Roper B400 Use And Care Manual

USE and CARE MANUAL

GAS BUILT-IN

model B400

INSTALLATION

l

I I

I 1

IIIllII IIIII)I )IIIIII

4356235 (343754-l )

THIS PAGE

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4.

Immediately call your gas supplier

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

L.P. Burner Adjustments

The adjustments in the Installation Section must be

made before you try to use your oven.

If you are using Liquified Petroleum Gas (bottled

gas) all L.P. adjustments in the Installation Section

must be made before use.

If your oven is not properly adjusted, flames may be

too high, or the oven may use too much fuel, release

toxic fumes or cook poorly.

WARNING: Improper

installation,

alteration, service or maintenance can cause in-

jury or property damage. Refertothismanual. For assistance or

additional information

consult a qualified

installer,

service

agency, manufacturer

(dealer) or the gas

supplier.

GNOTOB-1

NOTICES

INSTALLATION

USE AND CARE

Important Instructions for Your Safety

Your Oven and Its Features

Burner Ignition

Oven Cooking

Broiling

Favorite American Recipes

Continuous-Cleaning Oven Finish(only on selected models)

Cleaning Tips

Removable Oven Parts

SERVICE

Replacing Oven Light Bulb

What to Do before Calling for Service

Adjusting Oven Temperature

WARRANTY

GCOOl9

INSTALLATION

INSTALLER:

Leave these instructions with the

OWNER: Keep these instructions for future

appliance.

US.

TOOL LIST

1.

1 i8”drill bil

2. Electric or hand drill

3. Flat bladed screwdriver

4. No. 1 or No. 2 Phillips screwdriver

5. Pencil

6. Ruler and straight edge

7. Hand saw or saber saw

8. Pipe wrench

9. 5/8” wrench and l/2” wrench or adjustable wrench

10.

Pliers

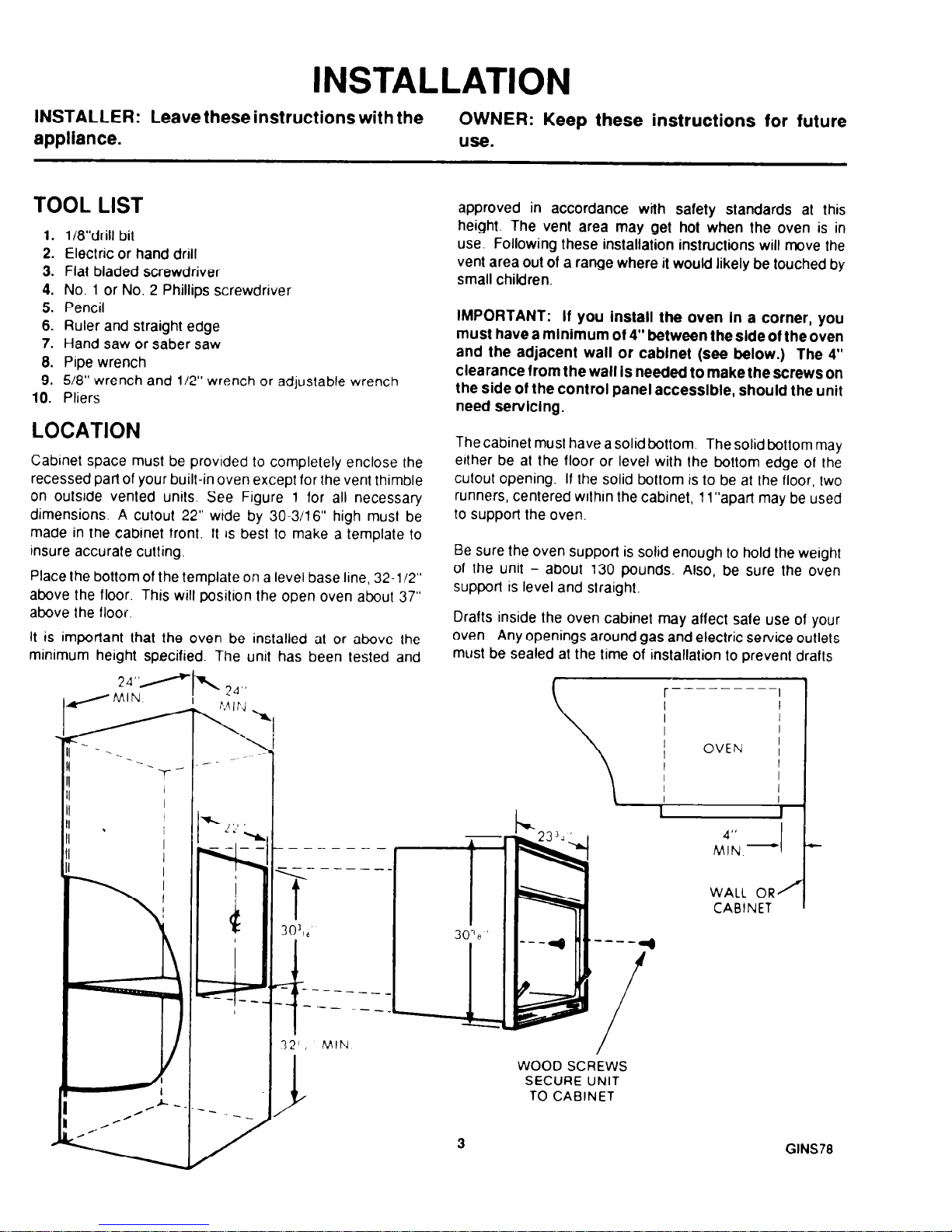

LOCATION

Cabinet space must be provided to completely enclose the

recessed part of your built-in oven except for the vent thimble

on outside vented units. See Figure 1 for all necessary

dimensions. A cutout 22” wide by 30.3/16” high must be

made in the cabinet front. It IS best to make a template to

insure accurate cutting.

Place the bottom of the template on a level base line, 32-112”

above the floor. This will position the open oven about 37”

above the floor.

It is important lhat the oven be installed at or above the

mlnlmum height specified. The unit has been tested and

24-A

{M’N

v 24”

approved in accordance with safety standards at this

height. The vent area may get hot when the oven is in

use. Following these installation instructions will move the

vent area out of a range where it would likely be touched by

small children.

IMPORTANT: If you install the oven In a corner, you

must have a minimum of 4” between the side of the oven

and the adjacent wall or cabinet (see below.) The 4”

clearance from the wall is needed to make the screws on

the side of the control panel accessible, should the unit

need

servicing.

The cabinet must have a solid bottom. The solid bottom may

either be at the floor or level with the bottom edge of the

cutout opening. If the solid bottom is to be at the floor, two

runners, centered within the cabinet, 1l”apart may be used

to support the oven.

Be sure the oven support is solid enough to hold the weight

of the unit - about 130 pounds. Also, be sure the oven

supporl is level and straight.

Drafts inside the oven cabinet may affect safe use of your

oven. Any openings around gas and electric service outlets

must be sealed at the time of installation to prevent drafts

r----

----I

I

I

OVEN

-rjfy &,-I

WALL OR/

CABINET

3

WOOD SCREWS

SECURE UNIT

TO CABINET

C

GINS78

ELECTRICAL CONNECTIONS

Check with your local utilities for electrical codes that apply

in your area If there are no local codes, Ihe National

Electrical Code, ANSI/NFPA No. 70-1987 must be followed

You can get a copy by wnting

National Fire ProtectIon Association

Batterymarch Park

Oulncy, MA 02269

An adequate electrical supply and outlet must be used to

operate the electrical parts of your oven The oven cord has

a ‘three prong plug and must be used with a properly

grounded three hole outlet with standard 120 volt 60 Hertz

AC household current.

Install the electrical outlet below the oven on the right side

It should be easily reached through cabinet doors below the

oven See Figure 5

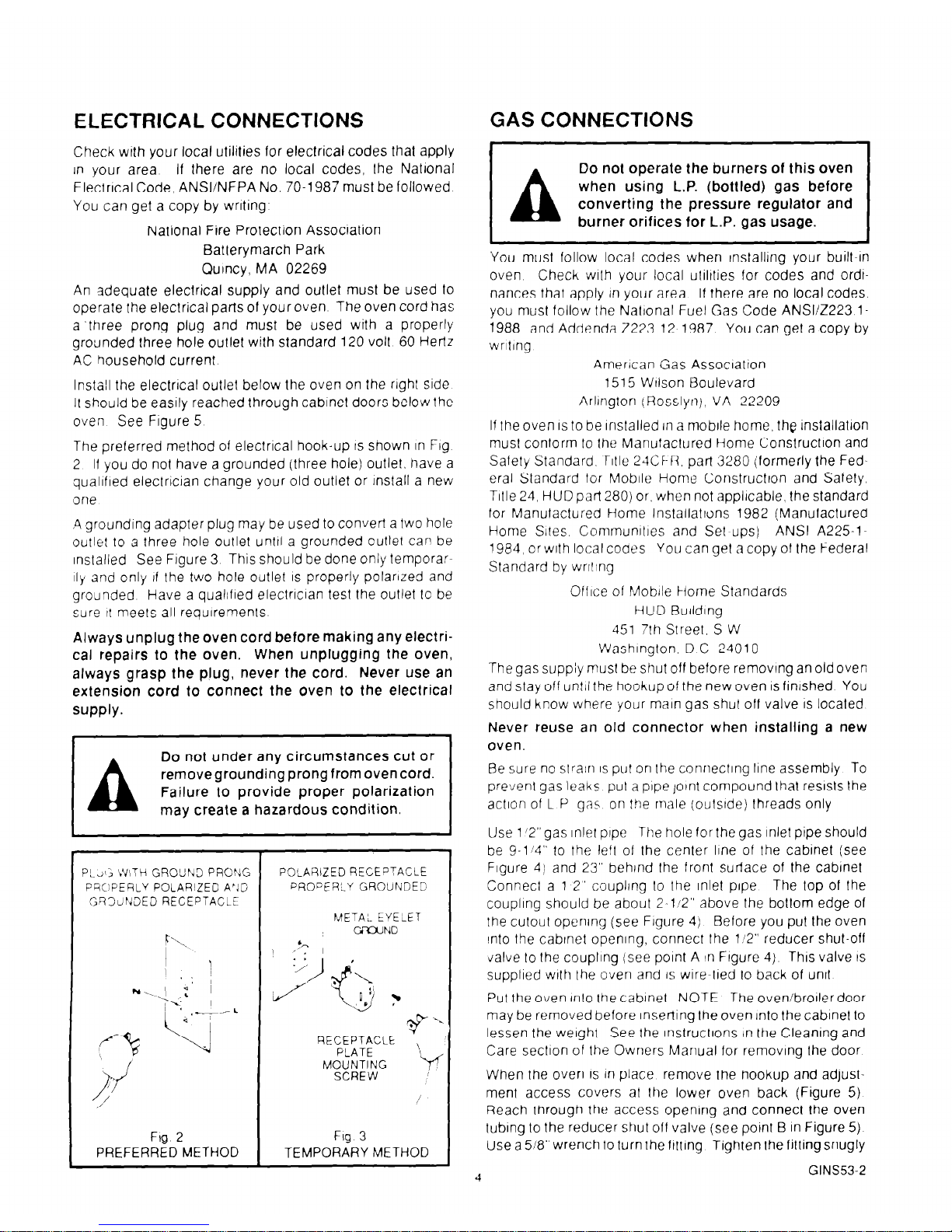

The preferred method of electrlcal hook-up IS shown In Fig

2 Ii you do not have a grounded (three hole) outlet, have a

qualified electrician change your old outlet or Install a new

lone

.4 grounding adapter plug may be used to convert a two hole

outlet to a three hole outlet until a grounded outlet can be

installed See Figure 3 This should be done only temporarsly and only

11

the two hole outlet

IS

properly polarized and

grounded Have a quaIlfled electrician test the outlet to be

sure it meets all requirements

Always unplug the oven cord before making any electrical repairs to the oven. When unplugging the oven,

always grasp the plug, never the cord. Never use an

extension cord to connect the oven to the electrical

supply.

A

Do not under any circumstances cut or

removegrounding prong from oven cord.

Failure to provide proper polarization

may create a hazardous condition.

P!~.J(; ~YITH GROUND PRONG

PG:)PERLY POLARIZED A’lG

GR3clNDED RECEPTACLE

POLARIZED RECEPTACLE

PROPERLY GROUNDED

METAL EYELEl

CiFWND

RECEPTACLE

PLATE

MOUNTING

SCREW

Fig. 2

Fig 3

PREFERRED METHOD TEMPORARY METHOD

GAS CONNECTIONS

Do not operate the burners of this oven

burner orifices for L.P. gas usage.

You must follow local codes when InstallIng your built-in

oven Check with your local utiltties for codes and ordtnances that apply in your area If there are no local codes.

you must follow the Natlonal Fuel

Gas

Code ANSI/Z223 l-

1988 and Addenda 2223

12

1987 You can get a copy by

wrltlng

American Gas Association

1515 Wilson Boulevard

Arlington (Rosslyn), VA 22209

If the oven IS to be Installed In a mobile home, the lnstallatlon

musl conform to the MdnufaClured Home Construction and

Safety Standard, Title 24CF-R part 3280 (formerly the Federal Standard for Mobile Home Construction and Safety,

Title 24, HUD part 280) or, when not applicable, the standard

for Manufactured Home Installations 1982 (Manufactured

Home Sites. Communitres and Set-ups) ANSI A225l1984, or with local cooes You can get a copy of the Federal

Standard by wrlllng

Ofllce of Mobile Home Standards

tHUD BulldIng

451 7th Street, S W

Washington. D C 24010

The gas suppiy must be shut off before removing an old oven

and stay off until the hookup of the new oven is finished

You

should know where your main gas shut off valve

IS

located

N.ever reuse an old connector when installing a new

oven.

Be sure no stralri

IS

put on the connecting line assembly To

prevent gas leaks put a pipe joint compound that resists the

action of L P gas on the male (outstde) lhreads only

Use 1 ‘2”gas inlet pope The hole for the gas inlet pipe should

be g-114” to the left of the center line of the cabinet (see

Figure 4) and 23” behlnd the front surface of the cabinet

Connect a 1 2” coupling to the Inlet pipe

The top of the

coupling should be about 2-1’2” above the bottom edge of

the cutout opening (see Figure 4) Before you put the oven

into the cabinet opening, connect the 112” reducer shut-off

Jalve to the coupling (see point A In Figure 4)

This valve IS

supplied wllh the oven and IS wire-tied to back of unit

Put the oven lnlo lhe cabinet NOTE The oven/brollerdoor

may be removed before Inserting the oven Into the cabinet to

lessen the weight See the inslructlons tn the Cleaning and

Care section of the Owners Manual for removing Ihe door

When the oven

IS

In place remove the hookup and adjuslment access covers at the lower oven back (Figure 5)

Reach lhrough the access opening and connect the oven

tubing to the reducer shut off valve (see point B in Figure 5)

Use a 518” wrench to turn the ftttlng Tighten the fitting snugly

4

GINS532

but do not force it, Forcing could damage the fitting and

tubing and cause leaking.

Apply liquid leak detector to all connections in the supply line,

manifold and oven to test tor gas leaks. Do

not use an open

flameto look

for leaks.

Bubbles will form where any gas is

leaking. Turn off the main gas supply before you try to stop

a leak. After all leaks are stopped, turn on the gas supply and

recheck all connections for leaks before lighting burners. All

leaks must be stopped before llghtlng any burners.

After electrical and gas connections have been made, use a

1!8”drill bit to drill holes in the cabinet front, through the holes

in the oven trim. Secure the oven in the cabinet with the

screws provided

Fig 4

&UT OFF VALVE HERE IF

BEQUIRED BY LOCAL REGULATIONS

1 II

1

Fg. 5

MAKING L.P. GAS ADJUSTMENTS

A

If you are using L.P. (bottled) gas, all the

adjustments described below must be

made before you make any burner ad-

justments or use the oven.

To adjust your oven for use with L.P.

gas,

follow the steps

below.

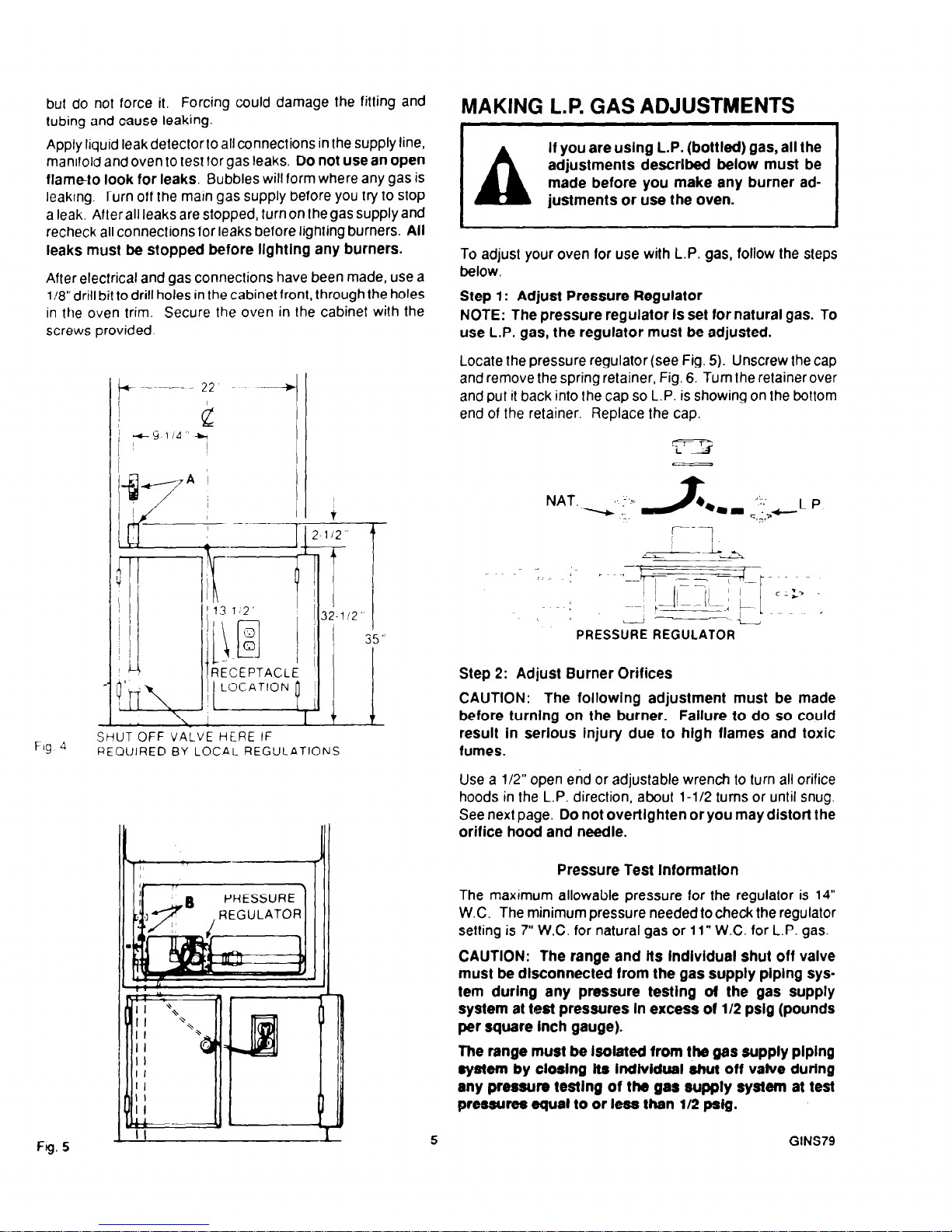

Step 1: Adjust Pressure Regulator

NOTE: The pressure regulator Is set for natural gas. To

use L.P. gas, the regulator must be adjusted.

Locate the pressure regulator (see Fig. 5). Unscrew the cap

and remove the spring retainer, Fig. 6. Turn the retainer over

and put it back into the cap so L-P. is showing on the bottom

end of the retainer. Replace the cap.

I *

--i

PRESSURE REGULATOR

Step 2: Adjust Burner Orifices

CAUTION: The following adjustment must be made

before turnlng on the burner. Failure to do so could

result in serious Injury due to high flames and toxic

fumes.

Use a l/2” open end or adjustable wrench to turn all orifice

hoods in the L.P. direction, about l-1/2 turns or until snug.

See

next page.

Do not overtlghten or you may distort the

orifice hood and needle.

Pressure Test Information

The maximum allowable pressure for the regulator is 14”

W.C. The minimum pressure needed to check the regulator

setting is 7” W.C. for natural

gas or

11” W.C. for L.P. gas.

CAUTION: The range and lts lndlvldual shut off valve

must be dlsconnected from the gas supply plplng system during any pressure testlng ot the gas supply

system at test pressures In excess of l/2 psig (pounds

per square Inch gauge).

The range must be Isolated irom the gas supply plping

system by closing its lndlvldual

shut

off valve during

any pressure testlng of the gas supply system at test

pressures equal to or less than l/2 psig.

5

GINS79

MAKING BURNER ADJUSTMENTS

If you are using L.P. (bottled) gas, all the

adjustments described on the previous

pagemust bemadebeforeyoumakeany

burner adjustments or use the oven.

All ovens are factory adjusted for use with the natural gas

used in most

areas. But, since the gas in

some

areas may

be different, you should check all adjustments described

below.

If youare using L.P. gas, all theadjustments must

be made.

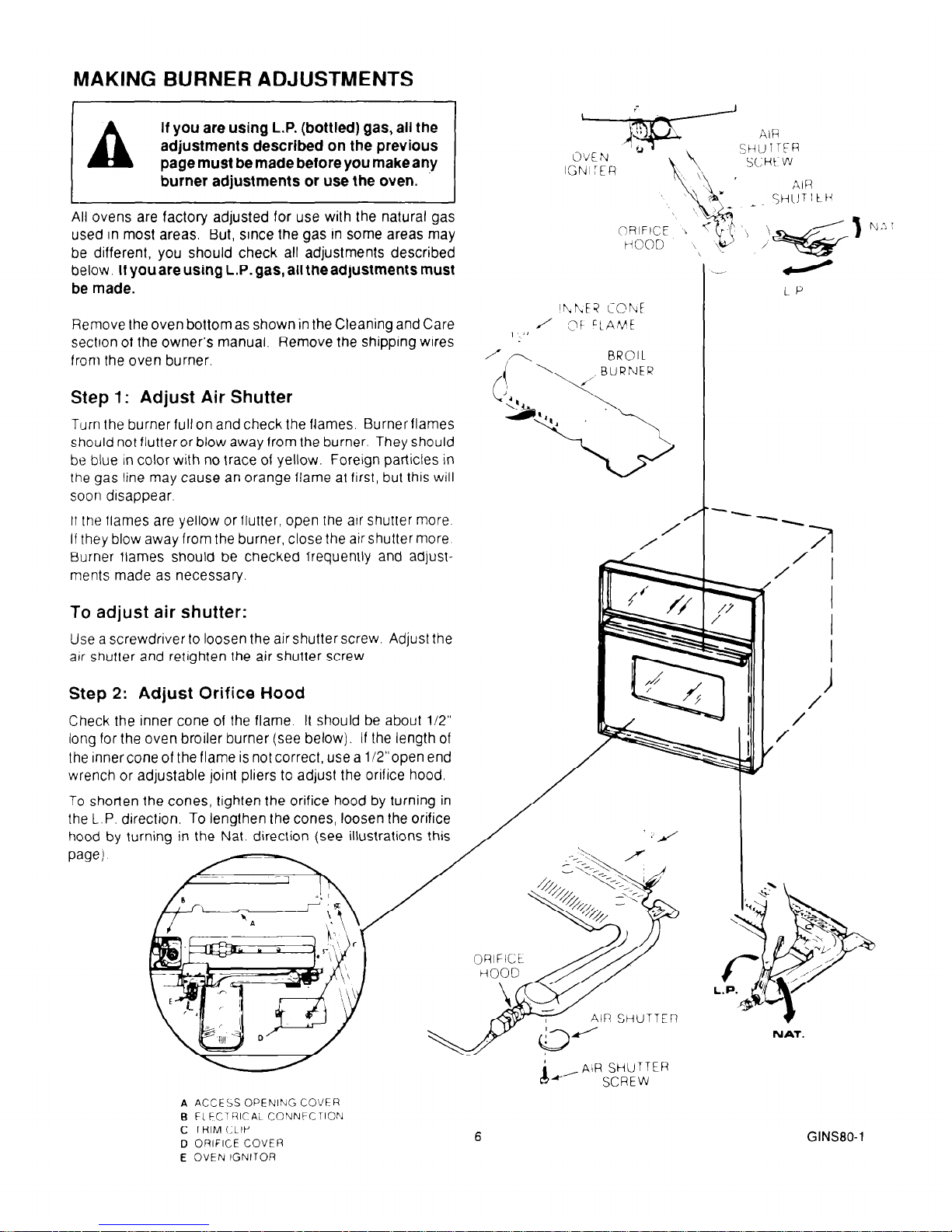

Remove the oven bottom as shown in the Cleaning and Care

section of the owner’s manual. Remove the shipping wires

from the oven burner.

Step 1: Adjust Air Shutter

Turn the burner full on and check the flames. Burner flames

should not flutter or blow away from the burner. They should

be blue in color with no trace of yellow. Foreign particles in

the gas line may cause an orange flame at first, but this will

soon disappear.

If the flames are yellow or flutter, open the arr shutter more

If they blow away from the burner, close the air shutter more

Burner flames should be checked frequently and adjustments made as necessary

To adjust air shutter:

Use a screwdriver to loosen the air shutter screw. Adjust the

air snutter and retrghten the air shutter screw.

Step 2: Adjust Orifice Hood

Check the inner cone of the flame. It should be about 112”

long for the oven broiler burner (see below). If the length of

the inner cone of the flame is not correct, use a li2”open end

6

GINS80-1

‘r\

BROll

To shorten the cones, tighten the orifice hood by turning in

the L.P. direction. To lengthen the cones, loosen the orifice

hood by turning in the

n (see illustrations this

AIR SHUTTER

AIR SHUTTER

A ACCESS OPENING COVER

B FI FCTRICAL CONNFCTION

C TRIM CLIP

D ORIFICE COVER

E OVEN IGNITOR

NAT.

Loading...

Loading...