Roper F400, F405, F430, F435, F445 Owner's Manual

...

c

USE

and

CARE

MANUAL

GAS RANGE

INSTALLATION

F400, F405, F430, F435, F445,

F450, F455, F650, F655

4356204 MNL020-1 (341381)

THIS PAGE

INTENTIONALLY

LEFT BLANK

?+-

F -w

FOR YOUR SAFETY

If you smell gas:

1 .Open windows.

2. Don’t touch electrical switches.

3. Immediately call your gas supplier.

.

I..

INSTALLATION

1

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of this or any other appliance.

c

---A

Important Instructions for Your Safety

Burner Ignition

Cooktop Cooking

Over. Cooking

Clock and Timer (some models)

Broiling

Favorite American Recipes

Continuous Cleaning Oven (some models)

Cleaning ‘Tips

Removable Range Parts

SERVICE

Replacing Oven Light Bulbs

What to do before Calling for Service

Adjusting Oven Temperature

WARRANTY

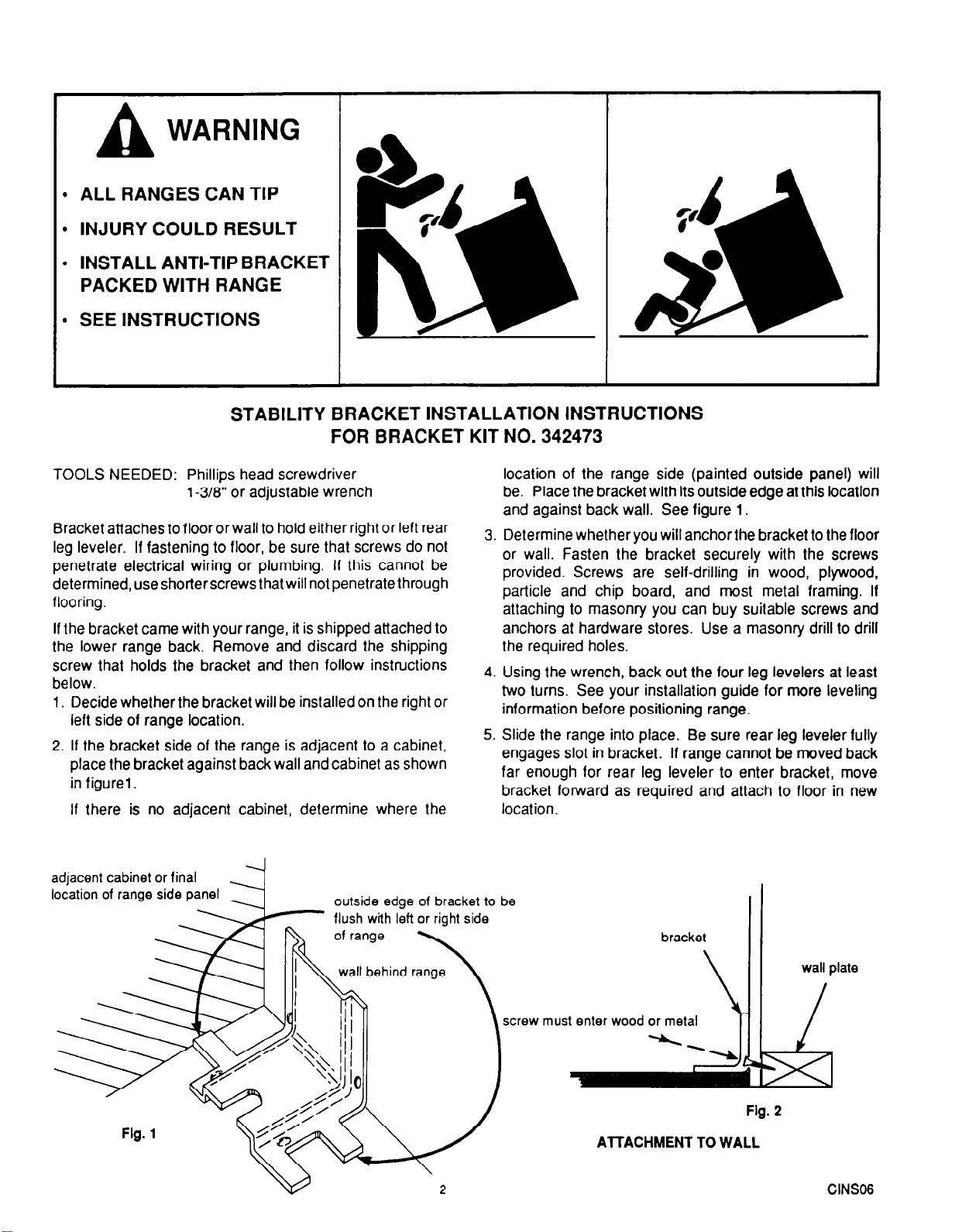

WARNING

A

l

ALL RANGES CAN TIP

. INJURY COULD RESULT

l

INSTALL ANTI-TIP BRACKET

PACKED WITH RANGE

. SEE INSTRUCTIONS

STABILITY BRACKET INSTALLATION INSTRUCTIONS

FOR BRACKET KIT NO. 342473

TOOLS NEEDED: Phillips head screwdriver

l-3/8” or adjustable wrench

Bracket attaches tofloororwall to hold either right or left rear

leg leveler. If fastening to floor, be sure that screws do not

penetrate electrical wiring or plumbing. If this cannot be

determined, use shorter screws that will not penetrate through

flooring.

If the bracket came with your range, it is shipped attached to

the lower range back. Remove and discard the shipping

screw that holds the bracket and then follow instructions

below.

1. Decide whether the bracket will be installed on the right or

left side of range location.

2. If the bracket side of the range is adjacent to a cabinet,

place the bracket against back wall and cabinet as shown

in figurel.

If there is no adjacent cabinet, determine where the

adjacent cabinet or final

location of range side panel

outside

edQe of bracket to be

location of the range side (painted outside panel) will

be. Place the bracket with its outside edge at this location

and against back wall. See figure 1.

3. Determine whether you will anchorthe bracket to the floor

or wall. Fasten the bracket securely with the screws

provided. Screws are self-drilling in wood, plywood,

particle and chip board, and most metal framing. If

attaching to masonry you can buy suitable screws and

anchors at hardware stores. Use a masonry drill to drill

the required holes.

4. Using the wrench, back out the four leg levelers at least

two turns. See your installation guide for more leveling

information before positioning range.

5. Slide the range into place. Be sure rear leg leveler fully

engages slot in bracket. If range cannot be moved back

far enough for rear leg leveler to enter bracket, move

bracket fotward as required and attach to floor in new

location.

screw must enter wood or metal

AlTACHMENT TO WALL

wall plate

c

Al

Fig. 2

CINSOG

L.P. Burner Adjustments

If the range was factory set for natural gas and you wish

to use L.P. gas, the adjustments in the Installation Section

must be made before you try to use your range.

If you are using Liquified Petroleum Gas (bottled gas)

all L.P. adjustments in the Installation Section must be

made before use.

If your range is not properly adjusted, flames may be too

high, or the range may use too much fuel, release toxic

fumes or cook poorly.

GNOT12

INSTALLATION

INSTALLER: Leave these instructions with the

appliance.

TOOL LIST

1. %“, 1%” and 1%” open end or adjustable wrenches

2. Pipe wrench

3. l/s” and %” flat blade screwdriver

4. Phillips screwdriver

5. Pliers

LOCATION

l

You should not put the range near an outside door or

where a draft may affect use.

l

Cabinet space directly over range should not be used.

You could be seriously injured when reaching over the

range for items stored in such cabinets. If cabinet

space is to be used, the risk of burns can be reduced by

installing a range hood that sticks out at least 5”

beyond the front of the cabinets. Cabinets installed

above the range may be no deeper than 13”.

OWNER: Keep these instructions for future use.

CLEAF?ANCES

l

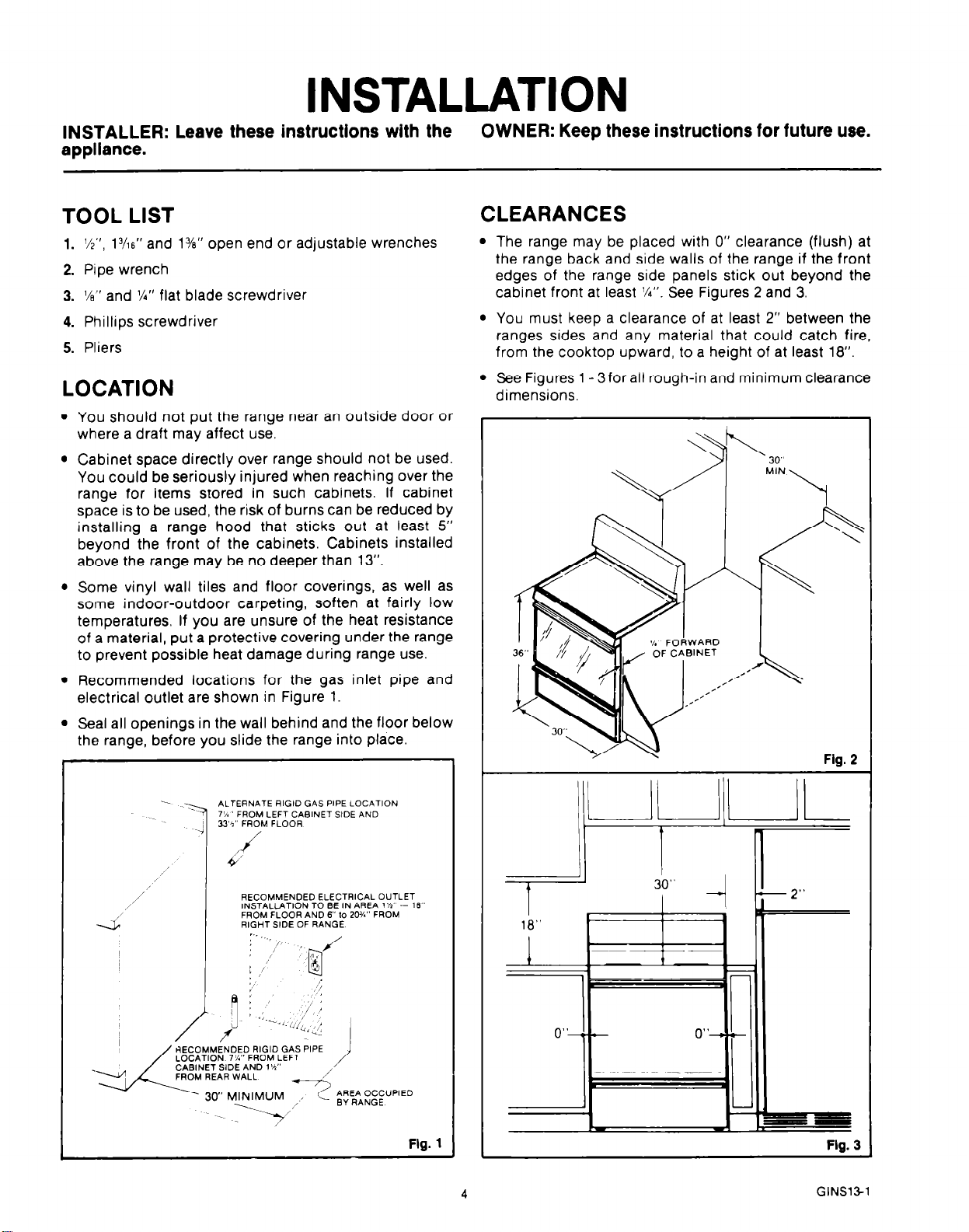

The range may be placed with 0” clearance (flush) at

the range back and side walls of the range if the front

edges of the range side panels stick out beyond the

cabinet front at least ‘A”. See Figures 2 and 3.

l

You must keep a clearance of at least 2” between the

ranges sides and any material that could catch fire,

from the cooktop upward, to a height of at least 18”.

l

See Figures 1 - 3 for all rough-in and minimum clearance

dimensions

l

Some vinyl wall tiles and floor coverings, as well as

some indoor-outdoor carpeting, soften at fairly low

temperatures, If you are unsure of the heat resistance

of a material, put a protective covering under the range

to prevent possible heat damage during range use.

l

Recommended locations for the gas inlet pipe and

electrical outlet are shown in Figure 1.

l

Seal all openings in the wall behind and the floor below

the range, before you slide the range into place.

AL.TERNATE RIGID GAS PIPE LOCATION

7% FROM LEFT CABINET SIDE AND

X3’/>” FROM FLOOR

/

RECOMMENDED ELECTRICAL OUTLET

INSTALLATION TO BE IN AREA lb” -- 18”

FROM FLOOR AND 6” lo 20%” FROM

RIGHT SIDE OF RANGE

Flg. 2

RECOMMENDED RIGID GAS PIPE

LOCATION 7%” FROM LEFT

CABINET SIDE AND 1%”

FROM REAR WALL

30” MINIMUM

AREA OCCUPIED

Flg. 1

Fig. 3

4

GINS181

PREPARATION

1.

Remove all tape and packaging. Be sure to remove

clear plastic film that covers some chrome and plastic

parts.

2 Take the accessory pack out of the oven

3. Check to be sure that no range parts have come loose

during shipping.

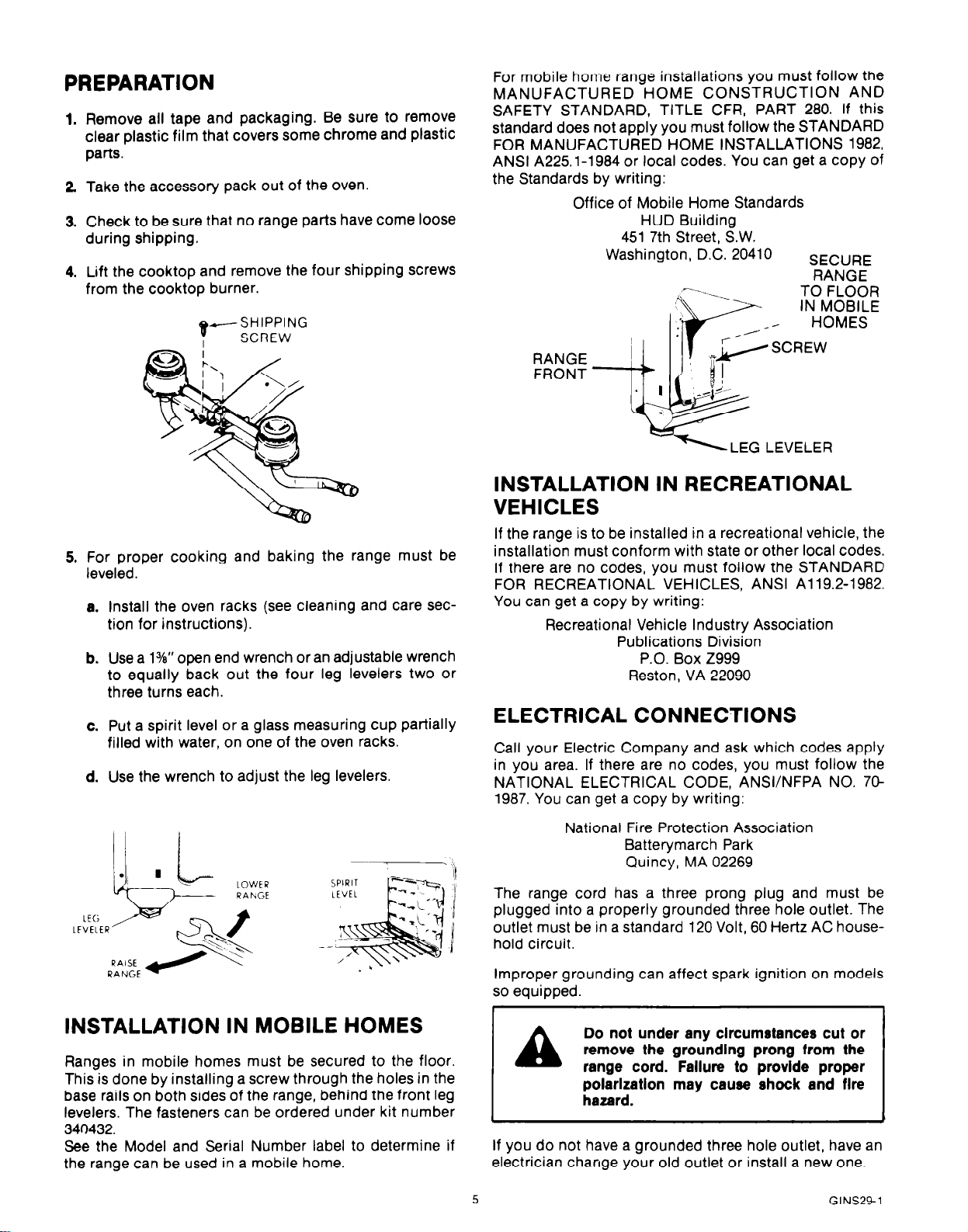

4. Lift the cooktop and remove the four shipping screws

from the cooktop burner.

SHIPPING

w-

SCREW

I

5. For proper cooking and baking the range must be

leveled.

a.

Install the oven racks (see cleaning and care sec-

tion for instructions).

b.

Use a 1%” open end wrench or an adjustable wrench

to equally back out the four leg levelers two or

three turns each.

c. Put a spirit level or a glass measuring cup partially

filled with water, on one of the oven racks.

d.

Use the wrench to adjust the leg levelers.

For mobile home range installations you must follow the

MANUFACTURED HOME CONSTRUCTION AND

SAFETY STANDARD, TITLE CFR, PART 280. If this

standard does not apply you must follow the STANDARD

FOR MANUFACTURED HOME INSTALLATIONS 1982,

ANSI A225.1-1984 or local codes. You can get a copy of

the Standards by writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, SW.

Washington, D.C. 20410

RANGE

FRONT

v LEG LEVELER

SECURE

RANGE

IN MOBILE

INSTALLATION IN RECREATIONAL

VEHICLES

If the range is to be installed in a recreational vehicle, the

installation must conform with state or other local codes.

If there are no codes, you must follow the STANDARD

FOR RECREATIONAL VEHICLES, ANSI A119.2-1982.

You can get a copy by writing:

Recreational Vehicle Industry Association

Publications Division

P.O. Box 2999

Reston, VA 22090

ELECTRICAL CONNECTIONS

Call your Electric Company and ask which codes apply

in you area. If there are no codes, you must follow the

NATIONAL ELECTRICAL CODE, ANSI/NFPA NO. 7Cj

1987. You can get a copy by writing:

~ RANGE

INSTALLATION IN MOBILE HOMES

Ranges in mobile homes must be secured to the floor.

This is done by installing a screw through the holes in the

base rails on both sides of the range, behind the front leg

levelers. The fasteners can be ordered under kit number

340432.

See the Model and Serial Number label to determine if

the range can be used in a mobile home.

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

The range cord has a three prong plug and must be

plugged into a properly grounded three hole outlet. The

outlet must be in a standard 120 Volt, 60 Hertz AC house-

hold circuit.

Improper grounding can affect spark ignition on models

so equipped.

Do not under any circumstances cut or

A

remove the groundlng prong from the

range cord. Fallure to provide proper

polarlzatlon may cause shock and fire

hazard.

If you do not have a grounded three hole outlet, have an

electrician change your old outlet or install a new one.

5

GINS241

ELECTRICAL CONNECTION (cont.)

To temporarily use a properly polarized and grounded two

hole outlet until a grounded three hole outlet can be installed,

a grounding adapter plug may be used. Have an electrician

test the outlet to be sure it meets requirements.

HtlAL tYtlt1

PLAlf

HOUNllNC,

SCREW

y,

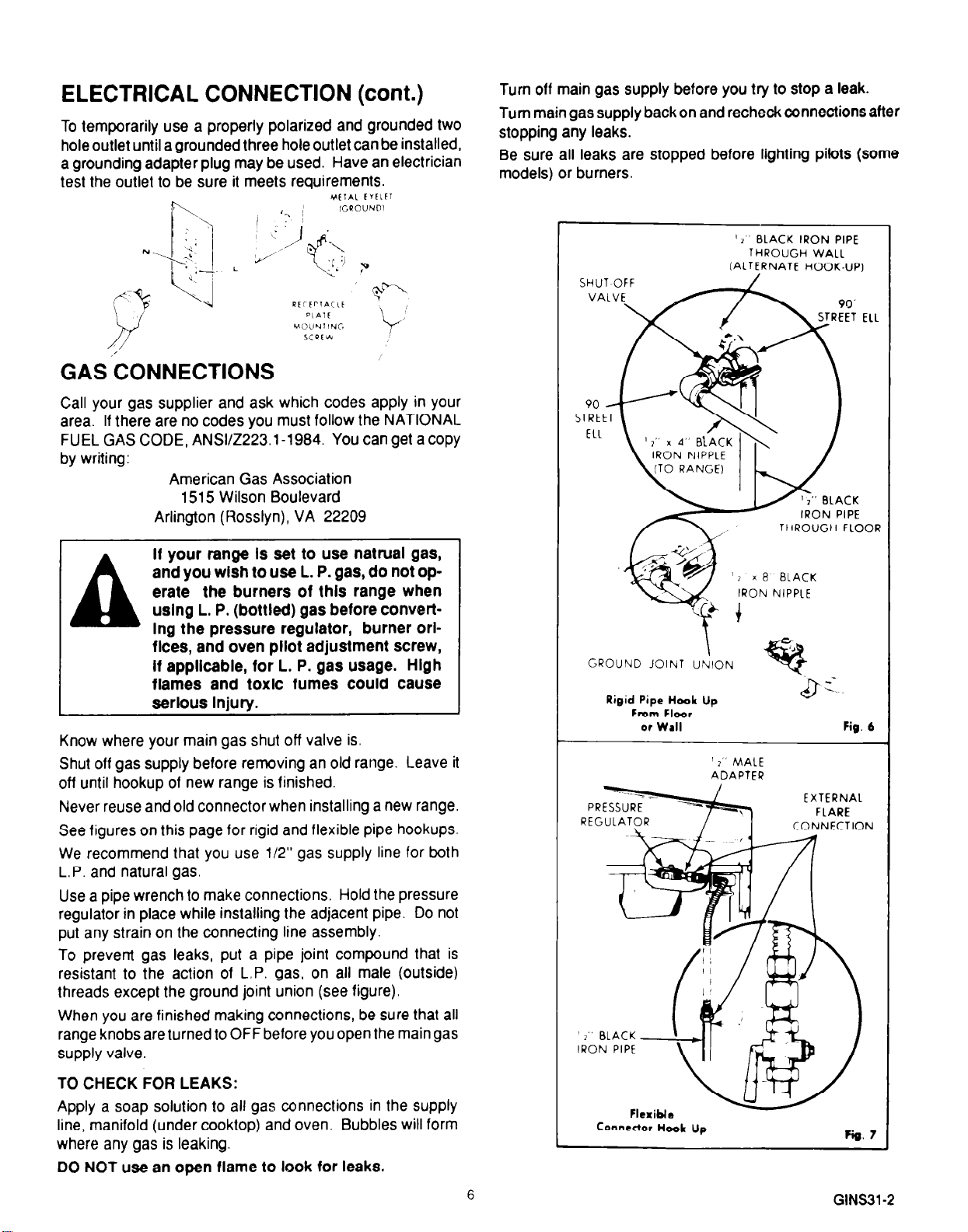

GAS’bONNECTlONS

Call your gas supplier and ask which codes apply in your

area. If there are no codes you must follow the NATIONAL

FUEL GAS CODE, ANSI/Z223. l-l 984. You can get a copy

by writing:

American Gas Association

1515 Wilson Boulevard

Arlington (Hosslyn), VA 22209

Turn off main gas supply before you try to stop a leak.

Turn main gas supply back on and recheck connections after

stopping any leaks.

Be sure all leaks are stopped before lighting pilots (some

models) or burners.

’ 3’ BLACK IRON PIPE

THROUGH WALL

(ALTERNATE HOOK4JP)

THROUGH FLOOR

If your range Is set to use natrual gas,

and you wish to use L. P. gas, do not operate the burners of thls range when

A

Know where your main gas shut off valve is.

Shut off gas supply before removing an old range. Leave it

off until hookup of new range is finished.

Never reuse and old connector when installing a new range.

See figures on this page for rigid and flexible pipe hookups.

We recommend that you use l/2” gas supply line for both

L.P. and natural gas.

Use a pipe wrench to make connections. Hold the pressure

regulator in place while installing the adjacent pipe. Do not

put any strain on the connecting line assembly.

To prevent gas leaks, put a pipe joint compound that is

resistant to the action of L.P. gas, on all male (outside)

threads except the ground joint union (see figure).

When you are finished making connections, be sure that all

range knobs are turned to OFF before you open the main gas

supply valve.

uslng L. P. (bottled) gas before conveftIng the pressure regulator, burner orlflees, and oven pllot adjustment screw,

If applicable, for L. P. gas usage. Hlgh

flames and toxic fumes could cause

serious Injury.

GROUND JOINT UNION

Rigid Pipe Hook Up

From Floor

0, Well

’ 2” MALE

ADAPTER

IRON NIPPLE

‘,

+Q

&L

Fig. 6

TO CHECK FOR LEAKS:

Apply a soap solution to all gas connections in the supply

line, manifold (under cooktop) and oven. Bubbles will form

where any gas is leaking.

DO NOT use an open flame to look for leaks.

Connector Hook up

6

GAS SUPPLY ( NATURAL OR L. P. )

Thisrangeoperatesoneithernaturalgas,at 1O”ofwater

column pressure, or on L. P. gas at 4” of water column

pressure. It is shipped from the factory set for either

natural gasor L.

number.

A

To adjust your range for use with L. P. gas, follow the steps

below.

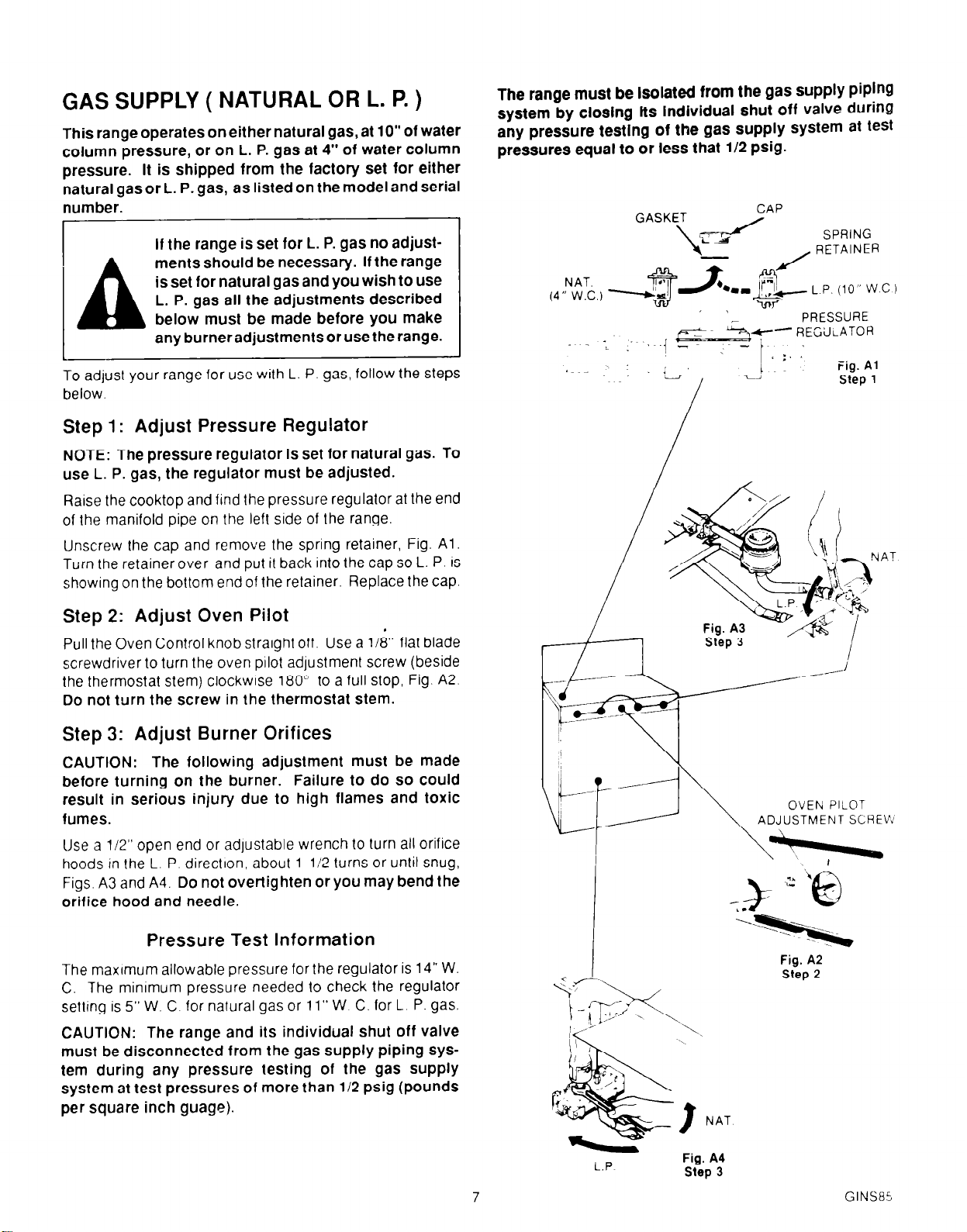

Step 1: Adjust Pressure Regulator

NOTE: The pressure regulator is set for natural gas. To

use L. P. gas, the regulator must be adjusted.

Raise the cooktop and find the pressure regulator at the end

of the manifold pipe on the left side of the range.

Unscrew the cap and remove the spring retainer, Fig. Al.

Turn the retainer over and put it back into the cap so L. P. IS

showing on the bottom end of the retainer. Replace the cap.

P.

gas, as listed on the model and serial

If the range is set for L. P. gas no adjustments should be necessary. If the range

is set for natural gas and you wish to use

L. P. gas all the adjustments described

below must be made before you make

any burneradjustments or use the range.

The range must be Isolated from the gas

system by closing lts Individual shut off valve

supply piplng

during

any pressure testlng of the gas supply system at

pressures equal to or less that l/2 psig.

test

Step 2: Adjust Oven Pilot

Pull the Oven Control knob straight off. Use a 116 flat blade

screwdriver to turn the oven pilot adjustment screw (beside

the thermostat stem) clockwise 180” to a full stop, Fig. A2.

Do not turn the screw in the thermostat stem.

Step 3: Adjust Burner Orifices

CAUTION: The following adjustment must be made

before turning on the burner. Failure to do so could

result in serious injury due to high flames and toxic

fumes.

Use a 112” open end or adjustable wrench to turn all orifice

hoods in the L. P. direction, about I-112 turns or until snug,

Figs. A3 and A4. Do not overtig hten or you may bend the

orifice hood and needle.

Pressure Test Information

l-he maximum allowable pressure for the regulator is 14” W.

C. The minimum pressure needed to check the regulator

setting is 5” W. C. for natural gas or 11” W C. for L. P. gas.

CAUTION: The range and its individual shut off valve

must be disconnected from the gas supply piping system during any pressure testing of the gas supply

system at test pressures of more than l/2 psig (pounds

per square inch guage).

OVEN PILOT

ADJUSTMENT SCHEvd

Fig. A2

step 2

NAT

t

L.P

Fig. A4

Slep 3

GINS85

Loading...

Loading...