Page 1

Service manual

Rondostar 3000

SFS6115, SFS6115C, SFS6117,

SFS6117C, SFS6117H, SFS6117DD

SFI6117, SFI6117H

Edition SD123402

T echnical specifications subject to change without notice

HEADQUARTERS

RONDO Burgdorf AG

Heimiswilstrasse 42

3400 Burgdorf

Switzerland

Phone +41 (0)34 420 81 11

Fax +41 (0)34 420 81 99

info@rondo-online.com

COMPETENCE CENTRE SCHIO

RONDO Schio s.r.l.

Via Lago di Albano, 86

36015 Schio (VI)

Italy

Phone +39 0445 575 429

Fax +39 0445 575 317

schio@it.rondo-online.com

SUBSIDIARIES

RONDO GmbH & Co.KG

Hoorwaldstrasse 44

57299 Burbach

Germany

Phone +49 (0)2736 203-0

Fax +49 (0)2736 203130

info@de.rondo-online.com

RONDO S.à.r.l.

PAE "Les Pins"

67319 Wasselonne cedex

France

Phone +33 (0)3 88 59 11 88

Fax +33 (0)3 88 59 11 77

info@fr.rondo-online.com

RONDO Ltd.

Unit 7, Chessington Park

Lion Park Avenue

Chessington, Surrey KT9 1ST

Great Britain

Phone +44 (0)20 8391 1377

Fax +44 (0)20 8391 5878

info@uk.rondo-online.com

RONDO Inc.

51 Joseph Street

Moonachie, N.J. 07074

USA

Phone +1 201 229 97 00

Fax +1 201 229 00 18

info@us.rondo-online.com

RONDO Inc.

267 Canarctic Drive

Downsview, Ont. M3J 2N7

Canada

Phone +1 416 650 0220

Fax +1 416 650 9540

info@ca.rondo-online.com

RONDO S.r.l.

Via Lago di Albano, 86

36015 Schio (VI)

Italy

Phone +39 0445 576 635

Fax +39 0445 576 641

info@it.rondo-online.com

OOO RONDO

Varschavskoge Chaussée, D 17, Str. 3

117105 Moskau

Russia

Phone +7 (495) 786 39 06

Fax +7 (495) 788 98 20

info@rondo-online.ru

RONDO Asia

Regional Office

No. 14-1 Mezzanine Floor

Jalan 11/116B

Kuchai Entrepreneurs Park

Off Jalan Kuchai Lama

58200 Kuala Lumpur

Malaysia

Phone +60 3 7984 55 20

Fax +60 3 7984 55 95

info@my.rondo-online.com

www.rondo-online.com

Page 2

1. Safety regulations

2. Full view of the machine

3. Recommended spare parts

3.1 Mecanical spare parts

3.2 Electrical spare parts

4. Notes for the service

4.1 Important notes

4.1.1 Improvements on the Rondostar

4.1.2 Software changes

4.1.3 Usage of the new software

4.1.4 General view of the special functions

4.2 Initialisation

4.3 Calibrating the roller gap

4.4 Parameter

4.5 Diagnostic program

4.5.1 Selecting the diagnostic program

4.5.2 Checking the inputs

4.5.3 Allocation of the outputs

4.6 Operating hours counter

Index

5. Important notes, testing the drives

5.1 Mains voltage, mains frequency

5.1.1 Modifying the machine for a different mains voltage

5.1.2 Modifying the machine for another frequency

5.2 Functions of the machine

5.2.1 Machine start function

5.2.2 Roller adjustment drive function

5.2.3 Turning knob

5.3 Testing the drives

5.3.1 Direction of rotation of the drives

5.3.2 Testing the table- and roller drive

5.3.3 Testing the roller adjustment drive

5.3.4 Testing the flour duster

5.3.5 Testing the reeler

5.3.6 Testing the roller adjustment drive brake

5.3.7 Testing the Cutomat

5.4 Final control test

Page 3

6. Compound operation

6.1 General comments

6.2 Function

6.2.1 Compound operation with one make-up line respectively donut line

6.2.2 Positioning the dough

6.2.3 Release signal for transfer

6.3 Special parameters for compound operation

7. Instructions for trouble shooting

7.1 Error messages

7.2 Construction of the control system

7.3 Checking the control system

7.3.1 Mains voltage

7.3.2 Control voltages

7.3.3 Control circuit main contactor K1M

7.3.4 Measure of the voltage on the plugs

7.4 Important notes to the frequency inverter

7.4.1 Types

7.4.2 Parameterization

7.4.3 Ground fault interrupter can be actuated when inverter is started

8. Part names, drawings

8.1 Machine head front housing

8.1 Machine head front housing Cutomat / Compound

8.2 Machine head intermediate parts

8.3 Machine head rear housing

8.4 Machine bases

8.4.1 Machine base

8.4.2 Maschine base with support

8.4.3 Machine base SFI

8.5 Machine tables

8.5.1 Machine table Inox to Cutomat

8.5.2 Machine table Inox to support type

8.5.3 Machine table Inox to socle type

8.5.4 Flour catch pan

8.6 Cutting station / Machine table Cutomat

8.6.1 Adjustment of spring range

8.7 Flour duster

8.8 Automatic dough reeler

8.8.1 Convert the automatical dough reeler from the right to the left machine table

8.8.2 Reeler raise SFI61 17.E

8.9 Electrical box

8.10 Electrical box Cutomat

8.1 1 Front cover: Electrical equipment

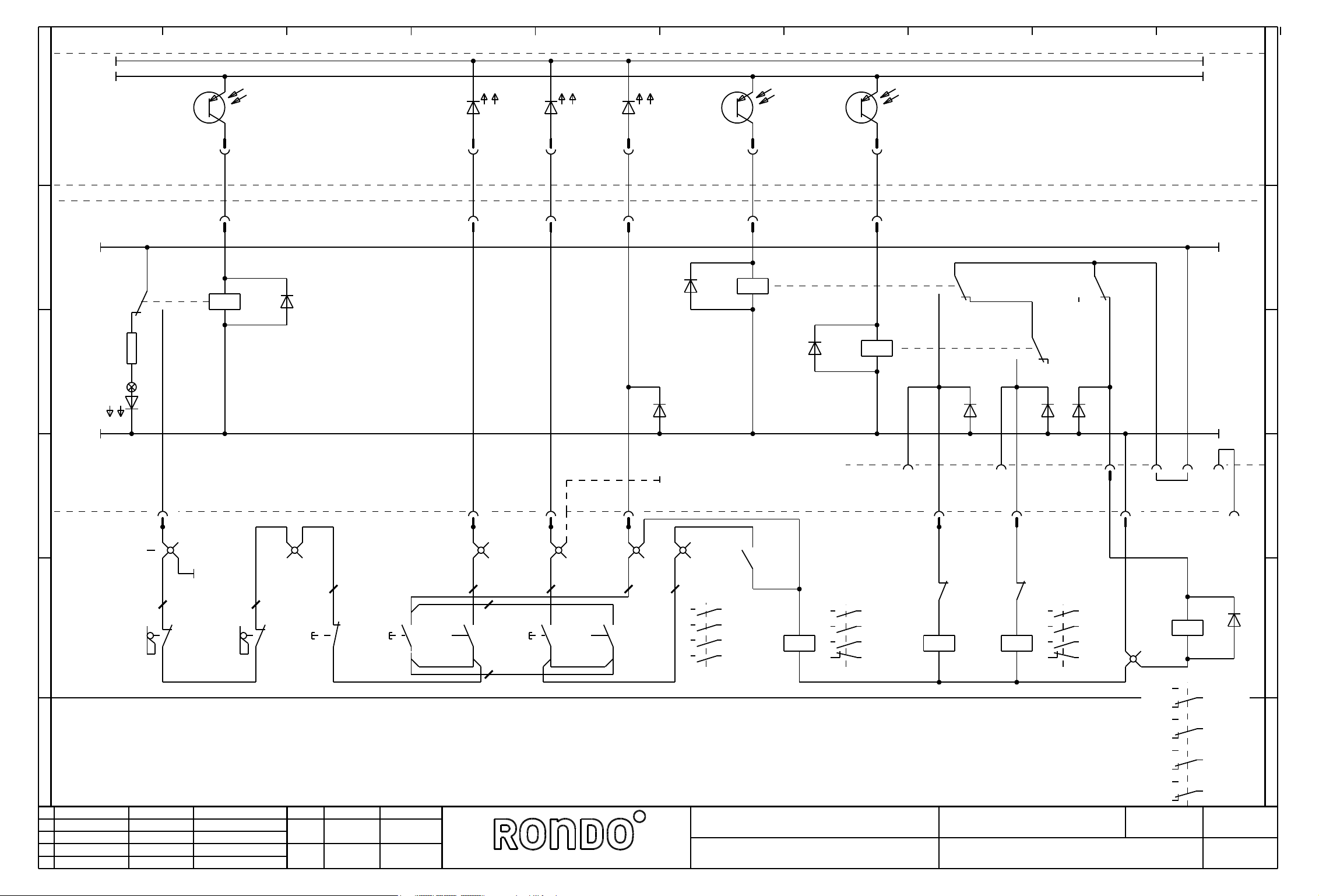

9. Electro circuit diagrams

Page 4

Unbedingt zu beachtende Sicherheitsvorschrif ten und -hinweise

Bei allen Reparatur-, Inst andhaltungs-, Reinigungs- und ähnlichen Arbeiten an Maschinen

sind vor Beginn die Netzstecker herauszuziehen und alle eventuell vorhandenen

Druckluftzuleitungen zu unterbrechen und zu entlüften!

Weiter sind sämtliche Sicherheitsvorschriften und -hinweise, gemäss Betriebsanleitung

Kapitel 1, zu beachten!

Prescriptions et conseils de sécurité à observer obligatoirement

Avant tout travail de rép aration, d'entretien, de nettoyage et de travail analogue à la

machine retirer la fiche de contact et, le cas échéant, arrêter et purger tout

approvisionnement d'air comprimé!

De plus, il faut observer toutes les prescriptions et conseils de sécurité selon chapitre 1

du mode d'emploi!

Safety instructions and information which must be followed

Before beginning any repair , maintenance, cleaning or similar work on the machine

disconnect the mains plug and interrupt and deaerate all possible existing feeding pipes

of compressed air!

In addition, follow all safety instructions and information according to chapter 1 of the

operating manual!

Page 5

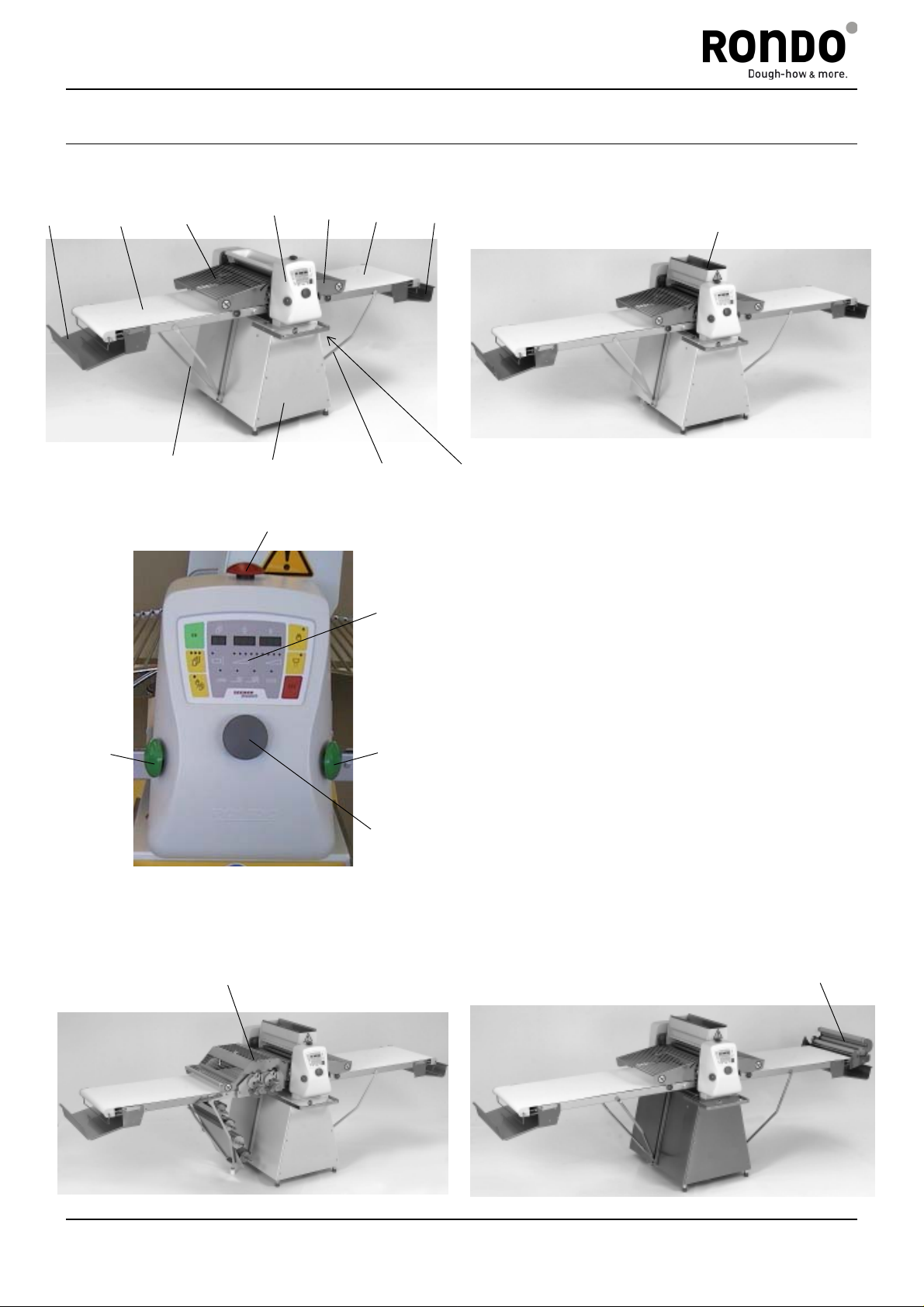

2 Full View of the Machine

1

SFS6115

5

8

4

11

3

6

10

4

5

11

12

1

7

1 Dough Catch Pan

2 Flour Duster (Option)

9

8

3 Roller Head

4 Safety Guard

5 Machine T able

6 Machine Base

7 Main Switch

8 Black Push Button for Starting

9 Control Panel

10 Red Push Button for Stopping

11 Forked Support

12 Turning knob for data input

13 Automatical Dough Reeler (Option)

14 Cutting Station (Option)

SFS6117

2

SFS6115C / SFS6117C

Edition: 04. 2005

14

SFS6117H

13

Service manual

Page 6

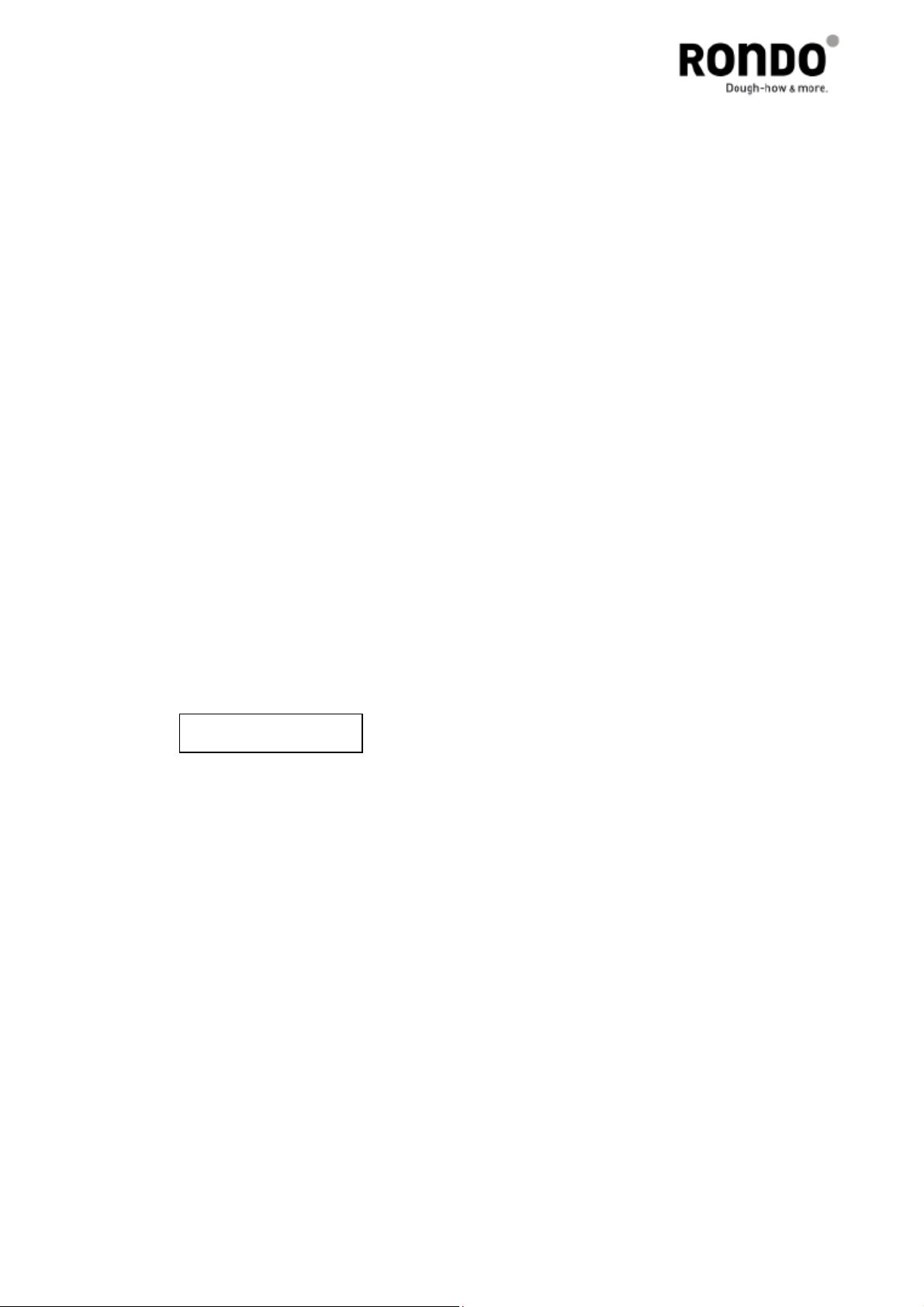

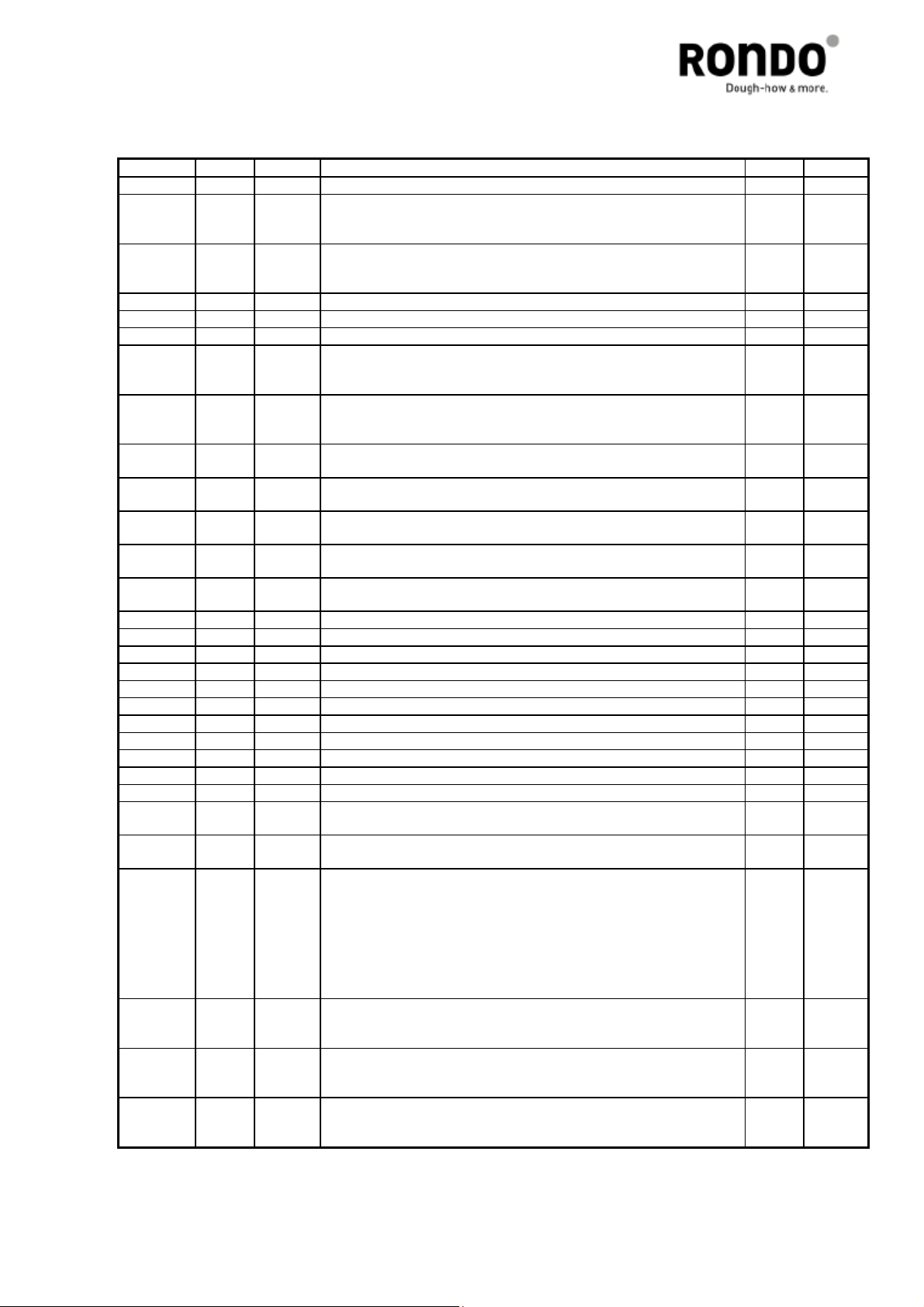

SFI6117

16

17

SFI6117H

15

17

13

13 Automatical Dough Reeler (Option)

15 Support

16 Lower Table

17 Forked Supports

Edition: 04. 2005

Service manual

Page 7

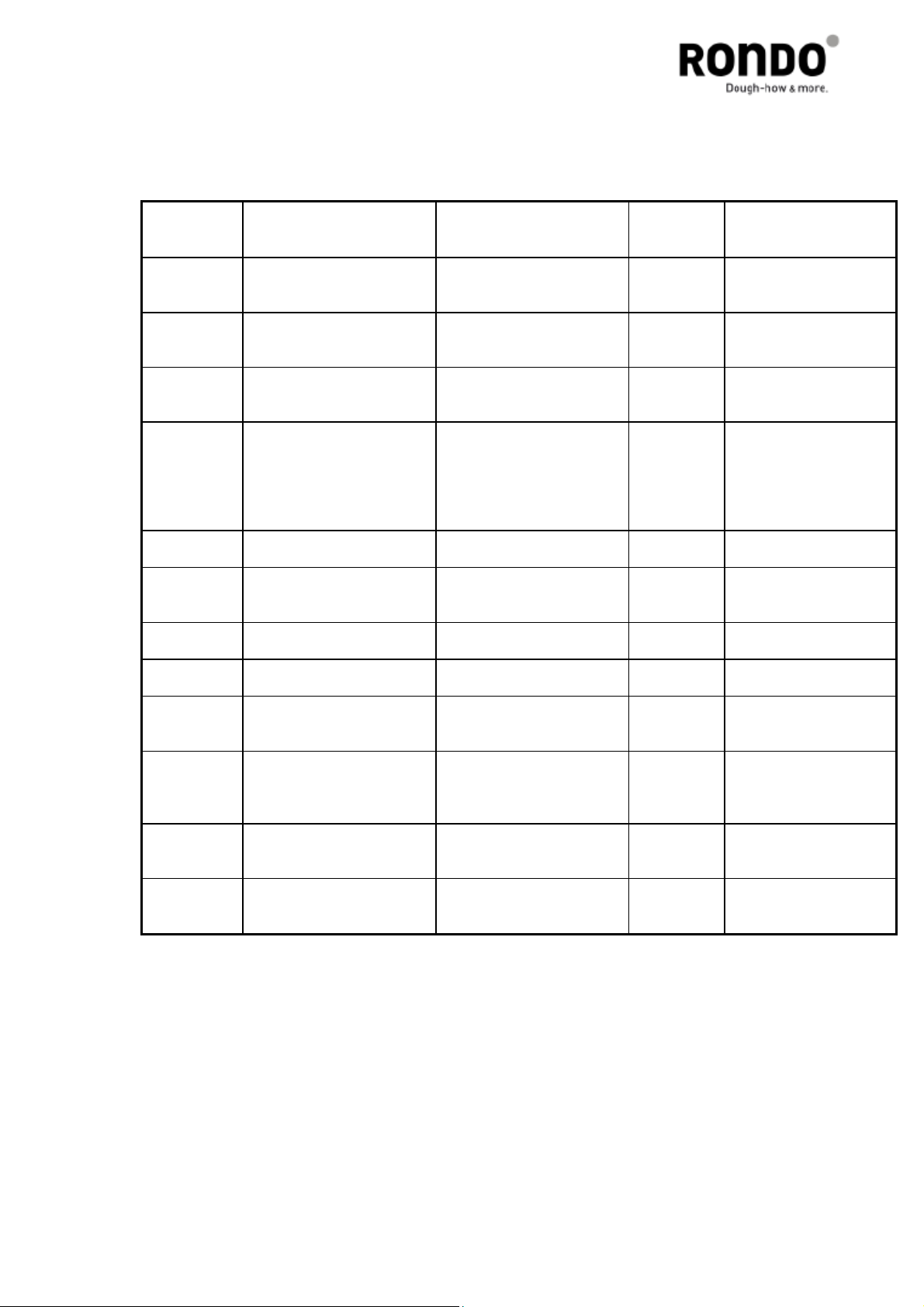

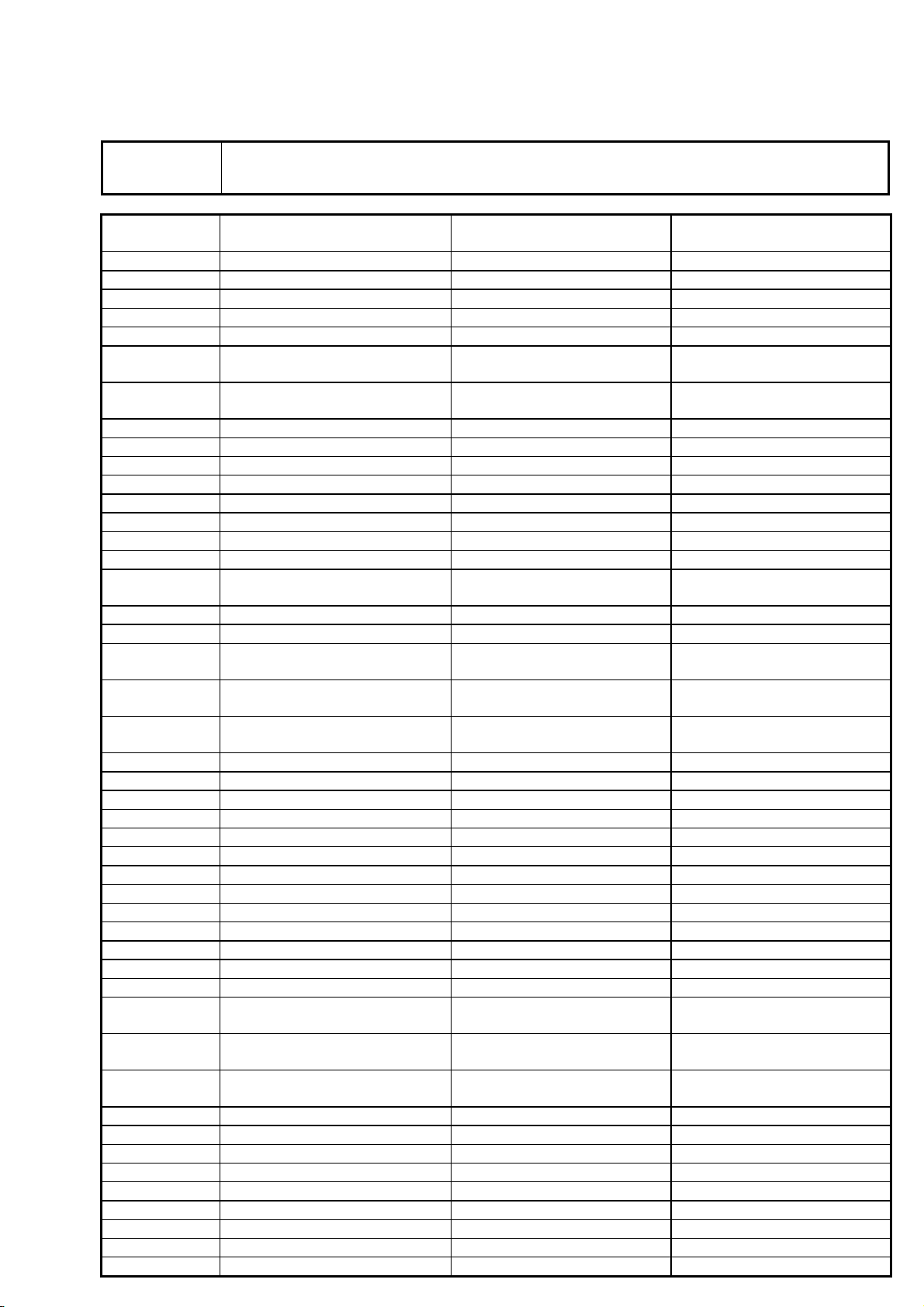

3. Empfohlene Ersatzteile / Pièces de rechange recommandes / Recommended spare parts

3.1 Mechanische Ersatzteile / Pièces de rechange mécaniques / Mecanical spare parts

Bestell-Nr.

No commande

Ordering no

50284 * Zahnriemen GT Courroie dentée GT Toothed belt GT

11532 Haltering Anneau de blocage Retaining ring

11935 Zahnriemen HTD Courroie dentée HTD Toothed belt HTD

11936 Zahnriemen HTD Courroie dentée HTD Toothed belt HTD

50048 Gasfeder 100N ohne

50283 Zahnriemen GT Courroie dentée GT Toothed belt GT

50453 Kupplung Dispositif d'accouplement Clutch

50474 Zahnriemen Courroie dentée Toothed belt

50485 Gasfeder 200N mit

50607 Rippenband Tapis gouffré Ribbed belt

91339T05 Antriebsrolle Rouleau d'entraînement Drive roller

105467 Kunststoffband 640 x 3280 Tapis synthétique

106570 Exzenterhebel Levier excentrique Eccentric lever

106593 Schaltsegment Segment Segment

108241 Schraubendruckfeder Ressort à pression Compression spring

121093 Teigrückhaltebügel Archet de retenue de pâte Dough retaining hoop

121344 Kunststoffband 640 x 3570 Tapis synthétique

121344T02 Kunststoffband 640 x 2680 Tapis synthétique

122775T03 Abstreifermesser Lame de racleur Scraper blade

123568 Zahnrad Z = 22 Roue dentée Z = 22 Gearwheel Z = 22

123570 Zahnrad Z = 15 Roue dentée Z = 15 Gearwheel Z = 15

124107 Zahnrad Z = 18 Roue dentée Z = 18 Gearwheel Z = 18

124108 Zahnrad Z = 16 Roue dentée Z = 16 Gearwheel Z = 16

124802 Zahnrad Z = 15 Roue dentée Z = 15 Gearwheel Z = 15

125908 Rippenbandscheibe Poulie courroie striée Ribbed V-belt pulley

125909 Rippenbandscheibe Poulie courroie striée Ribbed V-belt pulley

125910 Rippenbandscheibe Poulie courroie striée Ribbed V-belt pulley

125953 Feder Ressort Spring

125954 Abstreifer komplett Racleur complet Scraper complete

126055 Federstab Barre pour ressort Spring bar

126084 Rakel Racle Ductor

126088 Wischer Bras de monture d'essuie Wiper arm

133577T03 Abstreifermesser Lame de racleur Scraper blade

134823 Abstreifer komplett blau Racleur complet bleu Scraper complete blue

135341 Kunststoffband blau

* = Ausführung Cutomat/Version Cutomat/Type Cutomat

Automatischer Teighaspel / Enrouleur automatique de pâte / Automatic dough reeler

50466 O-Ring O-Anneau O-Ring

130530 Antriebsrad Z = 10 Roue dentée Z = 10 Gearwheel Z = 10

130531 Antriebsrad Z = 12 Roue dentée Z = 12 Gearwheel Z = 12

130532 Antriebsrad Z = 13 Roue dentée Z = 13 Gearwheel Z = 13

124595 Motor mit Kabel Linak Moteur avec câble Linak Motor with cable Linak

Teilebezeichnung

Désignation

Part name

automatischem Haspel

automatischem Haspel

640 x 3280

Vérin à gaz 100N sans

enrouleur automatique

Vérin à gaz 200N avec

enrouleur automatique

640 x 3280

640 x 3570

640 x 2680

Tapis synthétique bleu

640 x 3280

Pneumatic spring 100N

without automatic reeler

Pneumatic spring 200N with

automatic reeler

Synthetic conveyor belt

640 x 3280

Synthetic conveyor belt

640 x 3570

Synthetic conveyor belt

640 x 2680

Synthetic conveyor belt blue

640 x 3280

Page 8

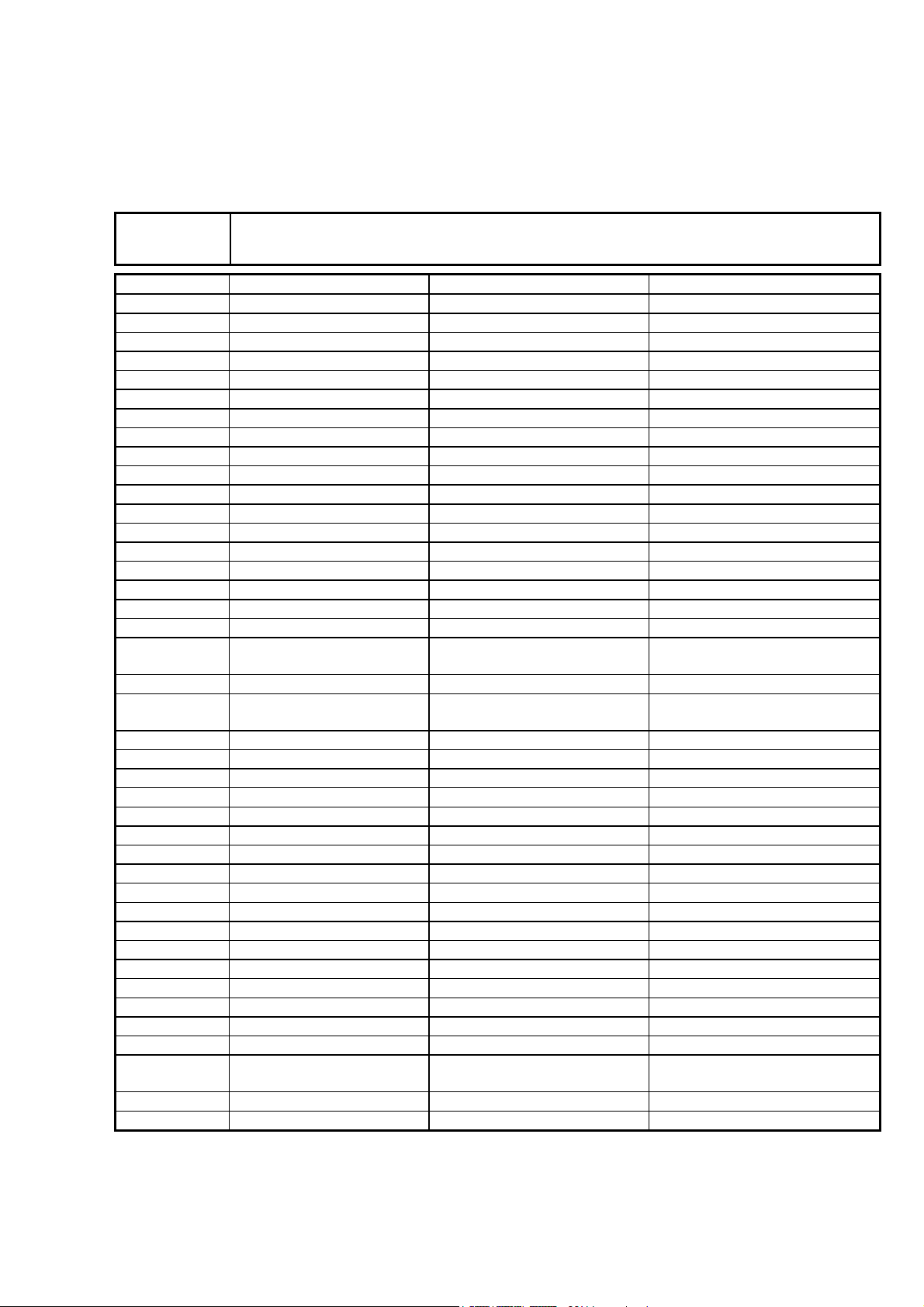

3.2. Elektrische Ersatzteile / Pièces de rechange électriques /

Electrical spare parts

Bestell.Nr.

No commande

Ordering no.

8935 Feinsicherung 2,0A träg Fusible 2,0A lent Fuse 2,0A slow

9371 Endschalter Interrupteur fin de course Limit switch

11334 Empfängerkopf Tête de récepteur Receiver head

11335 Senderkopf Tête de transmetteur Transmitter head

50477 Grundmodul Module de base Modul basic

50481 Handrad komplett Roue à main compl. Handwheel compl.

50482 Absolutwertgeber Codeur en valeur absolue Rotary encoder

50483 Drehknopf Bouton tournant Turning knob

50495 Feinsicherung 0,63A träg Fusible 0,63A lent Fuse 0,63A slow

50587 Prozessoreinheit Unité microprocesseur Microprocessor unit

106111 Lichtschrankenkabel Câble pour cell. photoélectr. Cable for light barrier

106112 Lichtschrankenkabel Câble pour cell. photoélectr. Cable for light barrier

135202 *** Frequenzumrichter 230 V Variateur de fréquenze 230 V Frequency inverter 230 V

135203 *** Frequenzumrichter 400 V Variateur de fréquenze 400 V Frequency inverter 400 V

Bestell.Nr.

No commande

Ordering no.

12061 Drehstrommotor 0,09 kW Moteur triphasé 0.09 kW Motor three-phase 0.09 kW

35493 Motor mit Bremse Moteur avec freinage Motor with brake

50044 El. magnetische Bremse El. freinage magnétique El. magnetic brake

50359 *** Hilfskontaktblock Module de contacts auxiliaires Contact component auxiliary

50361 Kleinleistungschütz Contacteur de petit calibre Contactor miniature

50362 Kleinleistungsschütz Contacteur de petit calibre Contactor miniature

50484 Flachbandkabel 20-pol. Câble plat, 20 pol. Ribbon cable, 20 pol.

50588 *** Elektrische Kupplung

50603 Motor 1,1 kW 50/60 Hz Moteur 1,1 kW 50/60 Hz Motor 1,1 kW 50/60 Hz

50604 *** Zeitrelais Relais temporisé Time relais

50925 Pilztaster schwarz Bouton poussoir noir Push button black

50926 Pilztaster rot Bouton poussoir rouge Push button red

50927 Hilfsschalterblock 2S Bloc de contacts auxiliaires Contact block auxiliary 2S

50928 Hilfsschalterblock 10 Bloc de contacts auxiliaires Contact block auxiliary 10

51309 Motor 1,1 kW 60 Hz, UL Moteur 1,1 kW 60 Hz, UL Motor 1,1 kW 60 Hz, UL

*** Nur für Cutomat

1. Stufe Teilebezeichnung

Echelon 1 Désignation

Variation 1 Part name

2. Stufe Teilebezeichnung

Echelon 2 Désignation

Variation 2 Part name

Embrayage électrique

Cutomat

Cutomat

Electrical clutch

Cutomat

Page 9

____________________________________________________________________________________________________________________________________________________________________________________________________________________

4. Notes for the service

4.1 Important notes

4.1.1 Improvements on the Rondostar

In August 1998 the following changes have been made on the Rondostar.

Table drive:

Rondostar SFS611 is new equipped with clutches instead of the reversing gear (Like

Compas 3000).

Rondostar SFS611C (Cutomat, compound operation) is still equipped with the

reversing gear.

Light barrier wiper (screen wiper):

New light barrier wipers, mounted directly on the roller, as by Compas 3000.

Scraper:

New scraper system, consisting of 4 single scrapers instead of the pairs of scrapers.

4.1.2 Software changes

The following software changes have been made:

- Control system for the table clutches

- Changes in the control system of the screen wiper

- Modifications for compound operation with make-up lines and transfer table.

Previous software: 125921T01B V1.02

New software: 125921T01D V1.10

The EPROM is new marked as follows:

125921T01D / V1.10

125921T01D: Software identification by Seewer Rondo

V1.10: Software version, which is indicated below parameter 99 on the

display

The software version is new also indicated on the processor beside the mark of the

serial number.

4.1.3 Usage of the new software

The new software V1.10 can be used for all previous Rondostar.

In doing so pay attention to:

- Table drive: Table clutches Parameter 31 = 1

Reversing gear Parameter 31 = 0

- Light barrier cleaning: new system on the roller Parameter 32 = 2

Parameter 33 = 450

old system with catch Parameter 32 = 320

Parameter 33 = 120

By delivery of the processors the parameters for clutches and for the new light

barrier wipers are set.

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 10

____________________________________________________________________________________________________________________________________________________________________________________________________________________

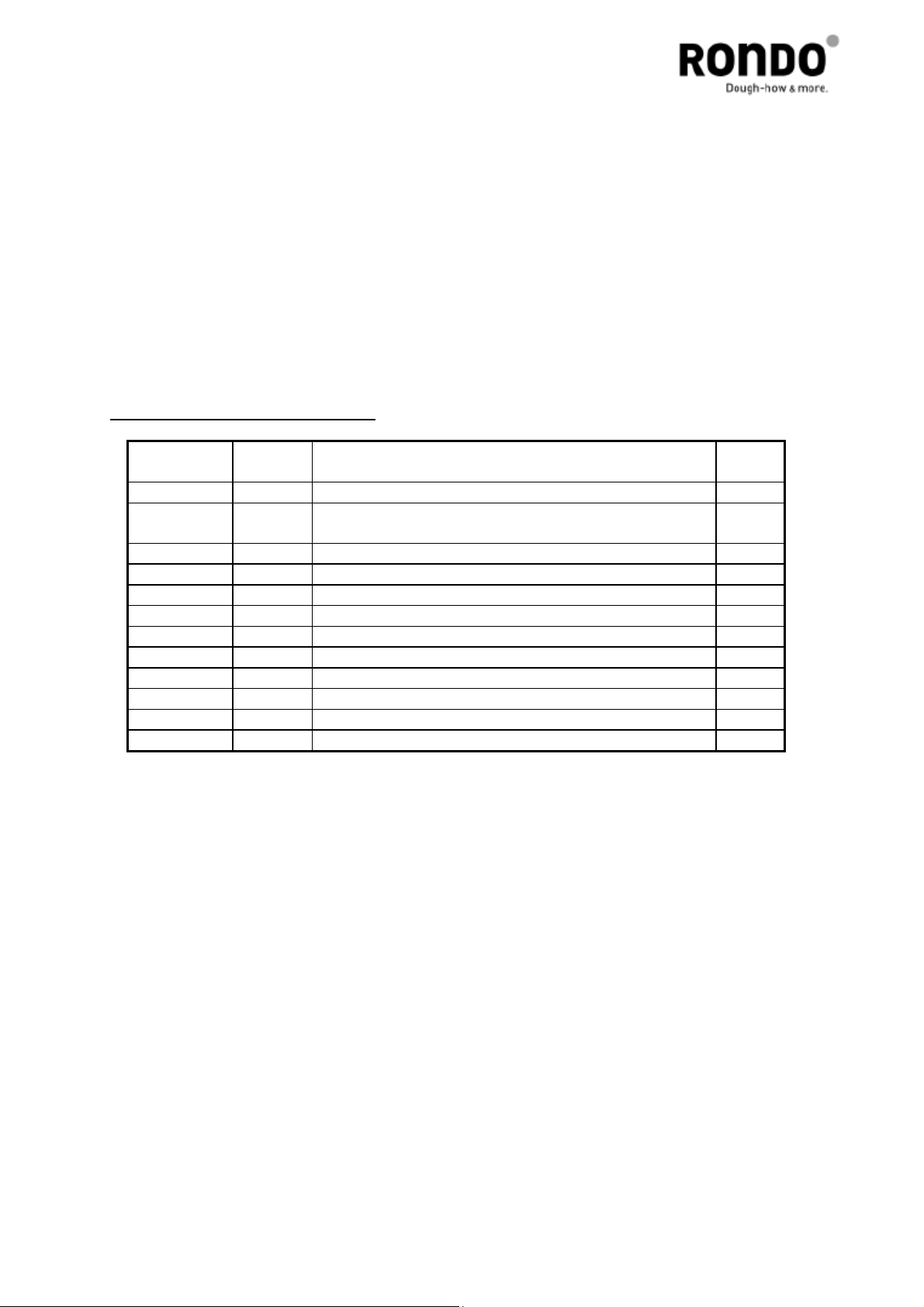

4.1.4 General view of the special functions

The software for the RONDOSTAR is equipped with special functions to assist the technical

service.

Functions 1, 2: Access by the customer is possible (see operating manual)

For entering press the key "OK".

Other functions: For entering press the key "flour duster". The information on these

functions is not contained in the operating manual.

The individual functions must be selected using a function code.

Allocation of the function codes:

with key function

code FU

Description of the function See

chapter

"OK" 1 Parameters, access for customer possible ##

"OK" 2 Diagnosis for customer, inputs indicated,

##

access to outputs is not possible

Flour duster 10 Parameters, for technical service 4.4

Flour duster 20 Final control test 5.4

Flour duster 30 Diagnosis for technical service 4.5

Flour duster 40 Test roller adjustment 5.3.3

Flour duster 51 Initialisation of the parameters 4.2

Flour duster 53 Initialisation of the programs 4.2

Flour duster 55 Full initialisation (parameters and programs) 4.2

Flour duster 67 Calibration of roller gap 4.3

Flour duster 70 Display operating hours counter 4.6

Flour duster 99 Indication of the software version -----

## For description of the functions see the operating manual

The functions listed above are described in detail in the following chapters.

Warning

Changing the functions requires great care and forethought.

4.2 Initialisation

Function

When the processor is initialised, the basic data (parameters, sheeting programs) are loaded

from the program EPROM into the processor's working memory.

When initialisating, all previously entered data such as customer programs, special parameters,

etc. are overwritten by the basic data.

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 11

____________________________________________________________________________________________________________________________________________________________________________________________________________________

When should the initialisation be carried out?

- Following the installation of a new processor in the machine

Full initialisation (FU 55)

- Where faults are suspected in the processor's control procedure (software errors)

In this case proceed as follows:

Initialise the parameters (FU 51) ---> then test the machine

- If the problems are not rectified

Full initialisation (FU 55) ---> then test the machine

This results in the loss of all sheeting programs

memorised by the customer!

- If only the customer programs are to be deleted

Initialise the programs (FU 53) ---> all sheeting programs are deleted

How to initialise?

Example: In order to initialise the parameters (FU 51) proceed as follows:

- Switch on working mode "Auto" LED "Auto" on continuously

- Press key "Flour Duster" for approx. 10 s Indication: FU 0 --

- Set "51" by turning knob Indication: FU 51 --

- Press key "OK" till Indication: FU 0 --

- Return to sheeting program Press the key "ESC"

4.3 Calibrating the roller gap

Calibration of the roller gap is imperative if:

- the processor has been changed

- changes are made to the absolute value sender (toothed belt, attachment of the sender,

etc.)

- the roller gap shown on the display does not coincide with the actual roller gap

The calibration of the roller gap takes place by a roller gap of 4,0 mm.

Proceed as follows:

- Switch off the machine at the main switch

- Set the roller gap to 4,0 mm, e.g. by turning the brake disk of the roller engagement

drive. Check the roller gap with e.g. a 4,0 mm large sheet.

- Switch on the machine at the main switch

- Press key "Flour duster" for approx. 10 s Indication: FU 0 --

- Set "67" by turning knob Indication: FU 67 XX,X-

- Press key "OK" till Indication: FU 67 4,0

Calibration is complete

Return to the sheeting program: Press the key "ESC"

XX,X = Numerical value

The calibration of the roller gap is not affected by initialisation and is not deleted.

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011

Service manual

Page 12

____________________________________________________________________________________________________________________________________________________________________________________________________________________

4.4 Parameter

Key Funct. Param. Description Value Unity

OK 1 0 Entering data: Side end for folding not defined 0

Side end for folding right 1

Side end for folding left 2

OK 1 1 Entering data: Side end for man. reeling not defined 0

Side end for man. reeling right 1

Side end for man. reeling left 2

OK 1 2 Compound operation: Time band stop waiting postion 15 0,1 s

OK 1 3 Compound operation: Time for transfer 300 0,1 s

FD 10 10 Entering data: no Auto-reeler 0

Auto-reeler right 1

Auto-reeler left 2

FD 10 11 Entering data: no cutomat 0

Cutomat right 1

Coutomat left 2

FD 10 12 Time Auto-reeler finished

photocell free --> conveyor belt stop

FD 10 13 Time handreeler finished

photocell free --> conveyor belt stop

FD 10 14 Position of the dough handreeler placement

Dough in photocell --> conveyor belt stop

FD 10 15 Time conveyor belt stop for folding

photocell free --> conveyor belt stop

FD 10 16 Time conveyor belt stop for cutomat

photocell free --> conveyor belt stop

FD 10 17 Roller opening by cutting (Cutomat) 50 0,1 mm

FD 10 18 Time open Auto-reeler 12 0,1 s

D 10 19 Time close Auto-reeler 15 0,1 s

FD 10 20 max. dough thickness in mm for Auto-reeler 90 0,1 mm

FD 10 21 Delay time dough in photocell 2 0,1 s

FD 10 22 Indicator period 8 0,1 s

FD 10 23 Indicator break 2 0,1 s

FD 10 24 Cutomat: running time high speed at the start 10 0,1 s

FD 10 25 On delay-time for flour duster 8 0,1 s

FD 10 26 Time for changing the program-no. (Flashing of the program-no) 50 0,1 s

FD 10 27 Time press the key for selecting the program mode 30 0,1 s

FD 10 28 "long time" for key OK respectively flour duster for special

functions

FD 10 29 "short time" for key OK respectively flour duster for special

functions

FD 10 30 Compound operation:

no compound operation 0

compound left 1

compound right 2

compound operation left/right no passages without roller

adjustment (special) 3

compound operation left/right: for left machine place dough on

left side, for right machine place dough on right side 4

FD 10 31 Rondostar with table clutch 1

Rondostar with reversing gear 2

(Cutomat/Compound, machine delivery before August 1998)

FD 10 32 Light barrier wiper "above"

For new screen wiper on the roller, inactive 2

For old screen wiper with catch, function active 320

FD 10 33 Light barrier wiper "below"

For new screen wiper on the roller, inactive 450

For old screen wiper with catch, function active 120

Values in brackets are valid for short tables

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011

Service manual

1

1

0

0

15

(10)

15

(10)

15

(10)

2 0,1 s

2 0,1 s

100 0,1 s

30 0,1 s

0

1

2

450

0,1 s

0,1 s

0,1 s

Page 13

____________________________________________________________________________________________________________________________________________________________________________________________________________________

Notes

Key: Select special functions with the key "OK" or with the key "flour duster"

The customer has the option, to change parameter 0, 1, 2 and 3.

See description in the operating manual.

Function: The function is selected with the turning knob.

Function 10 and the associated parameters are exclusively intended for the

Parameters: The parameters are selected with the turning knob and confirmed with "OK"

technical service (no notes in the operating manual).

Value: The figures given in the column "value" are loaded into the working memory from

the EPROM during initialisation and may subsequently be changed.

Attention: By the software version V1.02 it was as follows:

- Parameter 31: Time for transfer in the compound operation

- Parameter 32: Time band stop waiting position in the compound operation

There were no parameters for the light barrier wipers.

Changing the parameters:

Example: The time to switch to "programming" is to be changed from 3 s to 5 s.

Use function (FU) 10 to change parameter (PA) 27 from 30 to 50

- Switch on working mode "Auto" LED "AUTO" on continuously

- Press key "flour duster" during 10 s Indication: FU 0 --

- Set "10" by turning knob Indication: FU 10 --

- Press key "OK" till Indication: PA 10** (0)

- Set parameter "27" by turning knob Indication: PA 27** 30

- Press key "OK" till Indication: PA 27 30**

- Set value "50" by turning knob Indication: PA 27 50**

- Press key "OK" Indication: PA 28** XX,X

return to the sheeting program: Press key "ESC" twice

XX,X = Numerical value ** = Indication is flashing

4.5 Diagnostic program

The Rondostar is fitted with an automatic direction of rotation control, i.e. after switching on

the electricity supply (mains switch), when a sheeting program is started for the first time, the

direction of rotation of the mains is checked. The drives are subsequently controlled in

accordance with the direction of rotation of the mains.

Before using the diagnostic program, the machine is briefly started in a sheeting program or in

the working mode "manual" (direction of rotation check). As soon as the conveyor belts start to

move, the machine can be stopped and the program may be aborted using "ESC". The turning

direction of the net will be indicated with LED 9 (see chapter 4.5.2)

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 14

____________________________________________________________________________________________________________________________________________________________________________________________________________________

4.5.1 Selecting the diagnostic program

- Switch on working mode "Auto" LED "AUTO" on continuously

- Press key "flour duster" during 10 s Indication: FU 0 --

- Set function "30" by turning knob Indication: FU 30 --

- Press key "OK" till Indication: d. 1** 0

- Return to the sheeting program: Press key "ESC" twice

** = Indication is flashing

4.5.2 Checking the inputs

The statuses (On/Off) of the inputs are displayed on the LED of the roller reduction steps,

whereby they are numbered 1 - 9 from left to right.

LED No. 1 Control voltage processor Control voltage OK = 1

LED No. 2 General control voltage Control voltage OK = 1

LED No. 3 Right push button Right push button operated = 1

LED No. 4 Left push button Left push button operated = 1

LED No. 5 Main contactor K1M Main contactor engaged = 1

LED No. 6 Frequency inverter, Frequency inverter and

contactor K2M contactor K2M ON = 1

LED No. 7 Turning knob Slow turning of turning knob = 0/1

LED No. 8 Photocell Photocell covered = 1

Photocell free = 0

LED No. 9 Direction of rotation of mains Right rotating field = 0

Left rotating field = 1

"1" indicates that the corresponding LED illuminates

"0/1" indicates that the LED switches on and off when the turning knob is turned.

"0" indicates that the corresponding LED is switched off

If all inputs should be tested, proceed as follows:

Select the diagnostic program (FU30)

Safety guard open illuminate: LED1, LED2

These two LED have to illuminate always.

Close safety guard

Press right push button illuminate: LED3 LED5 LED6

Push button no longer pressed illuminate: LED5 LED6

Press left push button illuminate: LED4 LED5 LED6

Push button no longer pressed illuminate: LED5 LED6

Open safety guard LED5 has to switch off imediately

LED6 has to switch off with approx 1 s delay

Turn turning knob slowly LED7 has to illuminate

Photocell LED8 illuminates when photocell is covered

LED8 doesn't illuminate when photocell is free

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011

Service manual

Page 15

____________________________________________________________________________________________________________________________________________________________________________________________________________________

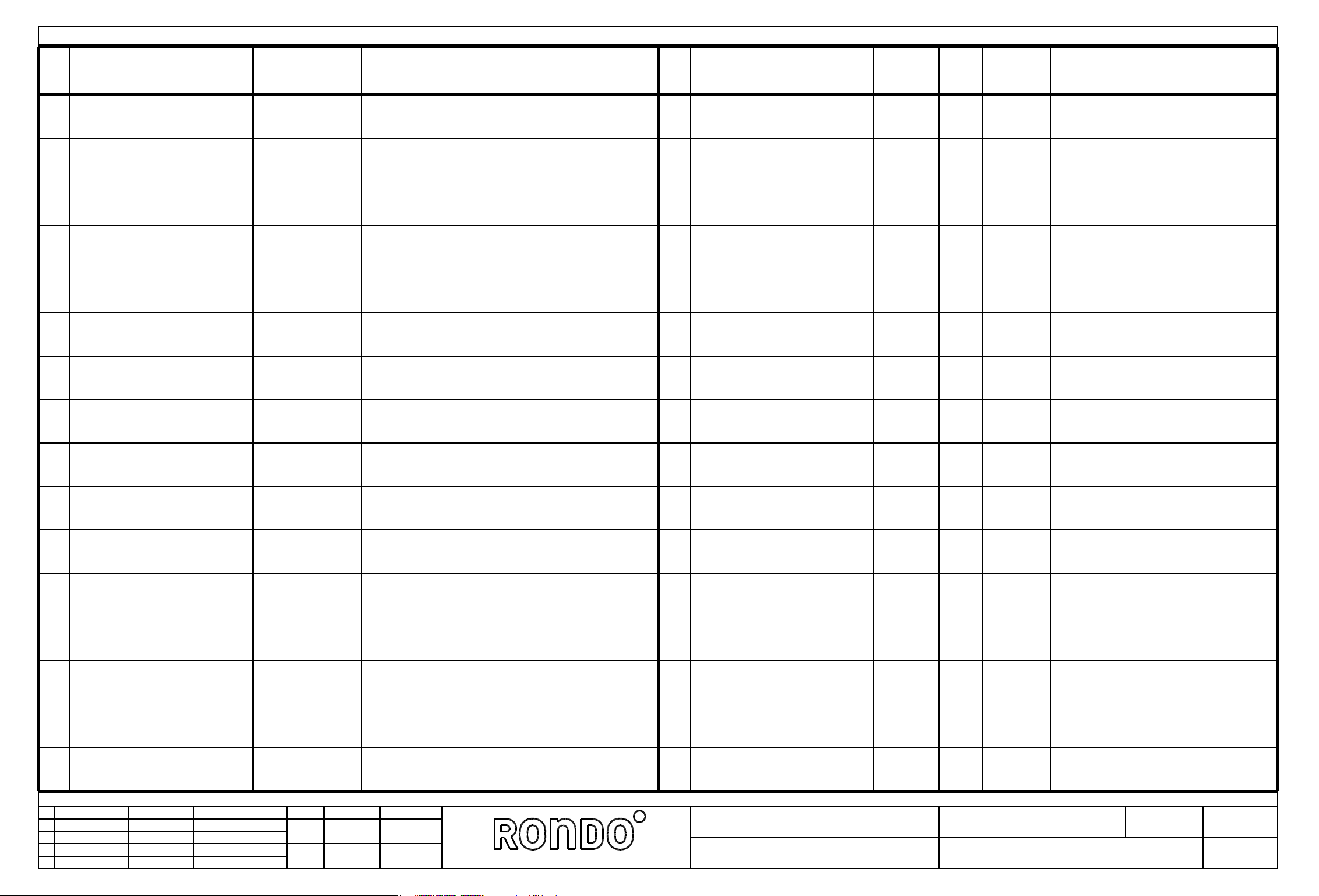

4.5.3 Allocation of the outputs

After leaving the diagnostic program, all outputs are automatically returned to their former status.

Functions of the processor outputs

Output

processor

A0 Supervision processor

A2 Table drive:Conveyor-

A11 Table drive:Conveyor-

A5 Table clutches

A6 Roller adjustment

A10 Roller adjustment

A7 Roller adjustment

A9 Flour duster

A8 Direction of rotation flour

A4 Selection between

A3 Auto reeler, table

A1 Reeler

Function by

mains right rotating field

LED No. 9 dark

(watch-dog)

belt runs to the left

belt runs to the right

0 = left clutch

1 = right clutch

Cutomat:

1 = small number of

revolutions

1 = drive ON

0 = upward

1 = downward

1 = Brake ON

1 = Flour duster ON

duster 0 by right rotating

field

0 = reeler

1 = table clutch /

Cutomat clutch

clutches, Cutomat clutch

1 = ON

0 = Open reeler

1 = Close reeler

Function by

mains left rotating field

LED No. 9 illuminates

Supervision processor

(watch-dog)

Table drive:

Conveyor-belt runs to the

right

Table drive:

Conveyor-belt runs to the

left

Table clutches

0 = left clutch

1 = right clutch

Cutomat:

1 = small number of

revolutions

Roller adjustment

1 = drive ON

Roller adjustment

0 = downward

1 = upward

Roller adjustment

1 = Brake ON

Flour duster

1 = Flour duster ON

Direction of rotation flour

duster 1 by left rotating

field

Selection between

0 = reeler

1 = table clutch /

Cutomat clutch

Auto reeler, table

clutches, Cutomat clutch

1 = ON

Reeler

0 = Open reeler

1 = Close reeler

Relay

contactor

K8 Cannot be switched on

K9/K2M

F-inverter

K10/K3MF

-inverter

K13 Rondostar with table

K1/ K2

K5

K7

K3 / K4

K6

K14

K12 Switch on / off

K11

Remarks

or off

processor fault A1=0

By Cutomat:

Conveyor-belt runs

always to the left

By Cutomat:

Conveyor-belt runs

always to the right

clutches

Note:

The drives for roller adjustment and reeler each have:

- 1 relay for drive ON/OFF

- 1 relay for the direction of movement up/down respectively open/close

With outputs A2, A8, A10, A11 the function changes when the direction of rotation of the

mains changes.

Output A2: SFS Contactor K2M motor main drive, direction dough to left/right

depends of mains direction of rotation.

SFS Cutomat Signal to frequency inverter, direction dough to the left

Output A11: SFS Contactor K3M motor main drive, direction dough to the

left/right depends of mains direction of rotation

SFS Cutomat Signal to frequency inverter, direction dough to the right

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011

Service manual

Page 16

____________________________________________________________________________________________________________________________________________________________________________________________________________________

Consider: - What do I want to switch on?

- Which output must be switched?

- Is the correct output selected?

The drives can only be started when the safety guards have been closed.

The individual outputs can be switched on and off as follows:

- Switch on working mode "Auto" LED "AUTO" on

continuously

- Press key "flour duster" during approx 10 s Indication: FU 0 --

- Set function "30" by turning knob Indication: FU 30 --

- Press key "OK" till Indication: d. 1** 0

- Select output (for example A7) by turning knob Indication: d. 7** 0

- Switch on output by key "OK" Indication: d. 7 1

- Switch off output by key "OK" Indication: d. 7 0

- Return to the sheeting program: Press key "ESC" twice

** = Indication is flashing

In order to test the drives a number of special test programs are available.

Testing of the individual drives is described in detail in chapter 5.3.

4.6 Operating hours counter

The processor is fitted with an operating hours counter. The counter reading can be called up

using function 70.

The display is given in hours.

In order to read the operating hours counter, proceed as follows:

- Switch on working mode "Auto" LED "AUTO" on continuously

- Press key "flour duster" during 10 s Indication: FU 0 --

- Set "70" by turning knob Indication: FU 70 --

- Press key "OK" (10 s) till Indication: h 000 045

(45 hours)

- Return to the sheeting program: Press key "ESC" twice

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 17

____________________________________________________________________________________________________________________________________________________________________________________________________________________

5. Important notes, testing the drives

Notes:

Rondostar without Cutomat:

The drive motor for tables and rollers is supplied directly from the mains.

Rondostar with Cutomat (variable speed):

The drive motor for tables and rollers is supplied by a frequency inverter during the sheeting and

also during the cutting process.

Attention:

For the operating voltages 200 - 230 V and 380 - 460 V different types of frequency inverters and

mains filters are necessary.

5.1 Mains voltage, mains frequency

The mains voltage and mains frequency must coincide with the data given on the machine

specification plate.

The specification plate is to be found on the substructure where the mains cable input is

located.

The prescribed maximum fusing must be observed.

5.1.1 Modifying the machine for a different mains voltage

Motors: Table drive motor, roller adjustment motor, flour duster motor

200 - 230 V Motors delta-connected

380 - 460 V Motors star-connected

Attention: Rondostar with Cutomat (variable speed) cannot be switched over

from 200 - 230 V to 380 - 460 V. (Different frequency inverters!)

Transformer:

The transformer in the basic module must be switched to the new voltage.

5.1.2 Modifying the machine for another frequency

The following parts depend of the value of the frequency:

50 Hz 60 Hz

motor 50400 50421

V-belt pulley 124128 124138

V-belt 50401 50403

Attention: Rondostar with Cutomat (variable speed) can be operated with 50 or 60 Hz

without a change.

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 18

____________________________________________________________________________________________________________________________________________________________________________________________________________________

5.2 Functions of the machine

5.2.1 Machine start function

When the machine is started, the following control process runs automatically:

1. One of the black push buttons is operated.

Here the black push buttons have a dual function.

On the one hand they switch on the main contactor, on the other hand they issue the

command for the direction of rotation of the conveyor belt to the processor.

2. Main contactor K1M engages.

3. At the time of the first start after switching on the mains, the direction of rotation of the

mains is checked automatically as follows:

The roller drive is briefly switched on and the direction of rotation of the motor is

checked. If the roller rises when given the command "close" (wrong direction), the

direction of rotation of the table, roller adjustment and flour duster drives is

automatically changed.

4. The roller adjustment drive starts and the roller moves to the roller gap shown in the

display. At the same time the automatic reeler is opened if it is not already in the upper

end position.

5. The table drive starts automatically when the roller end position is reached.

5.2.2 Roller adjustment drive function

The position of the roller gap is measured with an absolute value sender. With an angle of

rotation of 360° (roller gap 45.0 - 0.2 mm), the absolute value sender has 256 positions. A

specific roller gap is allocated to each of these 256 positions in the software.

Here the correct calibration of the absolute value sender at a roller gap of 4.0 mm is

paramount. (See chapter 4.3)

The direction of rotation of the mains is checked using the roller adjustment drive. The

controls of the table drive and the flour duster are dependent on the direction of rotation of

the roller adjustment drive.

5.2.3 Turning knob

The turning knob consists of an impulse sender with 128 impulses per revolution.

The turning knob is used to input the data during programming, when selecting the program

and during diagnostic work, etc.

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 19

____________________________________________________________________________________________________________________________________________________________________________________________________________________

5.3 Testing the drives

5.3.1 Direction of rotation of the drives

The machine automatically tests the direction of rotation of the mains and controls the

machine accordingly.

The roller adjustment drive always depends directly on the direction of rotation of the

mains.

If the direction of movement of the table drive or of the flour duster is incorrect, proceed as

follows:

Flour duster: Switch 2 phases on the motor terminals

Table drive: First check if the black push buttons are correctly connected.

(See checking the inputs, chapter 4.5.2, LED 3 and LED 4)

Are the push buttons correctly connected, switch 2 phases of the

motor cable on contactor K2M.

5.3.2 Testing the table- and roller drive

Testing the drive

Testing the drive is best not carried out in the diagnostics program but directly in the working

mode "Manual".

Proceed as follows:

- Select "Manual" working mode

- Operate left push button conveyor belt must run to the right

Stop by using red push button

- Leave the program with "ESC"

- Operate right push button conveyor belt must run to the left

Stop by using red push button

- Leave the program with "ESC"

Testing the clutches table drive

Note: The clutch of the infeed belt is always switched on.

The infeed belt only runs when the clutch is switched on!

For testing the clutches in the diagnostic program, proceed as follows:

Switch on diagnostic program as described under 4.5.1

Testing the left clutch:

- Set d = 4 by turning knob Indication: d 4** 0

- Switch on by key "OK" Indication: d 4** 1

- Set d = 3 by turning knob Indication: d 3** 0

- Switch on clutch by key "OK" Indication: d 3** 1

** = Indication is flashing

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 20

____________________________________________________________________________________________________________________________________________________________________________________________________________________

Testing the right clutch:

- Set d = 4 by turning knob Indication: d 4** 0

- Switch on by key "OK" Indication: d 4** 1

- Set d = 5 by turning knob Indication: d 5** 0

- Switch on by key "OK" Indication: d 5** 1

- Set d = 3 by turning knob Indication: d 3** 0

- Switch on clutch by key "OK" Indication: d 3** 1

** = Indication is flashing

5.3.3 Testing the roller adjustment drive

In order to test the roller adjustment drive, a special test program "Test roller

adjustment" is available. Proceed as follows:

- Switch on working mode "Auto" LED "AUTO" on continuously

- Press key "flour duster" during 10 s Indication: FU 0 --

- Set "40" by turning knob Indication: FU 40 --

- Press key "OK" till Indication: d. XX,X 45,0**

- Set roller gap (example 35 mm) by turning knob Indication: d. XX,X 35,0**

- Close safety guard

Start of the roller adjustment drive by black push button

Roller moves to the selected roller gap Indication: d. 35,0 35,0**

XX,X = Numerical value

** = Indication is flashing

5.3.4 Testing the flour duster

The correct direction of rotation for the flour duster has been determined by the automatic

check on the direction of rotation of the mains. (Do not change output A8).

To check the flour duster, switch on the diagnostic program as described under 4.5.1

- Switch on working mode "Auto" LED "AUTO" on

continuously

- Press key "flour duster" during approx. 10 s Indication: FU 0 --

- Set function "30" by turning knob Indication: FU 30 --

- Press key "OK" till Indication: d. 1** 0

Now the diagnostic program is switched on

** = Indication is flashing

Processor output 9, flour duster On / Off

- Close safety guard, press the black push button briefly

- Set d = 9 by turning knob Indication: d 9** 0

- Flour duster ON by key "OK" Indication: d 9** 1

- Flour duster OFF by key "OK" Indication: d 9** 0

** = Indication is flashing

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 21

____________________________________________________________________________________________________________________________________________________________________________________________________________________

5.3.5 Testing the reeler

The motor of the reeler drive is equipped with limit switches which automatically interrupt the

electricity supply in the end position.

To check the reeler in the diagnostic program proceed as follows:

Switch on diagnostic program as described under 4.5.1

Switch on reeler

- Set d = 3 by turning knob Indication: d 3** 0

- Reeler ON by key "OK" Indication: d 3** 1

The reeler is now switched on

Open / close reeler

- Set d = 1 by turning knob Indication: d 1** 0 (1)

The reeler can now be opened and closed by the key "OK".

- Press key "OK": Close reeler, wait until the reeler

is closed completely Indication: d 1** 1

- Press key "OK": Open reeler, wait until the reeler

is opened completely Indication: d 1** 0

** = Indication is flashing

Warning: Do not change the direction of rotation while the reeler is moving.

5.3.6 Testing the roller adjustment drive brake

In order to test the brake of the roller adjustment drive in the diagnostic program, proceed

as follows:

- Switch on the diagnosic program as described under 4.5.1

- Set d = 7 by turning knob Indication: d 7** 0

- Brake ON by key "OK" Indication: d 7** 1

- Brake OFF by key "OK" Indication: d 7** 0

** = Indication is flashing

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 22

____________________________________________________________________________________________________________________________________________________________________________________________________________________

5.3.7 Testing the Cutomat

For the operation Cutomat the Cutomat clutch (outputs A3 and A4 = 1) as well as the slow

speed (output A5 = 1) have to be switched on.

For testing the function Cutomat, set a simple auto-program with Cutomat in program 1,

3 positions:

Initial roller gap 10 mm

Final roller gap 6 mm

Roller reduction curve 5

Function Cutomat:

Now the program will start in the final test (See 5.4). If the endthickness is reached, start

the machine with the black push button.

Now the rollers open about 5 mm and the machine starts with the Cutomat speed. The

table on the infeed side has to run exactly as fast as the table on the outfeed side. A click

of the driving wheels in the front housing is audible (normal).

5.4 Final control test

For the final control test an automatic sheeting program (without dough) is used in a

continuous way. The running time for the table drive in either direction of operation is

approx. 3 s.

Warning:

Continuous operation is only possible using programs with the functions "Stop for

folding" or "automatic reeling".

- Switch on working mode "Auto" LED "AUTO" on continuously

- Press key "flour duster" during approx. 10 s Indication: FU 0 --

- Set "20" by turning knob Indication: FU 20 --

- Press key "OK" till Indication: FU 0 --

- Press key "OK", program no. 1 is displayed Indication: 01** XX,X XX,X

- Select desired testing program by turning knob

Start machine with black push button, stop machine with red push button or safety

guard.

Return to normal sheeting mode: Press key "ESC"

XX,X = Numerical value ** = Indication is flashing

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 23

____________________________________________________________________________________________________________________________________________________________________________________________________________________

6. Compound operation

The Rondostar SFS6117 is also qualified for compound operation with a transfer table

(dough transfer with sheeting speed).

The Rondostar SFS6117DD is qualified for compound operation with a make-up line or a

donut line. The variable speed for the dough transfer is approx. 1,5 - 7,5 m/min for make-up

lines and approx. 15 - 25 m/min for donut lines.

6.1 General comments

In compound operation with make-up lines respectively donut lines, the Rondostar can be used

together with one or two lines. The following operating modes are possible (parameter 30):

- Make-up line / donut line to the left of the Rondostar

- Make-up line / donut line to the right of the Rondostar

- One make-up line / donut line on each side of the Rondostar

Compound operation with make-up lines respectively donut lines is only possible with the

Rondostar SFS6117DD. The Rondostar SFS6117DD can also be used like a standard

machine (Function Cutomat not possible). Special processor parameters, see chapter 6.3.

The compound operation with a transfer table is possible with a normal Rondostar

(without variable speed). The release for transfer takes place by the transfer table (high

speed).

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 24

____________________________________________________________________________________________________________________________________________________________________________________________________________________

6.2 Function

6.2.1 Compound operation with one make-up line respectively donut line

For compound operation a program containing the final function "Cutomat" mus t

always be produced.

Sheeting takes place as for a normal sheeting program. The dough band is stopped in the

same position as for "place manual reeler". The dough position can be set by

parameter 2.

The dough transfer starts, if the release is given by the line (input E6).

The dough band is transferred at reduced speed. The time for transfer can be set by

parameter 3. When the transfer time is run down the sheeting program is finished (The rollers

revert to the initial roller gap).

Transfer speed:

Adjustable on the potentiometer as by Cutomat. The time for the transfer of the dough depends

on the speed! The time can be set by parameter 3.

6.2.2 Positioning the dough

During compound operation with one line (parameter 30 = 1 or 2) the dough piece can

be positioned on the left or right table.

During compound operation with two lines, sheeting takes place corresponding the

selected parameter 30.

- Parameter 30 = 3: without a passage without roller adjustment. The number of

sheeting passages (even/uneven) therefore determines the side on which for the left

respectively right line the dough must be positioned. By sheeting a dough piece it is

possible to determine the allocation of the side "position dough" to the left or right

line.

- Parameter 30 = 4: Side to place the dough is defined as follows:

for left machine place dough on the left side

for right machine place dough on the right side

6.2.3 Release signal for transfer

The release signal for transfer is given by the make-up line by means of a floating

contact.

Contact closed = release

Contact open = no release respectively stop during the transfer

In special circumstances the release signal can be given by operating the black push

button (the release is given as long as the black push button is operated).

6.3 Special parameters for compound operation

The following parameters have to be set on the processor for compound operation.

- Parameter 30: Definition of compound operation (left, right, both sides)

- Parameter 2: Stop position on the table end if the dough cannot be transferred.

- Parameter 3: Running time for the dough transfer (depends on the transfer speed).

The parameters 2 and 3 can also be set by the customer (operating manual)

Parameterization of the frequency inverter, see chapter 7.4.2

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 25

____________________________________________________________________________________________________________________________________________________________________________________________________________________

7. Instructions for trouble shooting

7.1 Error messages

The following error messages are indicated on the display:

Indication Error Causes

Err 1 Supervision of the control - Mains voltage to small

voltage of the microprocessor - Control voltage to small, replace

the basic modul

- Error processor (Input)

Err 2 Supervision of the control - Check control voltage

voltage, Error input E2 - Check fuse F2 in the basic

module

Err 3 Time-out roller adjustment - Motor runs only with 2 phases

drive, i. e. adjusting the roller - Mechanism of the roller

takes too long adjustment jams.

Err 4 No reaction of the sender, - Roller adjustment motor doesn't

if roller adjustment drive turn

is switched on. - The roller jams in the upper or

the lower final position.

- Sender defective.

- Sender cable is not plugged into

the processor

- Ribbon cable from the processor to

the basic module isn't plugged

in.

Err 5 Target value for roller gap, i. e. - Brake doesn't function

divergence between set point - The transmitter doesn't work

and actual value of roller gap properly (positions are partially

is too big missing

Err 6 The main contactor K1M is By switching on the main switch

welded. the contactor K1M is already

tightened.

Attention:

The black push button may only be

operated if the indications on the

display are illuminating, i. e. if the

processor is ready for working

Err 7 Error frequency inverter or - Check the frequency inverter

contactor K2M doesn't switch on. Switch of the mains switch for at

(Input E4) least 30 s.

- Check contactor K2M

- Check time relay K3T

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 26

____________________________________________________________________________________________________________________________________________________________________________________________________________________

Indication Error Causes

Err 8 Error frequency inverter or - Check the frequency inverter

contactor K2M switchs off to (See also Error 7)

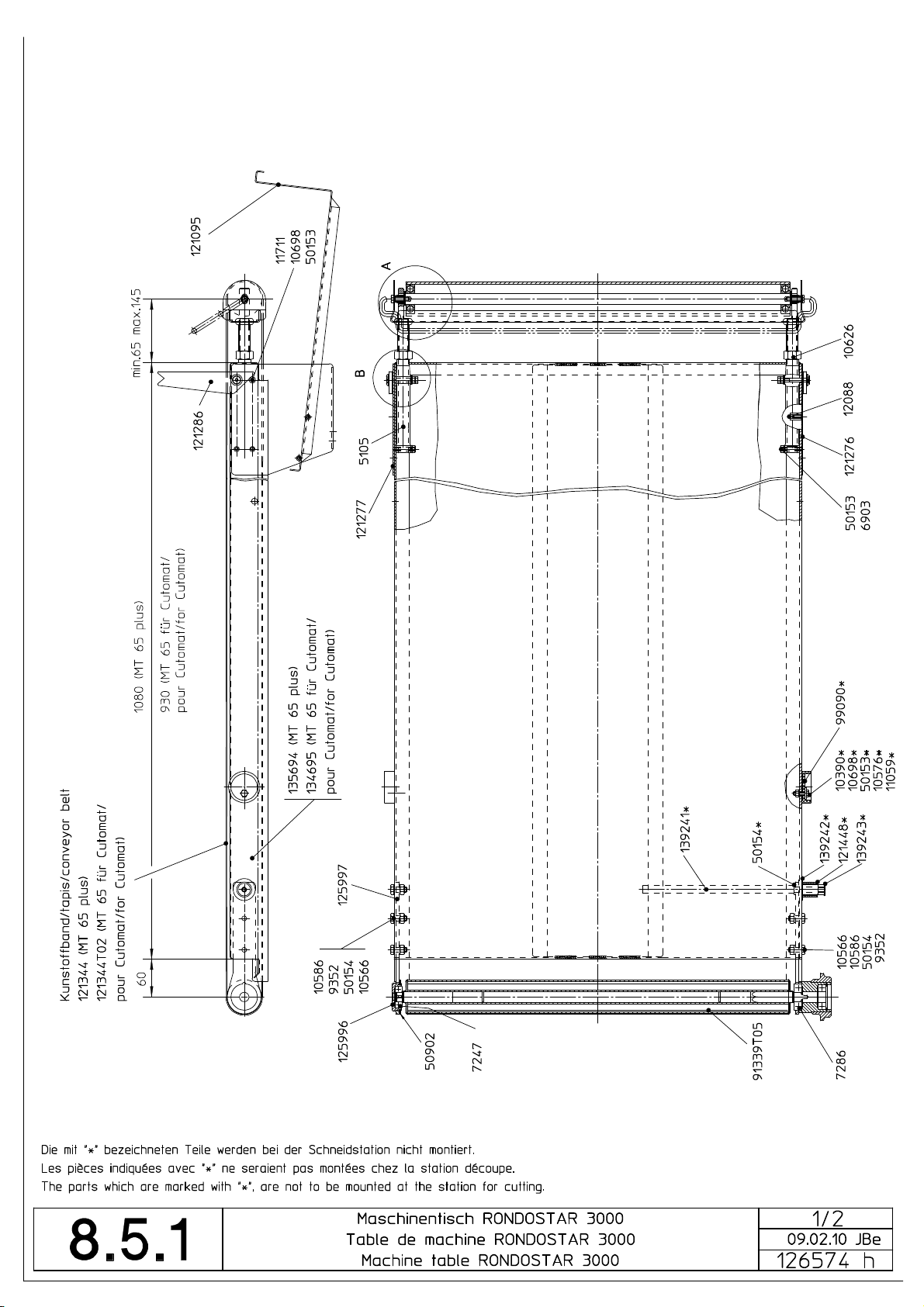

early (Input E4) - Check the adjustment of the

time relay K3T (1,0 s with

off-delay)

Err 9 Contactor K2M doesn't - Check contactor K2M

switch off - Check the adjustment of the

time relay K3T

The errors can be eleminated by switching off the mains switch.

The mains has to be switched off for at least 30 s, by machines with a frequency

inverter (Cutomat).

7.2 Construction of the control system

The electrical control consists basically of the following parts:

Processor with display

The machine is controled by the processor.

Basic module (fitted in electrical box)

The basic module contains:

- Power-pack consists of the transformer and the rectifier for the control voltages

24 VDC and 15 VDC.

- Relays for the control of the roller adjustment drive including the brake.

- Relays for the control of the flour duster.

- Relays for the control of the reeler.

- Contactors for the control of the roller drive / table drive

Contactor control system

The main contactor K1M carries out a safety function. When opening the safety guard

or pressing the red push button, all drives are disconnected.

The table drive is controled by the contactors K2M and K3M.

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 27

____________________________________________________________________________________________________________________________________________________________________________________________________________________

7.3 Checking the control system

7.3.1 Mains voltage

Switch on mains switch and measure all 3 phases on contactor K1M, terminals 2, 4, 6.

(by Cutomat terminals L1, L2, L3)

7.3.2 Control voltages

Attention: The connections of the control voltage transformer (fitted in the basic

module) have to coincide with the phase voltage of the net!

Control voltage 15 VDC

Control voltage for the processor.

Measure the voltage at plug X5 on the processor (Terminals 4 and 5).

Check fuse F1 (0,63 AT) in the basic module.

Control voltage 24 VDC

Control voltage for contactor control system, in- and outputs of the processor etc.

Measure the voltage at plug X5 on the processor (Terminals 1 and 2).

Check fuse F2 (2,0 AT) in the basic module.

The control voltages can also be checked at the basic modul on the terminals TP1 - TP6

(Close to the fuses)

TP1: +24V TP3: +15V TP5: 26VAC

TP2: G24V TP4: G15V TP6: 26VAC

Voltage 24 VDC for reeler drive (Up / Down)

Measure the voltage at plug X10-1 / X10-2.

Check fuse F3 (2,0 AT) in the basic module.

7.3.3 Control circuit main contactor K1M

The release of the control voltage is done by the relay K8 in the basic module.

(See circuit diagram 500680, side 3, path 1 respectively 500681 side 3, path 1)

Relay K8 switches on as soon as the processor works faultless.

If the processor doesn't run (Error in the processor), the red LED in the basic module is

illuminated.

The control voltage can be checked as follows:

- Measure against ground, e. g. earth terminal

- Terminal X1-1: Voltage existing if released off processor (Relay K8)

- Terminal X1-2: Voltage existing if safety guard OK

- Terminal X1-6: Voltage existing if red push button OK

- Terminal X1-5: Voltage existing if one of the black push buttons is operated

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 28

____________________________________________________________________________________________________________________________________________________________________________________________________________________

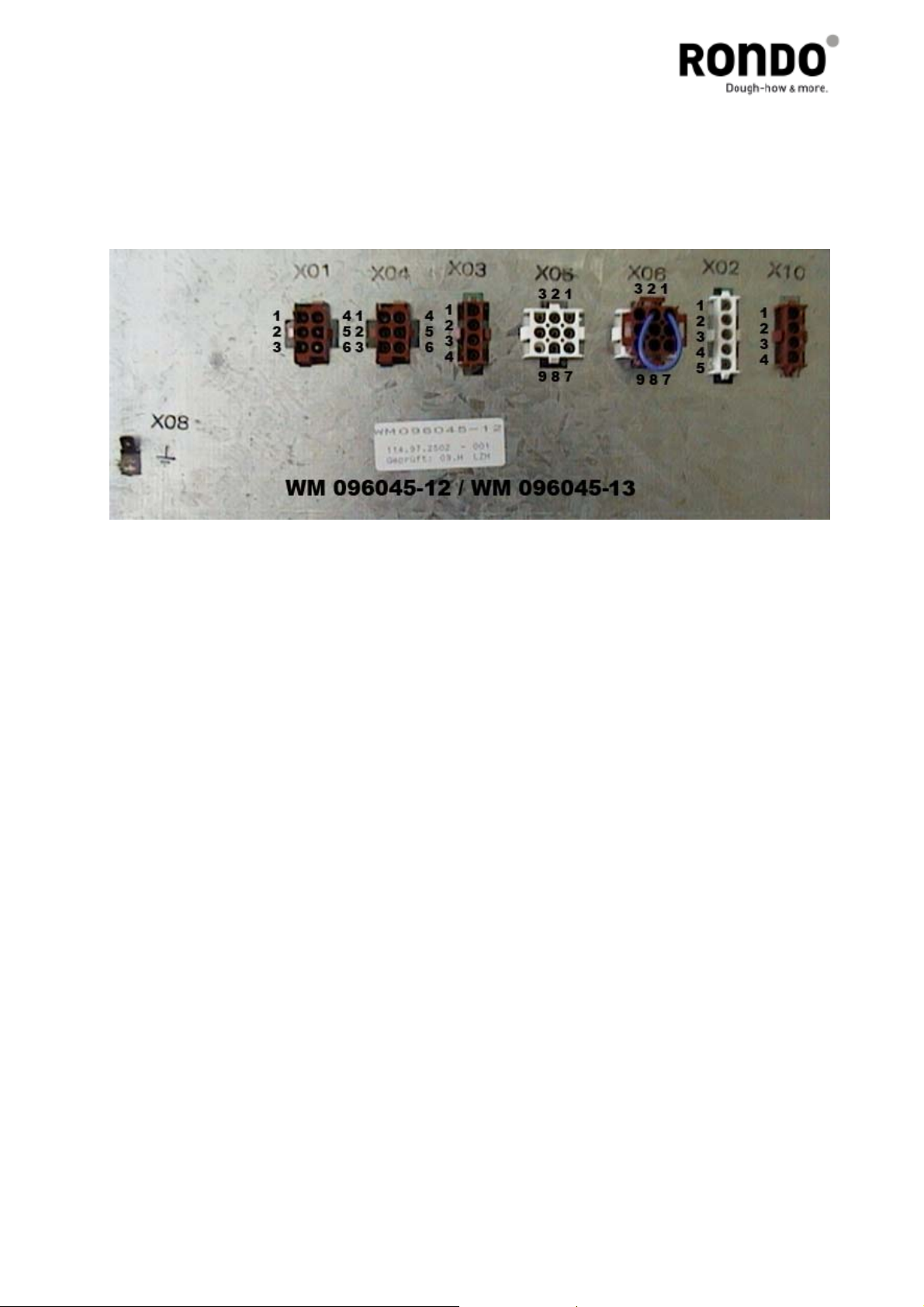

7.3.4 Measure of the voltage on the plugs

All connections to the basic module are plugable and allow a quick and faultless exchange.

The following picture shows the numbering of the plug connections. Based on these, in

combination with the diagram, the output voltage on the basic module can be

measured.

7.4 Important notes to the frequency inverter

7.4.1 Types

For 200 - 230 V and 380 - 460 V different types of frequency inverters and mains

filters are used.

7.4.2 Parameterization

The frequency inverters delivered by RONDO Burgdorf AG, CH are already

parameterized. The inverters can be used without a change for the sheeting

machine Compas SFA612.

Important: All other parameters must not be changed.

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 29

____________________________________________________________________________________________________________________________________________________________________________________________________________________

7.4.3 Ground fault interrupter can be actuated when inverter is started

Leakage current flows through the inverter.

The inverter performs internal switching. Therefore, a leakage current flows through the

inverter. This leakage current may actuate the ground fault interrupter, shutting the power

off.

Use a ground fault interrupter with a high leakage-current detection value (sensitivity

amperage of 200mA or more, operating time of 0,1 s or more) or one with high-frequency

countermeasures for inverter use.

In addition, remember that a leakage current increases in proportion to the cable length.

Normally, approximately 5 mA of leakage current is generated for each meter of cable.

______________________________________________________________________________________________________________________________________________________________________________________________________

Edition: 06.2011 Service manual

Page 30

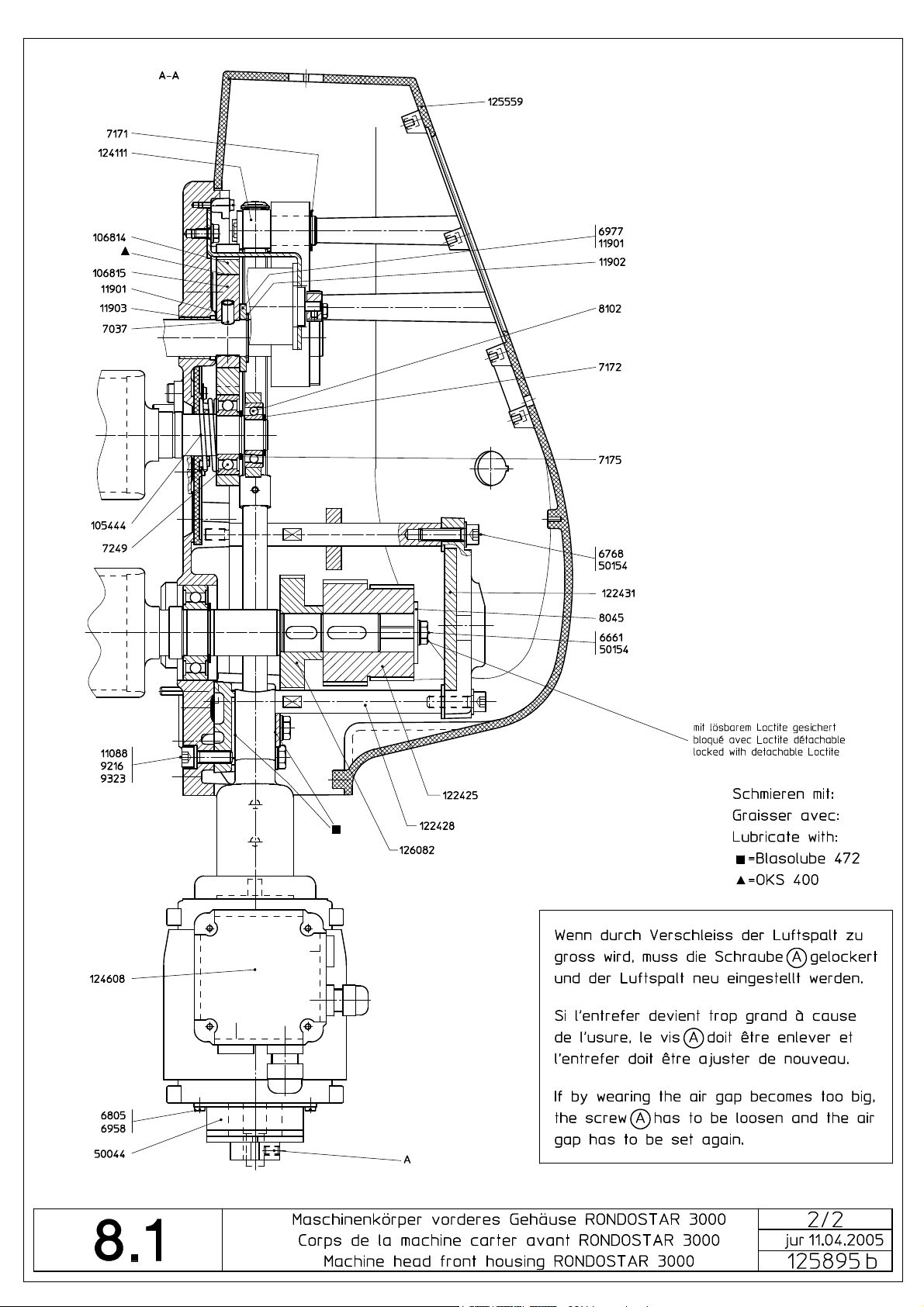

8. Teilebezeichnungen, Zeichnungen / Désignations des pièces,

dessins / Part names, drawings

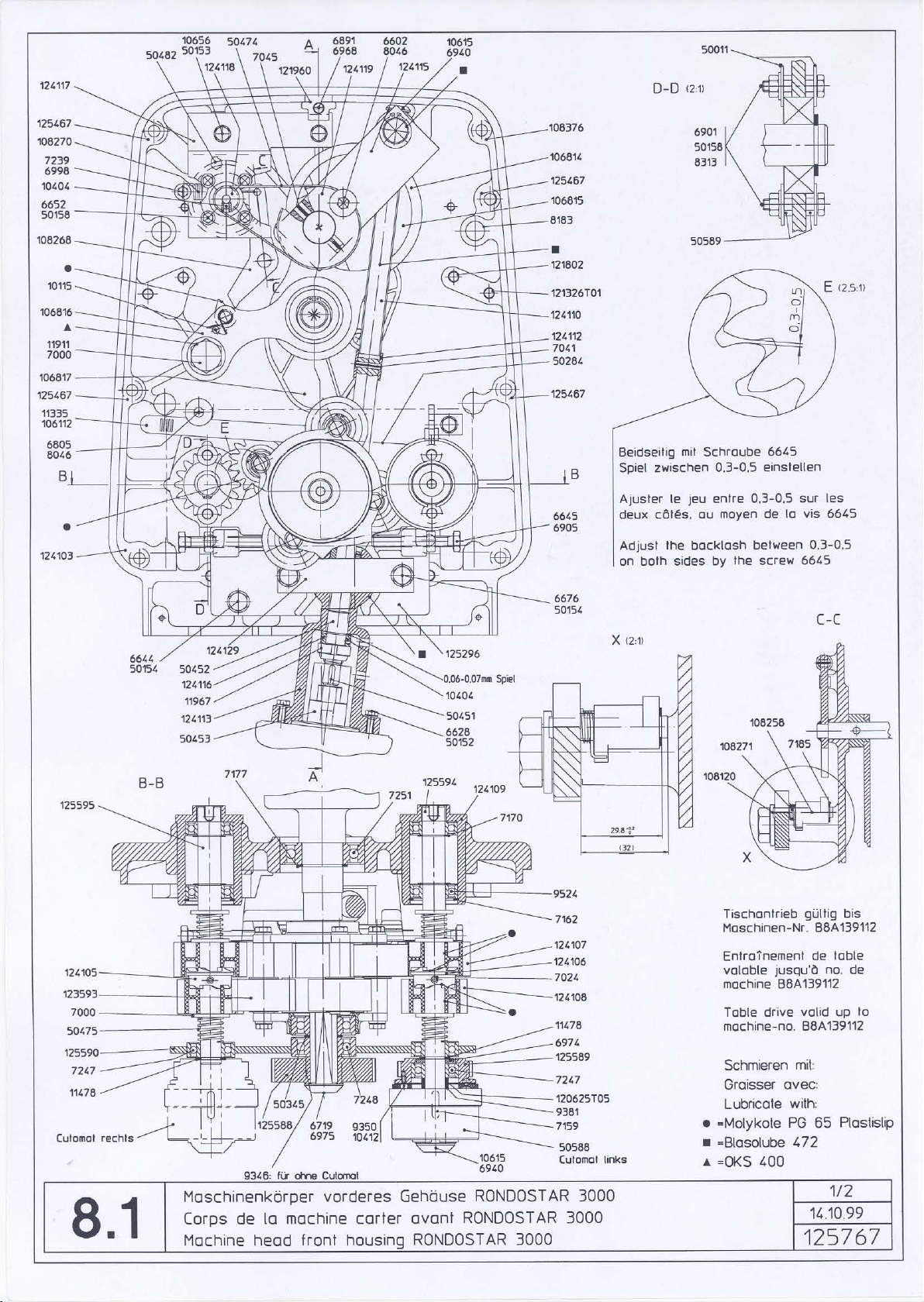

8.1 Maschinenkörper vorderes Gehäuse Corps de la machine carter avant 125895 Machine head front housing

Bestell-Nr.

No commande

Ordering no.

7153 Federkeil 8x25 Clavette 8x25 Key 8x25

7159 Federkeil 5x5x20 Clavette 5x5x20 Key 5x5x20

7249 Rillenkugellager Roulement à billes Ball bearing

7251 Rillenkugellager Roulement à billes Ball bearing

7272 Rillenkugellager Roulement à billes Ball bearing

7286 Rillenkugellager Roulement à billes Ball bearing

8102 Rillenkugellager Roulement à billes Ball bearing

10404 Gewindestift M4x4 Vis sans tête Set screw

11301 Kugellager Freilauf Roulement à billes libre Free wheeling with ball bearing

11335 Senderkopf Tête de transmetteur Transmitter head

11901 Distanzscheibe Rondelle d'espacement Spacing washer

11903 Lagerbüchse Coussinet Bearing bush

50044 El. Magnetbremse Frainage Brake

50283 Zahnriemen GT Courroie dentée GT Toothed belt GT

50284 Zahnriemen GT Courroie dentée GT Toothed belt GT

50451 Federkeil 4x4x14 Clavette 4x4x14 Key 4x4x14

50452 Lagerbüchse mit Bund Coussinet Bearing bush

50453 Wellenkupplung Dispositif d'accouplement Clutch

50474 Zahnriemen HTD Courroie dentée HTD Toothed belt HTD

50482 Absolutwertgeber mit

105444 Druckfeder Ressort à pression Compression spring

106112 Lichtschrankenkabel Câble pour cellule

106114T01 Kupplung mit Kabel Embrayage avec câble Clutch with cable

106814 Verstellschwinge Levier basculant Adjusting lever

106815 Exzenter Excentrique Eccentric

106817 Dichtteller Disque de joint Seal cover plate

122421 Kupplungswelle links Arbre d'embrayage à gauche Clutch shaft left

122422 Kupplungswelle rechts Arbre d'embrayage à droite Clutch shaft right

122423 Riemenscheibe Z=34 Poulie Z=34 Pulley Z=34

122425 Riemenscheibe Z=38/Z=44 Poulie Z=38/Z=44 Pulley Z=38/Z=44

122427 Riemenscheibe Z=46 Poulie Z=46 Pulley Z=46

122428 Distanzbolzen Bouton d'écartement Distance bolt

122431 Lagerbrille Plaque de palier Bearing plate

124110 Spindel Broche Spindle

124111 Mutter Ecrou Nut

124113 Spindellager Logement du broche Spindle bearing

124115 Hebel Levier Lever

124118 Riemenscheibe Z=21 Poulie Z=21 Pulley Z=21

124119 Riemenscheibe Z=65 Poulie Z=65 Pulley Z=65

124608 Motor für Walzenzustellung Moteur pour approche des

126050 Lager Palier Bearing

126063 Spindelhalterung Broche d'appui Holding device

Teilebezeichnung

Désignation

Part name

Stecker

Codeur en valeur absolue

avec prise mâle

photoélectrique.

cylindres

Rotary encoder with plug

Cable for light barrier

Motor for roller adjustment

Page 31

Page 32

Page 33

Page 34

Page 35

8.1 Maschinenkörper vorderes Gehäuse Cutomat / Verbund Corps de la machine carter avant Cutomat / Compoundage 126576 Machine head front housing Cutomat / Compound

Bestell-Nr.

No commande

Ordering no.

7159 Federkeil Clavette Key

7247 * Rillenkugellager Roulement à billes Ball-bearing

7248 Rillenkugellager Roulement à billes Ball bearing

7249 Rillenkugellager Roulement à billes Ball bearing

7251 Rillenkugellager Roulement à billes Ball bearing

8102 Rillenkugellager Roulement à billes Ball bearing

9524 Rillenkugellager Roulement à billes Ball bearing

10404 Gewindestift M4x4 Vis sans tête M4x4 Set screw M4x4

11335 Senderkopf Tête de transmetteur Transmitter head

11901 Distanzscheibe Rondelle d'espacement Spacing washer

11903 Lagerbüchse Coussinet Bearing bush

50044 Bremse Frainage Brake

50284 * Zahnriemen Courroie dentée Toothed belt

50451 Federkeil Clavette Key

50452 Lagerbüchse Coussinet Bearing bush

50453 Kupplung Disp. d'accouplement Clutch

50474 Zahnriemen Courroie dentée Toothed belt

50475 Druckfeder Ressort à pression Compression spring

50482 Absolutwertgeber Codeur en valeur absolue Rotary encoder

50553 Sicherungsring f.Welle Circlips pour arbre Circlip for shaft

50588 * Elektrische Kupplung Embrayage électrique Electrical clutch

105444 Druckfeder Ressort à pression Compression spring

106112 Lichtschrankenkabel Câble pour cell. photoélectr. Cable for light barrier

106814 Verstellschwinge Levier basculant Adjusting lever

106815 Exzenter Excentrique Eccentric

106817 Dichtteller Disque de joint Seal cover plate

123568 Zahnrad Z=22 Roue dentée Z=22 Gearwheel Z=22

123570 Zahnrad Z=15 Roue dentée Z=15 Gearwheel Z=15

123573 Achse Arbre Shaft

124107 Zahnrad Z=18 Roue dentée Z=18 Gearwheel Z=18

124108 Zahnrad Z=16 Roue dentée Z=16 Gearwheel Z=16

124110 Spindel Broche Spindle

124111 Mutter Ecrou Nut

124113 Spindellager Logement du broche Spindle bearing

124115 Hebel Levier Lever

124116 Lagerring Bague Ring

124118 Riemenscheibe Z=21 Poulie Z=21 Pulley Z=21

124119 Riemenscheibe Z=65 Poulie Z=65 Pulley Z=65

124137 Satellitenplatte Disque Disc

124608 Motor für Walzenzustellung Moteur pour approche des

124802 Zahnrad Z=15 Roue dentée Z=15 Gearwheel Z=15

125296 Spindelhalterung Broche d'appui Holding device

125588 * Zahnriemenrad Z=48 Roue courroie dentée Z=48 Pulley Z=48

125589 * Riemenscheibe Z=35 Poulie Z=35 Pulley Z=35

125590 Verbindungsplatte Plaque d'appui Bearing plate

125594 * Kupplungswelle Arbre d'embrayage Clutch shaft

125595 Kupplungswelle Arbre d'embrayage Clutch shaft

125850 Vorderes Gehäuse Carter avant Front housing

134615 Kupplungsscheibe links Roue libre gauche Free-wheel left

134616 Kupplungsscheibe rechts Roue libre droite Free-wheel right

* = Ausführung Cutomat / Version Cutomat / Type Cutomat

Teilebezeichnung

Désignation

Part name

Motor for roller adjustment

cylindres

Page 36

Page 37

Page 38

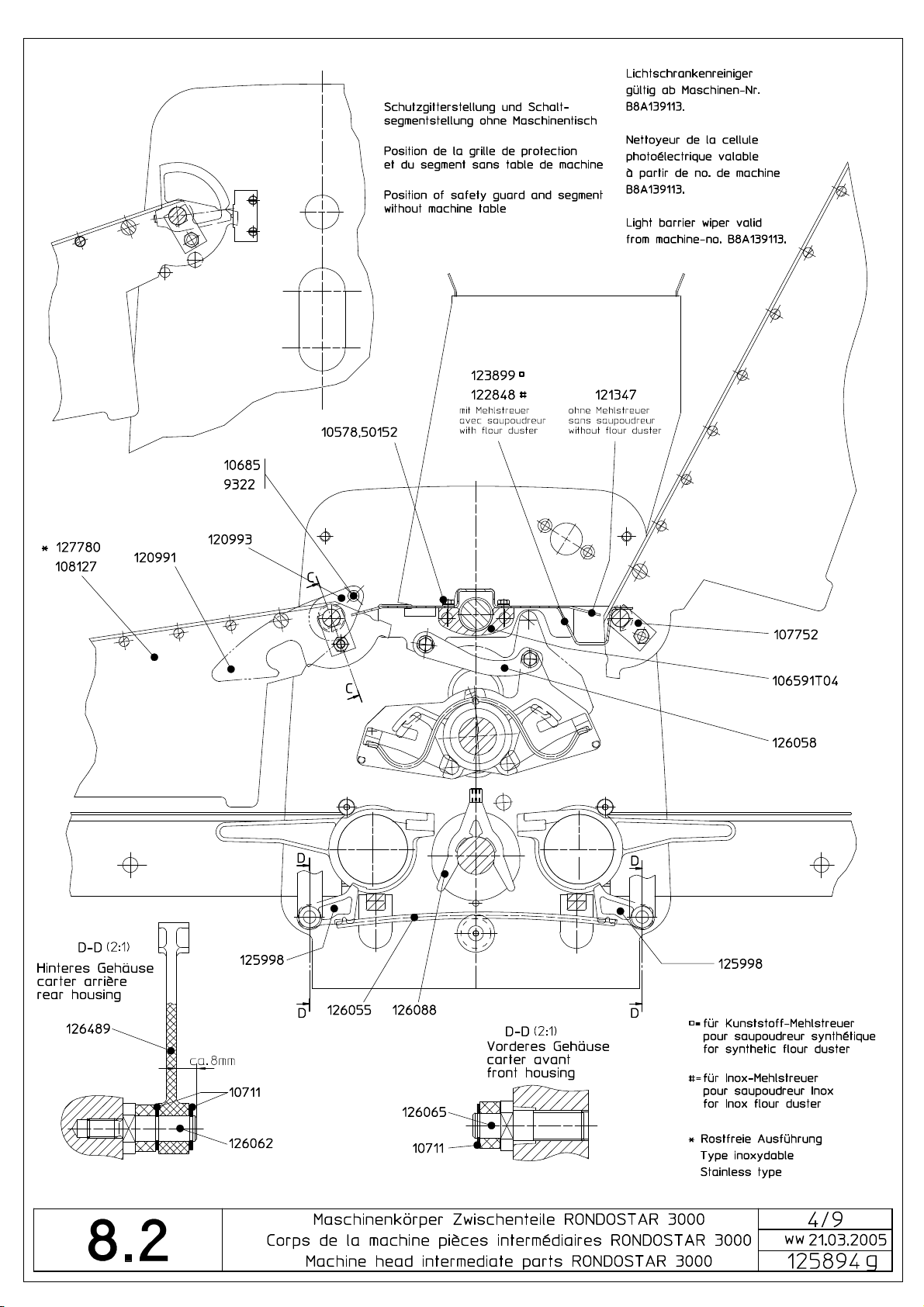

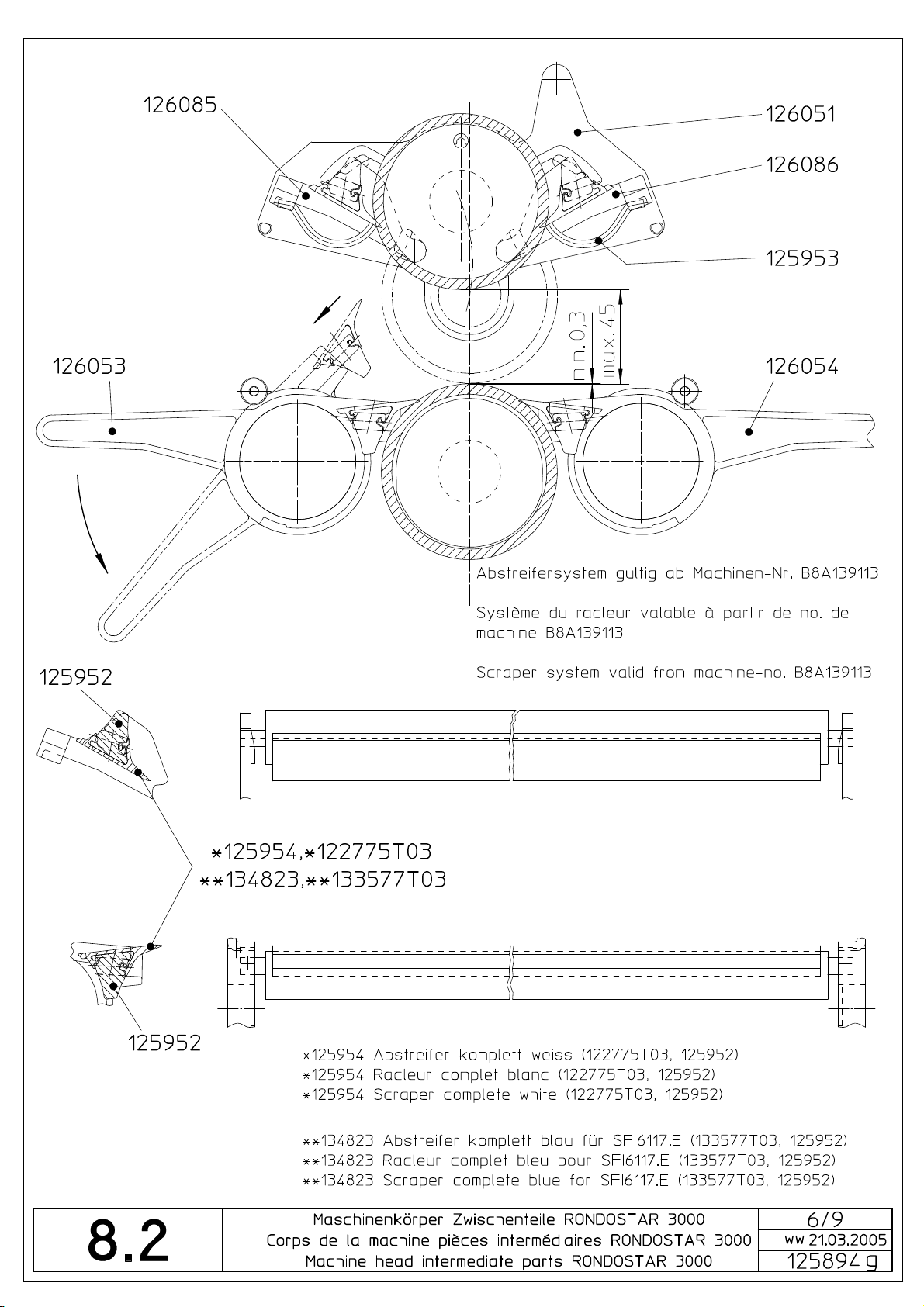

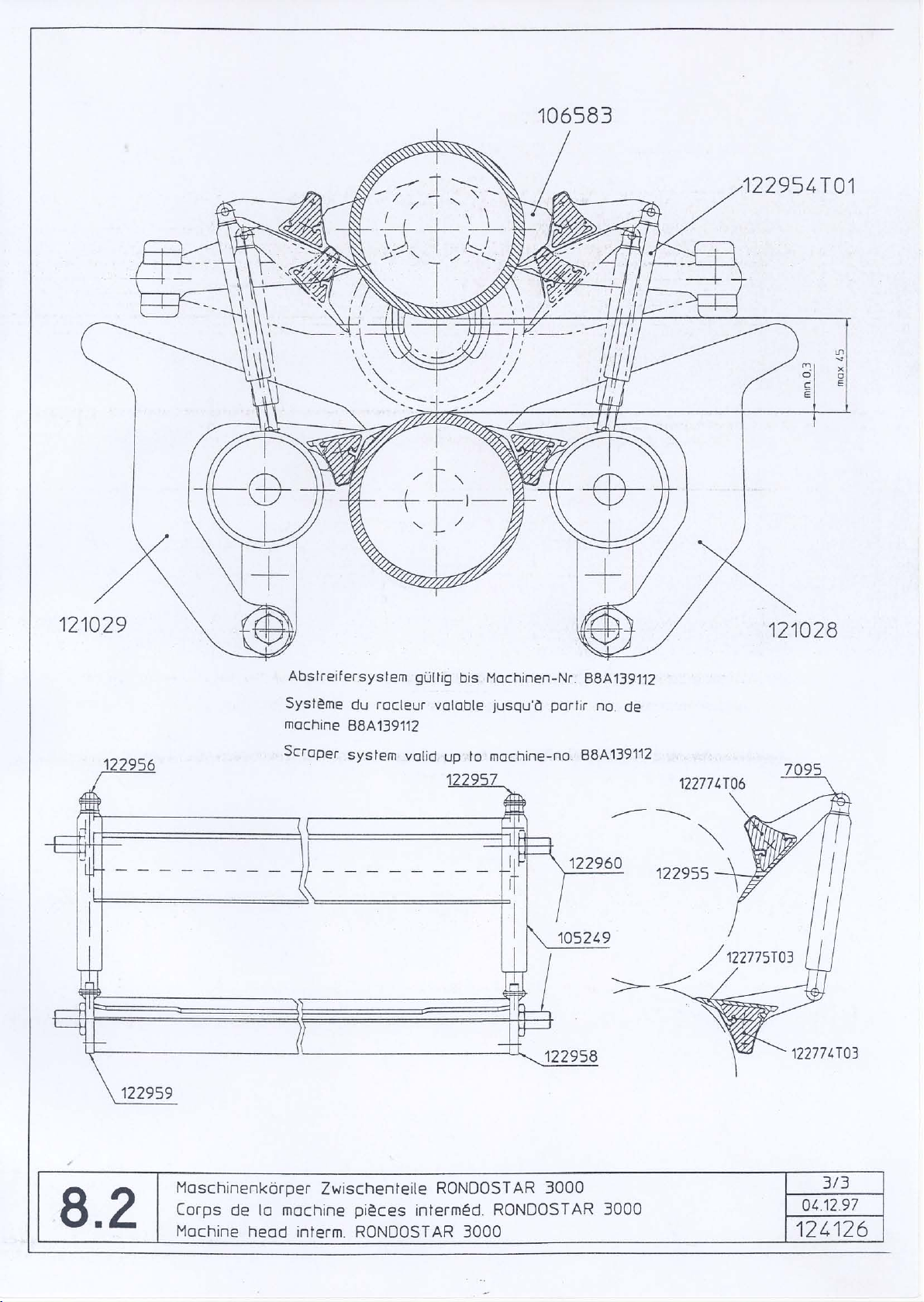

8.2 Maschinenkörper Zwischenteile Corps de la machine pièces intermédiaires 125894 Machine head intermediate parts

Bestell-Nr.

No commande

Ordering no.

8836 Spiral-Druckfeder Ressort à boudin Spiral compression spring

50692 Rillenkugellager Roulement à billes Ball bearing

50693 V-Sicherungsring für Welle

50694 V-Sicherungsring für Bohrung

107752 Arretierungsblech Tôle d'arrêt Locking sheet metal

108127 Schutzgitter Grille de sécurité Safety guard

120719T03 Hülse Douille Bush

120991 Tischhaken Crochet de la table Table-hook

120993 Halteblech Tôle de retenue Retaining sheet metal

121347 Abdeckblech Tôle de couverture Covering metal sheet

122775T03 Abstreifermesser Lame de racleur Scraper blade

122848 Abdeckblech für Inox-

123899 Abdeckblech für Kunststoff-

125593 Unterwalze Rouleau inférieur Lower roller

125872 Oberwalze Rouleau superieur Upper roller

125952 Abstreiferhalter Support pour lame de racleur Scraper blade support

125953 Feder Ressort Spring

125954 Abstreifer komplett Racleur complet Scraper complete

125998 Klinke Cliquet Catch

126051 Seitenplatte hinten Plaque latérale arrière Side-plate rear

126052 Seitenplatte vorne Plaque latérale avant Side-plate front

126053 Spannhebel links Levier de serrage gauche Tension lever left

126054 Spannhebel rechts Levier de serrage droite Tension lever right

126055 Federstab Barre pour ressort Spring bar

126058 Parallelführung Guide parallèle Guide parallel

126062 Bolzen hinten Boulon arrière Bolt, rear

126064 Halter Support Holder

126065 Bolzen vorne Boulon avant Bolt, front

126081 Unterwalze Rouleau inférieur Lower roller

126084 Rakel Racle Ductor

126085 Halter links Support gauche Holder left

126086 Halter rechts Support droite Holder right

126088 Wischer Bras de monture d'essuie Wiper arm

127780 Schutzgitter Inox Grille de sécurité Inox Safety guard Inox

133577T03 Abstreifermesser Lame de racleur Scraper blade

134823 Abstreifer komplett blau Racleur complet bleu Scraper complete blue

Teilebezeichnung

Désignation

Part name

30x1,5

47x1,75

Mehlstreuer

Mehlstreuer

V-Circlip pour arbre 30x1,5 Circlip for shaft 30x1,5

V-Circlip pour alésage

47x1,75

Tôle de couverture pour

saupoudreur Inox

Tôle de couverture pour

saupoudreur synthétique

Circlip for bore 47x1,75

Covering metal sheet for

Inox flour duster

Covering metal sheet for

synthetic flour duster

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

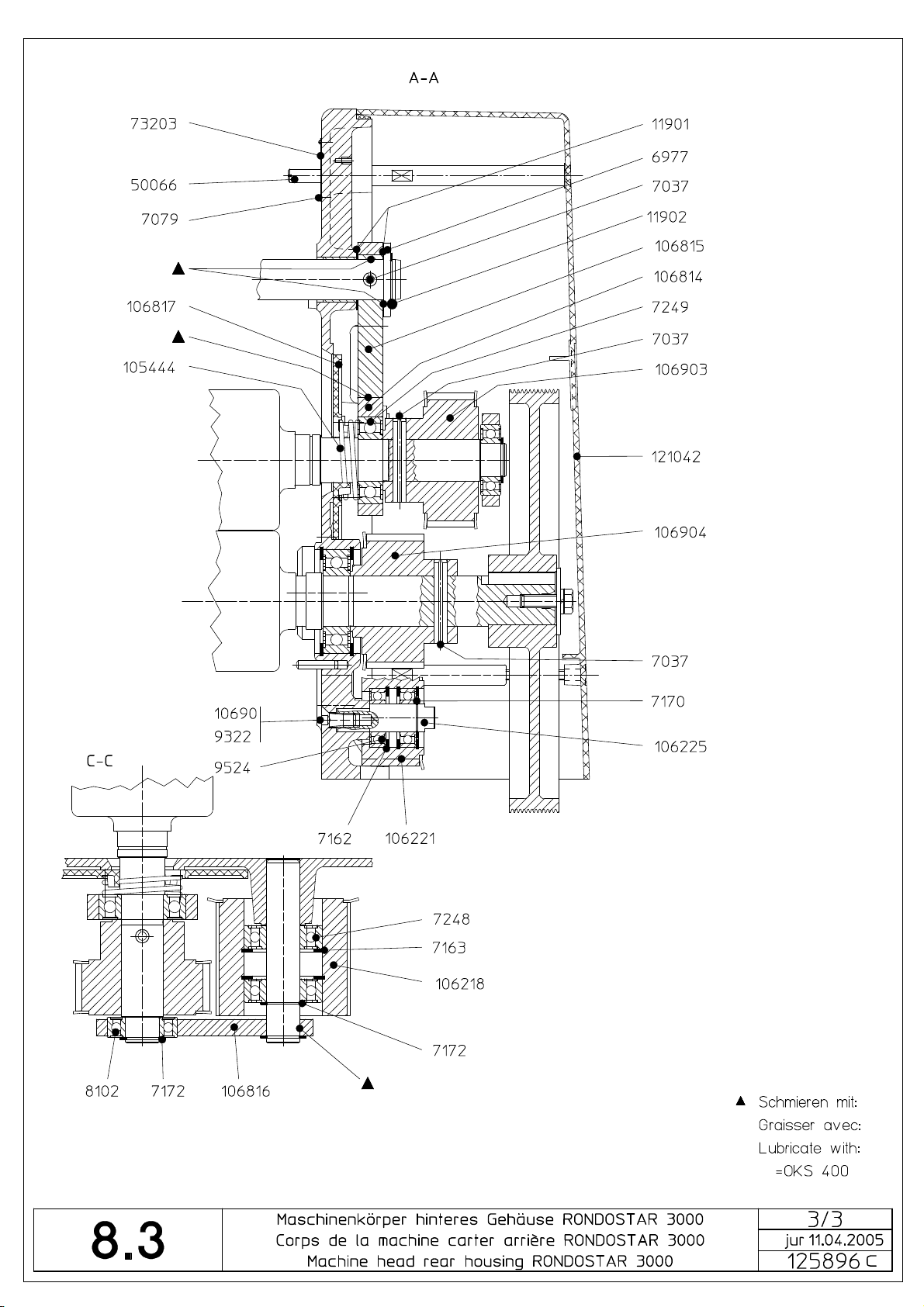

8.3 Maschinenkörper hinteres Gehäuse Corps de la machine carter arrière 125896 Machine head rear housing

Bestell-Nr.

No commande

Ordering no.

7037 Spannhülse Douille de serrage Clamping sleeve

7166 Sicherungsring Circlips Circlip

7248 Rillenkugellager Roulement à billes Ball bearing

7249 Rillenkugellager Roulement à billes Ball bearing

8102 Rillenkugellager Roulement à billes Ball bearing

8722 Halter Support Holder

9371 Endschalter Interr. fin de course Limit switch

9524 Rillenkugellager Roulement à billes Ball bearing

10185 Kabelbinder Colzon Cable binder

11334 Empfängerkopf Tête de récepteur Receiver head

11901 Distanzscheibe Rondelle d'espacement Spacing washer

11935 Zahnriemen Courr. dentée Toothed belt

11936 Doppelzahnriemen Courr. dentée double Double toothed belt

12021 Kabelbride Bride Clamp

12061 Schneckengetriebe-Motor Moteur d'engrenage de la vis

50056 Gewindestift M4x5 Vis sans tête M4x5 Set screw M4x5

50108 Gewindestift Vis sans tête Set screw

100423T05 Kabelbrücke Jonction de cable Cable link

105444 Druckfeder Ressort à pression Compression spring

106111 Lichtschrankenkabel Câble pour cell.photoélectr. Cable for light-barrier

106218 Riemenscheibe Poulie Pulley

106221 Riemenscheibe Poulie Pulley

106225 Exzenter Excentrique Eccentric

106593 Schaltsegment Segment Segment

106812 Winkel Angle Bracket

106814 Verstellschwinge Levier basculant Adjusting lever

106815 Exzenter Excentrique Eccentric

106816 Horizontalschwinge Levier horizontale Horizontal lever

106817 Dichtteller Disque de joint Seal cover plate

106903 Riemenscheibe Poulie Pulley

106904 Riemenscheibe Poulie Pulley

108240 Lagerbolzen Boulon d'arrêt Spring holding bolt

108241 Schraubendruckfeder Ressort à pression Compression spring

108359 Deckel hinten Couvercle arrière Rear cover

120978 Lagerschraube Vis Bolt

120979T01 Distanzbolzen Bouton d'écartement Distance bolt

120979T02 Distanzbolzen Bouton d'écartement Distance bolt

121016T03 Kabel zu Schutzgitter Câble pour grille de séc. Cable for safety guard

121017T01 Kabel zu Mehlstreuermotor Câble pour moteur

121042 Deckel hinten Couvercle arrière Rear cover

121057 Abdeckung Couverture Covering

121069 Zwischenscheibe Disque intermédiaire Intermediate disc

121070 Mitnehmer Entraîneur Catch

122516 Platte Plaque Plate

126066 Gehäuse hinten mit Einpress-

Teilebezeichnung

Désignation

Part name

Worm gear motor

sans fin

Cable for flour duster.-motor

saupoudreur à farine

Carter arrière Rear housing

teile

Page 46

Page 47

Page 48

Page 49

8.4 Unterbauten

Socles

Machine bases

8.4.1 Unterbau

Socle 125787

Machine base

Bestell-Nr.

No commande

Ordering no.

7668 Kabeltülle Passe-câble Cable grommet

7856 Fiberscheibe Rondelle Washer

9211 Sechskantmutter

9286 * Lenkrolle 80x115 Galet-guide 80x115 Guide roll 80x115

9322 Schutzstopfen Bouchon de protection Protection plug

10309 Lenkrolle 80x118 Galet-guide 80x118 Guide roll 80x118

10310 Bockrolle ø 80 Galet fixe ø 80 Frame caster ø 80

10520 Haltering Anneau de blocage Retaining ring

11341 (*) Scheibe Polyamid Disque Polyamid Disc Polyamid

11398 Kabeltülle Passe-câble Cable grommet

11938 Federkeil 8X40 Clavette 8X40 Key 8X40

50603 Motor 1,1 kW 50/60 Hz Moteur 1,1 kW 50/60 Hz Motor 1,1 kW 50/60 Hz

50607 Rippenband Poulie Ribbed belt

50805 * Bockrolle ø 80 Galet fixe ø 80 Frame caster ø 80

51309 Motor 1,1 kW 60 Hz, UL Moteur 1,1 kW 60 Hz, UL Motor 1,1 kW 60 Hz, UL

99259 Lenkrolle komplett Roulette de transport compl. Transport caster compl.

99261 Klinke Cliquet Catch

99264 Achse Axe Axle

99265 Welle Arbre Shaft

99265T02 * Welle Arbre Shaft

99269 Fuss Pied Foot

99528 Ueberstülppuffer Butoir Puffer

108398 Mäuseblech Protection Protection

108880 * Mäuseblech Protection Protection

120725 * Führungsschiene Guidage Guide

120726 * Abdeckung Couverture Covering

120733 Führungsschiene Guidage Guide

120734 Abdeckung Couverture Covering

120753T02 * Tischstütze 6 Support de table 6 Table support 6

120754T01 Tischstütze 6 Support de table 6 Table support 6

120759T02 Verstärkung Renforcement Reinforcement

121414 Schutzbügel Poignée Guard tube

122758 Tischstütze mit Fuss Support de table avec pied Table support with foot

122759 * Tischstütze mit Fuss Support de table avec pied Table support with foot

122761 (*) Gleiter Coulisse Slider

123040 (*) Schneidewellenhalter Porte rouleau de découpe Cutting roller holder

125786 Kasten komplett Boîtiers compl. Box complete

125908 Rippenbandscheibe Poulie Ribbed V-belt pulley

125909 Rippenbandscheibe Poulie Ribbed V-belt pulley

125910 Rippenbandscheibe Poulie Ribbed V-belt pulley

125911 Motorhalterung Fixation du moteur Motor mounting

125912 Spannwinkel Angle tendeur Fastening bracket

125940 * Kasten komplett Boîtiers compl. Box complete

126818 * Lenkrolle komplett Roulette de transport compl. Transport caster compl.

Teilebezeichnung

Désignation

Part name

selbstsichernd M8x8

Ecrou hexagonal

indesserable

M8x8

Nut hexagon self locking

M8x8

Page 50

Page 51

Page 52

8.4.2 Unterbau mit Ausleger Socle avec support 129160 Machine base with support

Bestell-Nr.

No commande

Ordering no.

9211 Sechskantmutter

9286 Lenkrolle 80 x 115 Galet-guide 80 x 115 Guide roll 80 x 115

11341 Scheibe Polyamid Disque Polyamid Disc Polyamid

92233 * Halter für Schneidewellen-

102526T07 Distanzstab Barre d‘espacement Distance bar

122761 Gleiter Coulisse Slider

125466 * Maschinentisch Cutomat,

128701 Stütze komplett Support complet Support complete

128703 Halter Support Holder

129159 Ausleger komplett Bras complet Bracket complete

129414 * Stütze komplett Cutomat Support complet Cutomat Support complete Cutomat

129415 * Strebe Contre-fiche Stanchion

Teilebezeichnung

Désignation

Part name

selbstsichernd M8 x 8

ablage

rechts/links

Ecrou hexagonal

indesserable

M8 x 8

Support pour rouleau de

découpe

Table de machine Cutomat,

droite/gauche

Nut hexagon self locking

M8 x 8

Holder for storage for

cutting roller

Machine table Cutomat,

right/left

Page 53

Page 54

8.4.3 Unterbau Rondostar SFI Socle Rondostar SFI 125899 Machine base Rondostar SFI

Bestell-Nr.

No commande