Page 1

DEVELOPMENT OF

TIME-AND-DISTANCE GUIDELINES FOR USE OF

THEATRICAL SMOKE EQUIPMENT:

ROSCO DELTA 3000

Prepared for:

Rosco Laboratories

Stamford, Connecticut

Prepared by:

ENVIRON International Corporation

Groton, Massachusetts

May 2004

Page 2

C O N T E N T S

Page

I. INTRODUCTION ...............................................................................................................1

A. Background..............................................................................................................1

B. Use of Time-and-Distance Guidelines.....................................................................2

II. TESTING METHODOLOGY.............................................................................................3

A. Monitoring Equipment.............................................................................................3

B. Monitoring Procedures.............................................................................................3

III. RESULTS AND DISCUSSION ..........................................................................................6

A. Aerosol Monitor Calibration....................................................................................6

B. Peak Exposure Characterization ..............................................................................6

C. How to Use the Time-and-Distance Guidelines Tables...........................................7

IV. REFERENCES .................................................................................................................15

ROSCO DELTA 3000 -i- E N V I R O N

Page 3

F I G U R E S

Figure 1: Rosco Delta 3000 fog machine................................................................................4

Figure 2: Monitoring configuration.........................................................................................5

Figure 3: Calibration curve for Rosco Clear Fog Fluid in Delta 3000 fog machine...............9

Figure 4: Calibration curve for Rosco Light Fog Fluid in Delta 3000 fog machine...............9

Figure 5: Calibration curve for Rosco Fog Fluid in Delta 3000 fog machine.......................10

Figure 6: Calibration curve for Rosco Stage and Studio Fluid in Delta 3000

fog machine............................................................................................................10

Figure 7: Guidelines for use of Rosco Clear Fog Fluid in Delta 3000 fog machine.............11

Figure 8: Guidelines for use of Rosco Light Fog Fluid in Delta 3000 fog machine ............12

Figure 9: Guidelines for use of Rosco Fog Fluid in Delta 3000 fog machine.......................13

Figure 10: Guidelines for use of Rosco Stage and Studio Fog Fluid in Delta 3000 fog

machine..................................................................................................................14

T A B L E S

Table 1: Summary of Calibration Factors..............................................................................6

Table 2: Summary of Time-and-Distance Guidelines for Smoke Generation.......................8

ROSCO DELTA 3000 -ii- E N V I R O N

Page 4

I. INTRODUCTION

A. Background

In 1997-99, at the request of Actors’ Equity Association (AEA) and the League of

American Theaters and Producers (LATP) and with the support of the Equity-League Pension

and Health Trust Funds, investigators from the Mount Sinai School of Medicine (Mt. Sinai) and

ENVIRON International Corporation (ENVIRON) conducted a study to determine whether the

use of smoke, haze, and pyrotechnics special effects in theatrical musical productions is

associated with a negative health impact in actors. The results of this study were presented in the

report Health Effects Evaluation of Theatrical Smoke, Haze, and Pyrotechnics (Mt. Sinai and

ENVIRON 2000).

Based on the results of the study, Mt. Sinai and ENVIRON recommended the following

peak guidance levels with respect to glycols and mineral oil:

The use of glycols should be such that an actor’s exposure does not exceed 40

•

milligrams per cubic meter (mg/m

•

Mineral oil should be used in a manner such that an actor’s exposure does not exceed

a peak concentration of 25 mg/m3.

•

For chronic exposures to mineral oil, the existing standards established for oil mists

(5 mg/m

3

as an eight-hour time-weighted average) should also be protective for actors

in theatrical productions.

Comparable guidance levels were developed for glycerol in a subsequent study (ENVIRON

2001c):

• Glycerol should be used in a manner such that an actor’s exposure does not exceed a

peak concentration of 50 mg/m

• For chronic exposures to glycerol, the existing standards established for glycerin

mists (10 mg/m3 as an eight-hour TWA) should also be protective for actors in

theatrical productions.

To ensure that peak smoke and haze levels are below these guidelines, theaters have the

option of conducting production-specific testing at their theaters using an aerosol monitor or

following equipment-based time-and distance guidelines. Rosco Laboratories (Rosco) retained

ENVIRON to develop time-and-distance guidelines for the use of the Rosco Delta 3000 fog

machine (Figure 1).

3

).

3

.

ROSCO DELTA 3000 -1- E N V I R O N

Page 5

B. Use of Time-and-Distance Guidelines

In the absence of other information, theater-specific monitoring would be required to

determine whether smoke/haze machines are being used in a production in a manner that avoids

peak exposures to actors. The Time-and-Distance Guidelines described in this report were

developed as an alternative

to conducting theater- and production-specific monitoring. These

Guidelines were developed under conservative use assumptions (e.g., no on-stage activities or

props that would enhance dispersion, cue release at breathing height level). By following these

Guidelines, a production can use smoke effects without

having to conduct its own stage-specific

testing, provided the machines are used in accordance with manufacturer specifications, are well

maintained, and are functioning properly. Table 2 and Figure 7 to 10 of this report describe the

distance (with respect to the discharge point on the equipment) and length of time that

concentrations exceeding the peak guidance levels would occur for various use patterns for the

Delta 3000 fog machine. Thus, by arranging the blocking and choreography such that an actor is

not situated within the restricted areas during the times specified in Table 2 and Figures 7 to 10,

actors should not receive peak exposures. Time-and-Distance Guidelines for other Rosco

machines have also been developed by ENVIRON (2001b).

It should be noted that these Time-and-Distance Guidelines may not be appropriate for all

productions. The Guidelines are based on the Delta 3000 being positioned between four and five

feet above the ground, and being operated to achieve 30 to 60 seconds of continuous smoke

generation. Productions may want to use different configurations for positioning the machines

(e.g., different heights), provide enhanced on-stage ventilation, or generate smoke for a longer or

shorter period of time. In addition, many productions may have other stage-specific conditions

(e.g., on-stage activities and props that enhance dispersion) that would allow actors to be present

in areas that are restricted under these Guidelines but which, in fact, do not exceed the guidance

levels. In those cases, production-specific monitoring would be recommended to determine

whether peak exposure may occur.

ROSCO DELTA 3000 -2- E N V I R O N

Page 6

II. TESTING METHODOLOGY

A. Monitoring Equipment

Monitoring of short-term concentrations was performed using portable real-time aerosol

monitors (personalDataRAM Model PDR-1000) manufactured by Monitoring Instruments for

the Environment, Inc. (MIE). The PDR-1000 is a high sensitivity nephelometric (i.e.,

photometric) monitor that uses a light scattering sensing chamber to measure the concentration

of airborne particulate matter (liquid or solid), providing a direct and continuous readout as well

as electronic logging of the data.

The PDR-1000 aerosol monitors as obtained are calibrated to Arizona road dust over a

measurement range of 0.001 to 400 mg/m

or oil mist concentrations, the monitors were first calibrated for the smoke or haze machines and

fluids being used. Calibration of the aerosol monitors was conducted by collecting simultaneous

measurements with a series of sampling pumps and PDR-1000 aerosol monitors, mounted on

tripods.

B. Monitoring Procedures

The testing is typically conducted in a two-step process. The first step involves

collecting sufficient data to calibrate the aerosol monitors for the equipment and fluid

combination being used. The second step involves using the calibrated aerosol monitor to

identify distances from the smoke release point where exceedances of the guidance levels occur.

These monitoring data are used to develop general Guidelines under conservative use conditions

that can be used to ensure peak exposures to actors do not occur. The calibration and sampling

procedures are discussed in detail in the ENVIRON Air Sampling Protocol (ENVIRON 2001a).

For the Delta 3000 fog machine, the calibration step has already been conducted for the

following fluids: Clear Fog Fluid, Light Fog Fluid, Rosco Fog Fluid, and Stage & Studio Fluid

(ENVIRON 2002).

To measure the levels of smoke present at different distances from the release point, a

series of six tripods equipped with aerosol monitors was used. The six tripods were placed at

distances ranging from 5 to 30 feet from the Delta 3000 release point for the 100% and 50%

settings, and at distances ranging from 3 to 18 feet for the 10% setting. The Delta 3000 was

turned on for 30 to 60 seconds, allowing sustained smoke generation to occur, and then turned

off. The aerosol monitors collected logged data on the smoke levels as the concentrations

gradually dissipated. Ventilation conditions typical for a theatrical stage were used.

Testing of the Delta 3000 was conducted on the stage of the Ginsburg Theatre at

Lawrence Academy in Groton, Massachusetts.

3

. In order to be utilized to measure short-term glycol

ROSCO DELTA 3000 -3- E N V I R O N

Page 7

Figure 1. Rosco Delta 3000 Fog Machine

ROSCO DELTA 3000 -4- E N V I R O N

Page 8

Figure 2. Monitoring configuration consisting of six tripod-mounted aerosol monitors situated

at five foot intervals from the Delta 3000 machine (far left). Each tripod is equipped with an

aerosol monitor.

ROSCO DELTA 3000 -5- E N V I R O N

Page 9

×

=

III. RESULTS AND DISCUSSION

A. Aerosol Monitor Calibration

Calibration data for the Delta 3000 were collected previously by ENVIRON (2002). To

develop a calibration curve for each glycol fluid, the average aerosol monitor readings for each

air sample were calculated and plotted against the total glycol concentration data. The

calibration curves for the glycol fluids tested are shown in Figures 3 to 6. First order regression

curves are also shown on these figures. The calibration factors for the glycol fluids, calculated

from the slopes of these regressions, are summarized in Table 1.

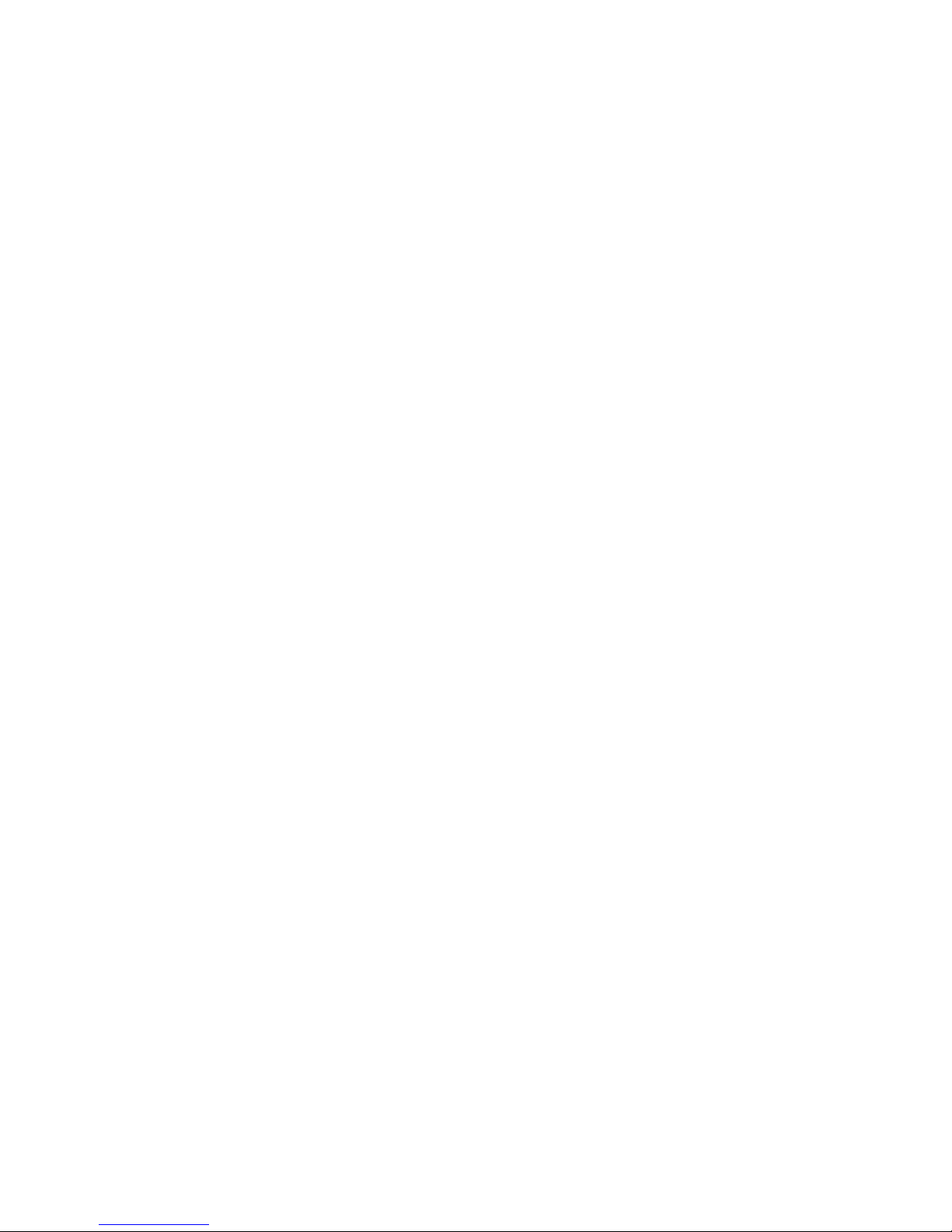

TABLE 1

Summary of Calibration Factors

Rosco Delta 3000 Fog Machine

Machine Fluid

Rosco Clear Fog Fluid 1.43

Rosco Delta 3000

Rosco Fog Fluid 1.00

Rosco Light Fog Fluid 1.35

Rosco Stage & Studio Fluid 1.97

Reference: ENVIRON (2002)

B. Peak Exposure Characterization

For 100% and 50% settings, monitoring data collected using aerosol monitors placed at

distances of 5, 10, 15, 20, 25, and 30 feet from the Delta 3000 machine were combined with the

calibration factors to determine the levels of smoke at different distances from the release point

and times following the release. For the 10% setting, the monitors were placed at distances of 3,

6, 9, 12, 15, and 18 feet. The real-time aerosol monitor readings were converted to glycol

concentrations using the appropriate calibration factor for the fluid, as follows:

PDRCCONC

where:

CONC = air concentration of total glycols, µg/L

C = aerosol monitor calibration factor (from Table 1), (µg/L)/(mg/m3)

PDR = aerosol monitor reading, mg/m

3

Calibration Factor,

(ug/L)/(mg/m3)

ROSCO DELTA 3000 -6- E N V I R O N

Page 10

Based on these calibrated data, the times after which the concentration of smoke at each

of the six distances drops below the guidance levels were determined. These Guideline values

are summarized in Table 2. Graphs showing the change in concentration at each location with

time are presented in Figures 7 through 10.

C. How to Use the Time-and-Distance Guidelines Table

For various distances from the cue release point, Table 2 provides the time (in seconds)

after the end of the cue release after which the glycol concentrations will have fallen below the

guidance levels. Thus, in order to prevent peak exposures to actors, the blocking and

choreography should be arranged such that actors are not situated within a particular distance

from the front of the smoke release point until the amount of time listed in Table 2 has elapsed

following the end of the cue. For example, if a production is using the Delta 3000 at a 50%

setting with Stage & Studio fluid, an actor should not be situated within five feet from the front

of the cue release point until at least 50 seconds following the end of the cue release; an actor

should not be situated within 10 to 15 feet from the front of the cue release point until at least 33

seconds following the end of the cue release.

It should be reiterated that the Time-and-Distance Guidelines provided in Table 2 are

intended to allow a production to use the Delta 3000 without

conducting monitoring. However,

these Guidelines may not be appropriate for all productions. Table 2 is based on the Delta 3000

being positioned between four to five feet above the ground, and being operated to achieve 30 to

60 seconds of continuous smoke generation. Productions may want to use different

configurations for positioning the machine (e.g., different heights), provide on-stage ventilation,

or generate smoke for a shorter or longer period of time. In addition, many productions may

have other stage-specific conditions (e.g., on-stage activities and props that enhance dispersion)

that would allow actors to be present in areas that are restricted under these Guidelines but

which, in fact, do not exceed the guidance levels. In those cases, production-specific monitoring

would be recommended to determine whether peak exposure may occur. For the fluids included

in this testing, the calibration factors summarized in Table 1 can be used.

ROSCO DELTA 3000 -7- E N V I R O N

Page 11

TABLE 2

Summary of Time-and-Distance Guidelines for Smoke Generation

Rosco Delta 3000 Fog Machine Based on 30-or 60-Second Releases

Time (in sec) After Which Air Concentrations Are Below Guidance Level (40 mg/m3)

Fluid

Machine

Setting

Release

Duration

(sec)

3 ft 5 ft 6 ft 9 ft 10 ft 12 ft 15 ft 18 ft 20 ft 25 ft 30 ft

100% 30 --- 215 --- --- 215 --- 215 --- 215 215 115

50% 30 --- 88 --- --- 88 --- 88 --- 88 88 70

Rosco Clear

Fog Fluid

10% 60 130 --- 130 130 --- 130 117 73 --- --- ---

100% 30 --- 157 --- --- 157 --- 157 --- 87 87 87

50% 30 --- 94 --- --- 94 --- 94 --- 57 56 44

Rosco Fog

Fluid

10% 60 58 --- 0 58 --- 58 10 0 --- --- ---

100% 30 --- 63 --- --- 63 --- 63 --- 53 53 53

50% 30 --- 60 --- --- 10 --- 0 --- 0 0 0

Rosco Light

Fog Fluid

10% 60 30 --- 0 0 --- 0 0 0 --- --- ---

100% 30 --- 53 --- --- 53 --- 53 --- 53 53 53

50% 30 --- 50 --- --- 33 --- 33 --- 28 28 23

Rosco Stage

& Studio

Fluid

10% 60 63 --- 13 13 --- 13 0 0 --- --- ---

ROSCO DELTA 3000 -8- E N V I R O N

Page 12

Rosco Laboratories

Delta 3000 / Rosco Clear Fluid

400

)

3

300

200

(Laboratory Analyzed)

100

Total Glycol Concentration (mg/m

0

0 50 100 150 200 250

Average PDR Concentration (mg/m³)

Figure 3. Calibration curve for Rosco Clear Fog Fluid in Delta 3000. Calibration factor, based

on slope of curve, is 1.43 (mg/m

400

)

3

300

200

(Laboratory Analyzed)

100

Total Glycol Concentration (mg/m

0

0 50 100 150 200 250

3

glycols)/(mg/m3 aerosol).

Rosco Laboratories

Delta 3000 / Rosco Light Fluid

Average PDR Concentration (mg/m³)

Figure 4. Calibration curve for Rosco Light Fog Fluid in Delta 3000. Calibration factor, based

on slope of curve, is 1.35 (mg/m

ROSCO DELTA 3000 -9- E N V I R O N

3

glycols)/(mg/m3 aerosol).

Page 13

Rosco Laboratories

Delta 3000 / Rosco Fog Fluid

500

)

3

400

300

200

(Laboratory Analyzed)

100

Total Glycol Concentration (mg/m

0

0 50 100 150 200 250 300 350

Average PDR Concentration (mg/m³)

Figure 5. Calibration curve for Rosco Fog Fluid in Delta 3000. Calibration factor, based on

slope of curve, is 1.00 (mg/m

500

)

3

400

300

200

(Laboratory Analyzed)

100

Total Glycol Concentration (mg/m

0

0 50 100 150 200 250

3

glycols)/(mg/m3 aerosol).

Rosco Laboratories

Delta 3000 / Rosco Stage & Studio Fluid

Average PDR Concentration (mg/m³)

Figure 6. Calibration curve for Rosco Stage & Studio Fluid in Delta 3000. Calibration factor,

based on slope of curve, is 1.97 (mg/m

ROSCO DELTA 3000 -10- E N V I R O N

3

glycols)/(mg/m3 aerosol).

Page 14

Clear Fog Fluid

250

200

150

100

Time After Release (sec)

50

0

0 5 10 15 20 25 30 35

Distance (ft)

100% (30-second release)

50% (30-second release)

10% (60-second release)

Figure 7. Guidelines for use of Rosco Clear Fog Fluid in Delta 3000 fog machine

ROSCO DELTA 3000 -11- E N V I R O N

Page 15

Light Fog Fluid

70

60

50

40

30

20

Time After Release (sec)

10

0

0 5 10 15 20 25 30 35

Distance (ft)

100% (30-second release)

50% (30-second release)

10% (60-second release)

Figure 8. Guidelines for use of Rosco Light Fog Fluid in Delta 3000 fog machine

ROSCO DELTA 3000 -12- E N V I R O N

Page 16

Rosco Fog Fluid

180

160

140

120

100

80

60

Time After Release (sec)

40

20

0

0 5 10 15 20 25 30 35

Distance (ft)

100% (30-second release)

50% (30-second release)

10% (60-second release)

Figure 9. Guidelines for use of Rosco Fog Fluid in Delta 3000 fog machine

ROSCO DELTA 3000 -13- E N V I R O N

Page 17

Stage & Studio Fluid

70

60

50

40

30

20

Time After Release (sec)

10

0

0 5 10 15 20 25 30 35

Distance (ft)

100% (30-second release)

50% (30-second release)

10% (60-second release)

Figure 10. Guidelines for use of Rosco Stage and Studio Fog Fluid in Delta 3000 fog machine

ROSCO DELTA 3000 -14- E N V I R O N

Page 18

IV. REFERENCES

ENVIRON International Corporation (ENVIRON). 2001a. Evaluation of short-term exposures

to theatrical smoke and haze: Air sampling protocol. Prepared for Equity-League

Pension and Health Trust Funds. May 14.

ENVIRON International Corporation (ENVIRON). 2001b. Equipment-based guidelines for use

of theatrical smoke and haze. Revision 1. Prepared for Equity-League Pension and

Health Trust Funds. June 8.

ENVIRON International Corporation (ENVIRON). 2001c. Theatrical Haze and Fog Testing for

Mamma Mia!, Winter Garden Theatre. Prepared for Mamma Mia! Broadway and Nina

Lannan Associates. November 12.

ENVIRON International Corporation (ENVIRON). 2002. Development of Calibration Factors

for Monitoring Theatrical Smoke and Haze. Prepared for Entertainment Services and

Technology Association. November 11.

Mount Sinai School of Medicine and ENVIRON International Corporation (Mt. Sinai and

ENVIRON). 2000. Health effects evaluation of theatrical smoke, haze, and

pyrotechnics. Prepared for Equity-League Pension and Health Trust Funds. June 6.

ROSCO DELTA 3000 -15- E N V I R O N

Page 19

June 22, 2004

MEMORANDUM

To: Eric Tishman, Rosco Laboratories

From: Alan Kao

Subject: Addendum to Time-and-Distance Guidelines for Rosco Delta 3000

In the report Development of Time-and-Distance Guidelines For Use Of Theatrical Smoke

Equipment: Rosco Delta 3000 dated May 2004 (“T&D Guideline report”), ENVIRON developed

time-and-distance (T&D) guidelines for the use of four Rosco fog fluids in the Delta 3000 fog

machine. These T&D guidelines were based on release durations of 30 seconds for the 100%

and 50% settings, and 60 seconds for the 10% setting. This memorandum provides an

adjustment factor (AF) for using different release durations than 30 or 60 seconds.

ENVIRON conducted additional testing with the Delta 3000 fog machine to evaluate the effect

on the T&D guidelines using different release durations. Release durations ranging from 5 to 60

seconds were evaluated. Figures 1 and 2 show the percent change from the 30-second and 60second T&D guidelines observed at different release durations. A linear regression was

performed on each plot to develop the following equations for:

For 100% and 50% settings:

AF = (1.36

×

RD + 59) / 100

For the 10% setting:

AF = (0.93

×

RD + 44) / 100

where:

AF = adjustment factor (unitless)

RD = release duration (sec)

For using the Rosco Delta 3000 at release durations that differ from those on which the T&D

Guideline report was based, the T&D guideline value from Table 2 can be multiplied by the

274 Main Street C P.O. Box 1220 C Groton, Massachusetts 01450 C USA C (978) 448-8788 C Fax: (978) 448-8825

www.environcorp.com

Page 20

Eric Tishman -2- June 22, 2004

calculated AF to generate an appropriate T&D guideline value for a wide range of release

durations. Values of AF for a range of release durations are provided below in Table A-1:

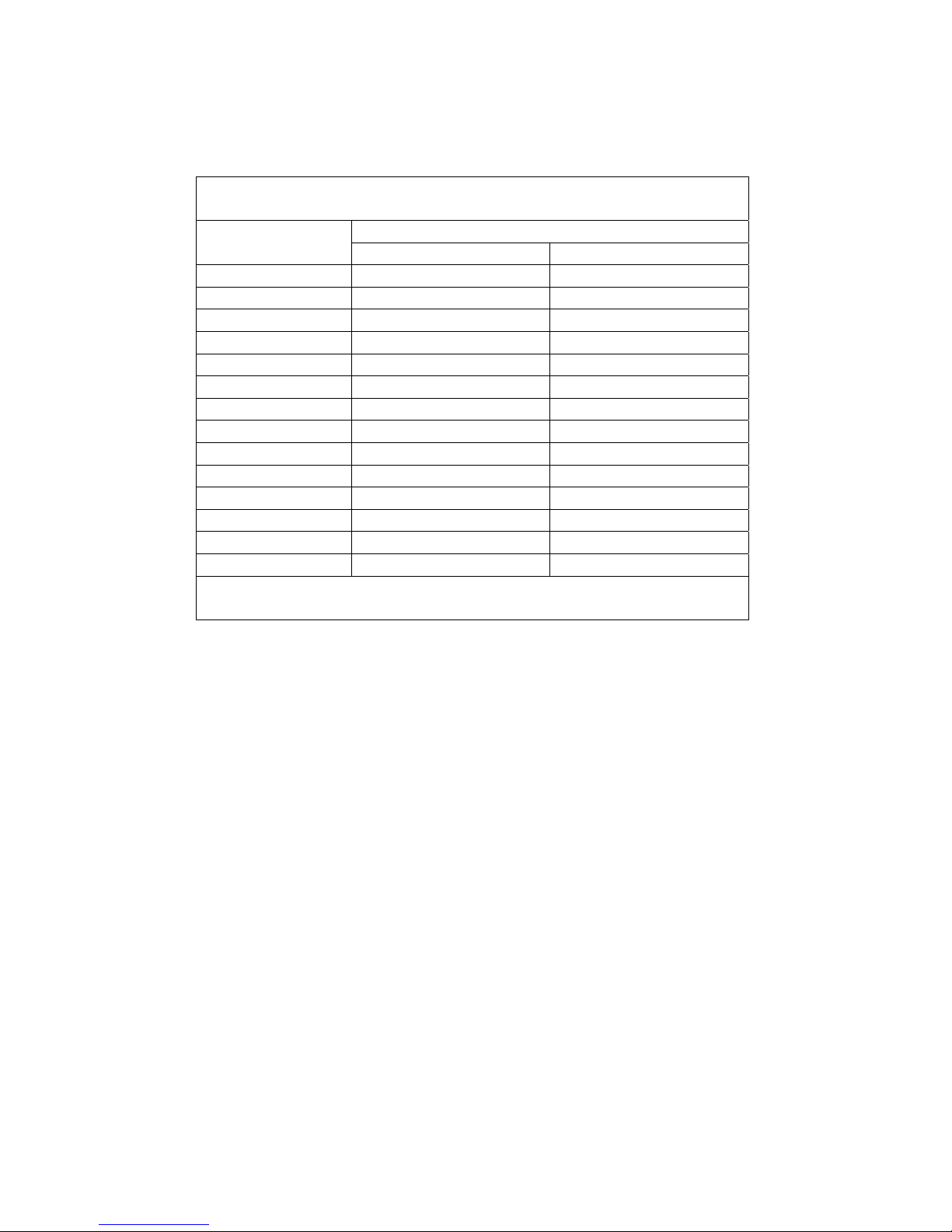

TABLE A-1

Adjustment Factors for Different Smoke Release Durations

Adjustment Factor (unitless) Release Duration

(sec)

(100% or 50% setting) (10% setting)

5 0.66 0.49

10 0.73 0.53

15 0.79 0.58

20 0.86 0.63

25 0.93 0.67

30 1.00 0.72

35 1.07 0.77

40 1.13 0.81

45 1.20 0.86

50 1.27 0.91

55 1.34 0.95

60 1.41 1.00

90 1.81 1.28

120 2.22 1.56

Note: For release durations other than those listed in this table, the

equations on page 1 of this addendum can be used to calculate AF.

Example calculations:

1. Using Rosco Fog Fluid with the Delta 3000 at a 50% setting, Table 2 from the T&D

Guideline report gives a value of 94 SECONDS at 10 feet from the release point. For a

release duration of 15 seconds, the adjustment factor is:

AF = (1.36

×

[15 sec] + 59) / 100 = 0.79

Therefore, the T&D value would be 94 seconds × 0.79 or 74 SECONDS.

2. Using Rosco Clear Fog Fluid with the Delta 3000 at a 10% setting, Table 2 from the T&D

Guideline report gives a value of 130 SECONDS at 6 feet from the release point. For a

release duration of 30 seconds, the adjustment factor is:

AF = (0.93

×

[30 sec] + 44) / 100 = 0.72

Therefore, the T&D value would be 130 seconds × 0.72 or 94 SECONDS.

Page 21

Eric Tishman -3- June 22, 2004

Figure 1. Percent change in T&D guidance value from 30-second value for 50% and 100%

settings at release durations other than 30 seconds.

Figure 2. Percent change in T&D guidance value from 60-second value for 10% setting at

release durations other than 60 seconds.

Loading...

Loading...