Roper B675, B460 User Manual

GAS BUILT-IN

INSTALLATION

models 8460

B675

CARE & USE

I

RECIPES

4356239 (343748)

CONTENTS

USE AND CARE

Important Instructions for Your Safety ,,,

Your Oven and Its Features

Using the Lower Oven

Oven Vent

Oven Ignition ..............

Your Electronic Range Control

Oven Cooking

Broiling .........

Continuous Cleaning Oven

Cleaning Tips .,

Removable Parts ..... ......... .........

.................

.......... ,,

................................ ......

....................................................................................................................

....................

... .... .... ....

,,,

,, .,

........

..............................................

................................................................................

.... ... ...

,,..,

.......... .... ... .... ....

., ..........................................................

.... .... .... ............................. ...................

....... ...

,,

,, ,., ........

..

..

.... ... .... .... .... ..........

... ........ ...

.............................................................

.....................................

....

... ... .... ... ......... ..............

......... ................

,,, .......... ..............

..

... .... ....

... ........

...........

... 10

...

... 10

.....

...................

,,.,

.................

.........................

............................

..............

1 1,12

,, .....

........

.7-9

10

10

13

14

15

16

17

SERVICE

Replacing the Oven Light .., ,..,,, ,....,,..., ,,,. ,,,....,... ,,... .., ,... ,,,.., ,, ..,,, ,,.,,,,.,., 18

What to Do before Calling for Service

Adjusting Oven Temperature ..,.,

,......,. ,,..,,.... ,..,.. 19

.,,, ,...,,,....,,.. .,,.,,, ...,...., ,,..,,,...,,........, 20

WARRANTY

GC0028

f

A

FOR YOUR SAFETY

If you smell gas:

I. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier

-_-..-

/

L.P. Burner

A

Adjustments

1 he adjustments In the Installatlon Section must be made

bt?lOre

you try10 use yourrange.

If you are using Liquified Petroleum

I P adjustments in the Installatlon Section must be made

before use.

If your oven is not properly adjusted, flames may be too high,

or the oven may use too much

luel, releasetoxicfurnesorcook

poorly.

Gas

(bottled gas) all

A

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

To insure safety for

yourself and your

home, please read

your Owner’s Manual

carefully. Keep it

handy for quick, easy

reference.

Pay close attention to

the safety sections of

your manual. You can

recognize the safety

sections by looking for

the A symbol or the

word safety.

/

WARNING: Improper

A

installation, alteration, service or malntenance can cause lnjury or property damage. Refer to thls manual. For assistance or

addltlonal lnformatlon

consult a quallfled

Installer,

agency, manufacturer

(dealer) or the gas

suppller.

. /

service

.

2 GNOT16

INSTA

ATION

INSTALLER: Leave these instructions with

the appliance.

TOOL LIST

1 l/8” drill bit

2. Electric or hand drill

3. Flat bladed screwdriver

4.

No. 1 or No. 2 Phillips screwdriver

5. Pencil

6. Ruler and straight edge

7. Hand saw or saber saw

8. Pipe wrench

9. 518” wrench and

l/2"

wrench or adjustable wrench

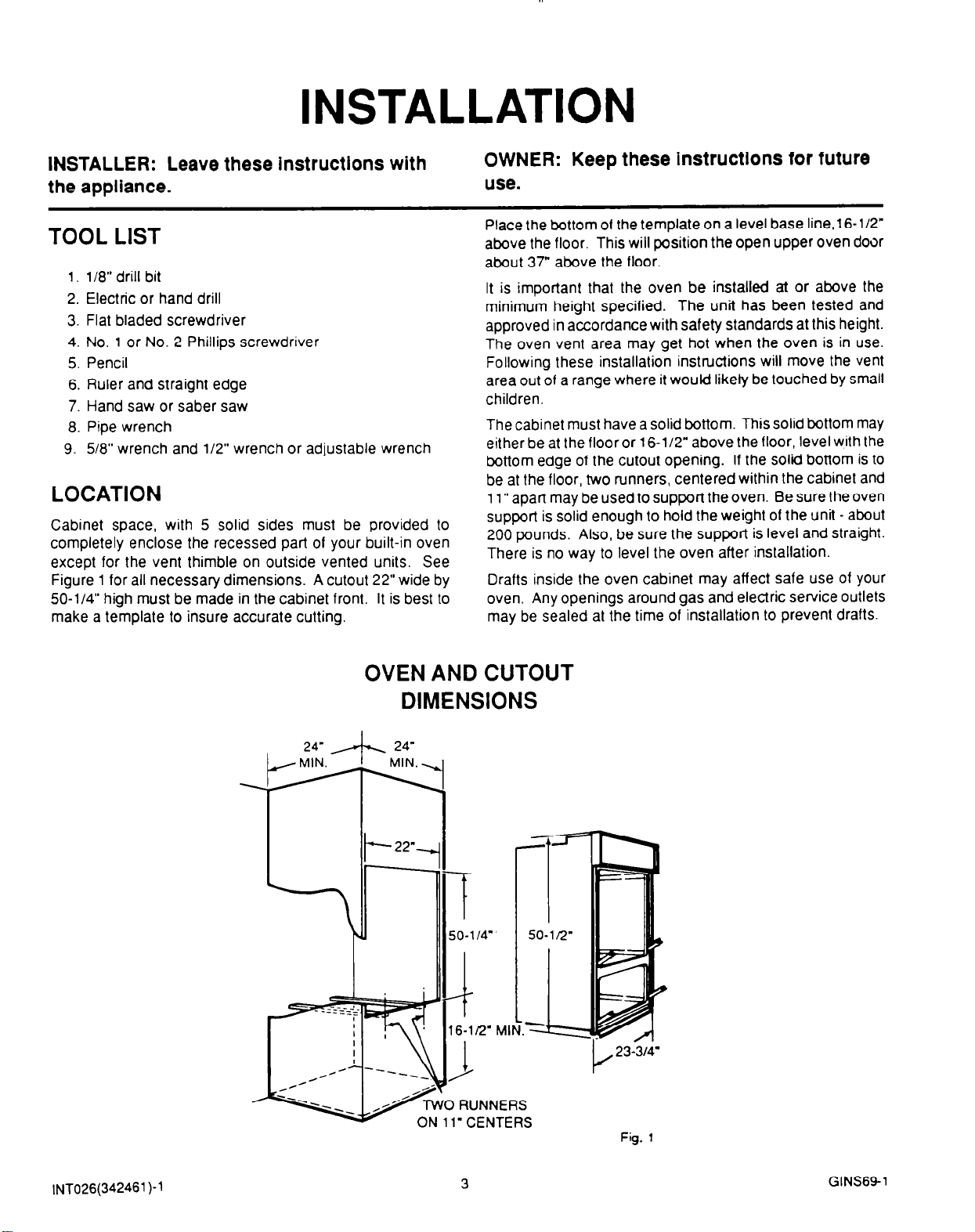

LOCATION

Cabinet space, with 5 solid sides must be provided to

completely enclose the recessed part of your built-in oven

except for the vent thimble on outside vented units. See

Figure 1 for all necessary dimensions. A cutout 22” wide by

50-l/4” high must be made in the cabinet front. It is best to

make a template to insure accurate cutting.

OWNER: Keep these instructions for future

use.

Place the bottom of the template on a level base line,1 6-112’

above the floor. This will position the open upper oven door

about 37” above the floor.

It is important that the oven be installed at or above the

minimum height specified. The unit has been tested and

approved in accordance with safety standards at this height.

The oven vent area may get hot when the oven is in use.

Following these installation instructions will move the vent

area out of a range where it would likely be touched by small

children.

The cabinet must have a solid bottom. This solid bottom may

either be at the floor or 16-l/2” above the floor, level with the

bottom edge of the cutout opening. If the solid bottom is to

be at the floor, two runners, centered within the cabinet and

11” apart may be used to support the oven. Be sure the oven

support is solid enough to hold the weight of the unit - about

200 pounds. Also, be sure the support is level and straight.

There is no way to level the oven after installation.

Drafts inside the oven cabinet may affect safe use of your

oven. Any openings around gas and electric service outlets

may be sealed at the time of installation to prevent drafts.

OVEN AND CUTOUT

24' A 24'

DIMENSIONS

lNT026(342461)-1

Fig. 1

GINS691

ELECTRICAL CONNECTIONS

C;tlt?ck wrth your local L,tillties for eiectrical codes that apply

in your area. If there are no local codes, the National

Eilecirical Code, ANSI/NFPA No 70-I 990 must be followed.

You can get a copy by tiriting:

National Fire Protection Association

Ba?terymarch Park

Qumy, MA 02269

A:I &equate electrical supply and outlet must be used to

opt rate the electrical parts of your oven. The oven cord has

a ttiree prong plug and must be used with a properly

gro Jnded three hole outlet with standard 120 volt, 60 Hertz

AC household current

install the electncar outlet below the oven on the right side.

It sl~ould be easily reached through cabinet doors below the

see Figure 5. A llole must be made In the cabinet for

oven

the electrlcal hook-up

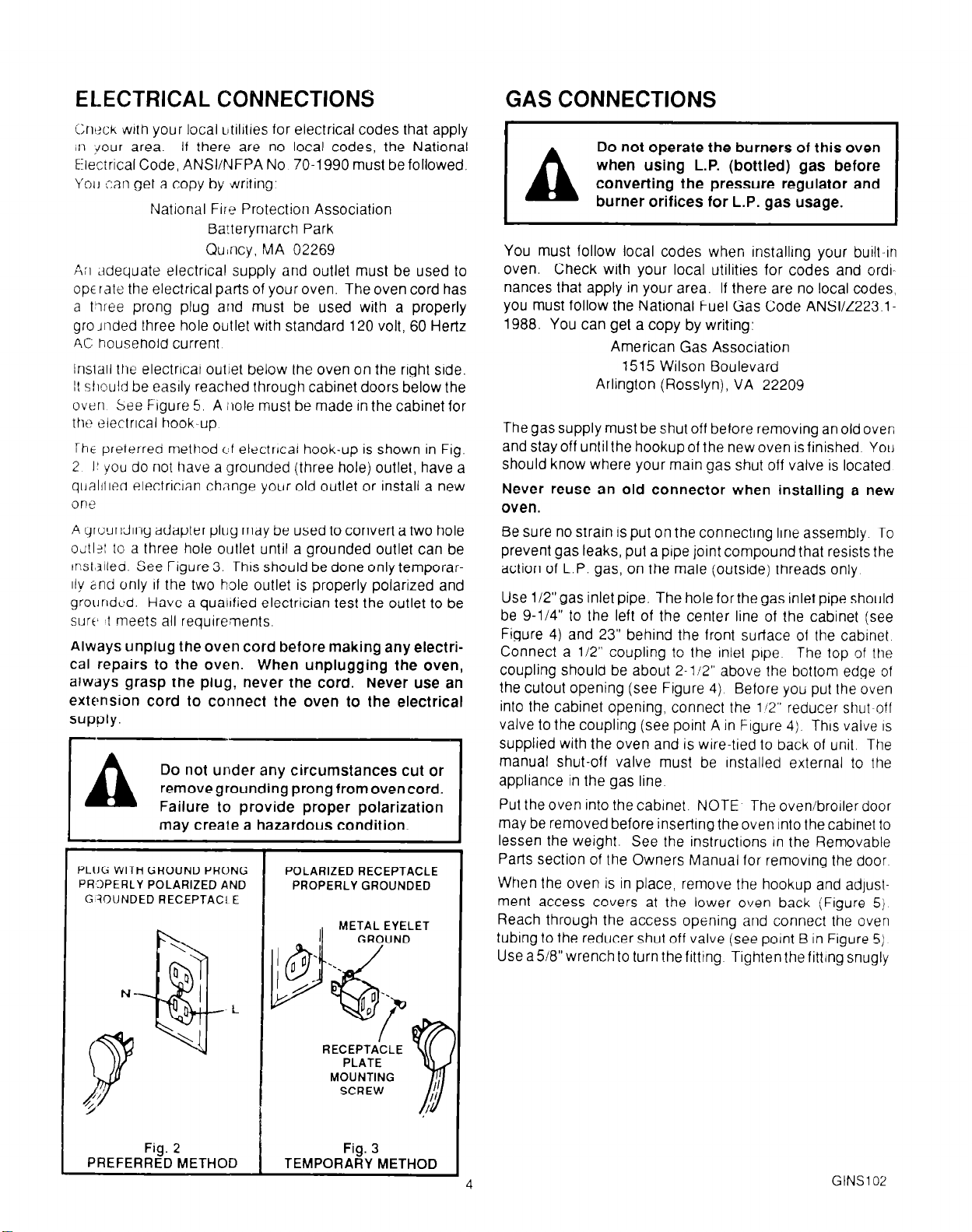

iht preterred method c;f electrlcal hook-up is shown in Fig.

2 I! you do not have a grounded (three hole) outlet, have a

qualiilea electricjan change your old outlet or install a new

0 n e

A qroundlng adapter plug may be used to convert a two hole

o~tl?l to a three hole outlet until a grounded outlet can be

tnst,lllea. See Figure 3. rh1.s should be done only temporar11y and only of the two hole outlet is properly polarized and

grounded. Have a qualified electrician test the outlet to be

surf’ ! meets all requirements.

Always unplug the oven cord before making any electrical repairs to the oven. When unplugging the oven,

always grasp the plug, never the cord. Never use an

extension cord to connect the oven to the electrical

supply.

Do not under any circumstances cut or

removegroundingprongfromovencord.

Failure to provide proper polarization

may create a hazardous condition.

WITH GROUND PRONG

PLIJG

PROPERLY POLARIZED AND

G’3OIJNDED RECEPTACI E

POLARIZED RECEPTACLE

PROPERLY GROUNDED

METAL EYELET

GAS CONNECTIONS

Do not operate the burners of this oven

when using L.P. (bottled) gas before

converting the pressure regulator and

burner orifices for L.P. gas usage.

I

You must follow local codes when installing your built-in

oven. Check with your local utilities for codes and ordlnances that apply in your area. If there are no local codes,

you must follow the National Fuel Gas Code ANSl/Z223.1-

1988. You can get a copy by writing:

American Gas Association

1515 Wilson Boulevard

Arlington (Rosslyn), VA 22209

The gas supply must be shut off before removing an old over;

and stay off until the hookup of the new oven is finished. You

should know where your main gas shut off valve is located

Never reuse an old connector when installing a new

oven.

Be sure no strain is put on the connecting line assembly

prevent gas leaks, put a pipe joint compound that resists the

action of L.P. gas, on the male (outside) threads only

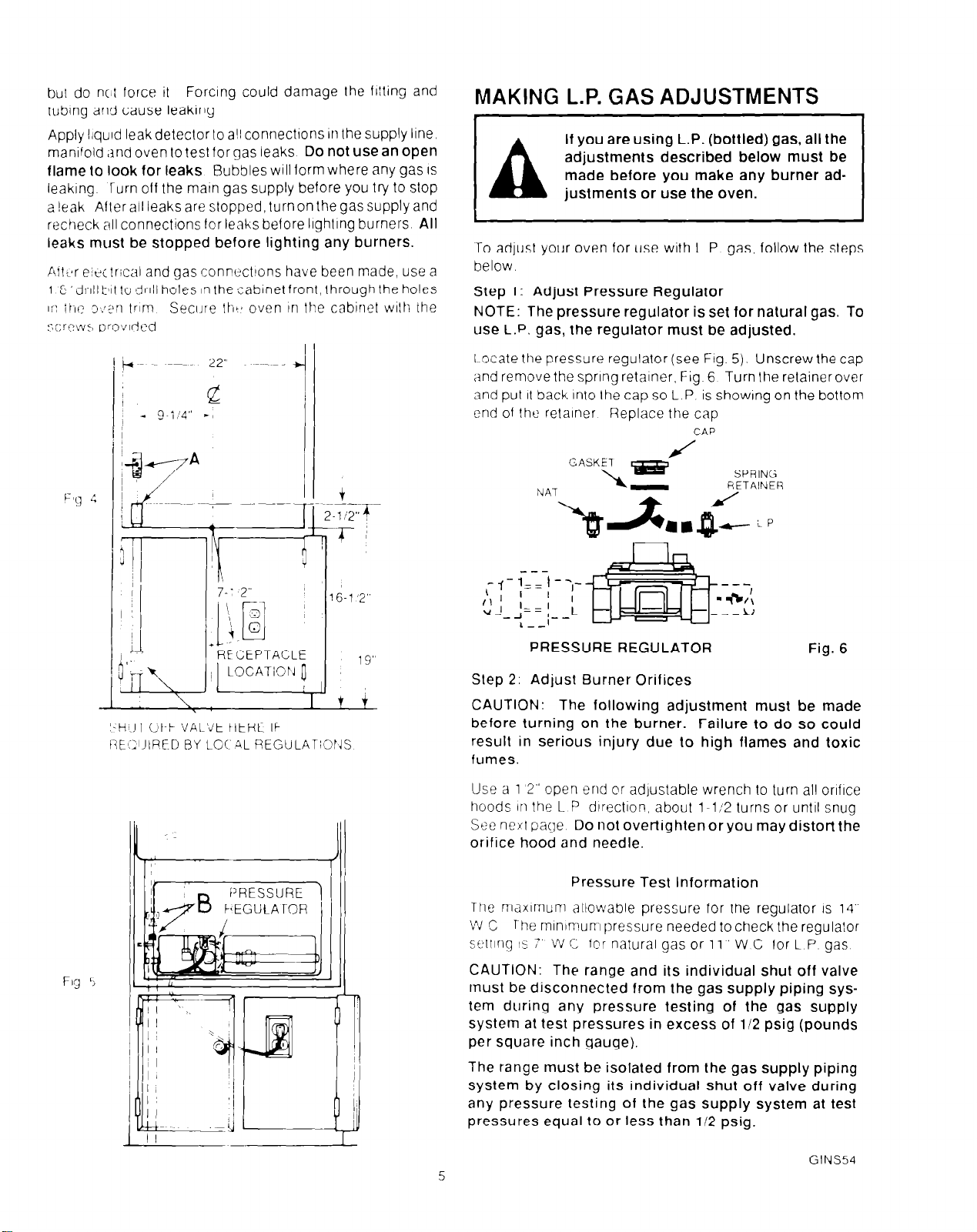

Use 1/2”gas inlet pipe. The hole forthe gas inlet pipe should

be 9-114” to the left of the center line of the cabinet (see

Figure 4) and 23” behind the front surface of the cabinet

Connect a 112” coupling to the inlet pipe The top of the

coupling should be about 2-112” above the bottom edge of

the cutout opening (see Figure 4)

Before you put Ihe oven

into the cabinet opening, connect the 1’2” reducer shut-off

valve to the coupling (see point A in Figure 4). This valve

supplied with the oven and is wire-tied to back of unit. The

manual shut-off valve must be Installed external to the

appliance in the gas line.

Put the oven into the cabinet. NOTE

The oven/broiler door

may be removed before inserting the oven rnto the cabinet to

lessen the weight. See the instructions In the Removable

Parts section of the Owners Manual for removing the door

When the oven is in place, remove the hookup and adjustment access covers at the lower oven back (Figure 5)

Reach through the access opening and connect the oven

tubing to the reducer shut off valve (see point B in Figure 5)

Use a 518” wrench to turn the fitting

Tighten the fitting snugly

To

IS

Fig. 2 Fig. 3

PREFERRED METHOD

RECEPTACLE

TEMPORARY METHOD

4

GINS1 02

but do not force it Forcing could damage the fitting and

tubing and cause leaking

Apply lrquld leakdetector to all connectlons 111 the supply Ilne.

Do

not

manifold ,Ind oven to test for gas leaks

flame 10 look for leaks

leaking rum off the matn gas supply before you try to stop

a !eak After all leaks are stopped, turn on the gas supply and

recheck all connections for leaks before llghtlng burners

leaks must be stopped before lighting any burners.

klt;jr e~t~ctrical and gas connections have been made, use a

1

E ‘drill t’lt !o droll holes In the cab/net front, through the holes

lr: it-10 3:‘z:i IrIm

?‘r!PLYc> rjro’Nfed

I .

Bubbles will form where any gas IS

Secure lh+d oven In the cabinet with ihe

use an open

All

MAKING L.P. GAS ADJUSTMENTS

If you are using L.P. (bottled) gas, all the

adjustments described below must be

made before you make any burner ad-

A

To adjust your oven for use with L.P gas, follow the steps

below.

Step 1: Adjust Pressure Regulator

NOTE: The pressure regulator is set for natural gas. To

use L.P. gas, the regulator must be adjusted.

1 ocate the pressure regulator (see Fig. 5). Unscrew the cap

and remove the spring retainer, Fig 6 Turn the retainer over

and put it back into the cap so L P. is showing on the bottom

2nd of Ihe retainer

justments or use the oven.

Replace the cap

CAP

rc

SPRING

RETAINER

‘-!+.I r OFF VA\-‘JE t IEHC IF

REZiJIF(ED BY LG( AL REGULATIOIIS

FqEGULATOR

PRESSUREREGULATOR Fig. 6

Slep 2: Adjust Burner Orifices

CAUTION: The following adjustment must be made

before turning on the burner. Failure to do so could

result in serious injury due lo high flames and toxic

fumes.

lJse a 1 2” open entl or adjustable wrench to turn all orifice

hoods in the L P dIrectIon, about l-l:2 turns or until snug

See nerl page

orifice hood and needle.

The max~rnuni allowable pressure for the regulator IS 14”

rhe minmurr pressure needed to check the regulator

W C

setting 15 7” W C for natural gas or 11” W C lor L P gas

CAUTION: The range and its individual shut off valve

must be disconnected from the gas supply piping system during any pressure testing of the gas supply

system at test pressures in excess of 112 psig (pounds

per square inch gauge).

The range must be isolated from the gas supply piping

system by closing its individual shut off valve during

any pressure testing of the gas supply system at test

pressures equal to or less than 112 psig.

Do not overtighten or you may distort the

Pressure Test Information

GINS54

5

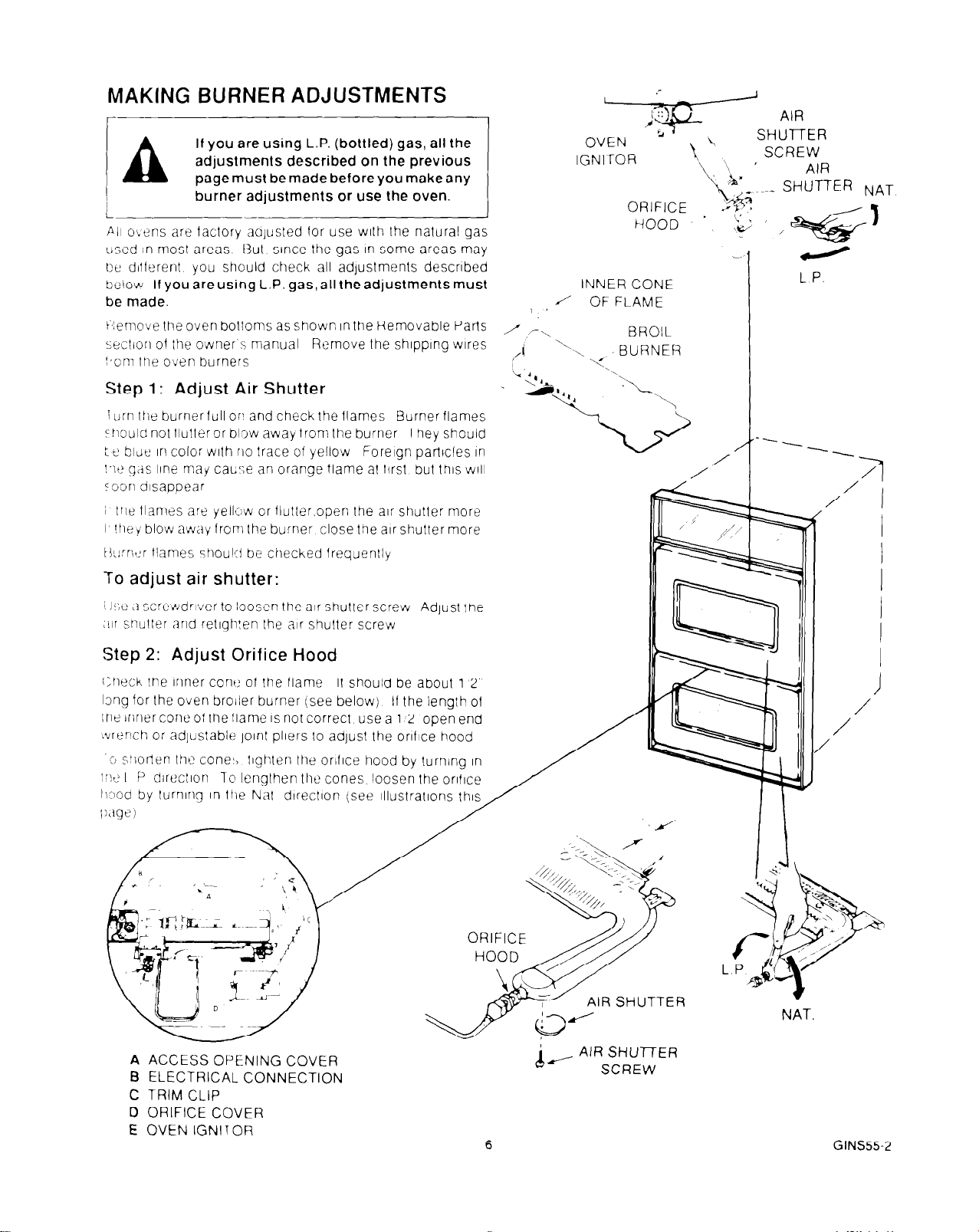

MAKING BURNER ADJUSTMENTS

If you are using L.P. (bottled) gas, all the

adjustments described on the previous

page must be made before you make any

burner adjustments or use the oven.

AII oLt;ns are factory adjusted for use with the natural gas

used in most areas

be dillerent you should check all adjustments described

below If you areusing L.P. gas, all the adjustments must

be made.

K.lemove the oven boltoms as shown in the Removable Parts

section of the owner s manual Remove the shlpplng wires

f,orn the oven burners

But since the gas In some areas may

, i,,

(i

INNER CONE

/-’ OF FLAME

1 ’

“..-lT,BURNER

BROIL

-.

2

L P.

Step 1: Adjust Air Shutter

i urn I~ie burner lull or’ and check the flames

rhould nol llulteror blow away from the burner

: t‘ bltie 111 color with no trace of yellow

!~t? gas IIne may caL’;e an orange flame al first but this ~111

loor disappear

i III~ flames are yellow or llutler.operi the air shutter more

I !hey blow away from the burner close the air shutter more

t3!!:r;,:r flames ~houlri be checked frequently

Burner flames

They should

Foreign particles In

To adjust air shutter:

! !:;t’ ,+ screirrdrlver to lOosen the air shuller screw

<III snuller and retlgh:en the air shutter screw

Adjust the

Step 2: Adjust Orifice Hood

c:heck the Inner conu of the flame It should be about 1 2’

lzng for the oven broiler burner (see below)

the inner cone of Ihe flame

\vrench or adjustable ]olnt pliers lo adjust the onfice hood

o sllorlen Iht? coneL, tIghten the orlflce hood by turning In

1~~2 I P directIon To lengthen the cones loosen the orifice

Ii?od by turning In the Nat dlrectlon (see illustrations this

IS

not correct, use a 1 2“open end

If the length ol

.a+

/’

/

A

ACCESS OPENING COVER

B

ELECTRICAL CONNECTION

C TRIM CLIP

D ORIFICE COVER

E

OVEN IGNITOR

AIR SHUTTER

N---

AIR SHUVER

d--

6

SCREW

NAT

GINS552

Loading...

Loading...