Page 1

Page 2

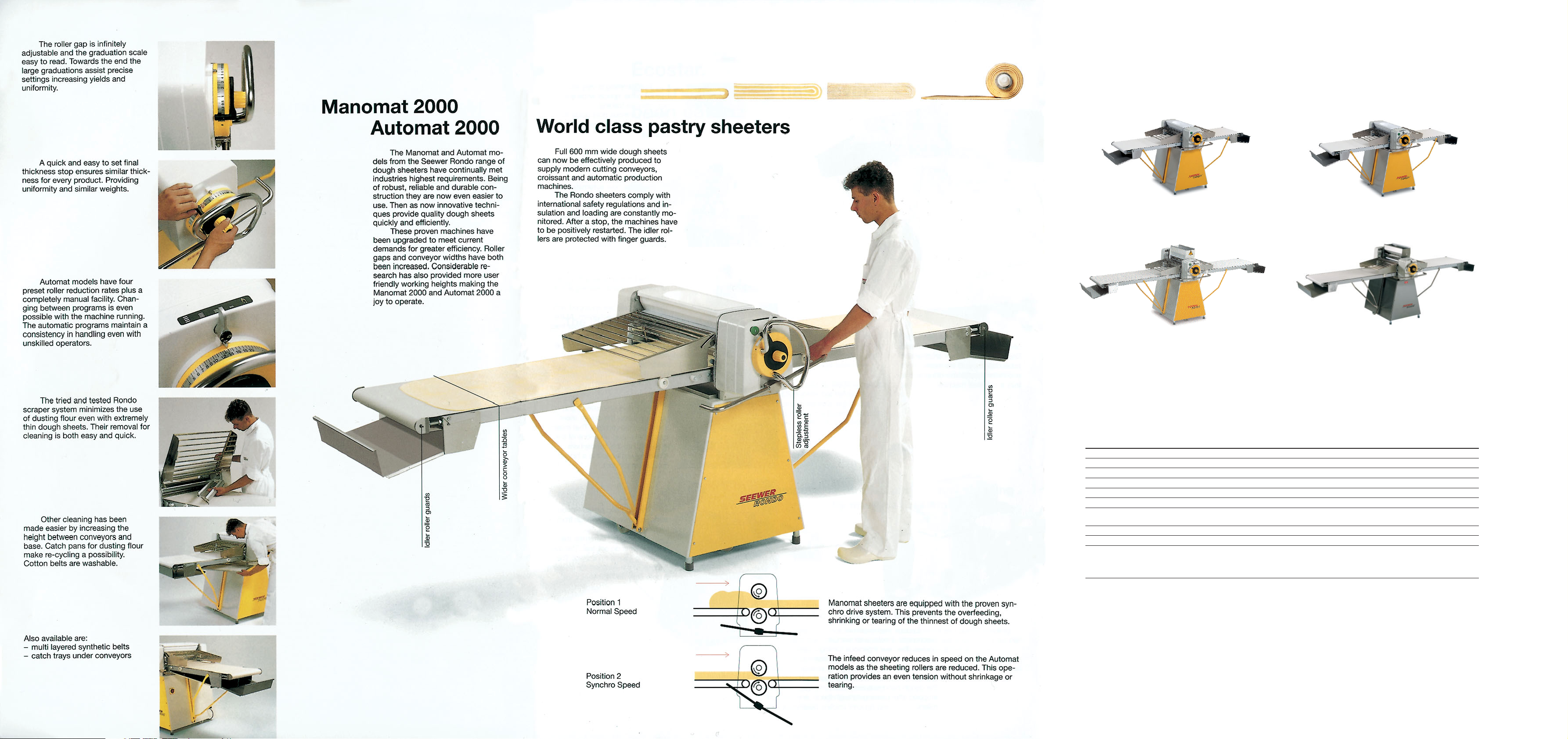

Manomat, Automat models.

Automat SSO 687 Inox

(Manomat SSO 677 Inox)

Manomat SSO 675

Automat SSO 685

Automat SSO 687

(Manomat SSO 677)

Technical data

Substructure

Autom. flour duster

Width of conveyor belts

Table length overall

Roller length

Roller gap

Speed of discharge

conveyor

Rated power

Supply voltage

Required floor-space in:

working position,

catch pans extended

resting position

SSO 675

Manomat

A-frame

optional

635 mm

2720 mm

660 mm

0,5– 45 mm

60 cm/sec.

1,5 kVA

3x200–420V, 50/60 Hz

12 15x 3200 mm

12 15x 1440 mm

SSO 677

Manomat

A-frame

optional

635 mm

3320 mm

660 mm

0,5– 45 mm

60 cm/sec.

1,5 kVA

12 15x 3800 mm

12 15x 1760 mm

SSO 685

Automat

A-frame

optional

635 mm

2720 mm

660 mm

0,5– 45 mm

60 cm/sec.

1,5 kVA

12 15x 3200 mm

12 15x 1440 mm

SSO 687

Automat

A-frame

optional

635 mm

3320 mm

660 mm

0,5– 45 mm

60 cm/sec.

1,5 kVA

12 15x 3800 mm

12 15x 1760 mm

Subject to technical changes without notice.

The type specific and the safety instructions of the operating manuals as well as the prohibition,

mandatory action and warning signs are to be observed.

Page 3

Ecostar models.

SSO 627 H

SSO 625

SSO 627

SSO 625 H

Technical data

Substructure A-frame

in stainless steel

Automatic flour duster

Width of conveyor belts

Table length overall

Roller length

Roller gap

Motorized roller gap reduction:

– 20 automatic programs

– 9 man/auto programs

– manual reduction steps

Speed of discharge

conveyor

Rated power

Supply voltage

Required floor space in:

working position,

catch pans extended

resting position

Net weight

SSO 625

painted

optional

optional

635 mm

2720 mm

660 mm

0,2– 45 mm

58 cm/sec.

1,0 kVA

3x200–420V, 50/60 Hz

1125 x3200 mm

1125 x1440 mm

225 kg

SSO 627

painted

optional

optional

635 mm

3320 mm

660 mm

0,2– 45 mm

58 cm/sec.

1,0 kVA

1125 x3800 mm

1125 x1700 mm

230 kg

SSO 627 H

painted

optional

optional

635 mm

3205 mm

660 mm

0,2– 45 mm

58 cm/sec.

1,0 kVA

1125 x3510 mm

1125 x2405 mm

265 kg

SSO 625 H

painted

optional

optional

635 mm

2905 mm

660 mm

0,2– 45 mm

58 cm/sec.

1,0 kVA

1125 x3210 mm

1125 x2265 mm

260 kg

Subject to technical changes without notice.

The type specific and the safety instructions of the operating manuals as well as the prohibition,

mandatory action and warning signs are to be observed.

The Ecostar is a baker’s dream

come true. Whether controlled manually or fully automatically – the pastry is sheeted fast, expertly and

easily. Intelligent technology has

made this possible.

For operations performed

repeatedly, automatic sheeting is

recommended. Ecostar has a

memory for 20 programs.

Ecostar handles all types

of doughs: from puff, croissant and

Danish, to yeast, short crust and

pizza doughs, and the more

and more popular thin doughs. It is

truly a universal machine.

Ecostar also excels as a

mechanical sheeter with manual

control. The new ingenious turning

knob allows easy, quick and precise

roller setting. In manual sheeting

too, the photo cells are working and

the dough band is automatically

stopped after passing through the

rollers.

Ecostar.

Pastry sheeting has never

been easier.

On the other hand, single

billets and very special doughs are

best processed with manual control, using individual reduction

steps.

For products requiring specific

reduction steps but being

processed regularly, e.g. pizza

or tart bases, the Ecostar features

the unique «Man/Auto»-mode.

Use manual control to select the

ideal reduction steps. When satisfied with the result, the machine

then memorises these steps and

converts them into an automatic

program.

Programming is very easy and

needs neither special knowledge

nor intensive training.

Blinking luminous dots guide the

operator through the programming

process.

With the new automatic dough

reeler, the dough band is reeled

gently and without tension.

The last stage of the reeling process

is performed on the conveyor belt.

Here, the dough is stopped and can

easily be carried away.

The Ecostar is easy to clean.

All parts that need cleaning are of

easy access.

The photo cells are equipped with

a self-cleaning mechanism. At the

end of each program, a wiper frees

them from dough and flour, providing a perfect functioning of the

machine.

Flour is dusted evenly and

accurately over the dough sheet

under program control. That means

less flour is used and none of it is

escaping into the atmosphere.

A subsequent benefit is a higher

quality final product.

The tried and tested Rondo

scrapers prevent the dough from

sticking to the rollers.

Even delicate and extremely thin

dough sheets do not tear. The use

of dusting flour is minimised. The

removal of the scrapers for cleaning

is both easy and quick.

Computer-controlled and manual sheeting

by one and the same machine.

The ideal machine for the craft baker.

Ecostar is a user-friendly computer-controlled machine for automatic operation.

The operator selects one of

the 20 programs. The machine then

performs the sheeting operation fully

automatically. Whoever is handling

the machine, dough and pastries

are guaranteed uniform through pre-

cise control and gentle handling.

Automatic operation frees your personnel for additional work.

The Ecostar is a valuable

instrument for reducing labour cost.

Automatic operation. Manual control.

Page 4

Econom, Ecomat models.

Ecomat SSO 615

Econom SSO 514

Technical data

Model

Width of conveyor belts

Table width

Table length overall

Roller length

Roller gap

Speed of discharge

conveyor

Rated power

Supply voltage

Required floor space in:

working position

resting position

STM 513

Econom

bench

475 mm

490 mm

1560 mm

500 mm

0,5– 30 mm

50 cm/sec.

0,75 kVA

3x200–420V, 50/60 Hz

1560x940 mm

850x 940 mm

STM 615

Ecomat

bench

605 mm

620 mm

2420 mm

633 mm

0,5– 30 mm

50 cm/sec.

1,0 kVA

1072 x 2420 mm

1072 x 1240 mm

SSO 514

Econom

A-frame

475 mm

490 mm

2055 mm

500 mm

0,5– 30 mm

50 cm/sec.

0,75 kVA

2500 x 940 mm

850 x 940 mm

SSO 615

Ecomat

A-frame

605 mm

620 mm

2420 mm

633 mm

0,5– 30 mm

50 cm/sec.

1,0 kVA

1072 x 2900 mm

1072 x 1240 mm

SSO 617

Ecomat

A-frame

605 mm

620 mm

3320 mm

633 mm

0,5– 30 mm

50 cm/sec.

1,0 kVA

1072 x 3800 mm

1072 x 1630 mm

Subject to technical changes without notice.

The type specific and the safety instructions of the operating manuals as well as the prohibition,

mandatory action and warning signs are to be observed.

The practical pistol grip allows

adjusting the rollers in a quick and

easy way and the newly designed

scale assists in precise settings. The

final thickness stop ensures identical

thickness for every product.

Econom and Ecomat are

dough sheeters especially designed

for hotels, restaurants and food

service kitchens, but also for small to

medium craft bakeries. On both

models, a new drive feature harmonizes the drive relationship between

infeed and discharge conveyors to

provide perfect dough sheets.

The machines are very easy

and safe to handle. For starting one

of the two green buttons in pressed.

For stopping, either the safety

guards are lifted or the red button is

pressed.

For the daily cleaning, the

scrapers can be removed in a few

seconds.

When not in use, the conveyors can be raised and precious

space becomes free for other tasks.

Thanks to the precise build

qualities, on Econom and Ecomat,

but also on Manomat, Automat and

Ecostar, paper thin dough sheets

can be produced. All types of

dough, including marzipan can be

sheeted to perfection.

Ecomat SSO 615

A 600 mm wide sheeter.

Econom STM 513

A 500 mm wide model to fit into

the smallest area.

Econom and Ecomat.

Great performance at an exceptional price.

Econom STM 513

Ecomat STM 615

Page 5

In the world of baking,

Rondo Doge represent quality,

reliability and innovation.

We have been the leading manufacturer of dough processing

machines and systems for generations, and continue to develop innovative and production-orientated

solutions for the baking industry.

Products bearing our name

combine high quality with high precision, and are manufactured with the

most sophisticated machinery in a

high technology environment.

Each product innovation is the

result of close cooperation with our

customers, frequently at our test

bakeries in Switzerland, Italy, Great

Britain and the U.S.A. These bakeries

are freely available to our customers

for testing new working methods or

new products, and also for demonstrations.

We take pride in ensuring our

customers fully understand the

operation of our products, and are

conversant with the simple cleaning

and maintenance routines.

Our subsidiaries and representatives offer technical assistance and

spare parts service around the world.

Customers are using this network of

competent resources to achieve

security and continuity of production.

A constant struggle for perfection, and professional worldwide

operation, have made Rondo Doge

global leaders in the baking industry.

Hägeli, CH-4950 Huttwil C0-6

For information about our entire product range,

please visit www.rondodoge.com

Seewer AG

CH-3400 Burgdorf/Schweiz

Tel. + 41 (0)34 420 81 11

Fax + 41 (0)34 420 81 99

info@ch.rondodoge.com

www.rondodoge.com

Seewer GmbH & Co.

D-57299 Burbach

Hoorwaldstrasse 44

Tel. + 49 (0)2736 203-0

Fax + 49 (0)2736 203130

info@de.rondodoge.com

Seewer Rondo S.à.r.l.

PAE "Les Pins"

F-67319 Wasselonne Cédex

Tel. + 33 (0)3 88 59 11 88

Fax + 33 (0)3 88 59 11 77

info@fr-rondodoge.com

Rondo Ltd.

Unit 7, Chessington Park

Lion Park Avenue

Chessington, Surrey KT9 1ST/ GB

Tel. + 44 (0)181 391 1377

Fax + 44 (0)181 391 5878

info@uk.rondodoge.com

Rondo Inc.

51, Joseph Street

Moonachie, N.J. 07074 / USA

Tel. + 1 201 229 97 00

Fax + 1 201 229 00 18

info@us.rondodoge.com

Rondo Bakery Equipment Inc.

267 Canarctic Drive

Downsview, Ont. M3J 2N7/ Canada

Tel. + 1 416 650 0220

Fax + 1 416 650 9540

info@ca.rondodoge.com

Rondo S.r.l.

Via Lago di Albano, 86

I-36015 Schio (VI)

Tel. + 39 0445 576 635

Fax + 39 0445 576 641

info@it.rondodoge.com

Seewer Moskau

Butyrsky Wal 68/70

103055 Moskau, Russland

Tel. + 7 095 956 79 08

Fax + 7 095 251 37 20

info@ru.rondodoge.com

Seewer Rondo

Asean Regional Office

No. 14 –1 Mezzanine Floor

Jalan 11/116B

Kuchai Entrepreneurs Park

Off Jalan Kuchai Lama

58200 Kuala Lumpur / Malaysia

Tel. + 60 3 784 55 20

Fax + 60 3 784 55 95

info@my.rondodoge.com

Doge

food processing machinery s.r.l.

Via Lago di Albano, 86

I-36015 Schio (VI)

Tel. + 39 0445 575 429

Fax + 39 0445 575 317

info@it.doge.rondodoge.com

Loading...

Loading...