has been

installed, a simulated signal can be generated at both

outputs. Pc1 or dO1 identifies output 1 (free residual

chlorine), and Pc2 or dO2 identifies output 2 (pH). Refer

to Figure 4-10.

A. Simulate Output in Percent. The simulated output

will be in percent full scale if Ot1 or Ot2 in Section 4.8

was configured to display percent (Pct).

1. Press the PV key once to ensure that the analyzer

is not in the set function menu.

2. Quickly double press the OUTPUT/PV key. Pc1

or Pc2 will show briefly in the display, then the

display will change to the last simulated output. If

the analyzer has dual outputs and the wrong output is displayed, double press the OUTPUT/PV

key a second time. The display will toggle to the

other output.

3. To make the analyzer generate the simulated output, press the SELECT key. SP1 or SP2,

depending on which output was selected in step

2, will appear momentarily, followed by a numeric

display with the right hand digit flashing.

4. To change the simulated output to a different

value, use the SCROLL (é) and SHIFT (ç )

keys.

5. Press ENTER to store the new value in memory.

The display will briefly show Pc1 or Pc2 followed

by the entered value. Because the analyzer is in

hold while the simulated current is being generated, the display flashes and the mnemonic HLd

appears occasionally. After one minute the display returns to the measured value (flashing), the

hold flag remains on, and the output remains at

the simulated value. The relays will operate as

programmed in Section 4.9.

6. To end the simulated output and remove the analyzer from hold, quickly double press the

HOLD/TEMP key. The display stops flashing, the

hold flag turns off, and the output returns to the

value determined by the scale expansion programmed in Section 4.12.

B. Simulate Output in Current. The simulated output

will be in mA if Ot1 or Ot2 in Section 4.8 was configured to display current (doc).

1. Press the PV key once to ensure that the analyzer is not in the set function menu.

2. Quickly double press the OUTPUT/PV key. dO1

or dO2 will show briefly in the display, then the display will change to the last simulated output. If the

analyzer has dual outputs and the wrong output is

displayed, double press the OUTPUT/PV key a

second time. The display will toggle to the other

output.

Model 1054B CL SECTION 4.0

CONFIGURATION

ACCESS

ENTER

OUTPUT

PV

é

ç

SELECT

ç

SELECT

Press

Twice

Press

Once

Displays

Briefly

Displays

Briefly

Numeric

Display

Change to

desired

value

Press

Once

FIGURE 4-10. Simulate Current Output

Si1/Si2

SP1/SP2

dO1/dO2

Pc1/Pc2

Numeric

Display of

Output

dO1/dO2

Pc1/Pc2

Displays

Briefly

Page 35

Model 1054B CL SECTION 4.0

CONFIGURATION

3. To change the simulated output, press the

SELECT key. Si1 or Si2, depending on which out-