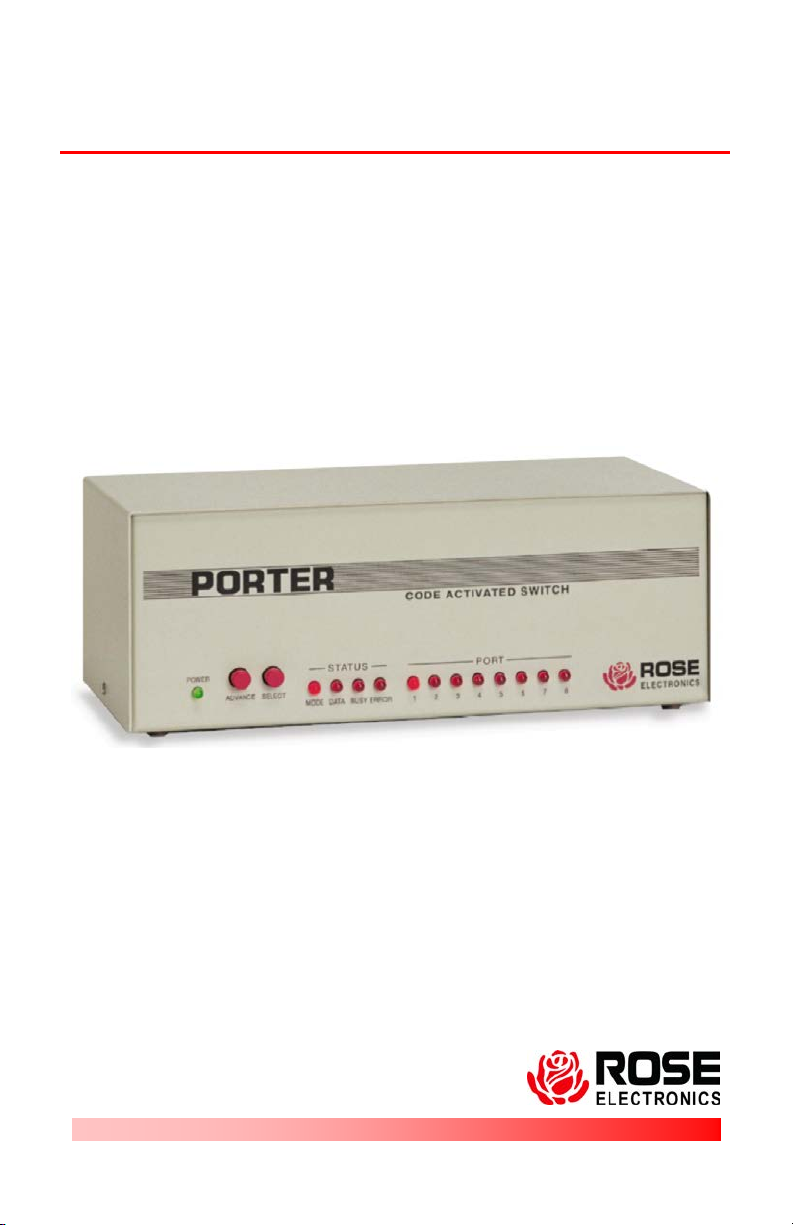

Porter

Code activated switch

INSTALLATION

AND

OPERATIONS MANUAL

TM

10707 Stancliff Road Phone: (281) 933-7673

Houston, Texas 77099 WWW.ROSE.COM

Limited Warranty

Rose Electronics warrants the Porter™ to be in good working order for one year from the date

of purchase from Rose Electronics or an authorized dealer. Should this product fail to be in

good working order at any time during this one-year warranty period, Rose Electronics will, at

its option, repair or replace the Unit as set forth below. Repair parts and replacement units will

be either reconditioned or new. All replaced parts become the property of Rose Electronics.

This limited warranty does not include service to repair damage to the Unit resulting from

accident, disaster, abuse, or unauthorized modification of the Unit, including static discharge

and power surges.

Limited Warranty service may be obtained by delivering this unit during the one-year warranty

period to Rose Electronics or an authorized repair center providing a proof of purchase date. If

this Unit is delivered by mail, you agree to insure the Unit or assume the risk of loss or damage

in transit, to prepay shipping charges to the warranty service location, and to use the original

shipping container or its equivalent. You must call for a return authorization number first. Under

no circumstances will a unit be accepted without a return authorization number. Contact an

authorized repair center or Rose Electronics for further information.

ALL EXPRESS AND IMPLIED WARRANTIES FOR THIS PRODUCT INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE

LIMITED IN DURATION TO A PERIOD OF ONE YEAR FROM THE DATE OF PURCHASE, AND

NO WARRANTIES, WHETHER EXPRESS OR IMPLIED, WILL APPLY AFTER THIS PERIOD.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

IF THIS PRODUCT IS NOT IN GOOD WORKING ORDER AS WARRANTIED ABOVE, YOUR SOLE

REMEDY SHALL BE REPLACEMENT OR REPAIR AS PROVIDED ABOVE. IN NO EVENT WILL

ROSE ELECTRONICS BE LIABLE TO YOU FOR ANY DAMAGES INCLUDING ANY LOST

PROFITS, LOST SAVINGS OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING

OUT OF THE USE OF OR THE INABILITY TO USE SUCH PRODUCT, EVEN IF ROSE

ELECTRONICS OR AN AUTHORIZED DEALER HAS BEEN ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES, OR FOR ANY CLAIM BY ANY OTHER PARTY.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES FOR CONSUMER PRODUCTS, SO THE ABOVE MAY NOT APPLY

TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE

OTHER RIGHTS WHICH MAY VARY FROM STATE TO STATE.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference

at his own expense.

IBM, AT, and PS/2 are trademarks of International Business Machines Corp. Microsoft and

Microsoft Windows are registered trademarks of Microsoft Corp. Any other trademarks

mentioned in this manual are acknowledged to be the property of the trademark owner.

Copyright 1986-1991 Rose Electronics. All rights reserved.

No part of this manual may be reproduced, stored in a retrieval system, or transcribed in any form or

any means, electronic or mechanical, including photocopying and recording, without the prior written

permission of Rose Electronics.

Rose Electronics Part # MAN-PO

Printed In the United States of America - Revision 1.0

Table of Contents

Contents

Tables

Appendices

Introduction ........................................................................................................................ 1

Features ............................................................................................................................. 1

Model Number and Options ............................................................................................... 1

First Steps .......................................................................................................................... 2

Contents ........................................................................................................................ 2

Connecting the Cables ................................................................................................... 2

Configuring the Porter ................................................................................................... 2

Configuring your Computers .......................................................................................... 2

If You Have A Problem ................................................................................................... 2

Where to Go From Here ................................................................................................ 2

Front panel..................................................................................................................... 3

Rear panel (Serial model) ............................................................................................... 4

Rear panel (Parallel model) ............................................................................................ 5

Quick set-up ....................................................................................................................... 6

Serial Porter ................................................................................................................... 6

Parallel Porter ................................................................................................................ 7

Configuring Your PC ...................................................................................................... 7

Cable connection ........................................................................................................... 8

Configuration of Serial Units .......................................................................................... 9

Serial Configuration Menu Items ................................................................................... 9

Configuration of Parallel Units ..................................................................................... 13

Operating Modes ......................................................................................................... 16

Front Panel .................................................................................................................. 19

Porter Commands ............................................................................................................ 20

Applications ..................................................................................................................... 26

Diagnostic ........................................................................................................................ 27

Diagnostic Tests .......................................................................................................... 27

Reloading Factory Defaults .......................................................................................... 30

Maintenance and Repair .............................................................................................. 30

Table 1 Configuration Menu Display .................................................................................. 9

Table II LED Power up Display ......................................................................................... 14

Table III LED Error Display ................................................................................................ 15

Table IV LED Operation Display ....................................................................................... 19

Table V Diagnostics LED Display...................................................................................... 28

Table VI Diagnostic LED Error Display .............................................................................. 29

Table VII Loopback Test Connectors ................................................................................ 30

Appendix A – Porter Pin outs ........................................................................................... 31

Appendix B – Cable Pin out ............................................................................................. 33

Appendix C – Specifications ............................................................................................ 34

Introduction

1

Introduction

Features

Model Number and Options

PO-4S – 4 port serial

Serial models have 2 options:

This manual contains information for the installation and operation of the Porter, Rose

Electronics' name for its series of code activated switches. The Porter consists of a

switch unit and a separate wall mounted power adapter. You have chosen a versatile

microprocessor controlled switch that allows a computer to access serial devices such as

modems or instruments. The selection is through a code that is transmitted intermixed

with the normal data to the device. Since the Porter has buffer memory, each device may

simultaneously load data into the unit. The serial models allow different baud rates and

protocols to operate independently on each port with full duplex communications. All

equipment is connected by cables to the Porter's rear panel. The unit's external power

adapter connector and on/off switch are also n its rear panel. The Porter's front panel has

13 LEDs which display status information and switches which are used to manually

control the unit and run the unit's diagnostics.

One computer to many peripherals

Compatible with any computer – PCs, Macs, minis

Compatible with all printers and plotters

Simultaneous inputs from all computers

Up to 256K buffer

Serial (RS232) or parallel (Centronics)

Models for either four or eight devices

Advanced features for trouble-free performance

LEDs show data activity and status

Self-text and diagnostic features

Made in USA

The Porter is available in several models, 4 or 8 channels, serial or parallel, and with a 16K

base buffer (Expandable to 256K). The model numbers are:

PC-8S – 8 port serial

PO-4P – 4 port parallel

PO-8P – 8 port parallel

/B buffer options = 64K or 256K

PORTER INSTALLATION AND OPERATIONS MANUAL

1- RS422 type ports

2- Max baud rate of 38400

(All standard baud rates are doubled

with this option)

Getting Started

2

First Steps

Contents

Connecting the Cables

Configuring the Porter

Configuring your Computers

If You Have A Problem

Where to Go From Here

Congratulations! You have chosen one of the best code activated switches on the

market. The paragraphs below summarize the steps to integrate the Porter into your

environment.

You should have received the Porter system unit, a power adapter, and this Porter

installation and operations manual. If additional cables were ordered, they usually arrive

in the same package.

Cabling is one area you should pay careful attention to. Consult the cabling guides in this

manual for the correct pin outs. If you need assistance, contact our tech support, we will

be happy to assist you.

The Porter is a versatile unit. It can be configured to match the type of equipment that

you have. To configure the switch requires connecting a computer or terminal to the

configuration port on the porter – port 0.

If you have a PC, then you run a terminal emulation program to setup the Porter. The

parameters are saved in the Porter. From time to time as you change the configuration of

your equipment, you may need to adjust the configuration of the Porter. You do not have

to have a PC to use the switch or configure it.

The final step is to make sure that your computer's software is configured to access the

features of the Porter. This involves setting up the proper communication settings for

serial ports and providing a method to issue commands to the Porter. The commands

are typically issued from PCs by user software or from batch files. If you use serial ports

on PCs, it is required to setup the AUTOEXEC,BAT file with the proper DOS MODE

statements.

Well we certainly hope all goes well with your installation, but if there is a problem, we

are only a phone call away. If you have already installed the switch and something is not

right, it can be helpful to be at the switch location and at the computer connected to port

0 on the Porter when you call. The front panel of the Porter is very useful to diagnose

problems that can occur.

We would like to think that you would read the rest of this manual, it may not be the most

exciting reading material, but at least scan through it for the key points. Use it to get the

correct cabling information. Thank you for choosing Rose Electronics and the Porter.

PORTER INSTALLATION AND OPERATIONS MANUAL

MODELS

3

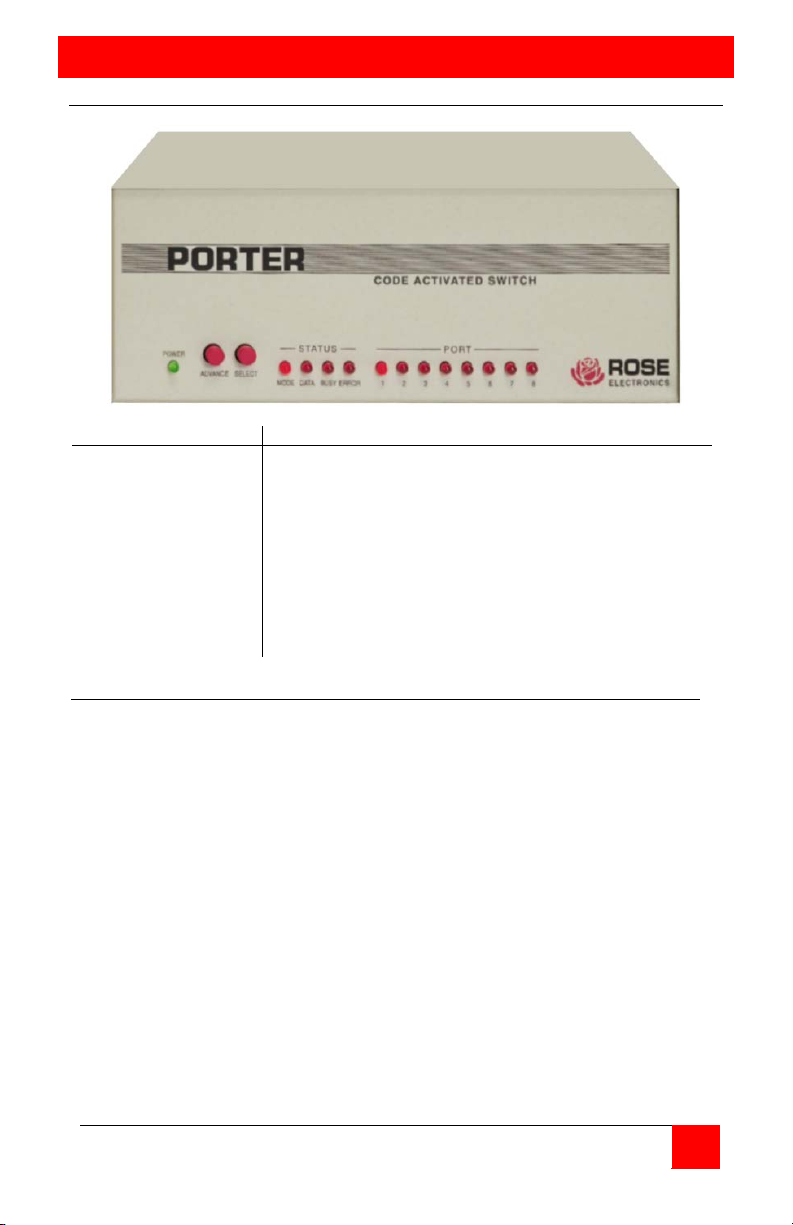

Front panel

Indicators

Description

Power

(1-8)

Green LED

On = active port

Buttons

Select

Select port

M D B E 1 2 3 4 5 6 7 8

ο ο ο

ο

•

ο ο ο ο ο ο ο

Note 1

ο ο ο

ο ο ο ο ο ο ο ο

ο

Note 2

ο ο ο

ο

• • • • • • •

•

Note 3

•

ο ο ο

x x x x x x x x

Note 4

• • •

ο ο ο ο ο ο ο ο

ο

Note 5

Note 1 ….. Unit operational, normal mode, connected to port 1

Note 2 ….. Unit operational, normal mode, null destination

Note 3 ….. Unit operational, broadcast mode, all ports selected

Note 4 ….. Unit in manual mode, displays current port connected

Note 5 ….. Unit in configuration (setup) mode

Status

Mode

Data

Busy

Error

Port

Advance

On=manual / Off = normal

On=data being transferred

On = dataflow inhibited

On = data error received on serial ports

Advance to next port

PORTER INSTALLATION AND OPERATIONS MANUAL

4

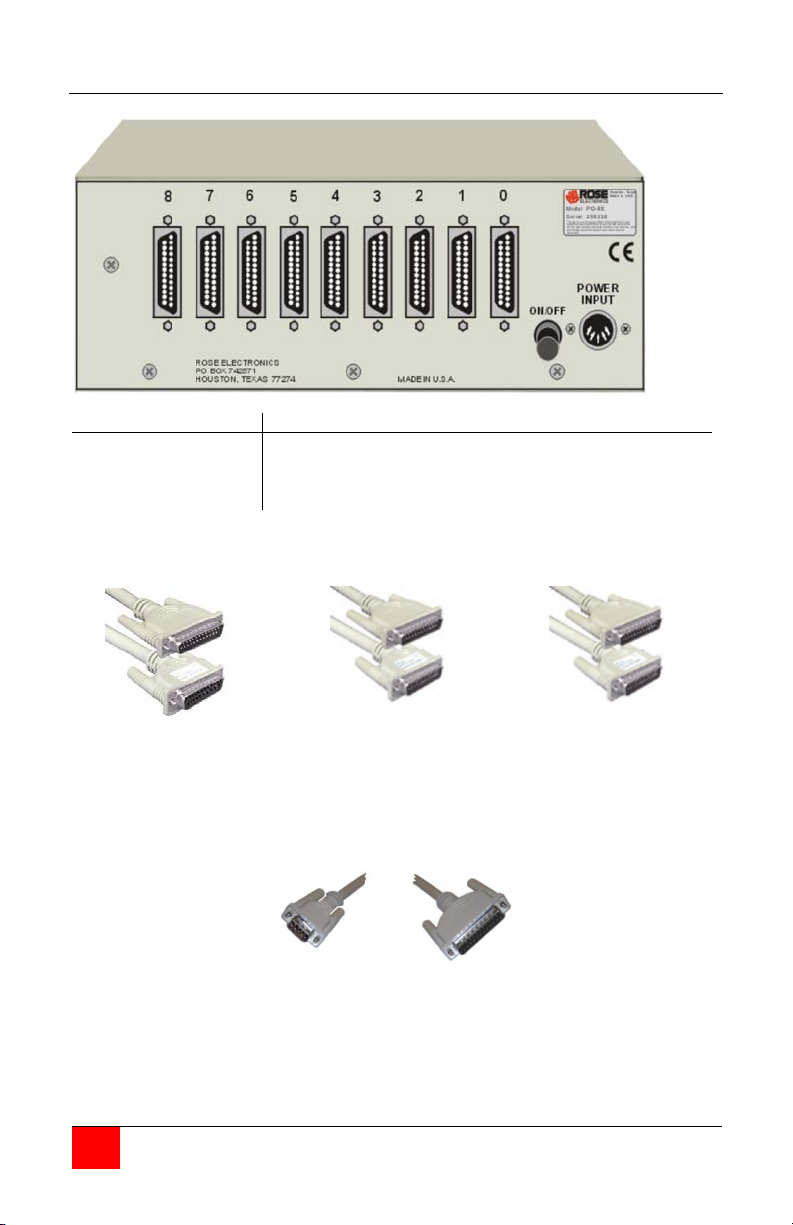

Rear panel (Serial model)

Connectors

Description

Port 0

Power input

DB25F – Connects to computer

Din5F

Switch ON/Off

Turn unit on or off

Serial 25 pin PC to PO-8S

Serial Printer to PO-8S

Modem to PO-8S

DB-25F

DB-25M

DB-25M

DB-25M

DB-25M

20

-

DB-25M

20

DB-9F

DB-25M

2

1-6-8

-

-

2

20

Ports 1-8

Rose part # CAB-PCRSx

2

3

7

5-6-8

-

-

-

-

3

2

7

20

DB25F - Connects to 8 serial devices

Rose part # CAB-PRRSx

Rose part # CAB-SMMx

2

3

7

20

-

3

-

2

-

7

-

6

Serial 9 pin PC to PO-8S

Rose part # CAB-ATRSx

2

3

6

7

-

2

-

3

-

6

-

7

3

-

5

3

-

7

PORTER INSTALLATION AND OPERATIONS MANUAL

5

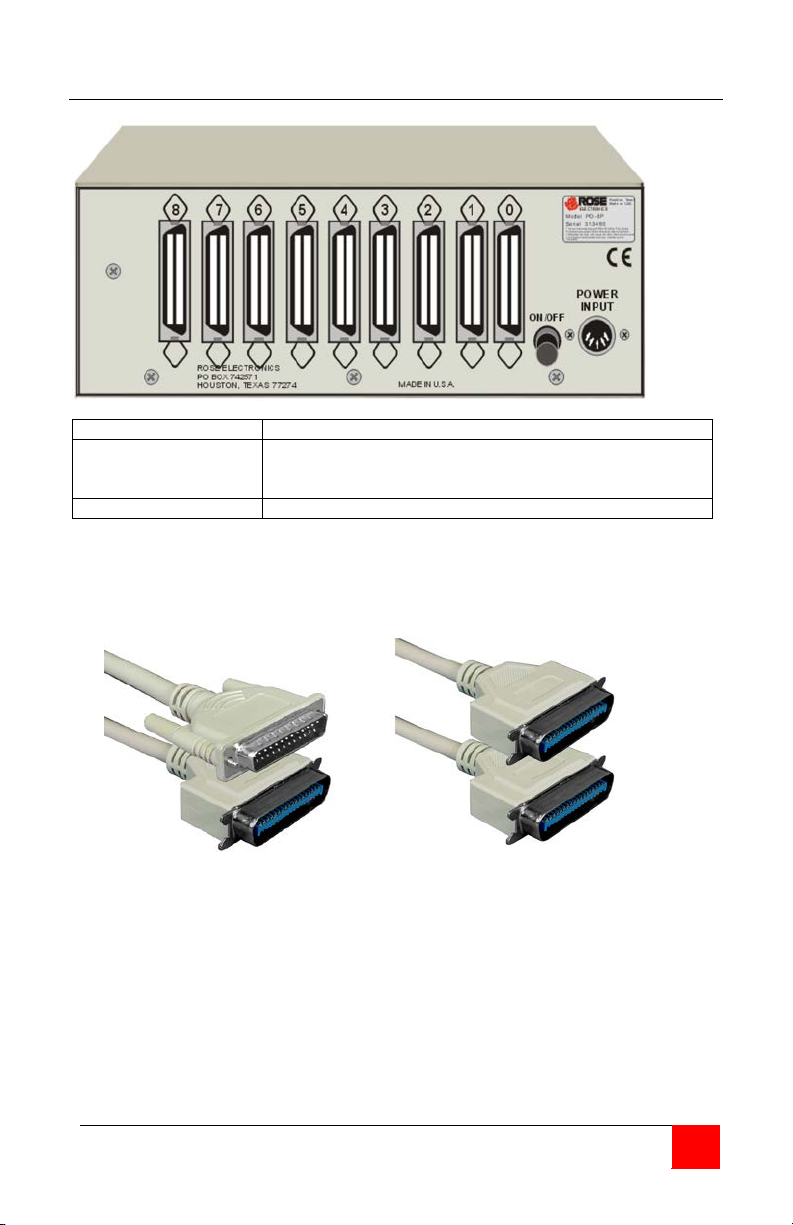

Rear panel (Parallel model)

Connectors

Description

Port 0

Centronics – Connects to computer

Switch ON/Off

Turn unit on or off

Parallel 25 pin PC to PO-8P

Rose part # CAB-IBMPx

Parallel printer to PO-8P

Rose part # CAB-PMMx

Pinout is that of a standard

PC parallel printer cable

Cable has Centronics male

Connectors on each end

Ports 1-8

Power input

Centronics - Connects to 8 parallel devices

Din5F

PORTER INSTALLATION AND OPERATIONS MANUAL

6

Quick set-up

Serial Porter

1. Connect your computer terminal to port 0 with the proper cable.

Refer to Appendix B for a list of common cables

2. Connect the power adapter, turn on the unit, power LED = Green

Power-up sequence test will start

3. If the serial factory default protocol of 9600 BAUD, no parity, 8-bits, 1-stop, and DTG

flow control for all ports is acceptable, skip step 4.

4. In this step, you will be shown a quick method of configuring the Porter. For

additional help, refer to the "Configuration" section for more detailed information.

a. Connect a computer (running a terminal emulator communication program such

a Procomm, or MasterLink supplied by Rose Electronics) or a dumb terminal to

port 0 on the Porter. Set your computer or terminal to 9600 baud, no parity, 8

bits, 1 stop bit, and full duplex.

b. Send ESC@S to the Porter. The MODE, DATA, and BUSY LEDs will light, the

configuration menu will appear.

c. For this step, you will be prompted to enter a choice of menu select numbers

(followed by a carriage return) for the item you wish to configure. You will be

prompted for all the proper responses. Enter 1 to change the protocol of any

port. Enter 7 to save the changes. Enter 8 to exit the configuration menu. A

configuration termination message appears, and the MODE, DATA, and BUSY

LEDs will go out. Note that you must save your changes before exiting the

configuration menu or they will be lost when you do step D.

d. Turn off the Porter.

5. Connect the Porter's ports 1-4 (or 8) to your devices with the correct cables.

Connect your computer to port 0. Cables must be wired correctly according to the

section on cabling.

6. If the Porter is not already on, power it on. The LEDs will sequence through power

up tests.

7. Send data from your application or print program. Data will be routed automatically

to the current connect port

8. Read this manual and use the configuration procedure if you want to change the

prefix, power-on connect port, or the broadcast group. See the section on

"Configuration" for further information.

PORTER INSTALLATION AND OPERATIONS MANUAL

7

Parallel Porter

Configuring Your PC

1. Cable your devices to ports 1-4 (or 8) with a straight-through cable that has male

Centronics connectors on each end.

2. Cable your computer to port 0 with your computer standard parallel Centronics cable.

3. Connect the power adapter and turn the unit on. The power light should glow green.

The LEDs sequence through the power up tests. The ERROR LED will be on for any

errors. See Tables II and III for the LED sequences.

4. Send data from your application or print program. Data will be routed automatically

to the current connect port.

5. Read this manual and use the configuration procedure if you want to change the

prefix, power-on connect port, or the broadcast group. See the section on PORTER

COMMANDS for further information.

If you have a serial Porter, you must make sure that you set up your serial port for the

correct baud rate and LPT1; redirection (if necessary). Redirection refers to the ability for

data sent to a parallel port to be sent to a serial port instead. Dos has a command (the

MODE command) to do this. So, for example, if you will be using the factory default

protocol of 9600 baud, 8-bit word length, no parity, and 1 stop bit, then you need to

include in your AUTOEXEC.Bat file the following statements:

MODE COM1;96,N,8,1,P

MODE LPT1:=COM1

Your application software must be set up to match the setting of the port on the Porter

that you will be using. If you will be using redirection, you must install your program(s) to

use the parallel port; otherwise, the setting of the serial port must exactly match the

setting of the Porter's port that you will be using. Many of today's software packages

have a flexible method of printing such as using the settings from the DOS MODE

command or a configurable printer setup. For these programs, setting up the program to

use the parallel port, and then redirecting LPT1 to COM1 using the DOS MODE command

is the simplest method.

However, some programs have fixed settings that can't be changed; and example of this

type of program is AutoCAD, Ventura Publishing, and others. Some of these programs

such as Ventura, can be setup to use the parallel port and redirect the output with the

DOS MODE command. For the rest of these programs this method will not work; in

these cases, you must set the serial port of your computer to exactly match the setting of

the Porter's port that you will be using.

If you have a parallel Porter, you don't need to worry about serial protocols and

redirection. You should install your software package(s) to use the parallel port when

printing. It will also be useful to put the following statement in your AUTOEXEC.BAT file:

MODE LPT1:;;P

This statement will set the parallel port for infinite retry.

PORTER INSTALLATION AND OPERATIONS MANUAL

Installation

8

Cable connection

Serial cables

Parallel cables

You should have received the Porter switch unit and a power adapter that connects to the

rear of the unit. You should have the necessary cables, supplied separately, to

interconnect the Porter with your other equipment. Ensure that the power switch is in the

off (out) position. Connect the AC power converter to a power outlet. Connect the other

end to the power input on the rear of the Porter.

Using the cables as described below connect your computer to the port labeled "0" on the

rear of the Porter. Connect your peripheral devices to the numbered ports on the rear of

the Porter.

Since industry standards vary regarding RS232 cabling, caution must be observed when

interconnecting your equipment with the Porter. Generally 5 signals or less must be

connected. They are receive, transmit, signal ground, busy in, and busy out. Porter's RxD

(pin 3) must be wired to the equipment transmit and Porter's TxD (pin 2) must be wired to

the equipment receive. Porter's signal ground (pin 7) must be connected to the

equipment signal ground. Busy in and busy out are not required when sing the X-on/X-off

protocol. When X-on/X-off is not used, busy out of the equipment must be wired to DSR

(pin 6) of the Porter and busy in of the equipment must be wired to DTR (pin 20) of the

Porter.

Busy out on the equipment is required to prevent the Porter from sending more data than

the equipment can handle. Conversely, busy in on the equipment prevents the

equipment from sending more data than the Porter can handle. While the Porter is

capable of handling data bursts at maximum baud rates, if it can not resend the data

received as fast as it gets the data, due to the equipment being busy and the input buffer

being full, then busy in on the equipment must be used. Consult your equipment manual

for information on pin numbers of your signals. Several popular cable pin outs are given

in Appendix B.

Additionally the Porter's RTS (pin 4) will be high when the Porter is powered on and may

be used to monitor whether the Porter is connected to your equipment. Refer to

Appendix A for further Porter pin out information. Refer to Appendix B for cable pin out

information. If you have a Porter with the /422 (RS-422) option, refer to Appendix A.

For a parallel unit the computer to Porter cable is the same one that would normally

connect to your printer. The Porter uses industry standard female Centronics connectors

the same as used on most parallel printers. So, instead of connecting your computer

cable t your printer, connect it to the port on the rear of the Porter labeled "0". Parallel

Porter to printer cables should have 36 pins male Centronics connectors at each end.

Connect these cables from your printers to connectors numbered 1-8 on the rear of

Porter.

PORTER INSTALLATION AND OPERATIONS MANUAL

Configuration

9

Configuration of Serial Units

The Serial Configuration Menu

Table 1 Configuration Menu Display

- - - - - - - - - - Current protocol - - - - - - - - - -

- - - - - - - - - - Power up protocol - - - - - - - - - -

Port

Baud

Parity

Len

Stop

Flow

DHS Baud

Parity

Len

Stop

Flow

DHS

0

9600

NONE 8 1

DTR

9600

NONE 8 1

DTR

1

9600

NONE 8 1

DTR

OFF 9600

NONE 8 1

DTR

OFF 2 9600

NONE 8 1

DTR

OFF 9600

NONE 8 1

DTR

OFF 3 9600

NONE 8 1

DTR

OFF 9600

NONE 8 1

DTR

OFF 4 9600

NONE 8 1

DTR

OFF 9600

NONE 8 1

DTR

OFF

Serial Configuration Menu Items

Change port protocol

After installing the Porter, it must be configured to match the protocol for your

equipment. This consists of identifying the desired characteristics of your system and

sending the appropriate control bytes to the Porter. Serial Porter units also can be

configured through an interactive menu. The configuration may be stored in the Porter’s

non-volatile memory, whose contents will not be lost when removing the Porter’s power.

The proper protocol, baud rate, number of stop / data bits, and parity information must be

set for each channel. This is done by using the interactive configuration menu, or by

sending the proper format commands to the Porter. The Porter factory set default is

9600 baud, 1 stop bit, no parity, 8 data bits, DTR/DSR handshaking. Refer to the format

command for further information.

You invoke the configuration menu – only on port 0 – by sending the command

<prefix>S from a computer funning a communication program or a dumb terminal set at

9600,N,8,1. the configuration menu will then appear as shown in Table 1. <prefix> is

factory set for the two characters ESC @ on a new unit, so initially use the string ESC @

S to get the menu.

PORTER CONFIGURATION MENU REV 3.5 COPYRIGHT 1985 – 1991 ROSE ELECTRONICS

Installed memory . . . . . . . 64K Prefix . . . . . . . . . . . . . .@

Power-on connect port . . 1 Broadcast group . . . . . 1 2 3 4 5 6 7 8

Front panel switches . . . ENABLED Command purge . . . . . DISABLED

1- Change port protocol 5- Change front panel switch control

2- Change prefix 6- Change command purge timeout

3- Change power-on connect port 7- save new configuration

4- Change broadcast port group 8- Exit configuration

Enter choice (1-8 or H for help)

In the examples below, <ENTER> means “press the ENTER key”, not type the characters

<ENTER>. Output from the Porter is shown in Courier type. Input from the user to the

menu is shown in Underlined Courier type.

This option allows the serial parameters for a port to be changed. The changeable items

are baud rate, parity, word length (data bits), stop bits, flow control, and DHS (direct

handshake). If the protocol for port 0 is changed, the menu will prompt you to change

your PC or terminal to the new baud rate and press <ENTER> to continue. Changes to

the port parameters are not made permanent until either the “Save new configuration”

option or the Keep command is used. You will be asked which port you want to change.

Enter the port number or R to change a range of ports.

PORTER INSTALLATION AND OPERATIONS MANUAL

10

Single Port

Range of Ports

Single Port with 38400 baud rate

Range of Ports with 38400 baud rate

The range option will set any changed item(s) (i.e. baud rate, parity, etc.) to the new

common value(s) for all the ports selected; however, any unchanged item(s) will remain at

the previous setting(s). If you enter “R”, you will be asked for the range of ports you want

to change. The ending port number *must* be greater than or equal to the starting port

number. Note that if you hit just a return to the ending port number, that port number will

be the same as the starting port number and only one port will be changed.

Enter choice (1-8 or H for help) 1<ENTER>

Enter the port number (0-8 or R) 3<ENTER>

Enter baud rate (19200, 9600, 7200, 4800, 3600,

2400, 1800, 1200, 600, 300, 150, 134.5, 110, 75, 50) 1200<ENTER>

Enter parity type (N=None, E+Even, O=Odd, M=Mark, S=Space) E<Enter>

Enter word length (5, 9, 7, 8) 7<ENTER>

Enter stop bits (1,2) 1<ENTER>

Enter flow control (D=DTR, X=XON/XOFF) X<ENTER>

Use DHS (direct handshaking ) (Y/N) N<ENTER>

Enter choice (1-8 or H for help) 1<ENTER>

Enter the port number (0-8 or R) R<ENTER>

Enter the starting port number (0-8) 3<ENTER>

Enter the ending port number (0-8) 4<ENTER>

Enter baud rate (19200, 9600, 7200, 4800, 3600,

2400, 1800, 1200, 600, 300, 150, 134.5, 110, 75, 50) 1200<ENTER>

Enter parity type (N=None, E=Even, O=Odd, M=Mark, S=Space) E<Enter>

Enter word length (5, 9, 7, 8) 7<ENTER>

Enter stop bits (1,2) 1<ENTER>

Enter flow control (D=DTR, X=XON/XOFF) X<ENTER>

Use DHS (direct handshaking ) (Y/N) N<ENTER>

Enter choice (1-8 or H for help) 1<ENTER>

Enter the port number (0-8 or R) R<ENTER>

Enter baud rate (38400, 19200, 9600, 7200, 4800, 3600,

2400, 1200, 600, 300, 150, 100) 1200<ENTER>

Enter parity type (N=None, E=Even, O=Odd, M=Mark, S=Space) E<Enter>

Enter word length (5, 9, 7, 8) 7<ENTER>

Enter stop bits (1,2) 1<ENTER>

Enter flow control (D=DTR, X=XON/XOFF) X<ENTER>

Use DHS (direct handshaking ) (Y/N) N<ENTER>

Enter choice (1-8 or H for help) 1<ENTER>

Enter the port number (0-8 or R) R<ENTER>

Enter the starting port number (0-8) 3<ENTER>

Enter the ending port number (0-8) 4<ENTER>

Enter baud rate (38400, 19200, 9600, 7200, 4800, 3600,

2400, 1200, 600, 300, 150, 100) 2400<ENTER>

Enter parity type (N=None, E=Even, O=Odd, M=Mark, S=Space) E<Enter>

Enter word length (5, 9, 7, 8) 7<ENTER>

Enter stop bits (1,2) 1<ENTER>

Enter flow control (D=DTR, X=XON/XOFF) X<ENTER>

Use DHS (direct handshaking ) (Y/N) N<ENTER>

* This question is not asked when configuring Port 0

PORTER INSTALLATION AND OPERATIONS MANUAL

11

Change prefix

Change power-on connect port

Change broadcast port group

Change front panel switch control

This option allows changing of the Porter’s prefix. As shipped, the unit’s prefix is set to

the two characters ESC@. The prefix change is not made permanent until either the

“Save new configuration” option or the Keep command is used.

Enter choice (1-8 or H for help) 2<ENTER>

Enter new prefix (1-6 characters) #S#<ENTER>

This allows changing of the port that the Porter initially connects to when it is powered

on. You may enter a port number (except port 0), N for null destination, or B for

broadcast. See the section on operation for more information on null destination and

broadcast mode.

Enter choice (1-8 or H for help) 2<ENTER>

Enter power-on connect port (1-4,N,B) 1<ENTER>

This option allows you to change the broadcast mask. This determines which ports have

data transmitted out to them when broadcast mode is used. You may enter any

combination of ports (except 0), but you must select at least one port or the change is

ignored. The following example sets ports 1, 2, and 4 to get data during broadcast. The

factory set default is for all ports (except 0) on the unit to be enabled for broadcast. The

broadcast mask can also be changed with the <prefix> + Mxx command (see the

sections on “Commands”.

Enter choice (1-8 or H for help) 4<ENTER>

Enter a port number to select for broadcast,

return only to terminate (1-4) 1<ENTER>

Enter a port number to select for broadcast,

return only to terminate (1-4) 2<ENTER>

Enter a port number to select for broadcast,

return only to terminate (1-4) 4<ENTER>

Enter a port number to select for broadcast,

return only to terminate (1-4) <ENTER>

This allows locking the front panel switches to prevent manual changing of the connect

port (see “Manual Mode”). You can also unlock the switches with this option. The

factory set default is to have the switches unlocked. Locking the switches does not

prevent use of the diagnostic modes at power-up.

Enter choice (1-8 or H for help) 5<ENTER>

Disable front panel switches (D=disables, E=Enables) E<ENTER>

PORTER INSTALLATION AND OPERATIONS MANUAL

12

Change command purge timeout

With 38400 baud option

Save new configuration

Exit configuration

Help

1- PROTOCOL

The protocol means the . . .

The command purge timeout determines whether to treat a partial prefix as a command

that hasn’t finished being received, or as data. When a value other than 0 is entered, it is

treated as a 20

second time value is used). If a command prefix is entered partially, and this time period

elapses, the partial prefix is purged and transmitted to the current connect port(s) as if it

were data. This is useful for certain programs that may leave a partial prefix at the end of

a data block. When this value is set to 0, partial prefixes will be held in the unit until

either the command is completed or a non-prefix character is received. This is the factory

set default.

Enter choice (1-8 or H for help) 6<ENTER>

Enter new command purge timeout in 20ths of a second (0-254;

0 disables) 30<ENTER>

Enter choice (1-8 or H for help) 6<ENTER>

Enter new command purge timeout in 40ths of a second (0-254;

0 disables) 80<ENTER>

This option allows the current configuration to be saved permanently in non-volatile

memory. Do not use this option until you are sure that the current settings are working

properly.

Enter choice (1-8 or H for help) 7<ENTER>

Are you sure (Y/N) Y<ENTER>

This option exits the configuration menu and returns the Porter to normal operation. All

data in buffer memory is erased. The default connect port is selected as if the unit was

just powered up.

Enter choice (1-8 or H for help) <ENTER>

This option gives a brief description of what each command does.

Enter choice (1-8 or H for help) H<ENTER>

The configuration menu shows the amount of memory installed, other various settings,

and the current and power-on protocol settings for each port. Configure the Porter by

entering the number of an item on the menu

th

of a second time value (if 38400 baud option is present, a 40th of a

2- PREFIX

3- POWER-ON CONNECT

4- BROADCAST GROUP

5- FRONT SWITCHES

6- PURGE TIMEOUT

7- SAVE CHANGES

8- EXIT

H- HELP

Hit enter key to see configuration parameters or enter choice

The programmable part . . .

Port 0 connects to . . .

Several ports that . . .

To disable/enable . . .

After this time . . .

Saving changes puts . . .

Exit from the . . .

Displays this screen . . .

PORTER INSTALLATION AND OPERATIONS MANUAL

13

Configuration of Parallel Units

The Centronics parallel interface is usually implemented consistently; however there are

some variations. Three lines are used to implement the flow control part of the interface.

They are strobe, acknowledge, and busy. Most Apple computer parallel interface cards

do not implement the busy signal. Some Radio Shack printers do not issue an

acknowledge signal. Most other printers use both the acknowledge and busy. There is a

provision for the Porter to handshake with all of this equipment. Each port except the

master port may be configured to ignore acknowledge, busy, or both signals by sending

the proper format commands to the Porter. The settings made by these format

commands can then be made permanent by using the keep command.

The Porter factory set default is to require acknowledge and busy for each port. Refer to

the format command for further information.

PORTER INSTALLATION AND OPERATIONS MANUAL

Power Up Tests

14

Power Up Initial Display

Table II LED Power up Display

M D B E 1 2 3 4 5 6 7 8

1st

All LEDS on

2nd

Test 1: EPROM checked

3rd

Test 2: 16K RAM buffer

Test 2: 64k RAM buffer

Test 2: 256k RAM buffer

4th

Test 3: Static ram

5th

Test 4: Non-Volatile ram

6th

Unit ready

Program Checksum Test

Buffer Memory Sizing And Read/Write Test

Static Ram Read/Write Test

Non-volatile Ram Tests

Push in the power switch to turn the unit on. Porter goes through a power up self-test

which checks the main functions of its electronics. The leftmost LED labeled POWER

should glow green and the other red LEDs should all turn on. Then the unit will cycle

through four tests lighting up LEDs 1 through 4 as each test is performed. Errors are

indicated by the ERROR LED lighting and the unit halting. See TABLE II for the full

sequence of the power up LED display and TABLE III for error displays.

Legend: M=Mode LED D=Data LED B=Busy LED E=Error LED

This test verifies that the unit’s internal program is valid by performing a checksum test.

If a fault exists, a program checksum error shows on the LEDs as error 1, as shown in

TABLE III. The unit will immediately halt. This error requires that the unit be serviced.

In this test, the Porter automatically determines the amount of butter memory present

and indicates the amount via the status LEDs as shown in TABLE III. The buffer memory

is then tested to ensure that the memory system is operational. Any failure will cause the

error 2 condition to be displayed, as shown in TABLE II, indicating that a buffer memory

data error has occurred. The unit will not continue its further tests and will halt. An error

indicates that the unit requires servicing.

The next test is for static ram. Since the Porter has no static ram, this test is displayed as

shown in TABLE II for consistency with other Rose products.

The fourth and final power-up test is for the non-volatile memory. A series of tests are

performed. An error shown by the LEDs as error 4 indicates that the data in the nonvolatile memory has been corrupted. To attempt to rewrite the default parameters push

the SELECT switch then the ADVANCE switch. If the error condition goes out, the unit

may be powered up again to see if it halts at error 4 again. If it still displays error 4, a fatal

error has occurred and servicing is required. If the unit displays an error 45, the default

parameters were not written correctly. This is a fatal error and servicing is required.

If the unit recovers from the error the configuration parameters have been returned to

their default settings and the unit must be configured again if these default settings are

unacceptable. This condition should not normally occur.

= LED off = LED on

PORTER INSTALLATION AND OPERATIONS MANUAL

15

Table III LED Error Display

M D B E 1 2 3 4 5 6 7 8

Error 1

Error 2

Error 3

Error 4

Error 41

Error 43

Error 45

Error 46

Error 47

Error 48

Error 1

. . . . . .

EPROM checksum failure

Error 2

. . . . . .

RAM buffer memory failure

Error 3

. . . . . .

Static ram failure

Error 4

. . . . . .

Non-volatile ram checksum failure

Error 41

. . . . . .

Non-volatile ram in wrong box type

Error 43

. . . . . .

Non-volatile ram memory failure

Error 45

. . . . . .

Restore to default configuration failure

Error 46

. . . . . .

A port that is not allowed is present

Error 47

. . . . . .

More ports in box than listed in the non-volatile ram

Error 48

. . . . . .

Wrong EPROM version

If it does it indicates that possibly the unit has been subjected to a strong static discharge

or surge on its incoming power or signal lines. The other possibility is an internal chip

failure.

In addition to the data in the non-volatile ram, several other tests on the non-volatile ram

are done. If any error 4 occurs and a reset t defaults does not correct it, the unit needs

servicing. The additional errors listed below are for technical support purposes only.

Legend: M=Mode LED D=Data LED B=Busy LED E=Error LED

= LED off = LED on

Any error not listed requires that the unit be serviced.

PORTER INSTALLATION AND OPERATIONS MANUAL

Operation

16

Initial state

Operating Modes

Normal mode

Sending data from the master to the selected port

Receiving data from a selected port

Null destination

Following the successful completion of its power up test, the Porter turns all its LEDs off.

The port LEDs will display the initial connect state (all dark for null destination, several lit

for broadcast mode, or one lit for single port connect). The status LEDs will display the

current port activity.

The Porter has several operating modes. Normal, null destination, and broadcast modes

are used for data transfer. Configuration (menu) mode is used to set up the unit.

Diagnostic mode is used to check the unit for faults. Manual mode allows front panel

switches to change the currently connected port.

Data flow is controlled by sending commands which may be intermixed with data. The

port selected may be changed by sending the proper command. When a port is selected,

normal communication occurs between the master port and the selected port. For serial

models full duplex communication is in effect; data may flow in either direction between

the master port and the selected port. For parallel models data is strobed into the master

port and out of the selected port. Also the status signals such as “PAPER END” are

passed through. Different protocols may be I effect on each port with the Porter making

the conversions automatically.

When transmitting data from the master port to the selected port the data will

immediately be sent unless the selected port is busy, in which case the data will go into

the selected port’s transmit buffer memory. If the buffer becomes full, the master port

will be signaled to stop sending data according to the flow control protocol set for it.

When a new port is selected and data remains in the previously selected port’s buffer,

data will continue to be sent from the previous port’s buffer to the device it is connected

to according to the flow control protocol currently in operation. Further data sent from

the master will go to the newly selected port or its buffer. Thus each port has its own

transmit buffer memory and data may be transmitted from each port’s buffer memory

simultaneously.

Data may be received from a selected port only on the serial models. Parallel units do not

allow incoming data on ports 1-8. Data received from a selected port will be immediately

sent out on the master port unless the master port is bus, in which case the data will go

into the selected port’s receive buffer. If the buffer becomes full the selected port will be

signaled to stop sending data according to the flow control protocol in operation.

Data received on a port which is not selected will be put in to that port’s receive buffer. If

a new port is selected which has data in it’s receive buffer, that data will immediately be

sent to the master port according to the flow control protocol in operation. Further data

received on the newly selected port will be sent to the master port immediately or placed

at the end of data currently in the buffer.

When the null destination (prefix + 9) command is in effect, no ports are considered

connected. Any data received on ports 1-8 will go into the respective receive buffer. All

the port LEDs remain off. Commands received via port 0 will continue to be recognized,

all other data received on port 0 is discarded. Null destination is terminated by sending

another connect command or the broadcast mode command.

PORTER INSTALLATION AND OPERATIONS MANUAL

17

Broadcast mode

Diagnostic mode

Configuration mode

Manual mode

When the <prefix>B broadcast mode command is entered, all ports enabled for

broadcast (via the configuration menu or the <prefix> +Mxx command) will light their

corresponding port LEDs. On serial units, all ports enabled for broadcast will immediately

have their receive buffers cleared.

Any data sent to port 0 during broadcast mode is transmitted simultaneously to all

enabled ports. Commands, with the exception of the <prefix>+Mxx command, continue

to be processed normally. Broadcast mode is terminated by sending a connect

command or the null destination command.

Side effects of broadcast mode

On serial units, port 0 must not be set to 19,200 baud (38400 baud if that option is

present) during broadcast mode. Due to the overhead of transmitting to multiple ports,

the Porter cannot process incoming data for broadcast at tis baud rate. Attempting this

will cause the ERROR LED to flicker and characters to be lost on output.

Also, on serial units during broadcast mode, incoming data on ports 1-8 is ignored.

However, X-on and X-off characters sent into ports set for X-on / X-off handshaking

continue to be processed.

On parallel units, the ERROR LED is always off during broadcast mode.

Also on parallel units the BUSY LED reflects the state of BUSY out on port 0,

not BUSY in on the connected port.

Also, on parallel units all ports enabled for broadcast must be hooked up to something. If

this is not done, broadcasting will stop when the unconnected port transmit buffer fills

up, as unconnected parallel ports are not set ot ready as with serial ports.

As mentioned before, the <prefix>Mxx (change broadcast mask) command does not

function during broadcast mode. To change the mask you ust first exit broadcast mode

(preferably with the <prefix>9 null destination command), issue the <prefix>Mxx

command, then reenter broadcast mode.

This mode allows the unit to self test itself. You can also restore the factory set

configuration from this mode. Refer to the section on “Diagnostic Modes” for

information on this mode.

This mode is activated by the configuration menu command <prefix>S. When this mode

is active, the MODE, DATA, and BUSY LEDs will all be lit. Data transfer from or to ports

1-8 is ignored in this mode. See “The Configuration Menu” for more information on this

mode.

This feature is used for manually establishing a port connection. It is useful for port

selection where software codes may not be desired to be sent. To enter the manual

mode, momentarily press both switches. The mode light will illuminate to indicate that

the manual mode has been entered. Pressing the ADVANCE switch will cause the port

selected to be changed to the next port. To leave the manual mode, momentarily press

both switches again. The mode light will go blank to indicate you are in the normal mode.

In the manual mode, connect commands sent to port 0 will still take effect.

PORTER INSTALLATION AND OPERATIONS MANUAL

18

The manual mode can be used to exit the null destination state, but it cannot be used to

set the unit to the null destination state. You must use the (prefix + 9) command to do

this.

Manual mode may be entered if the front panel switches have been disabled (locked) by

the <prefix>Lx command or the configuration menu. Manual mode may be entered and

then exited without altering the unit’s operating mode and port connection if the advance

switch is not pressed by itself while manual mode is active

PORTER INSTALLATION AND OPERATIONS MANUAL

19

Front Panel

Table IV LED Operation Display

M D B E 1 2 3 4 5 6 7 8

Note 1

Note 2

Note 3

X X X X X X X X

Note 4

Note 5

Note 1

. . . . . .

Unit operational, connected to port 1

Note 2

. . . . . .

Unit operational, null destination mode set

Note 3

. . . . . .

Unit operational, in broadcast mode with all ports enabled

Note 4

. . . . . .

Unit is in manual mode, displays current port connected

Note 5

. . . . . .

Unit is in configuration (setup) mode

The front panel is useful for observing the status of the Porter and manually changing the

port selection.

The front panel switches, labeled SELECT and ADVANCE are used to manually change

modes and port selection as described in the section on operating modes. They may be

disabled or enabled under program control

(see “Commands”).

The front panel LEDs are in two groups, the status LEDs and the port select LEDs. The

port select LEDs display the currently selected ports as long as the error light is not lit.

The status LEDs consist of Power, Mode, Data, Busy, and Error. The PORT SELECT LEDs

display the current connection between the master port and the peripheral ports. The

POWER LED is lit when power is connected to the unit and the on/off switch is in the on

position. The MODE LED displays the current mode that the Porter is in. When the LED

is lit the unit is in the manual mode, when it is dark the unit is in the normal mode. If it is

on along with the DATA and BUSY LEDs, the unit is in the configuration menu. The DATA

LED displays the presence of data being sent across the selected port. When illuminated

data is being transferred across the selected port connection. The BUSY LED displays

the state of the flow control of the selected port. When it is illuminated it indicates that

the flow of data has been inhibited across the selected port connection. The ERROR LED

displays any data receive errors encountered on serial ports and reflects the state of the

ERROR pin within the connected port on parallel ports.

Legend: M=Mode LED D=Data LED B=Busy LED E=Error LED

X + may vary, described below

= LED off = LED on

PORTER INSTALLATION AND OPERATIONS MANUAL

20

Porter Commands

Porter command set

Code

Description

Prefix + 1

Connect port 1 to port 0

Prefix + 2

Connect port 2 to port 0

Prefix + 3

Connect port 3 to port 0

Prefix + 4

Connect port 4 to port 0

Prefix + 5

Connect port 5 to port 0

Prefix + 6

Connect port 6 to port 0

Prefix + 7

Connect port 7 to port 0

Prefix + 8

Connect port 8 to port 0

Prefix + 9

Set null destination (connect to nothing)

Prefix + A

Any data available

Prefix + B

Set Broadcast mode

Prefix + Cnxx

Copy buffer n xx times

Prefix + Dn

Set initial power-up destination

Prefix + Fnxxxx

Set serial format and baud rate / xxxx in hexadecimal

Prefix + Gn

Go, resume flow of data on port n

Prefix In

Initialize printer on port n; valid on parallel units only

Prefix K

Keep current setup in non-volatile memory

Prefix Lx

Enable/Disable front panel switches

Prefix Mxxx

Set broadcast Mask (which port to broadcast to)

Prefix + Pxxxxxx = null

Set new Prefix from 1 to 6 characters

Prefix + Rn

Report state of Ready (DSR) on port n

Prefix + S

Start setup (configuration menu)

Prefix + Tnnn

Set prefix purge Timeout of nnn/20 seconds

Prefix + Wn

Wait, suspend flow of data on port n

Prefix + Zn

Zero (clear) buffer n

The command codes shown below control various functions of the Porter. All codes

begin with a user defined prefix that is 1-6 characters long. Zero (null, not ASCII “O”) may

not be used as part of the prefix. The prefix can be stored in non-volatile memory to

become a semi-permanent part of the control codes. The prefix should be chosen so as

not to interfere with other control codes used in you equipment. The purpose of the

prefix is to uniquely separate the code from the data you are transmitting. The factory set

prefix is 27,64 (the two characters ESC,@).Following the prefix is a one character

command and optional operands. The 8

or checking for an incoming prefix on port 0.

The + signs under “Code” are for illustrative purposes only. Do not use them in the

command string. All command letters are case sensitive – use upper case letters only.

th

(high) bit is ignored when setting a new prefix

xx is decimal, leading zero required is xx < 10

n = 1-8 for ports, 9 for null, B for broadcast

x = 0 unlocks, x = 1 locks

xx = two hexadecimal digits

must be terminated with null to delimit string

with 38400 baud option, nnn/ 40 seconds

PORTER INSTALLATION AND OPERATIONS MANUAL

21

Connect commands 1-8

Connect to Null Destination (9) command

Any Data Available Command

Broadcast mode command

Set port format command

Serial format codes by character

Character w

Character x

Character y

Character z

0 = none

0 = DTR/DSR

0 = 1 stop, 8 data

1 = 50

2 = odd

4 = Direct (DHS)*

2 = 1 stop, 7 data

2 = 75

6 = even

8 = X-on / X-off

4 = 1 stop, 6 data

3 = 110

A = mark

C = X-on / X-off + DHS*

6 = 1 stop, 5 data

4 = 134.5

E = space

8 = 2 stop, 8 data

5 = 150

A = 2 stop, 7 data

6 = 300

C = 2 stop, 6 data

7 = 600

E = 1.5 stop, 5 data

8 = 1200

9 = 1800

A = 2400

B = 3600

C = 4800

D = 7200

E = 9600

F = 19200

The connect commands allow selection of the current port connection. Commands 5-8

on a 4 port unit will connect to ports 1-4, respectively. The format of this command is

prefix + ASCII port number to connect to.

This command selects the null destination. No further data is passed through to the ports

1-8 transmit buffers until a connect 1-8 or broadcast mode command is received. For

further information see “Null Destination” under “Operating Modes”.

This command, applicable on serial units only, checks the buffers of ports 1-8 to see if

there is any data available and returns a coded byte containing the results. In this coded

byte, each bit position corresponds to a port; i.e. bit 0 corresponds to port 1, bit 1

corresponds to port 2, etc. If the port has any data available, the corresponding bit is set

to 1. The format of this command is prefix + A.

This command places the Porter into broadcast mode. See the section on “Broadcast

Mode” for further information. To end broadcast mode, send any connect command.

The serial format consists of the flow control protocol, baud rate, word length, parity, and

number of stop bits. Each port can be individually programmed with this command. The

format is the prefix + F + port number + wxyz where wxyz are send in hexadecimal

notation. The binary value of each bit is shown below. The default for each channel is

9600 baud, 8 bits, no parity, one stop bit, DTR/DSR handshake. For example to set the

default value on Port 5 the string would be prefix + F + 000E. Four hex digits are

required to enter the format code correctly. Note that with the 38400 baud option, the

baud rates are doubled. The only parameters changeable on parallel ports are bits 9,8 in

character x. These are also descried below.

Parity

Handshake

Stop & Data Bits

Baud rate

PORTER INSTALLATION AND OPERATIONS MANUAL

22

Format codes by bit

Character w : bits 15 - 12

Bits 15 – 14

00 = Odd parity

10 = Mark parity

Bit 13

0 = Parity off

1 = Parity on

Bit 12

unused

Ch ara cte r x: bi ts 1 1 - 8

Bit 11

0 = DTR flow control

1 = X-on/X-off flow control

Bit 10

0 = No DHS*

1 = Use DHS*

Bit 9**

0 = Busy required

1 = Busy ignored

Bit 8**

0 = Ack required

1 = Ack ignored

Character y: bits 7-4

Bit 7

O = 1 stop bit

1 = 2 stop bits

Bit 6-5

00 = 8 data bits

10 = 6 data bits

Bit 4

Unused

Character z: bits 3-0

Character

Binary

Baud Rate

Character

Binary

Baud Rate

1

0001

50 9 1001

1800

2

0010

75 A 1010

2400

3

0011

110 B 1011

3600 4 0100

134.5 C 1100

4800 5 0101

150 D 1101

7200 6 0110

300 E 1110

9600 7 0111

600 F 1111

19200

8

1000

1200 0 0000

INVALID

Serial format codes by character for 38400 baud option

Character w

Parity

Character x

Handshake

Character y

Stop & Data Bits

Character z

baud Rate

0 = none

0 = DTR/DSR

0 = 1 stop, 8 data

1 = 100

2 = odd

4 = Direct (DHS)*

2 = 1 stop, 7 data

2 = 150

6 = even

8 = X-on/X-off

4= 1 stop, 6 data

3 = INVALID

A = mark

C = X-on/X-off + DHS*

6= 1 stop, 5 data

4 = INVALID

E = space

8= 2 stop, 8 data

5 = 300

A= 2 stop, 7 data

6 = 600

C= 2 stop, 6 data

7 = 1200

E= 1.5 stop, 5 data

8 = 2400

9 = 3600

A = 4800

B = 7200

C = 9600

D = INVALID

E = 19200

F = 38400

01 = Even parity

01 = 7 data bits

11 = Space parity

11 = 5 data bits

PORTER INSTALLATION AND OPERATIONS MANUAL

23

Format codes by bit for 38400 baud option

Character w : bits 15 - 12

Bits 15 – 14

00 = Odd parity

10 = Mark parity

Bit 13

0 = Parity off

1 = Parity on

Bit 12

unused

Ch ara cte r x: bi ts 1 1 - 8

Bit 11

0 = DTR flow control

1 = X-on/X-off flow control

Bit 10

0 = No DHS*

1 = Use DHS*

Bit 9**

0 = Busy required

1 = Busy ignored

Bit 8**

0 = Ack required

1 = Ack ignored

Character y: bits 7-4

Bit 7

O = 1 stop bit

1 = 2 stop bits

Bit 6-5

00 = 8 data bits

10 = 6 data bits

Bit 4

Unused

Character z: bits 3-0

Character

Binary

Baud Rate

Character

Binary

Baud Rate

1

0001

100 9 1001

3600

2

0010

150 A 1010

4800

3

0011

INVALID

B

1011

7200 4 0100

INVALID

C

1100

9600 5 0101

300 D 1101

INVALID

6

0110

600 E 1110

19200

7

0111

1200 F 1111

38400

8

1000

2400 0 0000

INVALID

*

Copy from buffer command

Example of the copy command

If DHS (direct handshake) is set on a given port, the port, when selected, will pass its

DSR signal directly back to port 0’s DTR signal, and port 0’s DSR signal will pass directly

to the DTR signal on the selected port. DHS cannot be set on port 0. This is useful for

dealing with modems.

** For parallel units only. These are the only parameters used by parallel units. Ignored if

set on a serial unit. These parameters cannot be set for port 0.

The copy command is useful for sending multiple files of data while only storing one copy

of the data. The command requires an additional operand of the number of times to copy

the buffer. The format of this command is the prefix + the port number + a two digit

decimal number specifying the number of copies to be made. The zero buffer command

may be used to cancel a copy in progress. The maximum number of copies allowed is 14.

Entering the copy command with > 14 copies causes it to be ignored.

To use the copy command, first connect to the port you wish to send copies out of. Use

the Z (Zero Buffer) command to clear the buffer, and then send the first (original) copy.

Then issue the copy command to send the remaining copies. After sending the copy

command you may connect to other ports without disturbing the copying process.

01 = Even parity

01 = 7 data bits

11 = Space parity

11 = 5 data bits

PORTER INSTALLATION AND OPERATIONS MANUAL

24

Set Initial destination command

Go command

Initialize command (Parallel units only)

Keep command

Enable/Disable front panel switches command

Set broadcast mask command

Set prefix command

This command is used to set the initial destination the Porter selects when it is powered

up. The syntax of this command is prefix + Dx, where x is the port number (1-8), 9 for

null destination, or B for broadcast.

The Go command reverses the action of the Wait command. (See “Wait Command”,

below.) The port’s DTR is set to high, and if the port is configured for X-on/X-off operation

a X-on character is sent. Also, transmission suspended by a Wait command is resumed.

The syntax of this command is prefix + G + port number.

The initialize command causes a parallel port INIT signal to be pulsed low. This initializes

a printer if one is connected. The command is ignored on serial units. The syntax of this

command is prefix + I + port number.

This command allows the current setup parameter to be saved in non-volatile memory

and to become the default configuration. The parameters saved are the prefix characters,

initial destination, timeout, and format control. You should ensure that the unit is working

properly before using this command. Also make a written record of the configuration for

your future reference. The format of this command is prefix + K.

This command allows you to disable (lock) or enable (unlock) the front panel switches.

The syntax of this command is prefix + Lx, where x = 0 to unlock, or 1 to lock. Locking

the switches does not prevent use of the diagnostic mode at power up.

This command lets you change which ports are enabled for data transmission when the

broadcast mode is used. The factory setting is to have all available ports except port 0

enabled for broadcast. The syntax of this command is prefix + M + xy, where xy are two

hex digits. X controls ports 8-5, and y controls ports 4-1. The most significant bit controls

port 8, the next bit port 7, and so on with the least significant bit controlling port 1.

Setting a bit to 1 enables the corresponding port for broadcast; setting a bit to 0 disables

the port for broadcast.

This command alters the prefix used at the beginning of all commands. The new prefix

will take place immediately after receipt. It is recommended that the prefix be chosen

once and used consistently. Altering the prefix is useful for separating Porter’s select

codes from other device codes which may be used for other functions. It is also useful

for chaining multiple Porters together, described further in the section on chaining.

The syntax for this command is the old prefix + P + the new prefix + null. The null (byte

= 0, Ctrl-@ on a PC keyboard) is used to terminate the prefix code and is required to

determine the amount of characters in the prefix. Null may not occur as part of the prefix

code. The factory default for the prefix is ascii 27,64 representing the two characters

ESC@. The high (8

ignored when the unit checks for an incoming prefix on port 0.

th

) bit is always set to 0 when entering a new prefix, as the 8th bit is

PORTER INSTALLATION AND OPERATIONS MANUAL

25

Ready (Check DSR) command

If this command is issued when there is reverse channel data traffic, it may not respond.

Setup (Configuration) menu commands

Timeout (command purge) command

Wait command

Zero (clear) command

This command allows a program to determine if a given serial port’s DSR (pin 6) is in the

ready state (+12V), or the busy state (-12V). The syntax of this command is prefix + port

number 0-8. A single byte is returned: ASCII “0” if the specified port is in the busy state,

and “1” if it is in the ready state. Note that a port with no device connected will read as

“ready” due to the internal pull-up resistor provided for pin 6.

Since this command returns an answer, you must ensure that no reverse channel data

(data coming from ports 1-8) is present when this command is issued. The safest way to

use this command is to use the connect 9 (Null Destination) command first, then after

issuing the Ready command and receiving its answer re-issue the appropriate connect

command to re-connect.

The configuration menu is invoked by the prefix + S command. You would normally not

issue this command except by manual entry from a communication program or dumb

terminal. For more information on the configuration menu see “The Configuration Menu”.

This allows changing the command purge timeout. The timeout value may range from

000-255. Setting a value of 000 disables the command purge timeout. The syntax of this

command is prefix + T + nnn. Leading zeros are required. For more information on te

command purge timeout se the “Configuration Menu” section under “Change command

purge timeout value”.

The Wait command causes two things to happen to the port n that it is used on. First,

any transmission that may be in progress is suspended. Second, the port’s DTR is set to

low, and if the port is configured for X-on/X-off operation a X-off character is sent. This

state is cleared with the Go command. The syntax of this command is prefix + W + port

number.

This command is used to clear the buffer and cancel any pending data transfers on the

port specified. This command should be used prior to using the copy command to

ensure that the proper data will be copied. Zero is set for an individual port buffer by

sending the prefix + Z + port number.

PORTER INSTALLATION AND OPERATIONS MANUAL

26

Applications

Buffering

Chaining Multiple Porters Together

Writing Programs to Control the Porter

Procedure for sending Data

Procedure for Receiving Data

The switch may have a buffer of 16, 64, or 256 Kbytes of memory. The memory is

allocated evenly to each port. For the serial models half of the memory for each port

would be allocated to the transmit buffer and the other half to the receive buffer. For

example for an 8 channel serial model with 16k bytes of buffer each port would have 1k

for transmit and 1k for receive. For parallel models each port has only a transmit buffer

with the buffer being divided equally among all channels. For example a 4 channel

parallel model with 64k bytes of buffer would have 16k bytes allocated to each port.

When broadcast mode is used, the main port will go “busy” if any of the buffers

belonging to ports enabled for broadcast become full.

The units may be chained together in an unlimited fashion to connect 1 master port to

more than the number of peripheral ports available on one Porter unit by interconnecting

more than one Porter unit. The peripheral ports on a master unit are connected to the

master ports on the expansion units. In order to access ports on the expansion unit(s), a

different prefix code must be set into the expansion units. By sending the master unit’s

code followed by the expansion unit’s code, a peripheral port may be accessed.

For example, use the default prefix on the master unit. Set the prefix on the expansion

unit to %^. Connect peripheral port 2 on the master unit to the master port on the

expansion unit. To access port 5 on the expansion unit from the master port on the

master unit send the code ESC@2%^5. There is no limit to the number of expansion

units that may be added.

The procedure for sending data to multiple output devices using the Porter is

straightforward and easy to implement from a program.

1. Initialize the serial port connected to the Porter

2. Send the control code to connect to the first device.

3. Send the data to the first device.

4. Continue to step 2.

One common use of the Porter is to interrogate a group of devices to collect data from

them. A program that does this should use the following algorithm:

1. Initialize the serial port connected to the Porter, prepare to receive characters.

2. Use the any data available command and read the coded byte returned. If there is

any data available follow steps 3-5 below.

3. Send the control code to connect to the first device.

4. Receive and store data fro this device.

5. When the program wishes to change ports to listen to another device:

A. Either drop DTR (hardware handshake) or send an X-off (X-on/X-off).

B. Check the receiver to ensure that a character was not received while step 4a

was being carried out. Read and store the character if this happened.

C. Send the control code to connect to the next device

D. Carry out any steps needed to prepare to receive data from the next device.

E. Either raise DTR (hardware handshake) or send an X-on (X-on/X-off)

F. Proceed to step 3.

PORTER INSTALLATION AND OPERATIONS MANUAL

27

Diagnostic

Diagnostic Tests

Short Test

Long test without loopback

You can execute some special diagnostic tests to determine if the Porter has any

problems. There are three groups of tests as shown below.

The short test, which is exactly the same as the power up test, is executed by pressing

both ADVVANCE and SELECT while powering up the unit. The long test without loopback

is selected by powering on while holding in the SELECT switch only. The long test with

loopback (which requires loopback connectors as described below) is selected by

powering on while holding in the ADVANCE switch only.

The long tests do a more extensive memory test and do tests on the ports. For this

reason, all devices (except the loopback connectors on the loopback test) must be

disconnected from the unit’s ports when the long tests are running. The short test is

similar to the power up test but continuously cycles, and allows reloading of the factory

default settings. The tests continuously cycle and halt if an error is determined. See

Tables V and VI for the various LED displays.

This group of tests is entered by pressing both the ADVANCE and SELECT switches while

powering up the unit. They are also executed once on every power-up. These tests are

exactly the same tests as those performed during power up sequence. You enter this

state for a continuous test of the Porter functions or to reload the factory default settings

as described below.

Test 1 – EPROM program checksum test

Test 2 – Buffer memory sizing and read/write test

Test 3 – Static ram read/write test

Test 4 – Non-Volatile ram checksum test

Tests 1 – 4 are the same as the power-up test.

This group of tests are entered by pressing the SELECT switch only while powering up

the unit with the on/off switch. All equipment should be disconnected from the Porter

prior to running this test.

Test 1 – EPROM program checksum test

This test is the same as the “Short Test” described above.

Test 2 – Extended dynamic ram test

This test checks the dynamic ram more extensively than the short test or the power up

test. The test takes longer to perform. If this test fails (see Table VI) then the unit must

be serviced. Other LEDs may be lit also indicating the amount of memory that is installed

(see Table V). The failing board and memory device can be determined by pressing the

ADVANCE switch. The BUF LED will be lit if the failing board is the base mother board or

the bottom-most memory board installed. The DATA LED will be lit if the failing board is

the second from the bottom. The BUSY LED will be lit for the third board, and the LED

#0 will be lit for the fourth board. The LEDs 1-8 correspond to the physical placement of

the failing chip. If the failing chip is the one all the way to the left, then LED 1 will be lit.

If the failing chip is the one all the way to the right, then LED 8 will be lit. The chips in the

middle correspond appropriately. Hitting the SELECT switch will retry the test. In order

to bypass this test completely, both the ADVANCE and SELECT switches may be

pressed.

PORTER INSTALLATION AND OPERATIONS MANUAL

28

Table V Diagnostics LED Display

M D B E 1 2 3 4 5 6 7 8

1st

All LEDS on

2nd

Test 1: EPROM checked

3rd

Test 2: 16K RAM buffer

Test 2: 64k RAM buffer

Test 2: 256k RAM buffer

4th

Test 3: Static ram

5th

Test 4: Non-Volatile ram

6th

Test 5: Port type test

7th

Test 6: Module test

Test 3 – Static ram read/write test

This test is the same as in the ‘Short Test’

Test 4 – Non-volatile RAM checksum test

This test is the same as in the ‘Short Test’

Test 5 – Port addressing test

This test ensures that the contents of non-volatile memory agree with the port

configuration. If this test fails (see Table VI) then the configuration memory has been

corrupted or a port communication chip has failed. Reload the factory default settings as

described below and retry the test. Make sure there are no cables connected to the

Porter. Re-run the test, if the test still fails then the unit must be serviced. The ADVANCE

switch may be pressed to determine which port is the failing port. BUF, DATA, and BUSY

LEDs will all be lit. The LEDs of all ports which pass will be it. A failing port will have its

corresponding LED off. The SELECT switch may be pressed to execute the test again. In

order to bypass this test completely, both the ADVANCE and SELECT switches may be

pressed.

Test 6 – Module test without loopback

This test ensures that there are no signal shorts on a port. In order for this test to pass,

no equipment should be connected to the Porter. If this test fails (see TABLE VI) then a

port communication chip has failed and the unit must be serviced. The ADVANCE switch

may be pressed to determine which port is the failing port. BUF, DATA, and BUSY will all

be flashing. The LEDs of all ports which pass will be flashing. A failing port will have its

corresponding LED steadily lit. Ports not installed will have their corresponding LEDs off.

This test will continuously execute until all ports pass or the test is bypassed. In order to

bypass this test completely, both the ADVANCE and SELECT switches may be pressed.

Legend: M=Mode LED D=Data LED B=Busy LED E=Error LED

= LED off = LED on

PORTER INSTALLATION AND OPERATIONS MANUAL

29

Table VI Diagnostic LED Error Display

M D B E 1 2 3 4 5 6 7 8

Error 1

Error 2

Error 3

Error 4

Error 41

Error 43

Error 45

Error 46

Error 47

Error 48

Error 5

Error 6

Error 1

. . . . . .

EPROM checksum failure

Error 2

. . . . . .

RAM buffer memory failure

Error 3

. . . . . .

Static ram failure

Error 4

. . . . . .

Non-volatile ram checksum failure

Error 41

. . . . . .

Non-volatile ram in wrong box type

Error 43

. . . . . .

Non-volatile ram memory failure

Error 45

. . . . . .

Restore to default configuration failure

Error 46

. . . . . .

A port that is not allowed is present

Error 47

. . . . . .