Page 1

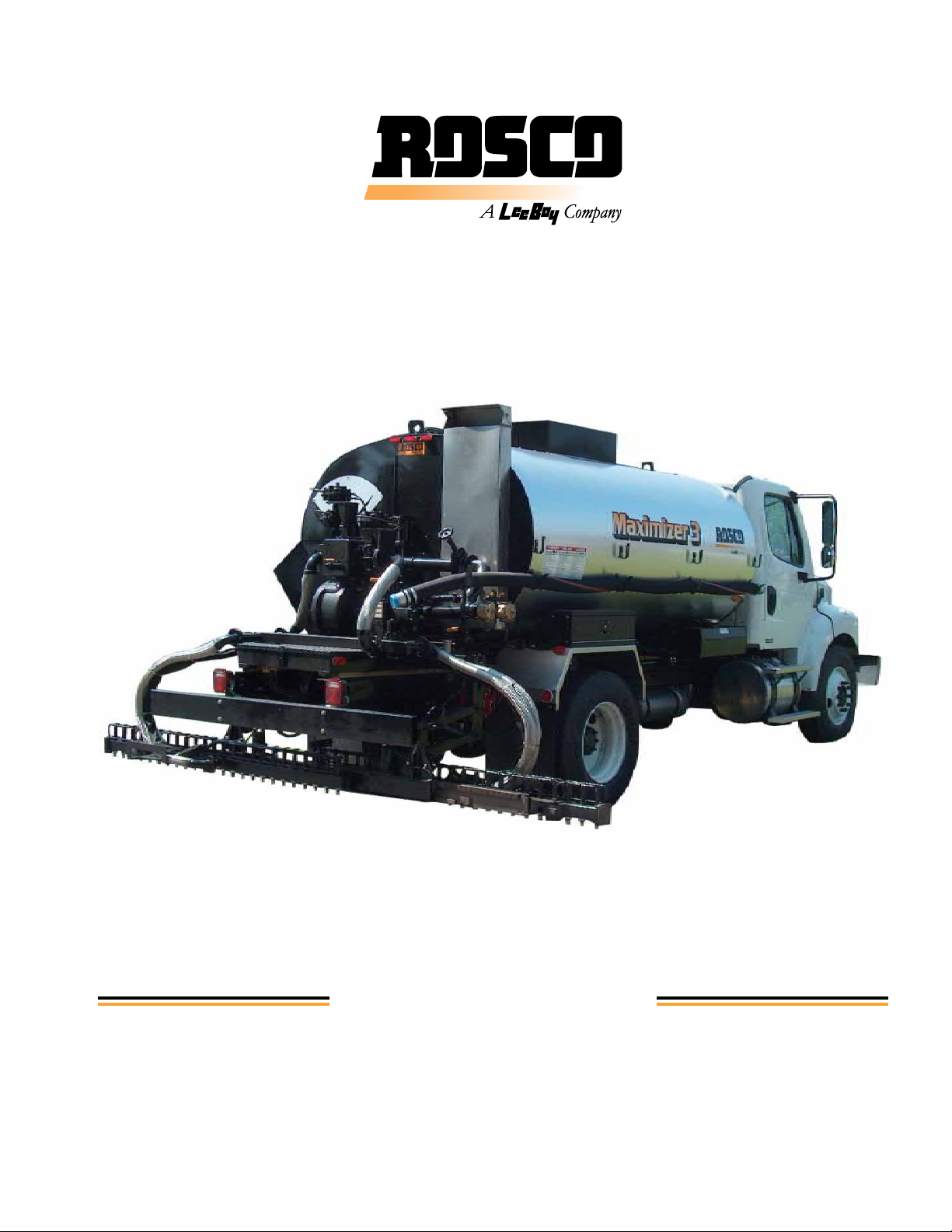

Operations, Service

And Parts Manual

Rosco Maximizer 3B Asphalt Distributor

Manual No. 1005234-01

Page 2

Page 3

Thumb Index

Introduction

Safety

General Information

Specifications

Component Location

1

2

3

4

5

Operation

Maintenance

Troubleshooting

Schematics

Illustrated Parts List (IPL)

6

7

8

9

10

Page 4

Disclaimer And Copyright

Disclaimer:

All information, illustrations and specications in this manual are based on the latest information available at the time

of publishing. The illustrations used in this manual are intended as representative reference views only. Moreover,

because of our continuous product improvement policy, we may modify information, illustrations and/or specications

to explain and/or exemplify a product, service or maintenance improvement. We reserve the right to make any

change at any time without notice. VT LeeBoy, Inc., VT LeeBoy, LeeBoy, and Rosco are all the same entity and are

used interchangeably.

©2010 VT LeeBoy, Inc.

LeeBoy reserves all copyright and other rights in this manual and the manual’s content. No part of this manual may

be reproduced or used in any way without the written permission of LeeBoy, except as necessary to operate LeeBoy

equipment.

This manual has been most recently updated 01/11 to apply to serial number and above:

46266

PDF le last modied on: 01/25/11

Return to

iv Rosco Maximizer 3B Asphalt Distributor

Thumb Index

Return to

Last Viewed

Page 5

Table Of Contents

Page

Table Of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety Label Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Limited Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Items Not Covered . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Other Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Record of Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Circulating System . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Burner System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Plus One Controller . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

In-Cab Operator System . . . . . . . . . . . . . . . . . . . . . . . 4-3

Material Considerations . . . . . . . . . . . . . . . . . . . . . . . 4-4

Specication Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Torque Specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Metric Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Return to

Rosco Maximizer 3B Asphalt Distributor v

Last Viewed

Return to

Thumb Index

Page 6

Table Of Contents

Inch Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Hydraulic Fittings . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Full Torque Nut Coupling Installation . . . . . . . . . . . . . . . . . 4-12

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Outside Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Main In-Cab Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Rear Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Run Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

LPG Burner System . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Operator Safety Considerations . . . . . . . . . . . . . . . . . . . . . . 6-3

Regeneration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Machine Break-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Before Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

After 2 Hours Of Operation . . . . . . . . . . . . . . . . . . . . . . 6-4

After 8 & 20 Hours Of Operation . . . . . . . . . . . . . . . . . . . 6-4

Pre-Operating Check List . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Service And Maintenance . . . . . . . . . . . . . . . . . . . . . . 6-4

Spraybar Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Hydraulic Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Hydrostatic Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Automatic Valve System . . . . . . . . . . . . . . . . . . . . . . . 6-6

Asphalt Spraybar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Preventing Spraybar Failure . . . . . . . . . . . . . . . . . . . . . 6-8

Valves And Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Nozzle Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Burners & Torch Operation . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Diesel Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Portable LPG Torch . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Plus One Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Distributor Operation . . . . . . . . . . . . . . . . . . . . . . . .6-16

In-Cab Controller Screens . . . . . . . . . . . . . . . . . . . . . . 6-17

Flow/Distance Calibration . . . . . . . . . . . . . . . . . . . . . . 6-19

Return to

vi Rosco Maximizer 3B Asphalt Distributor

Thumb Index

Return to

Last Viewed

Page 7

Table Of Contents

Plus One Controller Error Messages . . . . . . . . . . . . . . . . . 6-20

Electro Motive Radiation Interference . . . . . . . . . . . . . . . .6-20

Modes Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Load Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Tank Circulate Mode . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Spray / Bar Circulate Mode (Bar Circulate) . . . . . . . . . . . . . . 6-27

Spray / Bar Circulate Mode (Spray) . . . . . . . . . . . . . . . . . 6-29

Handspraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Handspray / Unload Mode . . . . . . . . . . . . . . . . . . . . . . 6-33

Handspray Mode (Spray / Bar Circulate) . . . . . . . . . . . . . . .6-35

Reverse Suction Mode . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Automated Clean-out Mode . . . . . . . . . . . . . . . . . . . . . 6-39

Clean-out Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

Transfer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

Unloading Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

Washdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-48

Combating Poor Visibility . . . . . . . . . . . . . . . . . . . . . . . . .6-48

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-49

Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-49

Run Simulation Example . . . . . . . . . . . . . . . . . . . . . . . 6-50

Trial Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

General Information . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Fluids And Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Asphalt Pump Lubrication . . . . . . . . . . . . . . . . . . . . . . 7-5

Grease For Other Components . . . . . . . . . . . . . . . . . . . 7-5

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Clean-out Solvent . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Truck Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Tank Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Tank Sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Top Opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Capacity Indicator Gauge . . . . . . . . . . . . . . . . . . . . . . 7-7

Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Return to

Rosco Maximizer 3B Asphalt Distributor vii

Last Viewed

Return to

Thumb Index

Page 8

Table Of Contents

Asphalt Pump System . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Asphalt Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Discharge Screen . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Load Line Screen . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Pump Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

Automatic Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Spraybar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13

Burner System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Diesel Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

LPG Burners (Option) . . . . . . . . . . . . . . . . . . . . . . . . 7-14

GPS Ground Speed Sensor . . . . . . . . . . . . . . . . . . . . . . . .7-15

Radar Horn (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Daily Exterior Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Hydraulic Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Hydraulic Oil Requirements . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Safety Label Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Troubleshooting Charts . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Electrical Schematic - Plus One Overview . . . . . . . . . . . . . . . . . 9-3

Electrical Schematic - Plus One 1 of 5 . . . . . . . . . . . . . . . . 9-5

Electrical Schematic - Plus One 2 of 5 . . . . . . . . . . . . . . . . 9-7

Electrical Schematic - Plus One 3 of 5 . . . . . . . . . . . . . . . . 9-9

Electrical Schematic - Plus One 4 of 5 . . . . . . . . . . . . . . . . 9-11

Electrical Schematic - Plus One 5 of 5 . . . . . . . . . . . . . . . . 9-13

Pneumatic Schematic - Control, Air 1 of 1 . . . . . . . . . . . . . . . . . . 9-15

Electrical Schematic - Control, Front Machine 1 of 1 . . . . . . . . . . . . . 9-17

Electrical Schematic - Control, Rear Machine 1 of 1 . . . . . . . . . . . . . 9-19

Electrical Schematic - Control, LH Spraybar 1 of 1 . . . . . . . . . . . . .9-21

Electrical Schematic - Control, RH Spraybar 1 of 1 . . . . . . . . . . . . .9-23

Electrical Schematic - Can Bus Kit 1 of 4 . . . . . . . . . . . . . . . . . . 9-25

Electrical Schematic - Can Bus Kit 2 of 4 . . . . . . . . . . . . . . . . . . 9-27

Return to

viii Rosco Maximizer 3B Asphalt Distributor

Thumb Index

Return to

Last Viewed

Page 9

Table Of Contents

Electrical Schematic - Can Bus Kit 3 of 4 . . . . . . . . . . . . . . . . . . 9-29

Electrical Schematic - Can Bus Kit 4 of 4 . . . . . . . . . . . . . . . . . . 9-31

Illustrated Parts List (IPL) . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Platform Installation, w/o Handrail . . . . . . . . . . . . . . . . . . 10-4

Rear Platform and Piping Assembly . . . . . . . . . . . . . . . . . 10-6

Asphalt Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Asphalt Pump Relief Valve . . . . . . . . . . . . . . . . . . . . . . 10-12

Transfer Line, Ground Level . . . . . . . . . . . . . . . . . . . . . 10-14

Automatic Valve, Cab Control . . . . . . . . . . . . . . . . . . . .10-16

Tank Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . .10-18

Flex Hose Assembly . . . . . . . . . . . . . . . . . . . . . . . . .10-20

Handspray Wand Assembly . . . . . . . . . . . . . . . . . . . . .10-22

Hydraulic, Front Live . . . . . . . . . . . . . . . . . . . . . . . . .10-26

Hydraulic, PTO . . . . . . . . . . . . . . . . . . . . . . . . . . .10-34

Hydraulic Reservoir . . . . . . . . . . . . . . . . . . . . . . . . .10-40

Drive Shaft Group . . . . . . . . . . . . . . . . . . . . . . . . . .10-42

Control Box, Plus One, 16 Ft Spraybar . . . . . . . . . . . . . . . .10-44

Ground Speed Sensor . . . . . . . . . . . . . . . . . . . . . . .10-46

Spraybar Assembly, 16 Foot . . . . . . . . . . . . . . . . . . . . .10-48

Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-54

Spray Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . .10-56

Air Reservoir Group . . . . . . . . . . . . . . . . . . . . . . . . .10-58

Valve Box, Subassembly . . . . . . . . . . . . . . . . . . . . . . 10-60

Solenoid Valve, 8 Valve . . . . . . . . . . . . . . . . . . . . . . .10-62

Diesel Burner, Double Flue, No Outre I . . . . . . . . . . . . . . .10-64

Diesel Burner, Double Flue, No Outre II . . . . . . . . . . . . . . 10-66

Control Box, Diesel Burner . . . . . . . . . . . . . . . . . . . . 10-68

Burner Covers & Flue Liners . . . . . . . . . . . . . . . . . . . . .10-70

Light & Reector Group . . . . . . . . . . . . . . . . . . . . . . .10-72

Decal Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-74

Ladder & Platform Group . . . . . . . . . . . . . . . . . . . . . .10-76

Tank Top Opening . . . . . . . . . . . . . . . . . . . . . . . . . .10-78

Fender Group, Single Axle . . . . . . . . . . . . . . . . . . . . . 10-80

Mud Flap Installation . . . . . . . . . . . . . . . . . . . . . . . . .10-82

Sampling Valve, Front Head . . . . . . . . . . . . . . . . . . . . .10-84

Overow Attachment Group . . . . . . . . . . . . . . . . . . . . 10-86

Return to

Rosco Maximizer 3B Asphalt Distributor ix

Last Viewed

Return to

Thumb Index

Page 10

Table Of Contents

Thermometers . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-88

Enviroush System . . . . . . . . . . . . . . . . . . . . . . . . . 10-90

Insulated Tank & Tank Components . . . . . . . . . . . . . . . . .10-92

Spraybar Assembly, 18 FT . . . . . . . . . . . . . . . . . . . . . 10-96

Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-102

Spray Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . 10-104

Spray Valve Assembly, 20 FT . . . . . . . . . . . . . . . . . . . . 10-106

Spray Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . 10-110

Solenoid Valve, 10/12 Valve (For 18 FT Spraybar) . . . . . . . . . . 10-112

Solenoid Valve, 12 Valve (For 20 FT Spraybar) . . . . . . . . . . . 10-114

Diesel Burner, Double Flue, Outre, No Thermostat I . . . . . . . . 10-116

Diesel Burner, Double Flue, Outre, No Thermostat II . . . . . . . . 10-118

LPG Burners, Double Flue, Auto Ignition . . . . . . . . . . . . . . 10-120

LPG Burners, Double Flue, Manual Ignition . . . . . . . . . . . . . 10-124

LPG Tank, 52 Gallon . . . . . . . . . . . . . . . . . . . . . . . . 10-126

Portable Torch Holder Assembly, LPG . . . . . . . . . . . . . . . 10-128

Fender Group, Tandem Axle . . . . . . . . . . . . . . . . . . . . 10-130

Fender Group, Triple Axle . . . . . . . . . . . . . . . . . . . . . 10-132

Mud Flap Group, Full Width . . . . . . . . . . . . . . . . . . . . . 10-134

Washdown System . . . . . . . . . . . . . . . . . . . . . . . . 10-136

Return Line Valve . . . . . . . . . . . . . . . . . . . . . . . . . 10-140

Tank & Ladder Group, 1000 Gallon Tank . . . . . . . . . . . . . . 10-142

Tank & Ladder Group, 1500 Gallon Tank . . . . . . . . . . . . . . 10-144

Tank & Ladder Group, 3000 Gallon Tank . . . . . . . . . . . . . . 10-146

Tank & Ladder Group, 3500 Gallon Tank . . . . . . . . . . . . . . 10-148

Tank & Ladder Group, 4000 Gallon Tank . . . . . . . . . . . . . . 10-150

Alphabetical Parts Index . . . . . . . . . . . . . . . . . . . . . . . . . 10-152

Return to

x Rosco Maximizer 3B Asphalt Distributor

Thumb Index

Return to

Last Viewed

Page 11

Section 1

Introduction

1

Thank you for purchasing the Rosco Maximizer 3B

Asphalt Distributor. We wish you many years of safe and

efcient operation of your machine.

READ THIS MANUAL PRIOR TO OPERATING the

unit. This manual is an important part of the machine

and should be kept with the machine at all times in the

dedicated storage container on the machine. Even

though you may be familiar with similar equipment,

you MUST read and understand this manual before

operating this machine. Reading the manual will help you

and others avoid injury and help prevent any damage to

the machine. If this manual becomes lost or damaged,

contact your authorized LeeBoy Dealer immediately to

order a replacement (see Contact Information Section

3).

This manual is intended as a guide for the safe and

efcient use of the machine. This manual covers the

procedures for proper operation and maintenance of

the machine. This manual contains information that was

available at the time of printing and is subject to change

without notice.

This manual should be used with all related

supplemental books, engine and transmission manuals,

and parts books. Related Service Bulletins should be

reviewed to provide information regarding some of the

recent changes.

This manual provides information for use by the

equipment operator under the following headings:

Safety—See Section 2 for important safety guidelines

information.

General Information—See Section 3 for important

warranty, contact, and nameplate information.

Specications—See Section 4 for all major system

specications and typical torque value tables.

Component Location—See Section 5 for general

overview of controls and major components.

Operation—See Section 6 for control functionality and

normal equipment operation.

Maintenance—See Section 7 for basic preventive

maintenance and repair procedures.

Troubleshooting—See Section 8 for problem

descriptions and recommended solution tables.

Schematics—See Section 9 for schematic diagrams of

electrical wiring.

Illustrated Parts List (IPL)—See Section 10 for

illustrations, descriptions and part numbers of available

service parts.

If any questions arise concerning this publication or

others, contact your local LeeBoy Dealer for the latest

available information.

Return to

Rosco Maximizer 3B Asphalt Distributor 1-1

Last Viewed

Return to

Thumb Index

Page 12

Introduction

NOTES

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor1-2

Page 13

Section 2

Safety

Page

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety Label Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Return to

Last Viewed

Return to

Thumb Index

2-1Rosco Maximizer 3B Asphalt Distributor

Page 14

Safety

This manual provides important information to familiarize

you with safe operating and maintenance procedures.

Even though you may be familiar with similar equipment,

you MUST read and understand this manual before

operating the Rosco Maximizer 3B Asphalt Distributor

and follow its instructions when operating the machine.

Safety is everyone’s business and is our top concern.

Knowing the guidelines covered in this section and in

Section 1 will help ensure your safety, the safety of those

around you and the machine’s proper operation.

LOOK FOR THESE SYMBOLS WHICH POINT OUT

ITEMS OF EXTREME IMPORTANCE TO THE SAFETY

OF YOU AND YOUR COWORKERS. READ AND

UNDERSTAND THOROUGHLY. HEED THE WARNING

AND FOLLOW THE INSTRUCTIONS.

Keep safety labels in good condition. If safety labels

become missing or damaged, replacement safety labels

are available from your LeeBoy Dealer (see Safety

Label Locations in Section 2).

7).

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Safety Precautions

General Safety

• Have a rst-aid kit available and know how to use it.

• Keep a “charged” re extinguisher within reach

whenever you work in an area where re may occur.

Have the correct type of extinguisher for your situation

and know how to use it:

Type A: Wood, paper, textile and rubbish

Type B: Flammable liquids

Type C: Electrical equipment

• Do not hurry. Use recommended hand holds and

steps with at least three points of support when

getting on and off the Maximizer 3B. Keep steps, oor,

hand holds and controls clean and free from grease.

Face the machine when climbing up and down and

never jump off or dismount while the machine is in

motion. Falling from the machine can cause serious

injury.

• Do not permit riders on the Maximizer 3B. Death or

serious injury can occur if riders fall off or under the

machine while it is in motion.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Indicates a situation which can cause damage to the

equipment, personal property and/or the

environment, or cause the Rosco Maximizer 3B

Asphalt Distributor to operate improperly.

NOTE: Indicates a procedure, practice, or condition that

should be followed in order for the machine or

component to function in the manner intended.

• Do not go into the tank! Death can occur due to lack

of oxygen, breathing poisonous fumes or explosion.

Keep others out!

• Do not smoke near the machine. Fuel, emulsion and

fumes can explode when exposed to ames or heat

from smoking or other sources.

The safety messages that follow have CAUTION level

hazards.

Pre-Operation Hazard

Read and understand this Operation

Manual before operating or servicing the

engine to ensure that safe operating

practices and maintenance procedures are

followed.

• Never permit anyone to service or operate the Rosco

Maximizer 3B Asphalt Distributor without proper

training.

• Contact LeeBoy or an authorized LeeBoy Dealer for

additional training.

2-2

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 15

Safety

• Safety signs and labels are additional reminders for

safe operating and maintenance techniques.

• Make sure you are aware of all laws and regulations

that are in effect where the machine is operated.

Ensure you have all necessary licenses to operate the

machine.

• Before starting or operating the machine, ensure all

controls are OFF or in neutral position.

• Know and understand the jobsite trafc ow patterns

and obey agmen, road signs and signals.

Starting and Stopping

• Walk around the machine and warn all personnel in

the area before starting the machine. Be sure the

area is clear before starting. Death or serious injury

can occur to bystanders from being crushed under a

moving machine or being hit by material.

• Always park the machine on level ground whenever

possible. Apply the parking brake. On grades, park the

Distributor with the wheels securely blocked.

• Stopping distances must be anticipated for all

conditions. If stopping on a grade, the distance

needed to come to a stop will be longer. Familiarize

yourself with these variables so you can anticipate

when a longer stopping distance is required.

• Keep the tank vents clear to avoid a buildup of

pressure in the tank when heating. Check the vents

before starting the burners.

• Never use gasoline, alcohol or any other unapproved

fuel in a diesel burner. Fire and explosion can occur.

• Do not operate the burners while the wash down

system is operating or has recently been used. Fire

and explosion can occur.

• Do not operate the burners with top tank cover open.

Fire and explosion can occur.

• Be sure to read, understand and follow all precautions

for the type of cleaning material you are using.

The safety messages that follow have WARNING

level hazards.

Crush Hazard

Keep bystanders away from work area before and

during operation.

Modification Hazard

Never modify the Rosco Maximizer 3B Asphalt

Distributor without written consent of LeeBoy. Any

modication can affect the safe operation of the

machine and may cause personal injury or death.

2

The safety messages that follow have WARNING

level hazards.

Burner Operation

• Never operate burner equipment when the vehicle is

being loaded or in transit. The ue tubes can become

exposed, causing an explosion inside the tank, or

ignite material being sprayed.

• Never operate the burners if the ue tubes are not

covered with at least 8 inches (20.32 cm) of material.

The ue tubes can become red hot and ignite the

vapors causing an explosion.

• Always park the truck so that the burners are up wind.

Some asphalt materials emit ammable vapors from

the vent that can be ignited by the burner ame and

cause an explosion.

• Never operate the burners in a conned area such

as a building or shed. Vapor build-up could cause an

explosion.

• Do not operate the burners if the tank is leaking or a

spill has occurred. Fire and explosion can occur.

Exposure Hazard

Always wear personal protective

equipment, including appropriate clothing,

gloves, work shoes, and eye and hearing

protection, as required by the task at hand.

Explosion Hazard

While the engine is running or the battery is

charging, hydrogen gas is being produced

and can be easily ignited. Keep the area

around the battery well-ventilated and keep

sparks, open ame and any other form of

ignition out of the area.

• Always disconnect the negative (-) battery cable

before servicing the machine.

• Do not start the engine by shorting the starter circuit

or by using any other starting method not stated in this

manual. Only use the starting procedure as described

in this manual to start the engine.

• Never charge a frozen battery. Always slowly warm the

battery to room temperature before charging.

Return to

Rosco Maximizer 3B Asphalt Distributor 2-3

Last Viewed

Return to

Thumb Index

Page 16

Safety

Fire and Explosion Hazard

• Diesel fuel is ammable and explosive under certain

conditions.

• Never use a shop rag to catch the fuel.

• Wipe up all spills immediately.

• Never refuel with the engine running.

• Store any containers containing fuel in a well-

ventilated area, away from any combustibles or

sources of ignition.

Fire Hazard

Have appropriate safety equipment

available. Have all re extinguishers

checked periodically for proper operation

and/or readiness.

• Always read and follow safety-related precautions

found on containers of hazardous substances

like parts cleaners, primers, sealants and sealant

removers.

• Undersized wiring systems can cause an electrical

re.

• No not leave the machine unattended. Never allow

anyone to reach into the machine while it is operating.

Exhaust Hazard

• Always stop the engine before beginning service.

• Verify that all machine guards and covers are attached

properly to the machine before starting the engine.

Do not start the engine if any guards or covers are not

properly installed on the machine.

• If you must run the engine during maintenance

procedures, make sure you have a helper to

keep bystanders clear of the machine and make

observations of moving parts as requested by the

operator.

• Always turn the start switch to the OFF position after

operation is complete and remove the key from the

switch. Keep the key in your possession when the

machine is not operating.

• Attach a “Do Not Operate” tag near the key switch

while performing maintenance on the equipment.

• Never operate the engine while wearing a headset to

listen to music or radio because it will be difcult to

hear the warning signals.

• Always start the engine or operate the controls while

you are seated in the operators seat.

Alcohol and Drug Hazard

Never operate the engine while under the

inuence of alcohol or drugs, or when ill.

All internal combustion engines create

carbon monoxide gas during operation and

special precautions are required to avoid

carbon monoxide poisoning:

• Never block windows, vents or other means of

ventilation if the Rosco Maximizer 3B Asphalt

Distributor is operating in an enclosed area.

• Always ensure that all connections are tightened to

specications after repair is made to the exhaust

system.

Entanglement/Sever Hazard

Verify there are no people, obstacles or

other equipment near the Rosco Maximizer

3B Asphalt Distributor before starting the

engine. Sound the horn as a warning

before starting the engine.

If the engine must be serviced while it is

operating, remove all jewelry, tie back long

hair and keep hands, other body parts and

clothing away from moving/rotating parts.

Piercing Hazard

Avoid skin contact with high-pressure

hydraulic uid or diesel fuel spray caused

by a hydraulic or fuel system leak. A broken

hydraulic hose or fuel injection line can

cause injury. High-pressure hydraulic uid

or fuel can penetrate your skin and result in serious

injury. If you are exposed to high-pressure hydraulic uid

or fuel spray, obtain prompt medical treatment.

• Never check for a hydraulic uid or fuel leak with your

hands. Always use a piece of wood or cardboard.

Have your authorized LeeBoy Dealer or distributor

repair the damage.

2-4

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 17

Flying Object Hazard

Safety

Always wear eye protection when cleaning

the Rosco Maximizer 3B Asphalt Distributor

with compressed air or high-pressure

water. Dust, ying debris, compressed air,

pressurized water or steam may injure your

eyes.

Coolant Hazard

Wear eye protection and rubber gloves

when handling engine coolant. If contact

with the eyes or skin should occur, ush

eyes and wash immediately with clean

water.

Burn Hazard

Some of the machine surfaces become

very hot during operation and shortly after

shutdown.

• Keep hands and other body parts away from hot

machine surfaces.

• Handle hot components with heat-resistant gloves.

The safety messages that follow have CAUTION level

hazards.

Poor Lighting Hazard

Ensure that the work area is adequately illuminated.

Always install wire cages on portable safety lights.

Tool Hazard

Always use tools appropriate for the task at hand and

use the correct size tool for loosening or tightening

Rosco Maximizer 3B Asphalt Distributor parts.

The safety messages that follow have NOTICE level

hazards.

Any part which is found defective as a result of

inspection or any part whose measured value does not

satisfy the standard or limit must be replaced.

Always tighten components to the specied torque.

Loose parts can cause Rosco Maximizer 3B Asphalt

Distributor damage or cause it to operate improperly.

Only use replacement parts approved by LeeBoy. Other

replacement parts may affect warranty coverage.

Follow the guidelines of the EPA or other

governmental agencies for the proper

disposal of hazardous materials such as

engine oil, diesel fuel and engine coolant.

Consult local authorities or reclamation

facility.

• Clean all accumulated dirt and debris away from

the body of the machine and its components before

you inspect the machine or perform preventive

maintenance procedures or repairs. Operating

a machine with accumulated dirt and debris will

cause premature wear of machine components.

Accumulated dirt and debris also hinders effective

machine inspection.

• Retrieve any tools or parts that may have dropped

inside of the machine to avoid improper machine

operation.

• Dispose of hazardous materials in accordance with

all applicable laws and regulations. Never dispose of

hazardous materials by dumping them into a sewer, on

the ground, or into groundwater or waterways.

• If any alert indicator illuminates during machine

operation, stop the engine immediately. Determine

the cause and repair the problem before continuing to

operate the machine.

2

Return to

Rosco Maximizer 3B Asphalt Distributor 2-5

Last Viewed

Return to

Thumb Index

Page 18

Safety

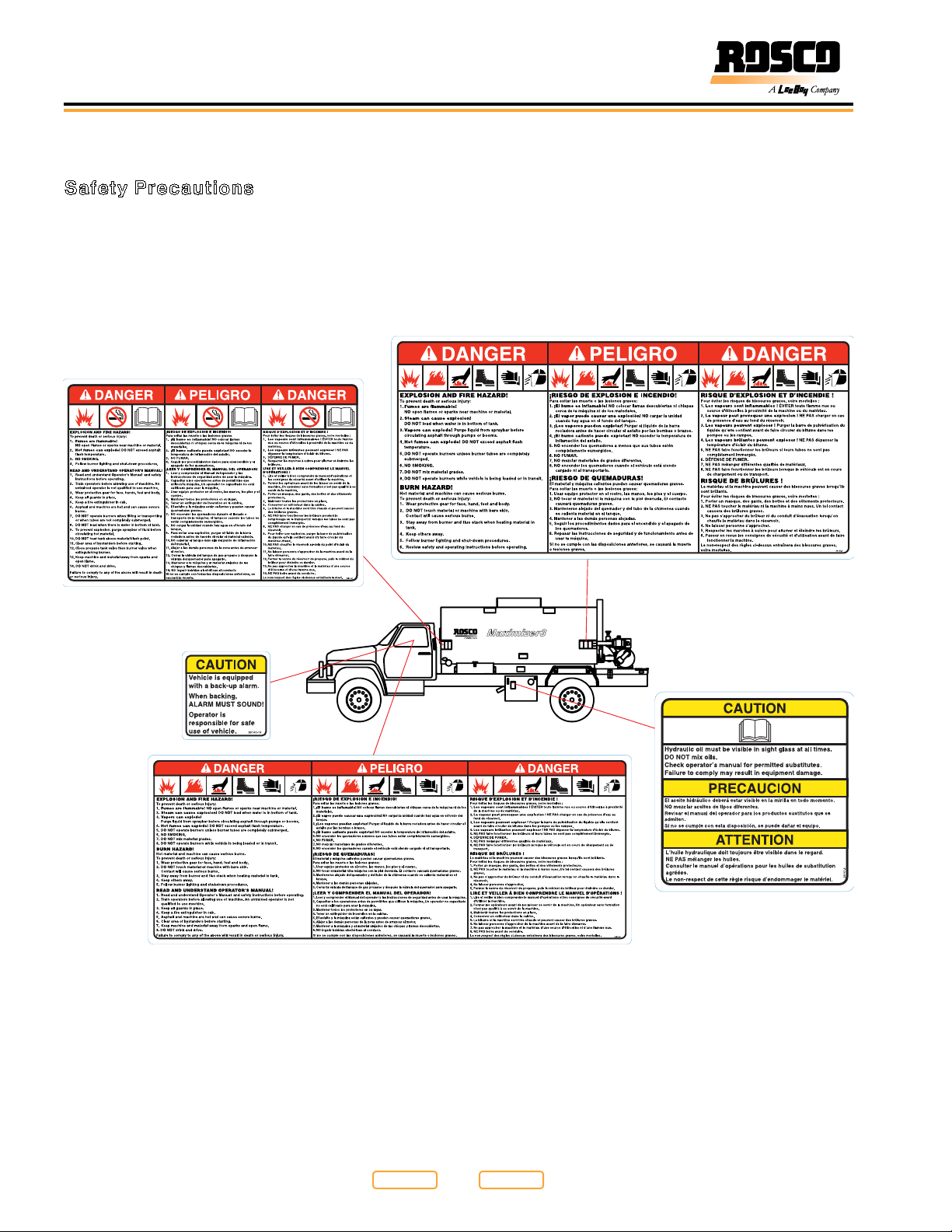

Safety Label Locations

Safety Precautions

If your machine has been repainted, it is extremely

important that all the decals referring to CAUTION,

WARNING, and DANGER be replaced in their proper

locations. The illustrations on this page will aid you in

determining the proper locations. For additional help,

you should refer to the parts listing in the parts section

of this manual and note the description column.

A description of location is provided below for each

safety label. For additional instructions, contact your

dealer (see Safety Label Installation in Section 7).

NOTE: It is the responsibility of the owner and operator

to make sure that all safety labels are readable

and located on machine as designated by

LeeBoy.

2-6

Safety Labels and Safety Label Locations

Figure 2-1

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 19

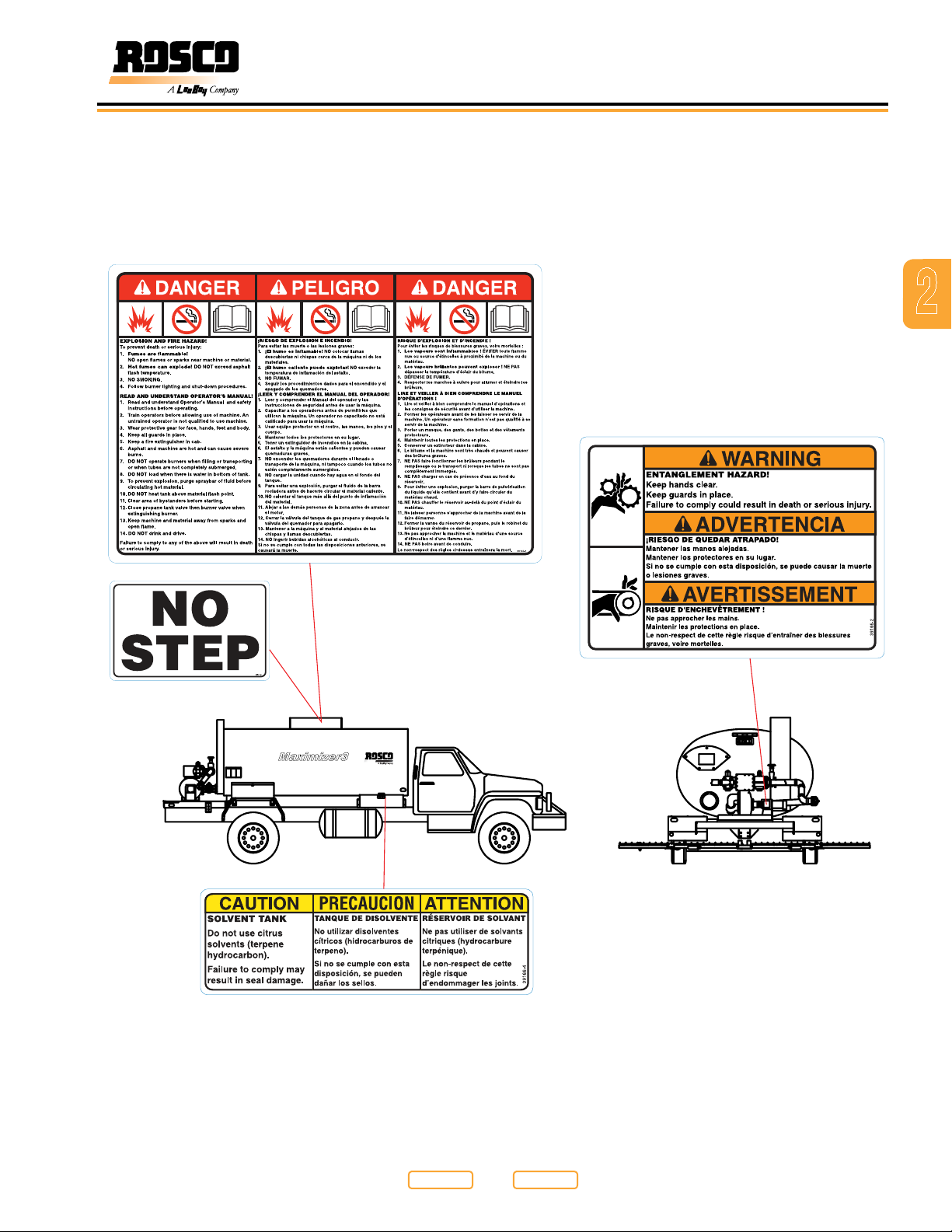

Safety

2

Safety Labels and Safety Label Locations

Figure 2-2

Return to

Rosco Maximizer 3B Asphalt Distributor 2-7

Last Viewed

Return to

Thumb Index

Page 20

Safety

NOTES

2-8

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 21

Section 3

General Information

Page

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Limited Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Items Not Covered . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Other Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Record of Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Return to

Rosco Maximizer 3B Asphalt Distributor 3-1

Last Viewed

Return to

Thumb Index

Page 22

General Information

Limited Warranty Policy

Warranty

1. Subject to the limitations, exclusions, and claims

procedures set forth herein, LeeBoy warrants [to

the rst retail purchaser] that this product will be

free from [substantial] defects in materials and

workmanship during the warranty period.

2. If a defect in material or workmanship is found, your

authorized LeeBoy Dealer is to be notied during

the warranty period. LeeBoy and its authorized

Dealer will repair or replace any part or component

of the unit or part that fails to conform to the

warranty during the warranty period.

3. The warranty period will begin on the initial start-up,

training and delivery of the unit by the Dealer to the

customer, and will expire after twelve (12) months

following the delivery of the machine to the rst retail

purchaser. (See Dealer for additional warranty.)

4. Manufacturers’ Warranties: Engines are warranted

by their manufacturers and may have warranty

coverage that differs from that of LeeBoy. LeeBoy

does not warrant any engine.

5. Replacement parts furnished by LeeBoy are

covered for the remainder of the warranty period

applicable to the unit or component in which such

parts are installed.

6. LeeBoy has the right to repair any component or

part before replacing it with a new one.

7. All new replacement parts purchased by a LeeBoy

Dealer will carry a six-month warranty.

8. This Limited Warranty is governed by the laws of the

State of North Carolina.

THE FOREGOING WARRANTY IS EXCLUSIVE AND

IN LIEU OF ALL OTHER EXPRESSED, STATUTORY

AND IMPLIED WARRANTIES APPLICABLE TO

UNITS, ENGINES, OR PARTS INCLUDING WITHOUT

LIMITATION, ALL IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR USE OR PURPOSE OR AGAINST

INFRINGEMENT.

Limitations

LeeBoy has no obligation for:

1. Any defects caused by misuse, misapplication,

negligence, accident or failure to maintain or use

in accordance with the most current operating

instructions.

2. Unauthorized alterations.

3. Defects or failures caused by any replacement

parts or attachments not manufactured by or

approved by LeeBoy.

4. Failure to conduct normal maintenance and

operating service including, without limitation,

providing lubricants, coolant, fuel, tune-ups,

inspections or adjustments.

5. Unreasonable delay, as established by LeeBoy, in

making the applicable units or parts available upon

notication of a service notice ordered by same.

6. Warranty Responsibility: The warranty responsibility

on all engines rests with the manufacturer of the

engine.

7. Warranty and Parts Support: LeeBoy may

have support agreements with some engine

manufacturers for warranty and parts support.

However, LeeBoy does not warrant the engine.

8. This Limited Warranty sets forth your sole remedy

in connection with the sale or use of the LeeBoy

product covered by this Limited Warranty.

9. This Limited Warranty extends only to the rst retail

purchaser, and is not transferable.

10. In the event any portion of this Limited Warranty

shall be determined to be invalid under any

applicable law, such provision shall be deemed null

and void and the remainder of the Limited Warranty

shall continue in full force and effect.

3-2

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 23

General Information

Items Not Covered

LeeBoy is not responsible for the following:

1. All used units or used parts of any kind.

2. Repairs due to normal wear and tear or brought

about by abuse or lack of maintenance of the

Machine.

3. Attachments not manufactured or installed by

LeeBoy.

4. Liability for incidental or consequential damages of

any type including, but not limited to, lost prots or

expenses of acquiring replacement equipment.

Other Limitations

IN NO EVENT, WHETHER AS A RESULT OF BREACH

OF CONTRACT OR WARRANTY OR ALLEGED

NEGLIGENCE OR LIABILITY WITHOUT FAULT, SHALL

LEEBOY BE LIABLE FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES INCLUDING, WITHOUT

LIMITATION, LOSS OF PROFIT OR REVENUE, COST

OF CAPITAL, COST OF SUBSTITUTED EQUIPMENT,

FACILITIES OR SERVICES, DOWNTIME COSTS,

LABOR COSTS OR CLAIMS OF CUSTOMERS,

PURCHASERS OR LESSEES FOR SUCH DAMAGES.

IN NO EVENT WILL WARRANTY COMPENSATION,

OR OTHER DAMAGES AVAILABLE FROM LEEBOY,

EXCEED THE PURCHASE PRICE OF THE PRODUCT.

3

Return to

Rosco Maximizer 3B Asphalt Distributor 3-3

Last Viewed

Return to

Thumb Index

Page 24

General Information

Contact Information

For information regarding parts and repairs about your

LeeBoy product, rst contact the dealer you purchased

your product from.

Sales Representative:

Dealership Name:

Dealership Address:

Dealership Phone:

Record of Ownership

Please ll out the following information and use it

when you need to contact LeeBoy for service, parts or

literature.

Machine Model Number:

Machine Serial Number:

Date of Purchase:

Nameplate

If you have a persistent problem your dealer is unable to

resolve, contact LeeBoy directly.

Record dealer information in the space provided.

For additional information about LeeBoy, please visit:

www.leeboy.com.

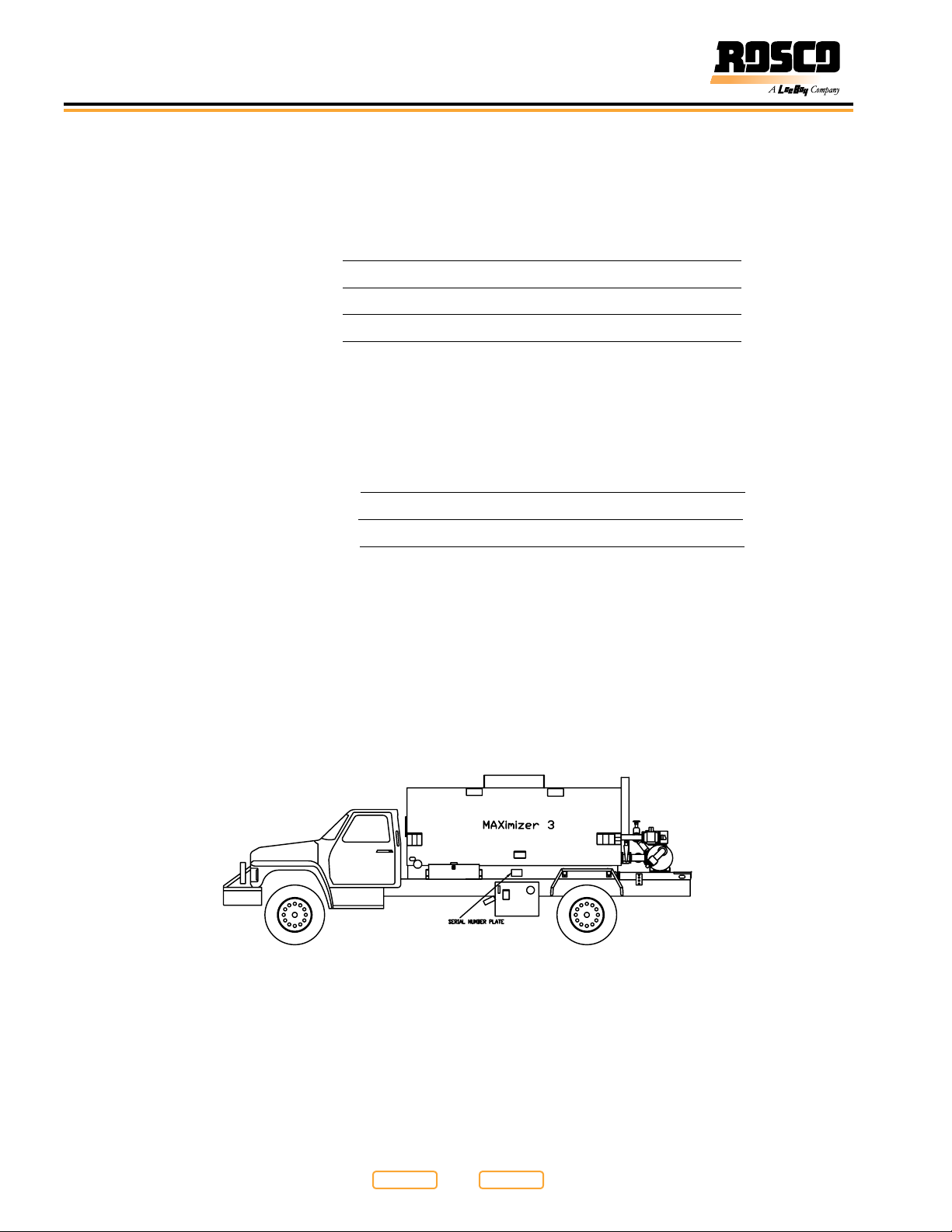

Nameplate (Figure 3-1) contains the specic model number and serial number used to identify the components for any parts or service information.

Nameplate Location

Figure 3-1

3-4

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 25

Section 4

Specifications

Page

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Circulating System . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Burner System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Plus One Controller . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

In-Cab Operator System . . . . . . . . . . . . . . . . . . . . . . . 4-3

Material Considerations . . . . . . . . . . . . . . . . . . . . . . . 4-4

Specication Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Torque Specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Metric Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Inch Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Hydraulic Fittings . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Full Torque Nut Coupling Installation . . . . . . . . . . . . . . . . . 4-12

Return to

Rosco Maximizer 3B Asphalt Distributor 4-1

Last Viewed

Return to

Thumb Index

Page 26

Specications

General Information

The descriptions and specications provided in this

section are applicable to the Rosco Maximizer 3B

Asphalt Distributor.

This section contains a description of how the major

components operate. It also includes specications for

the major system components. Included in this section

are machine weights, dimensions, performance, and

major system specications for the machine.

General

The Rosco Maximizer 3B Asphalt Distributor is used

for the transportation and distribution of asphalt-based

products for road maintenance and repair. The machine

can spray asphalt emulsions, asphalt cements and

cutback asphalts. LeeBoy strongly recommends the

use of asphalt emulsions. Water based emulsions

reduce the risk of re and explosion.

The Maximizer 3B should not be used

to distribute water, calcium chloride or other deicing liquids. These materials can corrode the pump

and valves and dangerously contaminate the tank.

If these materials are used in a Maximizer 3B, the

warranty is voided on those components affected by

the material.

System Overview

The Maximizer 3B consists of a truck-mounted insulated

tank ranging in capacity from 1,000 to 4,000 gal. (3,785

to 15,142 liters). ROSCO Distributors are equipped with

a heating system that will maintain the asphalt at the

proper spray temperature.

The Distributor has a power driven asphalt pump

capable of handling products ranging from light

applications of emulsied asphalt to heavy asphalt

cements heated to spraying viscosity. At the back of

the tank is a system of spraybars with nozzles through

which asphalt is forced under pressure and applied to

the road surface. The spraybars cover widths ranging

from 4 in. to 20 ft. (10 cm to 6.1 m) in one pass.

Circulating System

The circulating system has an engine driven hydraulic

pump which drives the hydraulic motor. The hydraulic

motor powers the asphalt pump, allowing the pump to:

• ll the distributor tank

• circulate material through the bar and tank

• spray material through the bar or hand spray

• draw material back to the tank from the bar or hand

spray

• pump material from the tank to outside storage

• transfer material from one storage tank to another

The spraybar must have a constant and uniform

pressure along the entire length of the bar for uniform

output at each nozzle.

The Rosco Maximizer 3B Asphalt Distributor delivers a

volume of asphalt to the spraybar which is regulated by

a number of variables, including:

• asphalt pump speed

• application rate setting

• truck speed

• spraybar width

The on-board computer senses the different values and

controls the asphalt pump speed to deliver the precise

amount of asphalt to the spraybar.

Both the application rate and spray pattern are

inuenced by factors such as the selected application

rate, the truck speed and nozzle size.

If the nozzles are too small for the application rate and

truck speed, the liquid will atomize, the spray pattern

will distort and the result will be excessive over-spray

or inconsistent application rate. If the nozzles are

too large, the result will be streaking caused by low

spraybar pressure (see Valves And Nozzles in Section

6).

The circulating system and the burner system are

the main systems on the Maximizer 3B. Read these

sections so you are aware of the functions and

capabilities of the unit and its systems.

Return to

4-2

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 27

Specications

Burner System

USE BURNERS PROPERLY! Burners are used to

increase the temperature of liquid asphalt material to

the correct spraying temperatures. The burners should

only be used while the liquid asphalt material is being

circulated in the tank.

If the material has cooled to the point

that it will not ow easily and will not circulate, the

operator must use extra care. Improper heating will

cause damage to the equipment and the material

being heated.

The burners in the Maximizer 3B have a very high

heat output which must be dissipated through the

asphalt. Asphalt is an excellent insulator and resists the

conduction of heat through the material.

If the material is heated too hot or too quickly without

the proper circulation, hot spots will be created near the

rear of the tank at the ue tubes. This will damage the

ue tubes and cause a break down of the material.

Operating the burners without

circulating the product can create explosive fumes.

If the product can not be circulated after 15 minutes

of heating, the fuel to the burners must be turned off,

while leaving the blowers running. Do not try to heat

material again for 30 minutes.

If it is necessary to heat asphalt that has cooled more

than 20 to 30 degrees below the optimum spraying

temperature, the operator must use extreme care in

reheating the material.

Run the burners for short periods of

time (15 minutes ON, 15 minutes OFF) to allow the

heat to dissipate through the material. This will

prevent damage to the ue liner.

The amount of time necessary to heat the asphalt

material to allow proper circulation and heating will

vary depending on the type of material, the type of

burners, the tank size and the amount of material in the

tank. If you have any doubts about the proper way to

heat cooled asphalt, contact your asphalt supplier or

equipment manufacturer.

The Burners are located at the left rear of the Maximizer

3B. The ame from the burner is directed through

the re tubes along the bottom of the tank. Diesel or

propane can be used as fuel, depending on the burner

option specied.

Never operate the burners without rst reviewing the

instructions.

Plus One Controller

The Plus One system is used to automatically control

the application rate of the asphalt distributor truck. It is

capable of automatically maintaining constant asphalt

application rates regardless of changes in distributor

speed and spraybar width. The controller has on/off

toggle switches to provide spray nozzle control along

the spraybar in 1 foot (.3 m) increments.

Distributor functions are set by selecting one of eight

modes of operation. Each mode of operation denes

the behavior of the automatic asphalt valves and the

spraybar valves for the distributor function selected. A

software memory feature is included to store up to 12

user dened presets of operating parameters for quick

setup of application rates and speed calibrations.

Selectable readouts on the in-cab control panel display

the following in real time; distributor ground speed (fpm),

asphalt spray rate (gpm), total distance sprayed (ft), total

gallons sprayed (gal), total area sprayed (sq.yd.), ow

& speed calibration application rate (gal/sq.yd.), tank

temperature (degree F), hour meter (hr), and spraybar

length (ft).

The controller uses either a GPS Speed Sensor or

an (optional) Radar Horn Speed Sensor to measure

distributor ground speed necessary for application rate

calculations and real time display of distributor metrics.

Rear controls are located in the tool box on the right

hand side rear fender and are used to control asphalt

pump speed, asphalt pump direction, spraybar hydraulic

functions and the optional washdown pump when rear

control priority is selected.

In-Cab Operator System

The main console located in the truck cab contains a

DP610 color display and utilizes a toggle switch system

for Maximizer 3B spraybar control. Truck control

parameters and modes of operation are selected

through the DP610 display using programmable soft

keys. Setup functions and real time monitoring functions

are stored and processed in the DP610.

In addition, the console includes a Master Power ON/

OFF toggle switch, Burner switch, and potentiometer for

the control of asphalt pump speed and direction when

in MANUAL mode and front control priority. Parameters

are used to congure options installed on specic trucks

as well as increase memory and data storage capacity.

A CAN signal allows communication between the In-Cab

Controller and the control modules located in the valve

box at the rear of the truck.

4

Return to

Rosco Maximizer 3B Asphalt Distributor 4-3

Last Viewed

Return to

Thumb Index

Page 28

Specications

Material Considerations

NOTE: All information in the Material Considerations

section was obtained from publications of the

Asphalt Institute.

This section will help the operator better understand the

properties of the asphalt product being used (see Table

4-4. Guideline Temperatures For Liquid Asphalts).

The selection of the right product is generally

dependent on the following considerations:

1. Availability of various types of aggregate.

2. Availability of various liquid asphalt grades.

3. Climate conditions during applications.

4. Trafc conditions during application.

5. Contract specications.

NOTE: The information given in the charts in this section

is based on industry standards. It is important to

note that some asphalt product manufacturers

have grades or mixtures which do not conform

to industry standards. These materials are often

tailored to local conditions and may provide

superior performance to standard grades.

There are many types and grades of asphalt products.

The best results can be obtained through the trial of

several different types of asphalt and aggregates. The

following classications and grades of asphalts are

provided to help in the selection.

Asphalt Cement (AC):

Cutback Asphalt:

• An asphalt cement which has been liqueed by

blending with petroleum solvents. Upon exposure to

the air, the solvents evaporate, leaving the asphalt

cement to perform its function of cementing and

waterproong.

When using cutback asphalts, extreme

caution must be used to prevent re or explosion. Do

not use open ames or sparks near these materials.

Use controlled heat only. Never use open ames to

examine tanks in which these materials have been

used or stored. Be sure all vehicles transporting

these materials are properly vented. Allow only

experienced personnel to handle these materials.

Be sure all applicable interstate and intrastate

commerce requirements are met.

Cutback asphalts are divided into three main grades.

1. Rapid Curing (RC) Asphalt: A cutback asphalt of

high volatility composed of asphalt cement using

naphtha or gasoline-type dilutant.

2. Medium Curing (MC) Asphalt: Cutback asphalt of

medium volatility composed of asphalt cement and

kerosene-type dilutant.

3. Slow Curing (SC) Asphalt: A cutback asphalt of low

volatility composed of asphalt cement and oils.

It is important to remember that

cutback asphalts are often used at temperatures

above their ash points. Serious injury can occur

from burns.

• Asphalt that is rened to meet specications for

paving, industrial, and special purposes.

Return to

4-4

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 29

Specications

Emulsified Asphalt:

• An emulsion of asphalt cement and water with a small

amount of an emulsifying agent. The emulsifying agent

determines the charge of the asphalt particles. It may

have a negative (-) charge called anionic, or a positive

(+) charge called cationic.

NOTE: An anionic type of emulsion will work best with

aggregates having positive (+) surface charges

such as limestone and dolomite.

A cationic type of emulsion will work best with

aggregates having negative (-) surface charges

such as siliceous or granitic aggregates.

DO NOT mix emulsion types,

especially anionic with cationic.

Standard grades of Emulsied Asphalt are:

Anionic (- charge):

• RS-1, RS-2, MS-1, MS-2, MS-2h, HFMS-1, HFMS-2,

HFMS-2h, HFMS-2s, SS-1, SS-1h.

Cationic (+ charge):

• CRS-1, CRS-2, CMS-2, CMS-2h, CSS-1, CSS-1h.

• RS, MS, SS: Indicate the emulsion setting rate. (Rapid

Set, Medium Set, Slow Set)

• h, s: Indicate if a hard or soft base asphalt is used in

the mix.

Contamination

It is very important to remember that when you are

loading a new material into the Maximizer, you must

be sure that the new material is compatible with the

residual material in the tank. The safest thing to do is

to completely clean out the tank and the entire system.

Total clean out is essential if you are not sure of the last

material that was used in the unit.

However, some materials can be loaded with a small

residual amount (0.5 % of capacity or less) of the

previous material remaining in the tank, (see Guide For

Loading Asphalt Products in Section 4).

To reduce the risks of re or explosion, follow Table

4-5. Guide For Loading Asphalt Products to eliminate

contamination.

When incompatible materials are mixed, it can increase

the possibility that the material will not meet the job

specications. More importantly, mixing materials can

increase the risk of re or explosion. For example, light

hydrocarbons may be present in a tank from previous

loads or from diesel oil or solvents used in cleaning the

tank.

Be sure the tank has no water in it

before loading. Hot material will turn water into

steam and can cause an explosion.

4

• HF: Indicates High-Float which means chemicals have

been added to permit a thicker lm of asphalt on the

aggregate particles to prevent drain off of asphalt

from the aggregate.

• C: Indicates a cationic asphalt. The absence of the

letter “C” means it is anionic asphalt.

Viscosity

Viscosity is a uid’s resistance to ow (how thick and

gluey a uid is). The recommended viscosity for spraying

with a distributor is 25 to 50 Saybolt Furol seconds (45 -

100 Centistokes Kinematic Viscosity).

The recommended viscosity for loading or pumping

is a maximum of 400 Saybolt Furol seconds (800

Centistokes Kinematic Viscosity).

Viscosities above these ranges will limit the

performance of the machine. Your asphalt provider will

be able to tell you the viscosity of your product.

Return to

Rosco Maximizer 3B Asphalt Distributor 4-5

Last Viewed

Return to

Thumb Index

Page 30

Specications

Specification Tables

The specications provided in this section are

applicable to the Rosco Maximizer 3B Asphalt

Distributor. Included in this section are dimensions,

performance, and torque values for both metric and

standard inch fasteners.

Replace original equipment only with

LeeBoy approved components.

Table 4-1. Tank Specication Table

ITEM SPECIFICATION

Tank Capacity 1000 U.S. gallons (3,785 L) to 4000 U.S. gallons (15,142

L) with overage for expansion.

Tank Meets all applicable Federal DOT tank regulations.

Elliptical shape. 10 gauge (3 mm) shell and 7 gauge

(4.5 mm) at heads, anged reinforced and welded to

shell inside & and outside of tank. All seams electrically

welded.

Shell 10 GA, elliptical shape shell. 7 GA at heads, ange

reinforced and electrically welded to shell inside and

outside of tank.

Thermometers Armored pencil inspector’s type 50° F to 500° F (10° C

to 260° C) and 5 inch (127 mm) dial type 50° F to 500°

F (10° C to 260° C) mounted on front left side of tank in

pipe well. Tank temperature sensor, located at rear of

tank, displayed on color display of in-cab controller.

Full Surge Plates 10 gauge (3 mm) steel with staggered openings.

Insulation 2 inch (51 mm) rock wool with spacers to prevent

compression, and clips to secure position of insulation.

Weatherproof aluminum jacket.

Top Opening 22 inch (558 mm) diameter with weather tight and safety

relieving cover. Inside splash guards, 3 inch (76 mm)

diameter, steel measuring stick, basket type strainer,

overow pipe, and tank vent.

Sump 8 inch (203 mm) diameter at rear of tank with 4 inch (102

mm) clean-cut plug. Suction line from pump includes

tank cut-off valve.

Heating System Double ue with 8 inch (203 mm) inside diameter tubing.

Exhaust Stack Stainless steel with rain cover.

Burners Dual diesel red burner with electronic ignition and heat

limit controls. Dual, U-type high-temperature ue pipe

running the length of the tank.

Asphalt Pump Viking 400 GPM (1514 LPM) capacity, rotary gear pump

with built in relief valve for safety. Located at rear of unit

with suction piping to tank sump. Driven by low-speed,

high-torque, xed displacement hydraulic motor.

Distributing Lines High-temperature, exible metal hoses.

Clean Out Connection to asphalt pump for clean-out of pump and

piping. 25 gallon (94.6 L) ush tank.

4-6

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 31

Specications

Table 4-1. Tank Specication Table (continued)

ITEM SPECIFICATION

Spray System 16 foot (4.9 m) full circulating, extendable spraybar,

comprised of two 8 foot (2.4 m) independently

controlled spraybar sections. When in spray mode and

if corresponding nozzle enable switches are enacted

each nozzle turns on when the spraybar is extended and

turns off when retracted. All functions operated by the

Plus One Controller in the cab.

Nozzles and Valves Brass, slotted nozzles. Non-clogging system. Manual

valve actuators allow the operator to control spray in 4

inch (10.16 cm) increments as the spraybar extends and

retracts.

Table 4-2. Controller Specication Table

ITEM SPECIFICATION

Controller Plus One Controller works with electronic pump speed

control to govern the application rate according to the

distributor speed and spraybar width. Provides On/Off

control of spray nozzles in 1 foot (.3 m) increments. 4

inch (10.16 cm) nozzle control is possible with spraybar

extension and retraction. Memory feature capable of

storing 12 preset application rates included. Provides

readouts for speed (FPM), pump ow (GPM), total

asphalt sprayed (gallons), total area covered (square

yards), tank temperature, total run time meter (hours),

spraybar width (feet and inches). System includes GPS

speed sensor and rear mounted controls for manual

control of asphalt pump speed and direction as well as

hydraulic spraybar functions.

4

Return to

Rosco Maximizer 3B Asphalt Distributor 4-7

Last Viewed

Return to

Thumb Index

Page 32

Specications

Table 4-3. Additional Standard and Optional Equipment Specication Table

STANDARD OPTIONAL

Handspray gun with 25 foot (7.6 m) hose PTO driven hydraulic pump from truck transmission

Front and rear dial contents gauge Outre protection on diesel burner

Sampling valve LPG burner in lieu of diesel burner

ICC clearance lights and reectors Portable LP torch with pressure regulators and

connections to frame mounted 52 gallon (197 L) tank

Back up alarm Low density electric heat

Rear bumper and a 4-way mirror Washdown system with pump and hose for cleaning the

spraybar

Mud aps Hose reel for the washdown hose

Ladder and platform assembly Loading hose 3 inch by 15 foot (7.6 cm X 4.6 m) exible

steel with quick couplers

Grease gun Loading hose 3 inch by 15 foot (7.6 cm X 4.6 m) rubber

with quick couplers

Enviro-Flush recirculating clean-out system 18 foot (5.5 m) spraybar system

20 foot (6.1 m) spraybar system

Radar Horn Speed Sensor (option in lieu of GPS)

Table 4-4. Guideline Temperatures For Liquid Asphalts

TYPE & GRADE SPRAY TEMP STORE TEMP MIN FLASH POINT

Asphalt Cements °C °F °C °F °C °F

AC -2.5 130+ 270+ 160 320 163 325

AC-5 140+ 280+ 166 330 177 350

AC-10 140+ 280+ 174 345 219 425

AC-20 145+ 295+ 177 350 232 450

AC-40 150+ 300+ 177 350 232 450

AR-1000 135+ 275+ 163 325 205 400

AR-2000 140+ 285+ 168 325 219 425

AR-4000 145+ 290+ 177 350 227 440

AR-8000 145+ 290+ 177 350 232 450

PEN 40-50 150+ 300+ 177 350 232 450

PEN 60-70 145+ 295+ 177 350 232 450

PEN 85-100 140+ 280+ 177 350 232 450

PEN 120-150 130+ 270+ 177 350 219 425

PEN 200-300 130+ 270+ 168 335 177 350

4-8

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 33

Specications

Table 4-4. Guideline Temperatures For Liquid Asphalts (continued)

TYPE & GRADE SPRAY TEMP STORE TEMP MIN FLASH POINT

Emulsied Asphalts °C °F °C °F °C °F

MC-30 30+ 80+ 54 130 38 100

MC-70 50+ 120+ 71 160 38 150

MC-250 75+ 165+ 91 195 66 150

MC-800 95+ 200+ 99 210 66 150

MC-3000 110+ 230+ 99 210 66 150

RC-70 50+ 120+ 71 160 - RC-250 75+ 165+ 91 195 27 80

RC-800 95+ 200+ 99 210 27 80

RC-3000 110+ 230+ 99 210 27 80

SC-70 50+ 120+ 71 160 66 150

SC-250 75+ 165+ 91 195 79 175

SC-800 95+ 200+ 99 210 93 200

SC-3000 110+ 230+ 99 210 107 225

RS-1 20 - 60 70 - 140 20 - 60 70 - 140

RS-2 50 - 85 125 - 185 50 - 85 125 - 185

HFRS-2 50 - 85 125 - 185 50 - 85 125 - 185

MS-1 20 - 70 70 - 160 10 - 60 50 - 140

MS-2 20 - 70 70 - 160 50 - 85 125 - 185

MS-2h 20 - 70 70 - 160 50 - 85 125 - 185

HFMS-1 20 - 70 70 - 160 10 - 60 50 - 140

HFMS-2 20 - 70 70 - 160 50 - 85 125 - 185

HFMS-2h 20 - 70 70 - 160 50 - 85 125 - 185

HFMS-2s 20 - 70 70 - 160 50 - 85 125 - 185

SS-1 20 - 70 70 - 160 10 - 60 50 - 140

SS-1h 20 - 70 70 - 160 10 - 60 50 - 140

CRS-1 50 - 85 125 - 185 50 - 85 125 - 185

CRS-2 50 - 85 125 - 185 50 - 85 125 - 185

CMS-2 20 - 70 70 - 160 50 - 85 125 - 185

4

CMS-2h 20 - 70 70 - 160 50 - 85 125 - 185

CSS-1 20 - 70 70 - 160 10 - 60 50 - 140

CSS-1h 20 - 70 70 - 160 10 - 60 50 - 140

Return to

Rosco Maximizer 3B Asphalt Distributor 4-9

Last Viewed

Return to

Thumb Index

Page 34

Specications

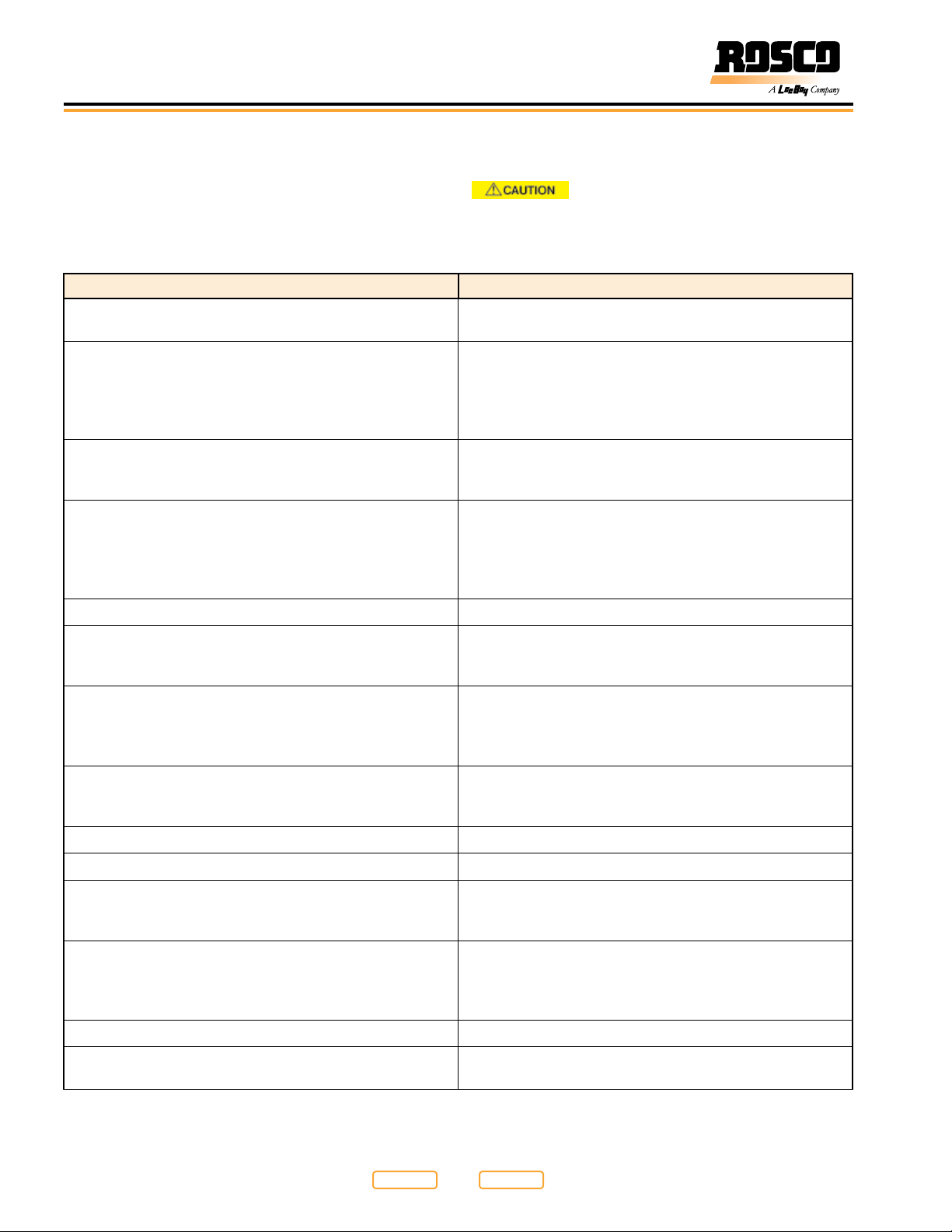

Table 4-5. Guide For Loading Asphalt Products

PRODUCT TO BE LOADED

LAST PRODUCT IN

TANK

Asphalt Cement OK to load Ok to load Empty to no

Cutaback Cement * Empty Tank Ok to load Empty to no

Cationic Emulsion * Empty Tank Empty to no

Anionic Emulsion * Empty Tank Empty to no

Crude Petroleum and

Residual Fuel Oils

Any Product not

listed above

ASPHALT CEMENT

* Empty Tank Empty to no

Tank must be

cleaned

CUTBACK

ASPHALT

measurable quantity

measurable quantity

measurable quantity

Tank must be

cleaned

CATIONIC

EMULSION

measurable quantity

measurable quantity

Ok to load Empty to no

Empty to no

measurable quantity

Empty to no

measurable quantity

Tank must be

cleaned

ANIONIC

EMULSION

Empty to no

measurable quantity

Empty to no

measurable quantity

measurable quantity

Ok to load

Empty to no

measurable quantity

Tank must be

cleaned

*

Torque Specs

Metric Fasteners

for standard hardware and are intended as a guide

for average application involving typical stresses

NOMINAL SIZE

& PITCH

M4 x 0.7 2.27 1.70 3.07 2.30 2.27 2.31 4.17 3.13

M5 x 0.8 4.58 3.43 6.20 4.65 6.22 4.67 8.43 6.33

M6 x 1 7.75 5.83 10.5 7.90 10.60 7.97 14.3 10.8

M8 x 1.25 18.89 14.17 25.6 19.2 18.95 19.26 34.8 26.1

M10 x 1.25 39.11 29.52 53.0 40.1 53.87 40.59 73.0 55.0

M12 x 1.75 64.94 48.71 88.0 66.0 88.56 66.42 120.0 90.0

M14 x 2 103.32 77.49 140.0 105.0 140.22 107.01 190.0 145.0

M16 x 2 162.36 121.77 220.0 165.0 221.40 166.05 300.0 225.0

M20 x 2.5 317.34 236.16 430.0 320.0 428.04 321.03 580.0 435.0

M24 x 3 516.12 409.59 740.0 555.0 754.38 557.19 1010.0 755.0

M27 x 3 797.04 597.78 1080.0 810.0 1084.86 811.80 1470.0 1100.0

M30 x 3.5 1084.86 811.80 1470.0 1100.0 1476.00 1107.00 2000.0 1500.0

Any material remaining in tank will produce dangerous conditions.

and machined surfaces. Values are based on

physical limitations of clean, plated and lubricated

hardware. In all cases, when an individual torque

value is specied, it should be followed instead of

The following Table lists torque values

Table 4-6. Torque Specications For Metric Fasteners

CLASS 8.8 [GRADE 5 EQUIVALENT] CLASS 10.9 [GRADE 8 EQUIVALENT]

TORQUE FT. LBS. TORQUE N•m TORQUE FT. LBS. TORQUE N•m

Dry Lubed Dry Lubed Dry Lubed Dry Lubed

values given in this table.

Replace original equipment with

hardware of equal grade.

4-10

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 35

Specications

Inch Fasteners

The following Table lists torque values

for standard hardware and are intended as a guide

for average application involving typical stresses

and machined surfaces. Values are based on

Table 4-7. Torque Specications For Standard Inch Fasteners

CAPSCREWS: SAE GRADE 5 CAPSCREWS: SAE GRADE 8

SIZE THREAD TORQUE FT. LBS. TORQUE N•m TORQUE FT. LBS. TORQUE N•m

Dry Lubed Dry Lubed Dry Lubed Dry Lubed

1/4 20 UNC 8 6 11 9 12 9 16 12

28 UNF 10 7 13 10 14 10 19 14

5/16 18 UNC 17 13 24 18 25 18 33 25

24 UNF 19 14 26 20 27 20 37 28

3/8 16 UNC 31 23 42 31 44 33 59 44

24 UNF 35 26 47 36 49 37 67 50

7/16 14 UNC 49 37 67 50 70 52 95 71

20 UNF 55 41 75 56 78 58 105 79

1/2 13 UNC 75 57 100 77 105 80 145 110

20 UNF 85 64 115 86 120 90 165 120

9/16 12 UNC 110 82 145 110 155 115 210 155

18 UNF 120 91 165 125 170 130 230 175

5/8 11 UNC 150 115 205 155 210 160 285 215

18 UNF 170 130 230 175 240 180 325 245

3/4 10 UNC 265 200 360 270 375 280 510 380

16 UNF 295 225 405 300 420 315 570 425

7/8 9 UNC 430 320 580 435 605 455 820 615

14 UNF 475 355 640 480 670 500 905 680

1 8 UNC 645 485 875 655 910 680 1230 925

14 UNF 720 540 980 735 1020 765 1380 1040

1-1/8 7 UNC 795 595 1080 805 1290 965 1750 1310

12 UNF 890 670 1210 905 1440 1080 1960 1470

1-1/4 7 UNC 1120 840 1520 1140 1820 1360 2460 1850

12 UNF 1240 930 1680 1260 2010 1500 2730 2050

1-3/8 6 UNC 1470 1100 1990 1490 2380 1780 3230 2420

12 UNF 1670 1250 2270 1700 2710 2040 3680 2760

1-1/2 6 UNC 1950 1460 2640 1980 3160 2370 4290 3210

12 UNF 2190 1650 2970 2230 3560 2670 4820 3620

physical limitations of clean, plated and lubricated

hardware. In all cases, when an individual torque

value is specied, it should be followed instead of

values given in this table.

Replace original equipment with

hardware of equal grade.

4

Return to

Rosco Maximizer 3B Asphalt Distributor 4-11

Last Viewed

Return to

Thumb Index

Page 36

Specications

Hydraulic Fittings

Tightening Flare Type Tube Fittings

1. Check the are and are seat for defects that might

cause leakage.

2. Align tube with tting before tightening.

3. Lubricate connection and hand tighten swivel nut

until snug.

Table 4-8. Torque Specications For Flare Type Tube Fittings

NUT SIZE

TUBE SIZE OD

(in) (in) (N•m) (lb-ft) (N•m) (lb-ft)

3/16 7/16 8 6 1 1/6

1/4 9/16 12 9 1 1/6

5/16 5/8 16 12 1 1/6

3/8 11/16 24 15 1 1/6

1/2 7/8 46 34 1 1/6

5/8 1 62 46 1 1/6

3/4 1 1/4 102 75 3/4 1/8

7/8 1 3/8 122 90 3/4 1/8

(ACROSS

FLATS)

TORQUE VALUE

4. To prevent twisting the tube(s), use two wrenches.

Place one wrench on the connector body and with

the second, tighten the swivel nut to the torque

shown in Table 4-8. Torque Specications For

Flare Type Tube Fittings.

NOTE: The torque values shown are based on

lubricated connections as in assembly.

RECOMMENDED TURNS TO

TIGHTEN (AFTER FINGER

TIGHTENING)

Full Torque Nut Coupling Installation

The only completely reliable method of creating a

consistent leak free, long lasting connection is to ensure

that the coupling is brought to the proper torque.

The best method of ensuring a coupling is brought to the

proper torque is to use a torque wrench with crowfoot.

To ensure the proper torque is met, use the ats method

of torque verication. Flats method may be used alone

in situations where a torque wrench is inaccessible or

unavailable.

There are 7 steps involved in proper coupling

installation:

1. Determine the correct torque value for your

coupling.

NOTE: Only use the torque values specied from

the manufacturer, do not use SAE torque

recommendations.

The minimum torque values are adequate for

sealing in most applications, and the maximum

torque values should never be exceeded.

2. Calculate the correct torque wrench setting using

(see Equations in Section 4).

NOTE: The most straight forward method of determining

the correct torque setting is to multiply the

desired torque by the length of the wrench from

the center of the handle to the center of the drive

(L) divided by the length of the wrench from the

center of the handle to the crowfoot center (LA),

(Figure 4-1).

LA

L

Torque Wrench - Crowfoot

Figure 4-1

NOTE: Torque Wrench Setting = Desired Torque * L / LA

3. Ensure that the seal face and threads are clean

and in good condition. Do not lubricate coupling

threads.

4-12

Return to

Thumb Index

Return to

Last Viewed

Rosco Maximizer 3B Asphalt Distributor

Page 37

Specications

NOTE: O-Rings should be lubricated with light oil, but

threads should be completely dry unless making

pipe thread connections (interference seal).

Attach the male end of the hose onto the

equipment rst, since it may be necessary to

rotate the entire hose assembly to tighten the

male threads. Then route the hose into position

while avoiding twisting the hose.

4. Hand tighten the connection by bringing seal face in

contact and rotating the nut by hand until it stops.