Romac Industries RomaGrip Installation Manual

INSTALLATION INSTRUCTIONS

ROMAC

INDUSTRIES,

INC.

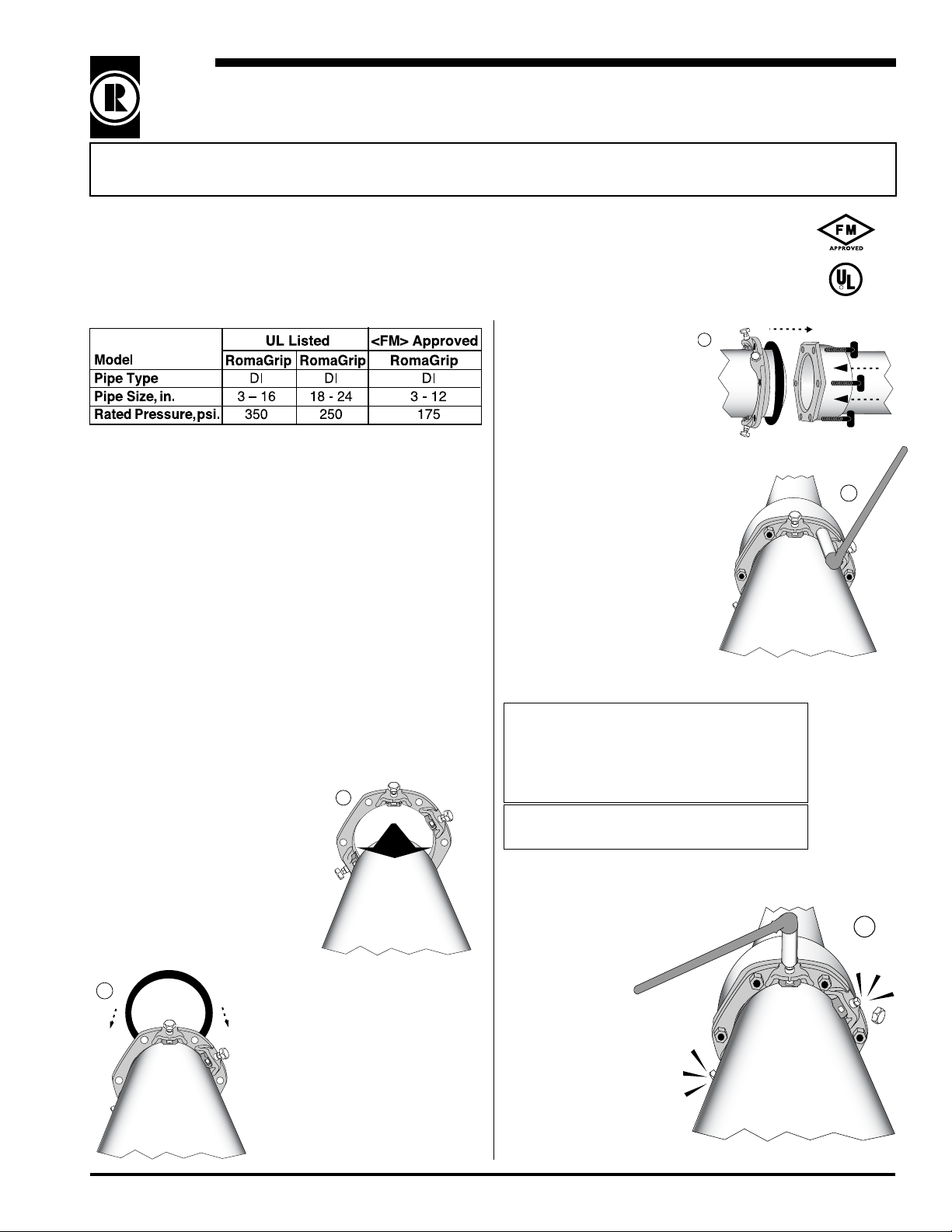

8

4

6

7

Read installation instructions rst before installing. Check parts to ensure that no damage has occurred during transit and that no

parts are missing. Also check the diameter of the pipe and the range marked on the restrainer to ensure you have the proper size.

Style RomaGrip Mechanical Joint Retainer

For use on: Ductile iron pipe 3" - 48", cast iron pipe 3" - 48" (same OD's as ductile iron),

IPS size and STD steel 3" - 12" with transition gasket and a minimum thickness of schedule 40.

Step 7 • Insert pipe in

mechanical joint tting and

insert bolts.

NOTE: Romac endorses the use of the RomaGrip tting for use

on steel pipe with a minimum thickness of Schedule 40 pipe.

This application is not UL Listed or <FM> Approved.

NOTE: Not for use on polyethylene pipe, plain

end mechanical joint ttings or PVC pipe.

Step 1 • Check the parts to insure that no damage has

occurred during transit and that no parts are missing.

Step 2 • Clean pipe end for a distance of at least 2" past

where the gland will sit.

Step 3 • Check area where gasket will seat to make

sure there are no dents, projections, gouges, etc., that will

interfere with the gasket seal.

Step 4 • Place gland on pipe.

Step 8 • Tighten T-bolts to

the torque recommended in the table

below. Maintain the same overall

gap between the RomaGrip and

the MJ bell face by tightening the

T-bolts in a uniform criss-cross

pattern (12 o’clock, 6 o’clock,

3 o’clock, 9 o’clock) until proper

torque is achieved.

Using a torque wrench is highly

recommended. For best

results, wait 10 minutes and

retighten bolts to proper torque.

Recommended Torque:

3" RomaGrip: 45-65 ft-lbs.

4 - 24" RomaGrip: 75 - 90 ft-lbs.

30 & 36" RomaGrip: 100 - 120 ft-lbs.

42 & 48" RomaGrip: 120 - 150 ft-lbs.

Note:

90 ft-lbs. torque = 12" wrench w/90 lbs. force

R

Step 5 • Lubricate the gasket

and pipe surface with soapy water

or other suitable gasket lubricant.

Step 6 • Stretch gasket over pipe

with beveled edge toward the bell.

Document #05-9-0008 05/06/2011

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Step 9 • Tighten the restrainer

bolts until the restraining pads

touch the surface of the

pipe. The bolts

should be tightened in a uniform

criss-cross pattern,

until the heads break off

above the notch.

9

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

Style RomaGrip Mechanical Joint Retainer

PRECAUTIONS

1. Check diameter of pipe to make sure you are using the correct size RomaGrip; also check gasket to make sure it is

the size you think it is.

2. Be sure to clean pipe of as much dirt and corrosion as possible in the area that the gasket will seal.

3. Lubricate both the gasket and the pipe end with soapy water or approved pipe lubricant per ANSI/AWWA C111/

A21.11.

4. Make sure no foreign materials lodge between gasket and pipe.

5. Avoid loose tting wrenches, or wrenches too short to achieve proper torque.

6. Keep threads free of foreign material to allow proper tightening.

7. Take extra care to follow proper bolt tightening procedures and torque recommendations. Bolts are often not tightened

enough when a torque wrench is not used.

8. Be sure that the gland is centered around the pipe.

9. Pressure test for leaks before backlling.

10. Backll and compact carefully around pipe and ttings.

11. Some initial axial movement may occur in lug style restraints as the lugs seat. Movement is directly related to the

size of the piping system and the system pressure. In general terms movement of approximately 0.25" can be

expected in restraints under 16”. For larger sizes, movement of approximately 0.4” may be seen.

If this is critical to your application please contact Romac Engineering for additional information.

COMMON INSTALLATION PROBLEMS

1. T-Bolts are not tightened to the proper torque.

2. Rocks or debris between pipe and gasket.

3. Dirt or debris between pipe and restraining pad.

4. Dirt on threads of bolts or nuts.

5. Restraining bolt heads not snapped off.

6. Not enough pipe inserted into bell.

7. Not using a transition gasket when using the RomaGrip on IPS size steel pipe.

8. Using the RomaGrip on IPS size steel pipe with wall thickness thinner than schedule 40 steel pipe.

IF RESTRAINER MUST BE REMOVED

1. Make sure pipe is not pressurized. Removing the restrainer could cause the pipe joint to separate.

2. To remove the RomaGrip restrainer, use a 5/8" hex wrench or socket.

3. To reassemble, follow installation procedures. For 3-24" tighten the restraining bolts using a 5/8" hex wrench to

75 ft-lbs. minimum. For 30 - 48" tighten the restraining bolts using

15

/16" hex wrench to 110 - 135 ft-lbs.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Loading...

Loading...