Page 1

Operating manual

Croissomat

SCM50

Edition BD414202

04.2014

Technical specication subject to change without notice

www.rondo-online.com

Page 2

Page 3

RONDO Burgdorf AG

Heimiswilstrasse 42

CH-3400 Burgdorf/Schweiz

Tel. +41 (0)34 420 81 11

Fax +41 (0)34 420 81 99

info.ch@rondo-online.com

www.rondo-online.com

RONDO Schio s.r.l.

Via Lago di Albano, 86

I-36015 Schio (VI)

Tel. +39 0445 575 429

Fax +39 0445 575 317

sales.it@rondo-online.com

RONDO GmbH & Co. KG

D-57299 Burbach

Hoorwaldstrasse 44

Tel. +49 (0)2736 203-0

Fax +49 (0)2736 203130

info.de@rondo-online.com

RONDO S.à.r.l.

PAE «Les Pins»

F-67319 Wasselonne Cédex

Tel. +33 (0)3 88 59 11 88

Fax +33 (0)3 88 59 11 77

info.fr@rondo-online.com

RONDO Ltd.

Unit 7, Chessington Park

Lion Park Avenue

Chessington, Surrey KT9 1ST/GB

Tel. +44 (0)20 8391 1377

Fax +44 (0)20 8391 5878

info.uk@rondo-online.com

RONDO Asia

A-2-21, Jalan Kuchai Maju 2

Kuchai Entrepreneurs Park

Off Jalan Kuchai Lama

58200 Kuala Lumpur/Malaysia

Tel. +60 3 7984 55 20

Fax +60 3 7984 55 95

info.my@rondo-online.com

RONDO China

Unit 1511, 15F, South Tower

Fuli Yingli Bulding, No. 3

Hua Qiang Road

Guangzou P.R.C. 510623

China

Tel. +86 20 838 822 11

Fax +86 20 838 886 01

info.cn@rondo-online.com

RONDO IBERIA

Ronda del Golf Este

Finca Doña María

Las Amapolas 8 -1b

29630 Benalmádena-Costa, Malaga

España

Tel. +34 952 961 043

Fax +34 952 961 088

info.es@rondo-online.com

RONDO Inc.

100, State Street

Moonachie, N.J. 07074/USA

Tel. +1 201 229 97 00

Fax +1 201 229 00 18

info.us@rondo-online.com

RONDO Inc.

267 Canarctic Drive

Downsview, Ont. M3J 2N7/Canada

Tel. +1 416 650 0220

Fax +1 416 650 9540

info.ca@rondo-online.com

OOO RONDO Rus

Dmitrovskoe Chaussée 157, Str. 4

RU-127411 Moskau/Russland

Tel. 007 495 665 67 93

Fax 007 495 665 67 94

info@rondo-online.ru

Page 4

Page 5

Page 6

Page 7

Index

1 Safety information 10

1.1 Explanation of Symbols 10

1.2 Explanation of warning signs 10

1.3 Safety elements 10

1.3.1 Safety guards 10

1.4 Safety instructions and information which must be followed 11

2 Transporting, setting up, connecting, dismounting and storing the machine 14

2.1 Machine delivery 14

2.2 Transportation 14

2.3 Unpacking the machine 14

2.4 Setting up the machine 15

2.4.1 Tightening the conveyor belts 15

2.4.2 Fitting tool 16

2.4.3 Croissant roller 16

2.4.4 Installing bypass table (option) 17

2.5 Requirements for putting the machine into operation 18

2.6 Moving direction test 18

3 General data about the machine 19

3.1 General information 19

3.1.1 Authorized use 19

3.1.2 Noise values 19

3.1.3 Temperatures 20

3.1.4 Ambient humidity 20

3.1.5 Machine weight 20

3.2 Prerequisites 20

3.3 Full view of the machine 21

3.4 Operating elements 22

3.4.1 Mains Switch 22

3.4.2 Safety guards 22

3.4.3 Emergency-stop key 22

3.4.4 Control panel 22

3.4.5 Longitudinal cutting 22

3.4.6 Guillotine 23

3.4.7 Hold-down rollers 23

3.4.8 Croissant roller 23

Edition BD414202

04.2014

Croissomat

Operating manual

7

Page 8

Index

4 Starting the machine 24

4.1 Preparing for operational readiness without bypass table 24

4.2 Preparing for operation readiness with bypass table 24

4.3 Starting/Stopping the machine 25

5 Operation 26

5.1 General functional description of the Croissomat 26

5.1.1 Operating elements 26

5.2 Operating instructions 27

5.2.1 Switching on the machine 27

5.2.2 General notes 27

5.3 Product selection and product definition 28

5.4 Pause times 28

5.5 Operating modes 29

5.5.1 Set-up mode 29

5.5.2 Normal mode 29

5.5.3 Bypass mode 29

5.6 Special functions 30

5.6.1 Maintenance function 30

5.6.2 Operating hours counter 30

5.6.3 Indication safety guard open 30

5.7 The longitudinal cutting device and the guillotine 31

5.8 Croissant roller 33

5.9 Lowering the infeed table 33

6 Cleaning 34

6.1 Cleaning 34

6.1.1 Croissant roller 34

6.1.2 Care 38

7 Maintenance 39

7.1 General information for maintenance of the machine 39

7.2 Maintenance list 39

7.3 Replacement parts list 40

Edition BD414202

04.2014

Croissomat

Operating manual

8

Page 9

Index

8 Trouble shooting 41

9 Technical data 44

9.1 Technical data Croissomat 44

9.2 Additional information 45

Hint for operating manual: The numbers of the illustrations

(Ex.

1) are numbered chapterwise.

Edition BD414202

04.2014

Croissomat

Operating manual

9

Page 10

Safety information

1 Safety information

1.1 Explanation of Symbols

All the sections in this operating manual containing safety instructions

which absolutely must be observed are marked with this symbol and

with a number.

All the sections in this operating manual containing information which

absolutely must be observed are marked with this symbol.

1.2 Explanation of warning signs

1.3 Safety elements

1.3.1 Safety guards

Sign indicating Prohibited Activity

Reaching under the closed safety guard is prohibited!

Instruction and Information Signs

Make sure to disconnect the mains plug before opening!

Danger Warning Sign

Danger Warning

High-voltage Warning Sign

Warning against electrical shock.

Disconnect mains plug before opening.

Edition BD414202

04.2014

Operation

1

The safety guards fulfill a dual purpose:

1. They protect the operator from inadvertent contact with the cutting

tool and the dangerous zone.

2. By lifting up the safety guard the machine stops immediately.

Raising the safety guard even just slightly will stop the machine

from continuing to operate. By closing the safety guard the

machine mustn't start by oneself.

Croissomat

Operating manual

10

Page 11

Safety information

1.4 Safety instructions and information which must be followed

Read the operating manual before operating the machine.

The machine from RONDO is intended for use in the foodstuffs indus-

2

try for the production of unfilled croissants by means of cutting, stamping and rolling-up of dough pieces in thicknesses of up to 7 mm.

However, the machine is not suitable for the processing of other products (e.g. modelling clay or other types of mouldable masses which are

not dough products).

Any other use of these units is not in accordance with the purpose for

which they are built. Therefore, the manufacturer will not be liable for

any accidents or damage resulting from unauthorized use; the risk in

any such instance will be borne solely by the user.

Authorized use also means that the user must follow all instructions

3

4

5

6

prescribed by the manufacturer in respect of operation, maintenance

and service.

Any work on the electrical components of the machine, in particular the

correct professional mounting of the mains plug, may only be carried

out by qualifield personnel who are familiar with the relevant safety instructions. Defective cables and mains plugs must be immediately replaced by qualified personnel.

Protective covers over the electrical controls and the mechanical moving parts may only be removed by professionally qualified personnel

and must be remounted before the machine is put back into operation.

Any unauthorized changes made to the machine, and in particular, to

the safety devices on the machine will automatically exclude any liability on the part of the manufacturer for accidents or damage sustained

as a result of such changes.

Edition BD414202

04.2014

The machine may only be connected to the mains using the mains

7

8

plug! No permanent electrical installation may be made using, for example, terminal screws. The mains plug serves as a mains isolation

device. It has to be clearly visible at all times and freely accessible.

The machine may only be connected to the mains once it has been

fully assembled.

Croissomat

Operating manual

11

Page 12

Safety information

9

10

11

12

Before beginning any repair, service or cleaning work on the machine,

the electricity supply to the machine must be disconnected (pull out

mains plug).

Safety devices on the machine may not be adjusted, by-passed or

expanded.

Operation of the machine when any of the safety devices is out of order

is prohibited.

Defective cables and plugs must be replaced immediately by qualified

personnel.

13

14

15

16

17

18

Defective safety devices must be immediately replaced with new original parts from RONDO.

When transporting the machine, the croissant roller must be dismount-

ed.

Fitting and take-off of croissant roller has to be done by 2 person. Special attention has to be paid to the correct engagement of the croissant

roller to the basic machine.

Reaching under the closed safety guard is prohibited!

Do not reach with the fingers into the safety guard!

Do not deposit any loose objects such as knives, tools or articles of

clothing, etc. in the area where the dough is processed.

Check periodically to ensure that there are no loose screws in the area

where the dough is processed.

Edition BD414202

04.2014

19

Due to the risk of injury at the sharp edges, cutting tools must be exchanged carefully and correctly. Wear suitable protective gloves to prevent injuries. Cutting tool that are not in the cutting station must be

stored in a safe place.

Croissomat

Operating manual

12

Page 13

Safety information

20

21

22

23

Any disposal of the installation must be carried out in accordance with

environmentally-accepted practices. The operators are fully responsible for ensuring that such practices are followed.

The machine may not be operated without the scrapers.

Machine parts located in the areas in which the dough is being processed, and whose surface coating becomes worn (e.g. chromium

plating), must be replaced.

The machine must never be cleaned using spray water, high-pressure

cleaner, steam-cleaning machine or any similar cleaning methods.

24

25

26

27

28

29

This machine is not designed to be used in explosive ambient.

Prior to the first starting-up, the complete machine must be thoroughly

cleaned.

All still existing protective foils on the machine must be removed.

Defective parts must be replaced with new original parts by RONDO.

After every use, the machine has to be cleaned thoroughly. Not thoroughly cleaned machines can be a health-hazard for the consumer.

Non-ionising radiation is not intentionally produced but only given off

for technical reasons by electric equipment (e.g by electric motors). In

addition the machine has no strong permanent magnets. By keeping a

safe distance (the distance from the source field to the implant)

of 30 cm, interference with active implants (e.g. pacemakers, defibrillators) can be excluded with a high degree of probability.

Edition BD414202

04.2014

RONDO will not accept liability when any of the above safety instructions / notes have not been complied with!

Croissomat

Operating manual

13

Page 14

Transporting, setting up, connecting, dismounting and storing the machine

2 Transporting, setting up, connecting, dismounting and stor-

ing the machine

2.1 Machine delivery

The machine is delivered in its original packaging.

• Report any claims for damage caused as a result of transportation

directly to the freight handlers (see the packaging: The delivery

documentations are contained on the outside of the packaging)

2.2 Transportation

15

2.3 Unpacking the machine

When transporting the machine must be packed in the original packaging or in accordance with the instructions of the manufacturer to guarantee stability. When being transported, the machine must be fastened

onto a pallet. The croissant roller must be separate to pack up.

The machine must not be tipped over. (For machine weight,

see 9.1 Technical data Croissomat)

The machine must be set up on a level, even floor surface.

For further information regarding the ambient conditions required for

the machine, see 3.1 General information.

• Unpack tool and attachments

• Check all items received against the delivery slip for complete-

ness

Edition BD414202

04.2014

Croissomat

Operating manual

14

Page 15

Transporting, setting up, connecting, dismounting and storing the machine

2.4 Setting up the machine

Two people are required to set up the machine.

According to the machine type, the infeed table must be put in a higher

positon before setting up.

2.4.1 Tightening the conveyor belts

The belts are installed and adjusted properly by the manufacturer.

Tension the belts just as much as they will not have slip.

For tightening proceed as follows:

• Retighten the left and right tension nut (1) evenly and parallel

"X"

• Remeasure Distance "X" on both sides using a millimeter measur-

ing instrument

The distance "X" must be exactly equal on both sides

• Switch on the machine (see 5.2.1 Switching on the machine)

1

If the belt runs off towards one side, proceed as follows:

• Loosen the tension nut on the opposite side

or

• Retighten tension nut on the side where it runs off

• Monitor the belt and, if necessary, correct it until it runs exactly in

the middle of the table

If necessary, repeat this procedure several times. Routinely monitor

the belt during the initial hours that the machine is operational and, if

necessary, correct it again.

Tighten and adjust the conveyor belts with patience!

Prior to carrying out each further correction, allow the machine to run

for at least 30 seconds.

Before putting the machine into operation, the conveyor belts must be

lightly rubbed with flour in order to prevent the dough from sticking to

the belt.

Edition BD414202

04.2014

Attention!

A gap can develop between the synthetic conveyor belt and the

idle roller if the belt is worn on the edge or is damaged. If this is

the case, the belt must be replaced.

Reason: Risk of injuries to fingers in the area of the idle roller.

Croissomat

Operating manual

15

Page 16

Transporting, setting up, connecting, dismounting and storing the machine

In order to adjust the delivery belt proceed as follows before carrying

out the actual belt tensioning:

3 4

• Press the red key (2)

• Set the main switch to position "0" (Off)

• Open the safety guard (3)

• Turn the turning table (4) by hand by 90°

2

5

D

C

2.4.2 Fitting tool

6

• Release the belt tension by Allen key (C) and box spanner (D)

• Mark the belt with a pencil (5),

dimension A has to be 800 mm (even)

• Tense the belt by hand by means of the Allen key (C),

dimension B = 801 mm +/- 0,5 mm (right and left)

• Secure the set screw by the box spanner (D)

7

The safety guard must be removed before fitting the tool. The stamping

tool (6) is inserted from the machine input side in the direction of belt

travel up to the stop in the pressing bar and tightened with the starhandle (7). The corresponding longitudinal cutting shaft is inserted into

the longitudinal cutting device. The longitudinal cutter is lowered onto

the belt using the handle.

19

2.4.3 Croissant roller

Edition BD414202

04.2014

Attention!

Risk of injury on the sharp cutting tool!

The croissant roller can easily be fitted to the machine by two people.

After attaching the croissant roller, the plug of the connection cable

must be fixed to the machine.

Croissomat

Operating manual

16

Page 17

Transporting, setting up, connecting, dismounting and storing the machine

2.4.4 Installing bypass table (option)

The protective cover (8) must be removed before inserting the bypass

table.

• Center the catch of the machine table's driving roller in the

8

receiver in the front section of the housing

• Unscrew the bolt (9)

• Guide the center of the machine table's driving roller to the bolt

9

In order to snap the machine table into place, proceed as follows:

• Tug lightly on the conveyor belt until the catch snaps into place

• Tighten the bolt (9) by a key SW6

• Push forked support into the support guide

• Insert catch plug (10) of the forked support into one side of the

table

• Bend up the forked support and secure it to the opposite side of

10

the table

• Connect cable to the plug

Edition BD414202

04.2014

Croissomat

Operating manual

17

Page 18

Transporting, setting up, connecting, dismounting and storing the machine

2.5 Requirements for putting the machine into operation

Power supply and frequency at the mains circuit to which the machine

4

8

is connected must be in accordance with specifications contained on

the sign "Electrical connected loads" (This sign is found on the cable

lead-through on the machine base).

Direct connection to the mains without a mains plug is prohibited!

The mains plug serves as a mains isolation device.

Any work on the electrical components of the machine, in particular the

correct professional mounting of the mains plug, may only be carried

out be qualified personnel who are familiar with the relevant safety in-

structions.

(An electro circuit diagram is delivered with every machine. It is to be

found next to the electrical control in the machine base).

7

2.6 Moving direction test

Connect the machine plug to the mains

The infeed table must be engaged in the working position according to

the model in order to commission the machine.

After the Croissomat has been connected to the mains supply, the

moving direction must be tested. If the belts run in reverse, two phases

must be switched in the mains plug.

Edition BD414202

04.2014

Croissomat

Operating manual

18

Page 19

General data about the machine

3 General data about the machine

3.1 General information

3.1.1 Authorized use

The machine is intended for use in the foodstuffs industry for the pro-

2

duction of unfilled croissants by means of cutting, stamping and rollingup of dough pieces in thicknesses of up to 7 mm.

However, it is not suitable for the processing of other products (e.g.

modelling clay or other types of mouldable masses which are not

dough products).

Any other use of these units is not in accordance with the purpose for

which they are built. Therefore, the manufacturer will not be liable for

any accidents or damage resulting from unauthorized use; the risk in

any such instance will be borne solely by the user.

3.1.2 Noise values

This product is a technical working tool which is designated to be used

exclusively for work.

Persons handling the product must be instructed accordingly and at

least 16 years of age.

Cutting

Making longitudinal cuts in a dough band with a maximum thickness of

7 mm.

Stamping

Stamping a dough-band into diagonally opposing dough triangles. The

weight of the stamping dies is between 8 and 12 kg. They are changed

maximum 2-3 times a day.

Rolling

Rolling up dough triangles in the croissant roller starting from the long

side.

The emission value at place of operation is less than “70 dB(A)”.

Edition BD414202

04.2014

The accuracy class of the acoustic emission measurement corresponds to class 2 (± 2.5 dB) according to:

DIN EN ISO 11201 / DIN EN ISO 11202 /

DIN EN ISO 11203 / DIN EN ISO 11204

Croissomat

Operating manual

19

Page 20

General data about the machine

3.1.3 Temperatures

3.1.4 Ambient humidity

The ambient temperatures permissible for the machine:

+5 ºC to +40 °C

Permissible temperatures for storage of the machine: -25 ºC to +55 °C,

for brief periods up to +70 °C

The admissible ambient humidity for the machine lies in the area

of 30 % - 95 %, relative humidity, uncondensed.

3.1.5 Machine weight

3.2 Prerequisites

Total weight = approx. 420 kg

(see 9.1 Technical data Croissomat)

In order that dough can be sheeted by the machine, the following prerequisites must be met:

• The infeed table is engaged in the working position according to

the model

• Longitudinal cutter and stamping tool are inserted

• The calibrator unit is engaged according to the model and connected to the power supply

• Dough band maximally 7 mm thick and 620 mm wide

Edition BD414202

04.2014

Croissomat

Operating manual

20

Page 21

General data about the machine

3.3 Full view of the machine

10

7

946

5

3 4

8

1 Infeed table

2 Longitudinal cutting device with cutting roller

3 Guillotine with stamping tools

4 Safety guard

2

1

5 Hold-down rollers

6 Panning belt

7 Transverse belt with turning mechanism

8 Croissant roller

9 Control panel with emergency stop key

10 Mains switch

11 Calibrator (Option)

12 Bypass table (Option)

12

11

Edition BD414202

04.2014

Croissomat

Operating manual

21

Page 22

General data about the machine

3.4 Operating elements

3.4.1 Mains Switch

10

3.4.2 Safety guards

The mains switch (10) interrupts the supply of electrical current.

1

3.4.3 Emergency-stop key

3.4.4 Control panel

9

3.4.5 Longitudinal cutting

14

3

2

16

The safety guard (4) protect the operator from danger injury.

If the safety guard is lifted during the machine operation, the machine

will stop.

The emergency-stop key (9) serves to stop the machine.

The control panel (9) is used to operate and program the machine.

(See 5.1.1 Operating elements)

The handle (13) on the brace serves for opening and closing the longitudinal cutting device (2).

13

Edition BD414202

04.2014

19

Warning!

Risk of injury when closing the longitudinal cutting device when

the cutting shaft is fitted.

Croissomat

Operating manual

22

Page 23

General data about the machine

3.4.6 Guillotine

3.4.7 Hold-down rollers

The star handle (14) bar serves to secure the stamping tool and must

always be tight in stamping mode.

3 rows 5 rows

15 17

4 rows 6 rows

3.4.8 Croissant roller

The narrow hold-down roller (15) can be adjusted to the product size

and used in the raster plate (16). Care should be taken to ensure that

the hold-down roller is parallel to the long hold-down roller (17). The

individual rollers are to be set according to the picture on the left.

16

Edition BD414202

04.2014

18

The three feed levers (18) on the croissant roller serve to optimise the

rolling-up behaviour of the croissants.

Croissomat

Operating manual

23

Page 24

Starting the machine

4 Starting the machine

4.1 Preparing for operational readiness without bypass table

• Engage the infeed table in the working position according to the

model

• Connect the croissant roller and, according to the model, the

calibrator using the connecting cable.

1

2

• Lower the output table (1) of the croissant roller into the desired

working position

• Insert stamping tool and cutting roller

Close the longitudinal cutting device (2)

Attention!

Risk of injury when closing the longitudinal cutting device when

the cutting roller is fitted.

• Close the safety guards

• Turn the main switch on the machine to "ON"

4.2 Preparing for operation readiness with bypass table

• Engage the infeed table in the working position according to the

model

• Connect the croissant roller and, according to the model, the

calibration unit using the connecting cable.

Edition BD414202

04.2014

19

• By-pass table fitted and checked that it is secure

See 2.4.4 Installing bypass table (option)

• Fit stamping tool and cutting shaft

Close the longitudinal cutting device

Attention!

Risk of injury when closing the longitudinal cutting device when

the cutting roller is fitted.

• Close the safety guards

• Turn the main switch on the machine to "ON"

Croissomat

Operating manual

24

Page 25

Starting the machine

4.3 Starting/Stopping the machine

Starting

• Press the green key on the foil key pad

Stopping

• Press the red key on the foil key pad

• Emergency-stop key and safety guard are not intended to be

used for stopping the machine as they serve as safety elements

Edition BD414202

04.2014

Croissomat

Operating manual

25

Page 26

Operation

5 Operation

5.1 General functional description of the Croissomat

The Croissomat croissant machine is computer controlled and is intended for the production of croissants in the following working modes:

Key (4) : Normal mode

Production of croissants in various sizes using

the croissant roller.

Key (3) : Set up mode

In set-up mode, two rows of croissants can be

produced each time the machine is switched on,

after which the croissant roller is stopped.

5.1.1 Operating elements

1 3 4

6 7813

2 5 15 11 12

Key (5) : Bypass mode

Operating mode for continuous operation. No one

croissants are rolled out.

Function keys

1. Start key green

2. Off key red

3. Set up mode

4. Normal mode

5. Bypass mode

6. Selection key 1 croissant roller mode

7. Selection key 2 croissant roller mode

14

8. ON/OFF key for guillotine

Data display

11. Display for product size with product selector key

Edition BD414202

04.2014

12. Display for pause time with pause key

13. "+" - key

14. "-" - key

15. Safety guard display

Croissomat

Operating manual

26

Page 27

Operation

5.2 Operating instructions

17

5.2.1 Switching on the machine

5.2.2 General notes

Before setting the machine into action, make sure that:

• it is made ready for operation as described in chapter 4.1 Preparing for Operational Readiness without bypass table

• no loose objects, such as knives, dough scrapers, reelers or

others are on the machine tables

When the main switch on the machine is switched on the machine

starts up in normal mode. The last product size value selected appears

in the product size display and the guillotine ON/OFF switch is active.

The machine is ready for operation.

Select working mode

Select the desired operating mode by pressing the corresponding key

1-3. The red LED indicates the selected working mode.

ON/OFF switch for guillotine

The guillotine can be switched on and off by pressing the guillotine ON/

Off switch (8). The red LED illuminates when the guillotine is switched

on. The guillotine automatically switches on when the machine is

switched on.

Selection keys 1 croissant roller mode and 2 croissant roller mode

They are used to switch between operation with one only or both croissant rollers when two croissant rollers are attached (depending on machine type). The current operating mode is displayed by means of the

corresponding LED next to the keys. If only one croissant roller is fitted,

the keys have no effect. On switching on the machine, the 2 croissant

roller mode is active if 2 croissant rollers are fitted.

Edition BD414202

04.2014

Safety guard display

On pressing the emergency stop key or on opening one of the safety

guards the machine is stopped immediately. The red LED next to the

safety guard display is activated. The machine can only be restarted

with the start key (1) when all safety guards are closed and the emergency stop key is unlocked.

Croissomat

Operating manual

27

Page 28

Operation

5.3 Product selection and product definition

Product selection and definition can only be carried out with the

machine stationary.

By pressing the product selector key (11), access is obtained to the

set-up mode for the product basis. The product size display flashes

slowly. Using the "+" - and "-" - keys (13/14), a choice can be made

from one of five stored values. After 5 s without change the displayed

value is accepted and the display ceases to blink.

If a value is to be changed or re-entered, the product selector key (11)

must be pressed for 2 s. The value begins to flash rapidly and can now

be adjusted with the "+" - and "-" - keys in a range of 60 - 220. After

5 s without change the displayed value is accepted and the display

ceases to blink.

A maximum of five values can be stored. If all five are in use, and a new

value is to be entered, one of the old ones must be overwritten.

5.4 Pause times

The pause time can be adjusted both while the machine is stationary and in operation.

By pressing the pause key (12), access is obtained to the set-up mode

for the pause time. The pause time display begins to flash. Using

the"+,-" keys (13/14), the pause time can be adjusted between 00.0 s

- 20.0 s in 0.5 s steps. After 5 s without change the displayed value is

accepted and the display ceases to blink.

Edition BD414202

04.2014

Croissomat

Operating manual

28

Page 29

Operation

5.5 Operating modes

5.5.1 Set-up mode

5.5.2 Normal mode

By pressing the set-up mode key (3), the red LED is activated. On

pressing the start key (1), two rows of croissants are produced. The

croissant roller runs until the stop key (2) is pressed and can be fed

with dough pieces by hand, in order to adjust the rolling-up quality. If

the start key (1) is kept depressed, the machine runs until the start key

is released. The croissant roller continues to run as previously described.

After switching on the main switch, the machine is always in normal

mode. The red LED is active. On pressing the start key (1), the machine starts up and is stopped by pressing on the off key (2).

5.5.3 Bypass mode

Bypass mode can only be used if the bypass table is fitted to the machine and the plug is connected. No other operating mode can then be

selected. In bypass mode, the selector key 1 croissant roller mode (6)

is activated automatically. In this way the advance rates of the two machine belts are identical. The dough pieces are not separated. By

pressing the selector key 2 croissant roller mode (7), the dough pieces

are separated at the belt change-over point.

Edition BD414202

04.2014

Croissomat

Operating manual

29

Page 30

Operation

5.6 Special functions

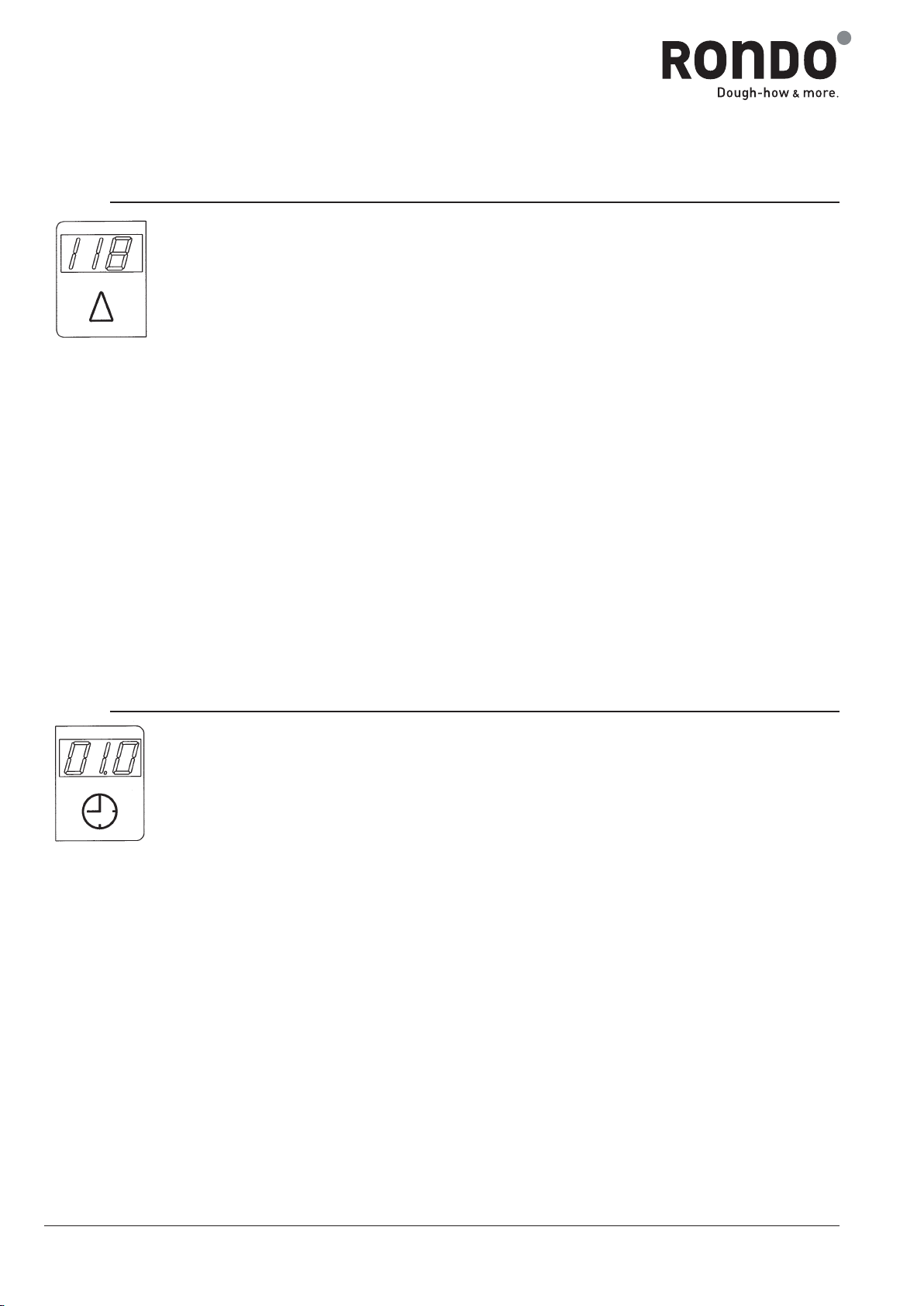

5.6.1 Maintenance function

+

5.6.2 Operating hours counter

+

By pressing the off key (2) and the "+"- key (13) for 10 seconds, the

discharge belt is brought into the return position in order that the transverse belt can be removed and the discharge belt tensioned or

changed. Resetting is only possible by switching off the mains switch.

By pressing the off key (2) and the pause key (12) for 10 seconds, the

number of operating hours is displayed to the nearest 10 hours. After

10 seconds the operating hours display mode is exited automatically.

5.6.3 Indication safety guard open

The display is only possible when stationary.

If safety circuit is open, the LED "safety guard" illuminates.

The red LED illuminates if:

• Safety guard open (infeed side)

• Safety guard open (outfeed side)

• Safety device on the outfeed side not mounted, respectively plug

on the bypass table not connected

• Protecting device on the Croissant roller has reacted or cable of

the Croissant roller is not pluged in the Croissomat

• Emergency-stop key on the Croissomat is operated

• Emergency-stop key on the calibrator is operated or cable for

calibrator not pluged in

(On the calibrator or in the parking socket on the Croissomat)

Edition BD414202

04.2014

• Protective motor switch Q2 not switched on (in the electrical box)

Croissomat

Operating manual

30

Page 31

Operation

5.7 The longitudinal cutting device and the guillotine

Safety guards

The longitudinal cutting device and the guillotine are covered by a

16

17

safety guard.

A defective pneumatic spring (16) on the safety guard must be

replaced immediately! Reason: risk of injuries caused by falling

safety guard.

Function of the guillotine

The dough triangle stamping tool is fitted to the guillotine. The guillotine

is lowered onto the stationary infeed belt by means of a cam. In this

way the triangles are stamped in the dough-band. The guillotine stops

in the upper dead point.

The cutting pressure is set at the factory and should not be adjusted by

the customer.

Adjusting the guillotine

Loose lock nut (17) completely. Remove pressure bar.

18

19

20

19

Adjust the second lock nut with key SW19. One turn corresponds to

1,75 mm difference in altitude. Turning direction left is decreasing, turn-

ing direction right is increasing the cutting pressure.

Place the pressure bar and fix it with the lock nut (17).

Attention: Adjust by half a turn at maxiumum!

Inserting and removing stamping tools

The stamping tools are designed in such a way that they can only be

fitted to the pressure bar in a certain position. If the stamping tool position is changed, the functional sequence of the machine is interfered

with.

For insertion, the stamping tool (18) together with the tenon blocks

must be slid up to the stop in the pressure bar and fixed by means of

the star handle (19). Removal of the stamping tools takes place in the

reverse order.

Risk of injury on the sharp cutting edges!

Function of the longitudinal cutting device

The longitudinal cutting device serves to hold the cutting shaft and

presses it with constant force onto the infeed belt. One pneumatic

spring (20) on each side ensures restricted contact pressure in order to

prevent the infeed belt from being cut. A defective pneumatic spring

must be replaced immediately since perfect cutting of the dough-band

cannot be guaranteed.

Edition BD414202

04.2014

Croissomat

Operating manual

31

Page 32

Operation

The cutting shaft cuts the dough-band in the longitudinal direction into

the required number of dough strips corresponding to the dough triangle sizes required.

Inserting the cutting shaft

21

Y

X

Risk of injury on the sharp cutting edges!

The longitudinal cutting device is opened using the handle (21) on the

brace. The cutting shaft must be inserted carefully. Always fit the longi-

19

tudinal cutting device correctly. When doing so pay attention to the

plastic part (Y) on the operator side and the plastic part (X) on the

other side. The longitudinal cutting device is closed using the handle.

The longitudinal cutting device must always be closed before closing

the safety guard.

Standard measurements of cutting rollers

Y

Number of rows Width of the dough strips

2 265

3 177

4 133

5 106

6 88

X

wrong right

Edition BD414202

04.2014

23

22

Adjusting the cutting shaft

The knives (22) cut the dough to the breadth.

The knives (23) have to be set 5 mm outside the dough band, so that

they never produce waste.

Croissomat

Operating manual

32

Page 33

Operation

5.8 Croissant roller

25

24

5.9 Lowering the infeed table

The roller gap can be infinitely adjusted from 0.5 - 5 mm by the roller

adjustment lever (24). The adjusted roller gap is fixed by turning the

star handle in clockwise direction on conclusion. The divisions

0.5 - 5 mm on the scale represent the actual roller gap in mm.

The two additional feed levers (25) serve to adjust the spacing between the upper and lower belt. This allows the rolling-up quality of the

croissants, loose or tightly rolled, to be adjusted.

The divisions of 0.5 - 10 on the scale serve only as guide values and

have no connection with the belt spacing.

If it is necessary to carry out a readjustment, it is recommended to set

both levers to the same value at the outset.

26

26

The infeed table (26) can be lowered when the machine is not in use.

To carry this out the table must be slightly lifted with one hand and the

supports (27) pressed upwards with the other hand. The table can then

be lowered.

The table must be raised for machine operation until it engages in the

working position.

Edition BD414202

04.2014

27

Croissomat

Operating manual

33

Page 34

Cleaning

6 Cleaning

6.1 Cleaning

3

3 1

Before cleaning the machine, pull out the mains plug.

9

22

The machine must never be cleaned using spray water, highpressure cleaner, steam-cleaning machine or any similar cleaning

methods.

Removing the Scraper Unit, cleaning and replacing

• Disconnect scraper (1) and loosen tension spring (2)

2

6.1.1 Croissant roller

21

• Dismantle with a key SW 13 the spring clamp (3) either on the left

or the right hand side and carefully slide the scraper blade off

Exchange of scraper blades

Attention

For protection of the fingers, please use a cloth. The edges of the

blades are sharp and there is danger of cutting oneself.

• Assemble the new scraper blades in reverse order

The croissant roller can be dismounted easily from the basic machine,

by 2 persons.

Procedure

• Unplug the connecting cable plug

• Raise the croissant roller

Edition BD414202

04.2014

• Lift the croissant roller away

The croissant roller is mounted by following the procedure in reverse

order.

As the rolling belt and scraper of the croissant roller can be removed

without the use of tools, the time required for the daily cleaning is reduced and optimal hygienic conditions are guaranteed.

Croissomat

Operating manual

34

Page 35

Cleaning

Dismounting the upper belt

• Fold back the swivel yoke (4)

4

• Press the upper belt (5) hard backwards against the spring bolt (6)

and lift out from the front (catch)

• Remove the upper belt

5

The upper belt is mounted by following the procedure in reverse order.

6

7

Adjusting the tension of the felt belt

• Loosen the front and back hexagonal screws (7) by a key (SW13)

and adjust the belt tension by means of the adjustment axle.

• After adjustment, retighten the hexagonal screws!

8

Dismounting the lower belt

• Loosen the front and back hexagonal screws by a key (SW8) and

push out the stopping plate (8)

• Raise the lower belt (9), press back hard against the spring bolt

and lift out at the front (catch)

• Remove the lower belt

9

The lower belt is mounted by following the procedure in reverse order.

7

Adjusting the tension of the felt belt

• Loosen the front and back hexagonal screws (7) by a key (SW13)

and adjust the belt tension by means of the adjustment axle.

Edition BD414202

04.2014

• After adjustment, retighten the hexagonal screws!

Croissomat

Operating manual

35

Page 36

Cleaning

5 11 10

Dismounting the scraper, upper roller

• Unhinge the tension spring (10) at the front and back

• Fold back the guard sheet (5)

• Remove the scraper (11)

The scraper is mounted by following the procedure in reverse order.

12 13

Dismounting the scraper, lower roller

• Turning the catch (12)

• Press the scraper (13) dismount it to the side

The scraper is mounted by following the procedure in reverse order.

Dismounting the infeed table

• Raise the infeed table (14), press back hard against the spring

bolt and lift out from the front (catch)

The infeed table is mounted by following the procedure in reverse or-

der.

Adjusting the conveyor belt. (See 2.4.1 Tightening the conveyor belts)

Edition BD414202

04.2014

14

Croissomat

Operating manual

36

Page 37

Cleaning

Dismounting the outfeed table

• Remove the cover yoke (15)

15

• Raise the outfeed table (16), press hard forwards against the

spring bolt and lift out at the back (catch)

16

The outfeed table is mounted by following the procedure in reverse

order.

Adjusting the prop belt. (See 2.4.1 Tightening the conveyor belts)

If the outfeed table (16) is folded up, the cover yoke (15) must also be

removed.

16

Edition BD414202

04.2014

Croissomat

Operating manual

37

Page 38

Cleaning

6.1.2 Care

daily

Part See

Casing 3.3 Full view of the machine A

Scraper 6.1 Cleaning A

Synthetic conveyor belt 2.4.1 Tightening the conveyor belts B/C

Driving roller 2.4.4 Installing bypass table (option) D

Idle roller 2.4.1 Tightening the conveyor belts D

Croissant roller 6.1.1 Croissant roller A/B

see legend

Only use cleaning agents with a ph-value of 6 to 8! Only cleaning

materials approved for use in the food industry may be used.

Legend

weekly

see legend

A Damp clean using cloth and soapy water

B Dry clean using a brush

C Wet clean using a brush

D Remove excess dough using a brush and plastic scraper

Edition BD414202

04.2014

Croissomat

Operating manual

38

Page 39

Maintenance

7 Maintenance

7.1 General information for maintenance of the machine

3

9

7.2 Maintenance list

Part Activity Period

Conveyor belts check, if necessary: replace

Safety clutch of turning table check if necessary: adjust or replace M

Final stop of turning table check the rubber cushion

Chains in Croissant roller check the tension of chain

Scraper blade check, if necessary: replace A

Chains in Croissant roller grease according to the Service manual A

11

12

For a competent maintenance of the machine, a service contract is

recommended.

Your dealer will be happy to inform you about the various possibilities.

Any defects or damage on the machine must be repaired by an

authorized customer service representative.

check the belt run

if necessary: replace

if necessary: retighten

13

W

M

M

Edition BD414202

04.2014

Legend

W weekly

M monthly

A annually

Croissomat

Operating manual

39

Page 40

Maintenance

7.3 Replacement parts list

13

Item-no. Description Dimensions Application

7536 Round rubber cushion 26 Stop of turning table

125506 Set disk Ø 60 x 21 mm Turning table

125884 Scraper mounted

13753 Tube (felt) Ø 45 x 50 mm Hold-down rollers

126335T02 Synthetic belt 2500 x 556 mm SCM50 Infeed belt

126336 Synthetic belt 1260 x 300 mm SCM50 Transverse belt

126337 Synthetic belt 2070 x 545 mm SCM50 Panning belt

121974 Synthetic belt 2390 x 604 mm SCM50 Bypass table

123398 Synthetic belt 590 x 254 mm Croissant roller infeed table

120702 Prop belt 1810 x 250 mm Croissant roller outfeed table

120666 Lower belt 568 x 248 mm Croissant roller felt belt

120667 Upper belt 531 x 248 mm Croissant roller felt belt

The use of replacement parts not delivered by RONDO can lead to

premature wear or to destruction of machine parts.

Edition BD414202

04.2014

Croissomat

Operating manual

40

Page 41

Trouble shooting

8 Trouble shooting

Symptom Cause/Defect Remedy/Repair

1. No indication on control panel Mains plug not plugged in?

Plug in mains plug.

2. Indication o.k., indication safety

guard open illuminates.

Mains switch not switched on?

Power Supply existing?

Mains plug defective?

Power Supply wrong?

Fuse in basic module not o.k.?

Safety guard closed?

Emergency-stop key unlocked?

Switch on mains switch.

To check by an electrician:

Check Power Supply (all 3 phases)

Check connections in plug

Supply must be according the informa-

tion on the sign "Electrical connected

loads" of the machine

Pull out the mains plug and check the

fuses.

Close safety guard.

Unlock emergency-stop key

(See 5.6.3 Indication safety guard

open).

Edition BD414202

04.2014

Croissomat

Operating manual

41

Page 42

Trouble shooting

Symptom Cause/Defect Remedy/Repair

3. Error messages: Reset the error messages by switching

001 Main switch not activated Let check it by an electrician.

off the mains (mains switch)

003 Sensor Guillotine does not respond

Clear the error (See also point 7).

(Timeout).

004 No impulses by infeed belt

Check sensor and position sensor.

(Timeout).

005 Sensor transport belt (Timeout). Check sensor and position sensor.

006 Sensor belt return front does not

respond (Timeout).

Check sensor and position sensor, or

wrong moving direction, check and

change the phase-sequence in the

plug.

007 Sensor belt return back does not

Check sensor and position sensor.

respond (Timeout).

008 Turning table limit switch right

Check sensor and position sensor.

moving direction don't functioning

(Timeout).

009 Turning table limit switch left moving

Check sensor and position sensor.

direction don't functioning (Timeout).

Edition BD414202

04.2014

Croissomat

Operating manual

42

Page 43

Trouble shooting

Symptom Cause/Defect Remedy/Repair

4. Machine runs intermittently,

stops.

Loose wires (Intermittent contact) By electrician: Adjust wires correctly

5. Conveyor belts loop up, motor

and driving roller are running.

6. Conveyor belt runs over to one

side, tears at the edges.

7. Guillotine stops in lower position. Pressure too high

Belt tension too weak

Driving roller dirty

Irregular conveyor belt tension

Driving roller dirty

Error message 003

Tighten the conveyor belts (see 2.4.1

Tightening the conveyor belts).

Clean driving roller (see 6.1.2 Care).

Tighten conveyor belt (see 2.4.1

Tightening the conveyor belts).

Clean driving roller (see 6.1.2 Care).

Loosen stop nut by a half turning.

New start of machine.

8. All other errors/failures. Inform nearest "RONDO" after-sales

service giving as much information as

possible.

Edition BD414202

04.2014

Croissomat

Operating manual

43

Page 44

Technical data

9 Technical data

9.1 Technical data Croissomat

Technical Data SCM50

Calibrator option

Bypass table option

Width of infeed belt 560 mm

Rated power 3,5 kVA /1,5 kW

Supply voltage 3 x 200 - 420 V, 50/60 Hz

Total length in resting position 1800 mm

Total length 2400mm

Total length with bypass table 3330 mm

Total length with calibrator 3830 mm

Total length with calibrator and bypass table 4760 mm

Width without croissant roller 900 mm

Width with croissant roller 2280 mm

Machine weight 420 kg

Weight of the croissant roller 80 kg

Technical specifications subject to change without notice.

Edition BD414202

04.2014

Croissomat

Operating manual

44

Page 45

Technical data

9.2 Additional information

The Croissomat from RONDO has the following quality features:

• The conveyor belts made of plastic material:

All plastic coated conveyor belts used on our machines are

approved for coming into contact with food stuff and correspond

with the requirements of the directives EU 10/2011 as well as the

FDA (Food and Drug Administration, USA).

• The felt conveyor belts are made of 100% woollen felt. Woollen

felt is used since many years in the bakery industry.

• The parts of the cutting knives and of the stamping dies that are

touching the dough are made of stainless steel (chromium nickel

steel, DIN Mat. no. 1.4301). This material is approved for coming

into contact with food stuff.

• The roller of the manual dough reeler that is touching the dough is

made of aluminium, anodised colourless and is approved for

coming into contact with food stuff.

• The rollers of the croissant roller are hard-chrome plated. This

coating is approved for coming into contact with food stuff.

• The scraper blades are made of POM-C plastic material. This

material is approved for coming into contact with food stuff and

corresponds with the requirements of the directives EU 10/2011

as well as the FDA (Food and Drug Administration, USA.

• The dough catch pans are made of stainless steel (chromium

nickel steel, DIN Mat. no. 1.4301).This material is approved for

coming into contact with food stuff.

Edition BD414202

04.2014

Croissomat

Operating manual

45

Loading...

Loading...