Page 1

GAS BUILT-IN

INSTALLATION

models 8460

B675

CARE & USE

I

RECIPES

4356239 (343748)

Page 2

CONTENTS

USE AND CARE

Important Instructions for Your Safety ,,,

Your Oven and Its Features

Using the Lower Oven

Oven Vent

Oven Ignition ..............

Your Electronic Range Control

Oven Cooking

Broiling .........

Continuous Cleaning Oven

Cleaning Tips .,

Removable Parts ..... ......... .........

.................

.......... ,,

................................ ......

....................................................................................................................

....................

... .... .... ....

,,,

,, .,

........

..............................................

................................................................................

.... ... ...

,,..,

.......... .... ... .... ....

., ..........................................................

.... .... .... ............................. ...................

....... ...

,,

,, ,., ........

..

..

.... ... .... .... .... ..........

... ........ ...

.............................................................

.....................................

....

... ... .... ... ......... ..............

......... ................

,,, .......... ..............

..

... .... ....

... ........

...........

... 10

...

... 10

.....

...................

,,.,

.................

.........................

............................

..............

1 1,12

,, .....

........

.7-9

10

10

13

14

15

16

17

SERVICE

Replacing the Oven Light .., ,..,,, ,....,,..., ,,,. ,,,....,... ,,... .., ,... ,,,.., ,, ..,,, ,,.,,,,.,., 18

What to Do before Calling for Service

Adjusting Oven Temperature ..,.,

,......,. ,,..,,.... ,..,.. 19

.,,, ,...,,,....,,.. .,,.,,, ...,...., ,,..,,,...,,........, 20

WARRANTY

GC0028

Page 3

f

A

FOR YOUR SAFETY

If you smell gas:

I. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier

-_-..-

/

L.P. Burner

A

Adjustments

1 he adjustments In the Installatlon Section must be made

bt?lOre

you try10 use yourrange.

If you are using Liquified Petroleum

I P adjustments in the Installatlon Section must be made

before use.

If your oven is not properly adjusted, flames may be too high,

or the oven may use too much

luel, releasetoxicfurnesorcook

poorly.

Gas

(bottled gas) all

A

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

To insure safety for

yourself and your

home, please read

your Owner’s Manual

carefully. Keep it

handy for quick, easy

reference.

Pay close attention to

the safety sections of

your manual. You can

recognize the safety

sections by looking for

the A symbol or the

word safety.

/

WARNING: Improper

A

installation, alteration, service or malntenance can cause lnjury or property damage. Refer to thls manual. For assistance or

addltlonal lnformatlon

consult a quallfled

Installer,

agency, manufacturer

(dealer) or the gas

suppller.

. /

service

.

2 GNOT16

Page 4

INSTA

ATION

INSTALLER: Leave these instructions with

the appliance.

TOOL LIST

1 l/8” drill bit

2. Electric or hand drill

3. Flat bladed screwdriver

4.

No. 1 or No. 2 Phillips screwdriver

5. Pencil

6. Ruler and straight edge

7. Hand saw or saber saw

8. Pipe wrench

9. 518” wrench and

l/2"

wrench or adjustable wrench

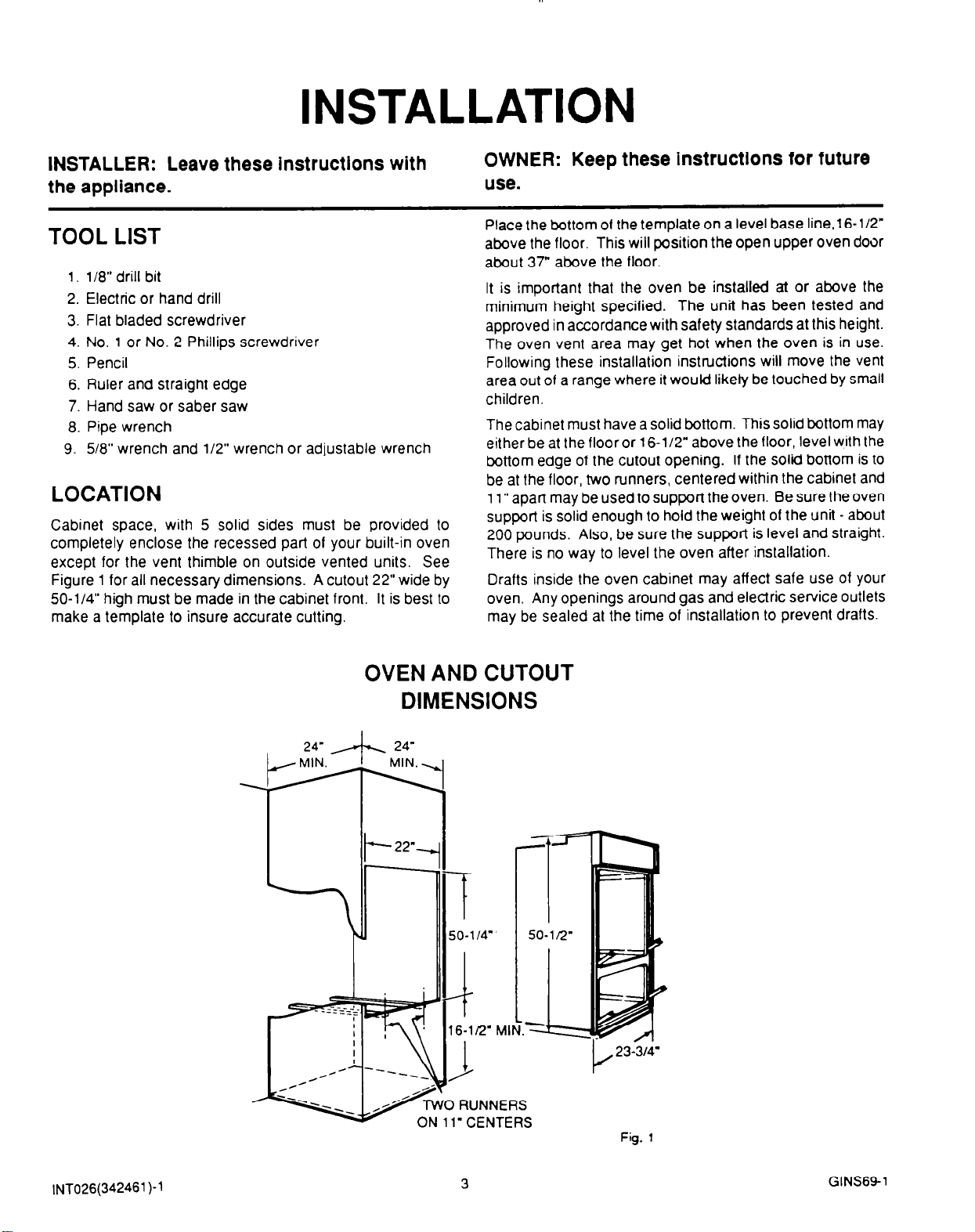

LOCATION

Cabinet space, with 5 solid sides must be provided to

completely enclose the recessed part of your built-in oven

except for the vent thimble on outside vented units. See

Figure 1 for all necessary dimensions. A cutout 22” wide by

50-l/4” high must be made in the cabinet front. It is best to

make a template to insure accurate cutting.

OWNER: Keep these instructions for future

use.

Place the bottom of the template on a level base line,1 6-112’

above the floor. This will position the open upper oven door

about 37” above the floor.

It is important that the oven be installed at or above the

minimum height specified. The unit has been tested and

approved in accordance with safety standards at this height.

The oven vent area may get hot when the oven is in use.

Following these installation instructions will move the vent

area out of a range where it would likely be touched by small

children.

The cabinet must have a solid bottom. This solid bottom may

either be at the floor or 16-l/2” above the floor, level with the

bottom edge of the cutout opening. If the solid bottom is to

be at the floor, two runners, centered within the cabinet and

11” apart may be used to support the oven. Be sure the oven

support is solid enough to hold the weight of the unit - about

200 pounds. Also, be sure the support is level and straight.

There is no way to level the oven after installation.

Drafts inside the oven cabinet may affect safe use of your

oven. Any openings around gas and electric service outlets

may be sealed at the time of installation to prevent drafts.

OVEN AND CUTOUT

24' A 24'

DIMENSIONS

lNT026(342461)-1

Fig. 1

GINS691

Page 5

ELECTRICAL CONNECTIONS

C;tlt?ck wrth your local L,tillties for eiectrical codes that apply

in your area. If there are no local codes, the National

Eilecirical Code, ANSI/NFPA No 70-I 990 must be followed.

You can get a copy by tiriting:

National Fire Protection Association

Ba?terymarch Park

Qumy, MA 02269

A:I &equate electrical supply and outlet must be used to

opt rate the electrical parts of your oven. The oven cord has

a ttiree prong plug and must be used with a properly

gro Jnded three hole outlet with standard 120 volt, 60 Hertz

AC household current

install the electncar outlet below the oven on the right side.

It sl~ould be easily reached through cabinet doors below the

see Figure 5. A llole must be made In the cabinet for

oven

the electrlcal hook-up

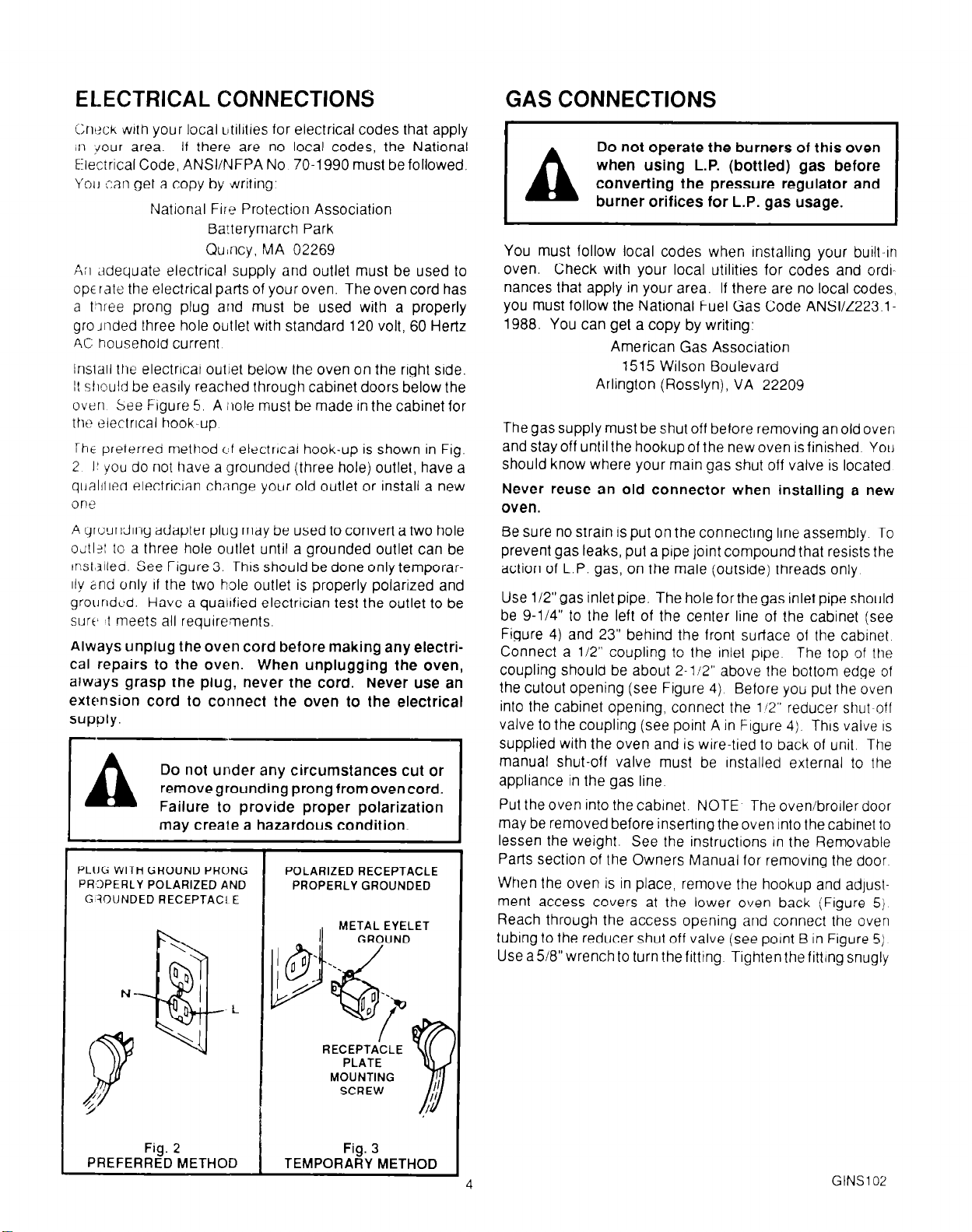

iht preterred method c;f electrlcal hook-up is shown in Fig.

2 I! you do not have a grounded (three hole) outlet, have a

qualiilea electricjan change your old outlet or install a new

0 n e

A qroundlng adapter plug may be used to convert a two hole

o~tl?l to a three hole outlet until a grounded outlet can be

tnst,lllea. See Figure 3. rh1.s should be done only temporar11y and only of the two hole outlet is properly polarized and

grounded. Have a qualified electrician test the outlet to be

surf’ ! meets all requirements.

Always unplug the oven cord before making any electrical repairs to the oven. When unplugging the oven,

always grasp the plug, never the cord. Never use an

extension cord to connect the oven to the electrical

supply.

Do not under any circumstances cut or

removegroundingprongfromovencord.

Failure to provide proper polarization

may create a hazardous condition.

WITH GROUND PRONG

PLIJG

PROPERLY POLARIZED AND

G’3OIJNDED RECEPTACI E

POLARIZED RECEPTACLE

PROPERLY GROUNDED

METAL EYELET

GAS CONNECTIONS

Do not operate the burners of this oven

when using L.P. (bottled) gas before

converting the pressure regulator and

burner orifices for L.P. gas usage.

I

You must follow local codes when installing your built-in

oven. Check with your local utilities for codes and ordlnances that apply in your area. If there are no local codes,

you must follow the National Fuel Gas Code ANSl/Z223.1-

1988. You can get a copy by writing:

American Gas Association

1515 Wilson Boulevard

Arlington (Rosslyn), VA 22209

The gas supply must be shut off before removing an old over;

and stay off until the hookup of the new oven is finished. You

should know where your main gas shut off valve is located

Never reuse an old connector when installing a new

oven.

Be sure no strain is put on the connecting line assembly

prevent gas leaks, put a pipe joint compound that resists the

action of L.P. gas, on the male (outside) threads only

Use 1/2”gas inlet pipe. The hole forthe gas inlet pipe should

be 9-114” to the left of the center line of the cabinet (see

Figure 4) and 23” behind the front surface of the cabinet

Connect a 112” coupling to the inlet pipe The top of the

coupling should be about 2-112” above the bottom edge of

the cutout opening (see Figure 4)

Before you put Ihe oven

into the cabinet opening, connect the 1’2” reducer shut-off

valve to the coupling (see point A in Figure 4). This valve

supplied with the oven and is wire-tied to back of unit. The

manual shut-off valve must be Installed external to the

appliance in the gas line.

Put the oven into the cabinet. NOTE

The oven/broiler door

may be removed before inserting the oven rnto the cabinet to

lessen the weight. See the instructions In the Removable

Parts section of the Owners Manual for removing the door

When the oven is in place, remove the hookup and adjustment access covers at the lower oven back (Figure 5)

Reach through the access opening and connect the oven

tubing to the reducer shut off valve (see point B in Figure 5)

Use a 518” wrench to turn the fitting

Tighten the fitting snugly

To

IS

Fig. 2 Fig. 3

PREFERRED METHOD

RECEPTACLE

TEMPORARY METHOD

4

GINS1 02

Page 6

but do not force it Forcing could damage the fitting and

tubing and cause leaking

Apply lrquld leakdetector to all connectlons 111 the supply Ilne.

Do

not

manifold ,Ind oven to test for gas leaks

flame 10 look for leaks

leaking rum off the matn gas supply before you try to stop

a !eak After all leaks are stopped, turn on the gas supply and

recheck all connections for leaks before llghtlng burners

leaks must be stopped before lighting any burners.

klt;jr e~t~ctrical and gas connections have been made, use a

1

E ‘drill t’lt !o droll holes In the cab/net front, through the holes

lr: it-10 3:‘z:i IrIm

?‘r!PLYc> rjro’Nfed

I .

Bubbles will form where any gas IS

Secure lh+d oven In the cabinet with ihe

use an open

All

MAKING L.P. GAS ADJUSTMENTS

If you are using L.P. (bottled) gas, all the

adjustments described below must be

made before you make any burner ad-

A

To adjust your oven for use with L.P gas, follow the steps

below.

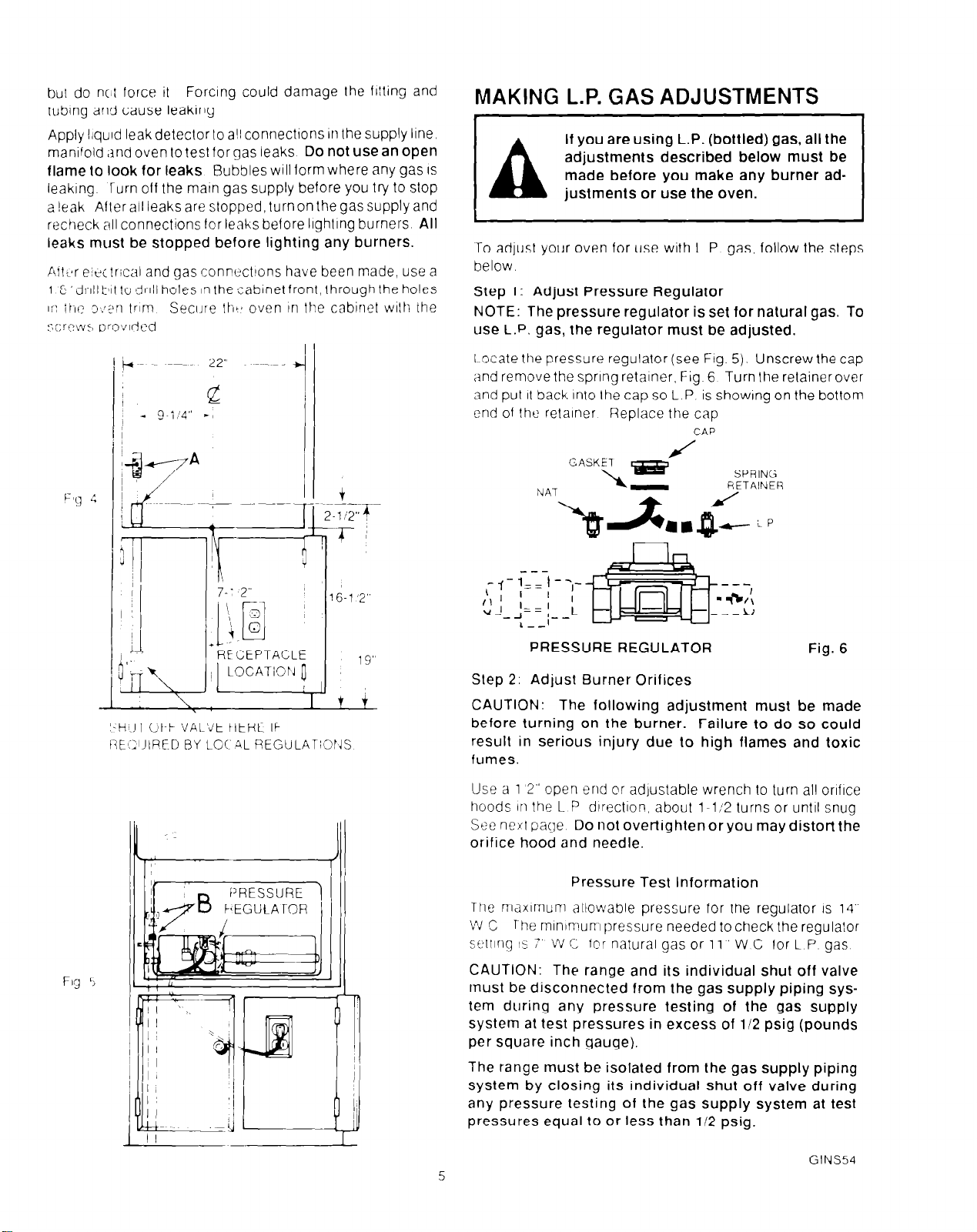

Step 1: Adjust Pressure Regulator

NOTE: The pressure regulator is set for natural gas. To

use L.P. gas, the regulator must be adjusted.

1 ocate the pressure regulator (see Fig. 5). Unscrew the cap

and remove the spring retainer, Fig 6 Turn the retainer over

and put it back into the cap so L P. is showing on the bottom

2nd of Ihe retainer

justments or use the oven.

Replace the cap

CAP

rc

SPRING

RETAINER

‘-!+.I r OFF VA\-‘JE t IEHC IF

REZiJIF(ED BY LG( AL REGULATIOIIS

FqEGULATOR

PRESSUREREGULATOR Fig. 6

Slep 2: Adjust Burner Orifices

CAUTION: The following adjustment must be made

before turning on the burner. Failure to do so could

result in serious injury due lo high flames and toxic

fumes.

lJse a 1 2” open entl or adjustable wrench to turn all orifice

hoods in the L P dIrectIon, about l-l:2 turns or until snug

See nerl page

orifice hood and needle.

The max~rnuni allowable pressure for the regulator IS 14”

rhe minmurr pressure needed to check the regulator

W C

setting 15 7” W C for natural gas or 11” W C lor L P gas

CAUTION: The range and its individual shut off valve

must be disconnected from the gas supply piping system during any pressure testing of the gas supply

system at test pressures in excess of 112 psig (pounds

per square inch gauge).

The range must be isolated from the gas supply piping

system by closing its individual shut off valve during

any pressure testing of the gas supply system at test

pressures equal to or less than 112 psig.

Do not overtighten or you may distort the

Pressure Test Information

GINS54

5

Page 7

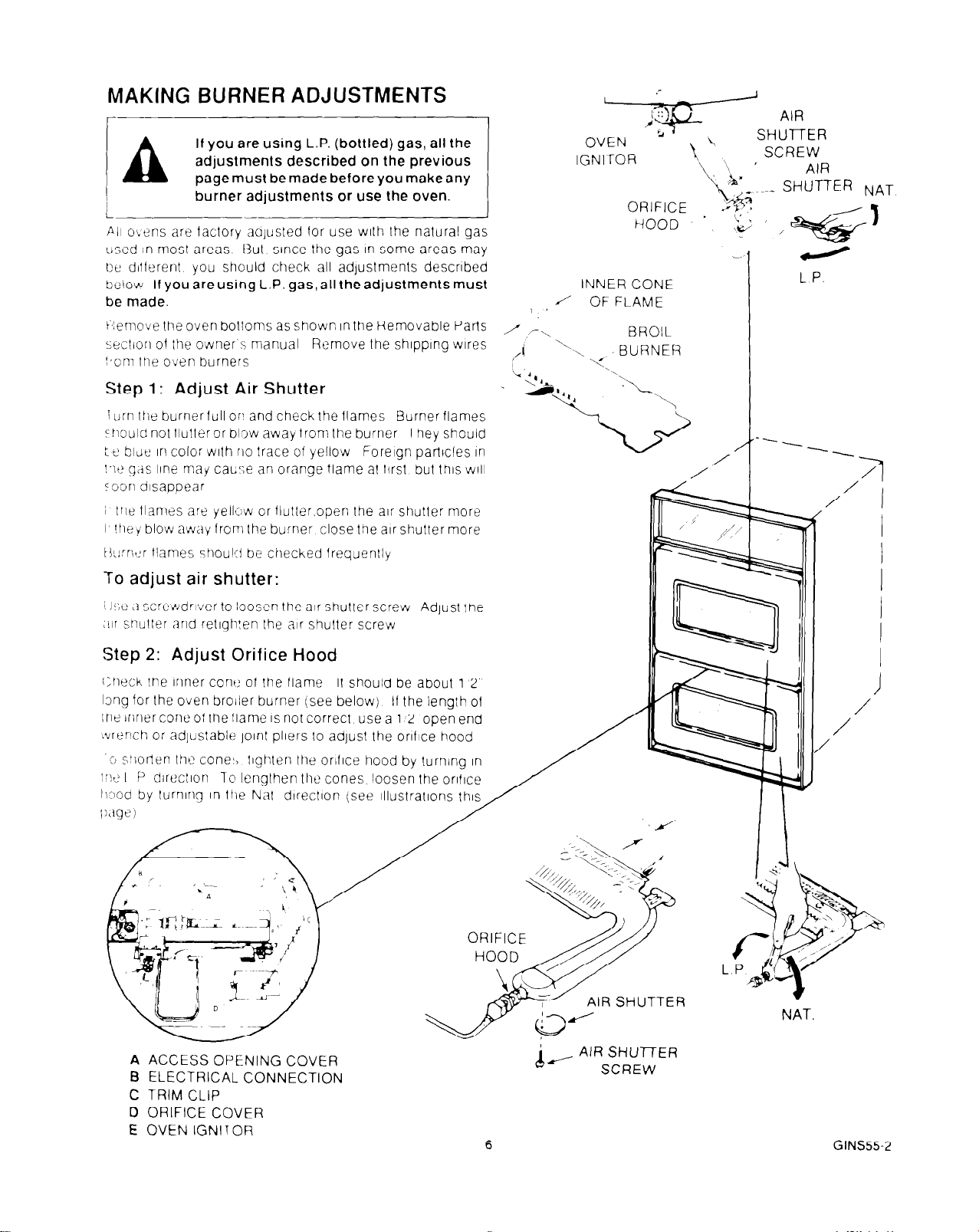

MAKING BURNER ADJUSTMENTS

If you are using L.P. (bottled) gas, all the

adjustments described on the previous

page must be made before you make any

burner adjustments or use the oven.

AII oLt;ns are factory adjusted for use with the natural gas

used in most areas

be dillerent you should check all adjustments described

below If you areusing L.P. gas, all the adjustments must

be made.

K.lemove the oven boltoms as shown in the Removable Parts

section of the owner s manual Remove the shlpplng wires

f,orn the oven burners

But since the gas In some areas may

, i,,

(i

INNER CONE

/-’ OF FLAME

1 ’

“..-lT,BURNER

BROIL

-.

2

L P.

Step 1: Adjust Air Shutter

i urn I~ie burner lull or’ and check the flames

rhould nol llulteror blow away from the burner

: t‘ bltie 111 color with no trace of yellow

!~t? gas IIne may caL’;e an orange flame al first but this ~111

loor disappear

i III~ flames are yellow or llutler.operi the air shutter more

I !hey blow away from the burner close the air shutter more

t3!!:r;,:r flames ~houlri be checked frequently

Burner flames

They should

Foreign particles In

To adjust air shutter:

! !:;t’ ,+ screirrdrlver to lOosen the air shuller screw

<III snuller and retlgh:en the air shutter screw

Adjust the

Step 2: Adjust Orifice Hood

c:heck the Inner conu of the flame It should be about 1 2’

lzng for the oven broiler burner (see below)

the inner cone of Ihe flame

\vrench or adjustable ]olnt pliers lo adjust the onfice hood

o sllorlen Iht? coneL, tIghten the orlflce hood by turning In

1~~2 I P directIon To lengthen the cones loosen the orifice

Ii?od by turning In the Nat dlrectlon (see illustrations this

IS

not correct, use a 1 2“open end

If the length ol

.a+

/’

/

A

ACCESS OPENING COVER

B

ELECTRICAL CONNECTION

C TRIM CLIP

D ORIFICE COVER

E

OVEN IGNITOR

AIR SHUTTER

N---

AIR SHUVER

d--

6

SCREW

NAT

GINS552

Page 8

THANK YOU

for buying this product.

We hope you enjoy many years of

safe, trouble-free service.

Please take a few minutes to read th/s sheet and the enclosed Use and Care Guide. Both contain

information that can improve your cooking results; they can also make it easier to maintain this

product. Most important. you’ll learn how to use this product safe/y. Save the Use and Care

Guide for future reference.

When reading the Use and

Care Guide . . I

Pq

special attention to sections marked by

the following words.

These help you avoid accidents that could lead to injury or

death for someone using the product incorrectly.

These help you avoid damage to the product and/or other

prve fly

Keep your kitchen safe

Thousands of people are hurt every year in kitchen fires.

Read the warning precautions in your Use and Care

Guide. Make sure other household members know about

them, too.

Cooking fires can be dangerous because they usually

involve grease.

only spreads the fire.

Smother a flaming pan on the cooktop be covering it with

a well-fitted lid, cookie sheet or flat tray. Flaming grease

outside the pan can be extinguished with baking soda, or

if available, a multipurpose dry chemical or foam-type

extinguisher.

If a fire starts in the oven, keep the oven door closed and

turn off all control knobs. If product damage occurs, do not

use the oven. Contact a qualified technician for service.

Don’t use water on a grease fire; water

Also, never pick up a flaming pan.

“NOTE:” or “IMPORTANT:”

These sections give you helpful tips on using the product.

GSAF12

Page 9

Important Safety Instructions

Gas cooking products have been thoroughly tested for safe and efficient operation. However, as

with any appliance, there are specific installation and safety precautions which must be followed to

ensure safe and satisfactory operation.

To reduce the risk of fire, electrical shock, injury to persons, or damage when using the cooking

product, follow basic precautions, including the following:

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or any

other appliance. The fumes can

create a fire hazard or explosion.

If you smell gas:

1.

Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flames.

4. Immediately call your gas supplier.

See your Use and Care gulde for addltlonal safety Information. Call your dealer or our

toll-free lnformatlon line if you have questions. We’ll be very glad to help,

1.

Read all instructions before using the product.

2.

Install or locate the product only in accordance

with the provided Installation Instructions.

3.

Gas fuels and combustion can result in potential

exposure to chemicals known to cause cancer or

reproductive harm. For example, benzene is a

chemical which is a part of the gas supplied to the

cooking product. It is consumed in the flame

during combustion. However, exposure to a small

amount of benzene is possible if a gas leak

occurs. Formaldehyde and soot are by-products

of incomplete combustion. Properly adjusted

burners with a bluish rather than a yellow flame

will minimize incomplete combustion.

To the Installer:

Please leave thls Instruction sheet wlth the

product.

To the consumer:

Please read and keep this sheet for future

reference.

INT112(344129)

GSAFl3

Page 10

IMPORTANT SAFETY INSTRUCTIONS

Keep this book for later use.

Be sure your oven is installed and grounded prop-

erly by a qualified technician.

Always keep the oven area clear and free from

things that will burn, gasoline and other flammable

vapors and liquids.

Always change oven rack positions while oven is

cool.

After broiling, always take the broiler pan out of the

oven andclean it. Leftovergrease in the broiler pan

can catch on fire next time you use the pan.

Always use dry pot holders when removing pans

from the oven. Moist or damp potholders can

cause steam burns.

Always use care when opening oven door. Let hot

air and steam out before moving food.

Always follow cleaning instructions in this book.

Teach children not to play with oven controls or any

other part of the oven.

Be sure the oven is securely installed to a cabinet

that is firmly attatched to the house structure.

Weight on the oven door could potentially cause

the oven to tip and result in injury. Never allow

anyone to climb, sit, stand, or hang on the oven

door.

Never try to repair or replace any part of the oven

unless instructions are given in this book. All other

work should be done by a skilled technician.

Never heat unopened food containers. Pressure

build up may make container burst and cause

injury.

Never leave jars or cans of fat or drippings near

the oven. Never let grease build up on your oven.

You can keep grease fires from starting if you

clean up grease and spills after each oven use.

Never use aluminum foil to line oven bottoms.

Improper use of foil could start a fire and cause

incomplete combustion.

Never block the flow of combustion and ventila-

tion air through oven vents.

Never try to move a pan of hot fat, especially a

deep fat fryer. Wait until the fat has cooled.

Never leave children alone or unattended where

a oven is in use.

Never use your oven for warming or heating a

room. Such use can be dangerous and could

damage oven parts.

Never wear loose fitting or hanging clothes when

using your oven. Such clothes could catch fire

and cause serious injury.

Never use a towel or other bulky cloth as a pot

holder. Such cloths could catch fire on a burner.

Never store things in an oven.

Never use water on a grease fire-it will only

spread the flames.

OVEN FIRE

Do not try to move the pan.

1. Close oven door and turn controls off.

2. If fire continues, throw baking soda on the

fire or use a dry chemical foam or halon type

extinguisher.

GSAF15

Page 11

IMPORTANT: Themodel

and serial number of

your oven is found on a

iag, behind the upper

oven door, on the left

side of the front frame.

Copy the numbers into

the space on page 2 of

this manual.

1. Oven Light Switch

2. Lower Oven Control

3. Oven Vent (area may get

hot during oven use; Do not

block vent)

4. Electronic Oven Control

5. Broil Pan and Grid

6. Removable Oven Racksand

Guides

7. Removable Oven Bottom

8. Removable Oven Door

9. Lower Oven

OVEN IGNITION

When you turn the upper or lower oven on, one of the glow

bar Igniter begins to heat

about 1 minute, the gas flows into the burner and is ignited.

The Igniter glows bright orange when hot. It cycles on and

off with the thermostat and will glow whenever the burner is

on

Duringapowerfailuretheburnercannot

belitandyoushouldnottrytodoso.

When the igniter is hot enough, in

LA

OVEN VENT

When the oven is on, heated arr moves through a vent under

the control panel

hot

The vent is necessary for proper air circulation in the oven

and good baking results

may cause cooking failure, fire or damage to the oven.

This hot air may make control panel area

Do not block this vent. Doing so

UPPER OVEN

See the following pages.

LOWER OVEN

To Bake:

1. Turn Lower Oven Control to desired temperature.

2. When finished turn Lower Oven Control to OFF. The

lower oven can be used while the upper oven is on. You

cannot broil in the lower oven

GBIFOs-1

Page 12

The Electronic Range Control (ERC)

TIMER CLOCK STOP OVEN

1.

TIME AND TEMPERATURE DISPLAY WINDOW -

Shows the time of day, the times you set for automatic

oven operations or the timer, oven temperature or

broil settings you have selected.

2.

SET KNOB - Turn to set times and temperatures,

3.

FUNCTION INDICATORS -

whether the oven is baking or broiling and whether

you are using the timer.

4.

AUTOMATICOVENINDICATORS-Showwhether

an automatic oven operation that will start later (delay) is currently programmed and whether oven or

stop time is being shown.

TItfE TI E

Y

Light up to show

8.

TIMER

9.

BAKE - Push before setting temperature.

10.

CANCEL -Cancels everything except the clock and

timer. Push to turn oven off or to clear everything if

you’ve made a mistake in programming.

11.

BROIL

- Push before setting amount of time.

- Push before selecting broil setting.

5.

OVEN TIME

oven will be on (for automatic oven operations).

6.

STOP TIME

you want the oven to turn off (for automatic oven operations).

7.

CLOCK - Push before setting clock or to bring time

of day back into the display.

- Push before setting length of time the

- Push before selecting the time when

11

1

Push

A

CERC02

Page 13

TO BAKE OR ROAST

AUTOMATIC OVEN ON AND OFF

PUSH

I-\

\, i’

PUSH WHEN

FINISHED

The display will show the oven temperature as it rises

A tone will sound when the oven is ready

AUTOMATIC OVEN OFF

PUSH

PUSH

TURN-OFF TIME

(TIME OF DAY)

LENGTH OF

COOKING TIME

SET TFMP

When oven time has ended, a tone will sound and the oven

will turn off.

TO USE THE TIMER

TURN TO SET

AMOUNT OF TIME

f?

TUAN TO Stl

LENGTH OF

COOKING TIME

TURN 10

SE7 1 EMP

The ERC Control will calculate when to turn the oven off

When Stop Time is reached, a tone will sound and the oven

will turn off.

INCOMPLETE OR INCORRECT

SETTINGS

1. Attention Tone will sound if oven has only been partially

programmed. For example, if you have selected a cook

trme but no temperature, you will hear the Attention

1 one until you select a temperature or push CANCEL

4’. Function Error Tone will sound if there is a problem with

one of the range functions

the CANCEL button. If the tone starts again. call for

service.

Cancel the tone by pushing

;‘USH

PUSH AND HOLD 3

SECONDS TO CANCEL

The maximum timer time is 9 hrs. 55 min.

A tone will sound when time is up.

NOTE: The timer is a reminder only and will not operate

the oven.

RECALLING FUNCTIONS

You may recall any set function by pushing the button ot that

function.

12

CCTL03-2

Page 14

Oven Cooking

.

Pivva;s tol!ob recipe :aretcllly

.

hleasure ingredients properly

.

i se proper pan

.

Flace pans on the obl.zn racks with 1 -l/2 - 2” of air space

on ali sides of each pan

.

F aris too close to each other, to oven walls or lo the oven

bottom, block the free movement of air. Improper air

movement causes uj\even browning and cooking.

placv:r!ierlt

Avoid overcrowding the oven.

.

Let the oven preheat thoroughly before cooking baked

products. Allow 10 - 15 minutes preheat time.

.

Avoid opening the door too often to check the food

during baking as heat will be lost. This may result in poor

baking results.

.

Cakes, cookies, muffins, and quick breads should be

baked in shiny pans - to reflect the heat - because

they should have a light golden crust. Yeast breads and

pie crusts should be baked in glass or dull (non-shiny)

pans -to absorb the heat-because they should have

a brown, crisp crust.

2 cake layers

4 cake layers

.

Most baking should be done on the second shelf position

from the bottom. When baking several items, use two

shelves placed on the second and fourth rack positions

fromthebottomoftheoven. Staggerpanssothatnopan

is directly above another

frrst shelf position from the bottom of the oven.

Bake angel food cakes on the

.

Oven temperatures should be reduced 25 degrees

below recommended temperatures if you use dark pans

or oven proof glass.

.

There may be some odor when the oven is first used.

This is caused by the heating of new parts and insula-

tion.

.

Do not cover the oven bottom or an entire oven rack with

foil. The foil can block normal heat flow, cause cooking

failures, and damage the oven interior.

13

COVCOI-1

Page 15

Broiling

.

PUSH WHEN

FINISHED 3

PP

Most foods can be broiled at the HI Broil Setting

LO Broil setting to avoid excessive browning or drying of

too& that should be cooked to the well-done stage (such

as thick pork chops or poultry).

.

All broiling should be done in the upper oven

.

Broiling is cooking by direct heat from the broil burner

Tender cuts of meat or marinated meat should be

selected for broiling. For best results steaks and chops

should be at least 3/4” thick.

1

TURN TO SET

HI OR LO BROIL

Select the

Brush chicken and fish with butter several times as they

broil When broiling fish, grease the grid to prevent

sticking and broil with skin side down. It is not necessary

to turn fish.

.

Never leave a soiled broiler pan In the range.

in the pan may smoke or burn the next time the oven is

use

s

Be sure you know the correct procedure for putting

out a grease fire. See the section on safety

Do not cover the entire broiler grid

with foil. Poor drainage of hot fat

may cause a broiler fire.

If a fire starts, close the oven door

A

PQSITIONING BROILER PAN

r

Food

Steak - 1” Thick

and turn controlsoff. If fire continues, throw baking soda on the fire.

Do not put water on the fire.

~.-_-

Rack

Position

4 = Highest

1 = Lowest

Total Time

Grease

(minutes)

- Atter placing food on the broiler pan, put the pan on an

oven rack in the proper rack positlon

mended rack position and cooktng time can be found

In the chart at right

.

I he closer the food IS to the broil burner, the faster the

rneat browns on the outside, yet stays red to pink in the

center. Moving the meat farther away from the burner

lets the meat cook to the centerwhile browning outside.

Side one should be cooked 1 2 minutes longer than

side two

.

Your oven door should be completely closed while

br3illng.

.

Use only the broiler pan and grid that came with your

range for broiling. They are designed for proper

drainage of fat and liquids and help prevent spatter,

smoke or fire.

.

Do

not preheat when broiling.

both sides, star-f the food on a cold pan.

.

Trim the outer layer of fat from steaks and chops. Slit

the fatty edges to keep the meat from curling.

.

Fcr maximum juiciness, salt the first side just before

turning the meat. Salt the second side just before

serving.

For even broiling on

The recom-

Rare

Medium

Well Done

Ground Beef Patties

Medium-l ” Thick

Medium-l/2” Thick

Lamb Chops - 1” Thicl

Pork Chops - 1” Thick

Pork Shoulder Steaks

Ham Slice - li2”Thick

Fish (Fillets)

Chicken ( Halves)

Frankfurters

I

Bacon

t

)pen-face Sandwiches

L4

This chart is a general guide. The size, weight, thickness,

and staning temperature of the food as well as your own personal preference will affect the cooking time

chart are based on the food being at refrigerator temperature

! 4

4

3

3

3

4

3

3

3

3

3

2

3

3

2

9-l I

13-15

21-23

16-48

18-21

27-29

16-18

11-12

11-13

45-55

8-1 1

9-11

I

6-10

Times in the

7-9

1

GBRL13

Page 16

Continuous-Cleaning Oven Finish (some models)

The rot,gh surfaces III your oven have a contlnuouscieamny frrrsh Spatters sL)read and fill the pores of this

specral frnrsh and then gradually burn away at medium to

htgh temperatures.

Heavv spllcvers or borrove.s need a lrttle help from you

tJct ;rear ihater ar!d a detergent or a cleanser such as

Fzart.xtlk

Pearl mixed In water, alld a sofr cloth or nylon brush

to clt:ari any heavy sprll(:vers

Do not use paper towels or sponges because partrcies

of these materrals WIII rub oft and clog the pores of the

oven tln:sh

Crusty and varnish-lrke sta,ns clog the pores In the

frnrst; and must be re-noved or broken up before

clearlrng takes place. They can be loosened by gently

taponq

After cleaning the over surface rinse it well using

three tabiespoons of v,liegar mixed with a quartpof

ccrd water Blot “p excess irqurd

Ne\tB, scrape or use aOr..> “-~vt: materrals such as scourrng Fowoers. comrriercidi oven cleaners or steel scourrng (lads for cieanrng

~111 scratch and damage the frnrsh

Tne rernarnlng so11 WII! gr,ldually burn off with normal

oven use

Lrqurd Ajax, rap Job Lrqurd L.ysol or Mr

the

stain wrth a wooden or plastrc utensrl

LIP

sptllovers These materrals

The continuous-cleaning process IS Illustrated below-

r’

1

1. A sprllover has formed a mound of SOII.

2. The sprllover has been wiped up

3. Amount of so11 remaining after four hours of oven use

at 400” F

4. After eight hours of oven use at 4OO”F, the soil IS

removed.

You can protect the oven bottom from spillovers by using

a piece of foil under your utenstl. Cut the foil slightly

larger than the pan and turn up the edges. Use two oven

racks and put the foil on the lower rack below the pan. Do

not use foil on the same rack as the pan. This will reflect

heat away.

Do not cover the oven bottom or an entire

oven rack with foil. The foil can block nor-

2

3 4

‘he :)W’II WI appear presentably clean, but some spat-

ters mai be present

he hgher the oven temperature, the faster the cleanrng

:lctroi Cleanrng ttme depends on type and amount of

,011, over’ temperature and length of oven use

If stubborn starns remain a’?er normal oven use, you can

operate the oven empty at 400°F for additional contrnuous cledriing action

Sorne foods may leave a jrscoloratron even when the

surface IS clean

Avoid sprllrng salt on the continuous-cleaning finish. Salt

may become trapped in the pores and may cause rusting.

Never use oven cleaners on the continuous-cleaning

finish Such cleaners will damage the finish.

15

CCCL01

Page 17

Cleaning Tips

On the following pages, all removable parts on

your oven are shown. Refer to those pages when

cleaning your range.

Warm water, a mild detergent and a soft cloth are

--

Control panel and knobs

Glass oven door/window

(some models)

Oven finishes:

Continuous-cleaning (some

models) See special instructions on previous page.

Standard porcelain enameled

ovens, porcelain enameled

(smooth) areas of continuous-cleaning ovens, broiler

compartment

PART

Detergent. warm water, soft cloth Do not use abrasive cleaners. Knobs pull off

Glass cleaner and paper towels

Detergent, warm water, scouring pad or

soap filled steel wool pad or non-aerosol

(brush-on) oven cleaner

CLEANING MATERIALS REMARKS

safe to use on all cleanable parts of your range.

purpose cleaners, such as Fantastik@ can also be

used. Do not use metal scouring pads, except

where recommended.

All

.-

for easier cleaning.

Remove stubborn soil with paste of baking

soda and water. Do not use abrasive cleaners. Rinse thoroughly.

Rinse thoroughly after cleaning. When using

oven cleaner on porcelain enameled parts of

continuous-cleaning ovens be sure to keep it

away from the continuous-cleaning finish.

Oven cleaners will damage the continuouscleaning finish. Oven bottom can be removed for easier cleaning. Remove oven

bottom of continuous-cleaning ovens if cleaning it with oven cleaner.

Oven racks (and guides on

some models)

Broiler pan and grid

Detergent, warm water and scouring pad

or soap filled steel wool pad

Detergent, water, soap-filled scouring

pad, commercial oven cleaner (pan only) fat or drippings. Fill pan with warm water.

16

Remove from oven to clean. Dry thoroughly.

Remove soiled pan from oven to cool. Drain

Sprinkle grid with detergent and cover with

damp cloth or paper towels. Let pan and grid

soak for a few minutes. Rinse or scour as

needed. Dry well Grid and pan may be

washed in a dishwasher.

GCCHI

1-4

Page 18

REMOVABLE OVEN RACKS AND

GUIDES

Be careful not to scratch the oven finish when installing

or removlng oven racks.

To Install:

1.

Put the pegs on the end of the rack guide into the holes

in the oven back.

2.

Lock the front hook in the slot in the oven side.

3.

Set the raised back edge of the oven racks on a pair

of rack guides so the hooks at the sides of the rack run

underneath the rack guides.

4.

Push the rack in until you reach the bump in the rack,

then lift the front of the rack a bit and push the rack all

the way in.

To

remove:

1.

Pull the oven rack out, then up.

2. Lift thefrontoftherackguidetounhookitfromtheoven

wall and pull out.

/

RACK HOOK

I

RACK

BUMP

REMOVABLE OVEN AND BROILER

DOORS

Remove the doors for easier cleaning.

To remove:

1.

Open the door fully and raise the release tab on each

door hinge (see fig. A).

2.

Raise the release tabs as far as they will go (see fig. B),

then close the door to the point where it will hold a

partially open position.

3.

Grasp the door firmly at the sides, pull the lower edge

away from the oven and lift the door off the hinge arms

(see fig. C).

To

replace:

1.

Slip the hinge arms into the upper portion of the slots in

the door.

2.

Lower the door to the fully open position and push the

release tabs down (see fig. A).

REMOVABLE OVEN BOTTOM

Remove the oven bottom for easier cleaning.

Be careful not to scratch the oven finish when removing or

installing oven bottom.

To remove:

1.

Remove the oven racks and guides (see above).

2. Lift the front of the oven bottom enough to clear the

front frame, then pull out.

To replace:

1. Slide the oven bottom into the oven so that the back

edge of the oven bottom rests on the ridge in the back

oven wall.

2. Lower the front of the oven bottom inlo place behind the

front frame.

17

II II

’ Fig. A ”

\

‘\

‘.

._

II

FRONT FRAME

II

‘/ II

Fig. B

~~

GMNT18

Page 19

REPLACING THE OVEN LIGHT (some models)

Do not touch hot oven bulb. Do not touch bulb wlth wet

hands. Never wipe oven light area wlth wet cloth.

Never touch the electrically live metal collaron the bulbwhen

replacing it.

Electrical power must be shut off if you have to replace

a broken bulb.

Replace the bulb with a 40 watt appliance bulb. An appliance bulb is smaller than a standard 40 watt household bulb

and is made to withstand high oven temperatures and have

a much longer bulb life.

18

CMNTo2

Page 20

Before Calling for Service

Save time and money-Check this list before you call for service.

To eliminate unnecessary servicecalls, first, read all the instructions in this manual carefully. Then, if you have a prob-

lem, always check this list of common problems and possible solutions before you call for service.

PROBLEM

. Oven burners do not work.

Foods do not bake properly

l

POSSIBLE CAUSE

. Gas supply not connected or

not turned on. If using L.P.

gas, tank may be empty

9 Appliance not properly

grounded or polarized. This

can affect spark ignition.

(spark ignition model only)

l

Controls not set correctly

Burners not adjusted properly

l

9 Oven not preheated long

enough

l

Improper rack or pan place-

ment

l

Improper use of foil

* Improper temperature setting

for utensil used

9 Recipe not followed

l

Using improper cookware

DON’T CALL FOR SERVICE UNTIL

-

Check the reducer shut-off valve and the

*

gas supply shut-off valve to be sure they

are open (see installation section)

If using L.P. gas; is there any gas in the

L.P. tank?

Check installation section in this manual.

l

. Check operating instructions in this

manual.

See the installation section in this manual

.

l

Be sure to preheat.

10 minutes below 350 degrees

15 minutes above 350 degrees

l

Maintziin uniform air space around pans

and utensils: see oven cooking section

Be sure oven vent is no! blocked

l

Reduce temperature 25 degrees for glass

9

or dull/darkened pans.

. Is recipe tested and reliable?

. See oven cooking section.

YOU CHECK

Foods do not broil properly

l

0 Oven smokes

* Oven light or work light does

not work (if equipped)

l

Improper rack placement

l

Oven preheated

l

Improper utensil used

. Improper broiling time

l

Dirty oven

Broiler pan full of grease left in

l

oven

9 Light switch in off position

. Light bulb or flourescent light

starter burned out

19

l

Check broil pan placement in broiling

section.

* Do not preheat when broiling

* Use broiler pan and grid supplied with j

range.

9 Check broiling chart in broiling section.

. Check for heavy spillover.

Clean pan and grid after each use.

l

--I

l

Check switch setting

. Check or replace light bulb;

see instructions

-_-.a

GSEH21 2

I

1

’

Page 21

Before Calling for Service

ADJUSTING OVEN TEMPERATURE

2.

T-he temperature in your new oven has been set correctly at

the factory, so be sure to follow the recipe temperatures and

times the first few times you bake in your new oven.

!f you Ihlnk the oven should be hotter or cooler, you can

adjusi it yourself. To decide how much to change the temperature, set the oven temperature 25°F higher or lower than

the temperature in your recipe, then bake.

“test” should give you an idea of how much the temperature

should be changed.

The results of this

To adjust upper oven temperature:

1. i$st~ the BAKE button.

2. Select the temperature between 500°F and 550 F with

the SET knob.

3. Quickly (within two seconds, before the BAKE function

energizes) push and hold the BAKE button. The display

WII go blank and then will show the amount of degrees

difierence between the original factory temperature setting

antlthecurrenttemperaturesetting. Iftheoventemperature

ha:; never been adjusted the display will read 00.

4. Th2 temperature can be adjusted up to 35°F hotter or

;35 F cooler, in 5°F steps, by turning the SET knob A

II-111x1s sign (-) before the number means?hat the oven will

tx cooler by displayed amount of degrees.

5. When you have made the desired adjustment, push the

CLOCK button to go back to the time of day display or use

yotlr oven as you would normally.

Note The self-clean temperature will not be changed by the

adjus!ments described above.

To acljust lower oven temperature:

1. Turn OVEN TEMP knob to OFF and remove the knob by

Dulling straight off.

Look at the back of the knob. The arrow pointing to the

center of the upper screw indicates the original factory

setting. The knob can be adjusted up to 50” hotter or 50”

cooler, in 10” increments.

3.

Use a screwdriver to loosen the two screws about 1 turn

each.

4

Hold the knob handle (A on illustration) while turning the

knob skit-t (B on illustration) in the desired direction. As

you turn you should be able to hearclicks and feel notches

or teeth. Each click or notch is 10”. You can turn up to 5

cltcks or notches in either direction.

5.

When you reach the desired adjustment, retighten both

screws.

6.

IMPORTANT: Before you replace the OVEN TEMP knob,

carefully read the instructions for replacing the knob

(above). Do not force the knob onto the thermostat stem

or you may damage it.

MAKES OVEN COOLER

(Screw Moved Toward Cooler)

MAKES OVEN HOTTER

(Screw Moved Toward Hotter)

20

ESER27

Page 22

LIMITED UMRRAHTY

Tiv Roper appliance 1s .varran\ed by Whirlpool corporation lo be lree lrom delec, ‘n maler~al and workmansnsp

IO Ihe orlglnai domesilc purchaser Any parts which we llnd lo be delecllve w~li be repaIred “1 replaced a~ 011,

opl~on subjecl lo !he folIowIng I~rn~lal~ons

I

: Repair or replace durfng Ihe hrsi ;hlrty (30) days from lhe dale of purchase any llmshes

2 Repair or replace during Ihe hrsl (lsr) year from dale of purchase any other part excepl for the finish which we hnd lo be defecllve

3 Repair or replace during Ihe hrsl live 15) years lrom dare 01 purchase any magnelron (on lhose unlls so equipped) which we hnd lo be defeclIve

warranty IS llmlled lo lhe firs1 (1st) year from dale of purchase

4 During Ihe second (2nd) through 111th (5lh) years lrom the dale 01 orIginal purchase on any producl so equipped, any part 01 Ihe relr~gerallng sysrem (compresso:. evapora:or

condenser, drier or connecting iublng) lound defecwe I” malerlal or workmanshlp will be supplled

(1 sr) year from Ihe date 01 orIgInal purchase

5 Replacemenl parls furnIshed under the lerms of this warranly a:~ warranled only for Ihe unex”lred pon~on 01 Ihe orlginsl warranty perlodard iransporlal~on charges rc.la:~ve ic

ohlalnlrlg parts involved 1s Ihe respomsb~l~fy of Ihe original cunsumer purchaser

G T’lls warranly applies only IO producls properly ~nslalled adlusled and operaied I” accordavce wilh

IO any product which has been sJDlecled

or 10 conl1rm proper operalion “I appliance

Under 10 c,rcun?~ances skall Wb~rlpool Carporallon be INable under IhIs wa?anty for any loss 01 any incidental or consecue?l~;i damages

ana all IMPLIED WARPANTIES ARE LIMITED TO THE SAME TIME PERIODS STATED HEREIN FOR ROPER EXPRESS WARPANTIES

Some slates dc ~“1 allow the exc!us~on or Ilm~lall”n of consequenllal damages or llmllallons of how long an Implied warraniy may lasl, so

the above Ilmlla’lons or excIus~ons may POI ,anply IO you

nay vary from s;a!e lo slate

THIS /S A LIMITED WARRANTY LYITHIN THE MEANING OF THAT TFRM AS DEFINED /N THE MAGNUSON~MOSS ACT OF 1975

II you need serwce for your Rope, branc appliance

IO AteratIOn

SHOULD YOU tiAVE AN)‘Ol:tSTICNS CONCERNING THIS VdARRANTY. PLEASE CONTACT

Cuslomer Relal’ons IlED:

ROPER Brand Appl~~xpc

2000 hl 63 Nofih

Ben!on Harbor Ml 69022

misuse

~rnproper

~nsl;i!la!~on “1 apl~be~? damage Nor does II apgly 10 cos1s lor any sewce requested

Thls warranty gives you speclllc legal rlghls, and you may have olhe, r,ghls wl>lch

(porcelan,

enamel or olher) and glass parts which we l~no :o be deleclive

Labor on any magnetron undur

Labor on the relr~geral~ng syslem under IhIs warranty 1s lfmlled lo Ihe 11:s;

~nslrucl~ons

Call loll Free l-(800) 44~ROPER

Between 8 00 a m 4 30 p m

Monday thru Friday. Easlern Time

lound I” lhe product l~Iera:u~e This viarranly does

b(800) 447 6737

lor

demons::a:lo?

nol

apply

Phone 1.(300144.ROFER :l-(800)447~673;] between 8 00~ d 30 Caslern Time Mopday lhru Friday

Loading...

Loading...