Ropox Vario

User manual

This manual should always be in close proximity of the

product.

PDF6210 / DRAFT Rev001

PDF 6210 / DRAFT Rev001

2

Table of content

1. Symbols used in this manual .................................................................................................................. 3

2. General safety ........................................................................................................................................... 4

2.1 Product label ................................................................................................................................. 6

3. General requirements .............................................................................................................................. 7

3.1 Product information ....................................................................................................................... 7

3.2 Intended use.................................................................................................................................. 8

3.3 Intended operator .......................................................................................................................... 8

3.4 Dimension sketch .......................................................................................................................... 8

4. Instructions for use .................................................................................................................................. 9

4.1 Receiving the Vario changing bed ................................................................................................ 9

4.2 Placering af el-udtag ..................................................................................................................... 9

4.3 Prepare the mounting .................................................................................................................. 10

4.4 Mounting to the wall .................................................................................................................... 12

4.5 Mount the tabletop on the lifting unit ........................................................................................... 16

4.6 Wire diagram ............................................................................................................................... 17

4.7 Connecting cables ....................................................................................................................... 18

5. Instructions for use ................................................................................................................................ 19

5.1 Operating the product .............................................................................................................. 19

5.1.1 Actuation of the product ................................................................................................... 19

5.1.2 Operation of the bed guards ................................................................................................. 20

5.1.3 Op/nedklapning af skifteleje ................................................................................................. 21

5.2 Recommendations in use ........................................................................................................ 23

6. Cleaning .................................................................................................................................................. 23

7. Maintenance ............................................................................................................................................ 23

7.1 Periodic maintenance of bed guards ....................................................................................... 23

7.2 Fejlsøgning .............................................................................................................................. 24

8. Environmental protection ..................................................................................................................... 24

8. Spare parts .............................................................................................................................................. 25

9. Accessories ............................................................................................................................................ 26

9.2 Bed guard ................................................................................................................................ 26

9.3 Cushion for bed guard ............................................................................................................. 27

9.4 Mattress ................................................................................................................................... 27

10. Electro magnetic compability ............................................................................................................... 28

10.1 Suitable Environments ......................................................................................................... 28

10.2 Basic safety and Essential performance ............................................................................. 28

10.3 Adjacent and stacked use .................................................................................................... 28

10.4 Cables .................................................................................................................................. 28

10.5 RF portable equipment ........................................................................................................ 28

11. CE – Declaration of conformity ............................................................................................................. 29

PDF 6210 / DRAFT Rev001

3

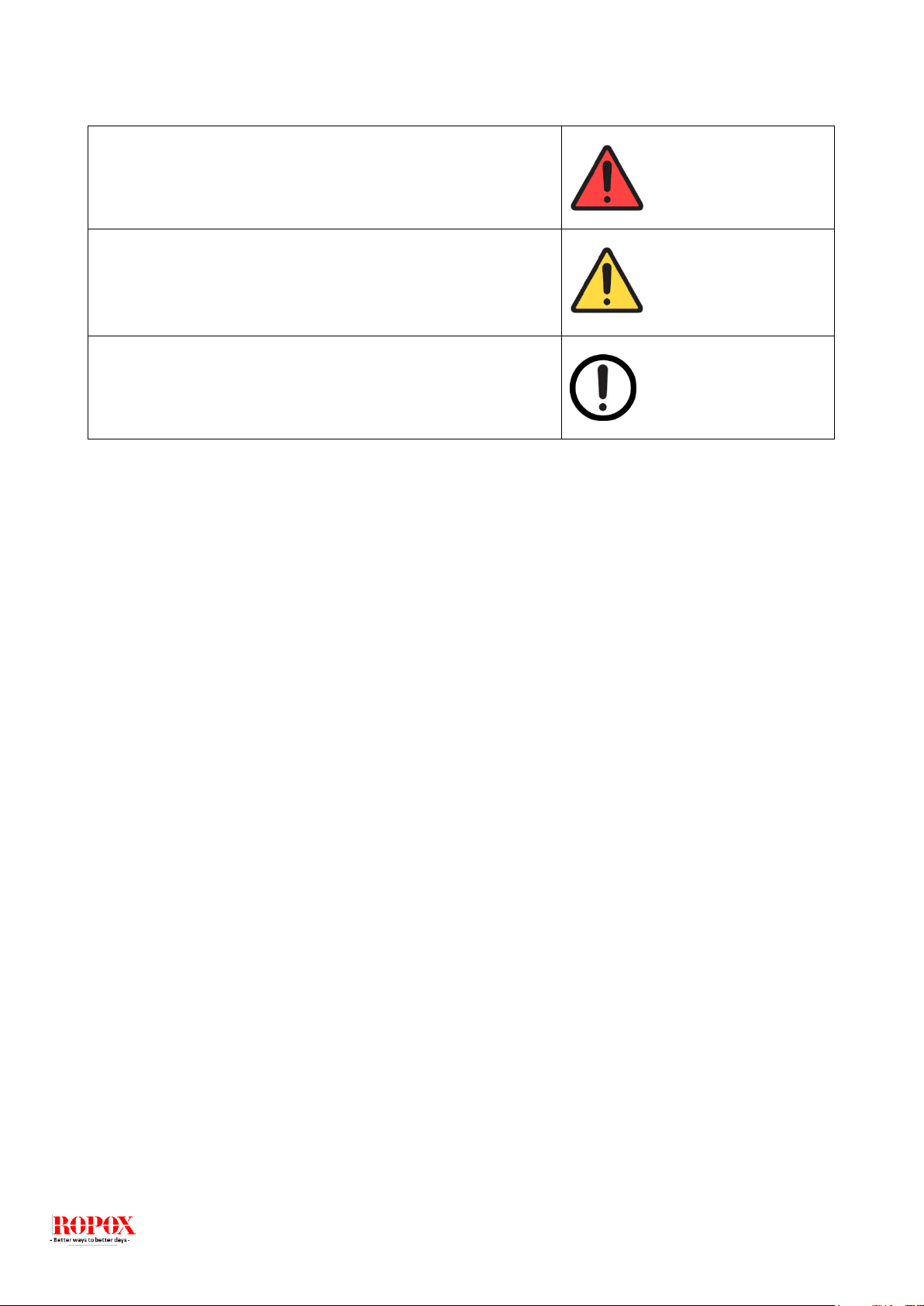

1. Symbols used in this manual

Warning Symbol

Indication of potentially hazardous situation. If not avoided it can

result in serious injury or death.

Caution Symbol

Indication of potentially hazardous situation which may result in

minor or moderate injury.

It may also be used to alert against unsafe practices.

Notification Symbol

This symbol is used to notify correct use and handling of the

product.

PDF 6210 / DRAFT Rev001

4

2. General safety

This manual must be read and understood before use.

Always keep this manual in close proximity of the product.

The use, installation and service of this product must be in

compliance with this manual to avoid accidents and serious

personal injury.

Never use or handle this product in other ways specified in

this manual as it can result in personal safety hazards and/or

cause damage to the product.

Persons installing and/or are using this product either as

operator or patient should have the necessary safety

information and access to this manual.

Always comply with instructions in this manual to avoid

damaging or destroying the product. Not doing so can cause

the safety of this product to be compromised.

Do not perform repairs, disassembly or assembly operations,

add-ons, re-adjustments or modification of the product

beyond what is described in this manual. These must be

carried out by Ropox or Ropox authorized personnel. Do not

perform service while in use with a patient.

Do not allow children to operate this product unless they are

under supervision from an adult that has read and

understood this manual. The product is not intended to play

with.

Do not use the product if it has defects or have become

damaged before being repaired or replaced

PDF 6210 / DRAFT Rev001

5

The information in this manual is based on correct installation

in accordance with installation instructions for this product.

Ropox cannot be held liable if the product is used in any way

that differs from stated in this manual and/or installation

instruction.

Ropox reserve the right to amend this manual and reference

documents without prior notice.

PDF 6210 / DRAFT Rev001

6

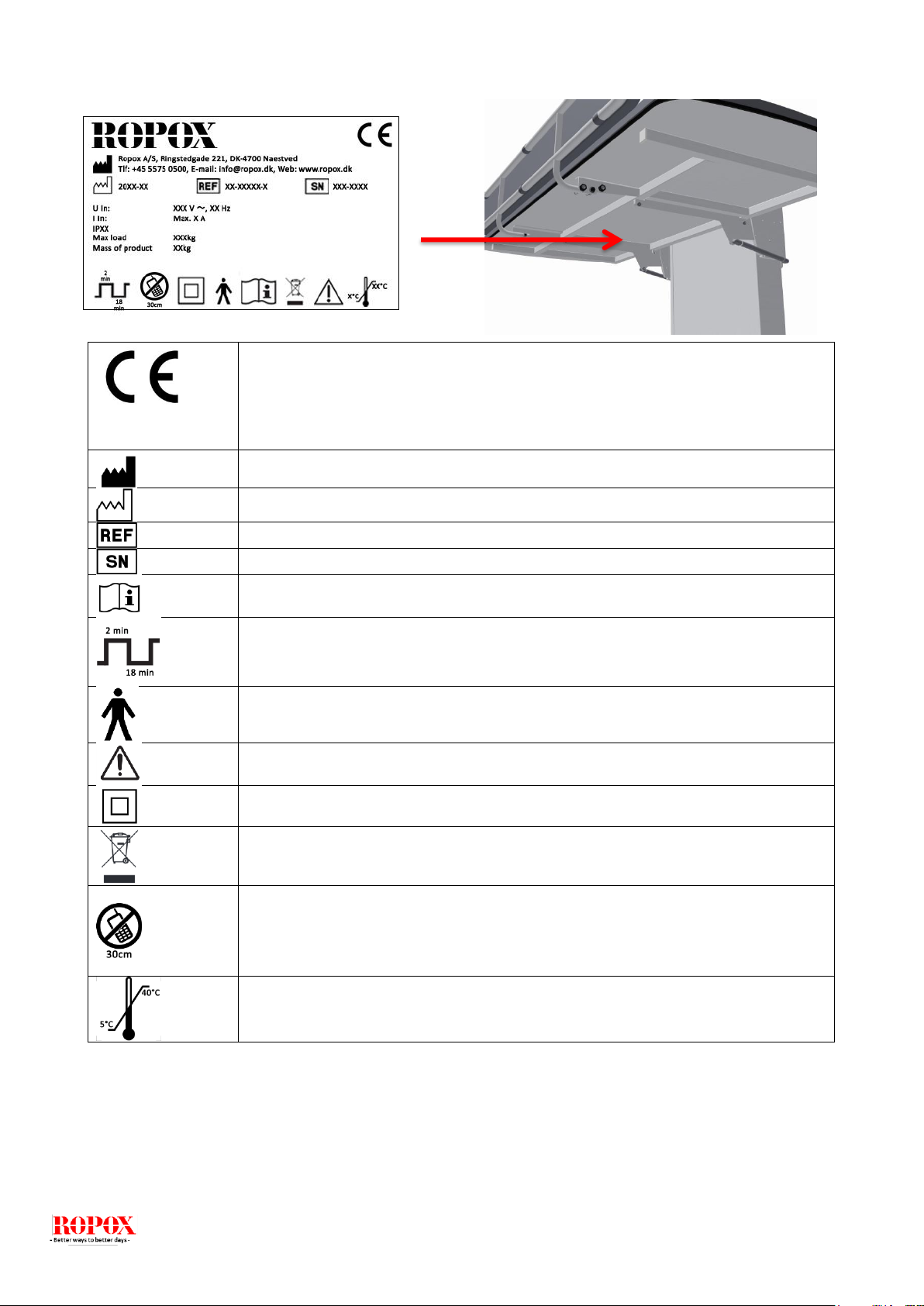

2.1 Product label

This product is CE-marked in accordance with the

European Medical Device Directive 93/42/EEC, including

amendments incorporated in Directive 2007/47/EEC.

It also complies with all relevant requirements in the

Council Directive 2006/42/EC on

machinery

Manufacturer name and address

Date of production

Stock number

Serial number

Consult manual before use

Operating interval of electrically operated equipment. The use of electrical height

adjustable equipment can run at maximum 2 minutes, followed by an 18-minute

break.

Type B applied part. The product complies with IEC 60601-1 requirements to

provide protection against electric shock.

Consult manual for important safety related information, warnings and safety

precautions.

Class II, double isolated electrical components.

Do not dispose as unsorted municipal waste. Product must be returned to a

designated recycling station.

Mobile phones or other portable RF emitting equipment should be no closer to the

product than 30cm.

Operating and storing temperatures may not exceed 5-40C°

PDF 6210 / DRAFT Rev001

7

3. General requirements

3.1 Product information

Manufacturer:

Ropox A/S

Ringstedgade 221, DK-4700 Naestved

+45 55 75 05 00

Info@ropox.com

Product models

Part number

Model

Configuration

40-30604-3

40-30606-3

40-30608-3

40-30610-3

40-30611-3

Vario 120x70cm

Vario 140x70cm

Vario 160x70cm

Vario 180x70cm

Vario 190x70cm

MDD Class

93/68/EEC

Class I

Applied part classification

60601-1

Type B applied part

MEE Class

60601-1

Class II

Height adjustment

30-100cm

Speed of actuation

≈ 26mm/s

Maximum user weight

according to

EN12182:2012

200kg

Power supply

230V ~50Hz

I in

Max 8A

Intermittence

2min on / 18min off

IP rating

IPX6

Ambient temperature

5-40C° Operation and storage

Materials in contact with

patient

Table top surface

Mattress

(accessories)

Bed guards

(accessories)

Lifting unit

Compact laminate surface.

Dahlia fabric

Backing: 100% polyester

Coating: 100% Polyurethane

ISO 10993-10 Non Allergic

St37 tube construction with powder coating.

St37 tube construction with powder coating.

Aluminium anodiseret with powder coating.

Intended environments

This product is to be used only in:

Proffesional Healtcare Environment

Homecare Environment

The device is not intended for use in special environments as defined by IEC

60601-1-2

Accessories

Mattresses

40-25760-1

40-25795-1

40-25796-1

40-25764-1

40-25765-1

Bed guards

40-30196-1

40-30197-1

Cushion for bed guard

40-25782-1

40-25783-1

For L= 120cm

For L= 140cm

For L= 160cm

For L= 180cm

For L= 190cm

For L=120cm, 140cm

For L=160cm, 180cm, 190cm

For L=120cm, 140cm

For L=160cm, 180cm, 190cm

PDF 6210 / DRAFT Rev001

8

3.2 Intended use

Vario is a fixed, height adjustable & foldable changing bed that can be used for care of children and adults

up to 200 kg. The changing bed is inteded for use i private homes, institutions, day care centers and similar

institutions and for people with physical or mental disabilities. The product is designed to provide optimum

working conditions for caregivers. The changing bed can be used in both dry and wet rooms (conditions), but

must not be used as a shower bed.

The height of tabletop (changing bed) can be adjusted infinitely from 30-100 cm using the hand control and

can be folded up for spare saving when not in use.

3.3 Intended operator

Reading and understanding this manual will be sufficient training for an intended operator. Children nor

patient are not considered intended operator.

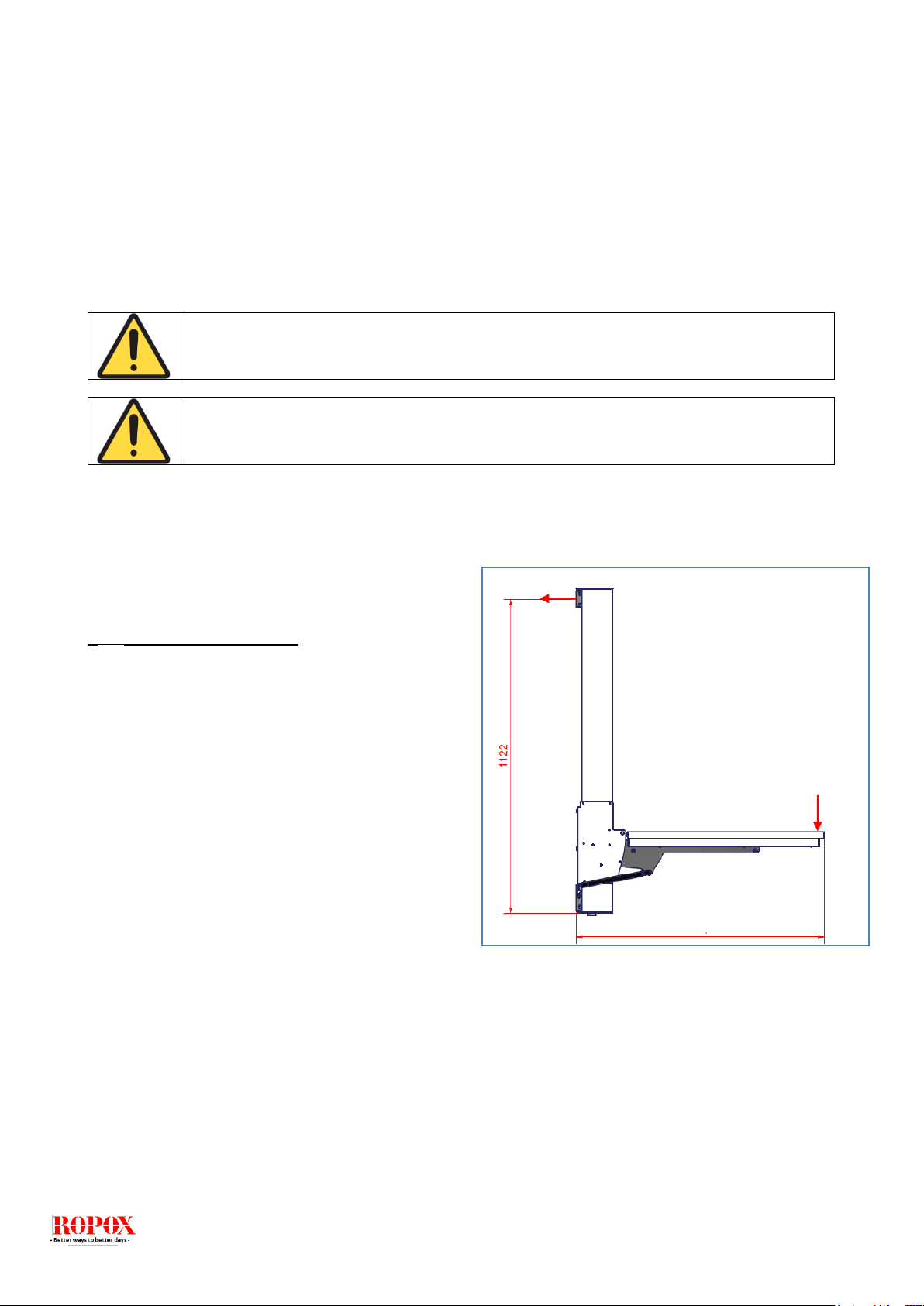

3.4 Dimension sketch

Model

Lenght

(L)

40-30604-3

120cm

40-30606-3

140cm

40-30608-3

160cm

40-30610-3

180cm

40-30611-3

190cm

The ceiling height must be at least 2,35m

32cm

115cm

13cm

PDF 6210 / DRAFT Rev001

9

4. Instructions for use

4.1 Receiving the Vario changing bed

Vario is a wall fixed changing bed. It is delivered partly assembled. Connecting the product to mains will

make it operational.

Vario will come in two packages. One for the “Lifting unit” and one for the “tabletop”.

4.2 Placering af el-udtag

Make sure that you allow free space on all sides of the changing bed.

The main power cable (230V) has a total length of approx. 320 cm of which 250 cm is outside the lifting unit.

The cable can be pulled out in either left or right side. The outlet for main power cannot be placed behind the

lifting unit.

Caution!

When connected to the mains the product must be placed in a manner according to

power outlets so that the operator will be able to disconnect the product during use in

case of an emergency.

Warning!

Make sure that the Main 230 V socket is placed according to the national requirements

for such installations.

300cm

250cm

PDF 6210 / DRAFT Rev001

10

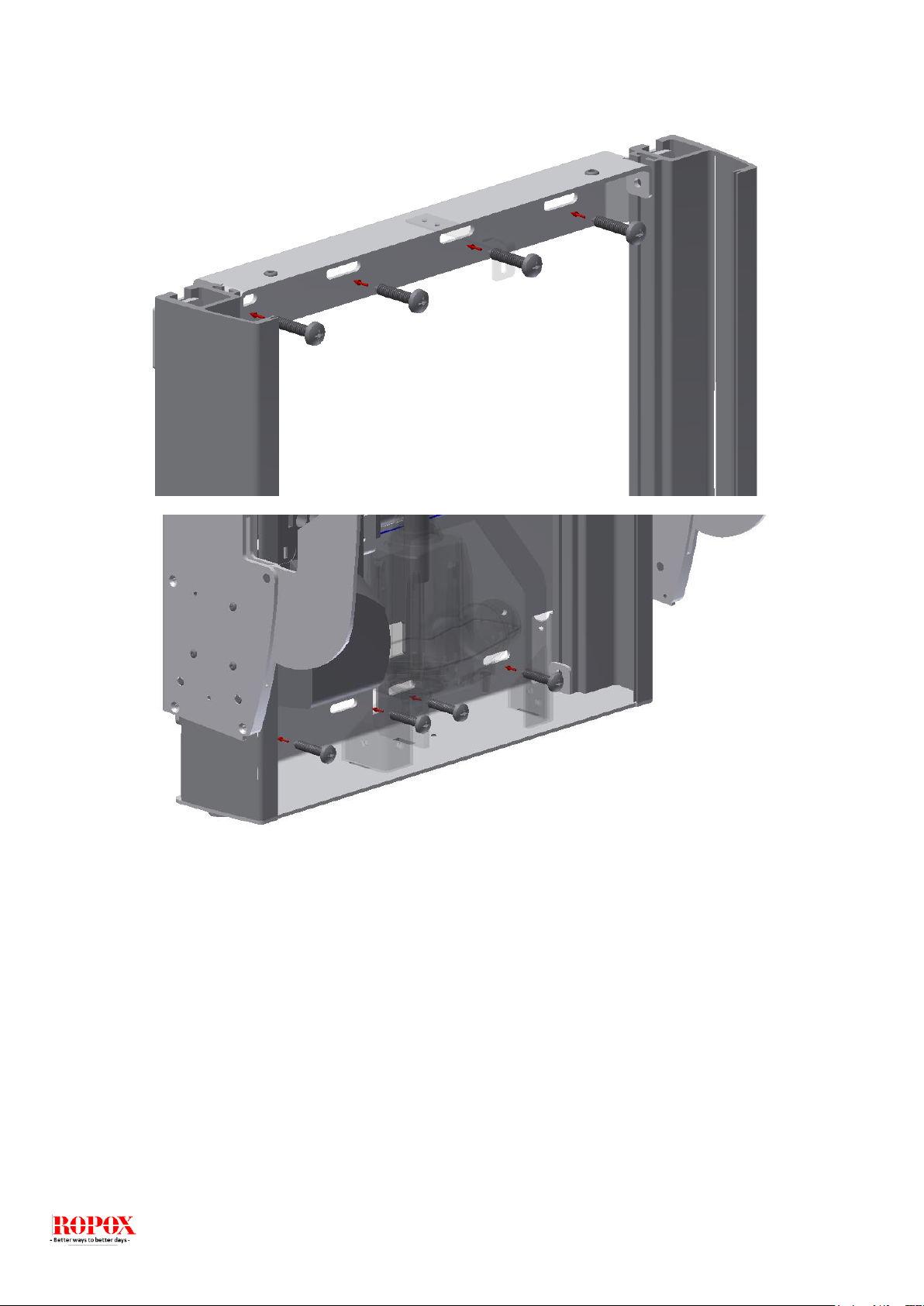

4.3 Prepare the mounting

Dismount the top cover plate

PDF 6210 / DRAFT Rev001

11

Slide the front plate out of the Lifting unit to get access to the wall mounting holes in the unit.

!! Be aware not to bend or scratch the front plate in the process !!

PDF 6210 / DRAFT Rev001

12

4.4 Mounting to the wall

The attachment holes can be marked up on the wall, four possibilities in the top, and four in the bottom of the

frame. Place the frame against the wall and make sure it is horizontal. The frame is standing on two

adjustable feet. The holes in the frame are all Ø 10 mm. Remove the frame and drill the holes.

Attach the frame securely to the wall by using adequate bolts and rawlplugs suitable for the type of wall

construction / material on site. The Shower bed is being supplied with a set (8 pcs) of screws and rawlplugs,

which is ONLY used to mount the unit in a concrete wall. If the unit must be mounted on another kind of wall,

other kinds of plugs and screws must be used.

Changing bed has a max user weight of 200 kg.

Maximum load in the top screws are 31kg for each screw.

If you have other objects mounted right next to this changing bed, you have to consider the

risk of trapping, and therefore consider a safe distance to the other objects.

Make sure that no dust or other obstacles are interfering with the rollers, chain, sprocket or

gas springs. This cancause malfunction and damage the system.

Force for each of the four screws in top of the unit::

K

screw

= (200kg * 992mm)/(1122mm * 4 screws)

K

screw

= 44kg for each screw

F=200kg

F=Screw

992

PDF 6210 / DRAFT Rev001

13

Mount the lifting unit to the wall with screws at the top and bottom.

PDF 6210 / DRAFT Rev001

14

Slide the front plate back into the lifting unit.

PDF 6210 / DRAFT Rev001

15

Mount the cover plate on the top of the lifting.

PDF 6210 / DRAFT Rev001

16

4.5 Mount the tabletop on the lifting unit

Slide the tabletop in between the Lifting unit and the support arms on the Lifting unit.

Fasten the tabletop to the Lifting unit with 4 pcs. Screws (M8x12) through the bushings in the support

arms.

Bed guard are accessories

PDF 6210 / DRAFT Rev001

17

5.

4.6 Wire diagram

The changing bed is delivered with the control box already mounted on the frame. The diagram

shows how the cables are connected to the control box.

All the plugs are water tight, and therefore they can be a little tricky to connect / disconnect. Make sure that

the plugs are positioned correctly before they are pushed into the sockets at the control box. The plugs must

be pushed into the sockets until the “O-ring” is no longer visible.

Motor, control box and control switch apply to IPX6. This

means that they are dustproof and water resistent.

The electronic system is designed for periodical use only,

this means a max. duty cycle of 10%; 2min on /18min off.

1. Control box

2. Mains cable 230V

3. Motor, connects to socket 1

4. End plugs, connects to socket 2, 3 & 4

5. Handcontrol, connects to HB socket

1

2 3 4

5

PDF 6210 / DRAFT Rev001

18

4.7 Connecting cables

The changing bed is delivered with the control box already mounted on the frame.

Control switch connects to ”HB”.

When all cables have been connected, use the safe locking

bracket. Pushed in until you hear a “click”.

Mains cable connects to the socket at the side of the box.

Disconnecting cables

Mains cable can be pulled out (no safe locking bracket).

Before the other cables can be disconnected, the safe locking

bracket needs to be released / removed

(use a screwdriver to remove). Locking clips at each end of the

safe locking bracket have to be released

before the bracket can be removed, and the cables can be

disconnected.

To obtain the full IPX6 value, it is very important that all the plugs have been pressed

firmly into the sockets and the safe locking bracket is mounted.

Placement of the handcontrol

Bracket for hand control can be placed at the

wall as shown. To be mounted with the two

screws which are delivered with the bracket.

Hand control should be placed out of

reach of children.

Hand control can be placed in either right

or left side.

PDF 6210 / DRAFT Rev001

19

5. Instructions for use

5.1 Operating the product

5.1.1 Actuation of the product

The product is operated with the spiral cord hand control. Arrow up will move the product

upwards and arrow down will move the product downwards.

Warning!

The product should always be able to travel the full range of actuation without colliding

with objects. Failing to do so will compromise the product stability.

Special care should be taken in ensuring that no children or adults are sited under the

product as severer injury from entrapment may occur.

Indstil KUN skiftelejet i højden når bordpladen er nedslået i vandret position.

Only adjust the product in height position, when the table top are in horizontal

Note!

The control buttons are «push and hold». Height adjustment stops as sonn as the button

is released. This is an inportant safety measure.

Warning!

Before use always make sure that mains cable and hand control cable will be able to

travel freely without the risk of squeezing or disconnecting the product as result of the

movement.

PDF 6210 / DRAFT Rev001

20

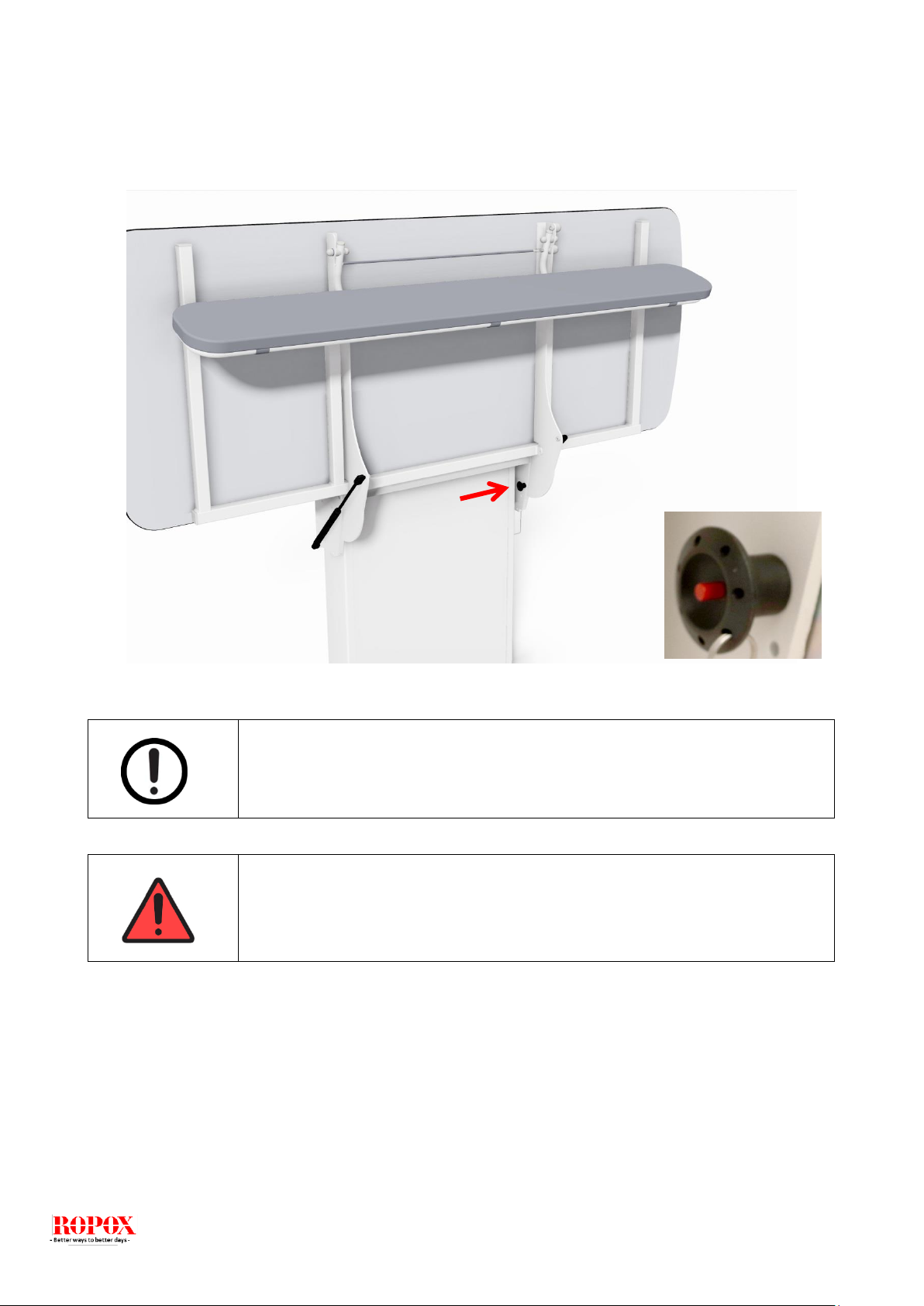

5.1.2 Operation of the bed guards

Vario is not supplied with bed guard as standard. This can be ordered as an accessory.

To operate the bed guards pull the rubber tubing placed under the table top to release the locking

mechanism. The bed guard can then be pivoted to the desired mode.

Warning!

Make sure that the bed guard is locked securely in place when in use. Locking is

checked by shaking the bed guard back and forth ensuring that the locking pin is

fully engaged.

PDF 6210 / DRAFT Rev001

21

5.1.3 How to fold changing bed up and down

The worktop can be secured against inadvertent folding in upright position by locking the table with the

locking pin.

For folding the worktop in downwards position, remove locking pin and lower top by hand.

Notification!

Prior to folding worktop in upright position, bed guard must be turned underneath

worktop.

Warning!

Always make sure worktop is securely locked in upright position with locking

pin.when left in this position. Check shower bed is locked by pulling the worktop to

ensure locking pin is fully engaged and worktop cannot be lowered.

PDF 6210 / DRAFT Rev001

22

Locking of shower bed

When worktop is folded up, insert locking pin as indicated. Press and hold the red button while inserting the

split. The shower bed is now locked against folding down.

Unlocking of shower bed

For unlocking & folding worktop in downwards position, remove pin. Pin is placed in second hole for storage

when shower bed is being used and folded down. The worktop can now easily be folded up and down.

PDF 6210 / DRAFT Rev001

23

5.2 Recommendations in use

Warning!

NEVER leave a person on the changing bed unattended - not even for a very

short period.

--If two changing beds are mounted next to each other, we recommend to mount a

side cover between, to avoid the trapping risk.

6. Cleaning

Cleaning can be done with lukewarm water and a suitable all purpose cleaning agent. Use a cloth or soft

sponge to wash the product. Dry the product of with a wrung cloth.

Mattresses and cushions

Cover:

Recommended cleaning detergent: Normal soap or alcohol. The alcohol can be used undiluted. The cover

can be removed and machine washed separately at max 95°.

Skum:

Cannot be washed

Notification!

Do not use cleaning agents containing abrasive e.g. scouring powder, steel wool, scouring

sponge.

This product is not designed to be sterilized, autoclaving and sterilization beyond normal

cleaning is may possibly change the product safety and function.

7. Maintenance

Notification!

Failing to comply with periodic maintenance may result of degrading of product function and

safety.

7.1 Periodic maintenance of bed guards

If the product is used humid or dry atmosphere the locking pin may be prone to seizing from lubricants

drying. Besides checking the function of the locking mechanism before every use, a periodic lubrication

of the locking pin every 6 month is recommended.

PDF 6210 / DRAFT Rev001

24

7.2 Fejlsøgning

Problem:

Check:

Vario does not move up or down when the handcontrol switch is pressed

1. Main power connected 230v

2. Motor cable is connected to control box

3. Hand control is connected to control box

4. Motor is overloaded

Hand control defect

1. The product works with another hand

control

By pressing the up or down button,

no movement is achieved, only

clicking sounds is are heard from

control box

1. Plugs are not connected correctly.

Dismount all cables and re-connect.

2. ”Reset”

Press and hold UP ( ) and DOWN ( )

buttons. Keep the buttons depressed until

the control unit has beeped approx. ten

times. After that, the bathtub may be

adjusted to the bottom position for

resetting.

8. Environmental protection

The product is not intended to be disposed as municipal waste. Proper disassembly, sorting

and disposal of components must be done by waste disposal professionals.

Part

Disposal recommendation

Table top

Hard plastic or phenolic composites

Bed guards

Steel waste

Lifting unit

Steel and aluminum

Controlbox

Electronics

Actuator

Electronics

Hand control

Electronics

PDF 6210 / DRAFT Rev001

25

8. Spare parts

#

Name

Part number

1

Control box CB6096-03

97000434

2

Actuator LA34.5

97000431

3

Motor cable L=300mm

97000423

4

230V cable

97000427

5

Ganter Pallet lock with axial

protection

95170115

6

Hand control

97001655

#

Name

40-30604-1

40-30606-1

40-30608-1

40-30610-1

40-30611-1

7

Bed guard

complete *

40-30196-1

40-30196-1

40-30197-1

40-30197-1

40-30197-1

8

Parts for

bed guards

40-30198-1

40-30198-1

40-30199-1

40-30199-1

40-30199-1

9

Table top

Vario

40-30891-1

40-30892-1

40-30893-1

40-30894-1

40-30895-1

*Bed guards complete contains necessary parts for mounting.

*Bed guards are accessories

PDF 6210 / DRAFT Rev001

26

9. Accessories

9.1 Bed guard

Part number

Size

Pcs.

40-30196-1

L= 120cm, 140cm

1

40-30197-1

L= 160cm, 180cm, 190cm

1

PDF 6210 / DRAFT Rev001

27

9.2 Cushion for bed guard

9.3 Mattress

Part number

Size

Pcs.

40-25782-1

L= 120cm, 140cm

1

40-25783-1

L= 160cm, 180cm, 190cm

1

Item number

Size

Thickness

40-25760-1

Madras L=120 cm m/underlag

3 cm

40-25795-1

Madras L=140 cm m/underlag

3 cm

40-25796-1

Madras L=160 cm m/underlag

3 cm

40-25764-1

Madras L=180 cm m/underlag

3 cm

40-25765-1

Madras L=190 cm m/underlag

3 cm

PDF 6210 / DRAFT Rev001

28

10. Electro magnetic compability

10.1 Suitable Environments

The device is suitable for use at home, at daycare centres, at day centres for persons with

physical or mental disabilities or at hospitals except near active HF surgical equipment and the

RF shielded room of an medical electrical system for magnetic resonance imaging, where the

intensity of electromagnetic disturbances is high.

10.2 Basic safety and Essential performance

The device does not have any function related to basic safety or essential performance. In case

of loss or degradation of performance, the user can get on and off the product.

10.3 Adjacent and stacked use

Warning!

Use of this equipment adjacent to or stacked with other equipment should be voided

because it could result in improper operation. If such use is necessary, this equipment

and the other equipment should be observed to verify that they are operating normally

10.4 Cables

Cable component

Lenght

Power cable

2,5m

Hand control spiral cable

Approx. 5 m extended

Warning!

Use of accessories, transducers and cables other than those specified or provided by the

manufacturer of this could result in increased electromagnetic emissions or decreased

electromagnetic immunity of this equipment and result in improper operation.

10.5 RF portable equipment

Warning!

Portable RF communications equipment (including peripherals such as antenna cables

and external antennas) should be used no closer than 30 cm (12 inches) to any part of

the device, including cables specified by the manufacturer. Otherwise, degradation of the

performance of this equipment could result.

PDF 6210 / DRAFT Rev001

29

11. CE – Declaration of conformity

I, the undersigned, hereby declare that the following products:

Ropox Mobilio

Part number

Model

40-30604-1

40-30606-1

40-30608-1

40-30610-1

40-30611-1

Vario 120x70

Vario 140x70

Vario 160x70

Vario 180x70

Vario 190x70

and all accessories belong to risk class I and conform to the following Directives and Standards:

DIRECTIVES European Medical Device Directive 93/42/EEC, including amendments

incorporated in Directive 2007/47/EEC.

Council Directive 2006/42/EC on machinery

STANDARDS

DS/EN 12182:2012 Assistive devices for persons with functional disabilities -

General requirements and test methods.

DS/EN 14971:2012 Medical devices – The use of risk management in connection

with medical devices

DS/EN 9999:2016 Assistive devices for persons with functional disabilities -

Classification and terminology

DS/EN 60601-1-2:2007

+Corr (Mar2010) Elektromedicinsk udstyr - Del 1-2: Generelle krav til grundliggende sikkerhed og

væsentlige funktionsegenskaber - Sideordnet standard: Elektromagnetiske

forstyrrelser - Krav og prøvninger

DS/EN 60601-1:2006 Medical electrical equipment – Part 1: General requirements for basic safety and

essential performance

Næstved, Dato 01-07-2018

ROPOX A/S

Ringstedgade 221

DK – 4700 Næstved

Tel.: +45 55 75 05 00 Fax.: +45 55 75 05 50

E-mail: info@ropox.dk

www.ropox.dk

Loading...

Loading...