Romac Industries SS1-H, SS2-H, SS3-H Installation Manual

INSTALLATION INSTRUCTIONS

ROMAC

INDUSTRIES,

INC.

5

4

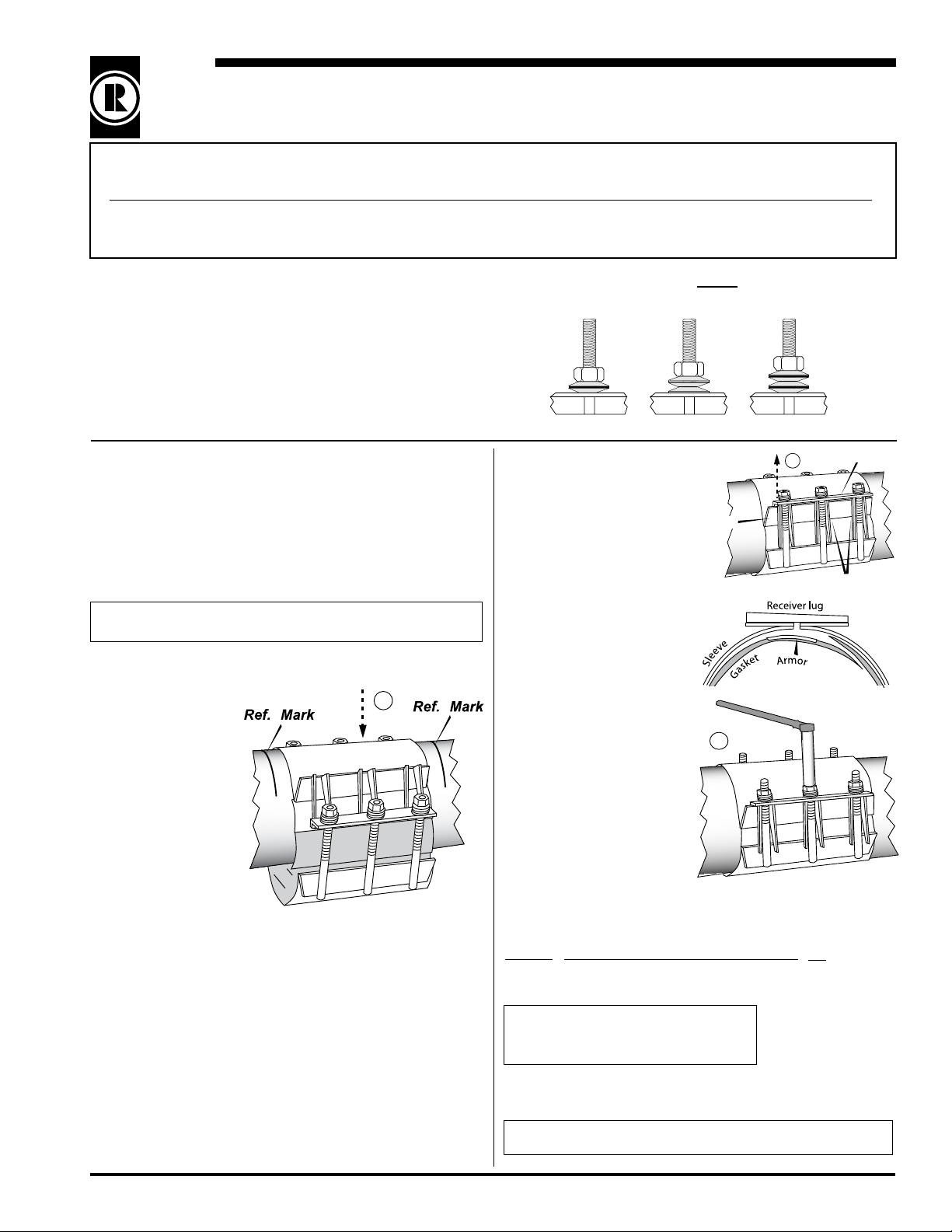

Side bar

Lifter bar

Receiver lugs

Read installation instructions rst before installing. Check parts to ensure that no damage has occurred during transit and that no

parts are missing. Also check the diameter of the pipe and the range marked on the clamp to ensure you have the proper size.

LIMITATIONS: For product limitations see reverse side. For more detailed information see the HDPE Products sec-

tion of the Romac Product Catalog, or phone Romac Engineering Department at 1-800-426-9341.

Spring Washers must be installed

in these congurations

Style SS1-H, SS2-H & SS3-H

Stainless-Seal Pipe Repair Clamp for HDPE

Two washers

Step 1 • Thoroughly clean pipe surface that will be

covered by the clamp.

Step 2 • Place reference marks on the pipe in line with

the crack or hole in the pipe slightly wider than the clamp. If clamp

is being placed over a weld, the weld must be ground ush.

If using tapped repair clamp, be sure that the outlet is positioned in the area where the tap is to be done.

Step 3 • Back

off nuts to end of bolts,

but DO NOT REMOVE

THEM.

SS1H: Separate

clamp and wrap it

around the pipe.

SS2H and SS3H:

Separate the clamp

sections. Center one

of the sections over

the crack or hole being repaired.

If possible, position one of the sections around the pipe so

the bolts and receiver lugs are in a convenient place to assemble and tighten.

Note: If necessary because of owing water, Steps 3 and

Document #10-9-SS2H-0021 04/18/2011

4 can be performed beside the pipe crack or hole. Slide

the clamp over the break after the lifter bars have been

snapped into place.

3

Step 4 • Slide

lifter bars up the receiver

lug prole and snap into

place over the

side-bar edge.

Make sure the gasket

tails are not folded

under, but are laying at

around the pipe.

Step 5 • Tighten

all nuts evenly in 20 ft-lbs.

increments. Start in the center and work toward each

end. Alternate from one

side to the other to equalize the gap between halves,

keeping torques as evenly

balanced as possible. Use

a wrench with at least a 12"

handle.

For SS2-H and SS3-H repair clamps, maintain an equal gap

between the sidebars.

Nom. Pipe Diameter Torque

4" and below 30-40 ft-lbs.

6" and above 75 ft-lbs.

Note:

35 ft-lbs. = 12" wrench w/ 35 lb. force

75 ft-lbs. = 12" wrench w/ 75 lb. force

For best results, wait 10 minutes and

then retighten to proper torque.

Three washers

Four washers

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

If using tapped repair clamp, pressure test before tapping.

Backll and compact carefully around clamp and service line.

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

Style SS1-H, SS2-H & SS3-H

Stainless-Seal Pipe Repair Clamp for HDPE

PRECAUTIONS

1. Check diameter of pipe to make sure you are using the

correctly sized clamp.

2. Clean pipe to remove as much dirt and corrosion as pos-

sible from the surface.

3. Place a mark on the pipe to reference the leak. After in-

stallation use this mark to assure that the clamp has been

properly positioned.

4. Make sure no foreign materials stick to the gasket as it

is brought around the pipe, nor become lodged between

gasket and pipe as nuts are tightened.

5. Avoid loose tting wrenches, or wrenches too short to

achieve proper torque.

6. Keep threads free of foreign material to facilitate tight-

ening.

7. Bolts are often not tightened enough when a torque wrench

is not used. Take extra care in this situation to make sure

proper tightening occurs.

8. Always pressure test for leaks before backlling.

9. Backll and compact carefully around clamp.

10. When reinstalling parts with stainless steel hardware there

may be a loss in pressure holding ability due to worn or

damaged threads during the orignal installation

COMMON INSTALLATION PROBLEMS

1. Bolts are not tightened to the proper torque.

2. Rocks or debris cutting gasket.

3. Dirt on threads of bolts or nuts.

4. Installing in the heat of the day.

5. Not grinding welds ush.

PRODUCT LIMITATIONS

High Density Polyethylene Pipe (HDPE) has a lower modules of elasticity and higher coefcient of thermal expansion than

other pipe materials. These properties cause HDPE pipe to expand and contract much more from changes in temperature

and/or pressure than other piping materials. Because of these and other properties, great care must be taken when installing

conventional tting on HDPE.

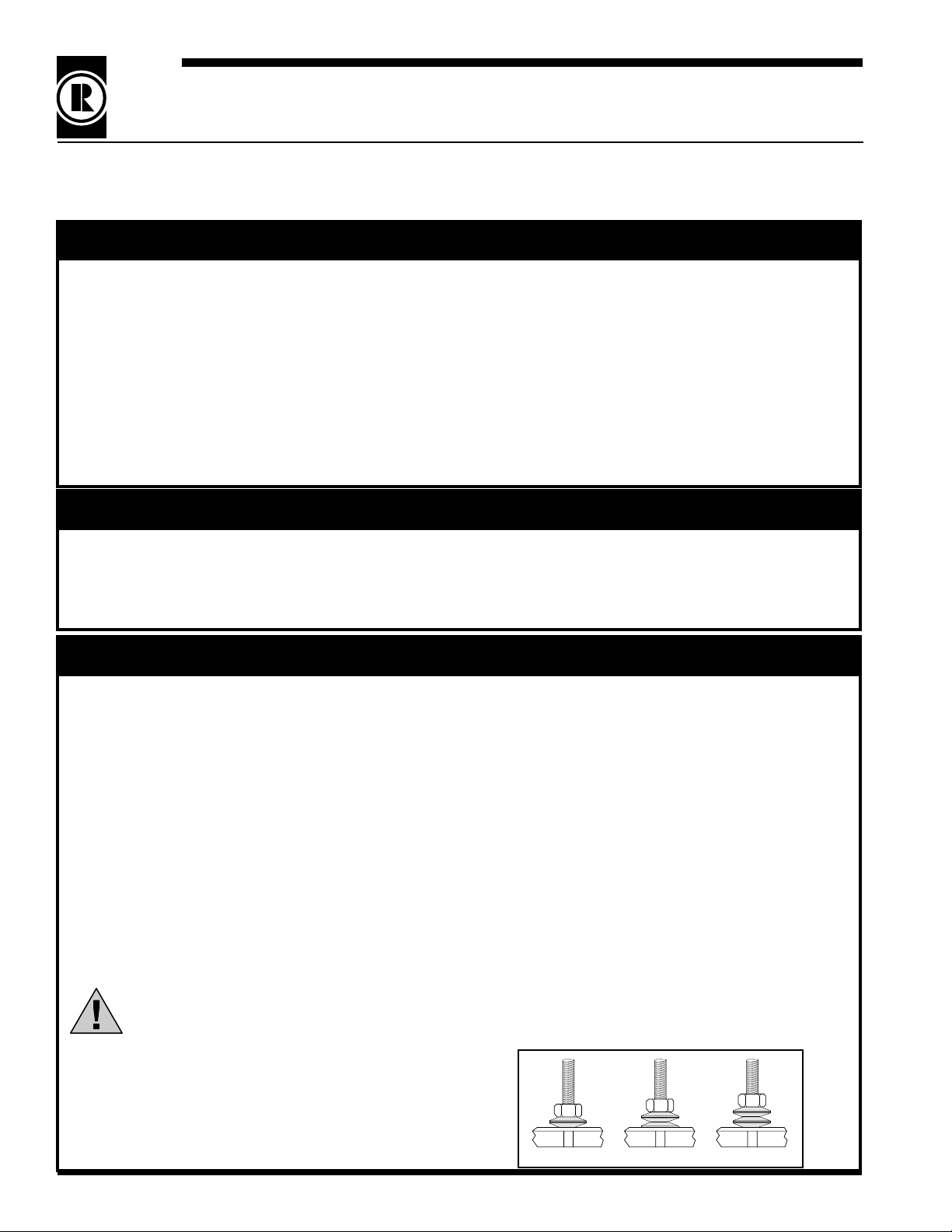

This product has been provided with the proper number of spring washers for the conditions described in the following limitations.

HDPE LIMITATIONS:

• Pipe must be manufactured in accordance with AWWA Standard C906-90.

• Operating temperatures are limited to 85° F maximum and 32° F minimum.

• Operating pressure is limited to 150 psi or the rating of the pipe, whichever is less.

• Pipe systems must be designed to compensate for pipe movement so as to prevent ttings from migrating or rotating on the

pipe.

• Products are intended for use in underground service only.

• Products are not to be used on pressurized HDPE pipe with an SDR greater than 26.

ROMAC CANNOT WARRANT PRODUCTS USED IN APPLICATIONS THAT ARE OUTSIDE ONE OR MORE OF

THESE LIMITATIONS. CONTACT ROMAC’S ENGINEERING DEPARTMENT AT 1-800-426-9341 IF YOU HAVE

QUESTIONS ABOUT THE USE OF OUR PRODUCTS ON HDPE PIPE.

HDPE PRECAUTIONS:

Try always to install ttings when pipe is at its coldest.

Be sure that spring washers are stacked properly (see drawing at

right).

This product is designed for a 53° F temperature range maximum.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Four washersThree washersTwo washers

Loading...

Loading...