Roof Zone 70755 User Manual

TMTM

Zip Rail

TMTM

System

Keep this Operations manual with the Zip Rail at all times. New users are required to read it before

installing and using the Zip Rail system.

It is the Zip Rail owner’s duty to arrange that all workers using this system are completely trained.

Present all workers with this manual and verify that they have read and understand its contents. If

necessary read the entire manual to each worker. Untrained and inadequately instructed workers should

not install or use this system as it may result in property or materials damage and or serious injury or

death to personnel.

Tie Down Engineering provides this operators manual with each Zip Rail System at the time of sale as

a means to help instruct the owner/worker in the correct installation and use of the Zip Rail system and

expects the reseller and owner/worker to make every effort to educate themselves regarding the

installation, use and limits of the Zip Rail system before placing into service.

Before installing Zip Rail on a roof, a competent professional must evaluate the roof and its

structure in order to determine whether it can hold the weight of not only the system but also

all workers and other equipment that will be in the work immediate area. In addition the roof

edge structure must also withstand the forces of a 200 lb. load onto the top rail per OSHA

1926.502 conveyed against the Zip Rail system in the event a worker would fall against it.

Thank you for purchasing the Zip Rail System by Tie Down Engineering. With normal use and standard

care, the Zip Rail System will serve you and your workers for many years. For Safety of the operator and

workers it is essential that those installing and using the Zip Rail System read and understand this manual

before setting up.

Date of Purchase: _______________ Purchased From: ________________________________

Instruction Sheet #08265

Page 1 of 12

TIE DOWN ENGINEERING • Atlanta, GA 30336

www.tiedown.com (404) 344-0000

E1473; 101017

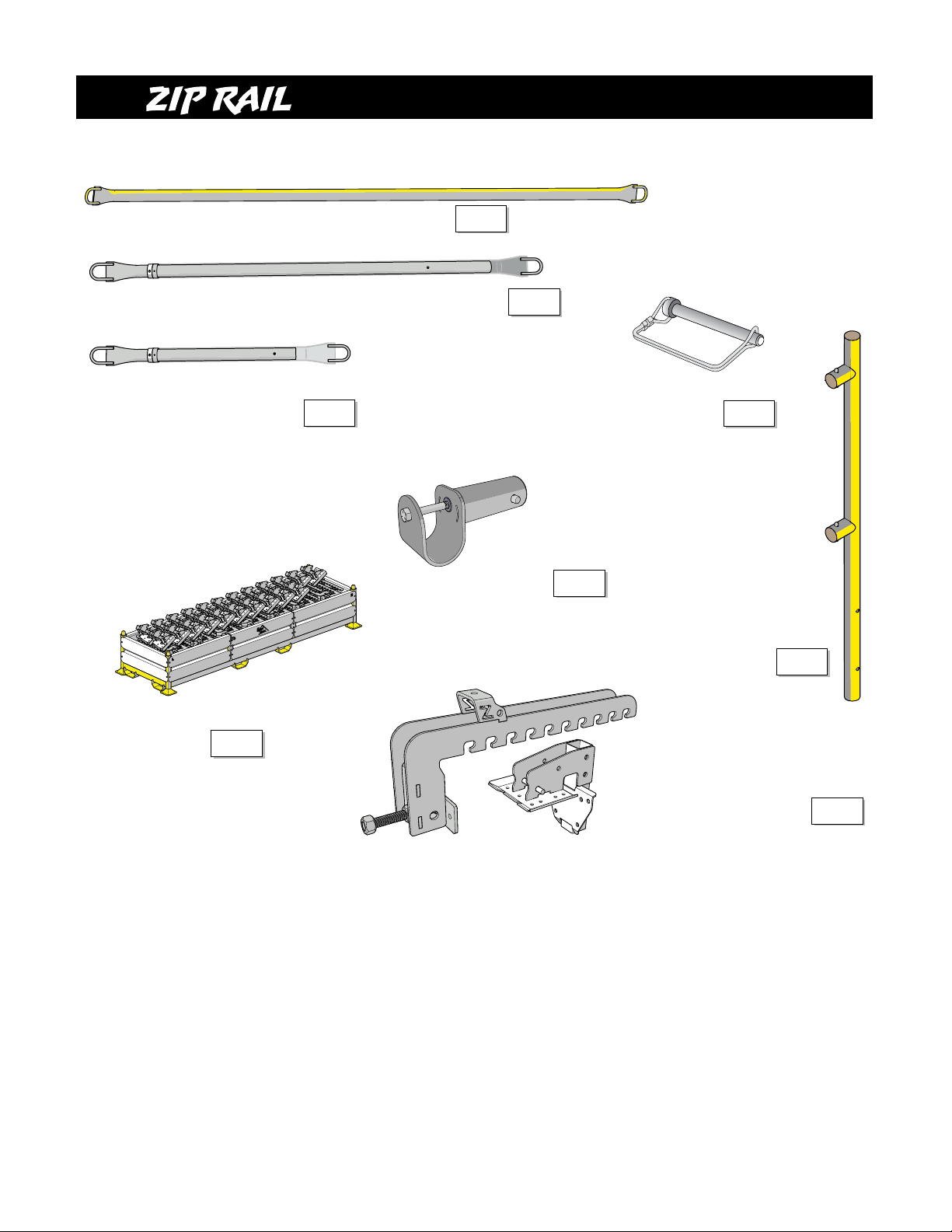

10 ft. Zip Rail - Painted Yellow #70733 (Qty. 63)

Adjustable Zip Rail 5’ - 8’ - Zinc Finish #70732 (Qty. 8)

Compression Kit #70736

Adjustable Zip Rail 32” - 48”

Zinc Finish #70731 (Qty. 4)

Zip Rail Stack Container

#70737 (Qty. 1)

Complete Kit with Container

#70736

Safety Locking Pin

#10500 (Qty. 36)

Corner Bracket Assembly

Painted Yellow #70730

(Qty. 12)

Compression Bracket

& Gravel Stop

#70725/70723 (Qty. 36 each)

Zip Rail Stanchion

Painted Yellow #70728

(Qty. 36)

2

10 ft. Zip Rail - Painted Yellow #70733 (Qty. 76)

Adjustable Zip Rail 5’ - 8’ - Zinc Finish #70732 (Qty. 8)

Adjustable Zip Rail 32” - 48”

Zinc Finish #70731 (Qty. 4)

Gravel Stop Kit #70755

Corner Bracket Assembly

Painted Yellow #70730

(Qty. 6)

Zip Rail Stack Container

#70737 (Qty. 1)

Complete Kit with Container

#70755

Safety Locking Pin

#10500 (Qty. 43)

Zip Rail Stanchion

Painted Yellow #70728

(Qty. 43)

Gravel Stop

#70723 (Qty. 43)

3

Intended Use

The Zip Rail System is designed for providing fall protection for workers near the roof edge according to

the standards set forth in OSHA 1926.502. These activities are to be performed on flat, level roofs only

with a maximum pitch of ½ in per foot (.5/12). Any other use of the Zip Rail System not mentioned here

voids the manufacturer’s warranty and is the sole responsibility of the owner/worker should any damage

or injuries occur.

Before work begins, install OSHA approved perimeter guarding systems around all

roof edges, openings, skylights, and roof hatches which are left open or removed.

It’s against the law to leave the above roof areas unguarded and will result in fines

against the contractor if any unguarded openings are on the roof

In the event of injury or death from falling due to an unguarded edge or opening,

litigation and prosecution may be brought against the contractor, equipment owner

and building owner.

WARNING: Working at or near the roof edge is dangerous and can subject the worker to

serious injury or death from falls. The roofing contractor and the worker must make every

effort to insure the area where he/she will be working is as safe as possible. This means

taking only the tools you need to the roof edge, removing all trip hazards and loose materials,

the wearing and proper use of OSHA approved fall arrest devices. Use harnesses and life-lines

when and where required, make no sudden or unplanned moves and always be constantly

aware of your surroundings and your position/location relative to the roof edge.

It is also imperative that the worker read the operators manual for this Zip Rail system and

thoroughly understand how to set up and use this system. This includes knowledge of what

the system can do and also how to avoid situations this system was not designed to handle.

Tie Down Engineering provides this manual at the time of sale as a tool to help instruct the

owner/worker in the proper use if the Zip Rail system and expects the reseller and owner/

worker to make every effort to educate themselves before putting this system into service.

4

Loading...

Loading...