RORZE RC-400 User Manual

RORZE CORPORATION

INDEX

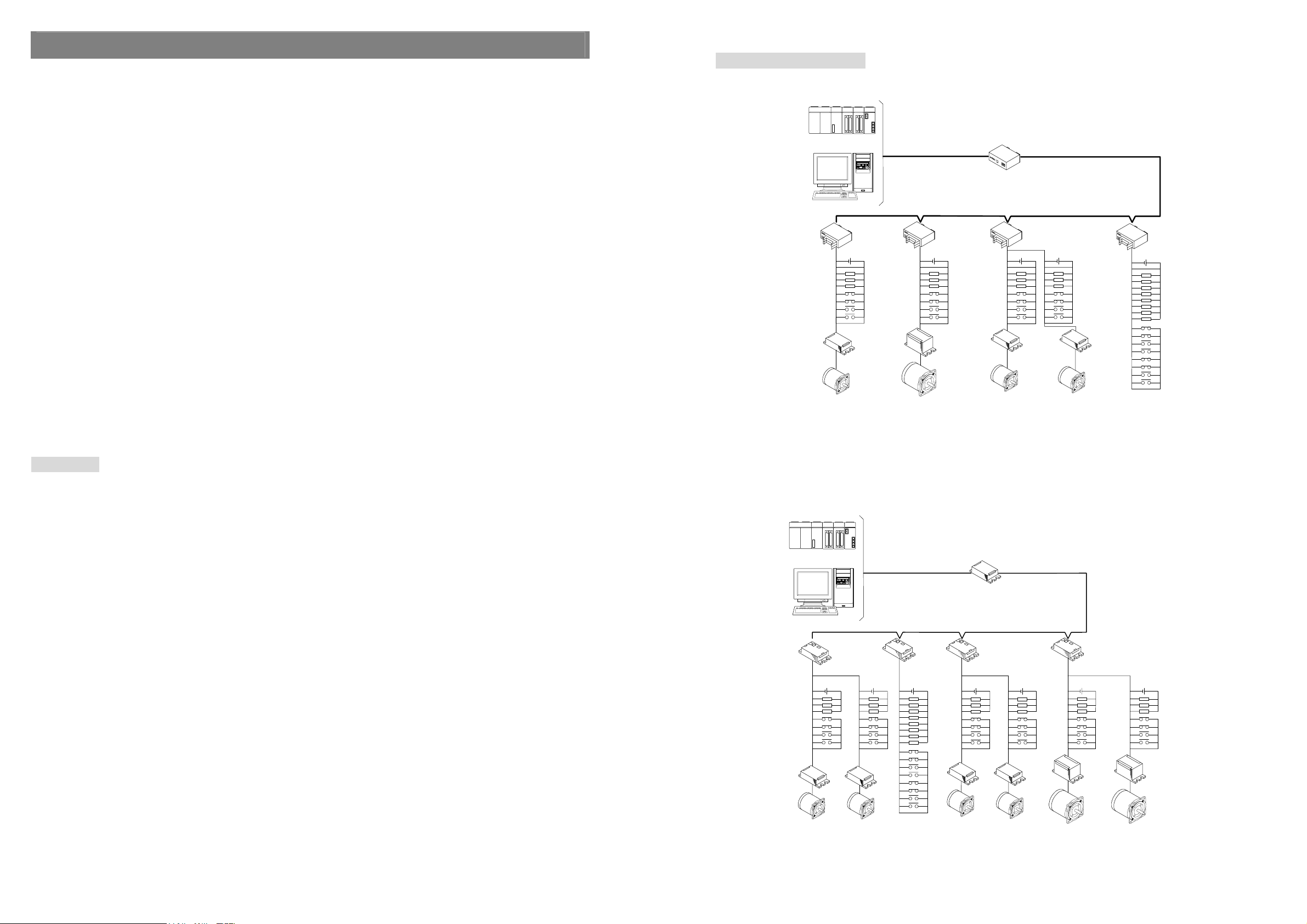

About the Masternet control system

Lineup

Controller, driver & stepping motor system configuration

Controllers RC-400 series

RC-410 RC-420 RC-400

Option connectors for wiring

Controllers RC-200 series

RC-204A RC-207A RC-234

RC-002 RC-003 RC-004

Option connectors for wiring

Stepping Motor Drivers RD series

Selection table

2-PH Stepping Motor Drivers

Pulse Input Drivers RD-022A/022NA RD-023A/023NA RD-021M8

RD-023MS RD-023MSH RD-026MSA

RD-023MB RD-026MB

Drivers with built-in RD-122A RD-123A/126A

pulse oscillator RD-323A/326A RD-323MS

RD-323M10(M50)HA/RD-326M10(M50)A

5-PH Stepping Motor Drivers

Pulse Input Drivers RD-053A/053NA RD-053MS RD-A051

Drivers with built-in

pulse oscillator RD-153A RD-353A

Stepping Motors RM series

Motor Specifications

2-PH Stepping Motors

RM2C5648-30S/D RM2C5675-60S/D

RM2414S/D RM2424S/D

RM2621S/D RM2640S/D

RM2690S/D RM26A3S/D

RM29A3S/D RM29B2S/D

5-PH Stepping Motors

RM5407SM/DM RM5411SM/DM

RM5414SM/DM RM5623S/D

RM5640S/D RM5685S/D

RM59A2S/D RM59B2S/D

RM59D0S/D

Recommended Damper

Productions to be discontinued

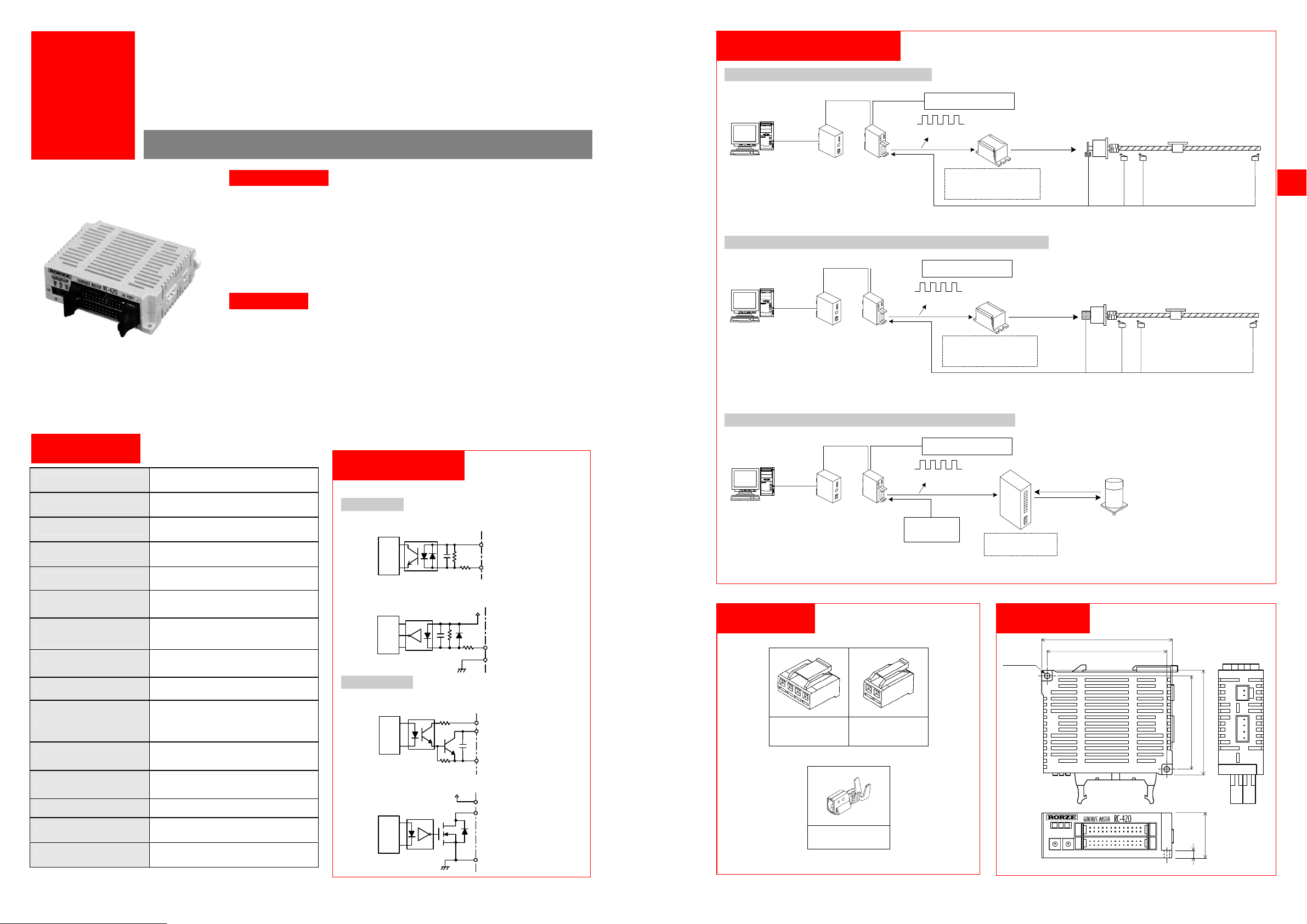

Masternet Control System

Masternet control s ystem is a system to make a control s ystem for central or remote control via a main controller

such as personal computer with RS-232C, etc.

System Configuration

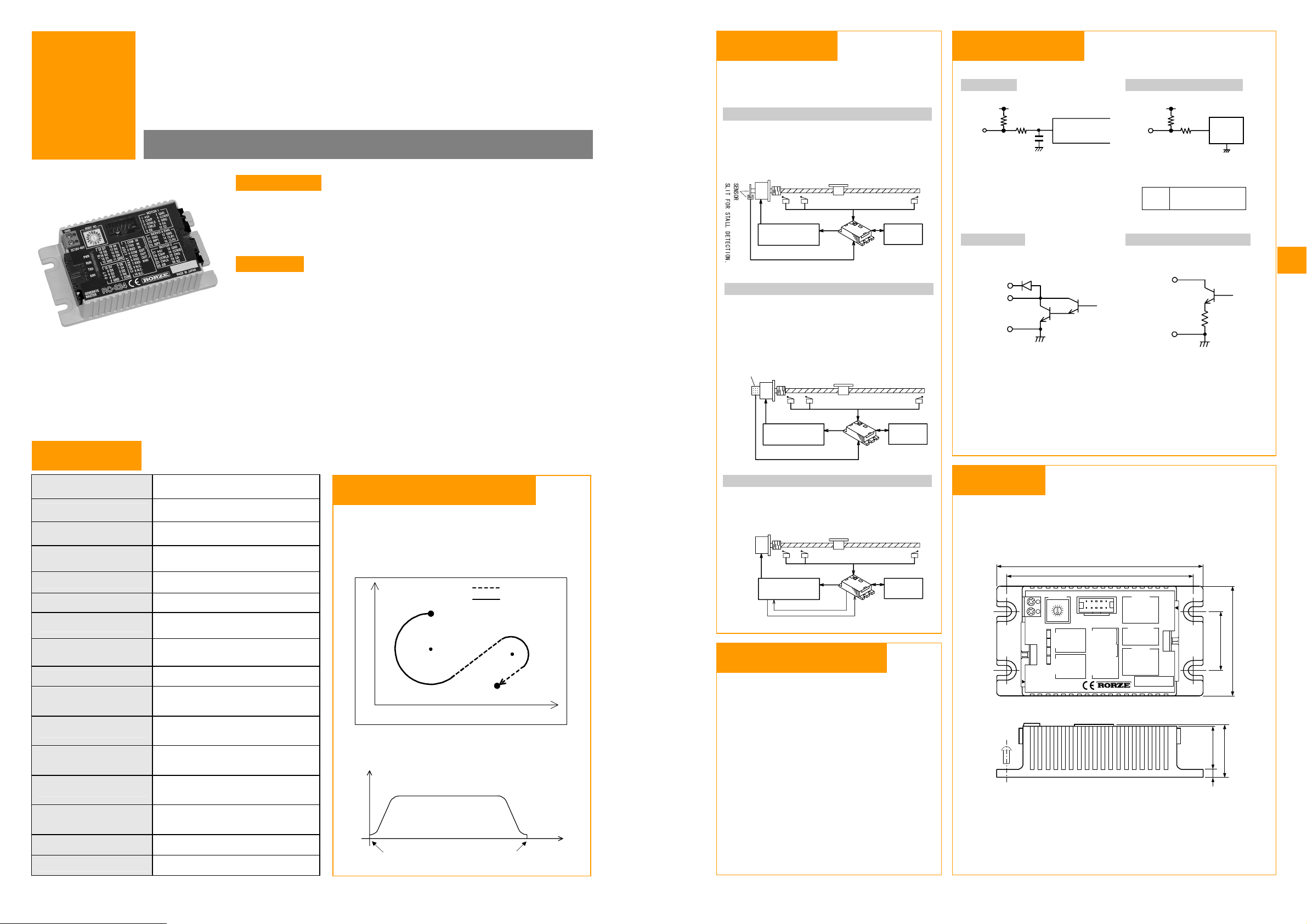

■The configlation whitch used RC-400 series

Because the system runs as a fully-distributed control system and each unit is light and compact, it can be

mounted near motors and sensors. Additionally, the number of wiring is much less because only two cables

(power and signal) are required.

These features allow you to:

(1) Start-up the system quickly.

(2) Reduce wire disconnection problems.

(3) Save time in exchanging modules in the case of a problem.

Individual subsystems are formed by the following four product lines.

1. Current Adapter, the Link Master RC-002 and RC-400 which provides th e communication between PC and

controllers.

2. Controllers with genera l I/O ports such as RC-204A, RC-207A, RC-234, R C-410 and RC-420 which can be

controlled by the communicatio n.

3. Compact stepping motor drivers (RD series) which can be mounted right near motors.

4. 2-ph/5-ph stepping motors (RM series) which are optimized to the specification of RORZE driver.

Features

・Because each controller is originally controlled by the commands received by the communication, the easy

program from PC can provide the high level control.

PLC

RS-232C

(115.2kbps max.)

LinkMaster

RC-400

PC

Generate Master

RC-420

2-ph Driver

RD-023MS

Motor

Generate Master

RC-420

2-ph Driver

RD-026MSA

Motor

・Polling is unnecessary

Link Master RC-400 m onitoring each controller by high speed RS-485 (921.6kbps max.) lightens the

burden imposed on th e host PC. (Automatic pollin g function) Also, comm unication speed between a

host PC and a RC-400 has become about 10 times faster than before. (115.2kbps max.)

■The configlation whitch used RC-200 series

I/O Master

RC-410

2-ph Driver

RD-323MS

Motor

RS-485

(921.6kbps max.)

2-ph Driver

RD-323MS

Motor

I/O Master

RC-410

・Operation software can be written in any high level language which can control RS-232C communication.

・Compact steel casings and simple wiring will make the system compact and provide free configurations.

・Because easy unit operates with DC power supply, it can built into autonomy robots.

・Modular systems make the time for development of devices shorter and the system easy to diagnose and repair.

・Can make a network system with one Link Master a nd two (RC-40 0 series) or t hree (RC-20 0 series ) cables and

subsystems can be control led from a control station up to 1.2 km (※1) away. R C-400 series can control up to

120 controllers and RC-200 series can control up to 20 controllers.

※1 In RC-200 series, the dis tance which can b e com municated var ies depend ing on the num ber of connected

controllers or the communication speed etc.

PLC

PC

2-ph Driver

RD-023MS

Motor

Generate Master

RC-234

2-ph Driver

RD-023MS

Motor

RS-232C

(9600bps)

I/O Master

RC-207A

Link Master

RC-002

I/O Master

RC-207A

2-ph Driver

RD-323MS

Motor

Current loop

(9600bps)

2-ph Driver

RD-323MS

Motor

I/O Master

RC-204A

5-ph Driver

RD-353A

Motor

5-ph Driver

RD-353A

Motor

2 3

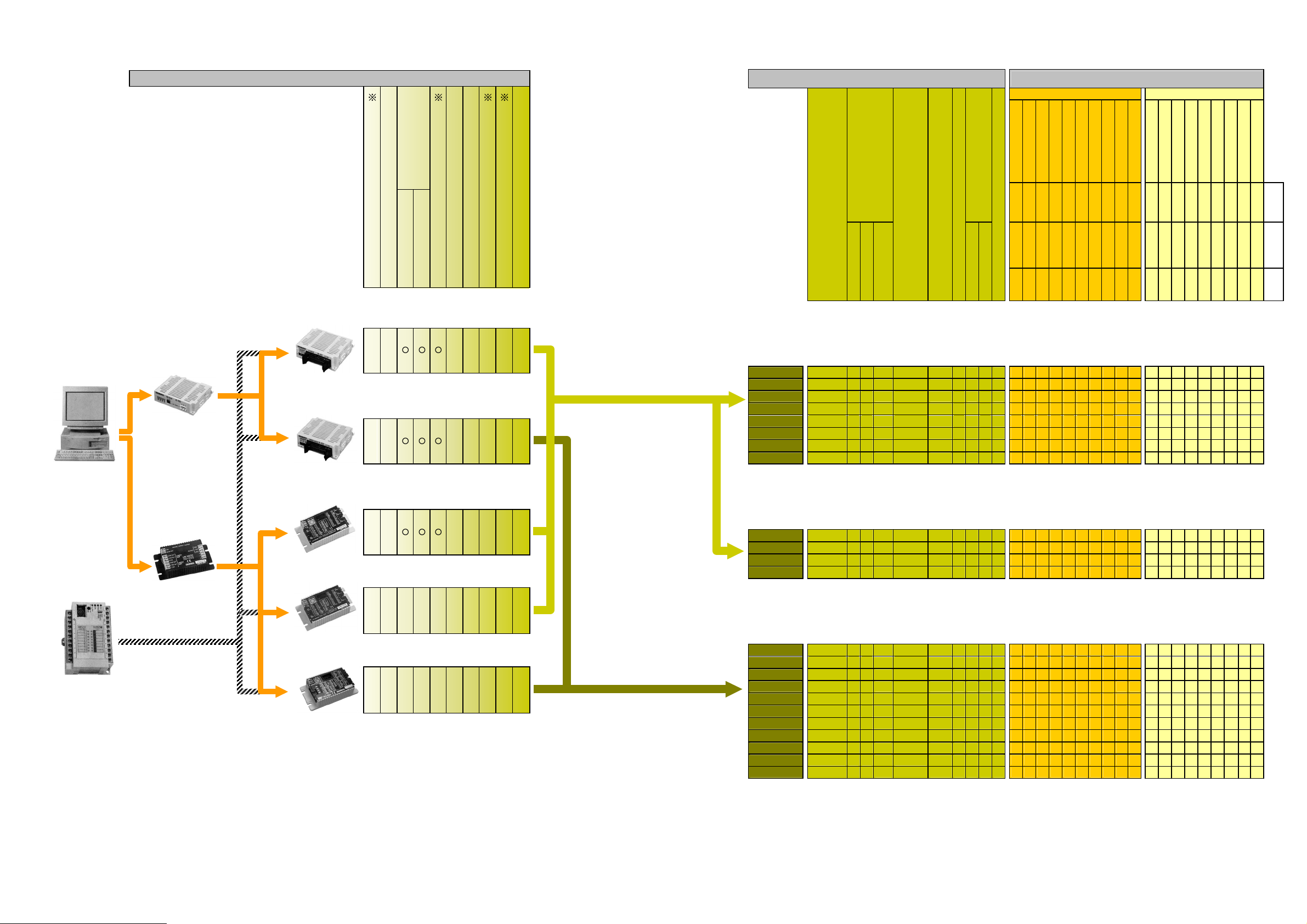

Controller, driver & stepping motor system configuration

Controllers RM seies

※

2 Control Motors (max)

No. of Profiles

Method

※

3 Stall Detection Function

Pulse Movement

User Program Memory C apacity

Maximum Pulse Rate (pps)

※

4 Input Ports ※4 Output Ports

Outside Dimensions

Drivers RD series

Motor Current (A/ph)

Excitation Method

Supply Voltage (VDC)

Stepping Motors RM series

Maximum Pulse R ate (max) (pps)

Speed Change Funct ion

Grow Out Terminal

Outside Dimensions

2-ph Stepping Motors

RM2C5648-30S/D

RM2C5675-60S/D

RM2414S/ D

RM2424S/ D

RM2621S/ D

RM2640S/ D

RM2690S/ D

RM26A3S/D

RM29A3S/D

5-ph Stepping Motors

RM29B2S/D

RM5407SM/DM

RM5411SM/DM

RM5414SM/DM

RM5323S/ D

RM5640S/ D

RM5685S/ D

RM59A2S/D

RM59B2S/D

RM59D0S/D

PC

PC

RC-400

Link Master

Dimensions: E

RC-002

Link Master

Dimensions: B

I/O

PLC

※1

※1 In case of controlling RC-207A, RC-234, RC-410 or RC-420 using PLC,

some program s downloaded via PC in advance are selected and started

by PLC.

※2

RC-410 and RC-234 can control two motors simultaneously.

RC-204A and RC-207A ca n cont rol two motors alternately. It’s impossible

for them to work two m otors together at the same time.

※3

The controllers with a stall detection function can detect stalls by

attaching a stall slit (ON-OFF cycle is fixed) and a stall sensor to moving

part. RC-420 and RC-234 can d etect a stall by encoder as well.

※4

The number of I/O port varies depending on the number and kind of m otor.

RC-410

RC-420

RC-204A

RC-207A

RC-234

Absolute

Incremental

(No. of command)

RC-410 I/O Master

2048

2048

1130

1130

1000

○ ○ ○

○ ○ ○

○ ○ ○

○

○

○

○

2

RC-420 Generate Master

1

RC-204A I/O Master

2

RC-207A I/O Master

2

RC-234 Generate Master

2

approx.

2000

200k

2000

300

○

1500

○

16

approx.

1M

16

100k

20

approx.

100k

20

approx.

1M

10

Outside Dimensions

A .....32(H)×50(W)×80(D)mm

B .....27.5(H)×105(W)×56(D)mm

C.....63(H)×56(W)×105(D)mm

D.....84(H)×40(W)×155(D)mm

E .....25(H)×86(W)×69(D)mm

F .....29.5(H)×86(W)×69(D)mm

G.....22.6(H)×105(W)×65.6(D)mm

16

10

16

16

10

Full Step

Half Step

Microstep

Resolution (max)

Digital

0.47

1.03

0.14

0.24

0.21

0.39

0.78

1.3

1.3

2.2

0.074

0.11

0.14

0.23

0.39

0.83

1.23

2.2

Analog

3.75

3.75

1.8

1.8

1.8

1.8

1.8

1.8

3.0

6.0

1.5

1.5

3.0

3.0

3.0

3.0

0.36

0.36

0.36

0.72

0.72

0.72

0.72

1.8

1.8

6.0

6.0

1.5

1.5

1.5

3.0

3.0

0.72

3.0

3.0

3.0

3.9

0.72

3.0

Holding Torque

(N・m)

Step Angle

(Degree)

Rated Current

(A/ph)

F

Drivers with built-in pulse oscillator

RD-3** Series

RD-323A 0.5~3 ○ ○ 18~40 18k ○ ○ C ○ ○ ○ ○ ○ ○

RD-326A 1~6 ○ ○ 18~40 18k ○ ○ C ○ ○

RD-323MS 0.3~3 ○ ○ 80 18~40 700k ○ ○ B ○ ○ ○ ○ ○ ○

RD-323M10HA

RD-323M50HA

F

RD-326M10A

RD-326M50A

RD-353A 0.5~3 ○ ○ 18~40 70k ○ ○ C ○ ○ ○ ○ ○ ○ ○ ○ ○

0.5~3 10 18~80 160k ○ ○ C ○ ○ ○ ○ ○ ○ ○

0.5~3 50 18~80 600k ○ ○ C ○ ○ ○ ○ ○ ○ ○

1~6 10 18~40 160k ○ ○ C ○ ○ ○

1~6 50 18~40 600k ○ ○ C ○ ○ ○

Drivers with built-in pulse oscillator

B

RD-1** Series

RD-122A 0.3~1.3 ○ ○ 18~40 14k ○ B △ △

RD-123A 0.5~3 ○ ○ 18~40 20k ○ C ○ ○ ○ ○ ○ ○

RD-126A 1~6 ○ ○ 18~40 20k ○ C ○ ○

RD-153A 0.5~3 ○ ○ 18~40 55k ○ C ○ ○ ○ ○ ○ ○ ○ ○ ○

B

Pulse Input Drivers

RD-0** Series

RD-022A 0.3~1.3 ○ ○ 18~40 25k B △ △

RD-023A 0.5~3 ○ ○ 18~40 20k C ○ ○ ○ ○ ○ ○

B

RD-021M8 0.1~1.5 ○ ○ 8 10~40 100k A ○ ○

RD-023MS 0.3~3 ○ ○ 400 18~40 500k B ○ ○ ○ ○ ○ ○

RD-023MSH 0.3~3 ○ ○ 400 18~80 500k C ○ ○ ○ ○ ○ ○ ○

RD-026MSA 0.5~6 ○ ○ 400 18~40 500k C ○ ○ ○

RD-023MB 0.1~3 ○ ○ 400 12~50 500k G ○ ○ ○ ○ ○ ○ ○

RD-026MB 0.2~6 ○ ○ 400 18~50 500k G ○ ○ ○

RD-053A 0.5~3 ○ ○ 18~40 200k C ○ ○ ○ ○ ○ ○ ○ ○ ○

RD-053MS 0.5~3 ○ ○ 400 18~40 500k C ○ ○ ○ ○ ○ ○ ○ ○ ○

RD-A051 0.2~1.5 ○ ○

AC100V

200k D ○ ○ ○

4 5

A

Compact

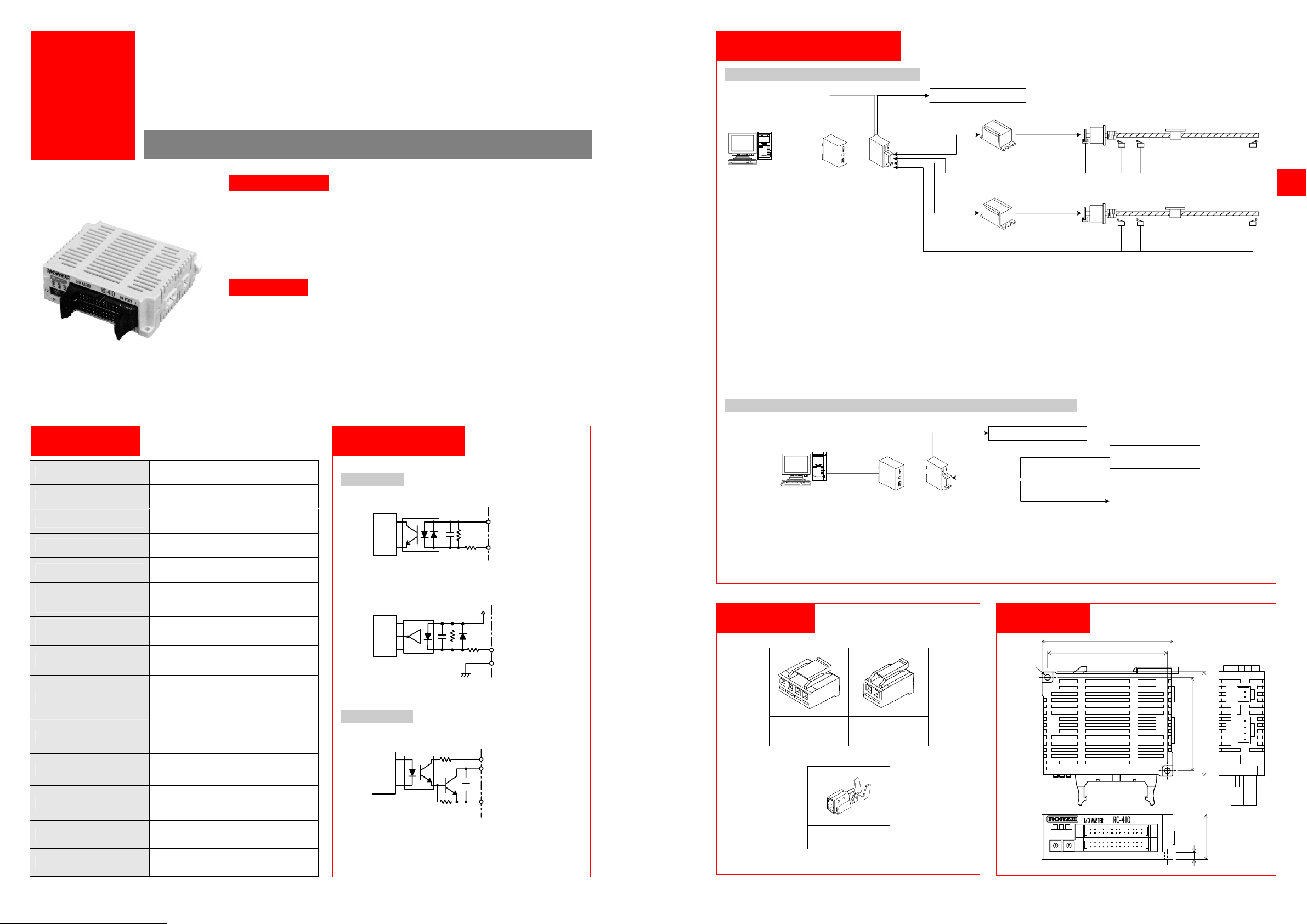

Light

Controllers to Control Stepping Motors and

1

1

1

0

0

0

I/O Ports

C

-

C

C

4

-

4

-

4

R

R

System configurations

Example 1 (Controlling two drivers)

RS-485

RS-485

To the adjacent controller

Stepping motor

I/O MASTER

Description

RC-410 is an I/O controller which has 16 Input ports and 16 Output ports.

This controller can control positioning of stepping motor using Rorze’s

original driver with built-in pulse oscillator.

(S-curve acceleration/deceleration and interpolation control are not

available.)

Features

●16 Input ports and 16 Output ports for general purpose can make system

control easy.

●Can control 2 motors simultaneously.

●Stall detection of stepping motor using a STALL sensor.

●Stand-alone operation and control from PLC is available by

downloading the user program.

●Isolated communication ports, inputs and outputs by photo-coupler

●

Light and compact (120g, 29.5 x 86 x 69mm) and DIN rail installation is available.

Specifications

Supply voltage 18 to 36VDC (including ripple)

Supply current Less than 200mA (at 24VDC)

Clock response 200kpps max.

Data memory position -999,999,999 to +999,999,999

Number of profiles 2,048 (each axis)

Input ports

Output ports

Acceleration/deceleration

method

Stall detection method STALL sensor

Communication method

User program

Recommended drivers

Control motors

Outside dimensions

Weight approx. 120g

16 (Including I/O ports to

16 control motors)

Trapezoidal

RS-485 (921.6kbps max.)

Distance: 1.2km max.

(use Link Master RC-400)

6,039steps

(approx. 2,000commands)

Drivers with built-in oscillator

(RD-100 and 300 series)

2 (Synchronized motion of the

2 axes is available.)

29.5(H)×86(W)×69(D)mm

Input/Output ports

Input port

Sensor, General-purpose Inputs

Internal

circui t

Pulse Inputs

Internal

circuit

5V

Output port

General-purpose Outputs

Internal

circuit

+COM(+24V)

IN

CLK1,CLK2

+COM(+24V)

OUT

50V/150mA

-COM(0V)

PC etc.

RS-232C

RORZE driver with

RC-400 RC-410

・By using a RC-410, two stepping motors c an be controlled simultaneously.

・Stall detection of stepping motors is available by connecting stall detection sens or to RC-410

・When using a RD-100 s eries driver, a low step pulse (pulses in deceleration period) needs to be set up in advance.

A RD-300 series driver has a “GROW OUT” terminal that outputs a signal during acc eleration.

A RD-410 counts the number of pulses while receiving this signal, and automatically calculates a low step pulse to

perform deceleration.

built-in oscillator (No. 1)

RORZE driver with

built-in oscillator (No. 2)

Stall de tectio n

sensor

Stall dete ction

sensor

Example 2 (All of the I/O ports are used as general purpose ports)

To the adjacent controller

ll of the I/O ports (16 points) can be used for any

purpose (in this mode).

Dimensions

PC etc.

Accessories

RS-232C

RS-485

RC-400 RC-410

RS-485

Socket (4 pins)

×1

Socket (2 pins)

×1

2-φ3.6

Contact

×10

ID

RUN

PWR

1

0

0

F

2

F

E

3

E

D

D

4

C

C

5

B

B

6

A

7

A

9

8

9

HL

485

1

2

3

4

5

6

7

8

CCWLS

Stepping motor

CCWLS

86

79

ORG(HOME)LS

ORG(HOME)LS

General Input D0-15

General Output D0-15

IN POR T 1

OUT PORT

62

5

69

29.5

POWER

RS-485

CWLS

RC-410

CWLS

(mm)

+ -

+ - + -

6 7

Compact

Mode Selections

Motion Controller

Light

Specifications

Supply voltage 18 to 36VDC (including ripple)

Supply current Less than 200mA (at 24VDC)

Pulse rate 1pps to 1Mpps

Data memory position -999,999,999 to +999,999,999

Number of profiles 2,048

Input ports

Output ports

Acceleration/deceleration

Interpolation function

Stall detection method Encoder or STALL sensor

Communication method

User program

Recommended drivers

Control motor 1

Outside dimensions

Weight approx. 120g

8 9

method

with Multi-axis Interpolation Control

C

-

4

2

0

R

C

-

C

4

-

4

R

Generate Master

10

16

Arbitrary S-curve, Trapezoidal

2-axis circular / linear

interpolation in a SCARA robot

RS-485 (921.6kbps max.)

Distance: 1.2km max.

(use Link Master RC-400)

6,039steps

(approx. 2,000commands)

Pulse Input Drivers

(RD-0 series)

29.5(H)×86(W)×69(D)mm

2

0

2

0

Description

RC-420 is a motion controller which can control stepping motor and servo

motor by pulse input.

Thanks to the high-speed CPU, various acceleration/deceleration patterns

of pulse generation are available by utilizing software.

Also, using with RC-400 allows synchronized motion by plural controllers.

Combining these functions provides you a multi-axis interpolation control

by plural RC-420s.

Features

●Circular and linear interpolation control in a SCARA robot are available

by using plural RC-420s.

●Can combine S-curve acceleration/deceleration having various

parameters flexibly

Closed loop control when used with an encoder for accurate positioning.

●

●Stand-alone operation and control from PLC are available by

downloading the user program.

●Isolated communication ports, inputs and outputs by photo-coupler

Light and compact (120g, 29.5 x 86 x 69mm) and DIN rail installation is available.

●

Input/Output ports

Input port

Sensor, General-purpose Inputs

Internal

Output port

circu it

Encoder Inputs

Internal

circuit

General-purpose Outputs

Internal

circuit

Pulse Outputs

5V

Internal

circuit

+COM(+24V)

IN

5V

EA,EB

+COM(+24V)

OUT

-COM(0V)

5V OUT

OUT

50V/100mA

GND

50V/150mA

1. Controlling a stepping motor driver

To the adjacent RC-4xx

series controller

MAX 1Mpps

RORZE RD-0 series driver

or other-company stepping

motor driver

PC etc.

RS-485

RS-232C

RC-400 RC-420

Stall detection of stepping motors is available by c onnecting stall detection sensor to RC-420.

RS-485

2. Controlling a stepping motor driver with an encoder input

To the adjacent RC-4xx

series controller

MAX 1Mpps

RORZE RD-0 series d river

or other-company stepping

motor driver

PC etc.

RS-485

RS-232C

RC-400 RC-420

Mode to control a stepping motor on the basis of the pulse put out from an incremental type enc oder.

This mode is eff ective when accurate positioning is required.

RS-485

3. Controlling a servo motor driver using a pulse train

To the adjacent RC-4xx

series controller

MAX 1Mpps

Input signals

& limit switches

a servo motor driver

using a pulse train

Dimensions

Accessories

PC etc.

RS-485

RS-232C

RC-400 RC-420

Mode to control a servo motor by connecting with a puls e input servo motor driver.

RS-485

Socket (4 pins)

×1

Socket (2 pins)

×1

2-φ3.6

Contact

×10

ID

Stepping motor

Stall detec tion

sensor

Stepping motor

Encoder

RUN

PWR

485

0

1

0

1

2

F

2

F

3

E

3

E

D

D

4

4

C

C

5

5

B

B

6

6

7

A

7

A

8

9

8

9

HL

CCWLS

CCWLS

Servo motor

86

79

ORG(HOME)LS

ORG(HOME)LS

IN POR T 1

OUT PORT

62

5

69

29.5

CWLS

CWLS

(mm)

+ -

POWER

RS-485

+ - + -

RC-420

s

s

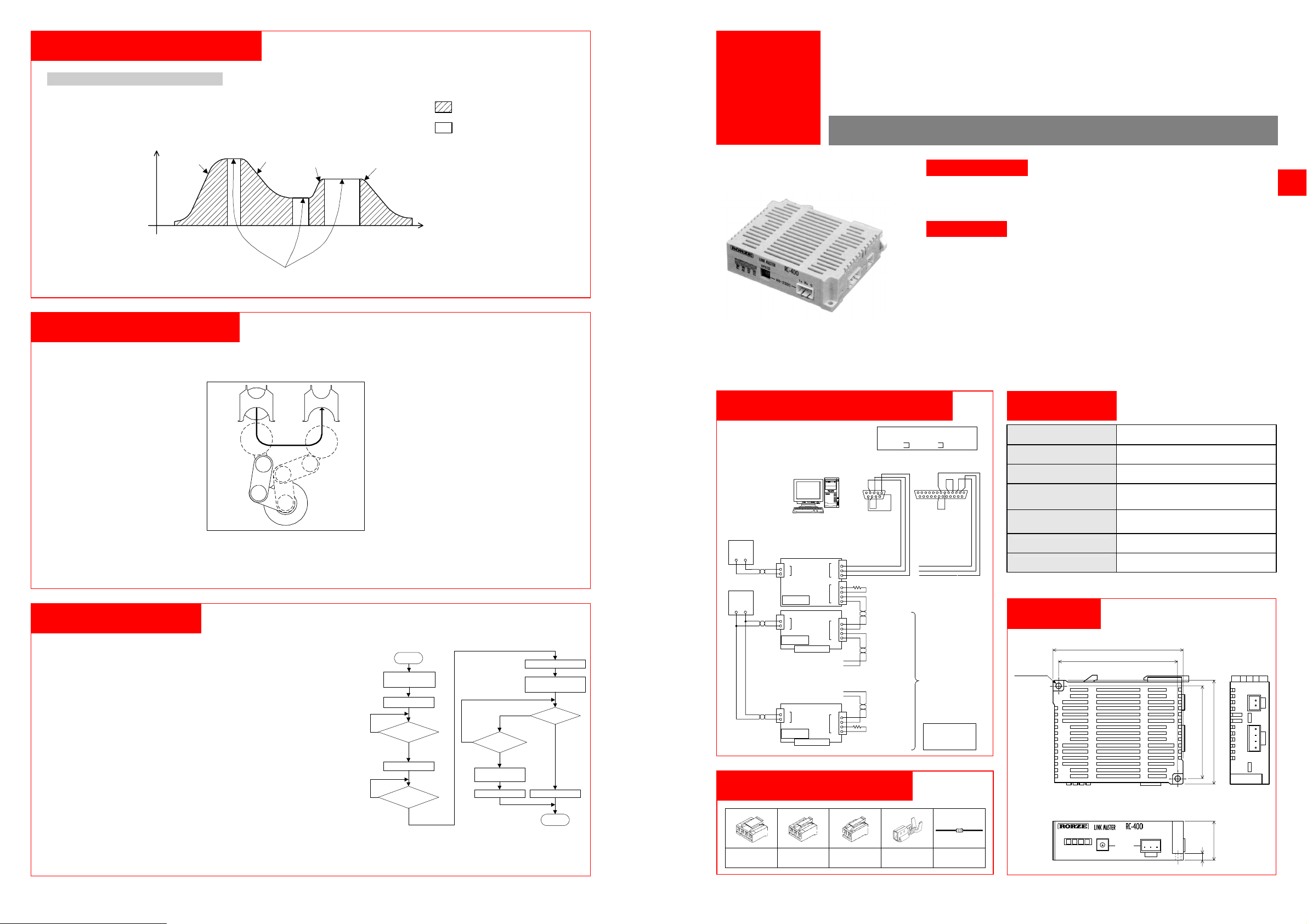

Acceleration/Deceleration pattern

Compact

Accel/decel pattern in RC-420

S-curve accel/decel

Acceleration pattern (①) and deceleration

pattern (②) can set separately.

①

②

①

②

f (speed)

t (time)

Position configuration allows for

multiple speed changes in one move.

Can configure more complex paths by combining circular

Multi-axis interpolation control

and linear interpolation by XY coordinate system in 2 or 3-axi

SCARA robot

wafer casette

wafer casette

wafer

wafer

The example in 2-axis SCARA robot

Sample of user program

Address Command Description (No. in the flowchart below)

0 COS H 0 Turns off all of the general output ports. (①)

1 00 M Performs a home search. (②)

2 JON MT,+0 Repeats address 2 if motor is moving.

3 SET OD0 Turns on general output D0.

4 JOF ID0,+0 Repeats address 4 if general input D0 is off.

5 RST OD0 Turns off general output D0. (⑥)

6 1AM1,25000

7 JOF MT,+3

8 JOF ID6,+4

9 JMP -2 Jumps to the 2nd previous address (i.e. address 7). (⑩)

10 SET OD1 Turns on general output D1. This informs an external circuit that a

11 END Exits the user program. (The next address is not executed.) (⑫)

12 5IS Stops the motor immediately. (⑬)

13 SET OD2 Turns on general output D2.

14 END Exits the user program . (⑮)

Proceeds to the next command after the home search is completed. (③)

This informs an external circuit that a home search is finished. (④)

Proceeds to the ne xt command when the p ort is turned on (1). (⑤)

Starts to run motor at a high speed toward the position of 25,000 pulses. (⑦)

Jumps to the 3rd next address (i.e. addre ss 10) if the mot or is stoppe d. (⑧)

Jumps to address 12 if general input D6 is off (while the motor is running). (⑨)

move is finished. (⑪)

This informs an external circuit that the move is aborted. (⑭)

①

②

NO

③

④

NO

⑤

Flowchart (Sample user program #1)

START

Turns off all of the

general output ports

Starts a home search

Home search finished?

YES

Turns on output D0

Input D0 Off?

YES

Constant-speed

⑥

⑦

NO

Input D6 Off?

⑨,⑩

YES

Immediately stop the

⑬

motor

Turns on output D2

⑭

Turns off output D0

Moves to the position of

25,000 pulses

NO

Move finished?

⑧

⑪

Turns on output D1

⑫,⑮

YES

END

Light

Communication Adapter

C

-

4

0

0

R

R

C

C

-

4

-

4

0

0

0

0

LINK MASTER

Description

RC-400 controls a communication among a host, RC-410s and RC-420s.

Also, a multi-axis interpolation control is available by using with RC-420.

Features

●Monitoring each controller all the time lightens the burden imposed

on a host PC. (Automatic polling function)

●High speed communication

between host PC and RC-400: Up to 115.2kbps

between controllers: Up to 921.6kbps

●Can control up to 120 RC-4xx series controllers by a RC-400.

●Communication distance is extensible up to 1.2km.

●Light and compact (90g, 25 x 86 x 69mm) and DIN rail installation i

available.

Wiring a power and communication line

The follo wing pins must b e connec te d

to commun icate succes sfully.

RTS

Short

CTS

IBM PC/AT comp atible

9 pin D-Su b (female)

RXD

15

DSR

PC

DC

18-36V

-+

DC

18-36V

-+

Accessories

Twisted

Twisted

2

1

2

1

2

1

+

POWER

-

RC-400

+

POWER

-

RC-4xx

+

POWER

-

RC-4xx

RS-232C

I/O port s

・

・

・

・

・

I/O ports

RS-485

RS-485

RS-485

3

Tx

2

Rx

1

G

4

+

3

-

2

+

1

-

4

+

3

-

2

+

1

-

4

+

3

-

2

+

1

-

Socket (4 pins)

×1

Socket (3 pins)

×1

Socket (2 pins)

×1

RS-232C port on a PC

SG

TXD

96

DTR

RTS

CTS

Carbon film resisto r

100Ω(1/4W)

(※1)

Shielded and

Twisted wir e pair

Shielded and

Twisted wire pair

Carbon film resistor

100Ω(1/4W)

(※1)

Contact

×14

DSR

Short

DTR

NEC PC-98xx co mpatible

25 Pin D-Sub (male)

RTS

CTS

SG

13

25 14

DTR

DSR

To TX on RC-400

To RX on RC-400

To G on R C-400

Connectab le to up to 120

RC-4xx ser ies controllers

(※1)

Please co nnect 100Ω

resistor t o the end of

the RS-48 5 line.

Resistor

×3

TXD

RXD

1

Specifications

Supply voltage 18 to 36VDC (including ripple)

Supply current 100mA (at 24VDC)

Communication with PC

Communication with

RC-400 series

Max. connected devices

Outside dimensions

Weight approx. 90g

Dimensions

2-φ3.6

RUN

PWR

485

RS-232C (115.2kbps max.)

RS-485 (921.6kbps max.)

Distance: 1.2km max.

120 units

25(H)×86(W)×69(D)mm

(mm)

86

79

+ -

POWER

69

62

SPEED

8

9

7

A

6

B

5

C

4

D

3

E

2

F

0

1

232C

Tx Rx G

RS-232C

5

25

RS-485

+ - + -

RC-420 / RC-400

10 11

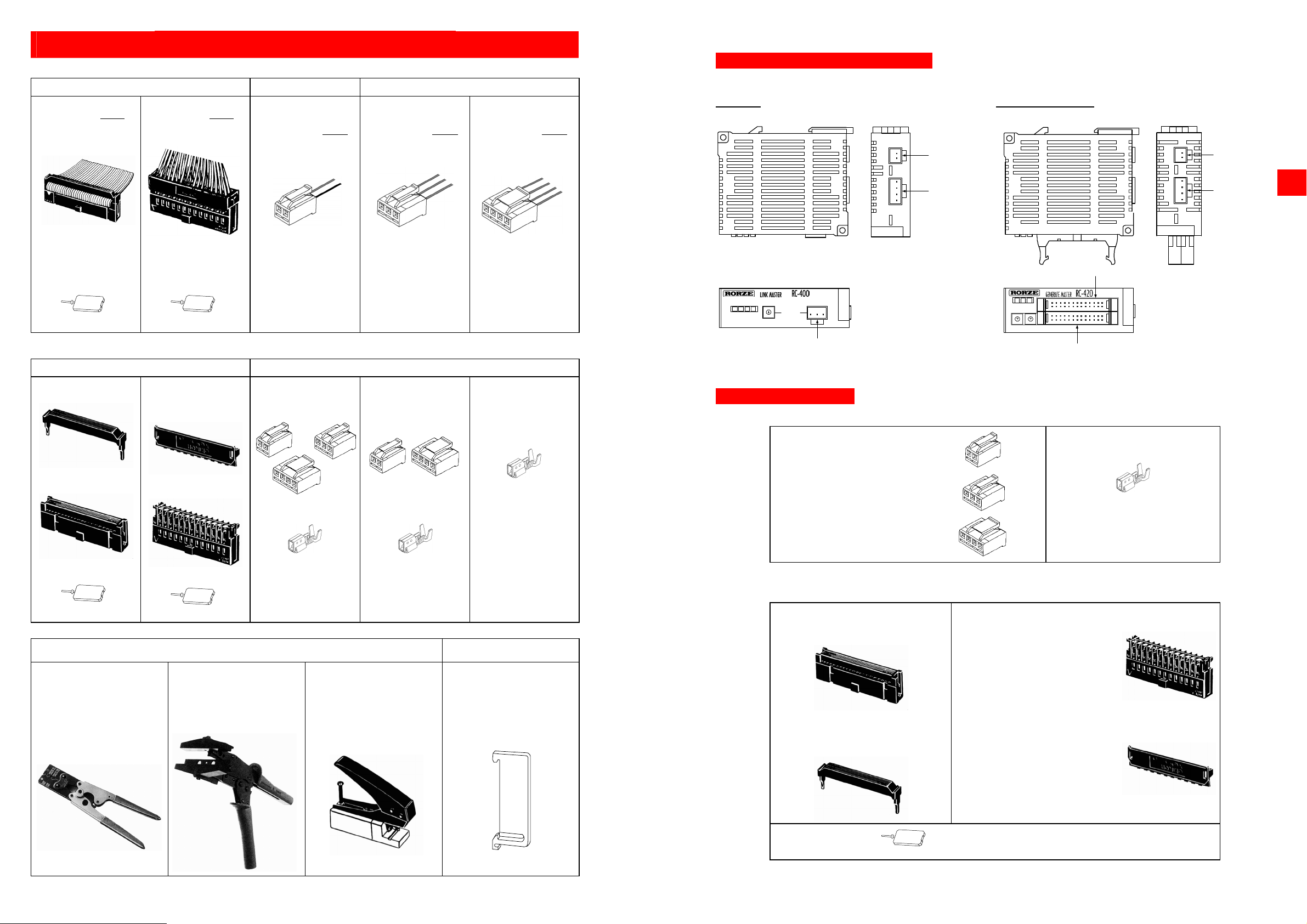

Option connectors for wiring

■ I/O Cables

Socket with flat cable

Model:RCC-26P

Length (cm):50, 100, 200, 300

Flat cable (26 conductors)

with a single-sided socket

×1

Coding pin ×1

※The coding pin is used to pr event confusion when many connectors with the s ame number of contacts are lined up.

□□□LC

↓

Socket with discrete wires

Model:RCB-26P

Length (cm):50, 100, 200, 300

Discrete wire (AWG#24,

BLUE, 26 pcs.) with a singlesided socket

Coding pin ×1

□□□LC

↓

×1

■ Connectors ■ Repair parts

Socket for flat cable

Model:RCF-26PC

Strain relief ×1

Socket ×1

Coding pin ×1

Socket for discrete

wires (for AWG#24)

Model:RCR-26PC

Semi cover ×2

Socket ×1

Coding pin ×1

■ Tools

Hand Crimper for MOLEX

connectors

Model:TOOL-57189-5000

Necessary when connecting

MOLEX sockets with discretewires.

Hand Crimper for

flat-cable connectors

Model:TOOL-901500

Necessary when connecting

sockets with flat-c able.

■

Power Supply Cable

Socket with discrete wires

(for Power Supply)

Model:RCM-2P

Length (cm):50, 100, 200, 300

Discrete wire (AWG#20,

BLACK, ORANGE, each 1 pc.)

with a single-sided

socket (2 pins)

Accessories

for RC-400

Model:RC4-ACC1

MOLEX socket (2・3・4 pins)

each 1 pc.

Contact ×14

Carbon film resistor

100Ω(1/4W ) ×3

■ Communication Cables

Socket with discrete wires

(for RS-232C)

□□□L

Model:RCM-3P

↓

Length (cm):50, 100, 200, 300

Discrete wire (AWG#24,

BLUE, 3 pcs.) with a single-

MOLEX

×1

sided

×1

MOLEX

socket (3 pins)

Accessories

for RC-410, 420

Model:RC4-ACC2

MOLEX socket (2・4 pins)

each 1 pc.

Contact ×10

Hand Crimper for

discrete-wire connectors

Model:TOOL-XY2B-7006

Necessary when connecting

sockets with discrete-wires.

□□□L

↓

■ Attachment

Spacer for DIN rail

Model:AESC-SA-406B

This is used when RC-4 series

controllers are inst alled on a

DIN rail at intervals of 5mm.

Socket with discrete wires

(for RS-485)

Model:RCM-4P

□□□

L

↓

Length (cm):50, 100, 200, 300

Discrete wire (AWG#24,

BLUE, 4 pcs.) with a singlesided

MOLEX

socket (4 pins)

×1

Contact for MOLEX

socket

Model:RC4-ACC3

Contact ×50

Sockets used for each controller

RC-400 RC-410, RC-420

+ -

POWER

①POWER (2P)

RS-485

+ - + -

③RS-485 (4P)

SPEED

8

9

7

A

6

B

5

C

4

D

3

E

2

F

0

1

RUN

PWR

485

232C

Tx Rx G

RS-232C

②RS-232C (3P)

ID

RUN

PWR

0

0

1

F

2

F

E

3

E

D

D

4

C

C

5

B

B

6

A

7

A

9

8

9

HL

485

1

2

3

4

5

6

7

8

④INPUT PORT (26P)

⑤OUTPUT PORT (26P)

Suitable connectors

①,②,③ (Manufactured by MOLEX)

Sockets

①: 51067-0200 (for 2P)

Contact

50217-8100

②: 51067-0300 (for 3P)

③: 51067-0400 (for 4P)

④,⑤ (Manufactured by OMRON)

For Flat cable

Socket

XG4M-2630 (for 26P)

Strain relief

XG4T-2604 (for 26P)

For Discrete wire

Sockets

for AWG#28 to 26

XG5M-2635 (for 26P)

for AWG#24

XG5M-2632 (for 26P)

Semicover

XG5S-1301 (for 26P)

IN PORT 1

OUT PO RT

+ -

POWER

RS-485

+ - + -

①POWER (2P)

③RS-485 (4P)

Option connectors

Coding pin

XG4Z-0005

12 13

y

r

Compact

Low cost

Controllers to Control Stepping Motors and

I/O Ports

C

-

2

0

4

A

,

R

C

-

2

0

7

A

R

C

-

2

0

R

C

-

2

0

4

I/O MASTER

A

,

R

C

-

2

4

A

,

R

C

0

-

2

0

Description

I/O Master RC-204A and RC-207A utilize serial communication

(RS-232C) to control step motor drivers and I/O ports. Also, because a

pulse counter is built in, trapezoidal acceleration is available b

combining with RORZE’s drivers with built-in pulse oscillator.

Features

●In case of controlling no motor, all I/O ports can be used as general

I/O ports.

●Stall detection by attaching a stall sensor and a stall slit to a device.

(Note: Stall sensor devices may not be rotary in shape.)

●Up to 20 controllers such as RC-204A, RC-207A and RC-234 can be

daisy-chained together in a MasterNet system from one PC and

multi-axis stand-alone control is available at a low price. (See the

example 2 in the system configuration.)

●RC-207A:

●RC-204A: Backup using battery (3.6V)

EEPROM for easy downloading and saving the user’s program

7

7

A

A

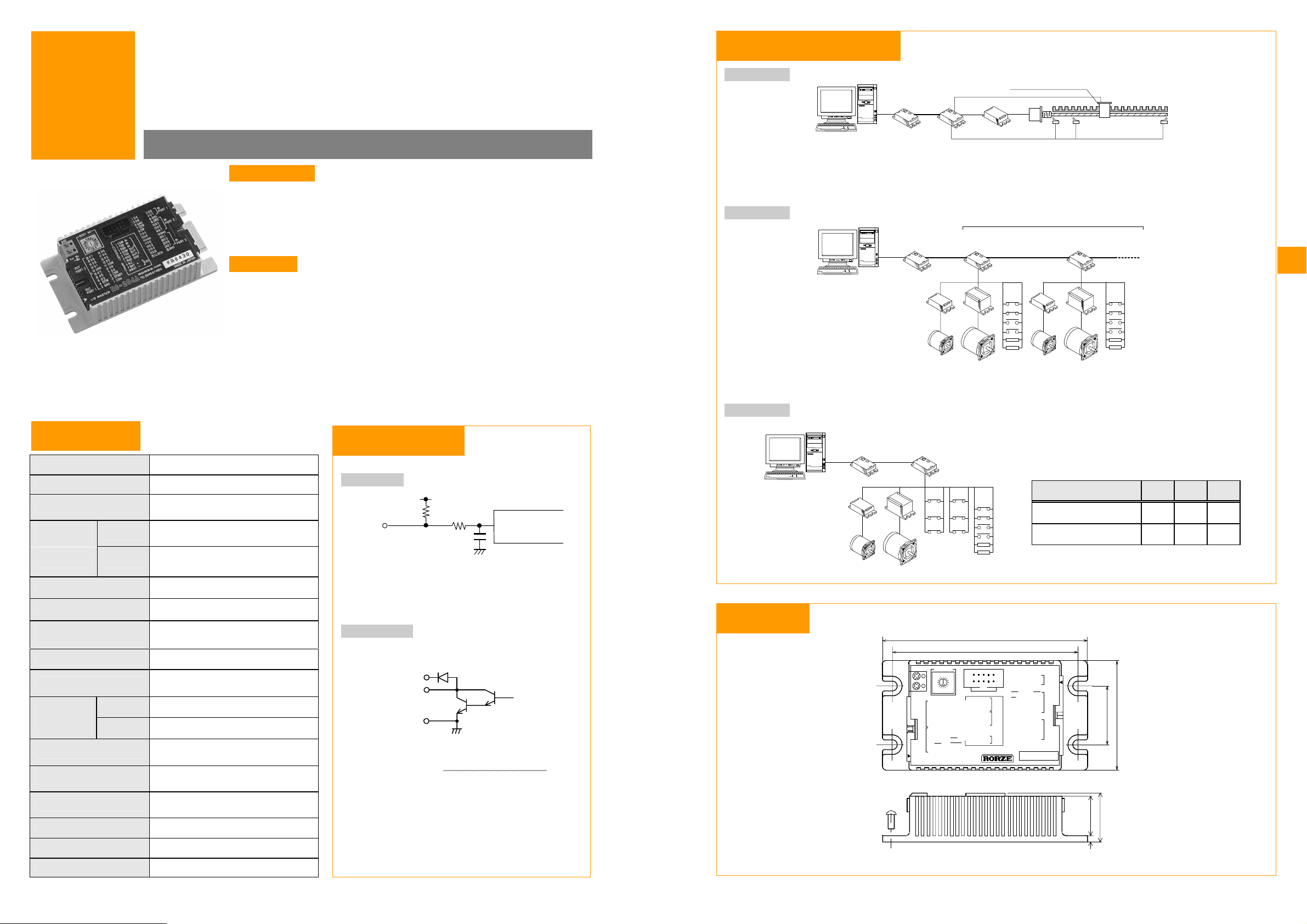

System configurations

Example 1

RS-232C

PC

Stall detection is possible,

in case of using two motors.

Example 2

PC

Controllers that can c onnect at this configuration: RC-204A, RC-207A, RC-234, RC-003

Example 3

Link Master

RC-002

Link Master

RC-002

RS-232C

Driver with builtin oscil lator

(RD-3 series)

Stepping motor

I/O Master

RC-204A

RC-207A

Driver with built-in oscillator

(RD-3 series)

Stall detection of stepping mot ors is available by connecting

stall detection sensor to RC-204A, 207A

I/O Master

RC-204A

RC-207A

STALL DETECTION SENSOR

CCWLS ORG (HOME) CWLS

Can control up to 20 controllers

Controller

Driver

I/O Circuits

Stepping motor

or Servo motor

I/O Circuits

RC-204A / RC-207A

Specifications

Supply voltage 18 to 40VDC (including ripple)

Supply current Less than 30mA (at 24VDC)

Clock response

Data memory

position

RC-204A

RC-207A

Number of profiles 1,130

Accel./Decel. method Trapezoidal

Input ports

Output ports

Stall detection method STALL sensor

Control signal line

Communication

speed

RC-204A

RC-207A

Back up method

User program

(RC-207A)

Recommended drivers

Control motors 2 of each, controlled alternately

Outside dimensions

100kpps max.

80kpps (at stall detection)

0 to 16,777,215 pulses

0 to 16,777,215 pulses

or -8,388,608 to +8,388,607

20 (Including I/O ports to

16 control motors)

Current loop method of RS232C

(use Link Master RC-002)

9600 bps

9600, 1200, 300 bps

RC-204A: battery

RC-207A: EEPROM

1,792 bytes

(approx. 300 commands)

Drivers with built-in pulse oscillato

(RD-100 and 300 series)

27.5(H)×105(W)×56(D)mm

Input/Output ports

Input port

5V

IN

2.2kΩ

Low Level : Less than 1.5V

High Level: More than 3.5V

Output port

COM

OUT

GND

Open Collector (Darlington・Transistor

Voltage: Less than 50V

Current: Less than 200mA (per one

contact)

Less than 800mA in total of

8 contacts

Vce(sat): Less than 1.1V (Ic:200mA)

CMOS 74HC

)

PC

Dimensions

RS-232C

Driver with builtin oscill ator

(RD-3 series)

Stepping motor

Link Master

RC-002

No.1 No.2

M4 Scre w

I/O MASTER

RC-204A

RC-207A

CCWLS

ORG

(HOME)

CWLS

No.1

GND

DC18V-40V

20 D7

18 D5

OUT

16 D3

PORT2

14 D1

12 GND

10 D7

8D5

6D3

OUT

4 CCW

PORT1

2 GND

I/O MASTER

CCWLS

ORG

(HOME)

CWLS

For Motor

No.2

BODY NO.

8

9

7

A

6

B

5

C

4

D

3

E

2

F

1

0

19 D6

17 D4

15 D2

13 D0

11 COM

9D6

7D4

5 LOW

3START

1 COM

RC-204A

General I/OFor Motor

1 COM IN

2 TXD IN

3 RXD IN

4 COM OUT

5 TXD OUT

6 RXD OUT

7 RXD END

8 N.C.

CURREN T L OOP

9BAT+

10 BAT -

105

95

Relation between No. of motor and general I/O ports.

No. of motor to control 0 1 2

General input ports 20 16 13

General output ports 16 13 10

(mm)

1D4

2D5

IN

4D7

6 GND

8 ORG

IN

10 D3

12 D5

14 D7

16 GND

18 D1

20 D3

22 D5

24 D7

26 GND

MADE IN JAPAN

PORT1

PORT2

IN

PORT3

30

56

22

27.5

4

3D6

5 GND

7 CCW

9CW

11 D4

13 D6

15 GND

17 D0

19 D2

21 D4

23 D6

3.6V

25 CLOCK

Weight approx. 250g

14 15

Y

g

y

(

g

V

Compact

Low cost

Specifications

Motion Controller

with Two-axis Interpolation Control

C

-

2

3

4

R

C

-

C

2

-

2

R

GENERATE MASTER

3

4

3

4

Description

RC-234 is a motion controller which can control stepping motor and

servo motor by pulse input. This can control 2 motors simultaneously,

and circular and linear interpolation controls are available in the X

plane.

Features

●Compliant with CE Marking.

●

S-curve acceleration provides smooth moves without shock or damping.

●

Closed loop control when used with an encoder for accurate positioning.

●Stand-alone operation and control from PLC are available by

downloading the user program.

●Pulse output frequency up to 1Mpps permits to be used with a high

resolution microstep driver.

●Up to 20 controllers such as RC-204A, RC-207A and RC-234 can be

daisy-chained together in a MasterNet system from one PC and

multi-axis stand-alone control is available at a low price.

Mode Selections

Input/Output ports

You can step up the following modes

arbitrarily to each axis.

1. Controlling stepping motor using stall detection function

If a stall is detected, a stepping motor

stops immediately.

Also, you can override a stall detection

and control a stepping motor as usual.

S

S

E

L

N

I

S

T

O

R

F

O

R

S

T

A

L

L

D

E

T

E

C

T

I

O

N

,

CCWLS

DRIVER

RD-0 SERIES

ORG(HOME)LS

STALL DETECT ION SIGNAL

CWLS

PC

PLC

SWITCH, ET C.

2. Closed loop control of stepping motor using encoder

Mode to control a stepping motor on

the basis of the pulse put out from an

incremental type encoder.

This mode is effective when accurate

positioning is required.

ENCODER

CCWLS

DRIVER

RD-0 SERIE S

A-PHA SE,B-PHA SE,(Z-PHAS E)

ORG(HOME)LS

CWLS

PC

PLC

SWITCH, ETC.

Input port Input for motor control

IN

5V

2.2k

Ω

Equivalent to

CMOS 74HC

5

R1

IN

Low Level : Less than 0.8V Low Level : Less than 1.5V

High Level: More than 2.0V High Level: More than 3.5V

470

R1

2.2K

Output port Output for motor control

COM

OUT

OUT

50V/100mA

GND

Open Collector (Darlington

Voltage: Less than 50V

Current: Less than 200mA (per one

contact)

Less than 800mA in total of

8 contacts

Vce(sat): Less than 1.1V (Ic

・Tr ans ist or)

:200mA)

GND

CMOS

74HC

Ω (EA, EB)

Ω(Others)

RC-234

18Ω

Supply voltage 18 to 40VDC (including ripple)

Supply current Less than 100mA (at 24 VDC)

Pulse rate 0.1 to 1Mpps

Data memory position

0 to 16,777,215 pulses

or -8,388,608 to +8,388,607

Number of profiles 1,000 (each axis)

Accel./Decel method S-curve, Trapezoidal

Interpolation function

Input ports

Output ports

2-axis circular interpolation

2-axis linear interpolation

10 (8 in a servo mode)

10 (8 in a servo mode)

Stall detection method Encoder or STALL sensor

Control signal line

Baud rate

User program

Recommended drivers

Control motors

Outside dimensions

Current loop method of RS232C

(use Link Master RC-002)

38400, 19200, 9600,

2400, 1200, 300 bps

8,000 bytes

(approx. 1,500 commands)

Pulse Input Drivers

(RD-0 series)

2 (Synchronized motion of the

2 axes is available.)

27.5(H)×105(W)×56(D)mm

Weight approx. 250g

Two-axis interpolation control

Circular and linear interpolation controls are

available in the XY plane.

Can configure more complex paths by combining

circular and linear interpolation.

Y

Starting point

Center 1

Linear move

Circular mov e

Center 2

Destination

Speed change during a interpolation control.

f (speed)

Starting point

Destination

X

t (time)

3. Servo motor control (Pulse input type driver)

Mode to control a servo motor by

connecting with a pulse input servo

motor driver.

CCWLS

SERVO MOTOR DRIVER

PULSE INPUT

INPOSITION (A LARM, Z-PHASE)

Sample of user program

ORG(HOME)LS

COUNTER・CLEAR

CWLS

PC

PLC

SWITCH, ETC.

/22000/JON3+1/J-2/4//END

(“/” is a separator between commands)

action: This pro

and when the input port D3 is turned ON,

moves a motor b

direction

is terminat ed.

You can also us e in the following stand alone mode:

Once the user pro

and autostart is enabled, the controller will start the

program automatically upon turning ON the power.

ram sets a position pulse number

2,000 pulses in the CCW

Command 4) and the user program

ram is transferred to EEPROM

Dimensions

M4 Screw

GND

DC18V -40

GENERATE

MASTER

PWR

RUN

TXD

ERR

BODY NO.

V

8

9

7

A

6

B

5

C

4

D

3

E

2

F

1

0

20 D7 19 D6

18 D5 17 D4

IN

16 D3 15 D2

14 D1 13 D0

12 GND 11 GND

10 D7 9 D6

8 D5 7 D4

6 D3 5 D2

OUT

4 D1 3 D0

2 GND 1 COM

RC-234

105

95

1 COM IN

2 TXD IN

3 RXD IN

4 COM OUT

5 TXD OUT

6 RXD OUT

7 RXD END

8 N.C .

CURRENT LOOP

9 N.C .

10 N.C .

MOTOR 1

1 +5V

3CW/P

5 CCWLS

7CWLS

9EB

SERVO&EMS

11 G ND

13 I NP1

15 INP2

MOTOR2

1

7 +5V

19 CW/P

21 CCWLS

23 CWLS

25 EB

2GND

4 CCW/ D

6ORG

8EA

10 EZ

12 EMS

14 CLR1

16 CLR2

18 GND

20 CCW/D

22 ORG

24 EA

26 EZ

MADE IN VIETNAM

(mm)

30

56

224

27.5

16 17

A

t

f

A

Compact

dapter RS-232C → Current loop

C

-

0

0

2

R

R

C

C

-

0

-

0

0

0

2

2

Compact

dapter Current loop → RS-232C

C

-

0

0

3

R

R

C

C

-

0

-

0

0

0

3

3

LINK MASTER

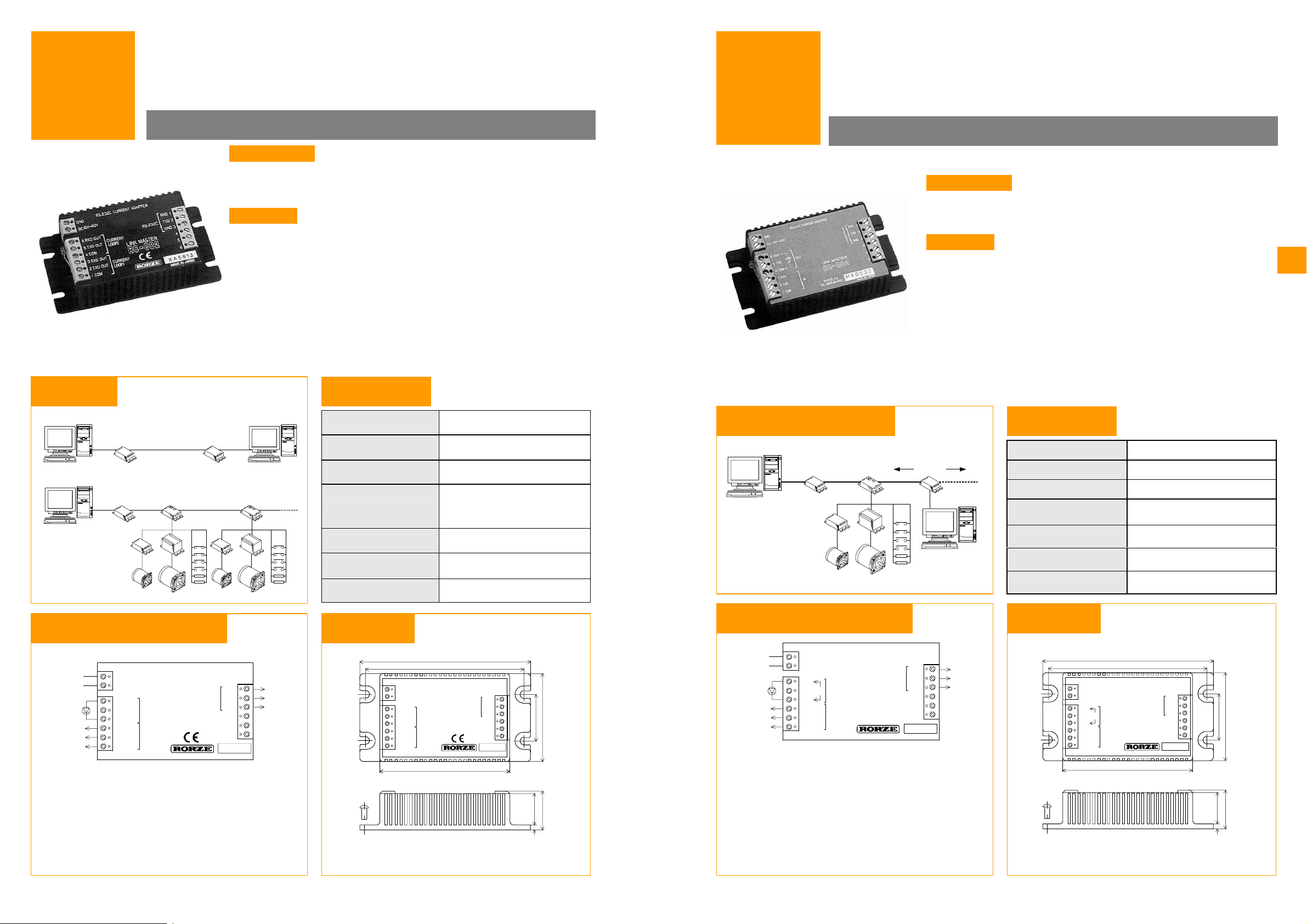

Examples

Example 1

RC-002 RC-003

PC

Example 2

RC-002

RS-232C

PC

Current LoopRS-232C RS-232C

RC-204A

RC-207A

Current Loop Current Loop Curr ent Loop

RD-3 series

Driver

Motor MotorI/O Circuits I/O Circuits

Connection Terminal Layout

Description

Link Master RC-002 converts the computer ’s RS-232C signal to curren

loop type.

Features

●Compliant with CE Marking.

●Communication by only 3 wires makes wiring and maintenance o

device easy.

●Current loop transmission system improves the noise-resistant and

long distance communication is available.

●With communication of the master slave system, the controller to 20

sets and RC-003 are connectable with one set of RC-002 as a slave.

●Communication speed is 40kbps max.

Specifications

Supply voltage 18 to 40VDC (including ripple)

Supply current Less than 20mA (at 24VDC)

RD-0 series

Driver

PC

RC-234

Communication method

Current loop transmission

Convert the computer’s

Function

RS-232C voltage signal to

current loop signal

Baud rate 40kbps max.

Outside dimensions

27.5(H)×105(W)×56(D)mm

Weight approx. 250g

Dimensions

(mm)

LINK MASTER

RC-204A

RC-002

RS-232 C

PC

RC-207A

RC-234

Current loop

Driver

Motor I/O Circuits

Current loop

Connection Terminal Layout

Description

Link Master RC-003 converts current loop signal to RS-232C.

Features

●Long distance communication by using with RC-002

●Can display commands sent from a PC to each I/O master/

generate master on the other PC’s monitor screen and thus

it becomes easy to debug the control program.

SpecificationsSystem configuration

Supply voltage 18 to 40VDC (including ripple)

AB

RC-003

Supply current Less than 20mA (at 24VDC)

Communication method

Function

Current loop transmission

Convert current loop signal

to RS-232C

Baud rate 40kbps max.

SUB PC

to Moni tor Comm ands

Outside dimensions

27.5(H)×105(W)×56(D)mm

Weight approx. 250g

Dimensions

RC-002 / RC-003

(mm)

GND

DC18V-40V

RXD

TXD

SHORT

COM

RXD

TXD

COM

END

RS-232C CURRENT ADAPTER

OUT

LINK MASTER

RC-003

IN

RS-232C

RS-232C

RXD

1

RXD

TXD

2

TXD

GND

GND

3

4

5

6

MADE IN JAPAN

PC side

TO TXD

TO RX D

TO GND

M4 Screw

GND

DC18V-40V

6RXD

5

TXD

4

COM

3

RXD

TXD

2

1

COM

SHORT

105

95

RS-232C CURRENT ADAPTER

END

OUT

IN

RS-232C

RS-232C

LINK MASTER

RC-003

79

1

RXD

RXD

TXD

TXD

2

GND

GND

3

4

5

6

MADE IN JAPAN

GND

18-40VDC

LED

(NOTE)

TO RXD IN

TO TXD IN

TO COM IN

Controller side

6

5

4

3

2

1

GND

DC18V-40V

RXD OUT

TXD OUT

COM

RXD OUT

TXD OUT

COM

RS-232C CURRENT ADAPTER

CURRENT

LOOP2

LINK MASTER

RC-002

CURRENT

LOOP1

RS-232C

1

RXD

2

TXD

3

GND

4

5

6

MADE IN JAPAN

PC side

TO TXD

TO RX D

TO GND

The voltage signal inputted from terminals to connect with a

PC is converted to current signal inside and outputted from

terminals to connect with a controller.

(Note)

When the total number of controllers to connect is over

10, please remove the LED connected at output side

of RC-002, and use both of the two output terminals.

You can connect up to 10 controllers to one of output

terminals of RC-002.

M4 Screw

GND

DC18V-40V

6RXD OUT

5

TXD OUT

4

COM

3

RXD OUT

2

TXD OUT

1

COM

105

95

RS-232C CURRENT ADAPTER

CURRENT

LOOP2

LINK MASTER

RC-002

CURRENT

LOOP1

79

RS-232C

RXD

TXD

GND

MADE IN JAPAN

GND

18-40VDC

1

2

3

4

5

6

30

56

LED

(NOTE)

TO RXD OUT

TO TXD OUT

TO COM OUT

Controller side

6

5

4

3

2

1

The current signal inputted from terminals to connect

with a controller is converted to the voltage signal inside

and outputted from terminals to connect with a PC.

(Note)

22

27.5

4

OUT: Terminals to connect additional controllers.

For connection, please remove the LED.

IN: Terminals which are connected host PC side

controllers.

18 19

22

30

4

56

27.5

A

Compact

dapter USB → Current loop

Light-weight

C

R

-

C

C

-

-

R

LINK MASTER

0

0

0

0

4

0

4

0

4

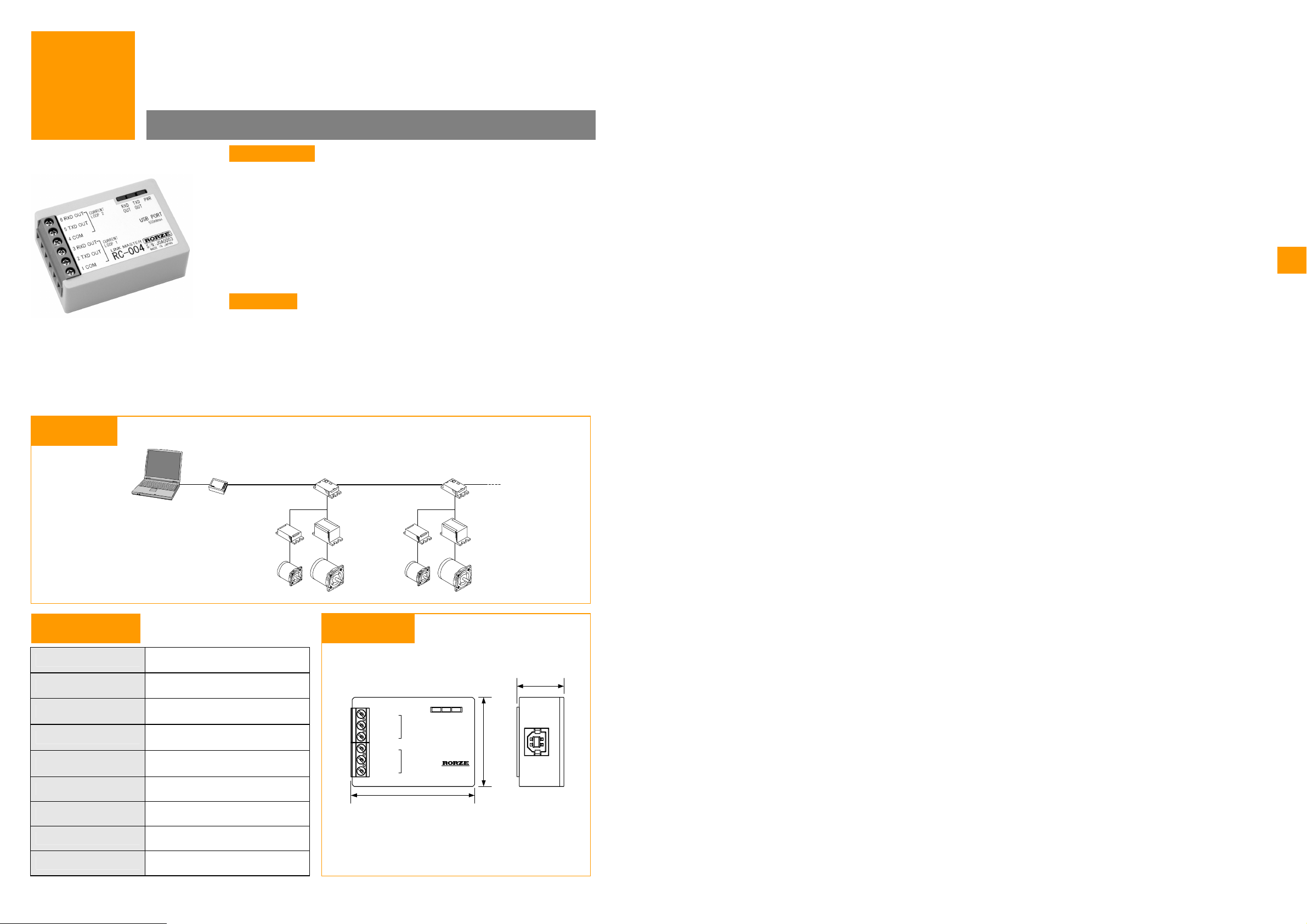

Description

The RC-004 is the communication adaptor (USB ⇔ current loop

converter) for the RC-200 series controller. The RC-004 is operated

only by the power supplied from the USB port, and using the device

driver, it can be used as a virtual port from the host side.

The RC-004 is designed as a development tool. Use the RC-002

instead of the RC-004 when mounting it on devices.

USB cable should be prepared by the user.

Features

●Compact and light-weight

●Power supply is unnecessary.

●Perfect for the development with the notebook computer without

RS-232C.

●Can be used as a virtual COM port and thus it can use the past

software data.

RC-004

Examples

Note PC

USB

RC-004

Curre nt loop

RD-0 series

Driver

Motor

RC-234

Current loop

Specifications Dimensions

Supply current Less than 500mA

Communication method

Function

Port insulation

Max. communication speed

USB standards In compliance with USB1.1

Operating System (OS)

Current loop transmission

Convert the computer’s USB

signal to current loop signal

Not insulated between USB

and current loop

38400 bps

(depending on controller specifications)

Windows98, 2000, XP

6 RXD OUT

5 TXD OUT

4 COM

3 RXD OUT

2 TXD OUT

1 COM

CURRENT

LOOP 2

CURRENT

LOOP 1

LINK MASTER

RC-004

56mm

RC-204A

RC-207A

RD-3 series

Driver

Motor

RXD TX D PWR

OUT OU T

USB PORT

S/N:J0A0000

MADE IN JAPAN

500mAm ax

21mm

40mm

Outside dimensions

Weight 33g

20 21

21(H)×56(W)×40(D)mm

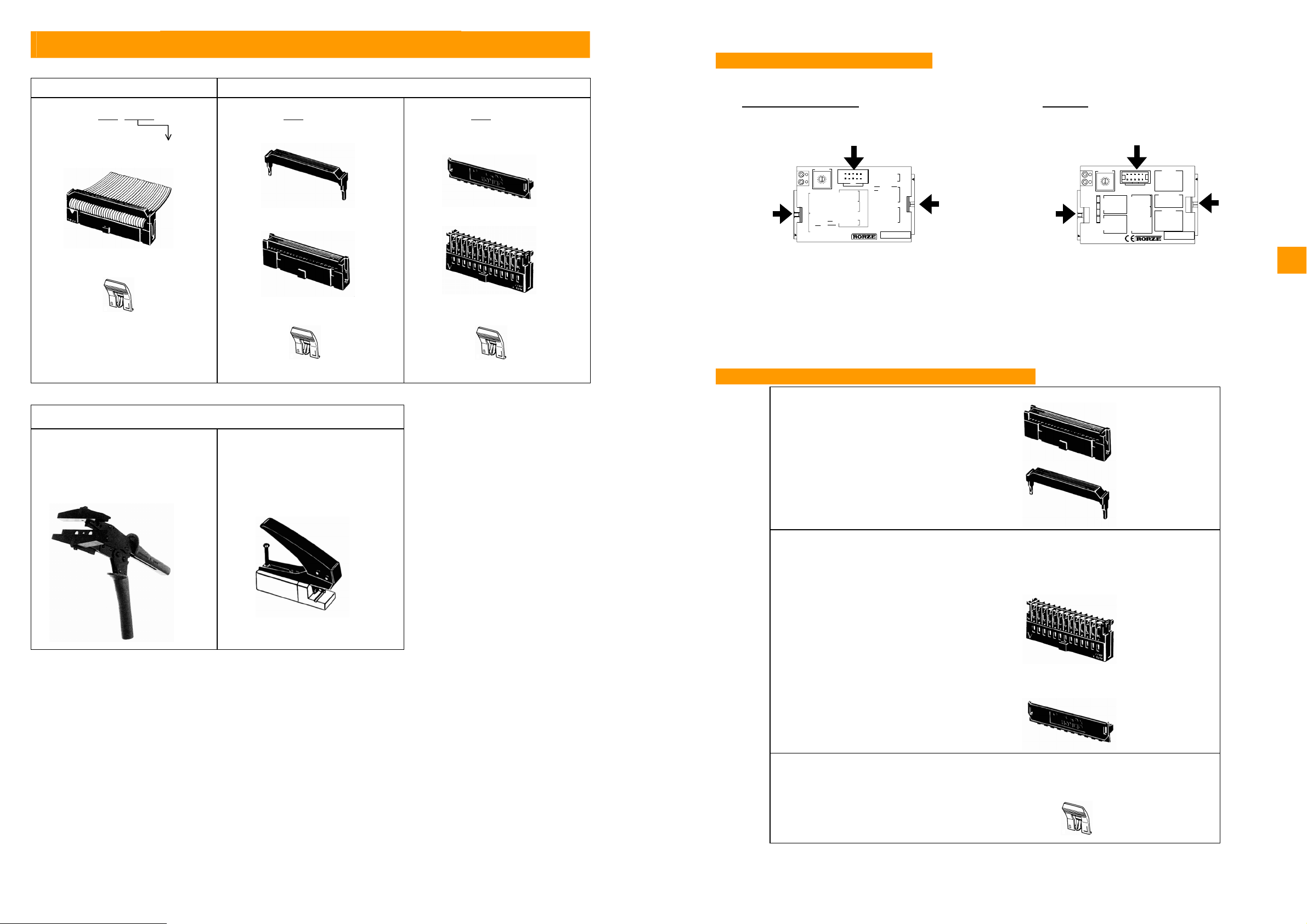

Option connectors for wiring

■ I/O Cable ■ Connectors

Socket with flat cable

Model:RCC-○○

P□□□L

↓

Number of pins:10, 20, 26

Flat cable with a single-sided socket ×1

Length (c m):50, 100, 200, 300

Lock lever ×1

■ Tools

Hand Crimper for flat-cable

connectors

Model:TOOL-901500

Necessary when connecting sockets with

flat-cabl e.

Socket for flat cable

Model:RCF-○○

↓

Number of pins:10, 20, 26

Strain relief ×1

Socket ×1

Lock lever ×1

Hand Crimper for discrete-wire

connectors

Model:TOOL-XY2B-7006

Necessary when connecting sockets with

discrete-wires.

P

Sockets used for each controller

Socket for discrete wires (for AWG#24)

Model:RCR-○○P

↓

Number of pins:10, 20, 26

Semi cover ×2

Socket ×1

Lock lever ×1

RC-204A, RC-207A RC-234

Output c onnector

20P

Communication connector

10P

GND

BODY NO.

8

9

7

A

DC18V-40V

OUT

PORT2

OUT

PORT1

I/O MASTER

6

5

4

3

2

20 D7

18 D5

16 D3

14 D1

12 GND

10 D7

8D5

6D3

4 CCW

2 GND

RC-204A

B

C

D

E

F

1

0

19 D6

17 D4

15 D2

13 D0

11 COM

9D6

7D4

5 LOW

3 START

1 COM

1COMIN

2TXDIN

3 RXD IN

4 COM OUT

5 TXD OUT

6 RXD OUT

7RXDEND

8 N.C.

CURRENT LOOP

9BAT+

10 BAT -

1D4

2D5

3D6

4D7

5 GND

6GND

7 CCW

8ORG

9CW

10 D3

11 D4

12 D5

13 D6

14 D7

15 GND

16 GND

17 D0

18 D1

19 D2

20 D3

22 D5

21 D4

24 D7

23 D6

3.6V

26 GND

25 CLOCK

MADE IN JAPAN

Utilized sockets : 10P×1

20P×1

26P×1

IN

PORT1

IN

PORT2

IN

PORT3

Input connector

26P

I/O connector

20P

Communication connector

10P

GND

DC18V-40

GENERATE

MASTER

V

PWR

RUN

TXD

ERR

BODY NO.

8

9

7

A

6

B

5

C

4

D

3

E

2

F

1

0

20 D7 19 D6

18 D5 17 D4

IN

16 D3 15 D2

14 D1 13 D0

12 GND 11 GND

10 D7 9 D6

8 D5 7 D4

6 D3 5 D2

OUT

4 D1 3 D0

2 GND 1 COM

RC-234

1 COM IN

2 TXD IN

3 RXD IN

4 COM OUT

5 TXD OUT

6 RXD OUT

7 RXD END

8 N.C.

CURRENT LOOP

9 N.C.

10 N.C.

MOTOR1

1+5V

3CW/P

5CCWLS

7CWLS

9EB

SERVO&EMS

11 GND

13 INP1

15 INP2

MOTOR2

7+5V

1

19 CW/P

21 CCWLS

23 CWLS

25 EB

2GND

4 CCW /D

6ORG

8EA

10 EZ

12 EMS

14 CLR1

16 CLR2

18 GND

20CCW/D

22 ORG

24 EA

26 EZ

MADE IN JAPAN

Utilized sockets : 10P×1

20P×1

26P×1

I/O connector

26P

Option connectors

Suitable connectors (Manufactured by OMRON)

For Flat cable

Sockets

XG4M -2630 (for 26P)

-2030 (for 20P)

-1030 (for 10P)

Strain reliefs

XG4T -2604 (for 26P)

-2004 (for 20P)

-1004 (for 10P)

For Discrete wire

Sockets

for AWG#28 to 26

XG5M -2635 (for 26P)

-2035 (for 20P)

-1035 (for 10P)

for AWG#24

XG5M -2632 (for 26P)

-2032 (for 20P)

-1032 (for 10P)

Semicovers

XG5S -1301 (for 26P)

-1001 (for 20P)

-0501 (for 10P)

Lock lever (Stopper to prevent from coming off a socket.)

XG4Z-0002

22 23

Loading...

Loading...